Patents

Literature

330 results about "Pyrolysis gasoline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis gasoline or Pygas is a naphtha-range product with a high aromatics content. It is a by-product of high temperature naphtha cracking during ethylene and propylene production. Also, it is a high octane number mixture which contains aromatics, olefins and paraffins ranging from C5s to C12s. PyGas has high potential for use as a gasoline blending mixture and/or as a source of aromatics. Currently, PyGas is generally used as a gasoline blending mixture due to its high octane number. Depending on the feedstock used to produce the olefins, steam cracking can produce a benzene-rich liquid by-product called pyrolysis gasoline. Pyrolysis gasoline can be blended with other hydrocarbons as a gasoline additive, or distilled (in BTX process) to separate it into its components, including benzene.

Desulfurization process and novel bimetallic sorbent systems for same

Novel sorbent systems for the desulfurization of cracked-gasoline and diesel fuels are provided which are comprised of a bimetallic promotor on a particulate support such as that formed of zinc oxide and an inorganic or organic carrier. Such bimetallic promotors are formed of at least two metals of the group consisting of nickel, cobalt, iron, manganese, copper, zinc, molybdenum, tungsten, silver, tin, antimony and vanadium with the valence of same being reduced, preferably to zero. Processes for the production of such sorbents are provided wherein the sorbent is prepared from impregnated particulate supports or admixed to the support composite prior to particulation, drying, and calcination. Further disclosed is the use of such novel sorbents in the desulfurization of cracked-gasoline and diesel fuels whereby there is achieved not only removal of sulfur but also an increase in the olefin retention in the desulfurized product. Such sorbents can also be utilized for the treatment of other sulfur-containing streams such as diesel fuels.

Owner:CHINA PETROCHEMICAL CORP

Method for deep desulfurization olefin hydrocarbon reduction of inferior gasoline

ActiveCN101492608AStructuring reaction does not affectReduce olefin contentRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the gasoline product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

