Patents

Literature

642results about How to "High surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rigid porous carbon structures, methods of making, methods of using and products containing same

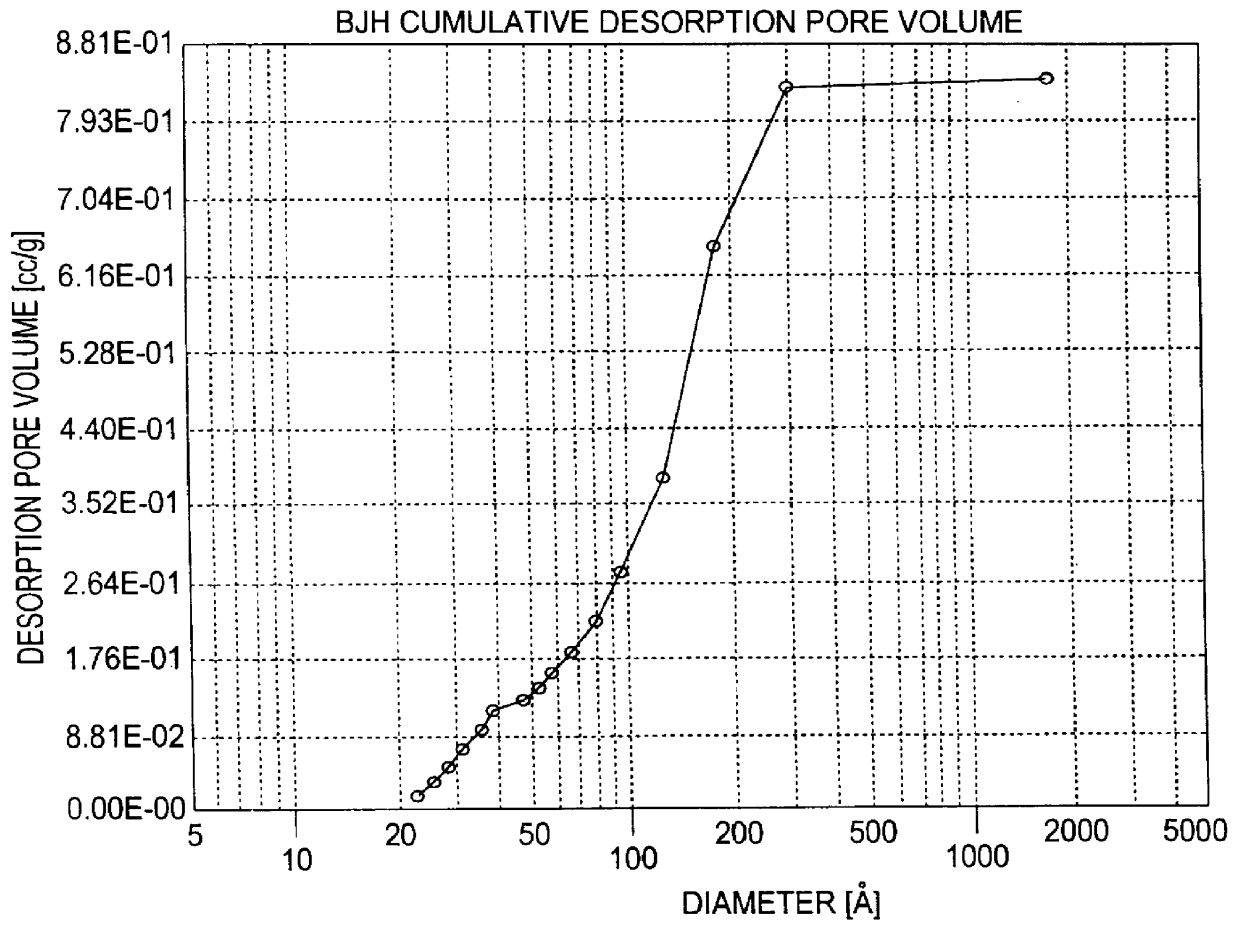

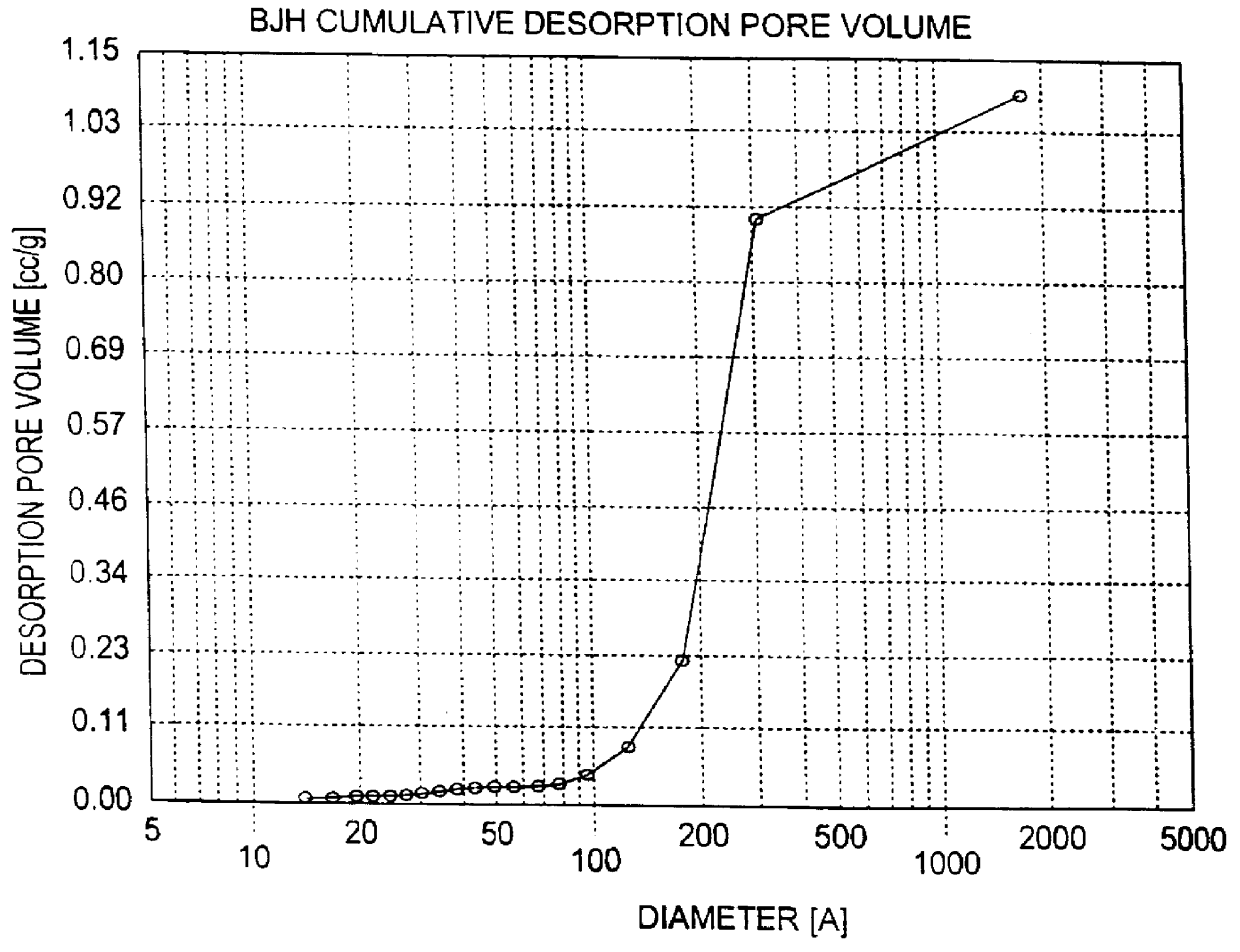

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

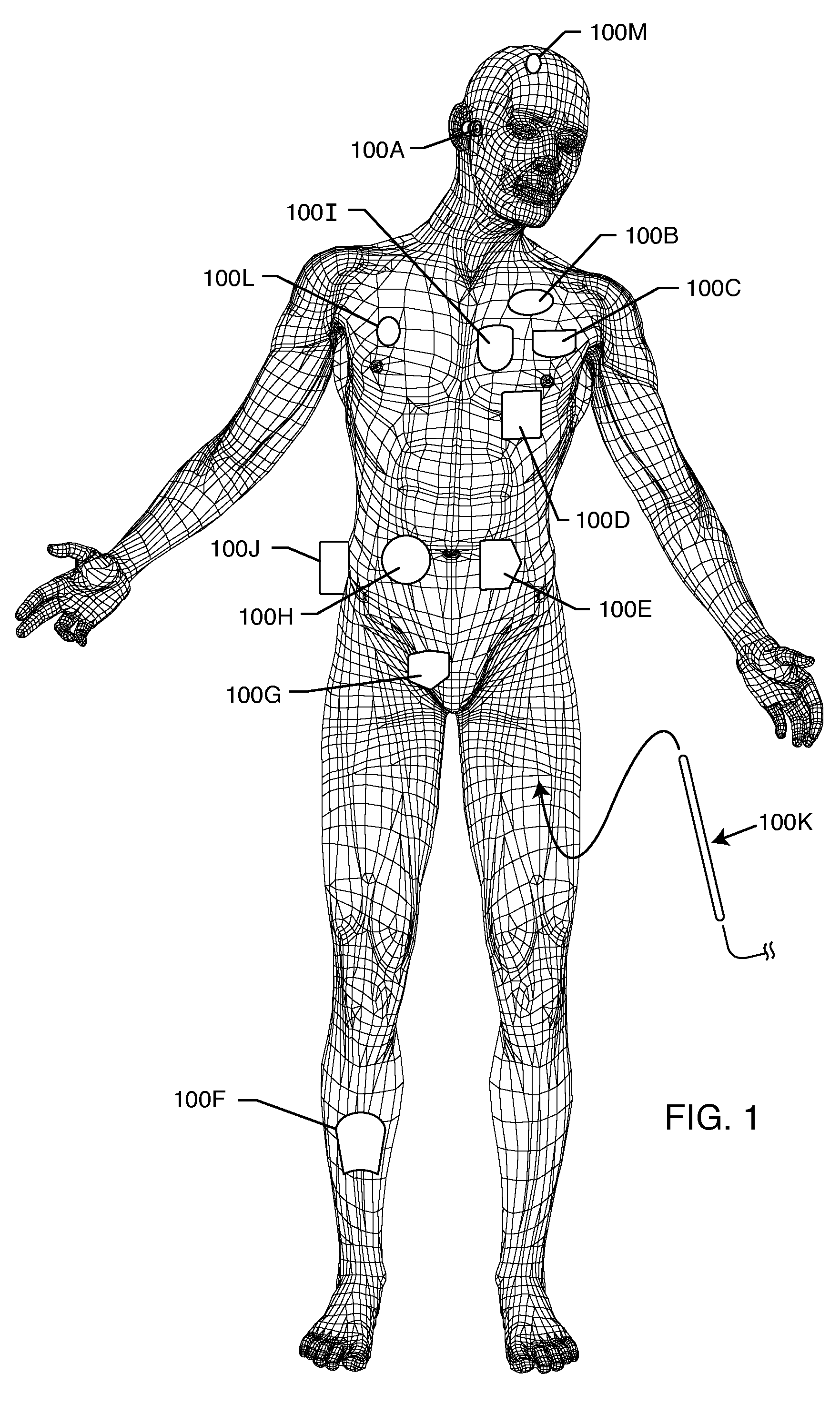

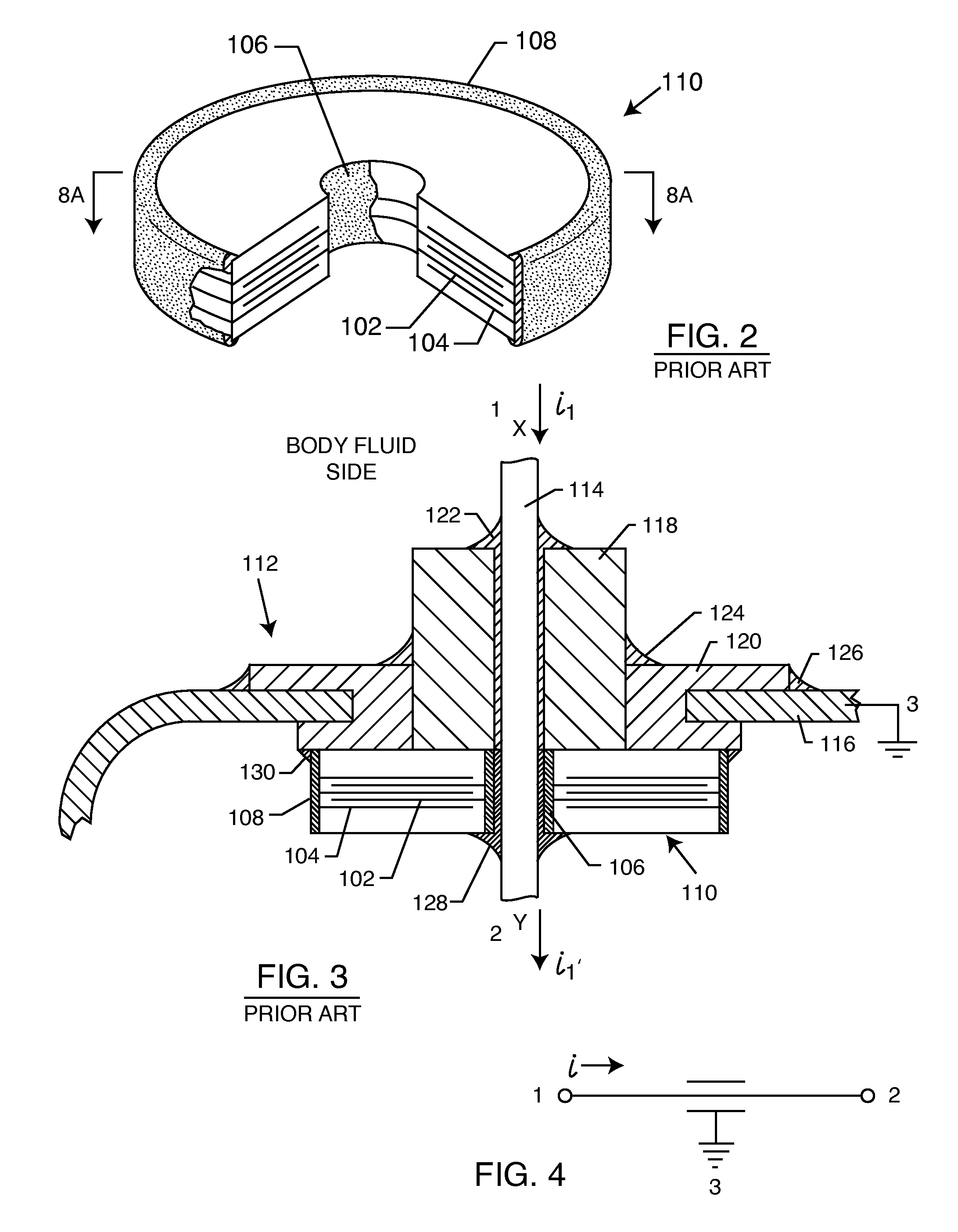

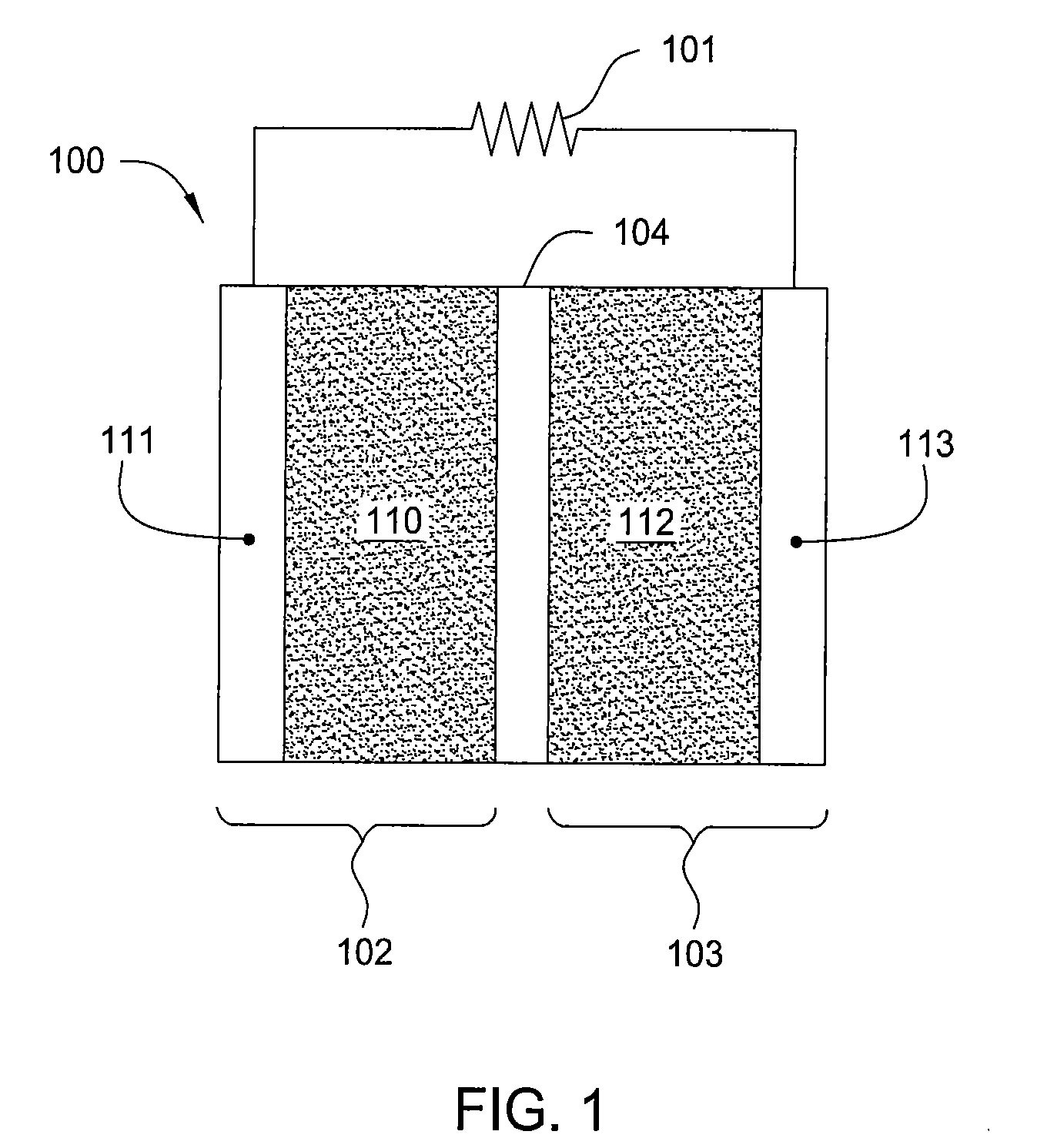

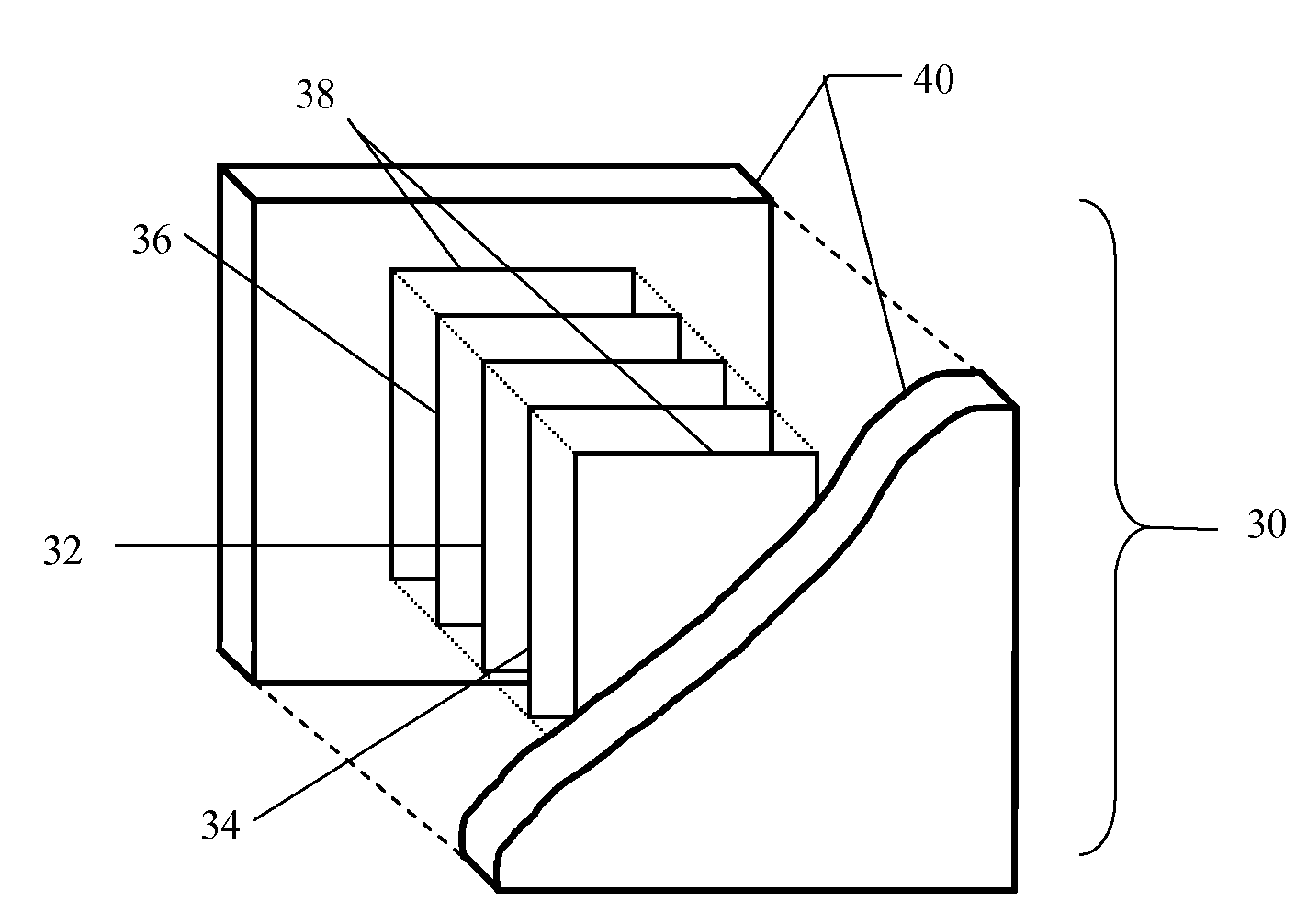

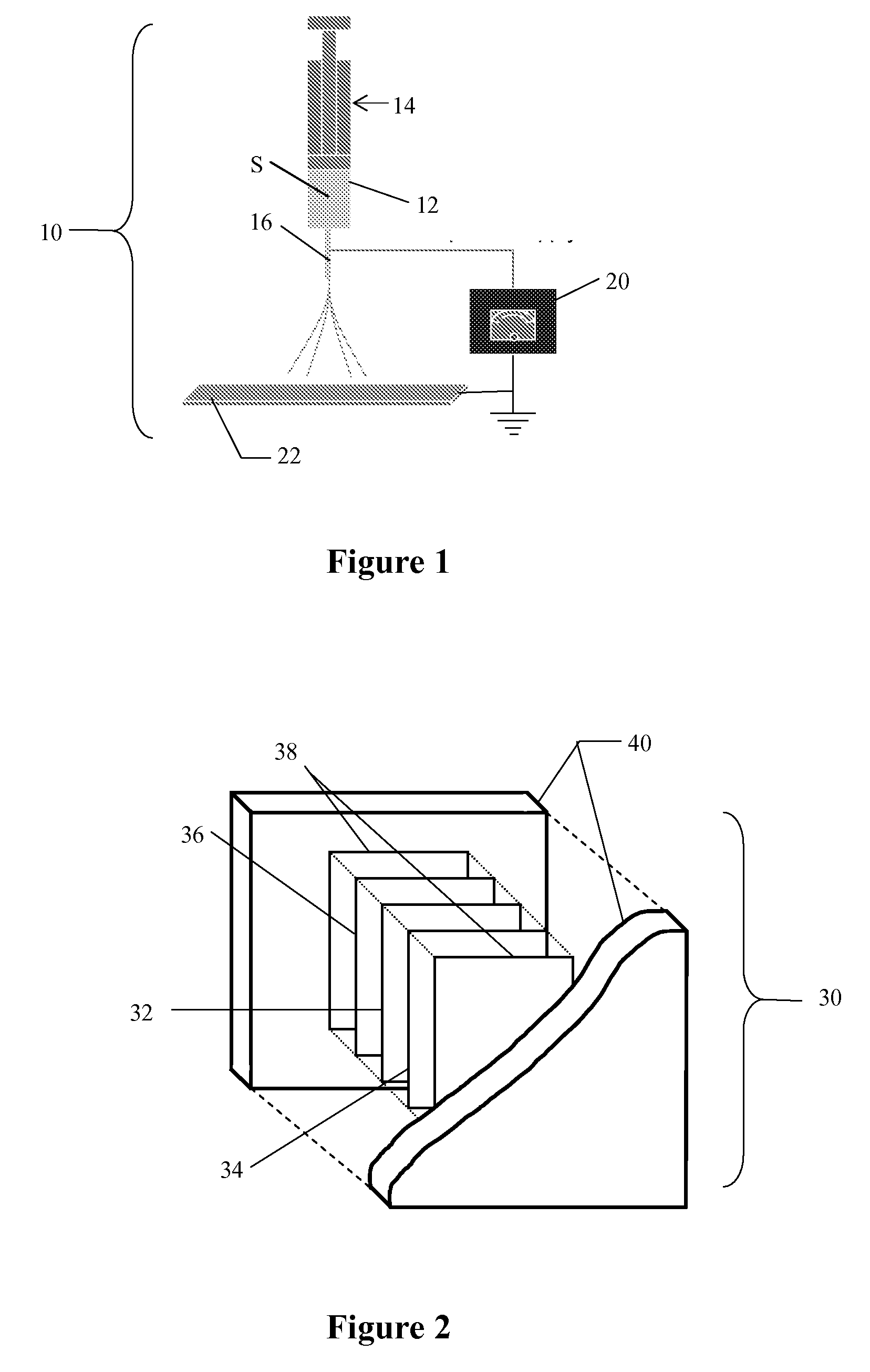

Shielded three-terminal flat-through emi/energy dissipating filter

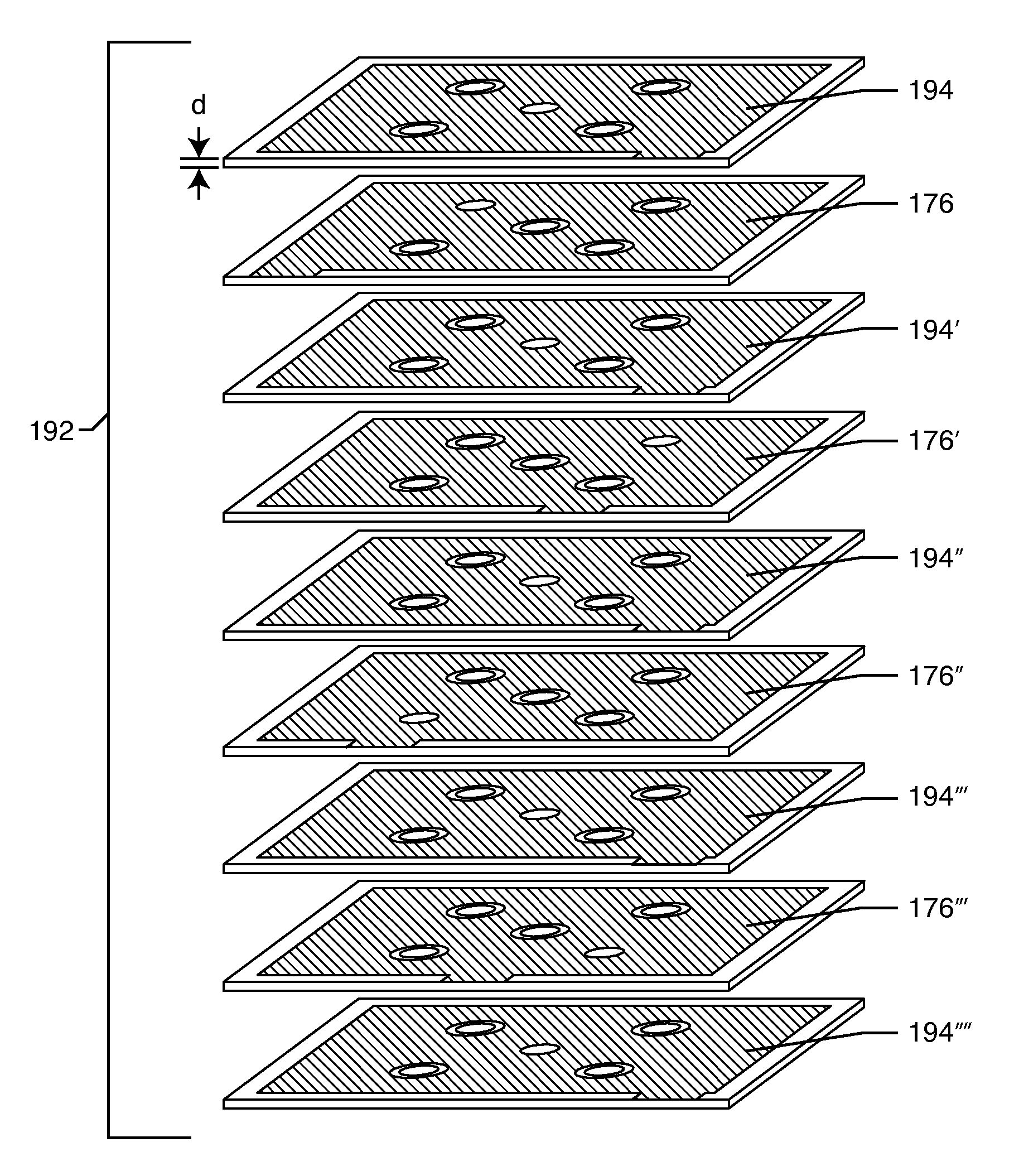

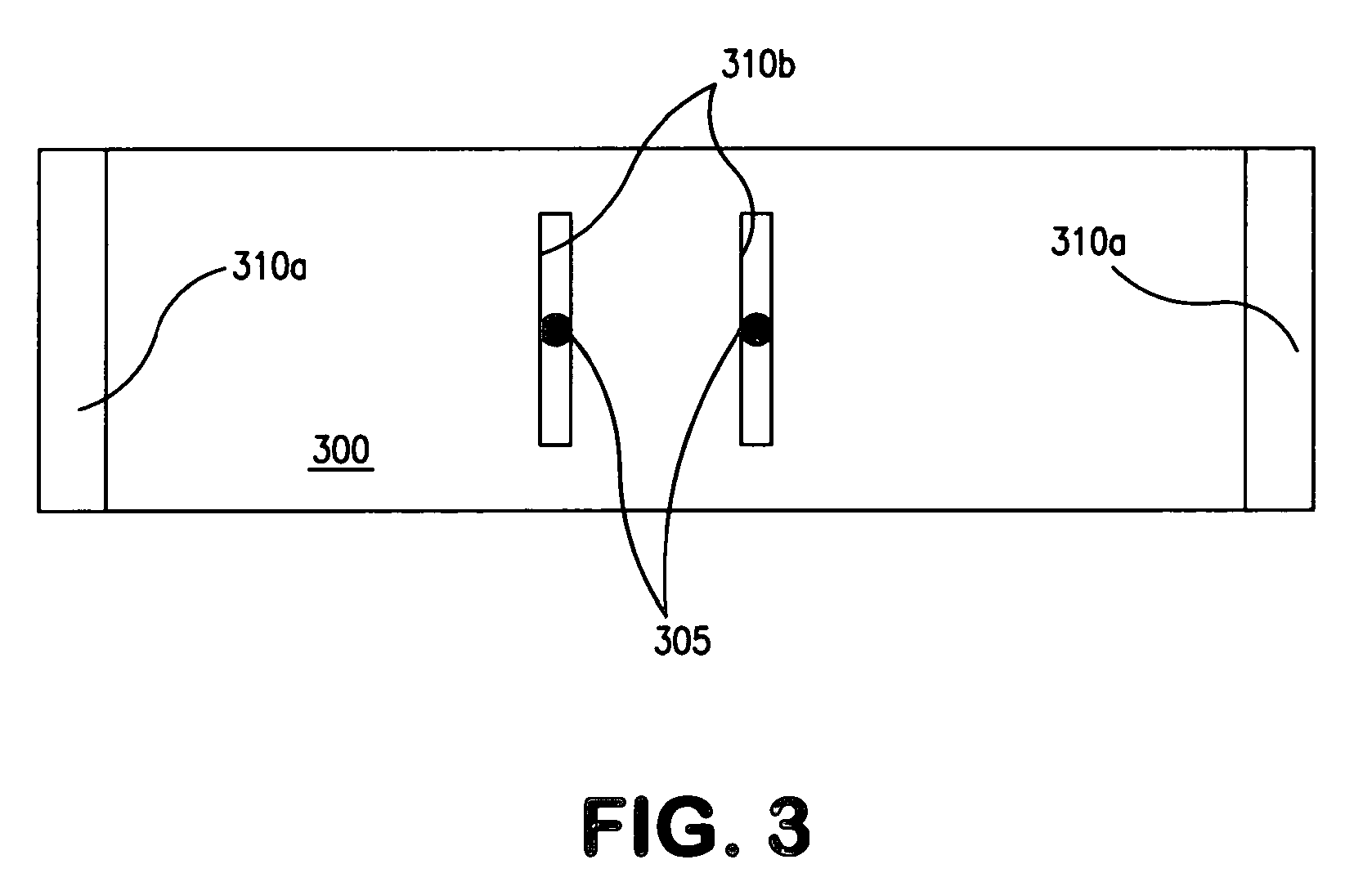

ActiveUS20090243756A1Maximize valueHigh surface areaMultiple-port networksAnti-noise capacitorsEngineeringFlexible cable

A shielded three-terminal flat-through EMI / energy dissipating filter includes an active electrode plate through which a circuit current passes between a first terminal and a second terminal, a first shield plate on a first side of the active electrode plate, and a second shield plate on a second side of the active electrode plate opposite the first shield plate. The first and second shield plates are conductively coupled to a grounded third terminal. In preferred embodiments, the active electrode plate and the shield plates are at least partially disposed with a hybrid flat-through substrate that may include a flex cable section, a rigid cable section, or both.

