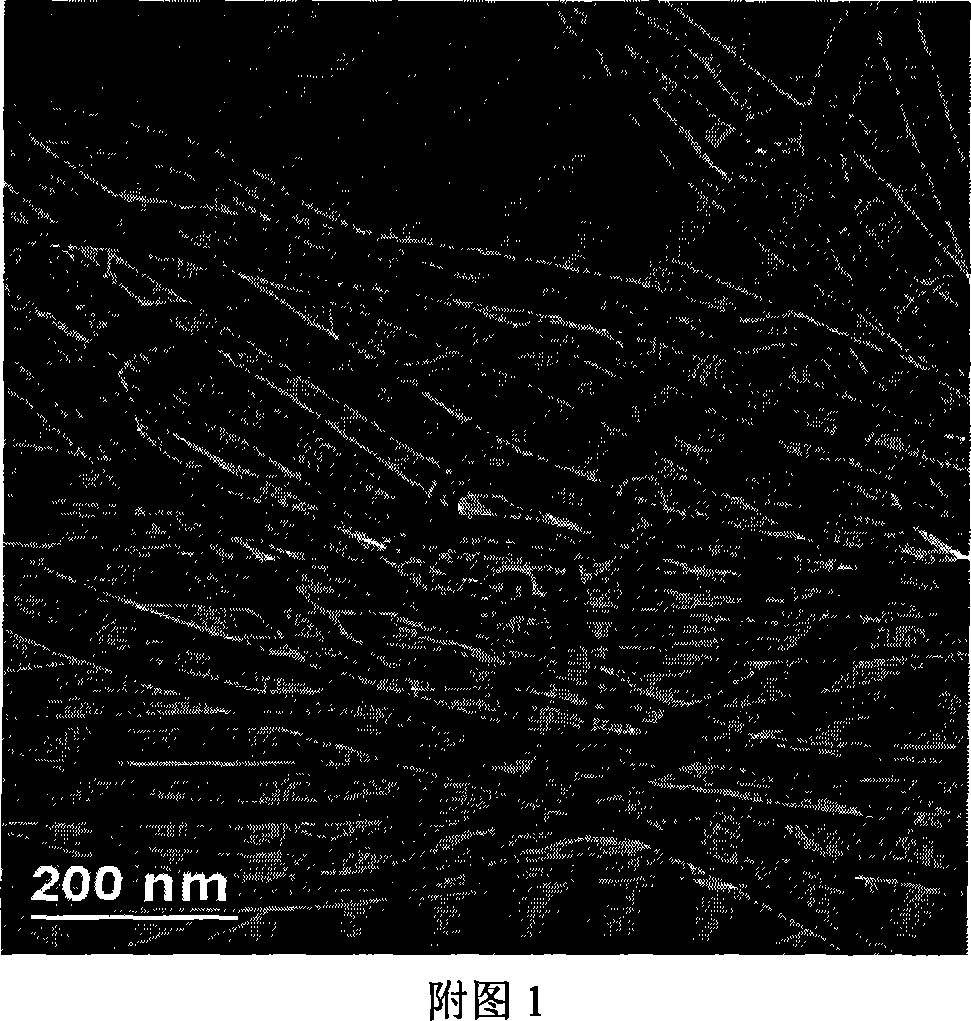

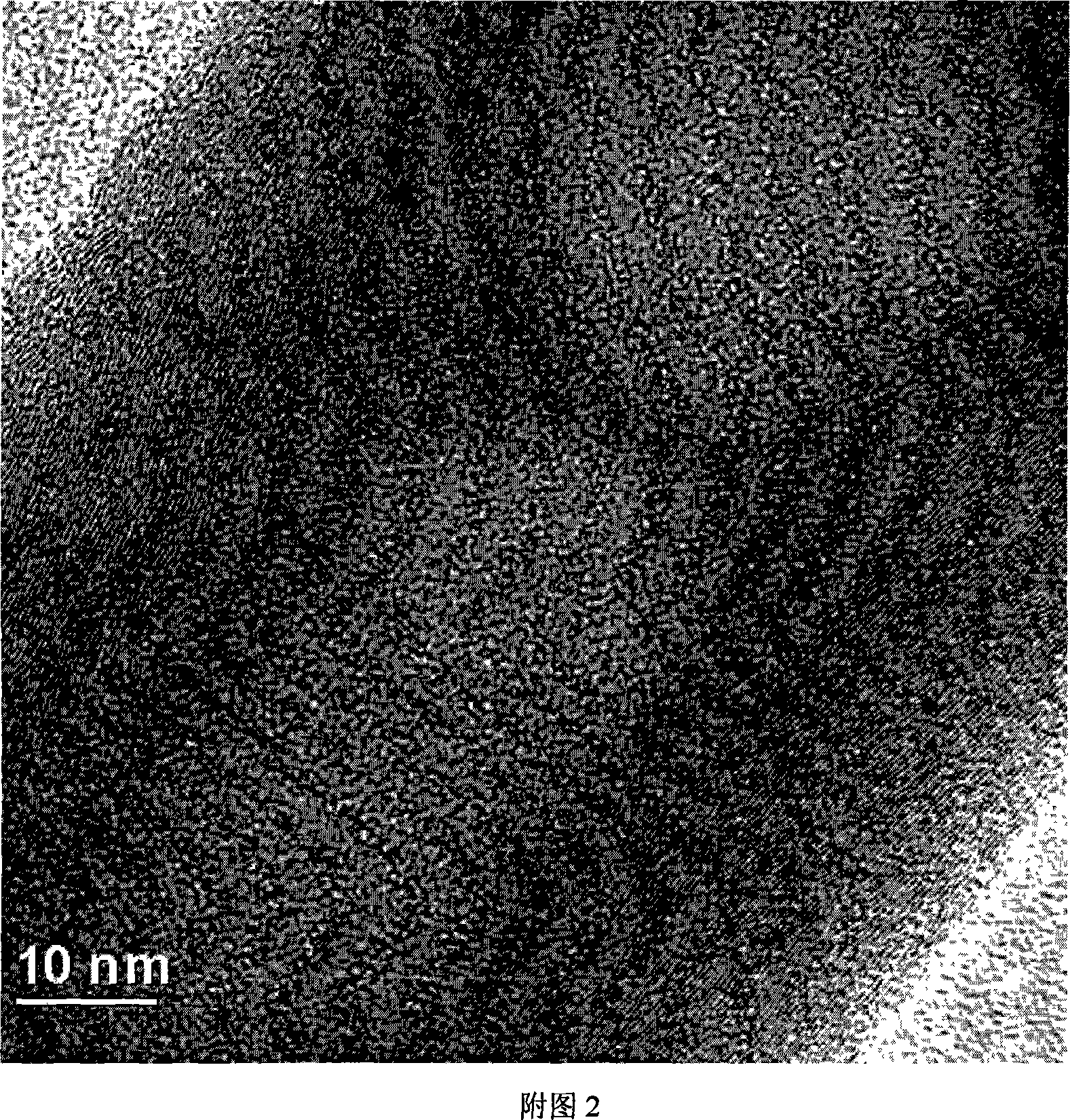

High nitrogen doped corrugated carbon nanotube material and its synthesis process

A carbon nanotube, synthesis method technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of high cost, low nitrogen content, complex operation method, etc., and achieve mild synthesis conditions, cheap raw materials, and sources of wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: 10.25g of SBA-15 molecular sieve roasted in 850°C high-temperature air was placed in a 5mL beaker; 0.1g Fe(NO) was weighed 3 9H 2 O was dissolved in 1.2mL of distilled water, then impregnated the solution on SBA-15 molecular sieves, stirred evenly, and left to stand for 12 hours; then dried in an oven at 150°C for 12 hours; In the tube furnace, the temperature was raised to 850°C, and 2mL of diethylamine was brought through the catalyst by the Ar protective gas, and the process was completed after 0.5 hours; then the heating was stopped, and the Ar protective gas was continued to drop to room temperature; the black sample was taken out as the high Nitrogen-doped bamboo-shaped carbon nanotube material, the molar ratio of C and N is 0.85:0.15.

Embodiment 2

[0021] Example 2: 1.0g of NaY molecular sieve calcined in 700°C high-temperature air is placed in a 5mL beaker; weigh 0.25gFe(NO) 3 9H 2 Dissolve O in 1.2mL of distilled water, then impregnate the solution on SAPO-11 molecular sieve, stir evenly, and let it stand for 12 hours; then put it in an oven at 150°C for 12 hours, bake it in the air