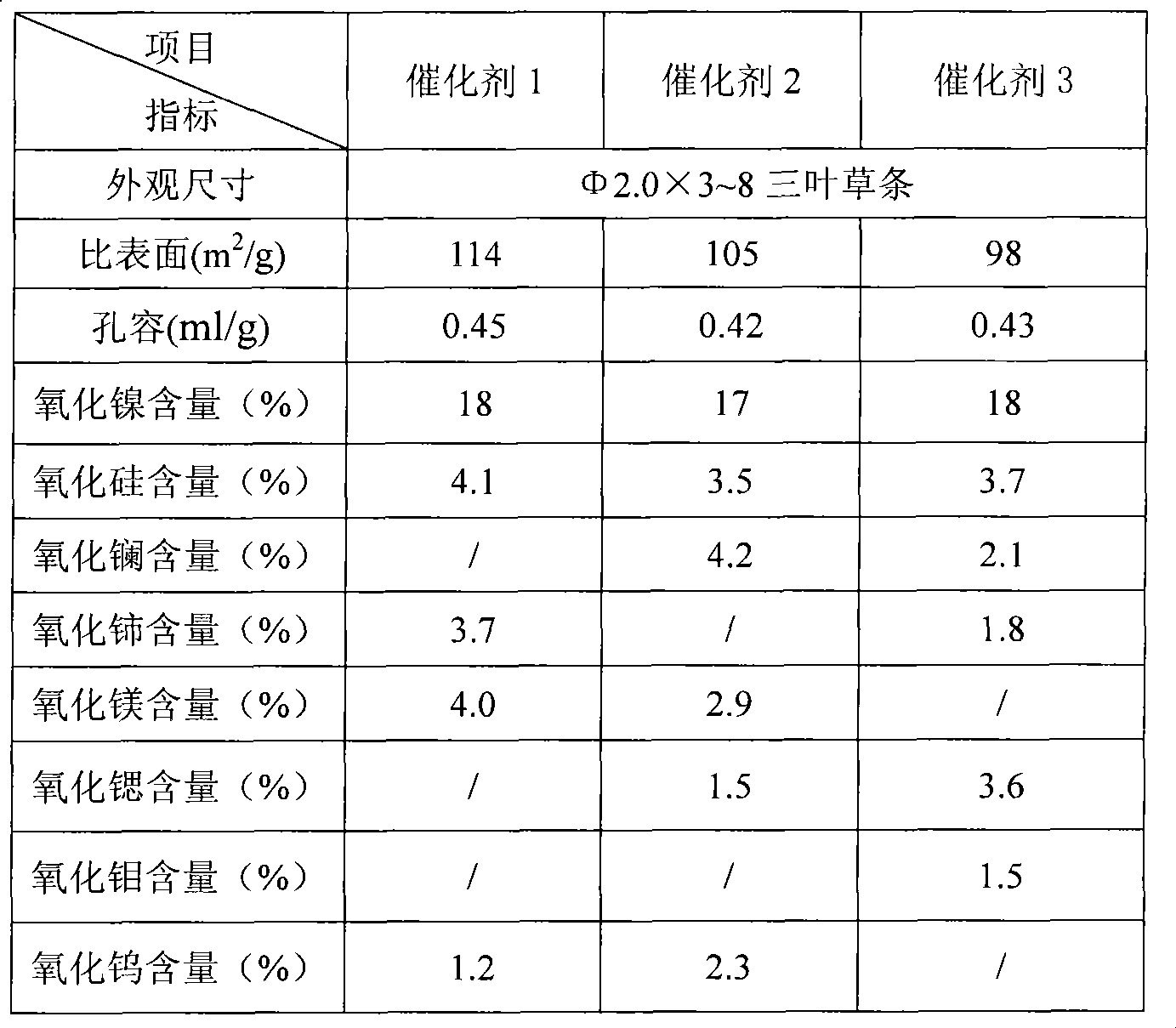

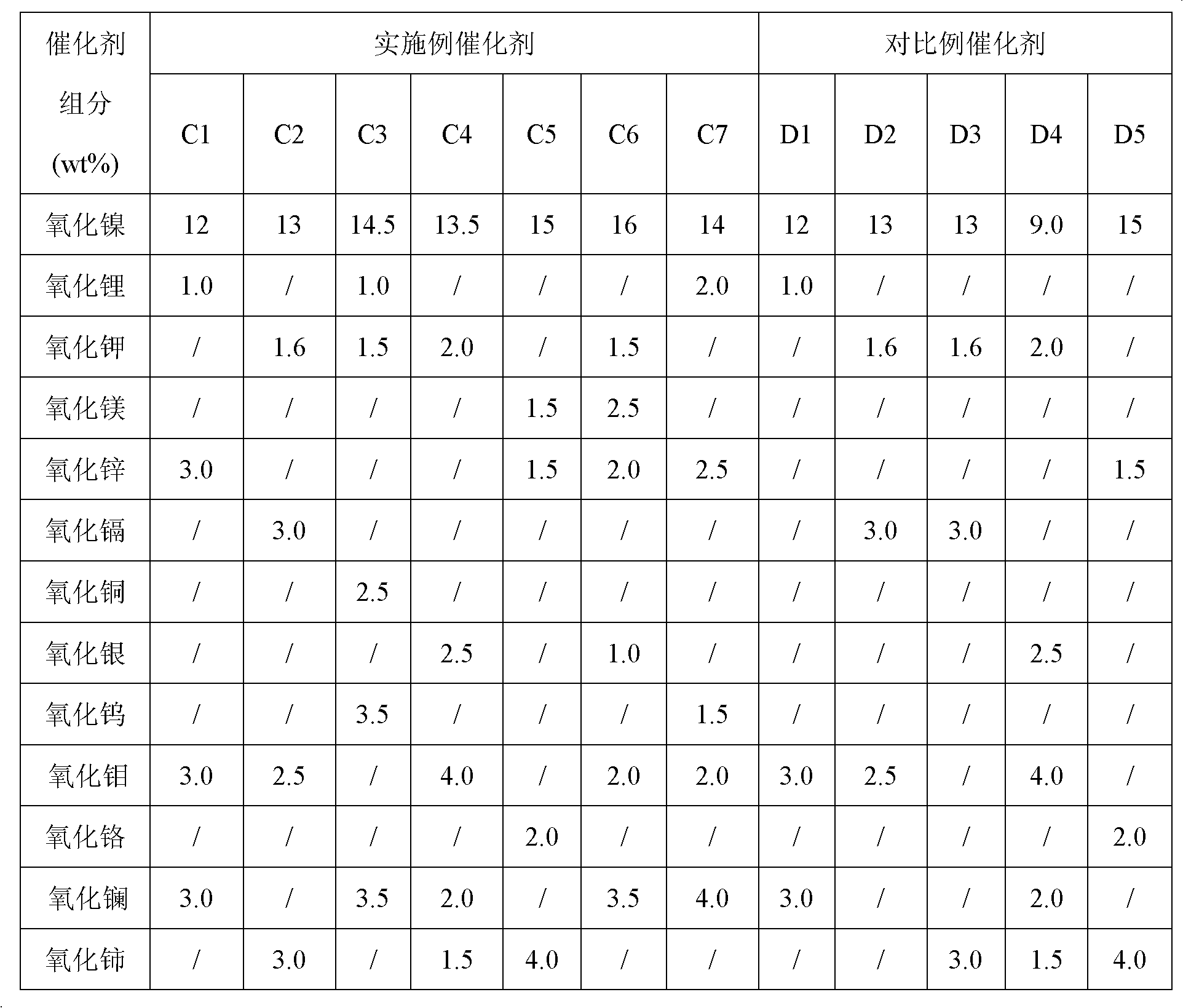

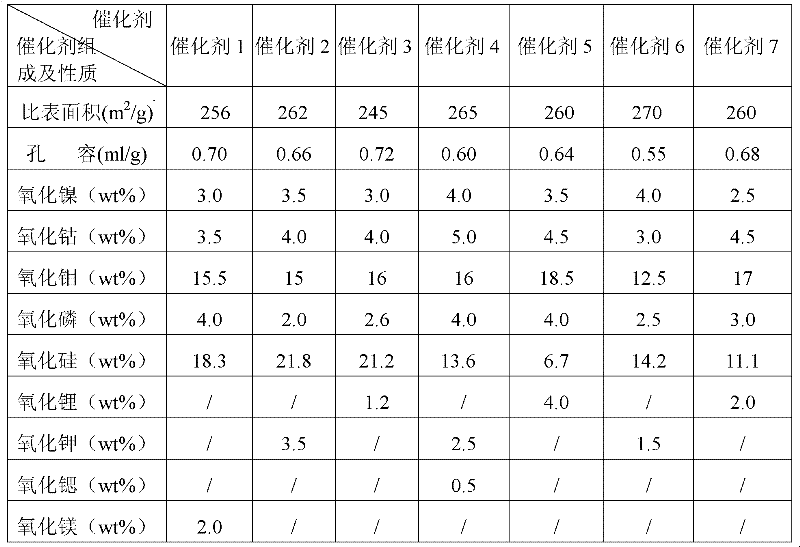

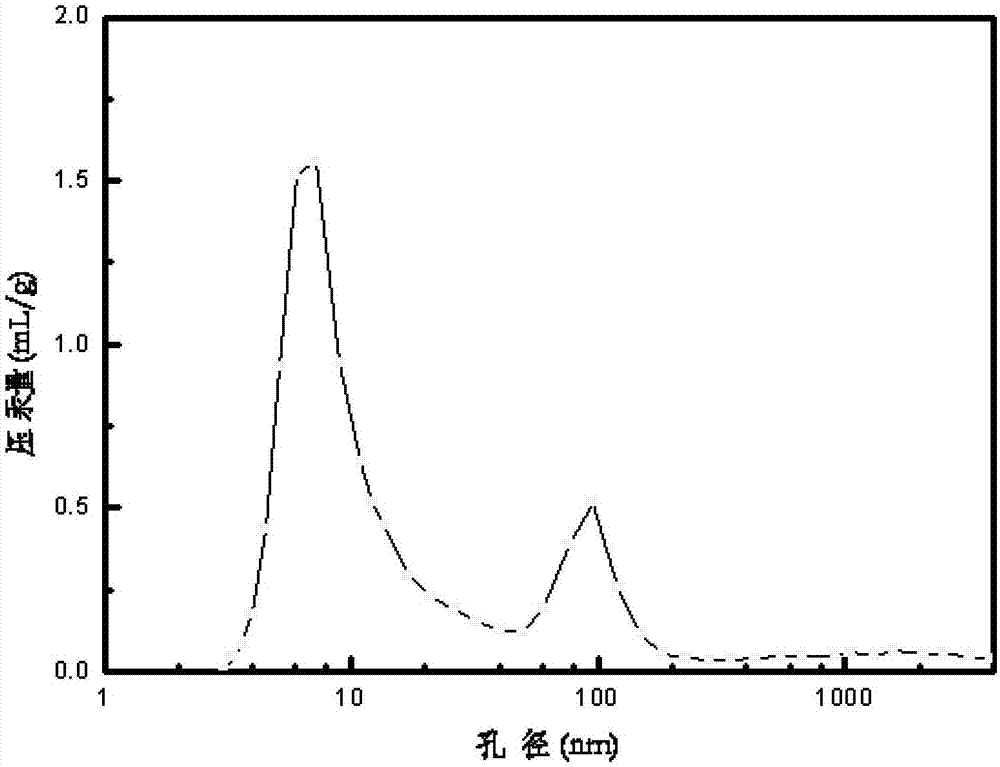

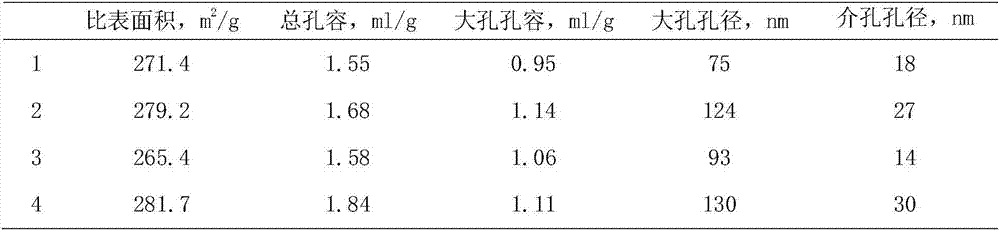

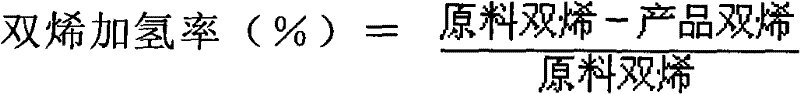

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

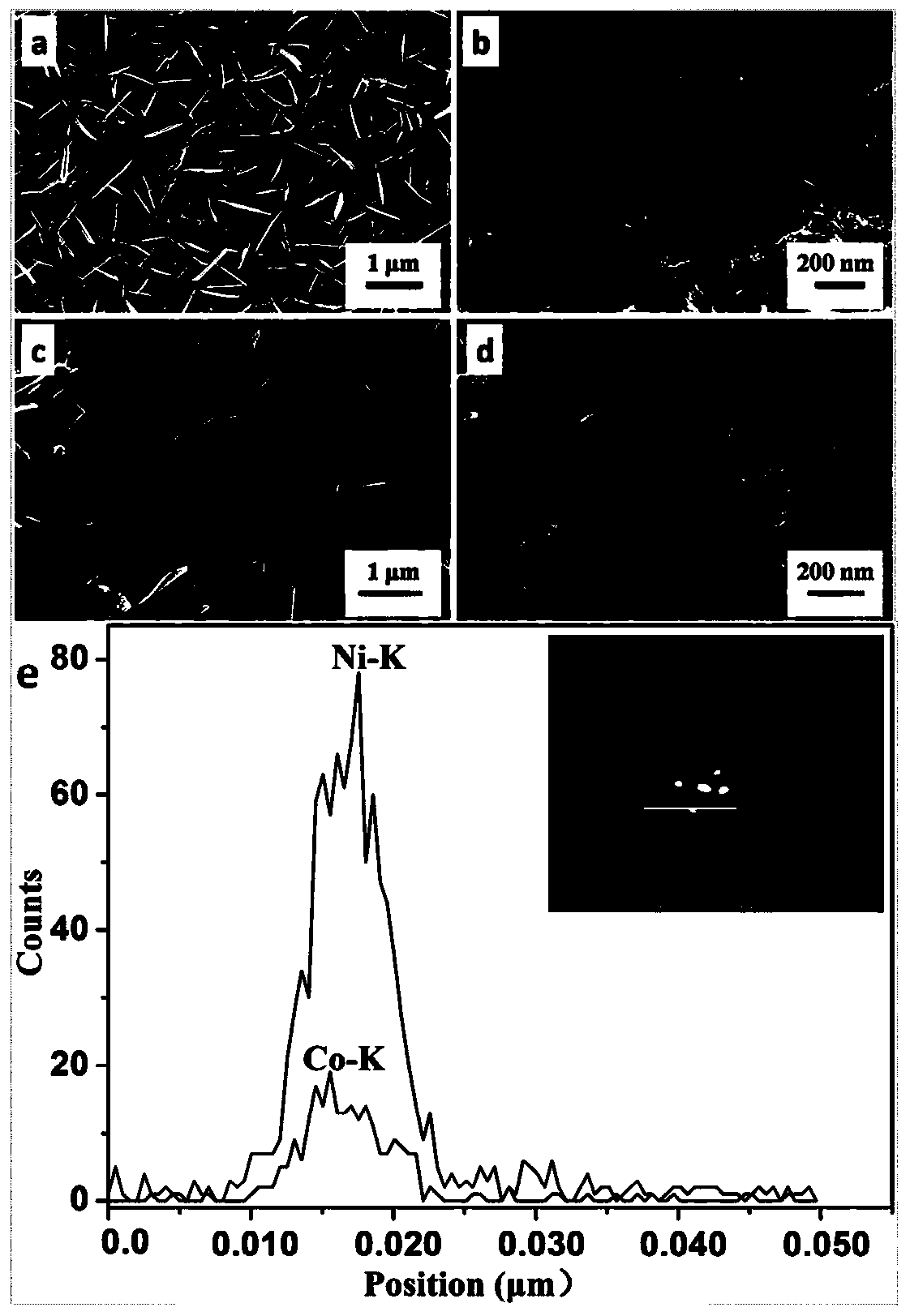

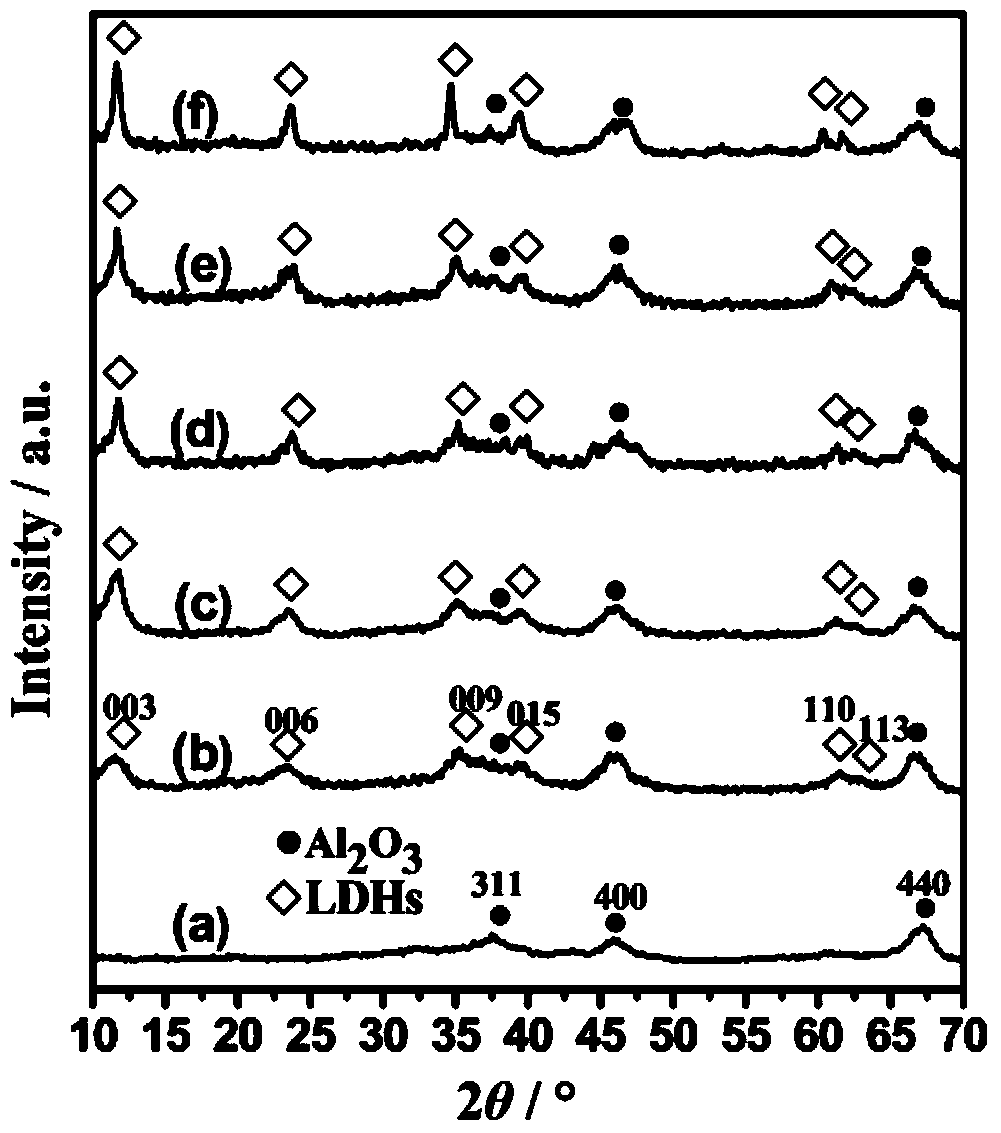

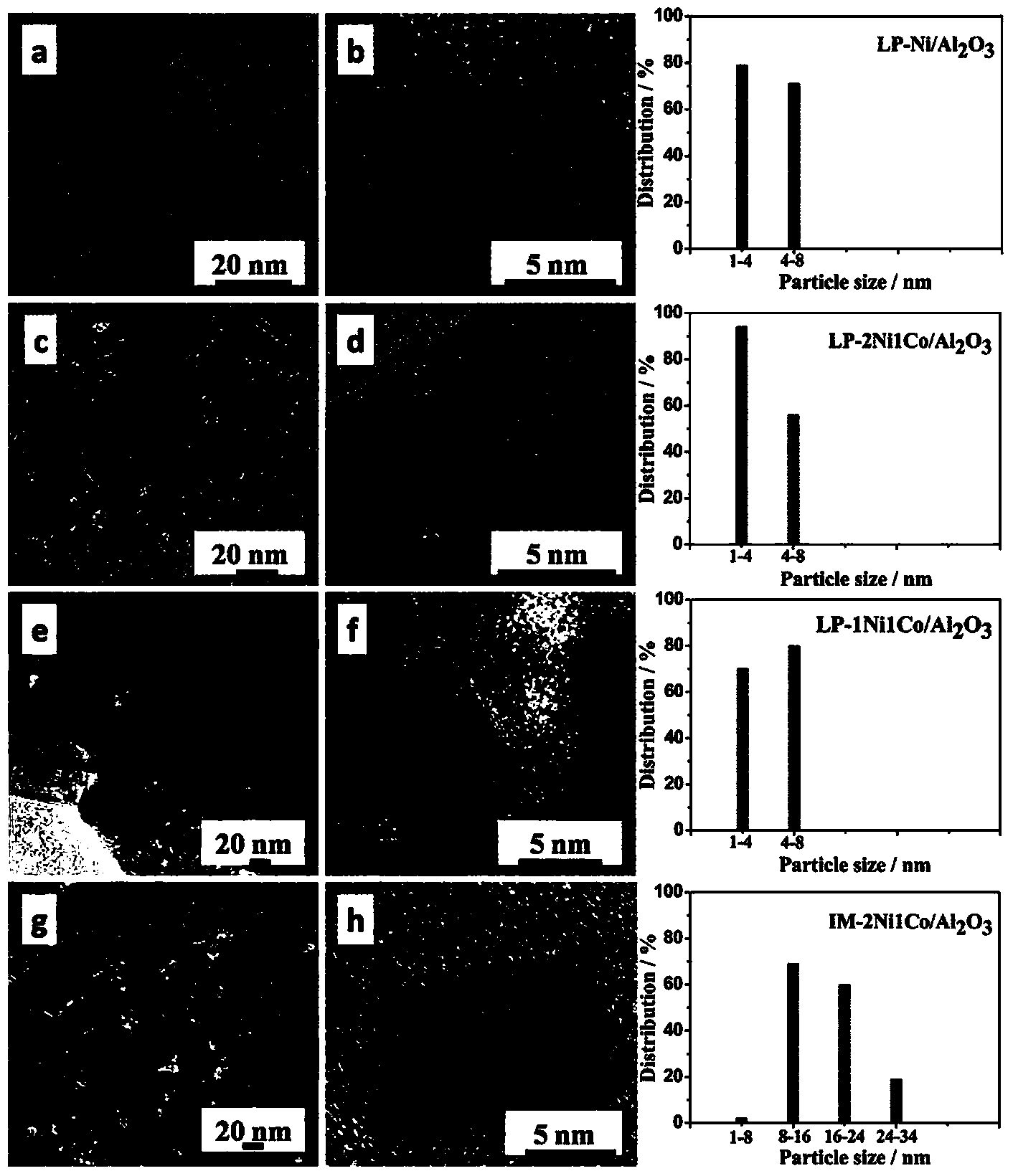

Preparation method and catalytic application of supported type high-dispersion nickel-based alloy catalyst

InactiveCN104368345AImprove conversion rateHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationPtru catalystAlloy catalyst

The invention discloses a preparation method and a catalytic application of a supported type high-dispersion nickel-based alloy catalyst. The preparation method comprises the following steps: by virtue of an in-situ growth method, supporting Ni, M (M=Co, Zn, Cu, Fe, Cr and the like) metal in the form of hydrotalcite on the surface of a microsphere-form gamma-Al2O3 carrier with grain size of 20-40 meshes and in a duct of the microsphere-form gamma-Al2O3 carrier, namely growing lamellar precursor LDHs containing Ni and M metal ions outside and inside a Al2O3 particle to form supported type high-dispersion distribution, converting the lamellar precursor LDHs into a corresponding composite metal oxide by drying and roasting at high temperature, and reducing the composite metal oxide to obtain the supported type high-dispersion nickel-based alloy catalyst with NiM distributed on the outer surface and in the duct of the carrier particle. The supported type high-dispersion nickel-based alloy catalyst is applied to first selective hydrogenation reaction of cracked gasoline, so that the conversion rate, the selectivity and the stability of the catalyst can be effectively improved; and moreover, the supported type high-dispersion nickel-based alloy catalyst can be used for methane reforming, and catalyzing reaction of preparing low-carbon hydrocarbon and alcohol by virtue of CO and CO2 hydrogenation.