Owner:WILSON GREATBATCH LTD

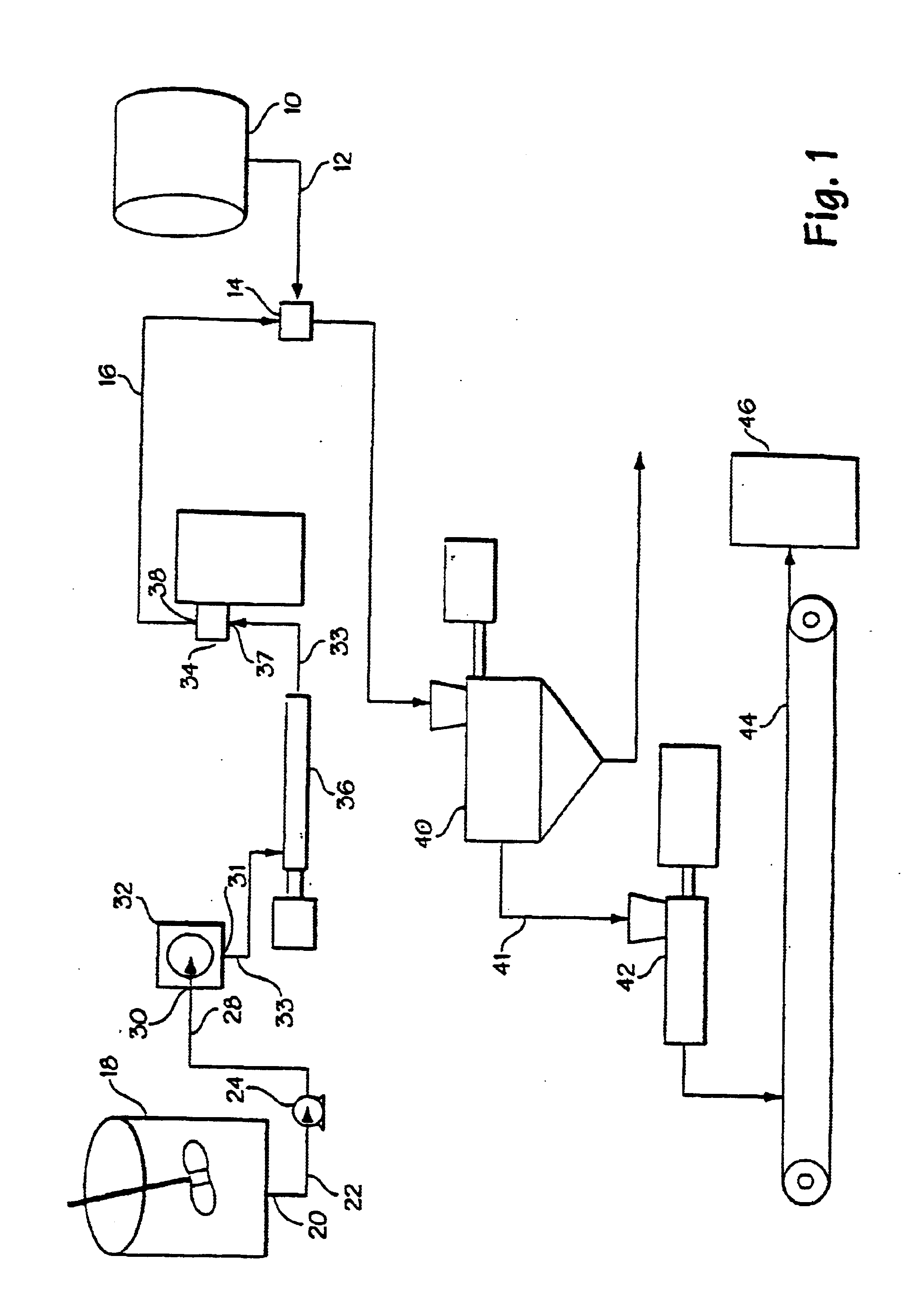

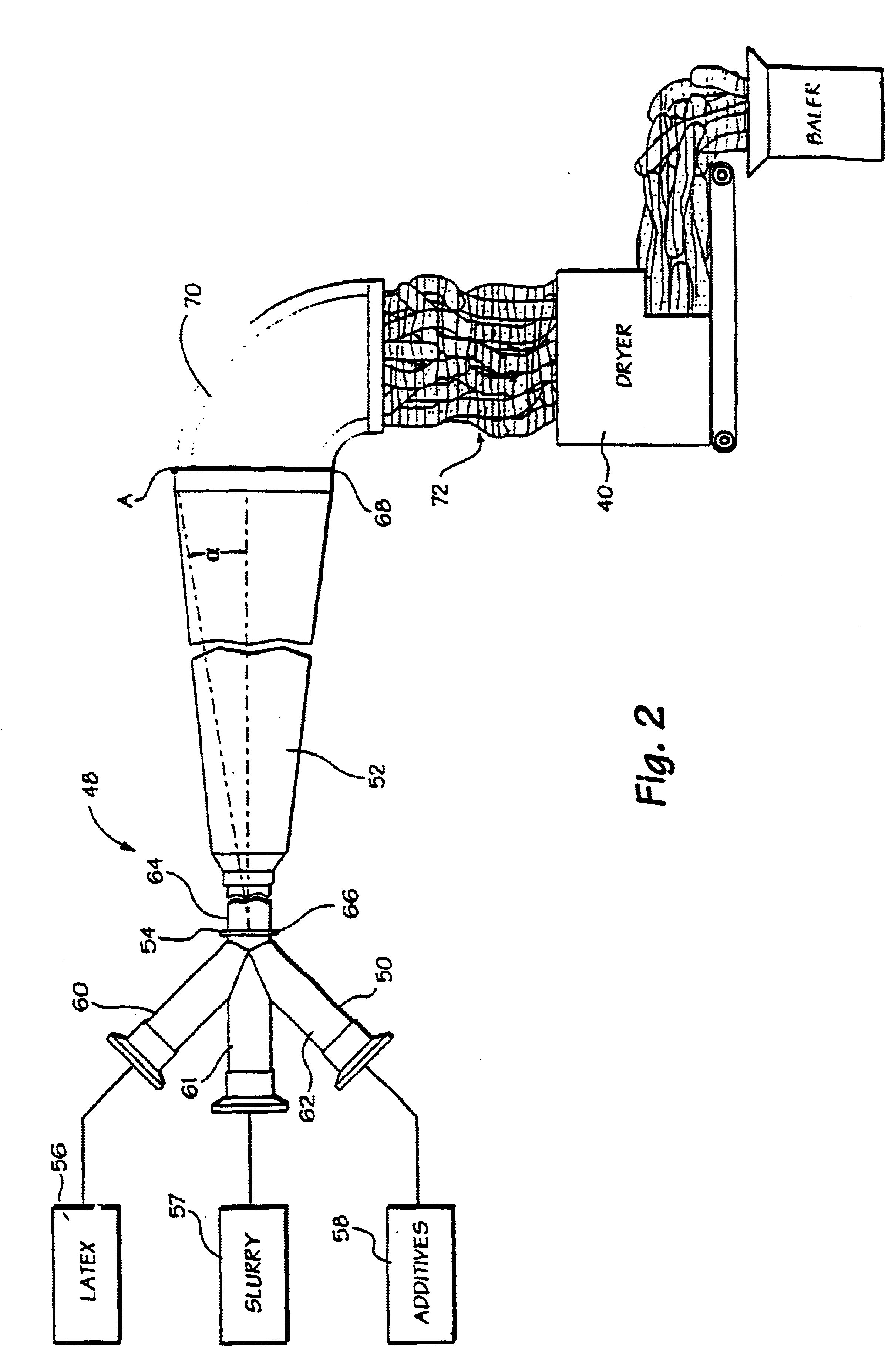

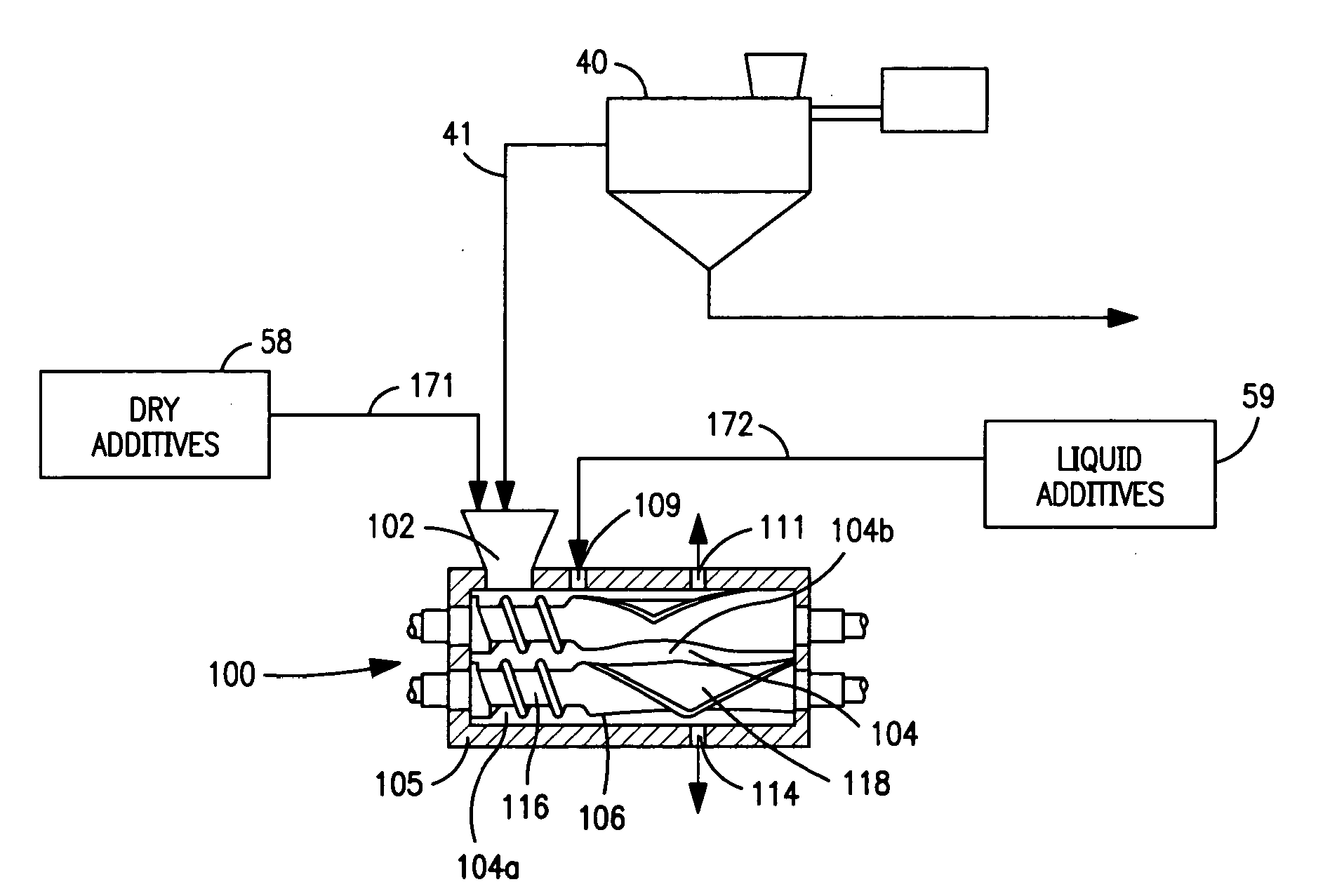

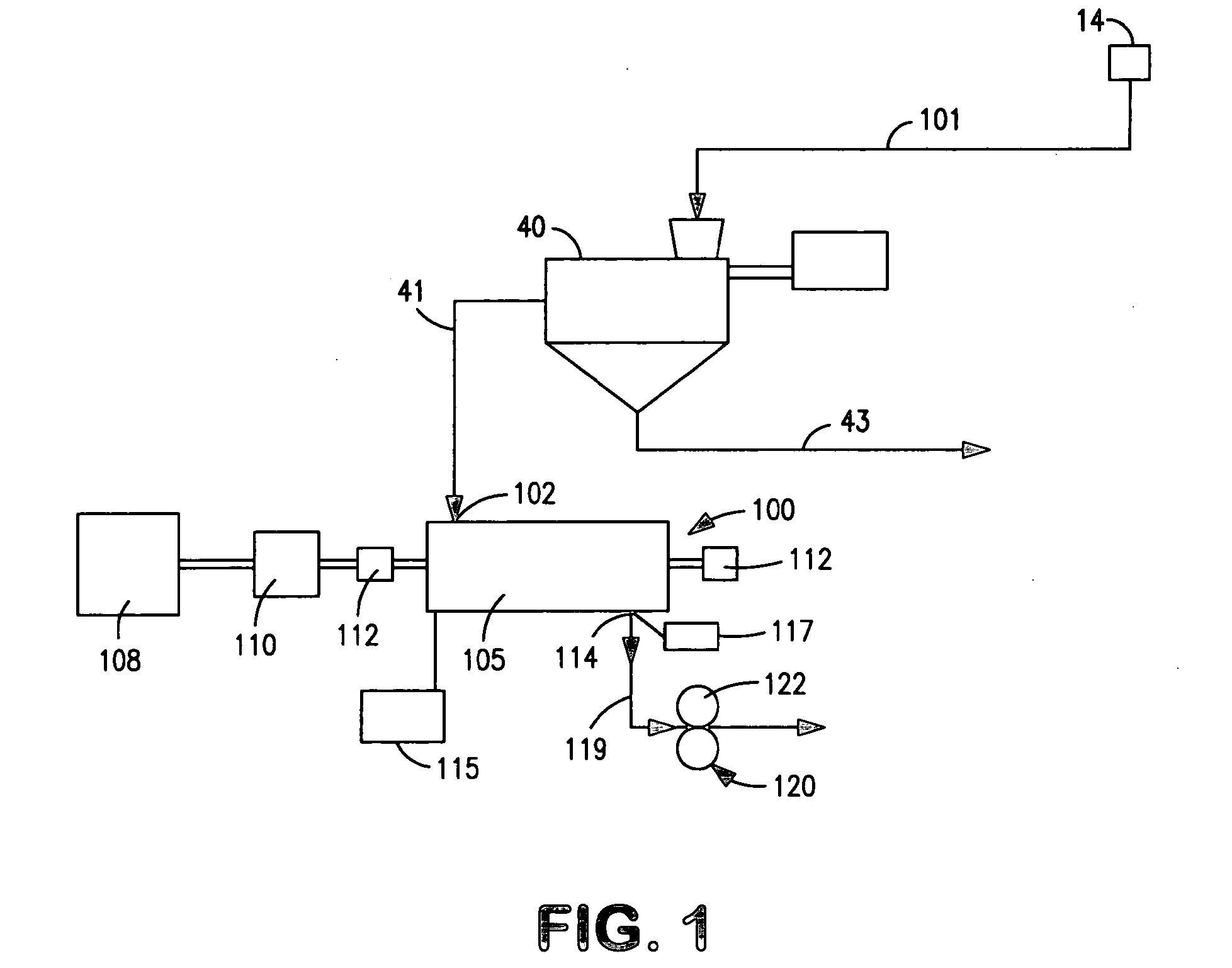

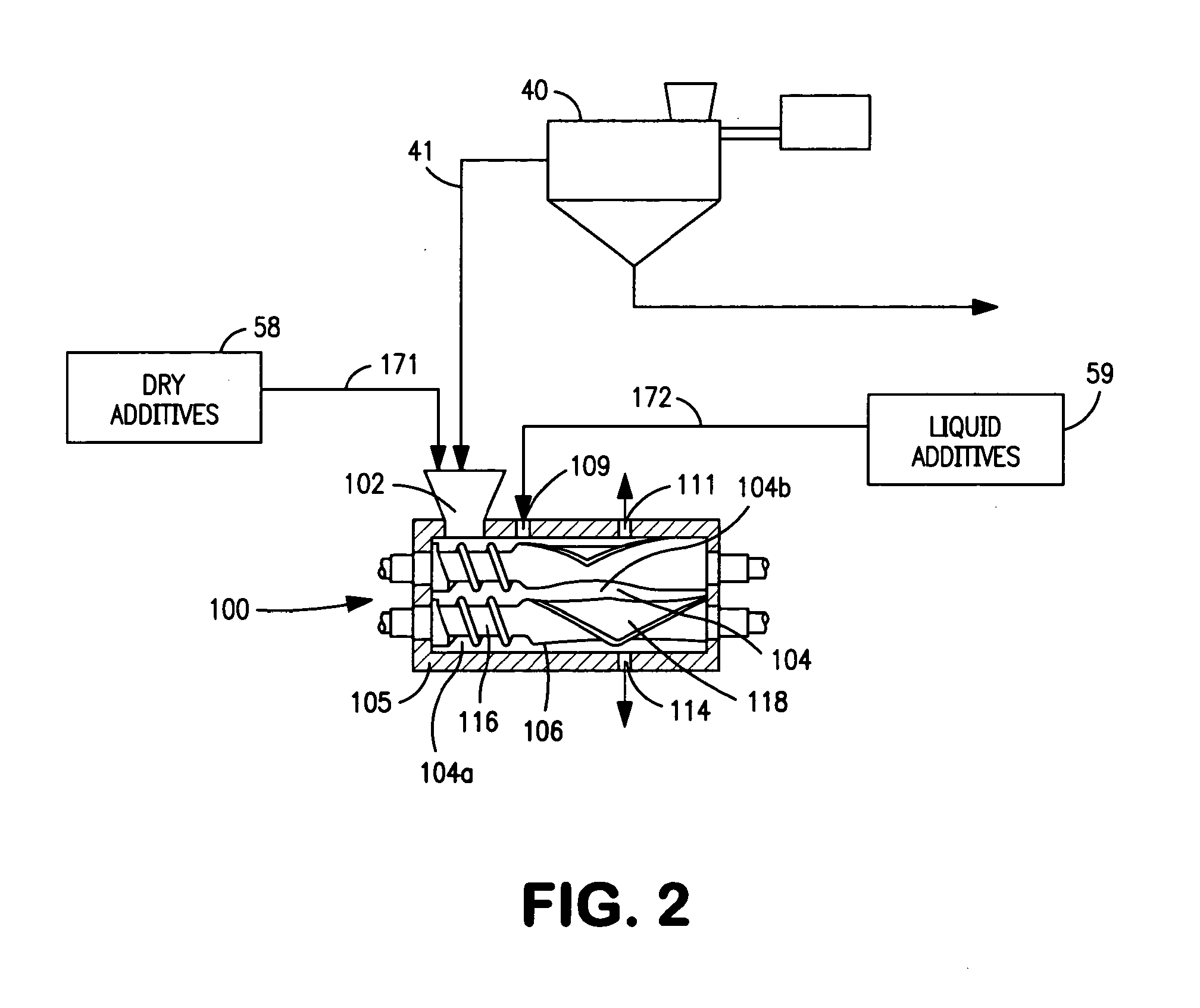

Elastomer composite blends and methods-II

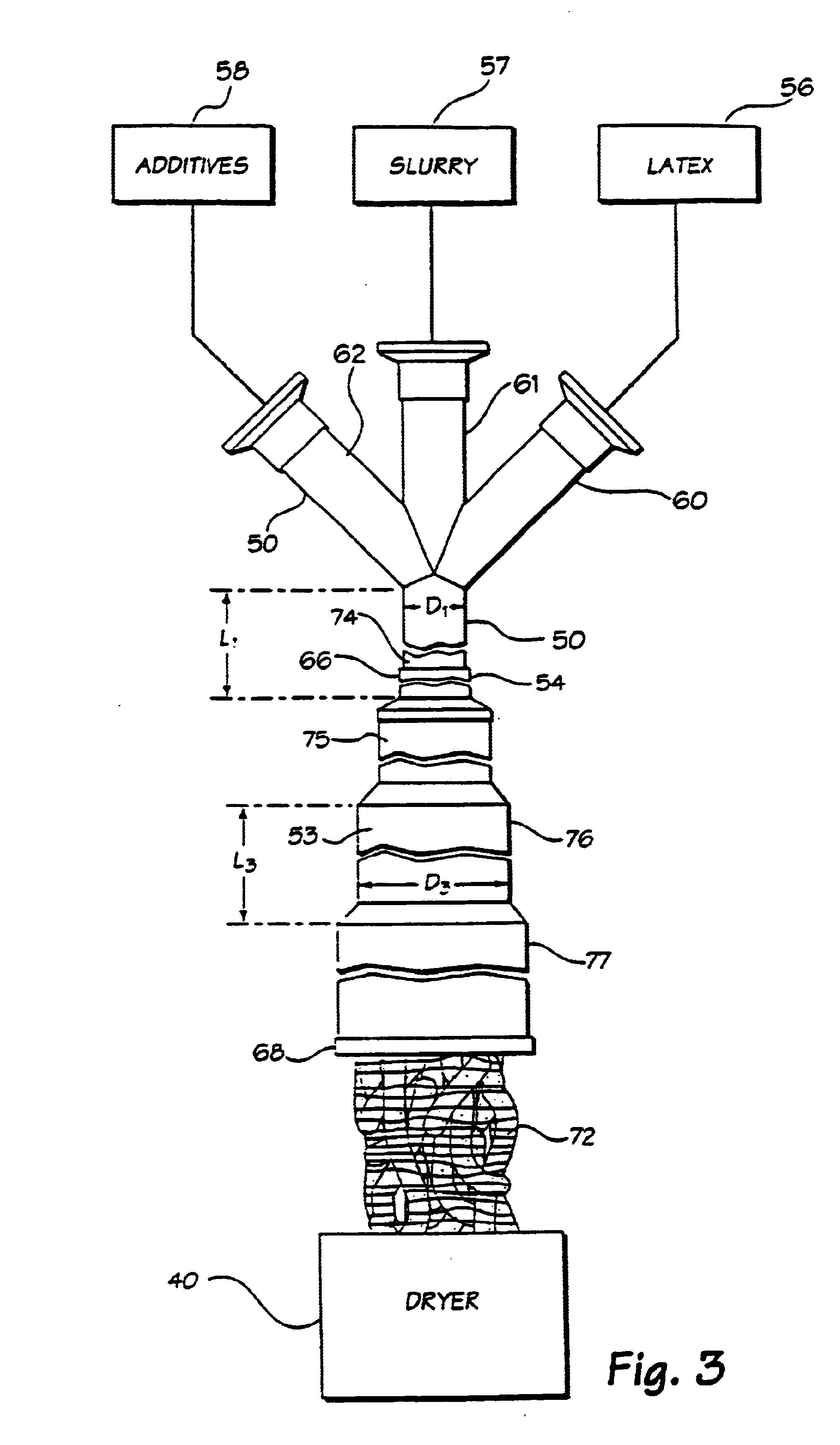

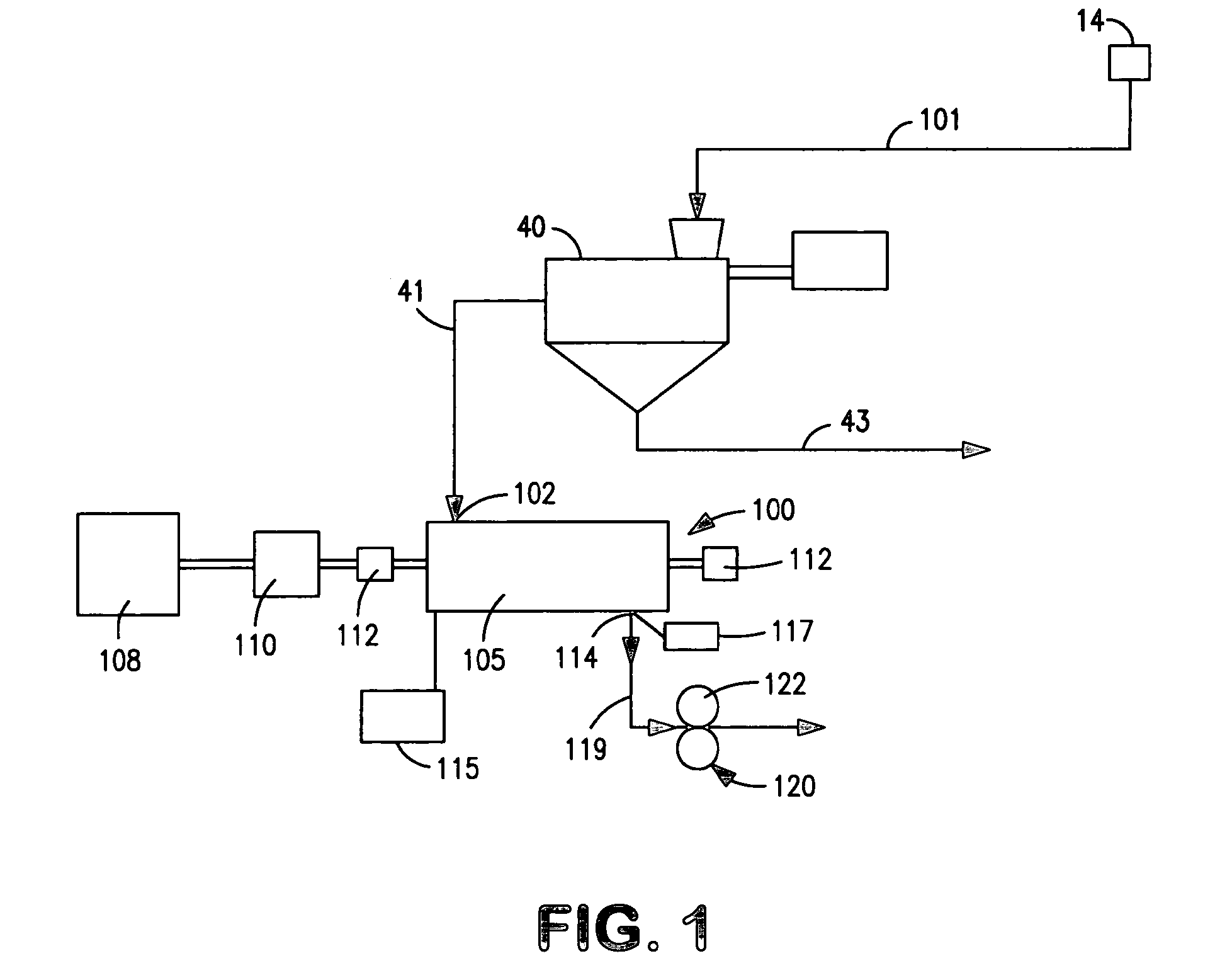

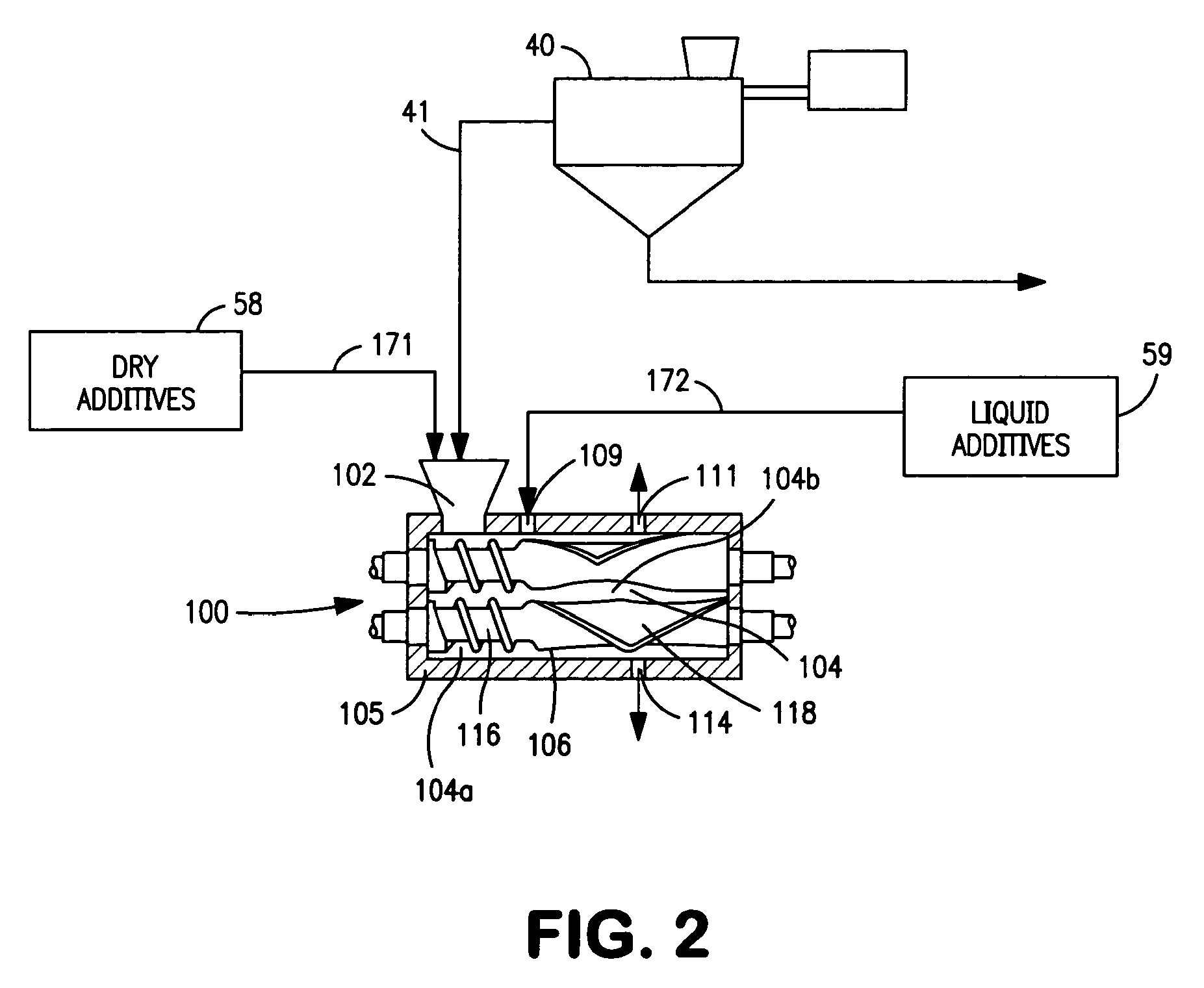

Elastomer composite blends are produced by novel wet / dry mixing methods and apparatus. In the wet mixing step or stage, fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end. Highly efficient and effective elastomer coagulation is achieved without the need for a coagulation step involving exposure to acid or salt solution or the like. Novel elastomer composites are produced. Such novel elastomer composites may be cured or uncured, and combine material properties, such as choice of filler, elastomer, level of filler loading, and macro-dispersion, not previously achieved. The coagulum produced by such wet mixing step, with or without intermediate processing steps, is then mixed with additional elastomer in a dry mixing step or stage to form elastomer composite blends. The additional elastomer to the coagulum may be the same as or different from the elastomer(s) used in the wet mixing step.