at 300°C for 24 hours, and cool it down to room temperature naturally Then place in a tube furnace with a quartz tube with nitrogen protection gas, heat up to 700°C, 2g hexamethylenetetramine and 0.05mL ethylenediamine are brought through the catalyst by nitrogen protection gas, and complete this process in 0.5 hours process; then stop heating, continue to pass nitrogen protection gas until it drops to room temperature; take out the black sample which is the high nitrogen-doped bamboo-shaped carbon nanotube material containing catalyst, and the molar ratio of C to N is 0.62:0.38.

Embodiment 3

[0022] Example 3: 1.0g of SBA-15 molecular sieve roasted in 850°C high-temperature air was placed in a 5mL beaker; 0.5g of newly prepared Fe(OH) was weighed 2 Stir with 5mL of distilled water, then impregnate the emulsion onto SBA-15 molecular sieves and stir evenly, let it stand for 12 hours; then place it in an oven at 150°C for 12 hours, bake it in the air at 1000°C for 0.5 hour, and then cool it down to room temperature naturally; In a tube furnace with a quartz tube with an Ar protective gas, the temperature was raised to 900°C, 2mL of diethylamine was brought through the catalyst by the Ar protective gas, and this process was completed after 0.5 hours; then the heating was stopped, and the Ar protective gas was continued until Cool down to room temperature; take out the black sample, which is a high-nitrogen-doped bamboo-shaped carbon nanotube material, and the molar ratio of C to N is 0.88:0.12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com