Owner:BEIJING UNIV OF CHEM TECH

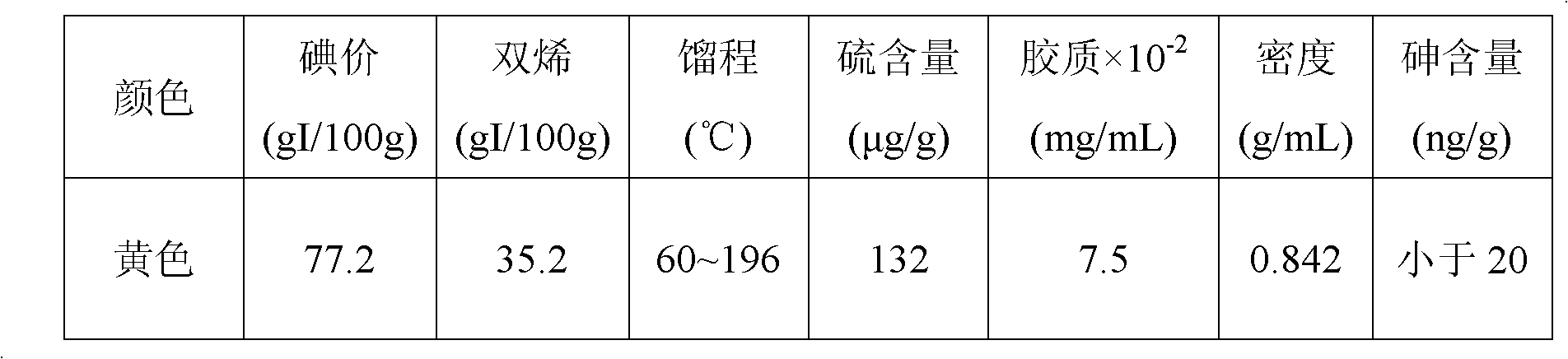

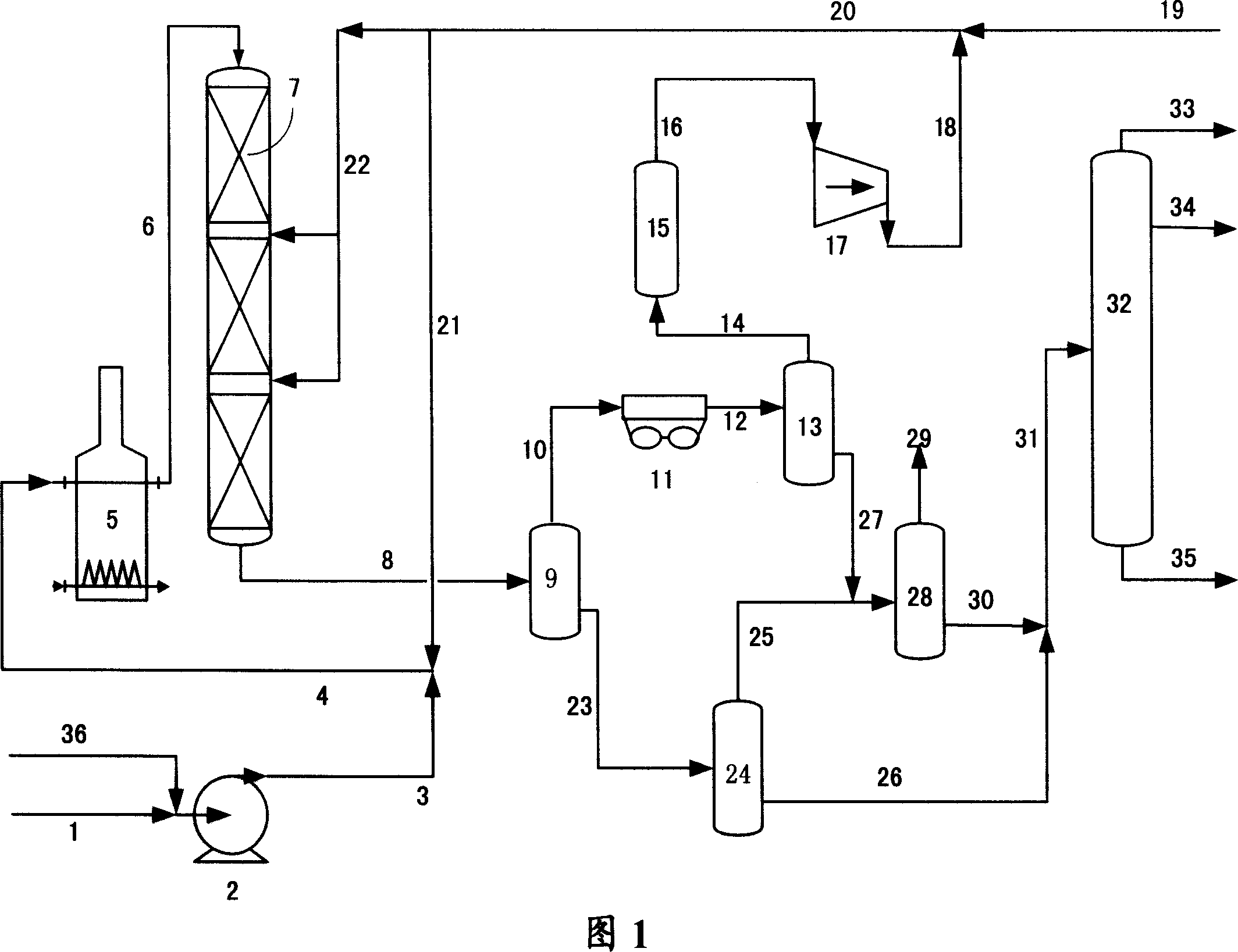

Selectivity hydrogenation method for whole fraction crack petroleum

ActiveCN101121899AGood activity at low temperatureGood choiceRefining by selective hydrogenationRefining by aromatic hydrocarbon hydrogenationPore distributionReaction temperature

The invention relates to a method for selective hydrogenation of full-run pyrolysis gasoline, which mainly solves the technical problem in the prior art that it is difficult to selectively hydrogenate full-run pyrolysis gasoline with high colloid and free water content. The present invention adopts the pyrolysis gasoline and hydrogen of the hydrocarbon compound fraction with C5 hydrocarbon to dry point of 204 DEG C as raw materials, the reaction temperature is 30 to 80 DEG C, the reaction pressure is 2.0 to 3.0 MPa, and the fresh oil space velocity is 2.5 to 5.0 hour-1, under the condition that the hydrogen / oil volume ratio is 60-120:1, the raw material is contacted with the catalyst and reacts to convert the diolefin and alkenyl aromatic components in the raw material into monoolefin and alkylaromatic. Including alumina support, active component metal palladium or its oxide, at least one element selected from IA or IIA in the periodic table or its oxide, at least one element selected from IVA or VA in the periodic table or its oxide Oxide, the specific surface area of the carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the carrier has a technical solution of composite pore distribution, which solves this problem well and can be used for full-run pyrolysis gasoline In the industrial production of selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

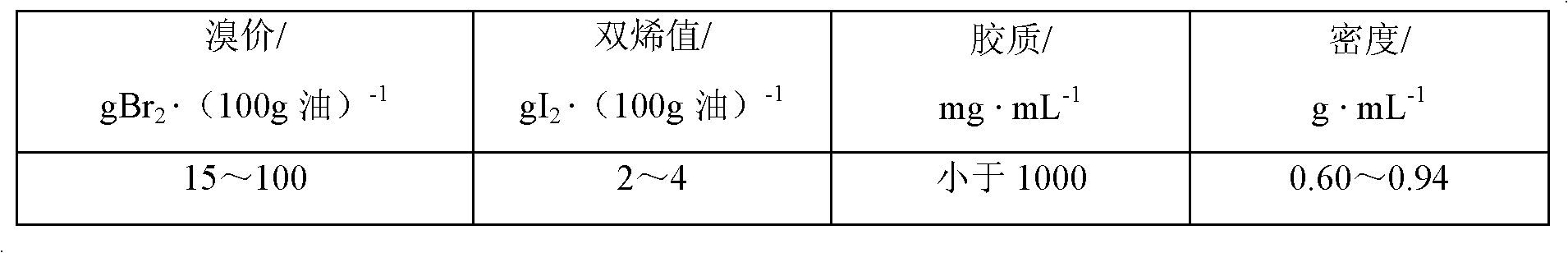

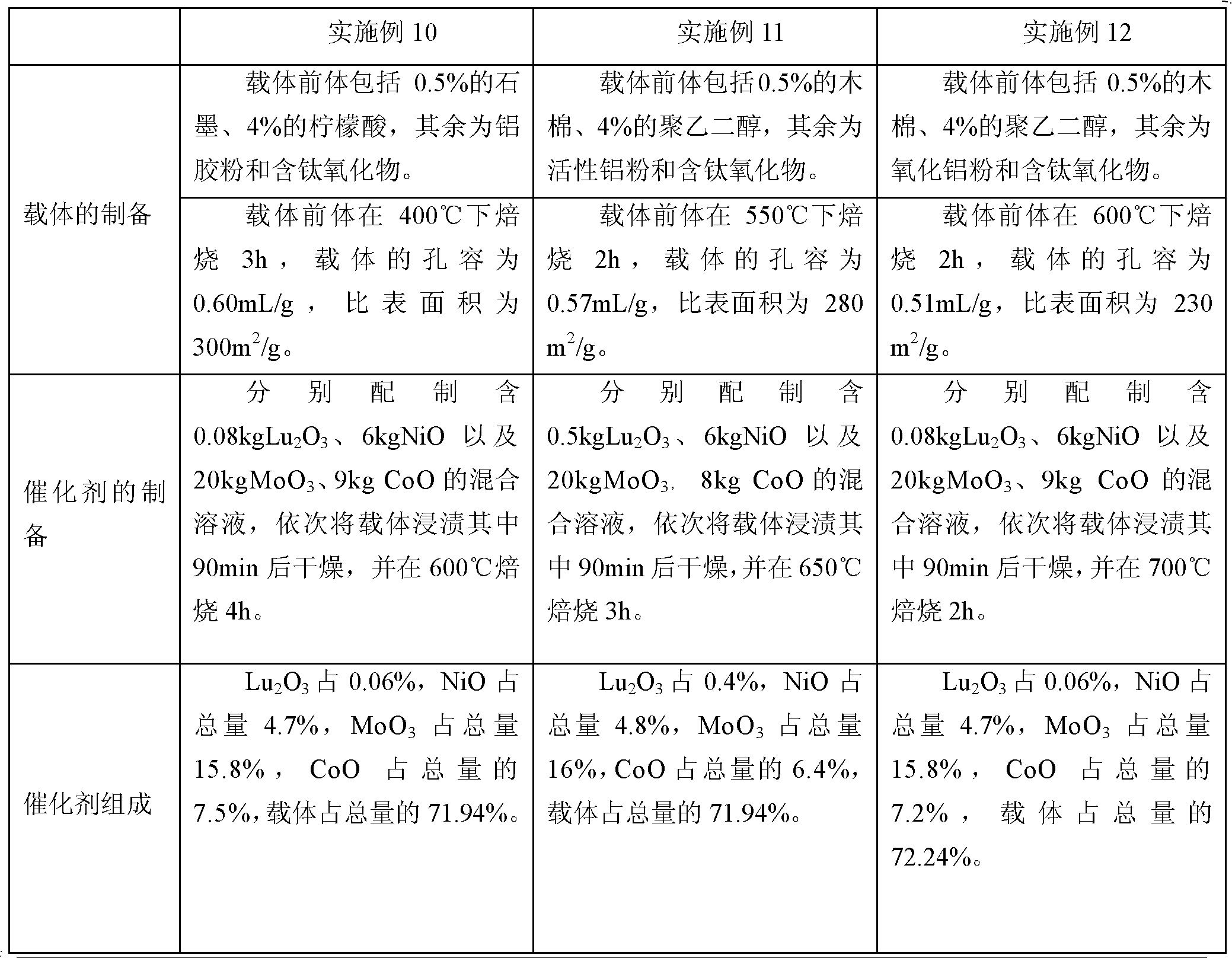

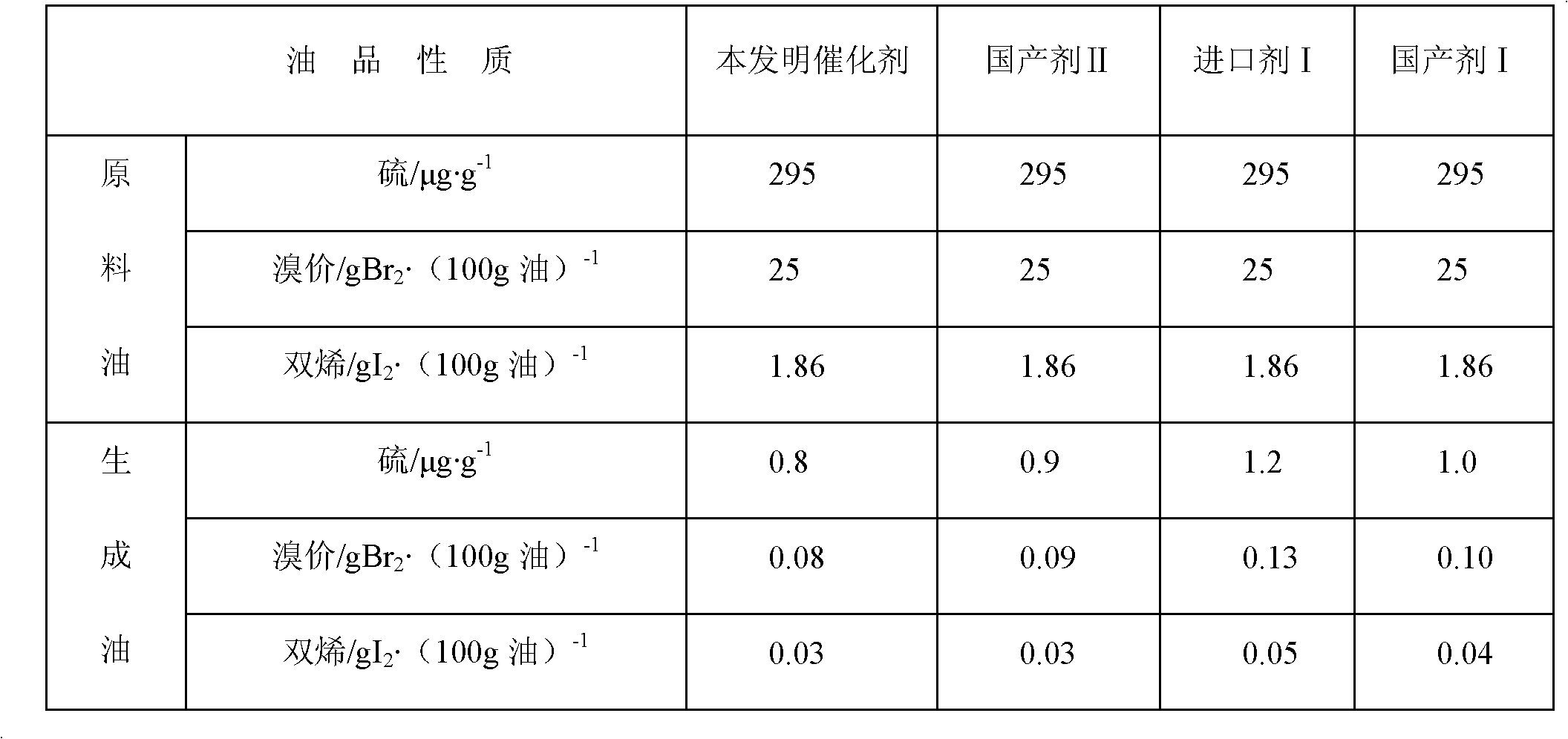

Hydrofining catalyst and preparation method thereof

ActiveCN102861593ALarge hole volumeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemical industryRare-earth element