Owner:CABOT CORP

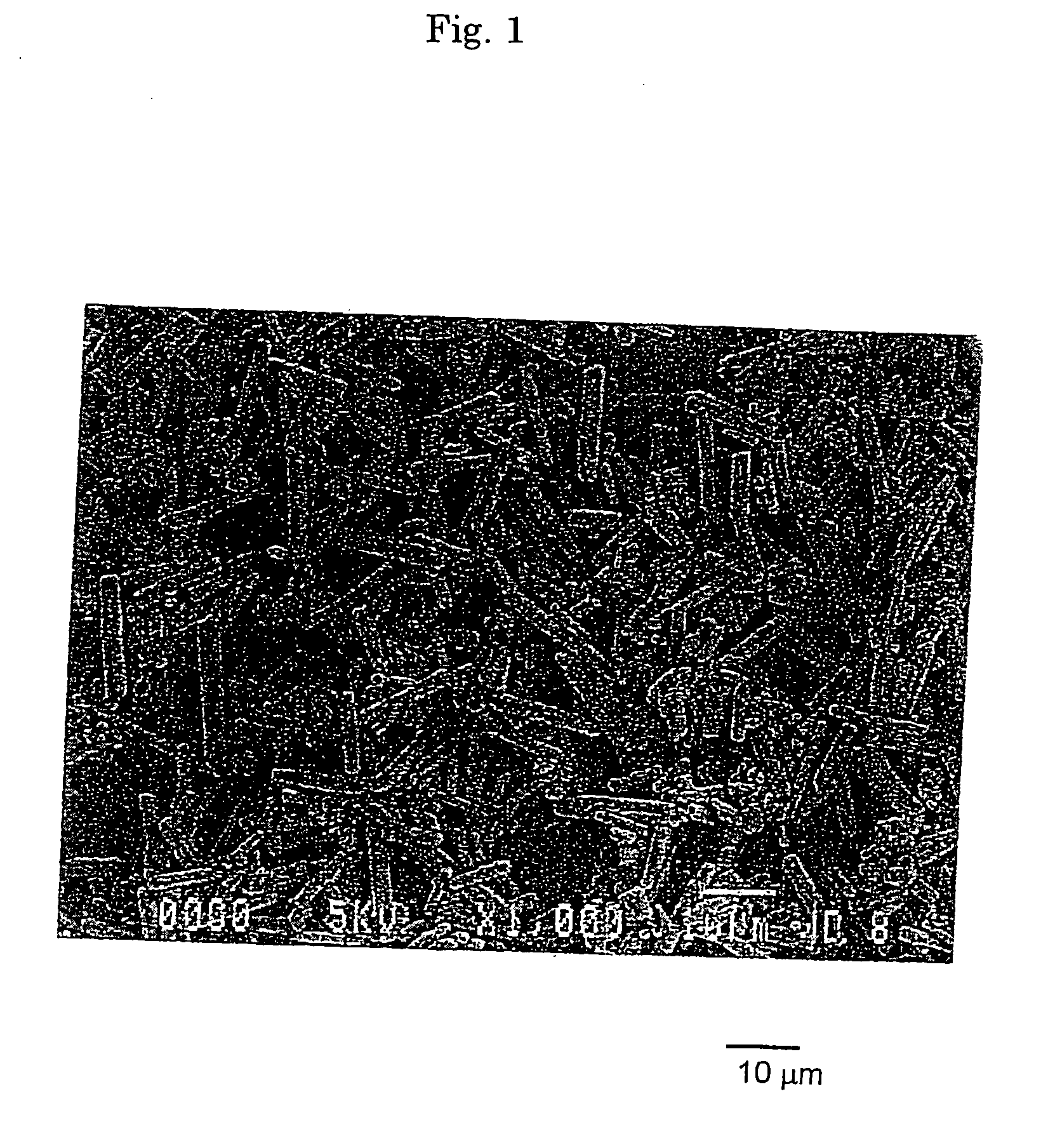

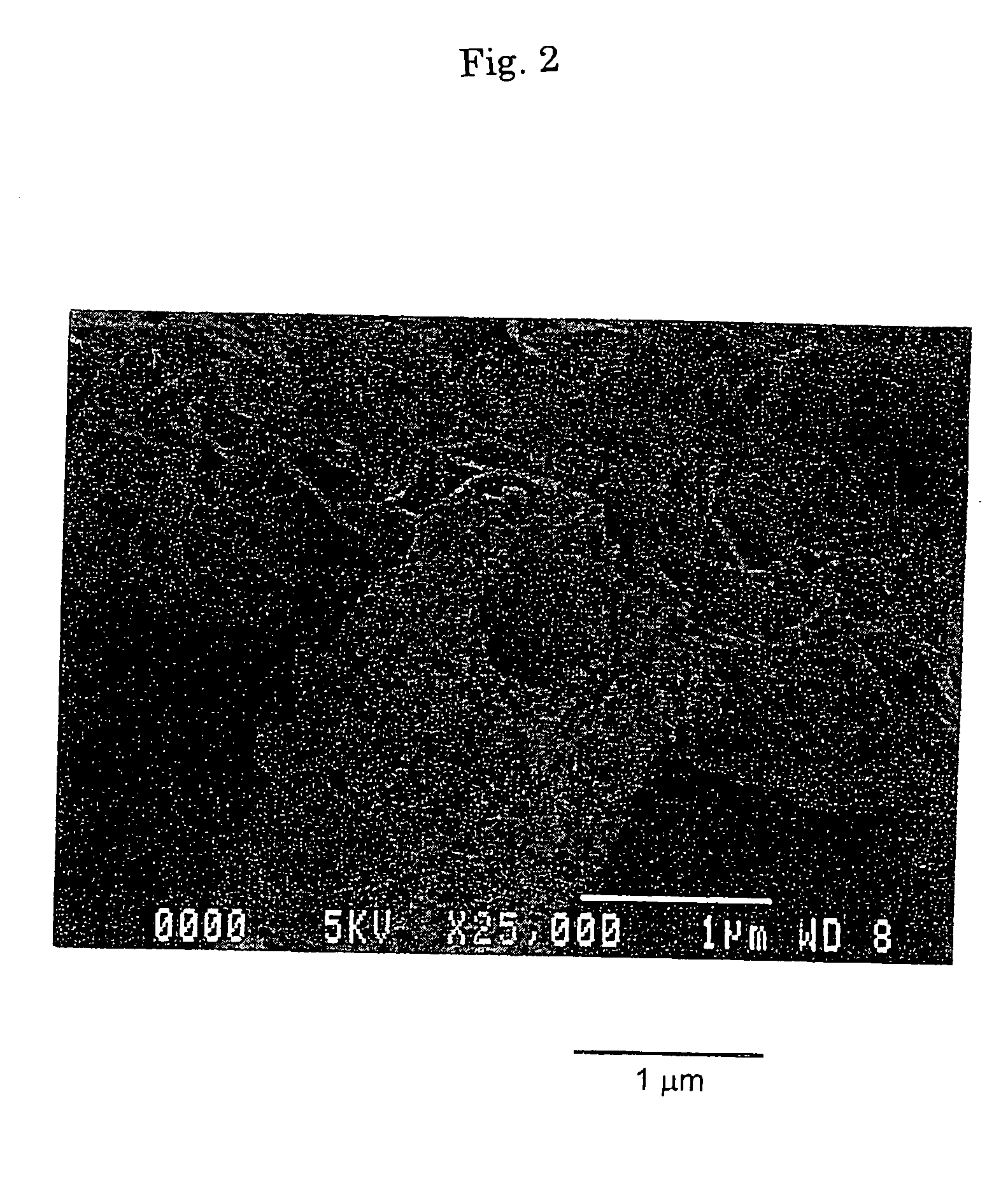

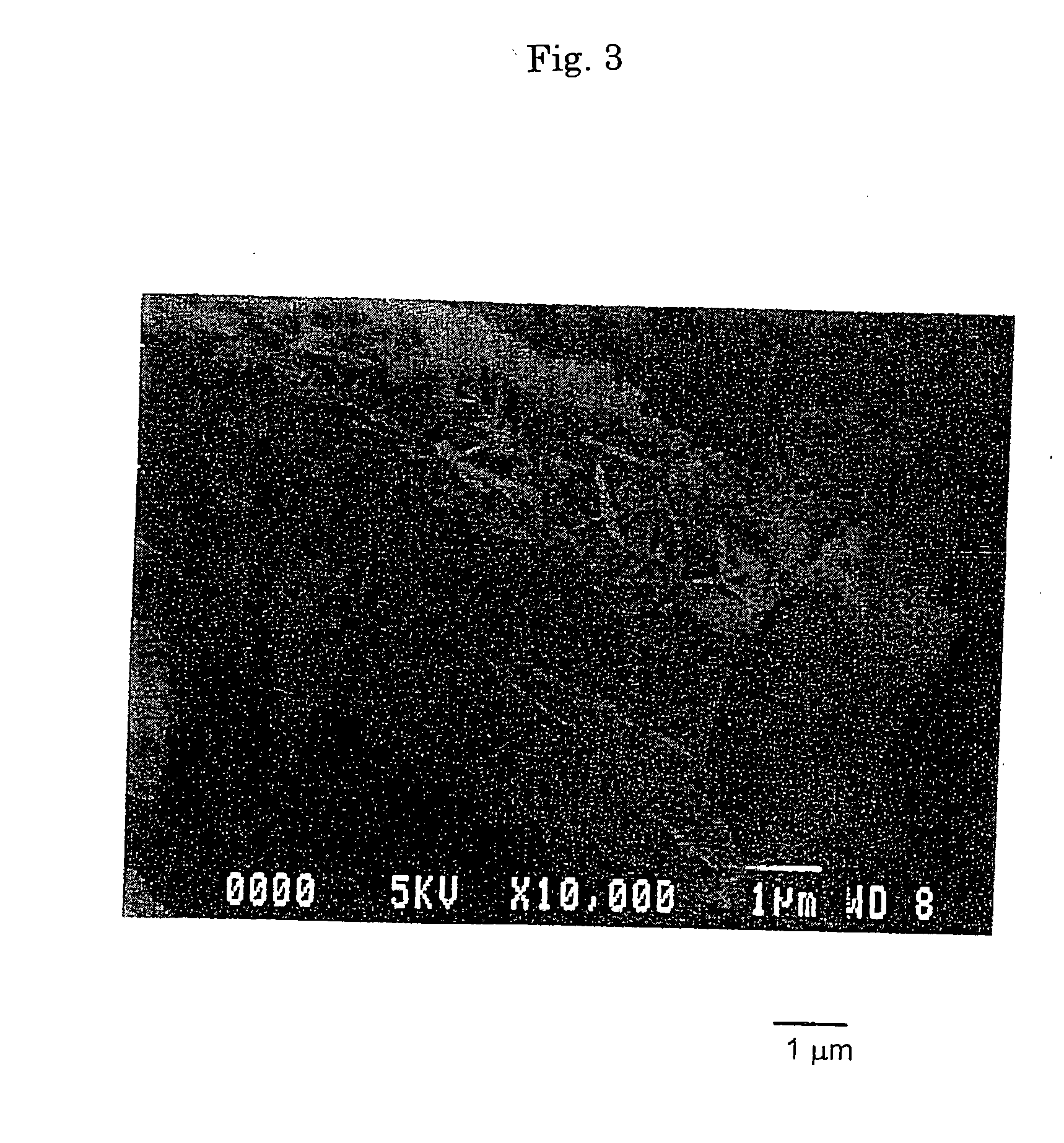

Basic magnesium carbonate, production method and use of the same

ActiveUS20050129606A1Large specific surface areaImprove featuresCalcium/strontium/barium carbonatesBiocideCarbonateMagnesium carbonate hydroxide

