Silicon carbide foamed ceramics and preparation method thereof

A foamed ceramic and silicon carbide technology, which is applied in the field of functional materials and their preparation, can solve the problems of the limitation of the wide application of silicon carbide foamed ceramics, the difficulty in controlling the pore volume and size, and the incompactness of the foamed ceramics, and achieves low cost and high yield. , easy to formulate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

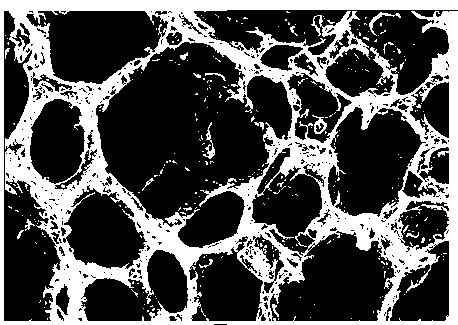

Image

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: silicon carbide foamed ceramics, calculated in parts by weight, its material includes 90 parts of silicon carbide micropowder particles with an average particle size of 0.3 μm (using a commercially available β-SiC model product), 10 parts of poly Carbosilane powder, 40 parts tetrahydrofuran; its template is polyurethane sponge.

[0018] The preparation method of silicon carbide foam ceramics is to add silicon carbide micropowder particles and polycarbosilane powder into tetrahydrofuran for mixing, and then obtain an organic solvent slurry after fully stirring; after cutting the polyurethane sponge into the required shape and size, extrude it Put it in the organic solvent slurry after depressurizing and removing the air, let it stretch freely and keep stirring, extruding and kneading, so that the organic solvent slurry is evenly coated on the polyurethane sponge, and the excess organic solvent slurry on the polyurethane sponge is rem...

Embodiment 2

[0019] Embodiment 2 of the present invention: silicon carbide foamed ceramics, calculated in parts by weight, its material includes 85 parts of silicon carbide micropowder particles with an average particle size of 0.3 μm (using commercially available β-SiC model products), 15 parts of poly Carbosilane powder, 40 parts tetrahydrofuran; its template is polyurethane sponge.

[0020] The preparation method of silicon carbide foam ceramics is to add solid silicon carbide micropowder particles and solid polycarbosilane powder into tetrahydrofuran for mixing, and obtain an organic solvent slurry after fully stirring; after cutting the polyurethane sponge into the required shape and size, the Put it in the organic solvent slurry after extruding to remove the air, let it stretch freely and continue to stir, extrude and knead, so that the organic solvent slurry is evenly coated on the polyurethane sponge, and the excess organic solvent slurry on the polyurethane sponge is removed. Make...

Embodiment 3

[0021] Embodiment 3 of the present invention: silicon carbide foamed ceramics, calculated in parts by weight, its material includes 95 parts of silicon carbide micropowder particles with an average particle size of 5 μm (using commercially available β-SiC model products), 20 parts of polycarbonate Silane powder, 170 parts tetrahydrofuran; its template is polyurethane sponge.

[0022] The preparation method of silicon carbide foam ceramics is to add silicon carbide micropowder particles and polycarbosilane powder into tetrahydrofuran for mixing, and then obtain an organic solvent slurry after fully stirring; after cutting the polyurethane sponge into the required shape and size, extrude it Put it in the organic solvent slurry after depressurizing and removing the air, let it stretch freely and keep stirring, extruding and kneading, so that the organic solvent slurry is evenly coated on the polyurethane sponge, and the excess organic solvent slurry on the polyurethane sponge is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com