The invention discloses a hydrofining catalyst and a preparation method thereof, belonging to the field of catalysts used in the petroleum-chemical industry. The hydrofining catalyst disclosed herein comprises a carrier, an active component and an auxiliary agent, wherein the carrier is Ti-modified gamma-alumina, the active component comprises oxides of Mo, Co and Ni, and the auxiliary agent comprises oxides of rare earth. The catalyst is characterized in that: based on 100% of the total weight of the catalyst, Co (measured in CaO) in the active component accounts for 2.0-7.5% of the total weight of the catalyst, Mo (measured in MoO3) in the active component accounts for 4.0-18.0% of the total weight of the catalyst, Ni (measured in NiO) in the active component accounts for 0.2-5.0% of the total weight of the catalyst, the auxiliary agent accounts for 0.05-1.0% of the total weight of the catalyst, and the balance consists of the carrier. According to the invention, the catalyst prepared by the formula and the method disclosed in the invention can carry out hydrogenation on saturated monoolefine while the catalyst is used for carrying out hydrodesulfurization on oils, can be suitable for technical requirements of heavy oriention, changeable sulphur content, and high air speed of hydrogenation liquid for pyrolysis gasoline two-stage hydrogenated raw materials, and simultaneously, the catalyst has the advantages of low activation temperature and low loss of aromatics in the hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP

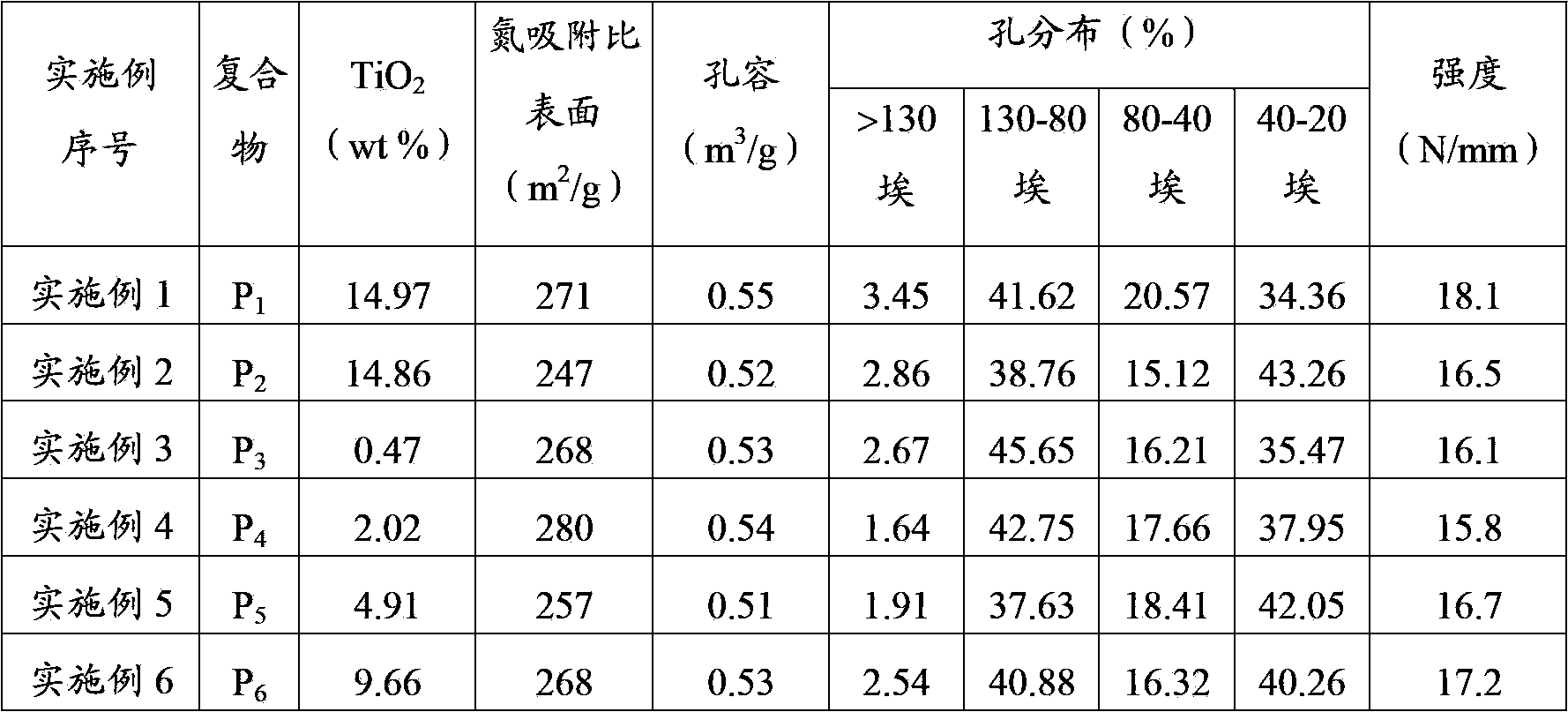

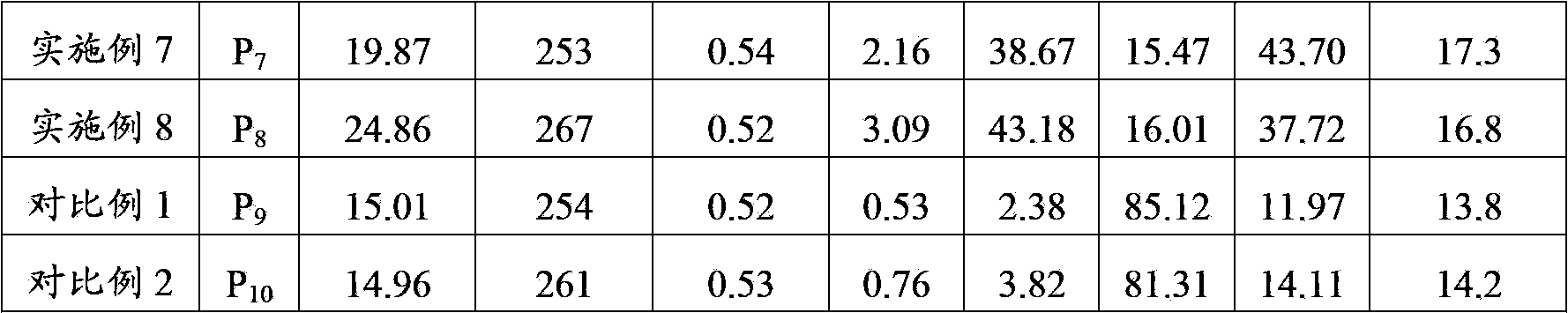

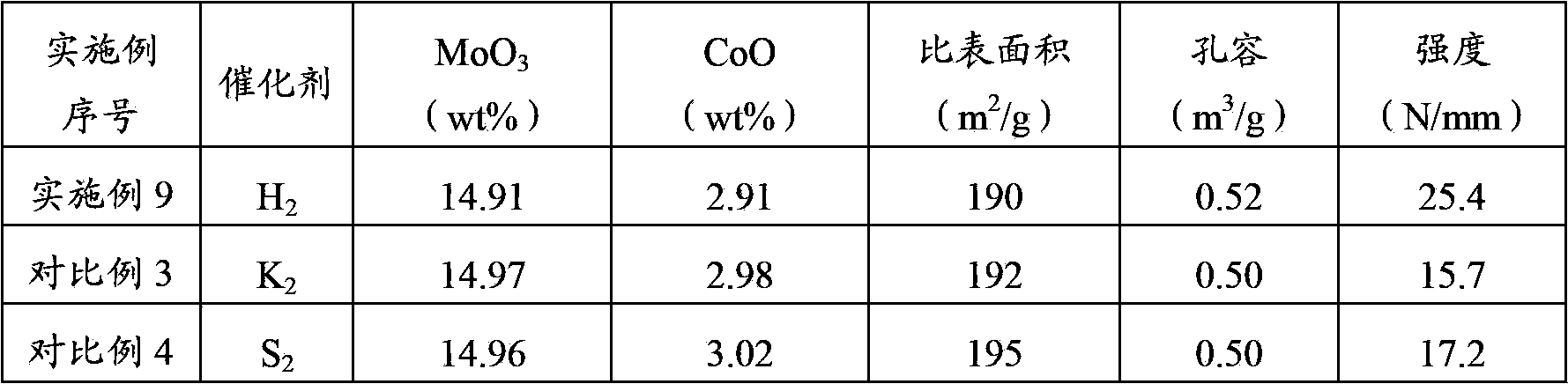

Titanium oxide-aluminum oxide compound as well as preparation method and application thereof

ActiveCN103721693ALong active periodHigh low temperature activityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationTitanium oxide

The invention provides a titanium oxide-aluminum oxide compound, which comprises 0.3-25 wt% of titanium oxide based on the compound, wherein, the compound is distributed in diplopore channel. In the compound, preferably diameters of 30-50% of apertures are 20-40 angstrom, furtherly, diameters of 30-50% of apertures are 80-130 angstrom. The invention also provides a preparation method of titanium oxide-aluminum oxide compound, and the diplopore channel compound is obtained by controlling the pH value of the reaction solution to alternatively stay within two scopes for a certain time. In addition, the invention also provides an application of the titanium oxide-aluminum oxide compound as a catalyst carrier. A catalyst using the titanium oxide-aluminum oxide compound of the present invention as a carrier can be applied to pyrolysis gasoline hydrodesulfurization reaction, and the catalyst has the advantages of high low temperature activity and high hydrogenation conversion rate, and the hydrodesulfurization rate can reach to 99.9%.

Owner:CHINA PETROLEUM & CHEM CORP +1

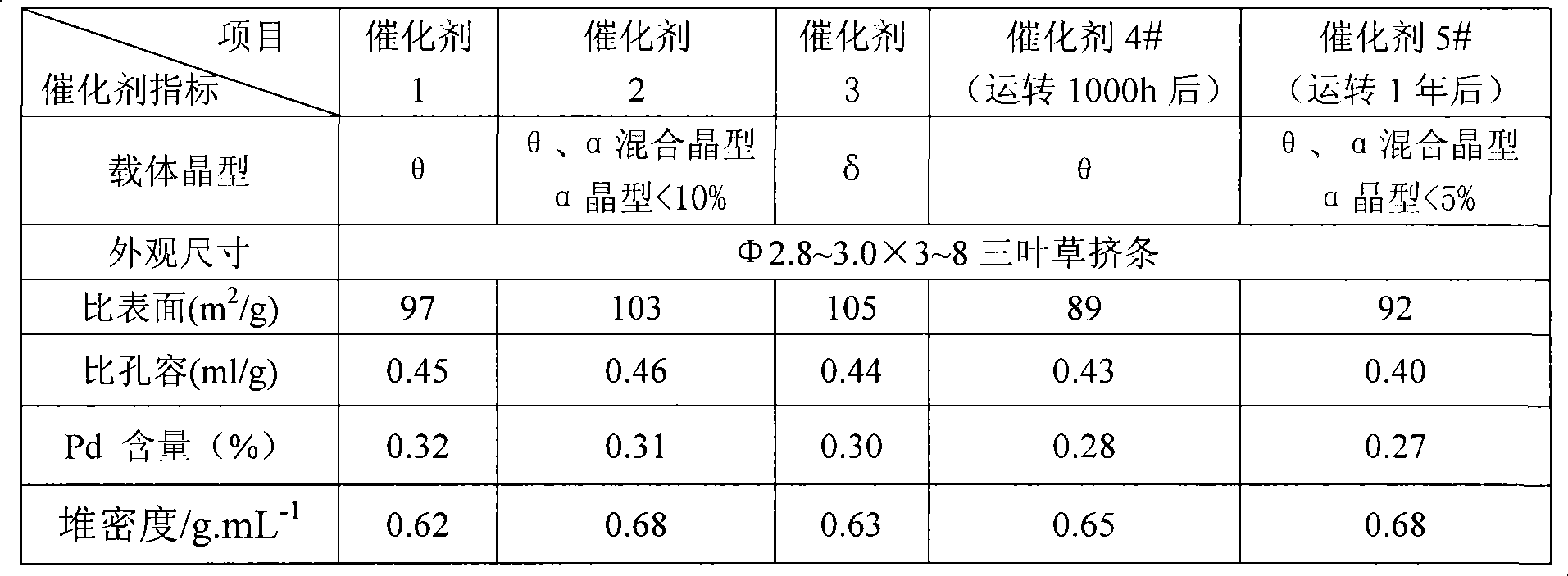

Pyrolysis gasoline cut fraction section selective hydrogenation method

ActiveCN101429453AImprove hydrogenation performanceImprove hydrogenation activityRefining by selective hydrogenationAlkaline earth metalCerium

The invention relates to a first-stage selectivity hydrogenation method for pyrolysis gasoline fractions, which uses palladium series hydrogenation catalyst which is used after being reduced. The first-stage selectivity hydrogenation method for the pyrolysis gasoline fractions is characterized in that the hydrogenation technological conditions are as follows: the volume space velocity of a liquid is less than or equal to 5h<-1>, the inlet temperature of a reactor is between 28 and 120 DEG C, the reaction pressure is more than or equal to 2.4 MPa, and the hydrogen / oil volume ratio is between 50 and 500; the palladium series hydrogenation catalyst takes theta-type alumina or theta and alpha mixed crystal type alumina giving priority to theta type as a carrier, takes metallic palladium as an active ingredient, and contains 0.2 to 0.5 weight percent of the active ingredient-the palladium, 2 to 8 weight percent of auxiliary agent-lanthanum and / or cerium, and 2 to 8 weight percent of alkaline earth element as calculated by 100 weight percent of the catalyst; and the catalyst can still be used by regeneration after being subjected to coking and deactivation. Under the condition of the application method and the technological conditions, the catalyst has good hydrogenation performance, and particularly still has good hydrogenation activity and stability when hydrogenation raw materials contain trace water and colloids.