Owner:NITTETABU MINING CORP

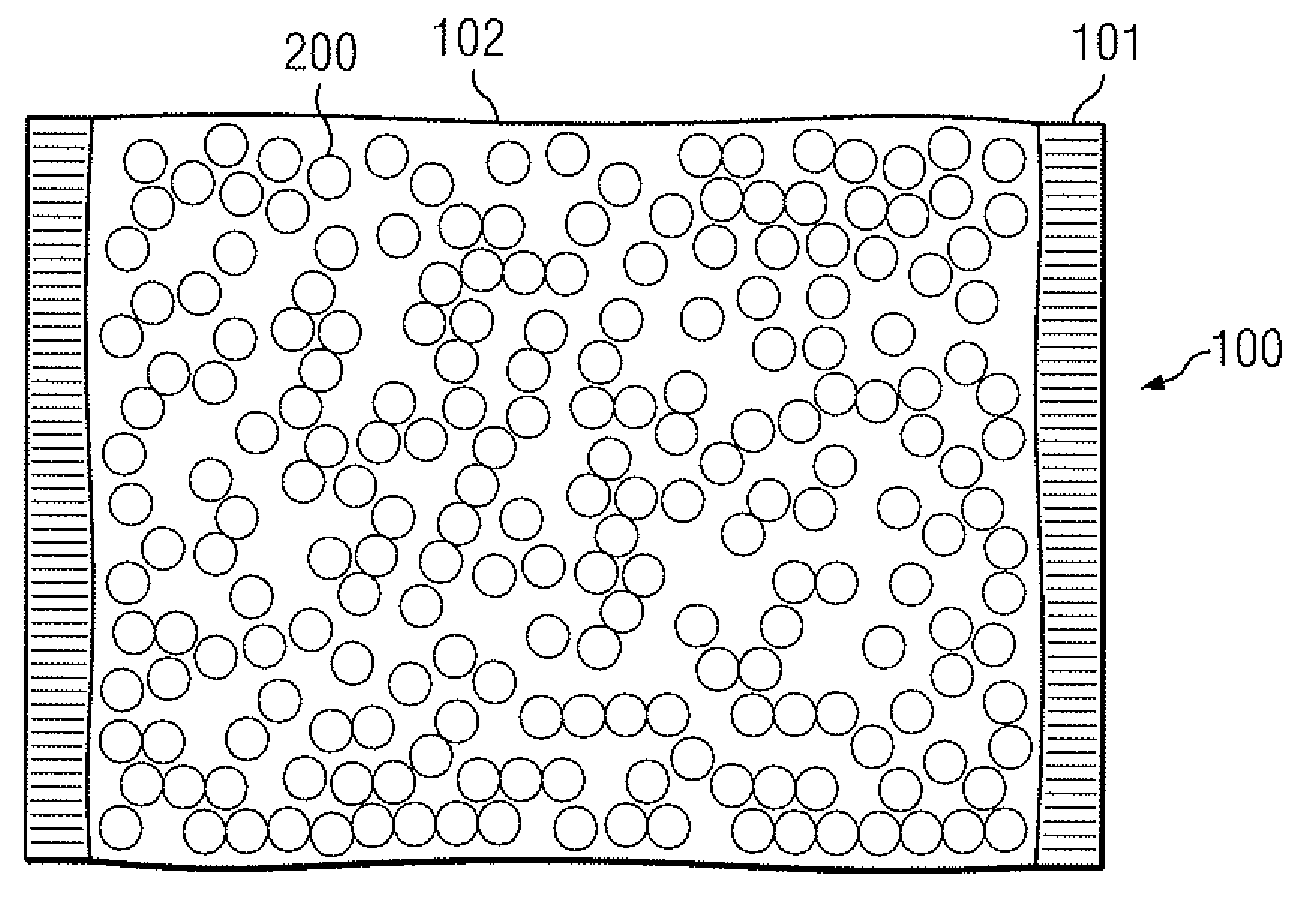

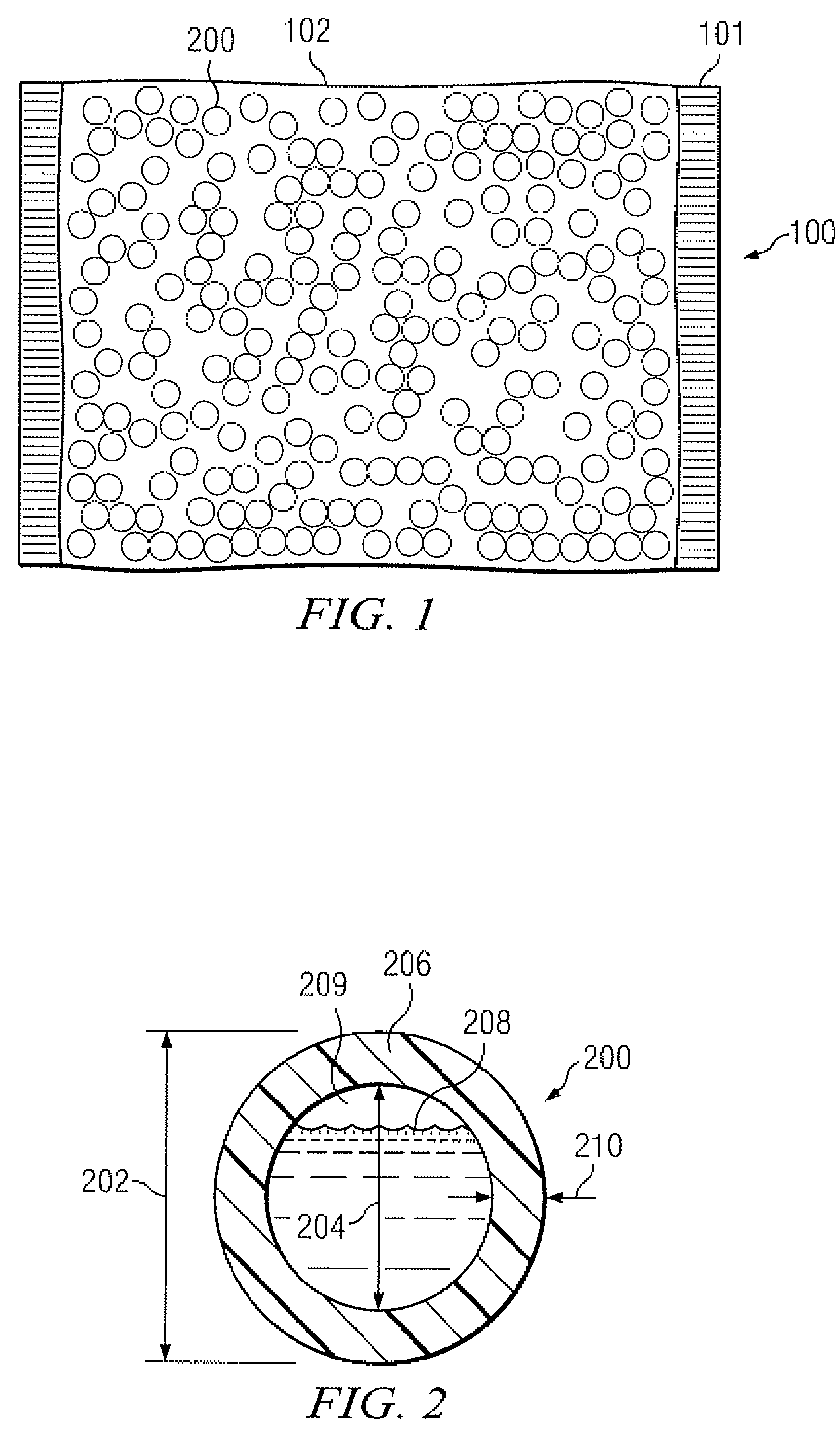

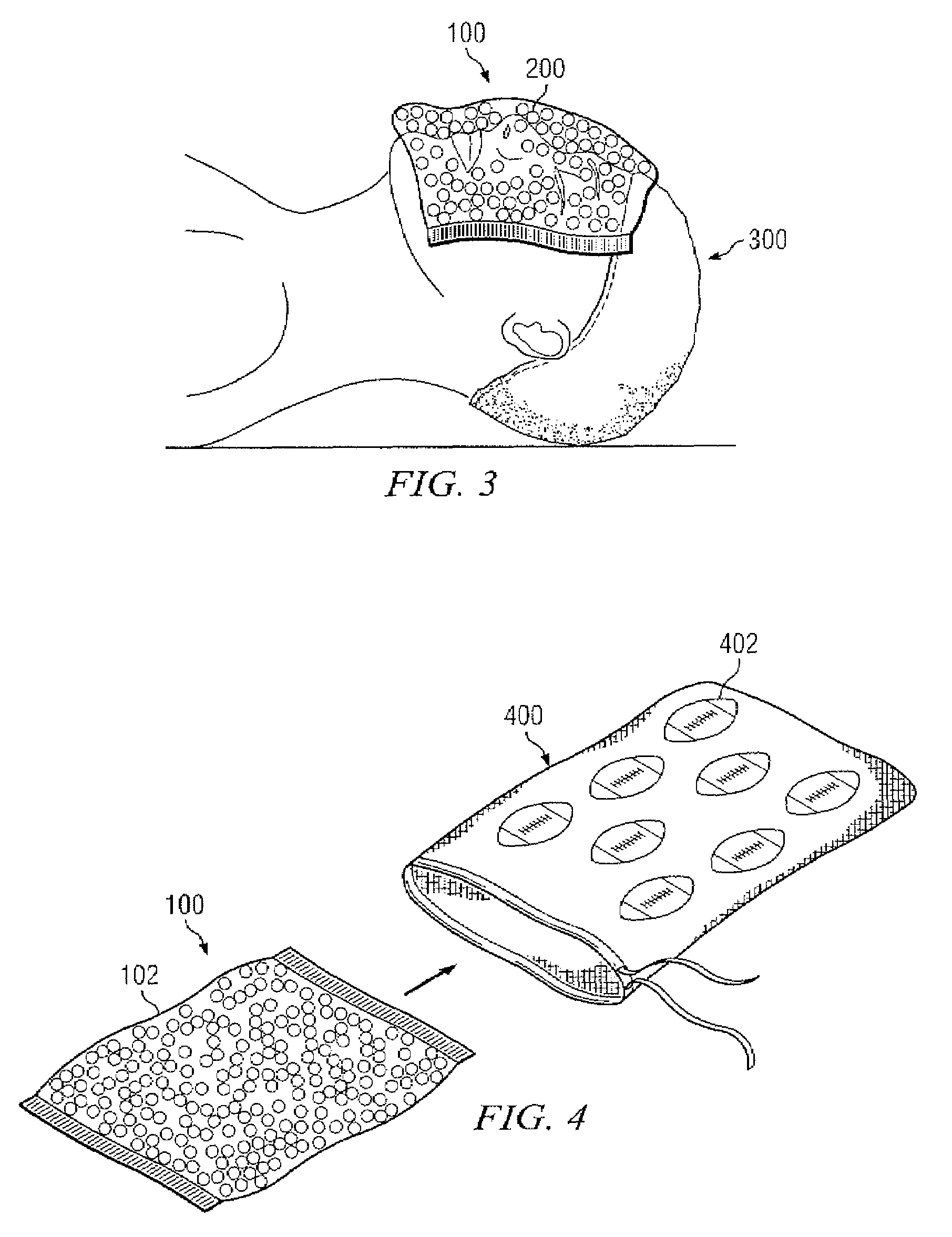

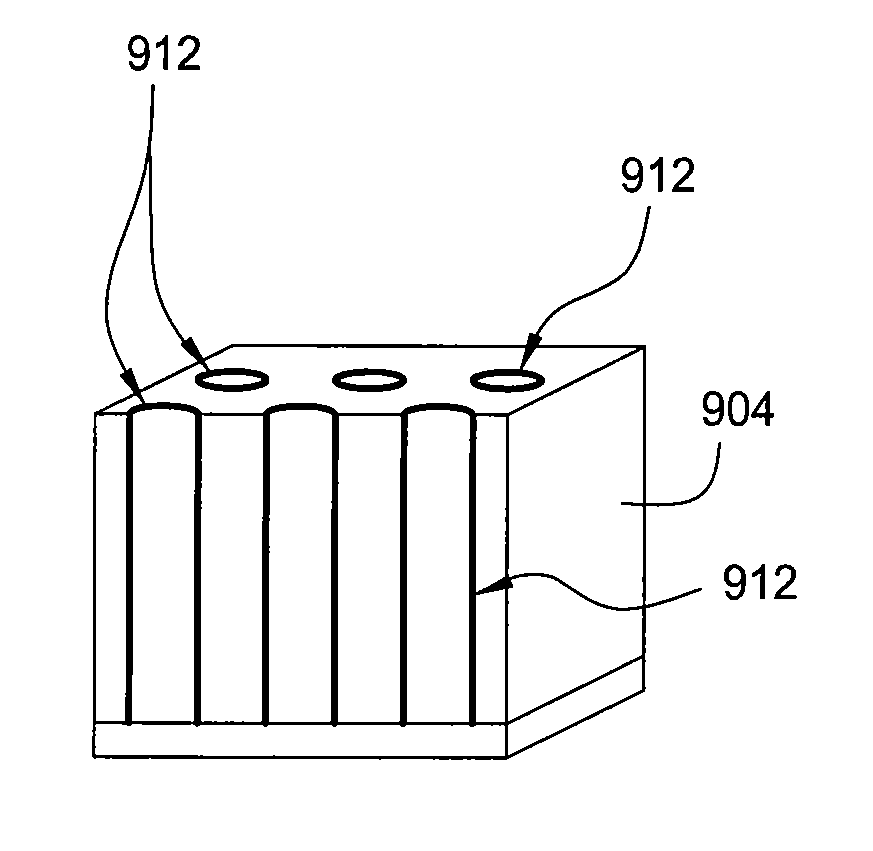

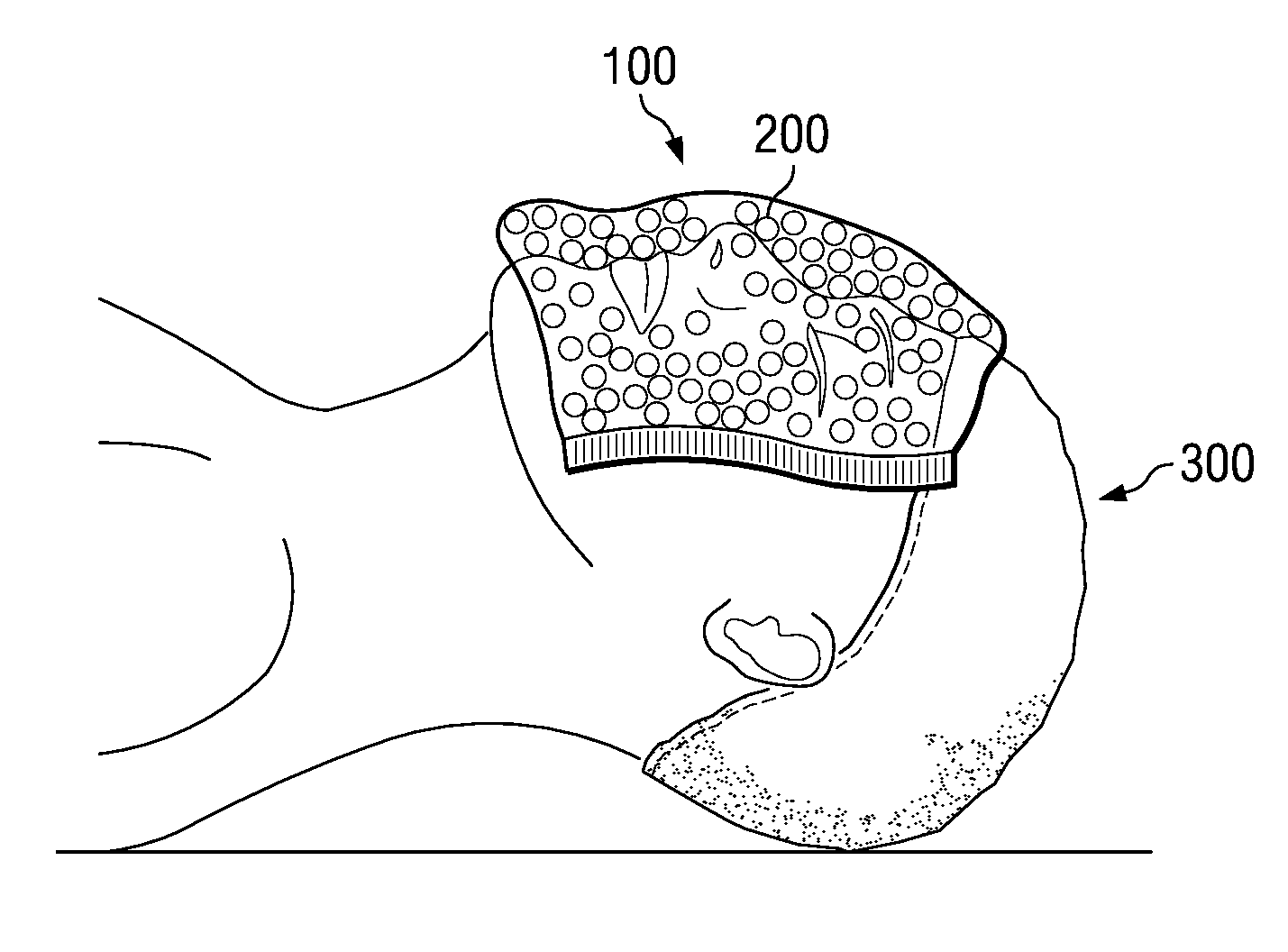

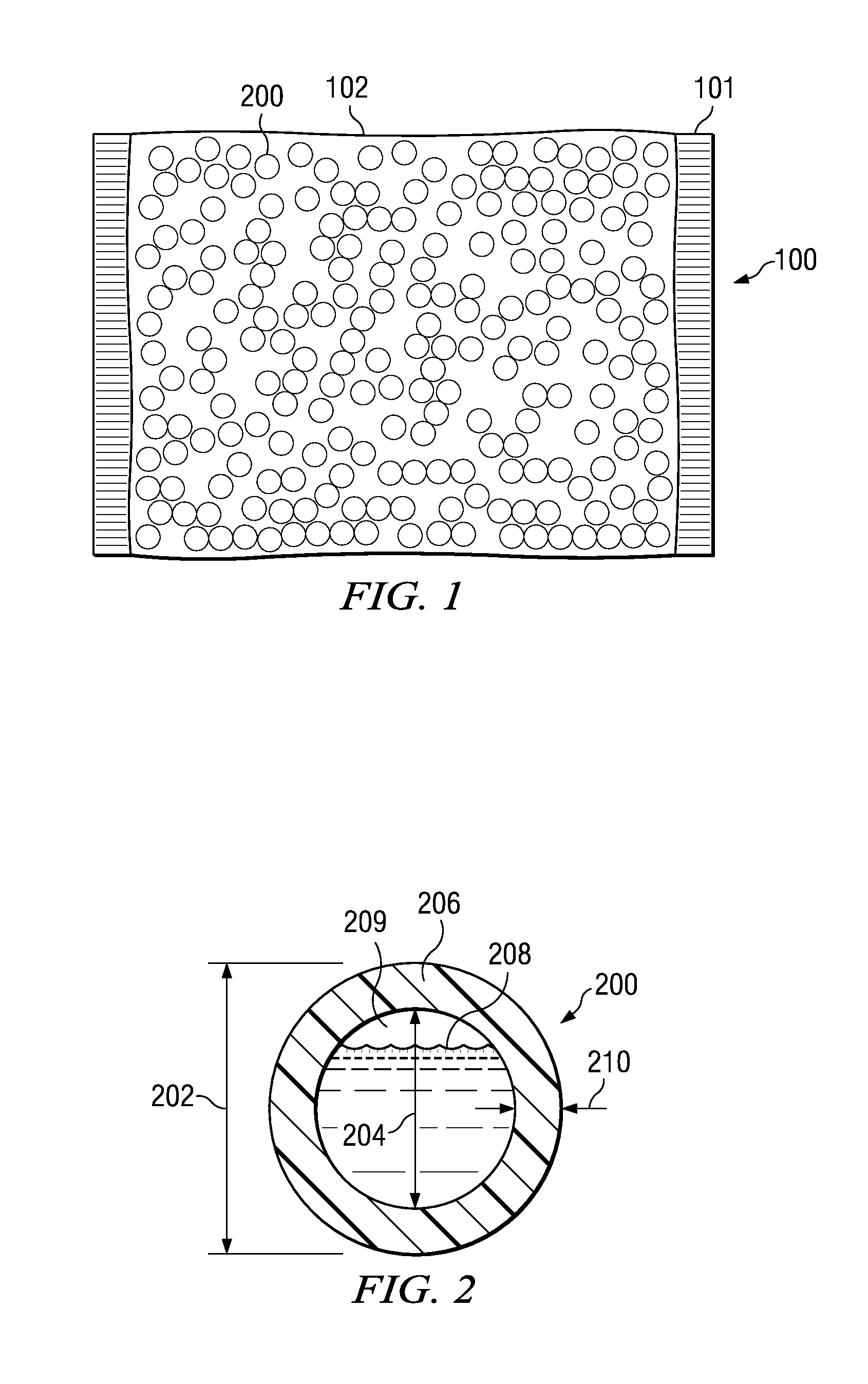

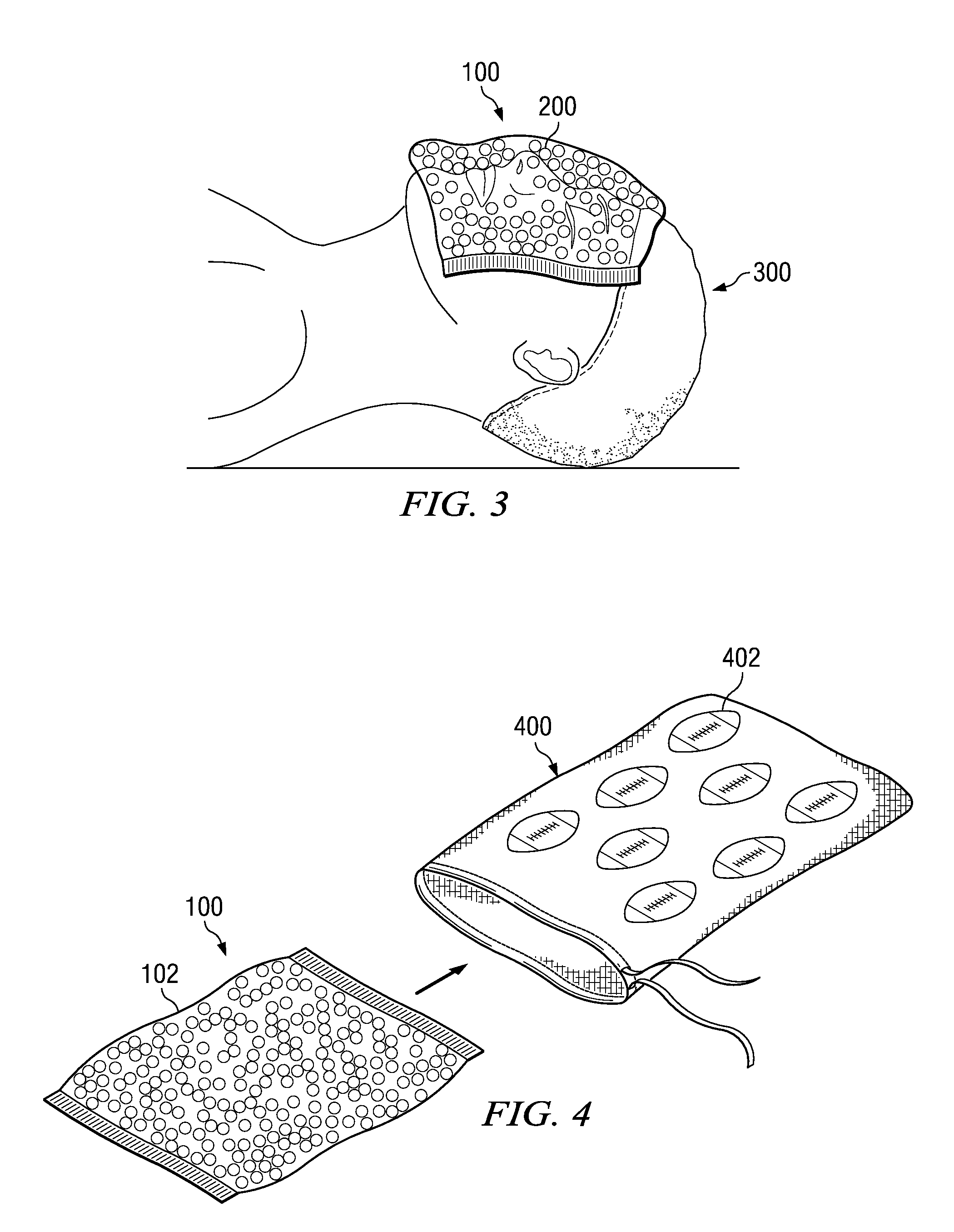

Cold Compress for Therapeutic Cooling

InactiveUS20080119916A1High heat transfer and flexibility and contour abilityIncrease the volume ratioTherapeutic coolingTherapeutic heatingCold compressesHeat transfer fluid

A novel cold compress designed for use as a cooling medium. The cold compress comprises a flexible bag having a plurality of spheres. Each sphere contains a heat transfer fluid. As the bag is cooled or frozen, each sphere and the fluid they contain become cool or frozen. The bag is then placed on a body pail of the patient who is recovering from surgery or injury. The small spheres allow maximum surface contact with the body part. This allows maximum and efficient heat transfer.

Owner:CHOUCAIR RAMSEY JOE +2

High polymer-based graphene composite material with positive resistance temperature coefficient and preparation method

InactiveCN102532669AReduce dosageImprove conductivityState of artElectrical resistance and conductance

The invention relates to a high polymer-based graphene composite material with positive resistance temperature coefficient, and a preparation method of the material. The composite material comprises a base body and conductive filler; the content of conductive material is 0.01-10wt%; all components are mixed uniformly and are formed through mold-pressing or extrusion / injection molding; and the formed material is irradiated after being dried, so that the high polymer-based graphene composite material with positive resistance temperature coefficient can be obtained. Compared with the prior art, the graphene composite material and the preparation method have the advantages that the manufacturing process is simple, less influence is caused to the performance of base material, oxidation is unlikely to occur, the resistivity is more stable, the circulation stability of the material is better, and NTC (Negative Temperature Coefficient) effect is not generated easily.

Owner:SHANGHAI JIAO TONG UNIV

