Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and pyrolysis gasoline technology, applied in the field of pyrolysis gasoline nickel-based selective hydrogenation catalyst and its preparation, can solve the problems of frequent regeneration, small pore volume, large pore volume, etc., and achieve good arsenic capacity and good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

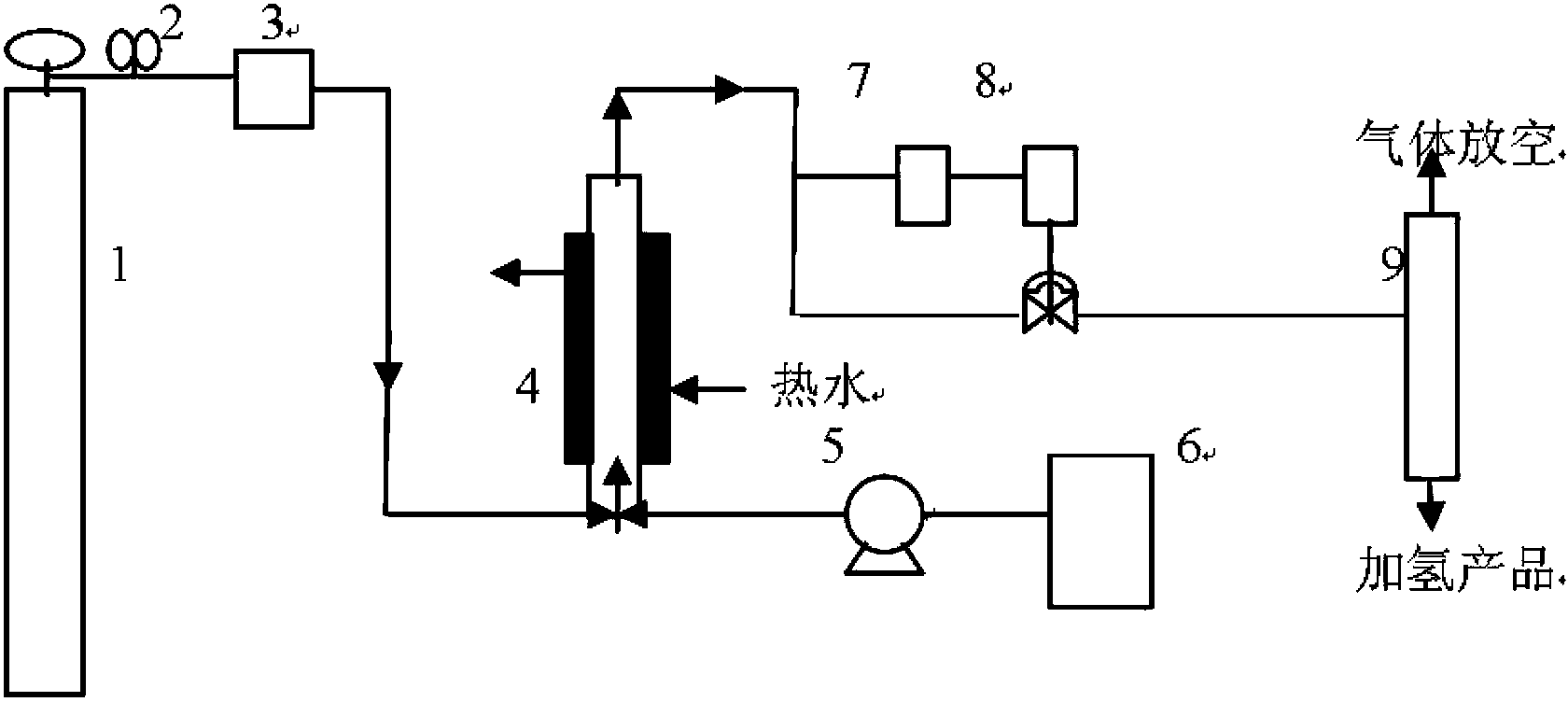

Image

Examples

Embodiment 1

[0062] Weigh 4.0g of polyethylene glycol and 3.6g of maltose and dissolve them in 100mL of water, then add 37.6g of aluminum nitrate and stir in a 60°C water bath for 40min to obtain solution 1, weigh 14.0g of basic nickel carbonate, 1.65g of ammonium molybdate, 0.8 Dissolve g lanthanum nitrate and 4.0 g ammonium carbonate in 10 mL ammonia water to obtain solution 2, slowly add solution 2 to solution 1 to obtain solution 3, then adjust solution 3 to pH 10.5 with ammonia water to obtain solution 4, weigh 9.0 g starch and add Put the solution 4 into ultrasonic waves for 20 minutes, take out the precipitate, wash it, and dry it at 100°C for 24 hours. Raise the temperature to 440°C at a speed of 2°C / min, roast at a constant temperature for 1.5h, and then raise the speed to 550°C for 2.5h at a speed of 2°C / min. The obtained catalyst powder was mixed with 0.5 g of scallop powder and 0.6 g of citric acid, and extruded to obtain catalyst A. The physical and chemical properties and co...

Embodiment 2

[0064] Weigh 4.0g of polyethylene glycol and dissolve it in 100mL of water, then add 37.6g of aluminum nitrate and stir in a 60°C water bath for 40min to obtain solution 1, weigh 11.7g of basic nickel carbonate, 1.5g of ammonium molybdate, 1.18g of lanthanum nitrate, Dissolve 4.0 g of ammonium carbonate in 10 mL of ammonia water to obtain solution 2, slowly add solution 2 to solution 1 to obtain solution 3, then adjust solution 3 with ammonia water to a pH value of 10.0 to obtain solution 4, weigh 9.0 g of starch and add it to solution 4 Into the ultrasonic wave for 18 minutes, the precipitate was taken out and washed, and dried at 100°C for 12 hours. Raise the temperature to 440°C at a speed of 2°C / min, roast at a constant temperature for 1.5h, and then raise the speed to 550°C for 2.5h at a speed of 2°C / min. The obtained catalyst powder was mixed with 0.5 g of scallop powder and 0.6 g of citric acid, and extruded to obtain catalyst B. The physical and chemical properties an...

Embodiment 3

[0066] Weigh 4.0g of ethylene glycol and dissolve it in 100mL of water, then add 37.6g of aluminum nitrate and stir in a 60°C water bath for 40min to obtain solution 1, weigh 14.0g of basic nickel carbonate, 1.5g of ammonium molybdate, 2.2g of lanthanum nitrate, 4.0 Dissolve 1 g of ammonium carbonate in 10 mL of ammonia water to obtain solution 2, slowly add solution 2 to solution 1 to obtain solution 3, then adjust solution 3 to pH 8.0 with ammonia water to obtain solution 4, weigh 9.5 g of starch and add it to solution 4 Ultrasonic for 15 minutes, the precipitate was taken out and washed, and dried at 100°C for 24 hours. Raise the temperature to 400°C at a speed of 2°C / min, roast at a constant temperature for 1.5h, and then raise the speed to 650°C for 2.5h at a speed of 2°C / min. The obtained catalyst powder was mixed with 0.5 g of scallop powder and 0.6 g of citric acid, and extruded to obtain catalyst C. The physical and chemical properties and composition of catalyst C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com