Owner:PETROCHINA CO LTD

Method for hydrogenation pyrolysis of prolific benzene and xylene by using pyrolysis gasoline

InactiveCN101734986AModerate hydrogenation performanceIncrease added valueHydrocarbon by hydrocarbon crackingNaphtha reformingAlkaneIsomerization

The invention relates to a method for hydrogenation pyrolysis of prolific benzene and xylene by using pyrolysis gasoline. The method mainly solves the problems that only BTX (B is benzene, T is toluene and X is xylene) arene is separated in the traditional process of the pyrolysis gasoline, and the light arene output contains a great amount of toluene with lower utilization value with the separated heavy arene. In the invention, alkyl transfer reaction is carried out among the pyrolysis gasoline material of C7+, the heavy arene hydrogenation and the light arene are in the presence of catalyst, and isomerization reaction is carried out on the light arene into the component rick in BTX light arene; and the liquid-phase is separated into benzene, toluene, xylene and C9+ distillate according to different boiling points, wherein the toluene and the C9+ distillate can be returned for further processing as the feedstock and the light alkane can be separated from gas-phase output, thereby favorably solving the technical problem. The method can be used for the industrial production of light arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

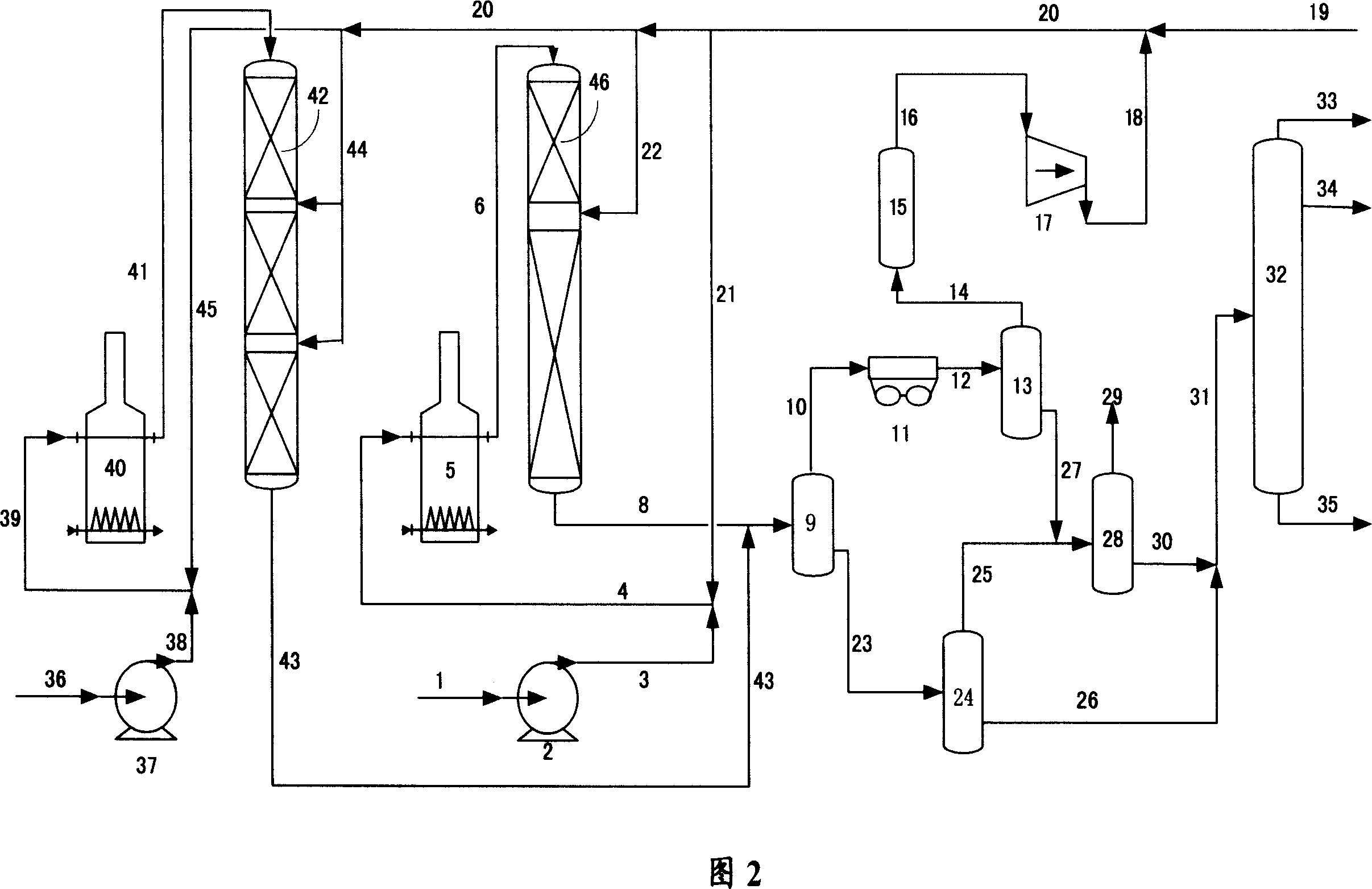

Full-cut fraction pyrolysis gasoline diolefin selective hydrogenation method

ActiveCN101429454AGood hydrogenation effectGood hydrogenation stabilityRefining by selective hydrogenationSilicon dioxideImpurity

The invention provides a selectivity hydrogenation method for diolefin of full-fraction pyrolysis gasoline, which comprises reduction and passivation of catalyst and application of technological conditions. The catalyst is nickel series hydrogenation catalyst which is used after being reduced or being subjected to reduction and passivation. The selectivity hydrogenation method is characterized in that the hydrogenation technological conditions are as follows: the volume space velocity of a liquid is less than or equal to 4h<-1>, the inlet temperature of a reactor is between 40 and 130 DEG C, the reaction pressure is more than or equal to 2 MPa, and the hydrogen / oil ratio is between 100 and 500 (v / v); the nickel series catalyst takes alumina as a carrier, is prepared by the immersion method, and contains 14 to 20 percent of nickel oxide, 1 to 8 percent of lanthanum oxide and / or cerium oxide, 1 to 8 percent of 4B oxide auxiliary agent, 2 to 8 percent of silicon dioxide and 1 to 8 percent of alkaline earth oxide as calculated by 100 weight percent of the catalyst; and the specific surface of the catalyst is between 60 and 150 square meters per gram, and the pore volume of the catalyst is between 0.4 and 0.6 milliliter per gram. The invention also provides a method for performing reduction and passivation on the catalyst on a hydrogenation unit. Under the conditions of the application method and the technological conditions, the nickel catalyst has good hydrogenation performance, and particularly has strong impurity and colloid resistance and good hydrogenation stability.

Owner:PETROCHINA CO LTD

Nickel catalyst for selective hydrogenation

ActiveCN101147871AGood activity at low temperatureGood choiceHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementNickel catalyst

The present invention relates to a nickel catalyst for selective hydrogenation. The catalyst composition includes the following components: (by wt%) (a), 5.0-40.0% of metal nickel or its oxide; (b), 0.01-20.0% of at least one element selected from molybdenum or tungsten or its oxide; (c), 0.01-10.0% of at least one element selected from rare earth elements or its oxide; (d), 0.01-2.0% of at least one element selected from IA or IIA of periodic table of chemical elements or its oxide; (e), 0-15.0% of at least one element selected from Si, P, B or F or its oxide; (f), 0-10.0% of at least one element selected from IVB of periodic table of chemical elements or its oxide; and (g), the rest is aluminium oxide. Said catalyst can be used for pyrolysis gasoline hydrotreating production.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Aluminium oxide carrier with composite holes structure and preparation method thereof

ActiveCN101121120AImprove hydrogenation activityExcellent high-resistant gelatinPhysical/chemical process catalystsRefining to eliminate hetero atomsPore distributionPore diameter

The invention relates to an alumina carrier with a composite pore structure and a preparation method thereof. The method mainly solves the technical problem that it is difficult to obtain macroporous alumina carriers with different pore distributions above 20 nanometers and the preparation method thereof in the prior art. In the present invention, the specific surface area of the alumina carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the pore volume with a pore diameter of less than 30 nanometers accounts for 5-60% of the total pore volume. The pore volume of 30 to 60 nanometers accounts for 20 to 75% of the total pore volume, and the pore volume with a pore diameter > 60 nanometers accounts for 20 to 60% of the total pore volume as a composite carrier; the preparation method of the composite carrier adopts firstly alumina A Mixing with alumina B, molding, drying at 50-100°C for 1-24 hours, and then roasting at 800-1150°C for 1-10 hours to obtain a technical solution to the composite carrier solves this problem well, and can be used for pyrolysis gasoline In the industrial production of hydrogen catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for deep desulfurization olefin hydrocarbon reduction of gasoline

ActiveCN101492609AStructuring reaction does not affectReduced responseRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization catalyst and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective nickel series hydrogenating catalyst and its preparing process and uses

ActiveCN1995290AAnti-scorchHas anti-arsenic propertiesRefining to eliminate hetero atomsActive componentCerium

The invention discloses a selectivity nickel-system hydrogenating catalyst based on alumina as carrier, which comprises the following parts: 100g catalyst, 12-20g nickel oxide, 2-8g lanthanum oxide and / or cerium oxide, 2-8g VIB element oxide, wherein the specific surface of catalyst is 60-200m2 / g with pore content at 0.4-0.7ml / g. the making method comprises the following steps: adding active component nickel and lanthanum and or cerium, VIB element compound in the water; dissolving completely; adjusting pH value to 3. 8-5; immersing alumina carrier in the leaching liquid; loading each component on the alumina carrier; drying under 100-120 deg. c; sintering under 200-480 deg. c for 3-5h.

Owner:PETROCHINA CO LTD

Diene selective hydrogenation catalyst and preparation method

InactiveCN102641740AGood activity at low temperatureImprove applicabilityRefining by selective hydrogenationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The invention discloses a diene selective hydrogenation catalyst, wherein alumina or modified alumina serves as a carrier, nickel serves as an active component, and alkali metals or alkaline earth metals, VIB metals, X metals and rare earth metals serve as auxiliaries; and when the total weight of the catalyst is metered by 100% in weight percentage, the catalyst contains 10% to 20% of nickel oxide, 0.5% to 5% of the alkali metals and / or the alkaline earth metals, 1% to 7% of oxide of VIB elements, 0.5%to 5% of oxide of auxiliary X metal elements and 2% to 5% of oxide of rare earth elements, wherein the X metals is one or more out of cadmium, zinc, copper and silver. The catalyst has very high hydrogenation activity and selectively under a relatively low temperature, is good in stability, and is mainly applicable to diene selective hydrogenation reaction of pyrolysis gasoline and FCC gasoline.

Owner:PETROCHINA CO LTD

Desulfurization and novel sorbent for same

InactiveUS20060081499A1Improve the immunityMinimizing saturationOther chemical processesLiquid carbonaceous fuelsSorbentHydrocarbon

A sorbent composition comprising a support, a promoter, and a silicate can be used to desulfurize a hydrocarbon-containing fluid such as cracked-gasoline or diesel fuel.