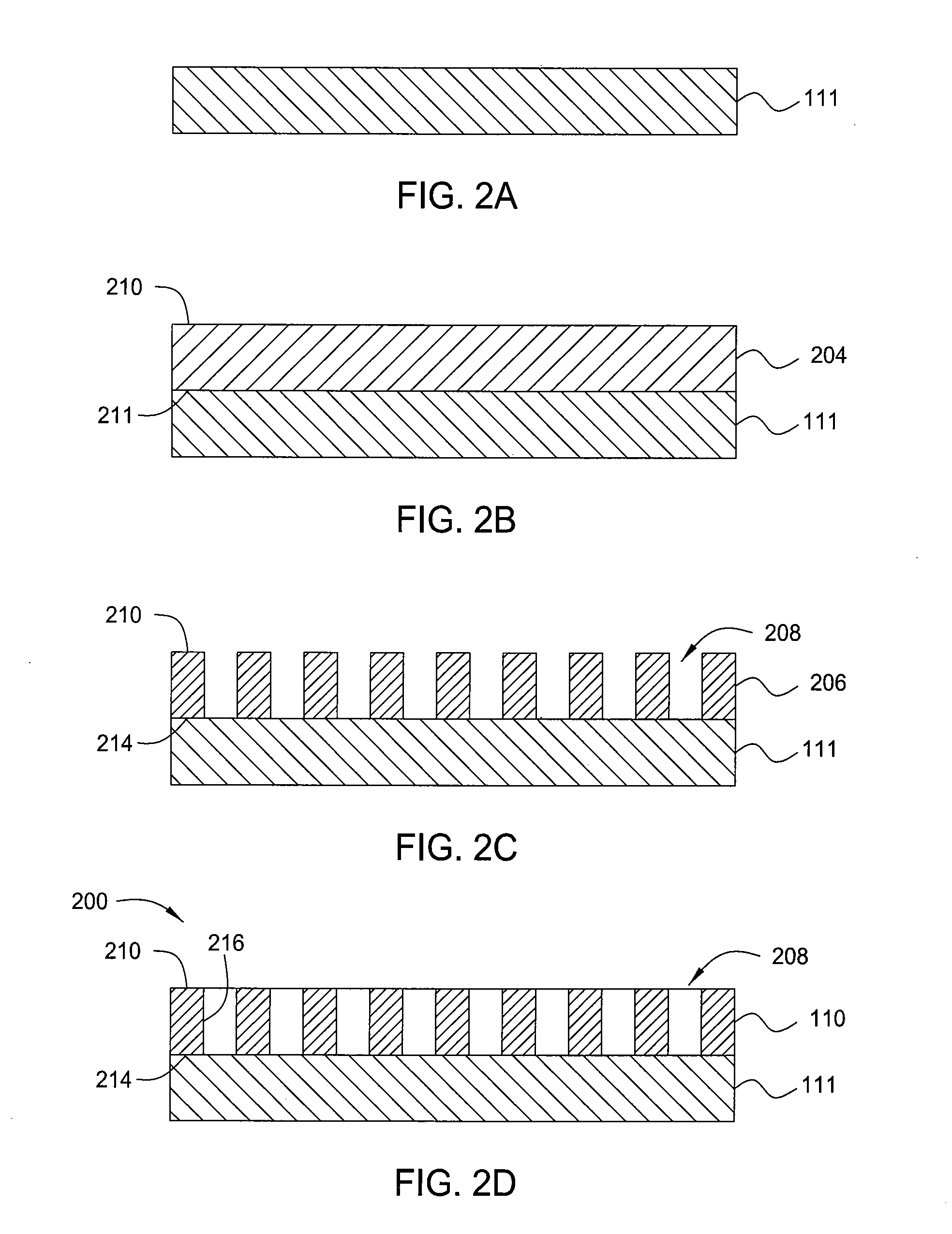

Porous amorphous silicon-carbon nanotube composite based electrodes for battery applications

InactiveUS20110051322A1High surface areaAnodisationLiquid surface applicatorsCarbon nanotubeCurrent collector

Embodiments of the present invention generally relate to methods and apparatus for forming an energy storage device. More particularly, embodiments described herein relate to methods of forming electric batteries and electrochemical capacitors. In one embodiment a method of forming a high surface area electrode for use in an energy storage device is provided. The method comprises forming an amorphous silicon layer on a current collector having a conductive surface, immersing the amorphous silicon layer in an electrolytic solution to form a series of interconnected pores in the amorphous silicon layer, and forming carbon nanotubes within the series of interconnected pores of the amorphous silicon layer.

Owner:APPLIED MATERIALS INC

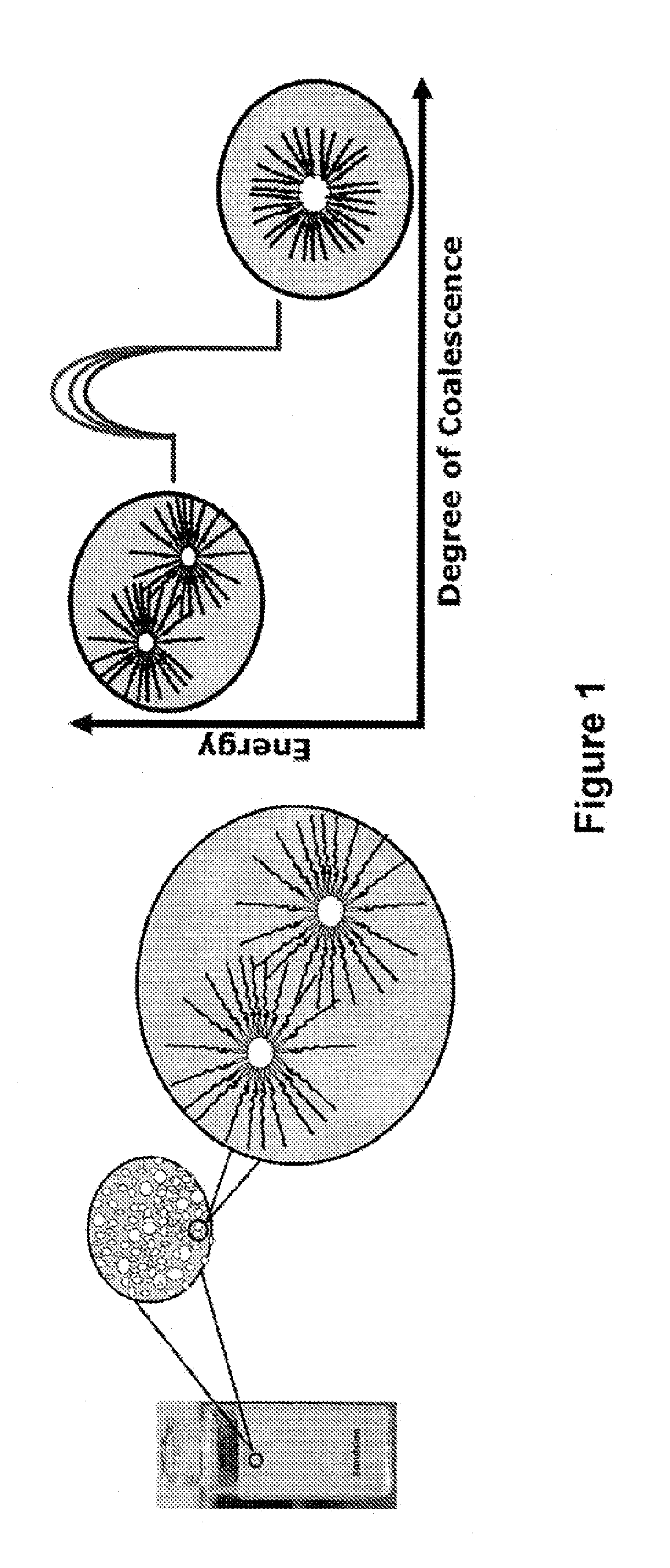

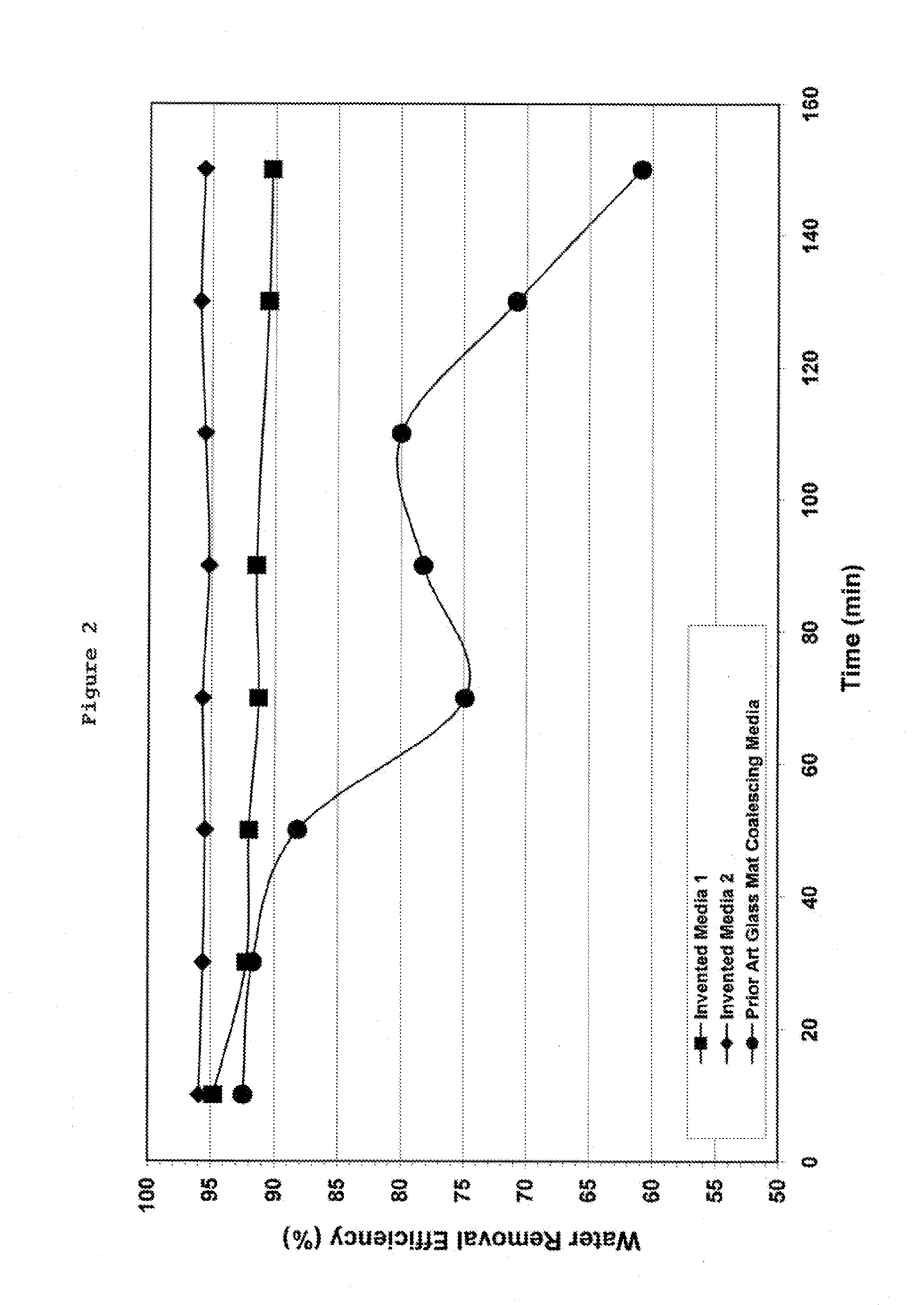

Coalescence media for separation of water-hydrocarbon emulsions

ActiveUS20110147299A1Low energyHigh surface areaLoose filtering material filtersGravity filtersNatural fiberMicrofiber

A coalescence media for separation of water-hydrocarbon emulsions comprises an emulsion-contacting sheet formed of: (a) at least one component of the group consisting of natural fibers, cellulose fibers, natural-based fibers, and cellulose-based fibers, at least one component of the group consisting of high-surface-area fibrillated fibers, surface-area-enhancing synthetic material, glass microfibers, and nanoceramic functionalized fibers; and (c) at least one component of the group consisting of a dry strength additive, and a wet strength additive, wherein the fibrous components of the media constitute at least about 70% of the media. In preferred embodiments, the coalescence media comprises kraft fibers, fibrillated lyocell fibers, glass microfibers or nanoceramic functionalized fibers, a wet strength additive, and a dry strength additive. Preferably, the coalescence media is formed as a single, self- supporting layer from a wet-laid process using a homogenously distributed, wet-laid furnish. It may also be formed as a multi-layer structure.