Owner:CHINA PETROCHEMICAL CORP

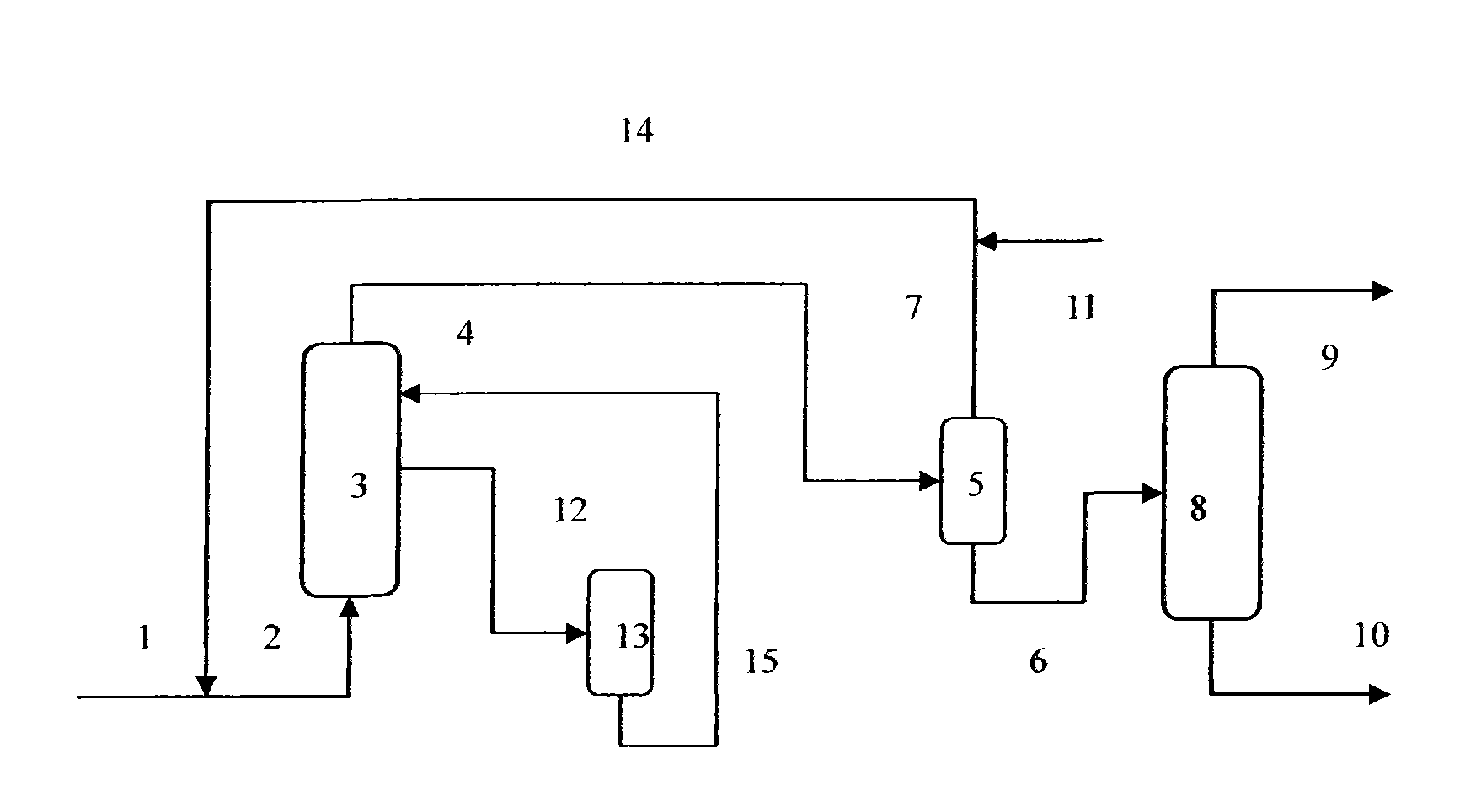

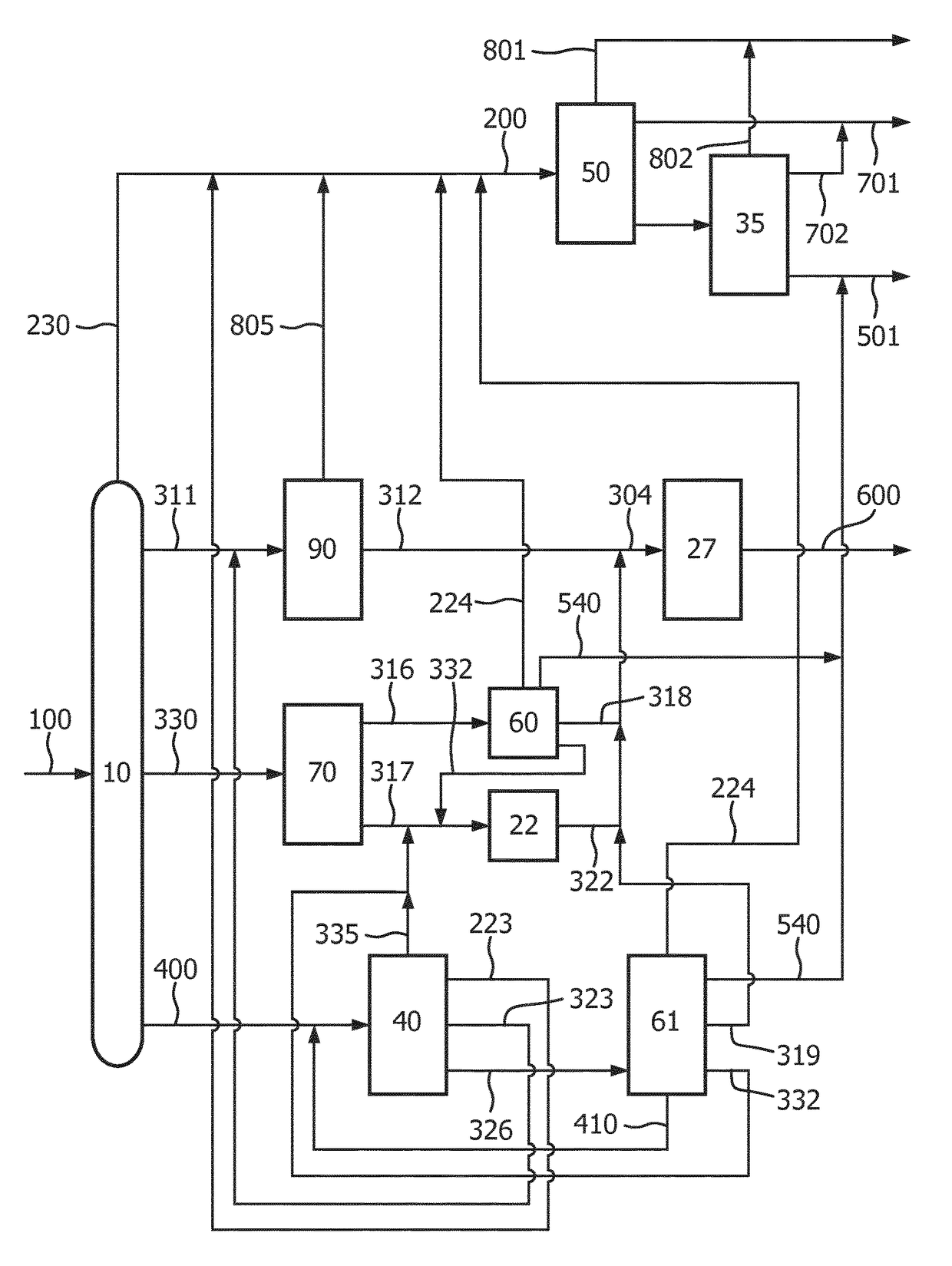

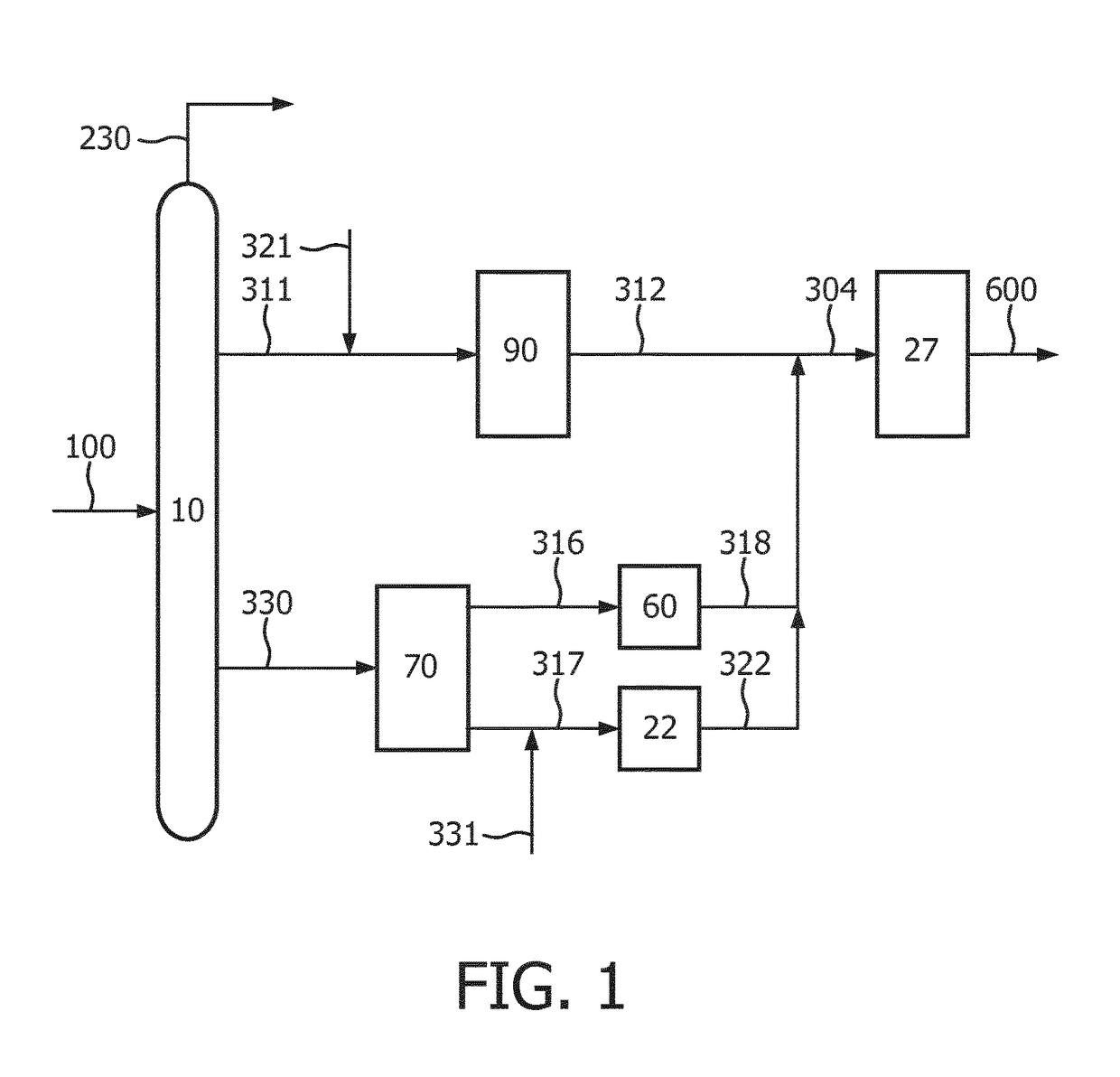

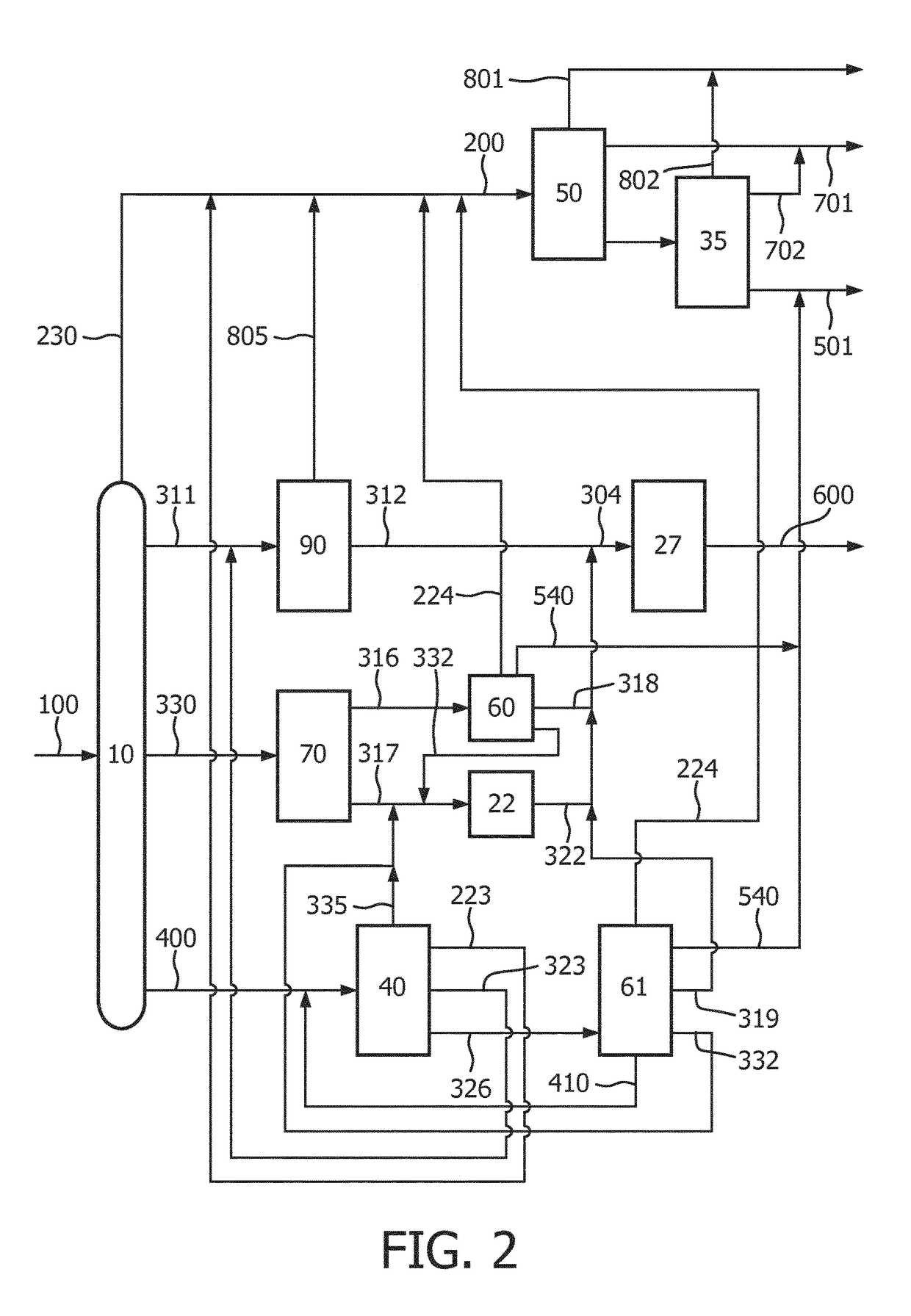

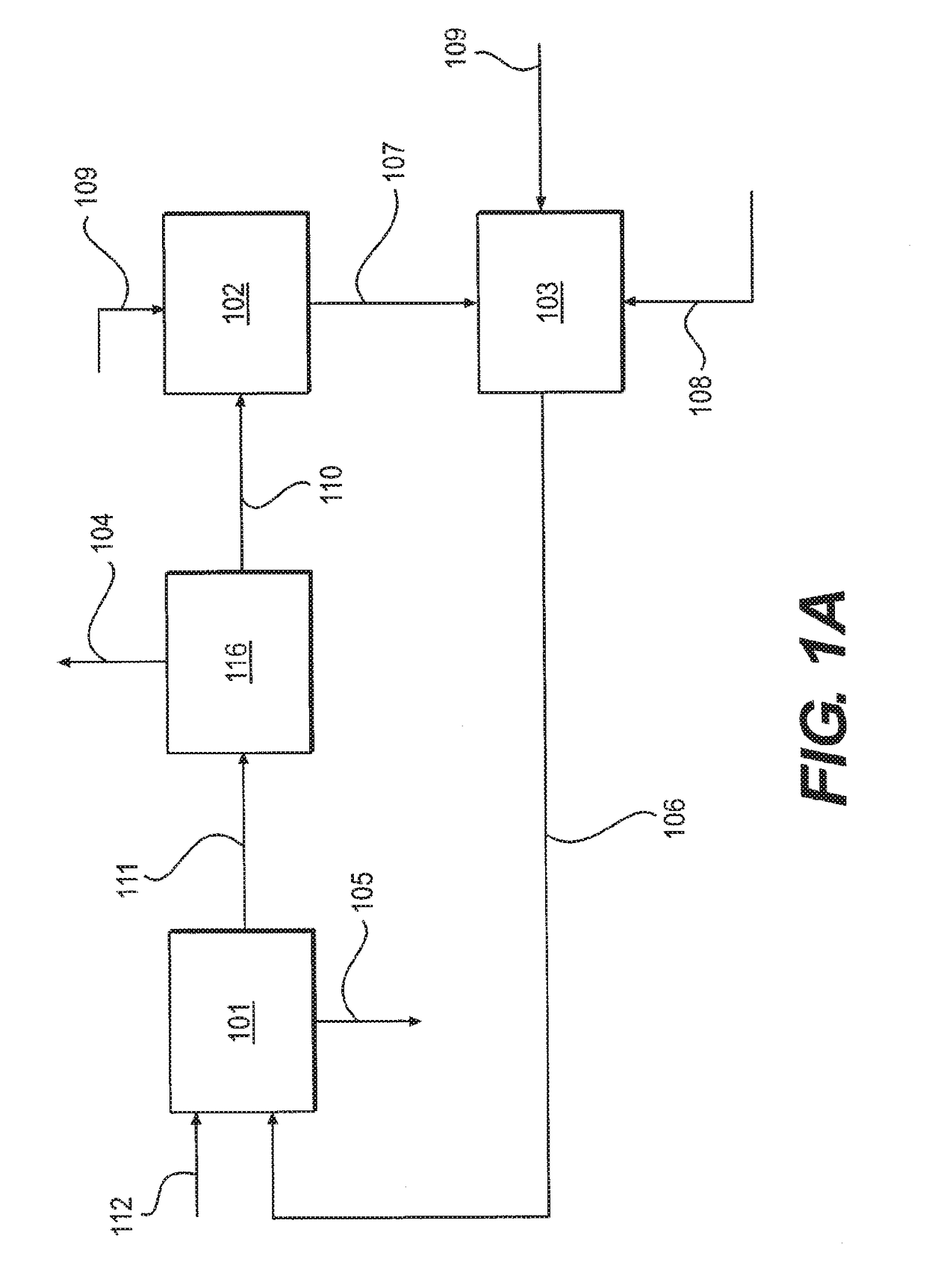