Owner:A AHLSTROM CORP

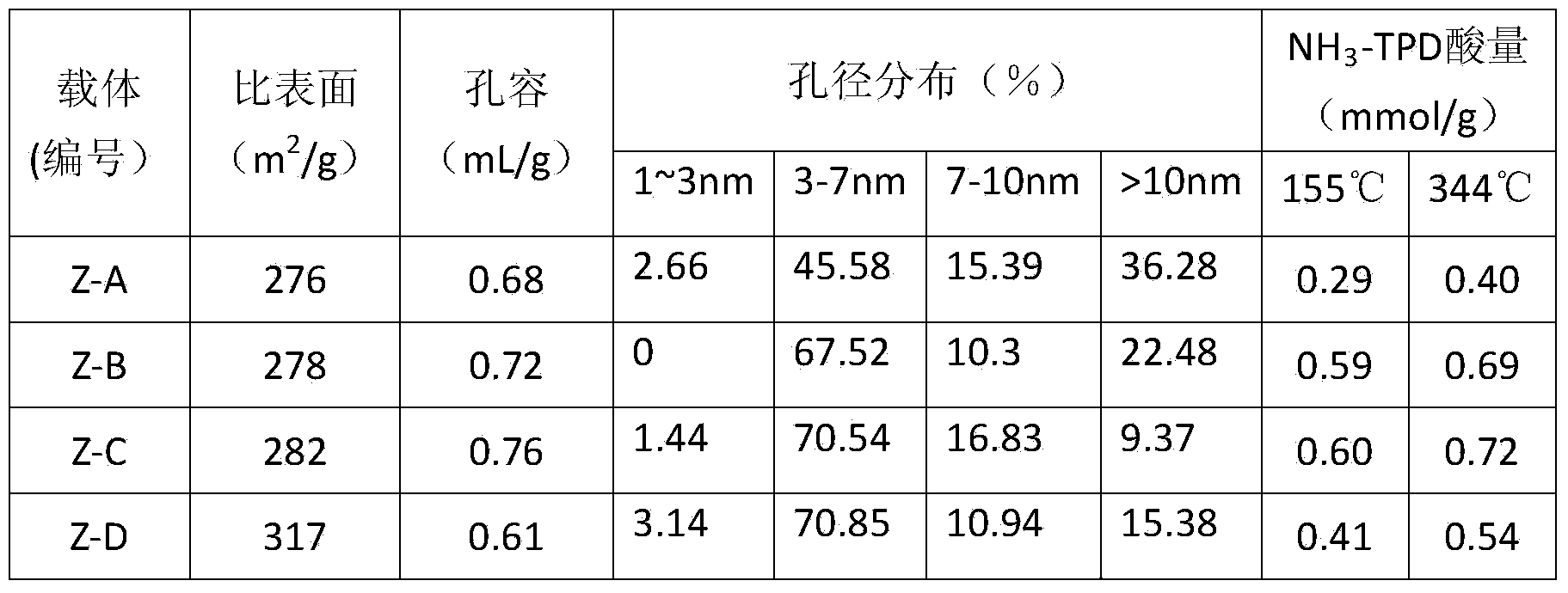

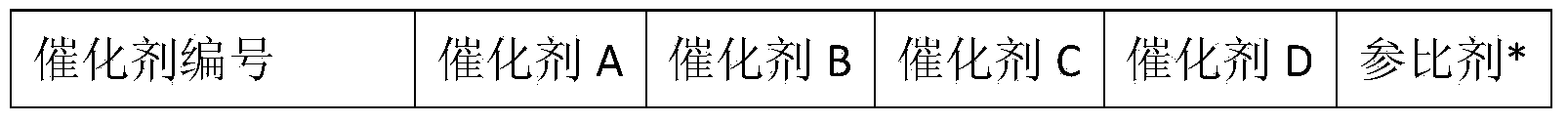

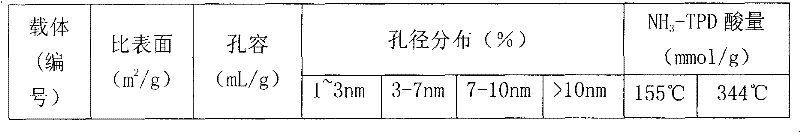

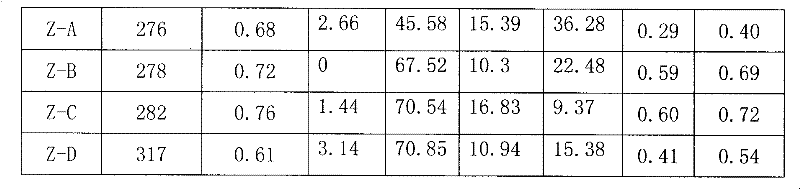

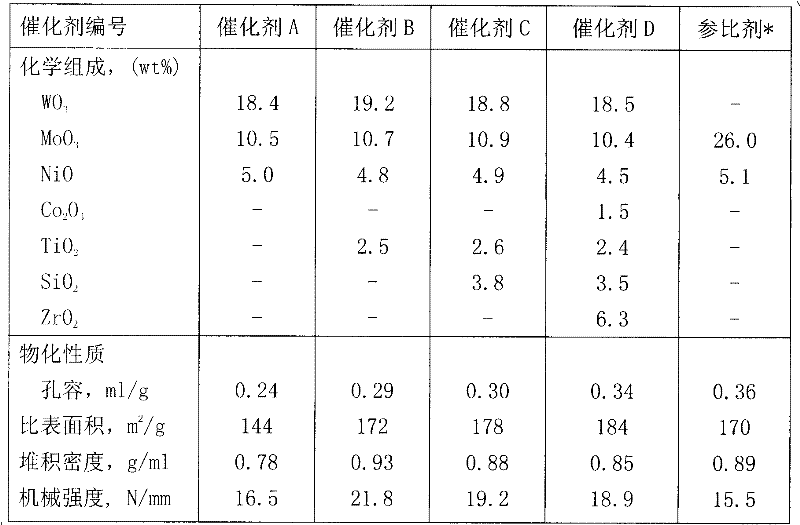

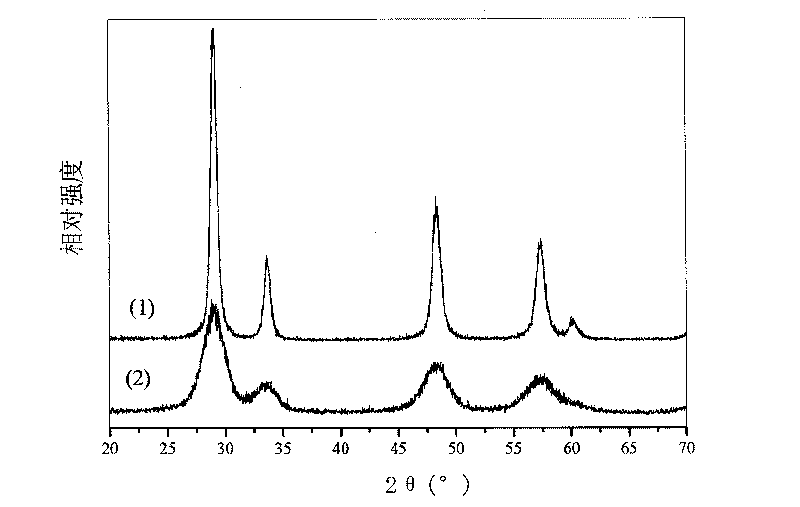

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Cold compress for therapeutic cooling

InactiveUS20120165910A1High heat transferIncrease flexibilityTherapeutic coolingTherapeutic heatingCold compressesHeat transfer fluid

A novel cold compress designed for use as a cooling medium. The cold compress comprises a flexible bag having a plurality of spheres. Each sphere contains a heat transfer fluid. As the bag is cooled or frozen, each sphere and the fluid they contain become cool or frozen. The bag is then placed on a body part of the patient who is recovering from surgery or injury. The small spheres allow maximum surface contact with the body part. This allows maximum and efficient heat transfer.

Owner:CHOUCAIR RAMSEY JOE +2

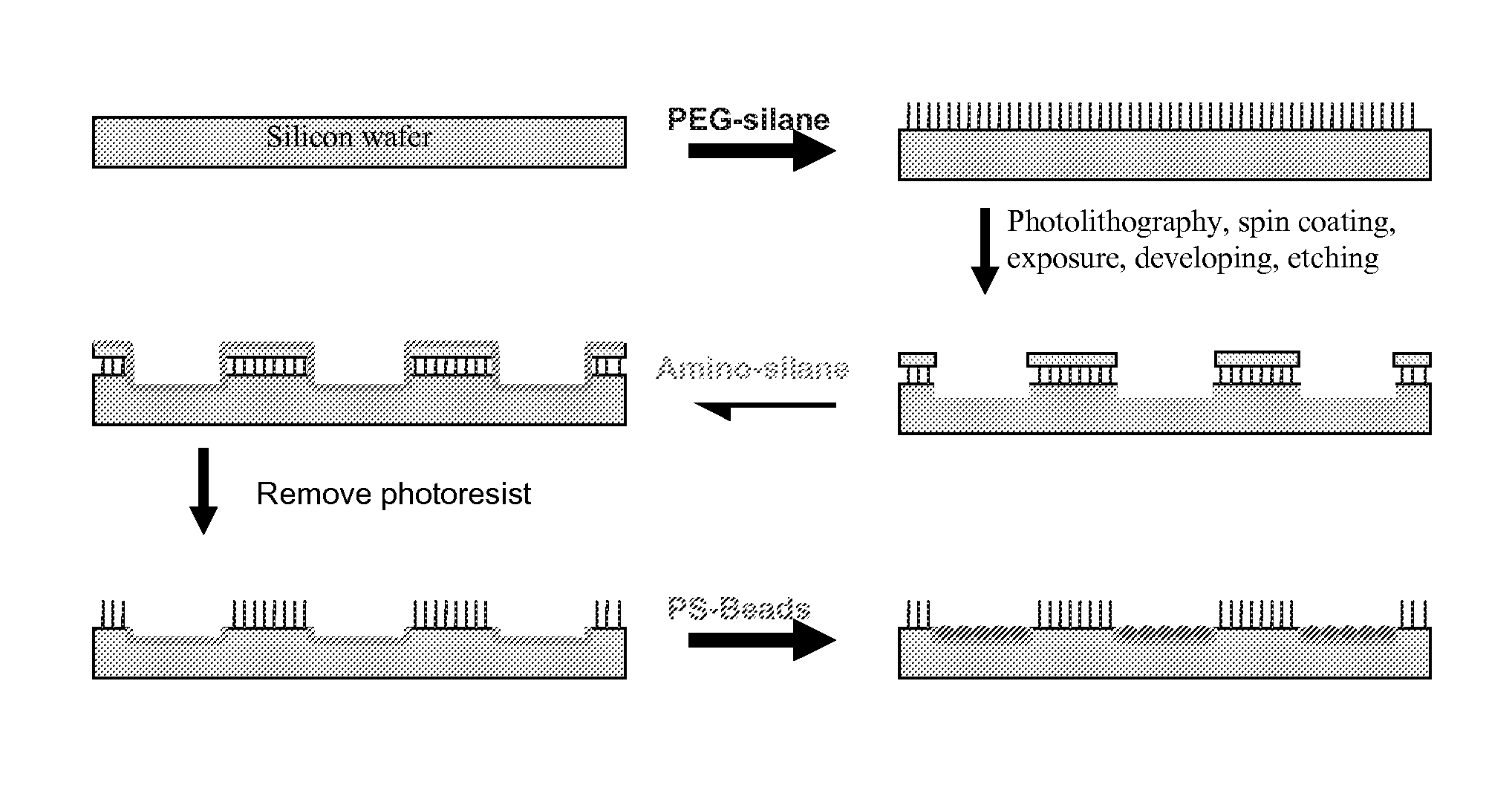

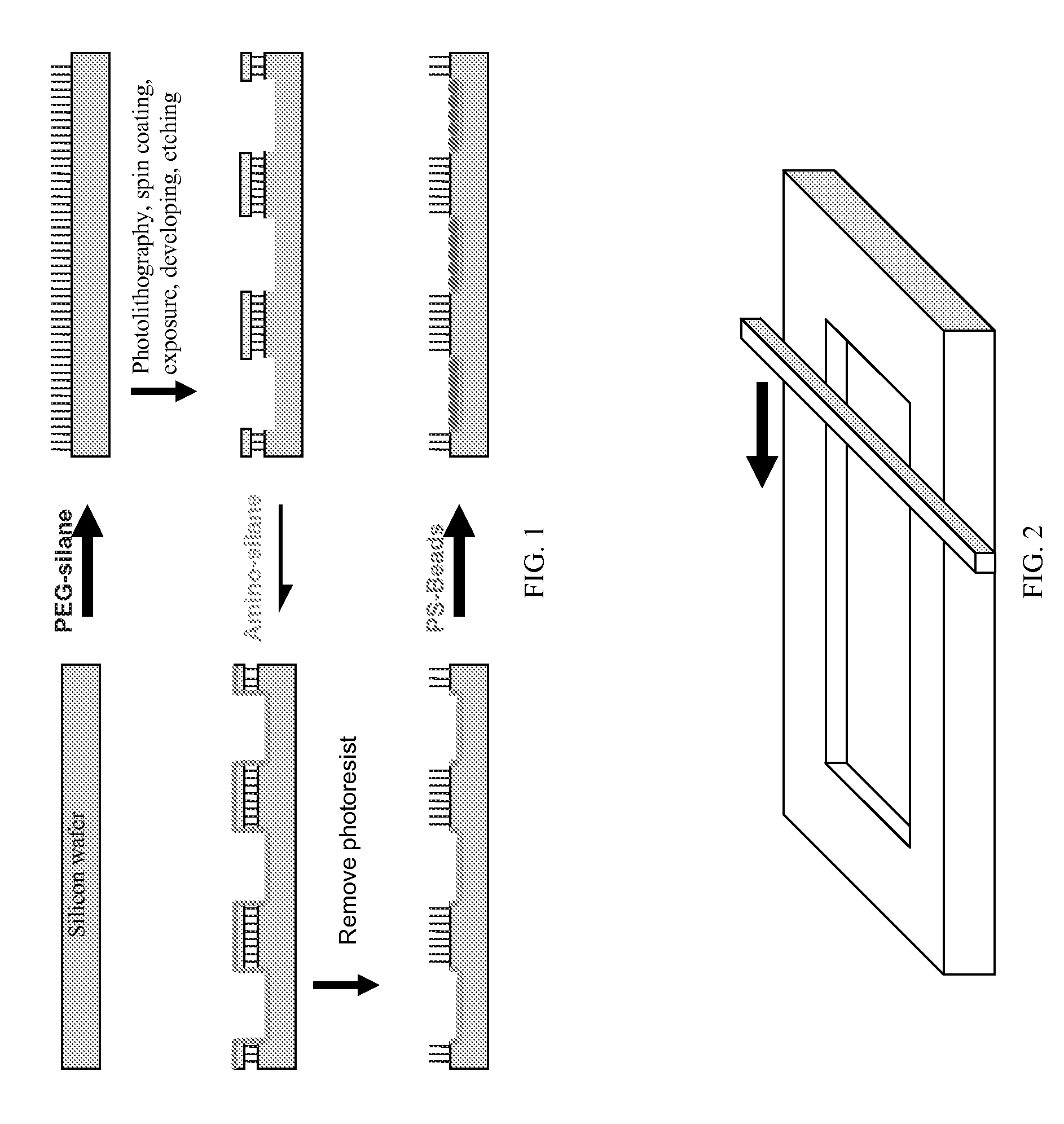

Signal amplified biological detection with conjugated polymers

The devices and method are provided for detecting labeled and label-free analytes, such as nucleic acids and proteins, employing conjugated cationic, anionic and neutral polymers. The analytes can be immobilized on a solid support material. The solid support material can be disposed in the pre-fabricated patterns on a substrate. The chemical structures of the polymers employed by the various embodiments of the present invention are described herein.

Owner:NAT UNIV OF SINGAPORE +1

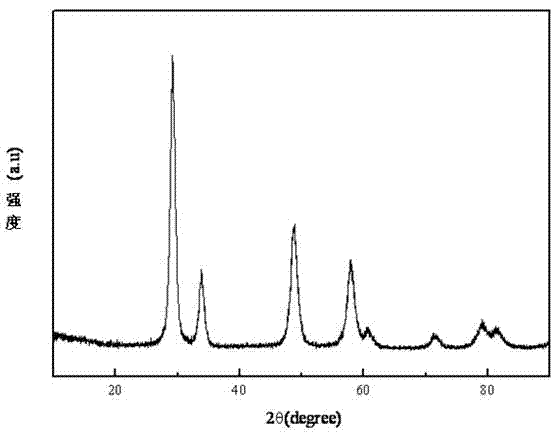

Process for producing iron phosphate for producing iron lithium phosphate material

The preparation method of iron phosphate used for preparing lithium iron phosphate material in the present invention relates to heavy metal phosphate, and the steps are: dissolving analytically pure soluble iron salt in distilled water to prepare a 0.05-5M aqueous solution, and the added mass is the iron salt mass 0.01~3% of anionic surfactant, then add analytically pure phosphoric acid according to the molar ratio of Fe3+:PO43-=1:0.8~1.2 and stir evenly, and slowly add alkaline solution with a concentration of 1~9M under stirring , the feeding time is more than 1 hour, until the pH value of the solution reaches 6-7, the iron phosphate precipitate is filtered, and the filtered iron phosphate is washed 3-5 times with distilled water 2-5 times its weight. Dry at ~90°C to obtain the product FePO4·2H2O powder. The iron phosphate product with two crystal waters prepared by the method of the invention has high reactivity, and the performance of the lithium iron phosphate material made by using it is better than that of the lithium iron phosphate material made by commercially available iron phosphate products.

Owner:HEBEI UNIV OF TECH

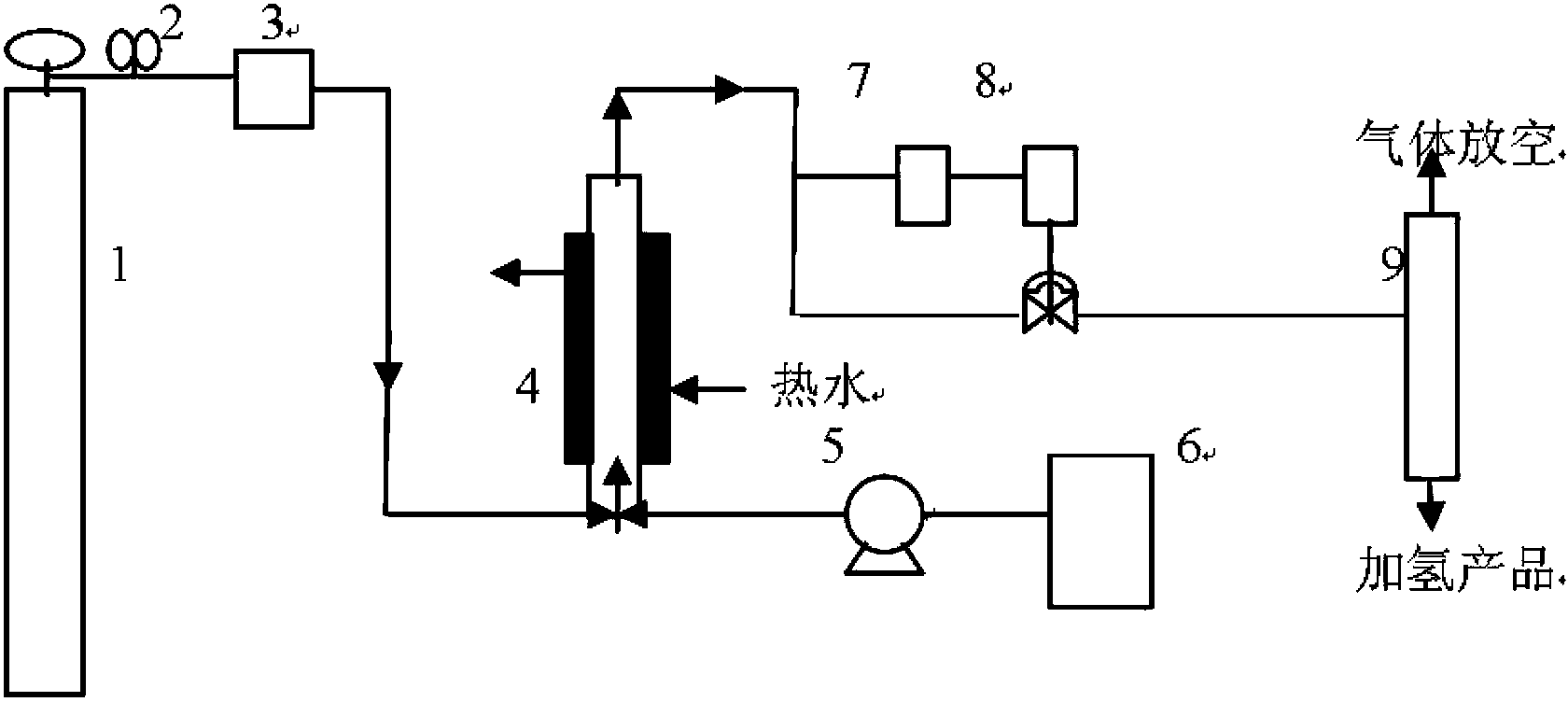

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

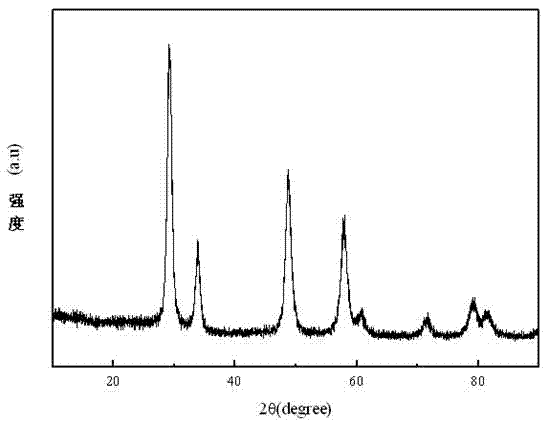

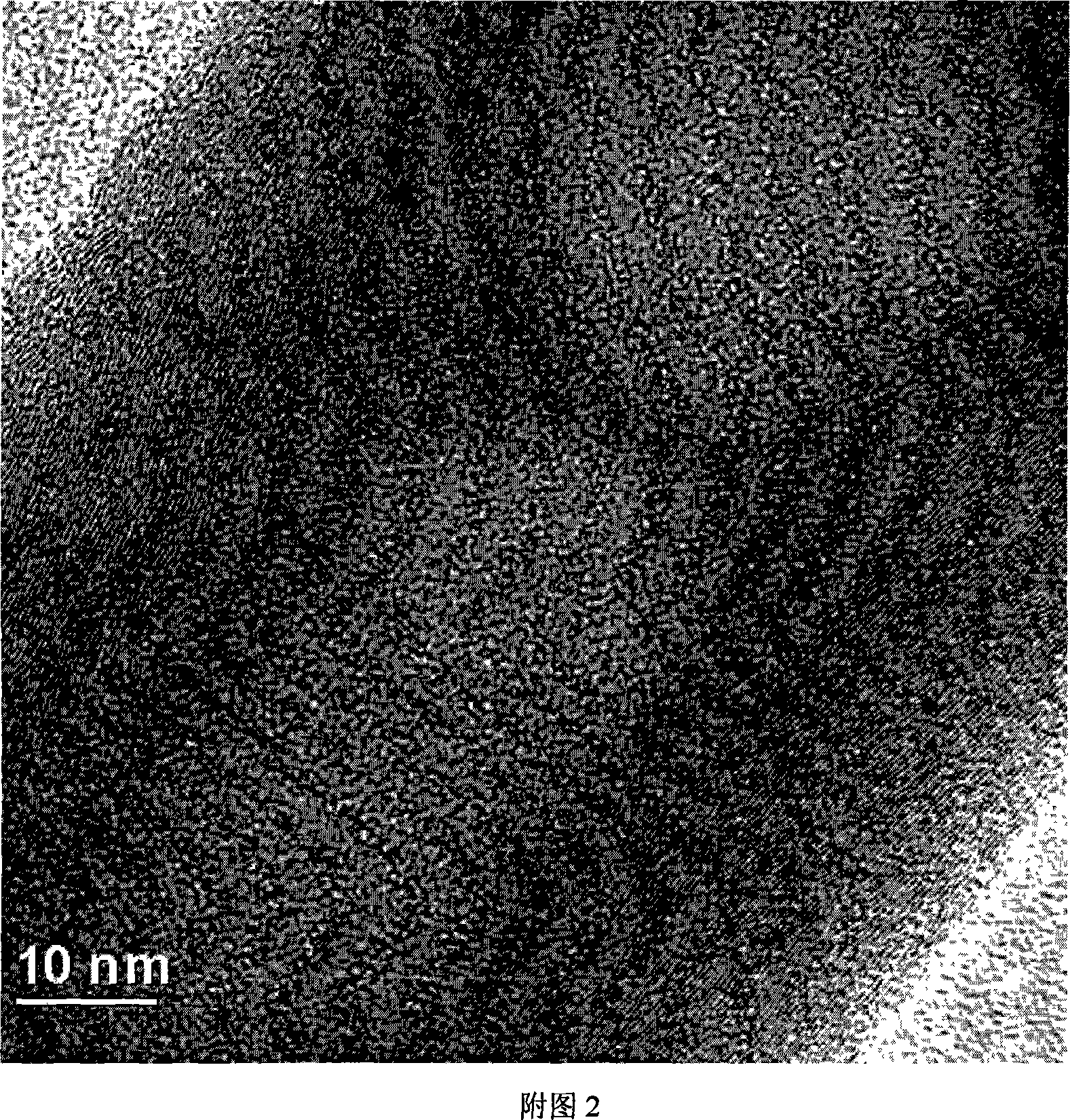

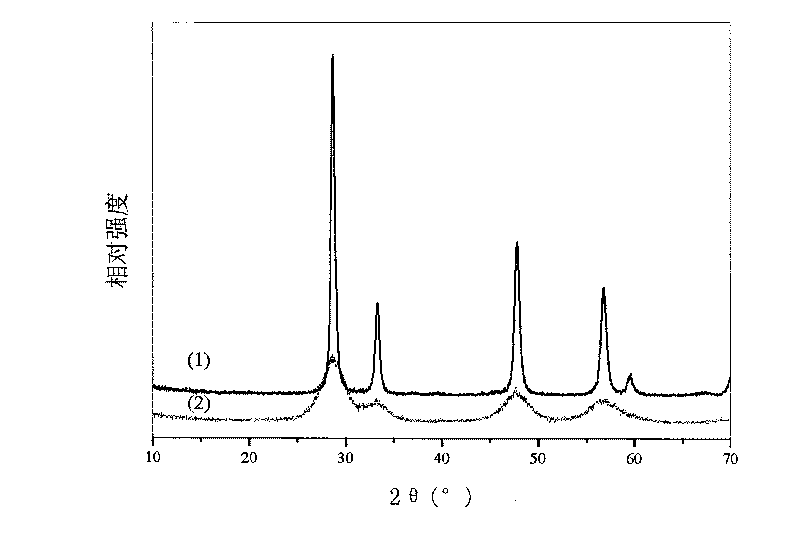

Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

ActiveCN102247826AThe reaction process is easy to controlSave raw materialsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPhysical chemistry

The invention discloses a cubic phase cerium and zirconium based composite oxide with high specific surface area. Rare earth elements are doped in the cerium-zirconium composite oxide and are selected from two or three of Pr, Nd and La, wherein the molar ratio of Zr to Ce is (1.8-2.5):1; the molar ratio of Pr to Ce is (0-0.32):1; the molar ratio of Nd to Ce is (0-0.32):1; the molar ratio of La toCe is (0-0.16):1; and the cerium and zirconium based composite oxide exists in a form of cerium-zirconium solid solution. The invention also discloses a preparation method of the cerium and zirconiumbased composite oxide. The composite oxide is prepared through different precursor precipitating and drying methods; the method has the advantages of simple reaction process and low requirements on drying equipment; the obtained cerium and zirconium based composite oxide has high specific surface area, high thermal stability and high oxygen storage and discharge capacity; and after sintering is performed at the temperature of 1,000 DEG C for 12 hours, the specific surface area is more than 35m<2> / g, particularly more than 60m<2> / g.