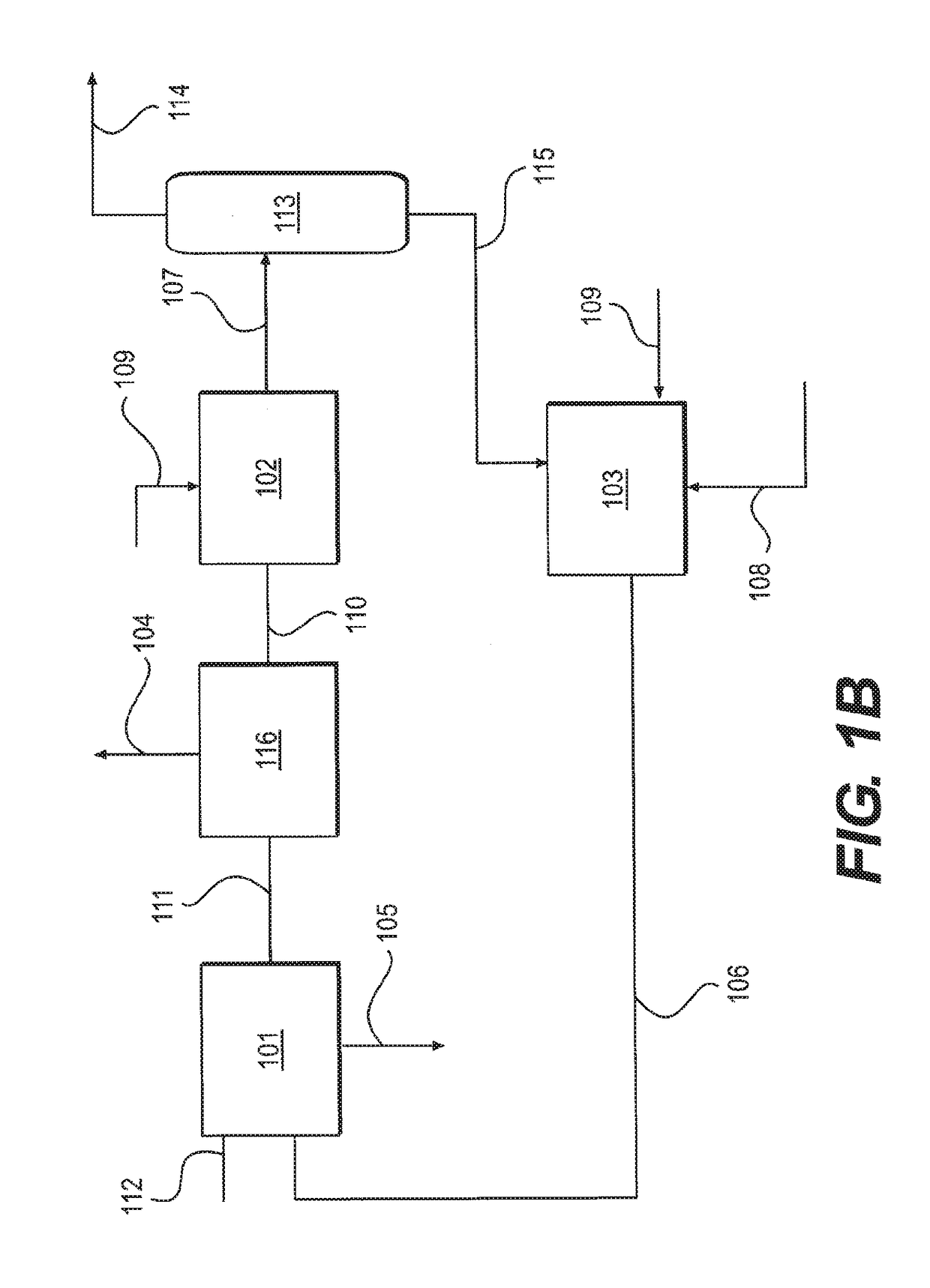

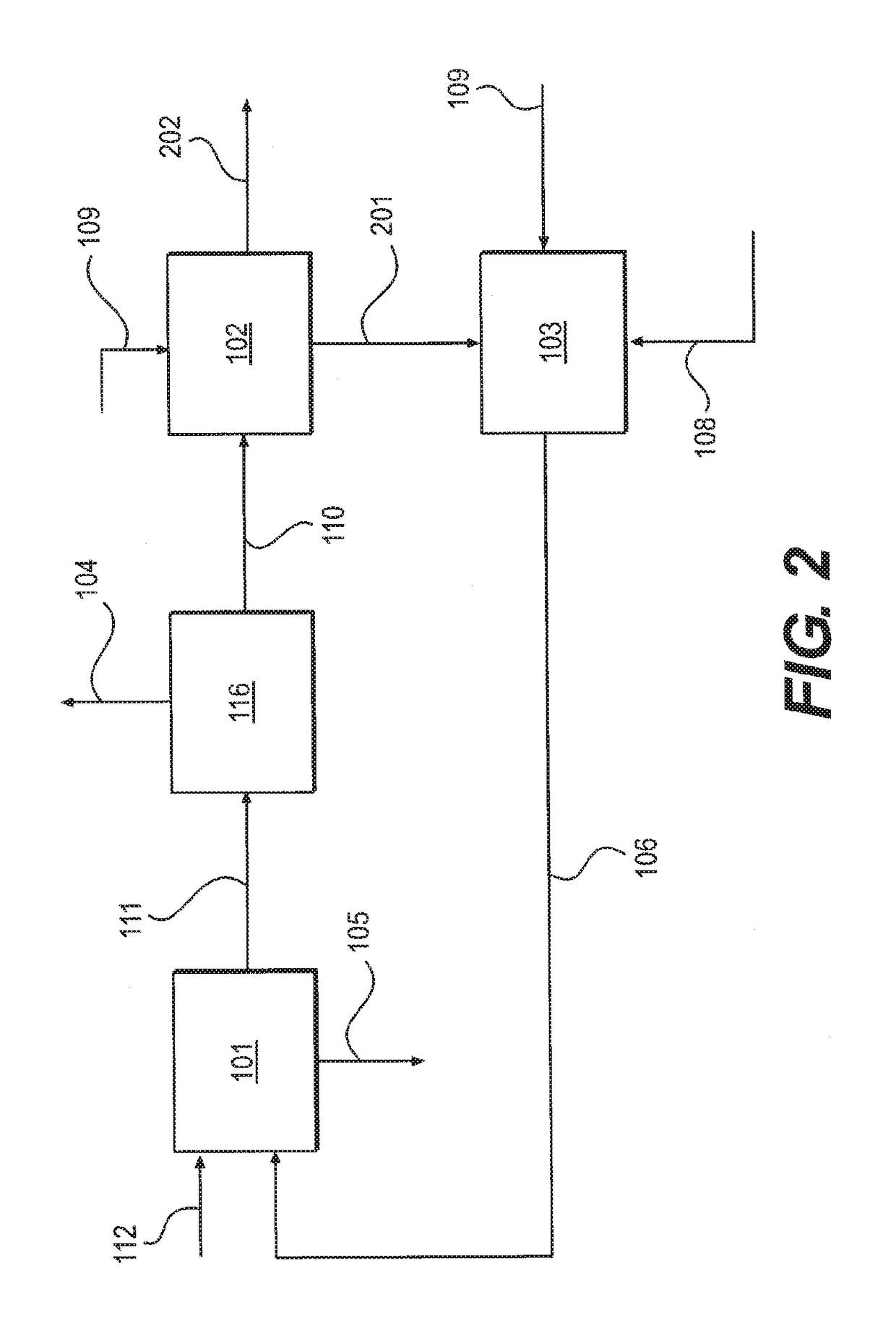

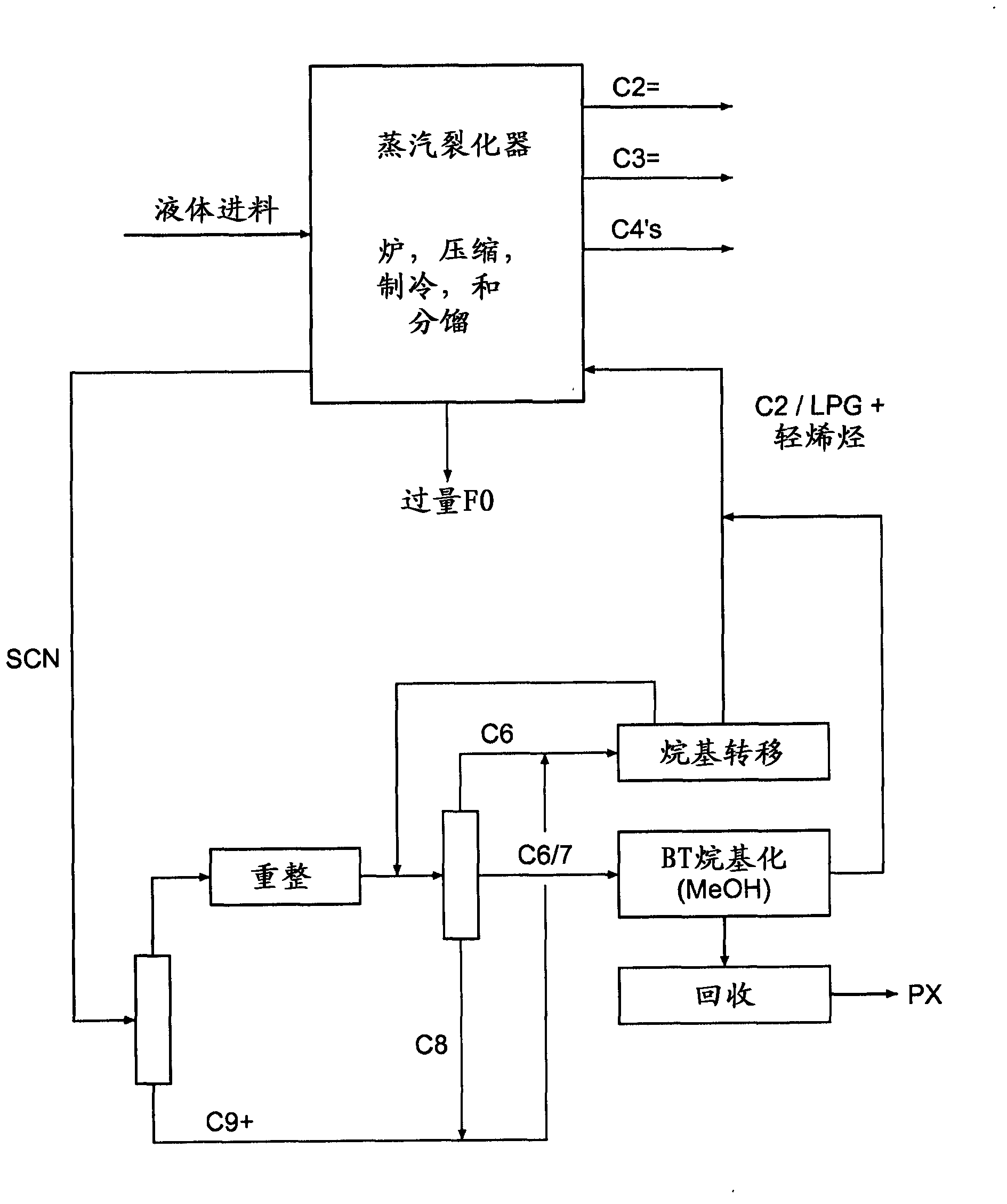

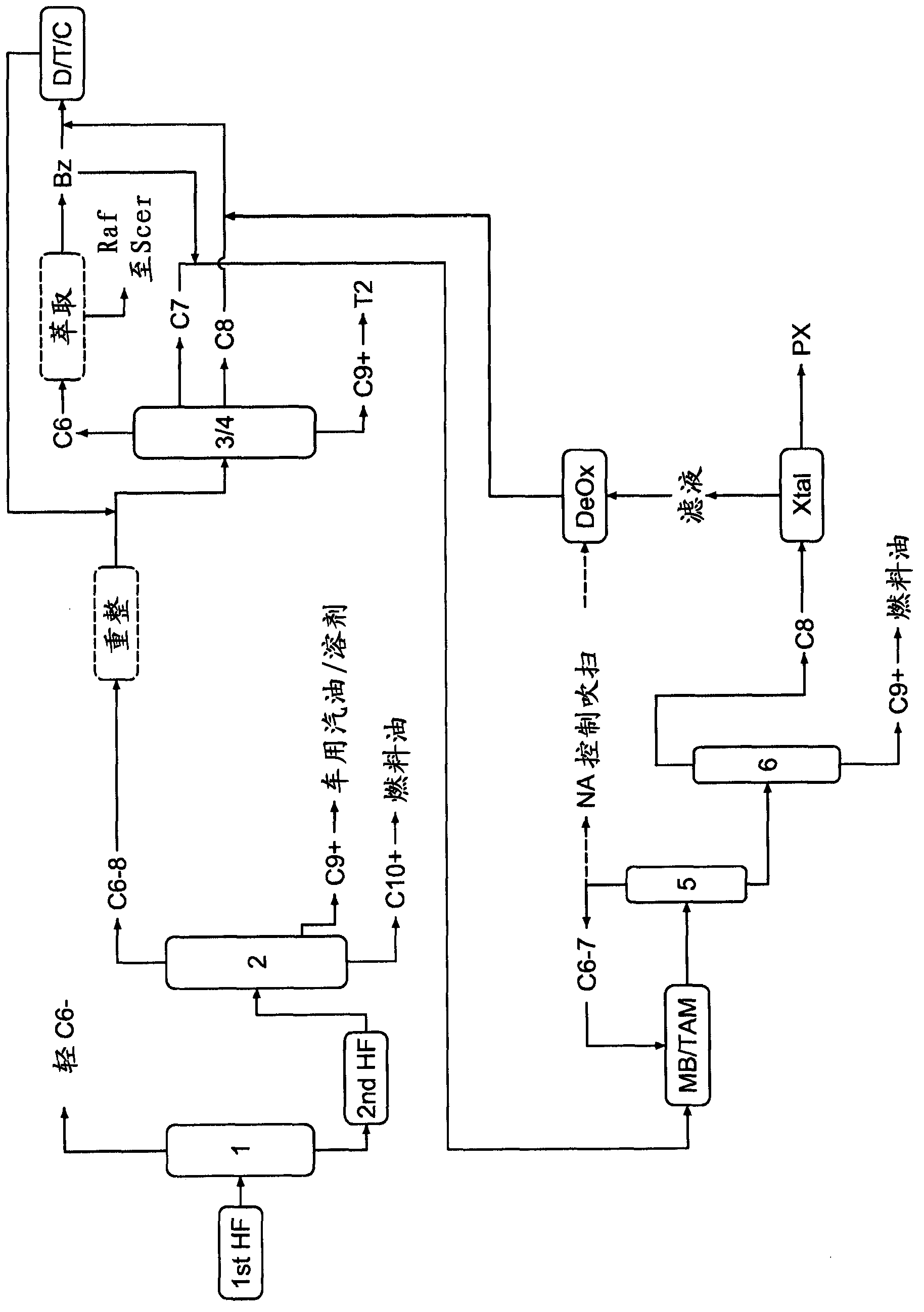

Process and installation for the conversion of crude oil to petrochemicals having an improved BTX yield