Owner:UNIV OF JINAN

Catalytic cracking auxiliary agent for reducing sulfur content in gasoline and preparation method thereof

The catalytically cracking assistant capable of lowering the sulfur content in gasoline is composite oxide including aluminum zinc spinel, homogeneously distributed zinc oxide and at least one optional RE oxide. It is prepared through roasting the mixture of laminar aluminum zinc in hdrotalcite structure and optional RE oxide hydrate. The preparation process is simple, and the assistant has the features of high dispersion, high specific surface area, etc. The assistant after being formed is mixed with conventional FCC catalyst and / or active reinforcing assistant for application in catalytically cracking process, and has the function of lowering the sulfur content in gasoline and excellent hydrothermal stability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Elastomer Composite and Method for Producing It

A method of producing an elastomer composite. The method includes A) combining a first fluid comprising elastomer latex with a second fluid comprising particulate filler; B) causing the elastomer latex to coagulate, thereby forming masterbatch crumb; C) bringing the masterbatch crumb to a water content of about 1 weight percent to about 20 weight percent, thereby forming a dewatered coagulum; D) removing water from the dewatered coagulum by subjecting the dewatered coagulum to mechanical energy, thereby causing the dewatered coagulum to heat as a result of friction, while allowing the dewatered coagulum to achieve a temperature of about 130° C. to about 190° C., wherein water content is reduced to about 0.5% to about 3% and wherein substantially all of the decrease in water content is accomplished by evaporation, thereby producing a masticated masterbatch; and E) subjecting the masticated masterbatch to at least an additional 0.3 MJ / kg of mechanical energy while further reducing the water content.

Owner:CABOT CORP

Silicon carbide foamed ceramics and preparation method thereof

The invention discloses silicon carbide foamed ceramics which comprises the following raw materials in parts by weight: 80-95 parts of silicon carbide micro powder particles, 5-20 parts of polycarbosilane powder and 40-170 parts of organic solvent. A template of the silicon carbide foamed ceramics is made of polymeric sponge. According to the invention, by using the characteristic that the polycarbosilane can be dissolved in the organic solvent, the polycarbosilane and ceramic powder are made into organic solvent slurry, polyurethane foam is dipped in the organic solvent slurry through adopting a powder sintering process principle, and thermally oxidized so that the yield of polycarbosilane ceramics is increased, the silicon carbide foamed ceramics is prepared through sintering under an inert atmosphere. A preparation method has the advantages of low sintering temperature, high efficiency and high production purity, and effectively avoids the difficulties of complex procedures, too many introduced impurities and high sintering temperature of the traditional preparation method for preparing the silicon carbide foamed ceramics.

Owner:GUIZHOU NORMAL UNIVERSITY

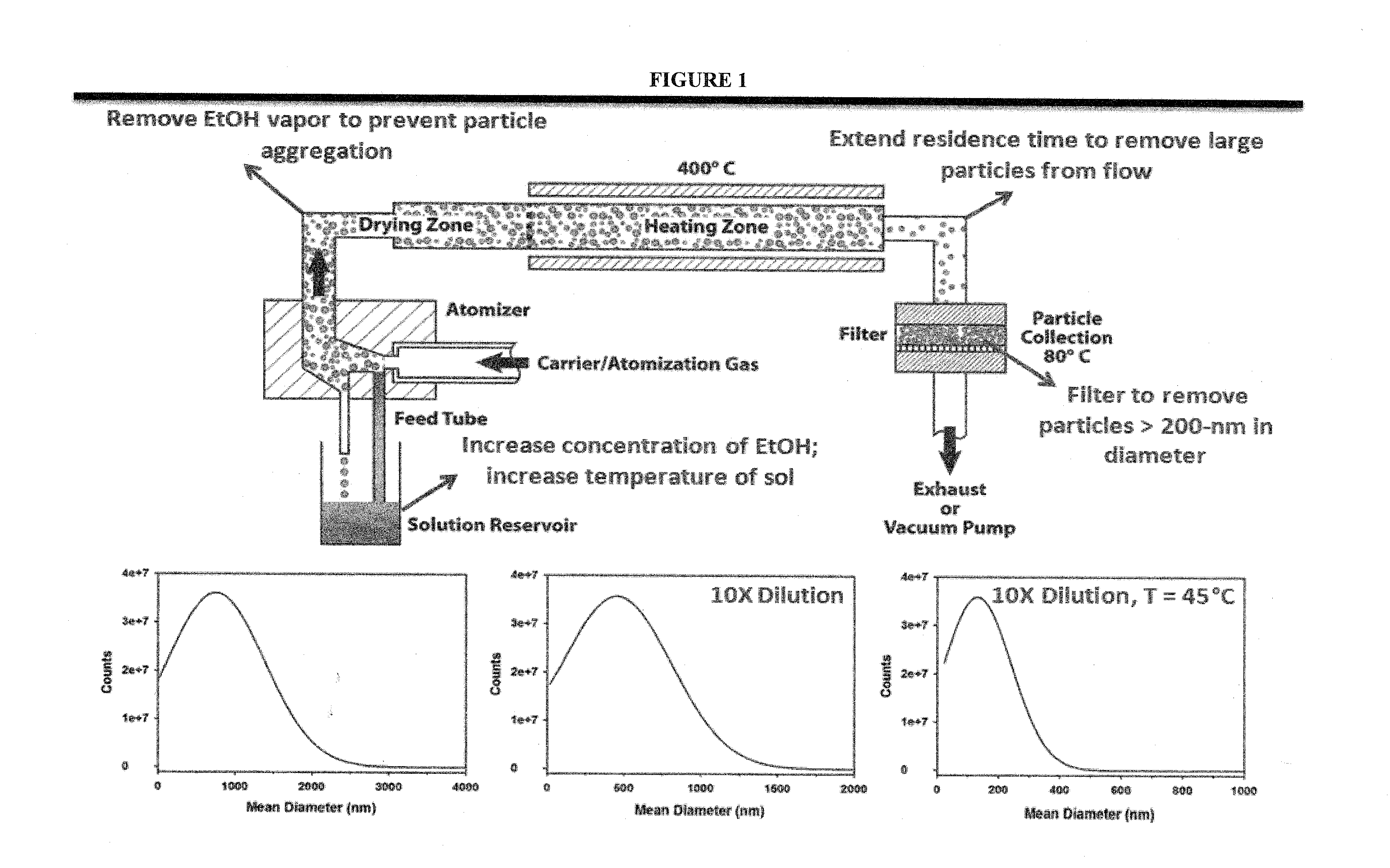

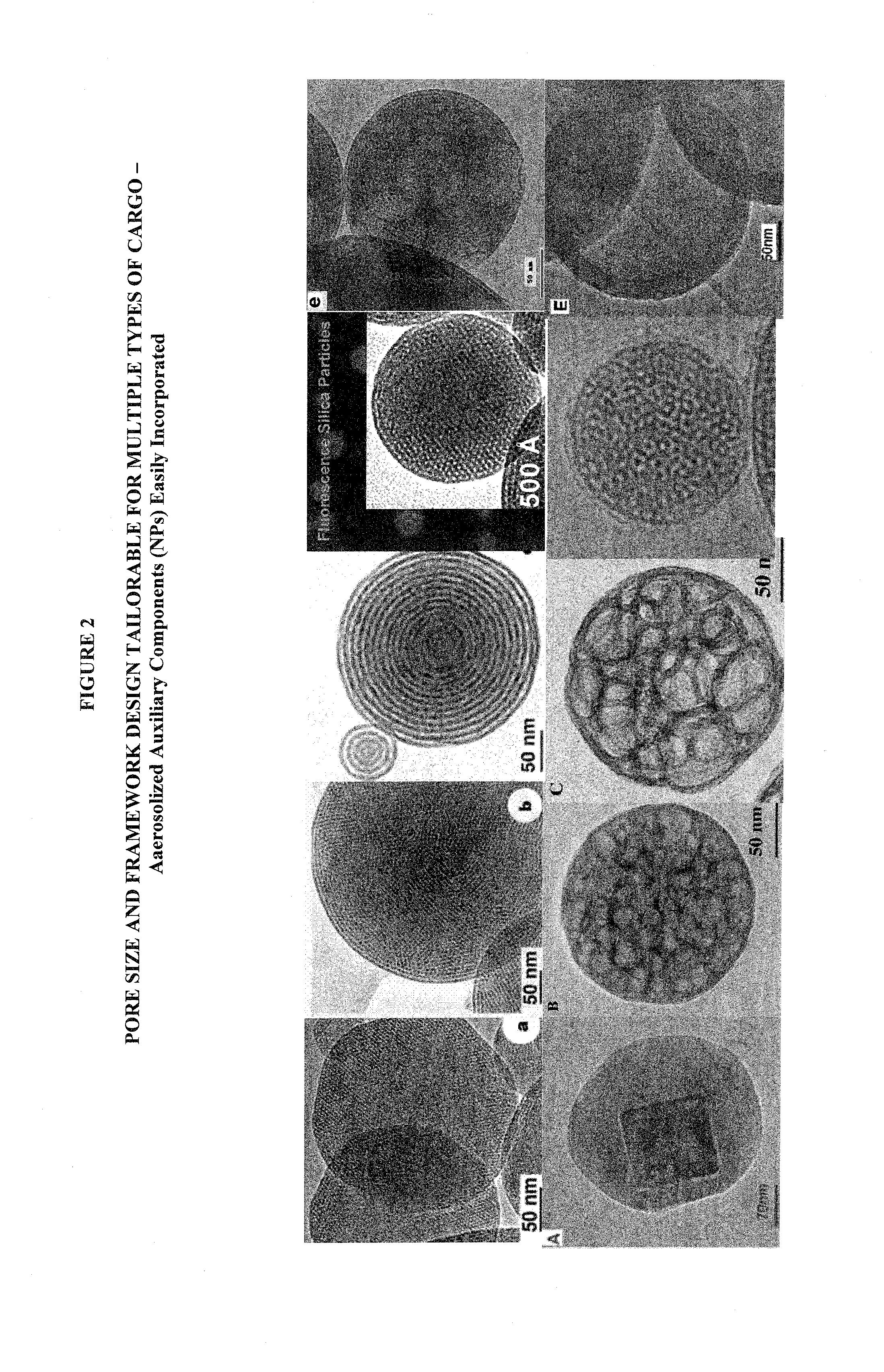

Porous nanoparticle-supported lipid bilayers (protocells) for targeted delivery including transdermal delivery of cargo and methods thereof

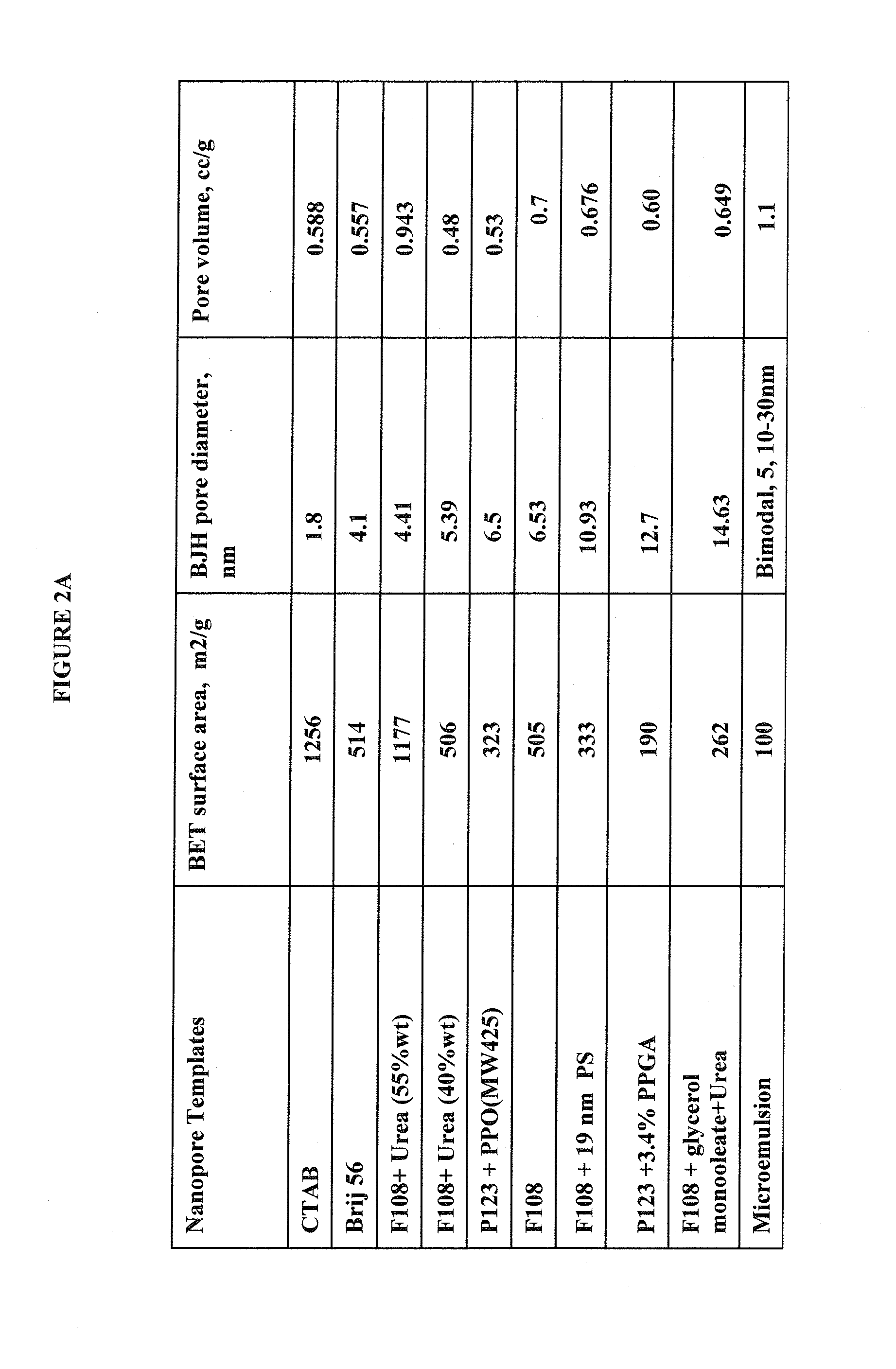

InactiveUS20150272885A1Large specific surface areaAmenable to high capacity loadingOrganic active ingredientsPowder deliveryCancers diagnosisBinding peptide

The present invention is directed to protocells for specific targeting of hepatocellular and other cancer cells which comprise a nanoporous silica core with a supported lipid bilayer; at least one agent which facilitates cancer cell death (such as a traditional small molecule, a macromolecular cargo (e.g. siRNA or a protein toxin such as ricin toxin A-chain or diphtheria toxin A-chain) and / or a histone-packaged plasmid DNA disposed within the nanoporous silica core (preferably supercoiled in order to more efficiently package the DNA into protocells) which is optionally modified with a nuclear localization sequence to assist in localizing protocells within the nucleus of the cancer cell and the ability to express peptides involved in therapy (apoptosis / cell death) of the cancer cell or as a reporter, a targeting peptide which targets cancer cells in tissue to be treated such that binding of the protocell to the targeted cells is specific and enhanced and a fusogenic peptide that promotes endosomal escape of protocells and encapsulated DNA. Protocells according to the present invention may be used to treat cancer, especially including hepatocellular (liver) cancer using novel binding peptides (c-MET peptides) which selectively bind to hepatocellular tissue or to function in diagnosis of cancer, including cancer treatment and drug discovery.

Owner:STC UNM +1

Foam metal hydrogenating catalyst and its preparing method and use

ActiveCN1781595ALow densityHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPorosityChemical plating

The present invention discloses hydrogenating catalyst of foam metal and its preparation process and application. The hydrogenating catalyst includes foamed metal carrier and active noble metal component in effective amount supported onto the carrier, the carrier is prepared through powder metallurgical process, and the active component is supported via chemical plating process and distributed homogeneously on the port surfaces of the foamed carrier. The catalyst has the advantages of high catalytic activity, firm combination between the active component and the carrier, high stability, simple preparation process, high porosity of the carrier, great specific surface area, etc. in addition, the catalyst provides sufficient gas-liquid contact area, is favorable to mass transfer between gas phase and liquid phase, may be used in catalytic rectification and possesses both reaction and separation effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

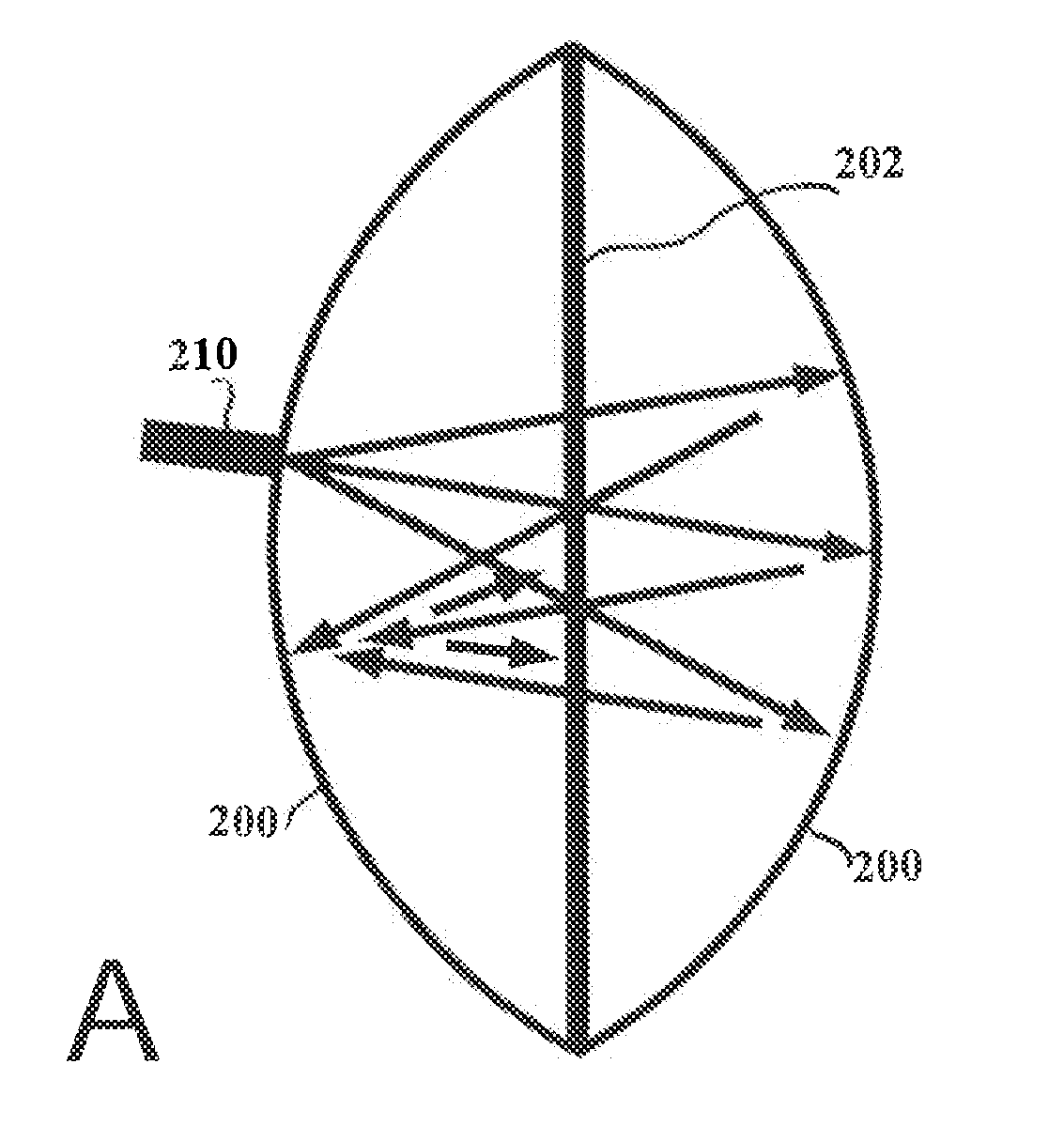

Stimulated lighting devices

InactiveUS20120033403A1Easy to operateEasy to handleLight source combinationsPoint-like light sourceLight equipmentEffect light

A stimulated lighting device for stimulatable light emission including a luminescent sheet including light stimulatable particles which emit secondary light upon receiving primary light. The lighting device includes a source configured to generate and direct the primary light obliquely onto the luminescent sheet, at least one reflector configured to reflect at least a part of the primary light and a part of the secondary light onto the luminescent sheet and configured to reflect at least a part of scattered primary light and a part of the secondary light from the luminescent sheet toward the light exit, and a light exit configured to emanate light as a combination of the primary light and the secondary light.

Owner:RES TRIANGLE INST

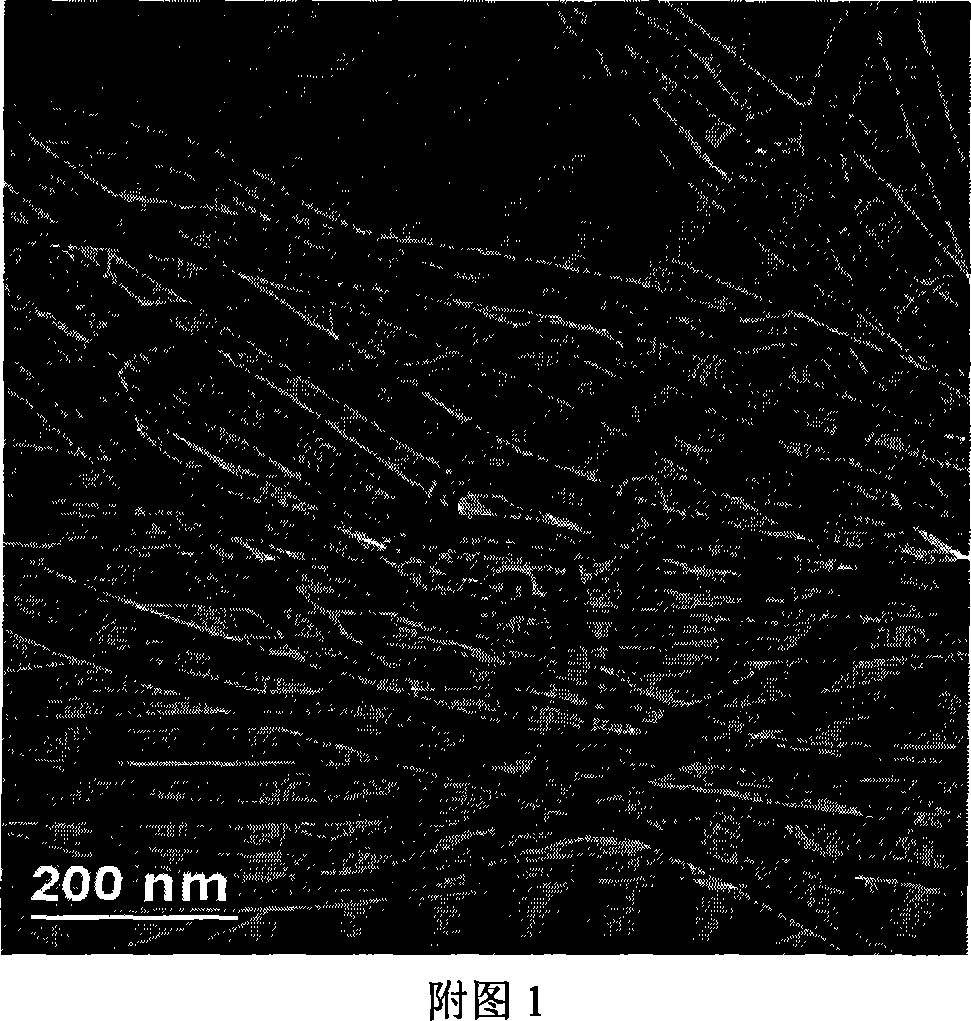

Method for preparing three-dimensional porous graphene material by solution

InactiveCN102701188AMass production availableAvailable for mass productionGrapheneStretchable electronicsPorous graphene

The invention discloses a method for preparing a three-dimensional porous graphene material by solution. The method comprises the following steps of: immersing a three-dimensional porous template into a graphene oxide solution, and then depositing the graphene oxide on the template to realize three-dimensional assembling of the graphene oxide on the template, and then preparing the three-dimensional porous graphene material containing the template by reduction; removing the template from the three-dimensional porous graphene material containing the template, and then washing to obtain the three-dimensional porous graphene material. The aperture of the three-dimensional porous graphene material can be regulated and controlled by using the templates with different apertures the material prepared by the invention has the advantages of low density, high specific surface area, high heat conductivity, high-temperature resistance, and corrosion resistance; the preparation method is economical and simple and suitable for large-scale production. And the prepared material is applicable to aspects such as catalytic carriers, preparation of flexible conductors, and stretchable electronics.

Owner:HUAZHONG UNIV OF SCI & TECH

High nitrogen doped corrugated carbon nanotube material and its synthesis process

InactiveCN101066758AWide variety of sourcesSimple production processNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsIron(II) oxideCarbon nanotube

The present invention relates to high nitrogen doped corrugated carbon nanotube material and its synthesis process. The synthesis process includes the following steps: mixing Fe source and proper amount of distilled water, soaking porous molecular sieve to carry ferric oxide or ferrous oxide, stoving and roasting at 300-1000 deg.c for 0.5-24 hr to obtain catalyst; setting the catalyst inside a pipe furnace, leading organic amine into the furnace under the protection of Ar or N2 and reacting at 650-1000 deg.c for 0.2-4.0 hr to obtain high nitrogen doped corrugated carbon nanotube mixture containing the catalyst; soaking the mixture in proper amount of or excessive hydrofluoric acid, sulfuric acid, nitric acid or acid for 0.5-24 hr; and washing in distilled water, suction filtering and drying to obtain high nitrogen doped corrugated carbon nanotube material. The material has nitrogen content of 10-40 %, reinforced surface polarity, etc, and is suitable for industrial production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Catalyst for synthesizing methanol by hydrogenating carbon dioxide and preparation method thereof

InactiveCN102240553AHigh selectivityImprove conversion rateOrganic compound preparationHydroxy compound preparationMixed oxideSlurry

The invention relates to a catalyst for synthesizing methanol by hydrogenating carbon dioxide and a preparation method thereof, belonging to the technical field of catalysts. The catalyst for synthesizing the methanol by hydrogenating the carbon dioxide comprises a mixed oxide of one or more of Cu, Zn, La, Ce and M, wherein M is Al, Si, Ti or Zr; the catalyst comprises the following components in percentage by weight: 30-70% of CuO, 10-40% of ZnO, 1-5% of accelerative activators Ln2O3, 1-5% of stabilizers CeO2 and 5-20% of carrier oxides MxOy. The preparation method of the catalyst comprises the following steps of: firstly mashing the carrier oxides MxOy; and then adding active matter components and precipitators into oxide slurry in a parallel flowing manner for coprecipitation. The catalyst disclosed by the invention has the advantages of high specific surface reaching 200 m<2> / g, stable structure, contact compactness among all the components and high synergistic effect, so that the catalyst has higher activity and selectivity; the preparation process of the catalyst has the advantages of simplicity, good repeatability and convenience for industrial production; in addition, by means of the catalyst disclosed by the invention, the conversion rate of the carbon dioxide is high and reaches 35 percent under appropriate reaction conditions, and the selectivity of the methanol is higher and reaches more than 80 percent.

Owner:大连瑞克科技股份有限公司

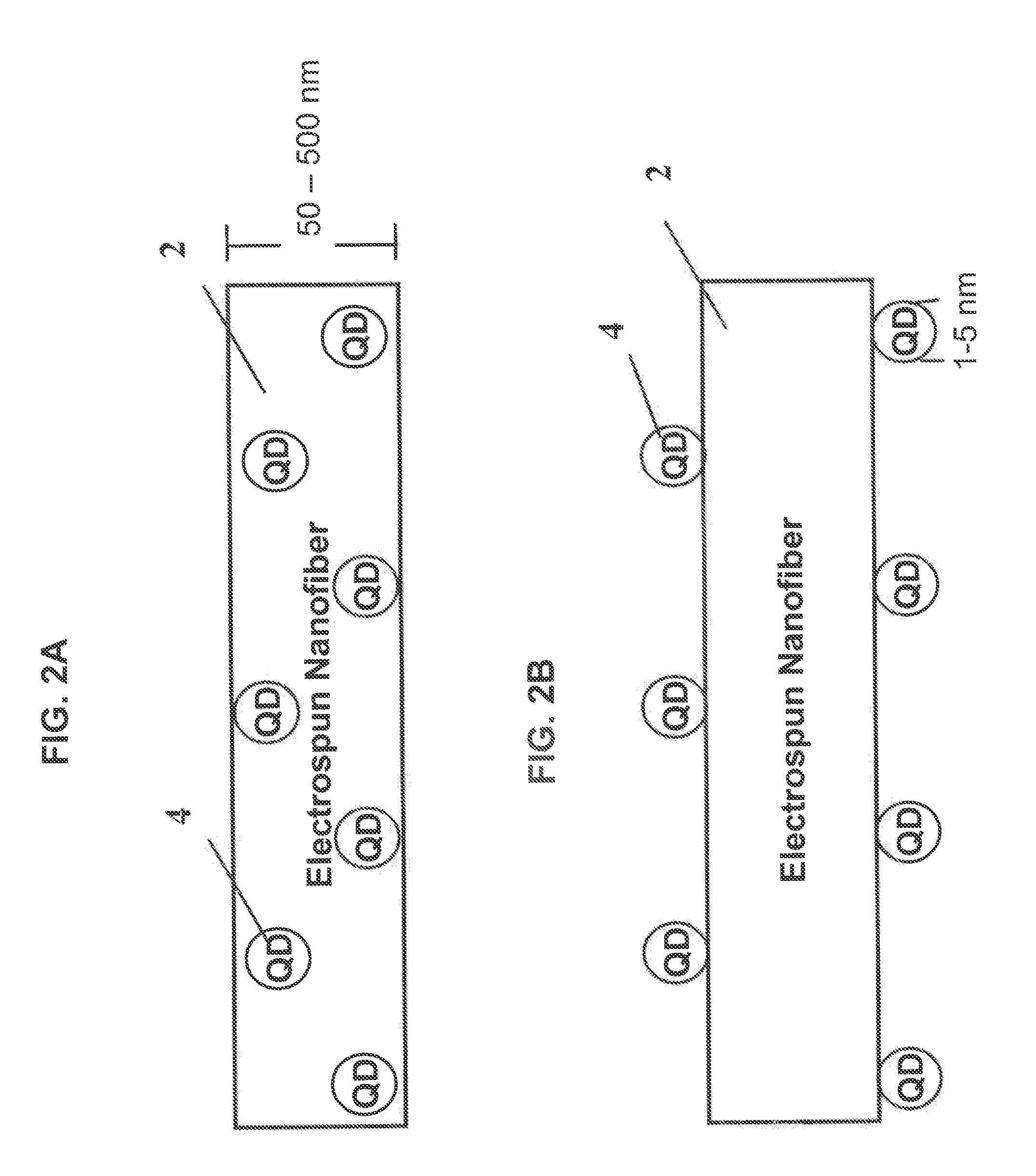

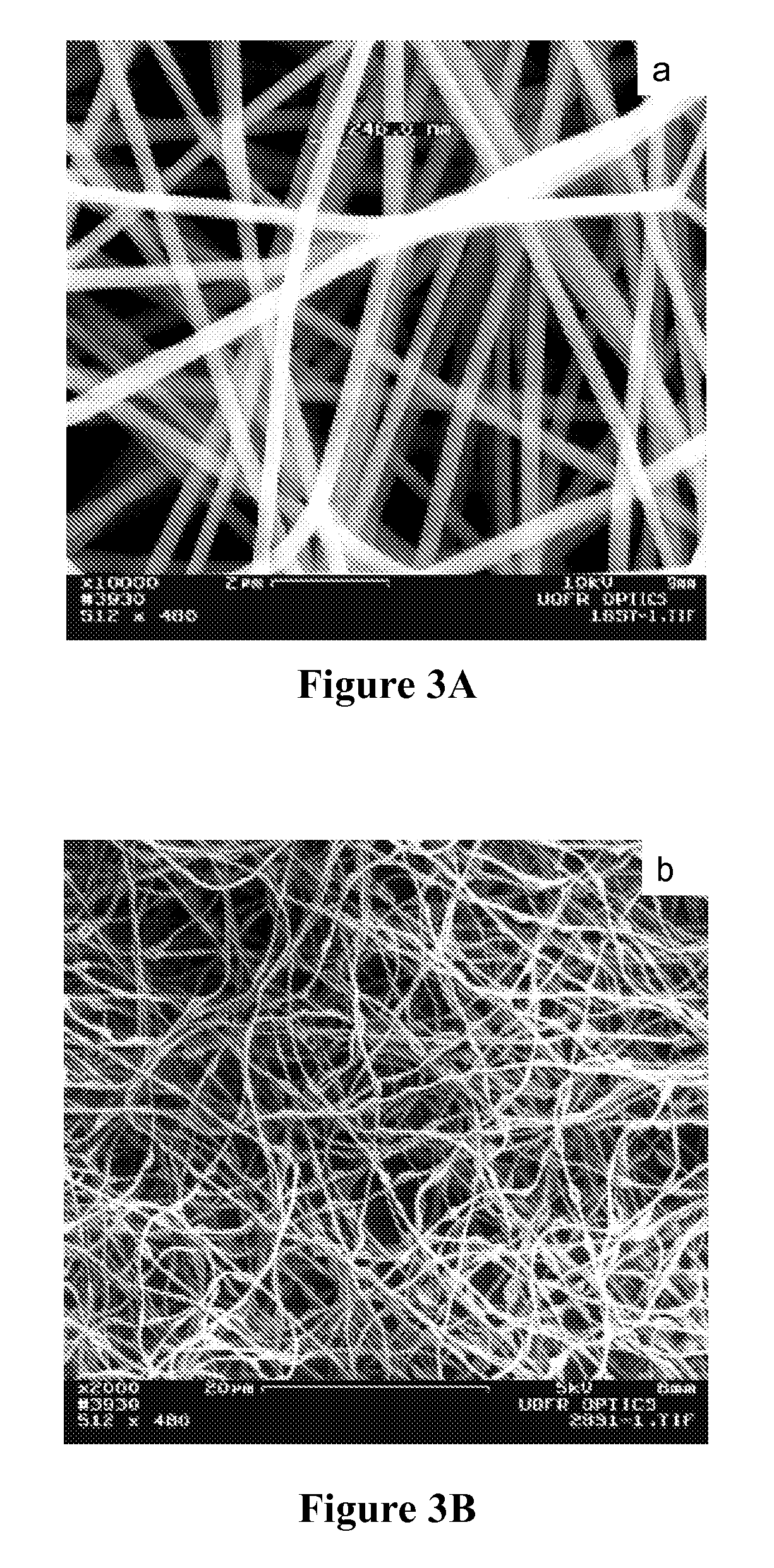

Long metallic nanowires, methods of making, and use thereof in proton exchange membrane fuel cell

InactiveUS20080305377A1High surface areaHigh durabilityMaterial nanotechnologyCell electrodesFiber structureNanofiber

A method and apparatus for making a metallic nanofiber structure are disclosed. The method includes the steps of: providing a first solution including a first material and a second material, wherein the second material includes at least one metal; forming the first solution into composite fibers including the first material and the second material; and removing the first material from the composite fibers under conditions effective to produce a metallic nanofiber structure that includes a plurality of metallic nanofibers. Also disclosed are metallic nanofiber structures prepared according to a process of the present invention, which can be used as fuel cell catalysts. Fuel cells containing electrodes that include these metallic nanofiber structures are also disclosed.

Owner:UNIVERSITY OF ROCHESTER

Dechlorinating agent used for removing HCl from gas by dry method and preparation method thereof

InactiveCN101773768AImprove dechlorination activityHigh activityOther chemical processesAluminium silicatesPorosityCross-link

The invention relates to a dechlorinating agent used for removing HCl from a gas by using a dry method and a preparation method thereof. The dechlorinating agent is prepared from Na2CO3, CaCO3, CaO and MaO as active constituents, crosslinked bentonite as a porous auxiliary agent, and methyl cellulose as a foaming agent and an auxiliary extrusion agent through extrusion forming, drying and roasting. The cross-linked bentonite is prepared by exchanging large-size poly aluminum cation with small-size simple cation, so that the crosslinked bentonite has great porosity factor and large specific surface. The specific surface and the pore volume of the crosslinked bentonite are larger than those of non-crosslinked bentonite. By using the crosslinked bentonite as the porous auxiliary agent, the specific surface of the dechlorinating agent is enlarged, and the dechlorinating activity and the chlorosity of the dechlorinating agent are increased. The dechlorinating agent prepared by using the crosslinked bentonite has a pore volume of 0.3-0.4 mL / g, a specific surface of 70-90 m<2> / g and a crushing strength of 60-80 N / cm, not only has lower price than pseudo-boehmite and a molecular sieve, but also has simple preparation process, high dechlorinating activity and great low-temperature penetration chlorosity.

Owner:长春惠工净化工业有限公司

Elastomer composite and method for producing it

A method of producing an elastomer composite. The method includes A) combining a first fluid comprising elastomer latex with a second fluid comprising particulate filler; B) causing the elastomer latex to coagulate, thereby forming masterbatch crumb; C) bringing the masterbatch crumb to a water content of about 1 weight percent to about 20 weight percent, thereby forming a dewatered coagulum; D) removing water from the dewatered coagulum by subjecting the dewatered coagulum to mechanical energy, thereby causing the dewatered coagulum to heat as a result of friction, while allowing the dewatered coagulum to achieve a temperature of about 130° C. to about 190° C., wherein water content is reduced to about 0.5% to about 3% and wherein substantially all of the decrease in water content is accomplished by evaporation, thereby producing a masticated masterbatch; and E) subjecting the masticated masterbatch to at least an additional 0.3 MJ / kg of mechanical energy while further reducing the water content.

Owner:CABOT CORP

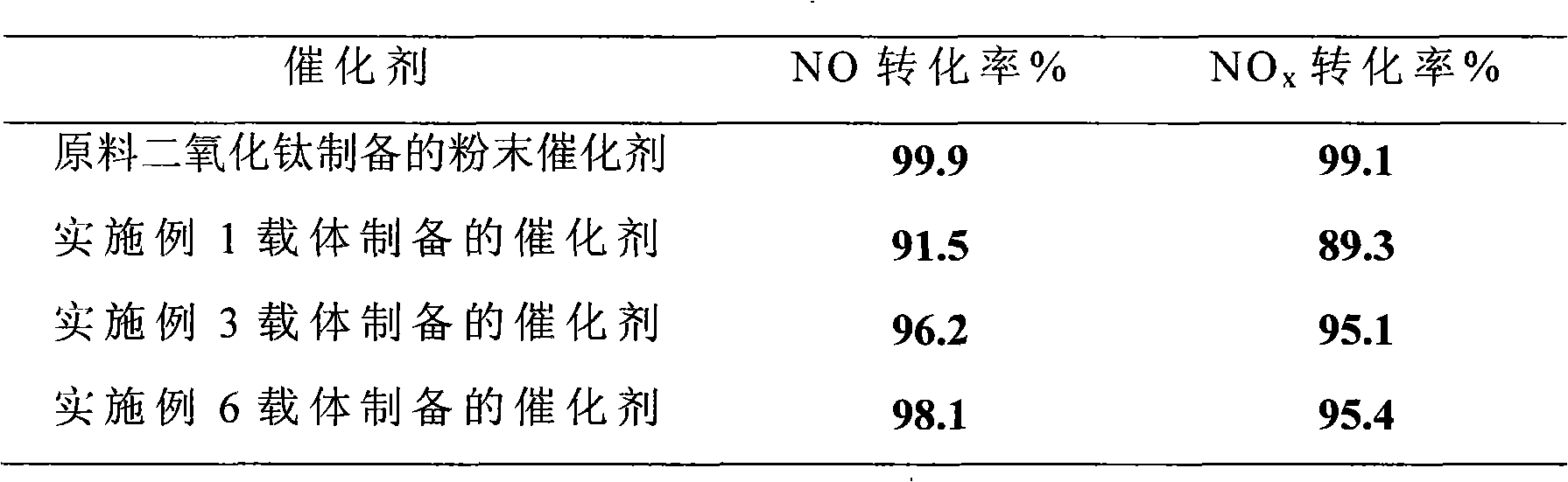

Preparation method for titanium dioxide group catalyst carrier

InactiveCN101513620AGood formabilityImprove catalytic performanceCatalyst carriersDispersed particle separationTitanium tetrachlorideMetatitanic acid

The invention provides a preparation method for a titanium dioxide group catalyst carrier with excellent moldability, high strength and high specific surface. The method comprises the following steps: using titanium dioxide or metatitanic acid prepared by hydrolyzation and neutralization of precipitate with titanium tetrachloride as the raw material; by weight portions, mixing and grinding 60-85% of titanium dioxide or dried metatitanic acid powder (counted as titanium dioxide), 1-10% of temporary adhesive and 1-5% of pore-forming material into uniform powder; adding 5-35% of constitutive adhesive, 0.5-2% of molding adhesion promoter, 1-10% of extrusion aid and water followed by evenly mixing and making into mud; extruding for molding after the mud decays; seasoning the extrudate at room temperature; baking and dehydrating at a temperature below 80 DEG C; and then iglossing at 400-600 DEG C to obtain the titanium dioxide group carrier. After molding, the specific surface of the carrier is 80-150m / g, and the pressive strength thereof is 15-100N / mm. The carrier is mainly used for selective catalytic reduction (SCR) to remove nitrogen oxide.

Owner:NANJING UNIV

Preparation method of catalyst for hydrogenation desulfurization and denitrification of light-weight oil

InactiveCN102247864AGood dispersionIncrease profitCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideTitanium oxide

The invention discloses a preparation method of a catalyst for hydrogenation desulfurization and denitrification of light-weight oil and is characterized in that the composition of the catalyst comprises a carrier, an auxiliary agent and active metals, wherein the carrier contains aluminum oxide, titanium oxide and silicon oxide; the auxiliary agent is phosphorus; the active metals are oxides of nickel, molybdenum and tungsten; and on the basis of the catalyst, the contents of all components in percentage by weight are as follows: 1 to 4 percent of cobalt oxide, 3 to 10 percent of nickel oxide, 2 to 12 percent of molybdenum oxide, 18 to 30 percent of tungsten oxide, 2 to 5 percent of phosphorus pentoxide, 2 to 15 percent of titanium oxide, 2 to 20 percent of silicon oxide, and the balance of aluminum oxide. The catalyst is obtained by the steps of carrier preparation, co-immersion, calcination and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

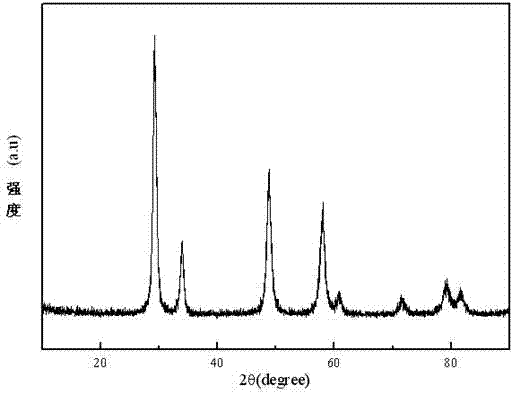

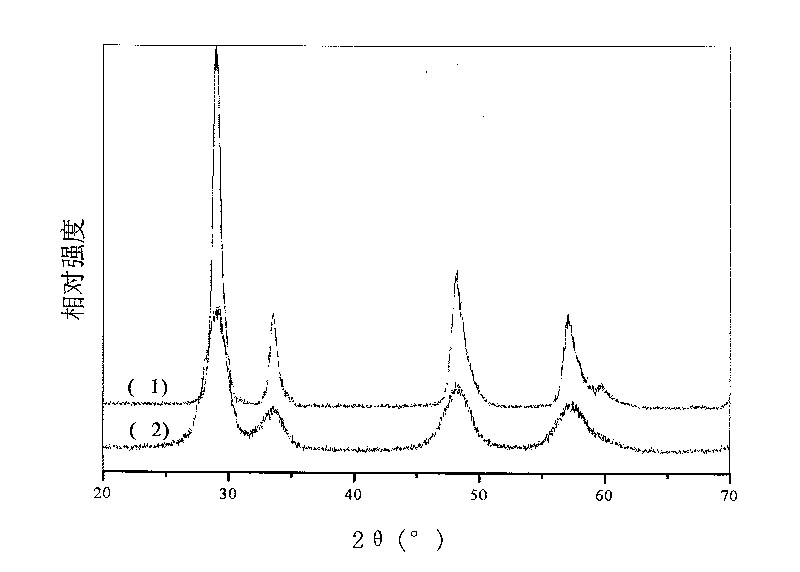

Method for preparing high-thermal-stability cerium-based oxygen storage material

InactiveCN101690890AWeaken the interaction forceGood dispersion effectDispersed particle separationCatalyst activation/preparationIndustrial scaleComposite oxide

The invention relates to a method for preparing a high-thermal-stability cerium-based oxygen storage material, which is characterized in that the cerium-based oxygen storage material comprises cerium dioxide, zirconium dioxide, aluminum oxide in a small amount and at least one rare-earth crystal stabilizer selected from lanthanum oxide, praseodymium oxide, yttrium oxide and terbium oxide. The method comprises the following steps in the preparation process: adding a proper amount of surfactant, to obtain a cerium-based composite oxide material having the characteristics of single crystalline phase, high oxygen storage performance and high specific surface area; and ageing the cerium-based composite oxide material at a high temperature (1,050 DEG C) for 5h until the specific surface area thereof is higher than 35m<2> / g and the oxygen storage capacity thereof is higher than 400 mu mol / g. According to the phase results, the cerium-based oxygen storage material has a uniform-phase structure, moreover, a uniform solid solution with a cubic fluorite structure can be prepared from zirconium dioxide, aluminum oxide, stabilizer and cerium dioxide. The preparation process of the oxygen storage material has the characteristics of simple process, lower production cost, easy industrial scale-up, etc.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com