The present invention relates to an integrated process to convert crude oil into petrochemical products comprising crude oil distillation, reforming, dearomatization, fluid catalytic cracking and aromatic ring opening, which process comprises: subjecting crude oil to crude oil distillation to produce naphtha and one or more of kerosene and gasoil; subjecting naphtha to reforming to produce reformer gasoline; subjecting kerosene and / or gasoil to dearomatization to produce a first stream enriched for alkanes and naphthenes and a second stream enriched for aromatics; subjecting the stream enriched for alkanes and naphthenes to pyrolysis to produce a pyrolysis gasoline or to fluid catalytic cracking to produce a FCC gasoline; subjecting the stream enriched for aromatics to aromatic ring opening to produce a ARO gasoline; and subjecting one or more of reformer gasoline, FCC gasoline and ARO gasoline to gasoline treatment to produce BTX. Furthermore, the present invention relates to a process installation to convert crude oil into petrochemical products using the process of the present invention. The process and the process installation of the present invention have an increased production of petrochemicals at the expense of the production of fuels and an improved BTX yield.

Owner:SAUDI BASIC IND CORP SA +1

Method of dense raw material hydrotreatment-catalytic cracking for improving propylene productivity

ActiveCN101063047AHigh yieldTreatment with hydrotreatment processesHydrogenation reactionCutting oil

The invention discloses a heavy raw material hydrotreating-catalytic cracking method to increase propone productivity, which comprises the following steps: choosing light circling oil and or weight circling oil from catalytic cracking unit; adding into hydrogenation reaction zone with heavy cut oil; or adding into two hydrogenation reaction zone with different hydrogenation catalyst to react; getting effluent; cooling; separating; fractionating; getting heavy liquid phase fraction; moving catalytic cracking unit; separating the catalytic cracking reacting product; getting the final product. This invention can dispose cycloalkyl heavy raw material, which propone receiving ratio can increase by 5-7 percent dot.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrorefining method of distillate oil

ActiveCN102268283AImprove hydrogenation activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentSlurryCobalt

The invention provides a hydrorefining method of distillate oil. In the hydrorefining method, a cobalt molybdenum nickel hydrogenation catalyst is used; hydrogenation process conditions are as follows: the inlet temperature is 200-320 DEG C, the operation pressure is larger than or equal to 2.4MPa, the volume space velocity of a liquid is 1-5h<-1>, and the volume ratio of hydrogen to oil is 100-500; in the cobalt molybdenum nickel hydrogenation catalyst, silicon-containing alumina is used as a carrier, cobalt, molybdenum and nickel are used as active components, and phosphorus and alkali metal are added to be used as auxiliaries; and the precursor of the silicon-containing alumina carrier is pseudo boehmite containing amorphous silica-alumina and is obtained by the steps of firstly preparing an amorphous silica-alumina slurry and a pseudo boehmite slurry, mixing the two slurries, ageing, and then carrying out posttreatment processes such as filtering, washing and drying. According to the invention, hydrorefining is carried out on a first-stage hydrogenation product of full-fraction cracked gasoline by using the hydrorefining method, wherein the bromine value in the hydrogenation product is less than 1.0*10<-2>g / g and the content of sulfur in the hydrogenation product is less than 1.0mu g / g, thereby meeting the second-stage hydrogenation requirements of the cracked gasoline.

Owner:PETROCHINA CO LTD

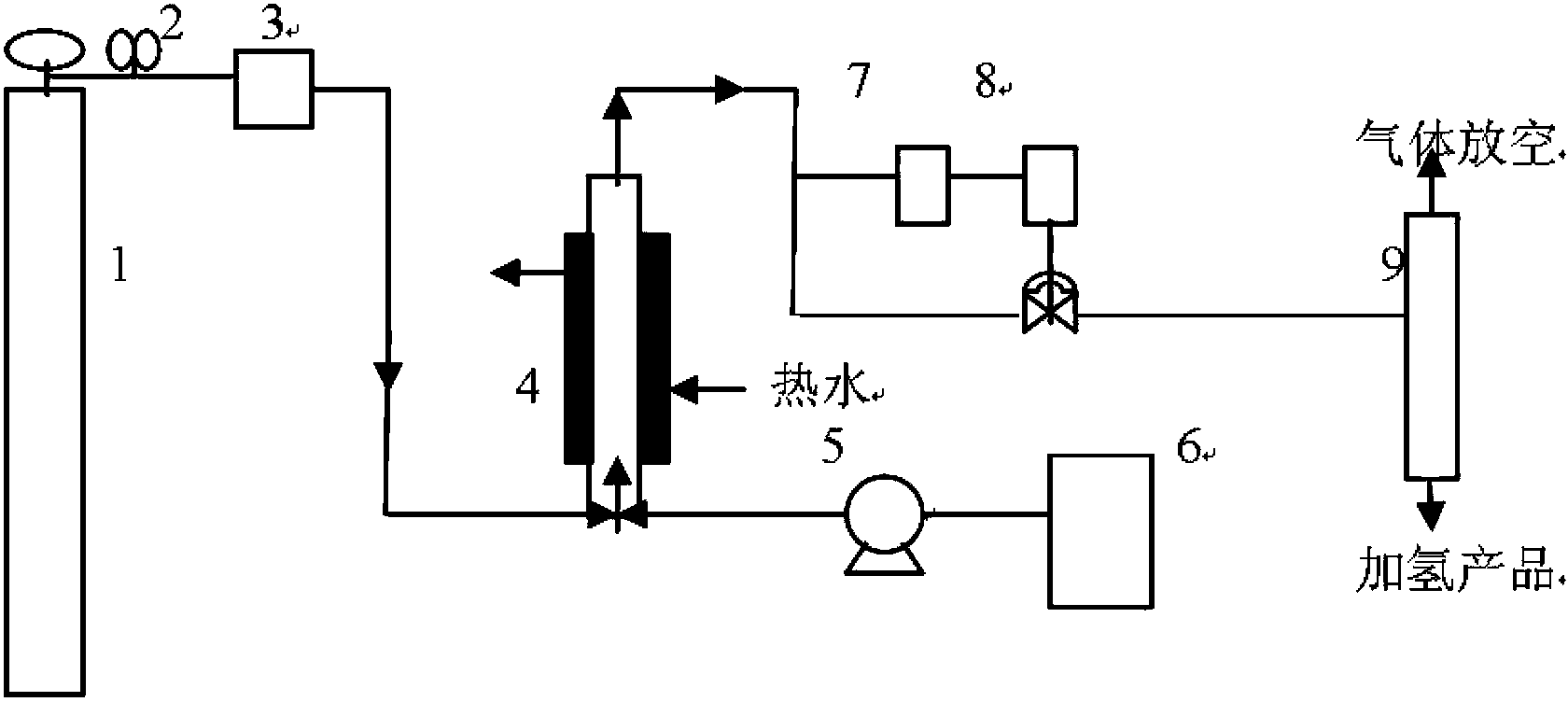

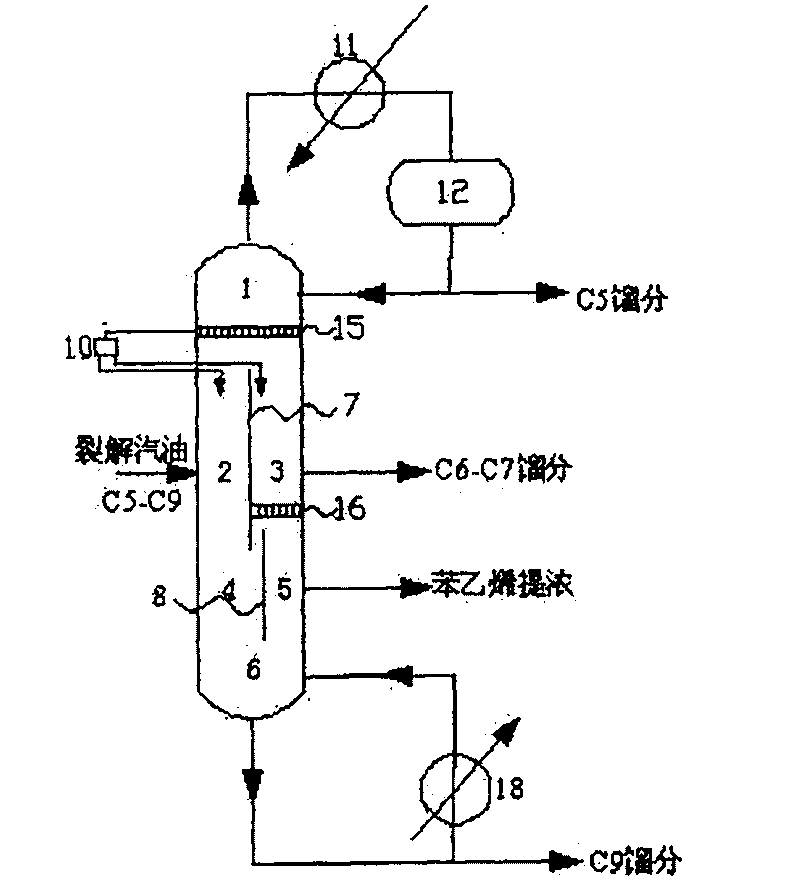

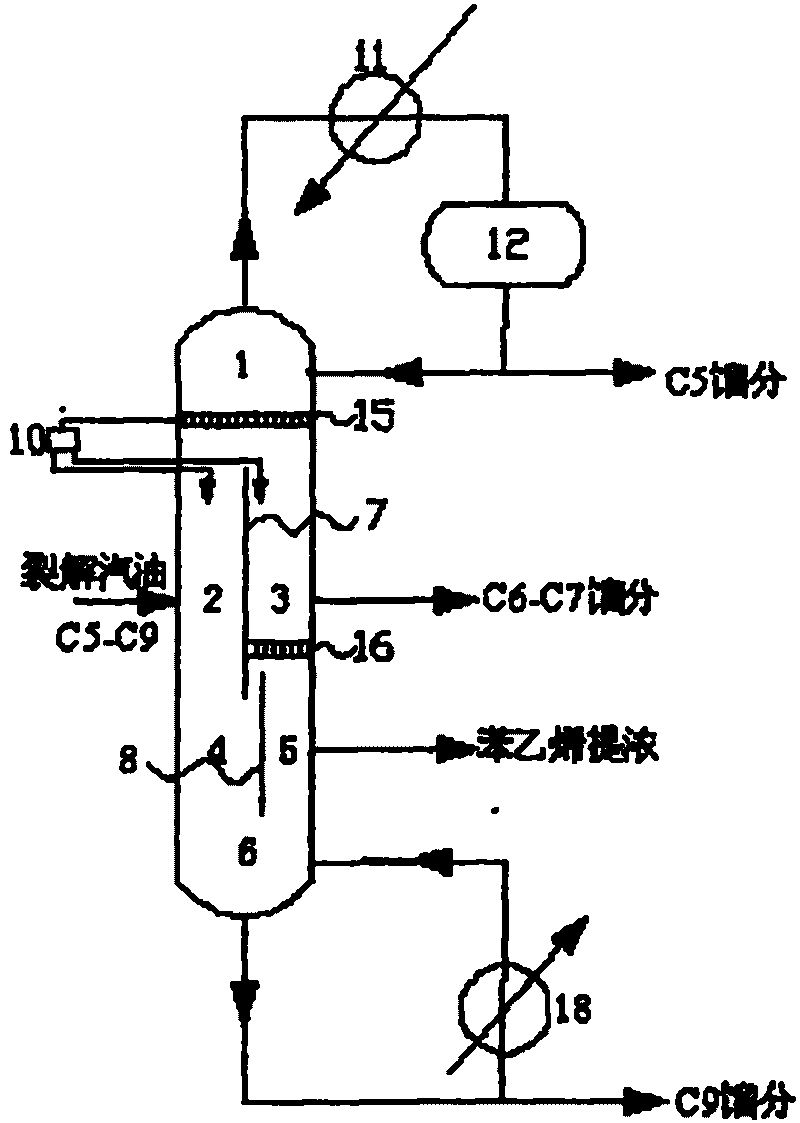

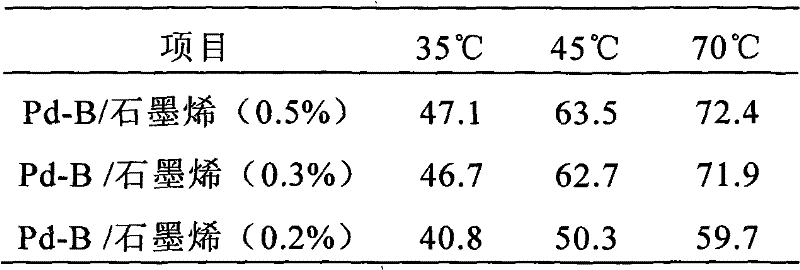

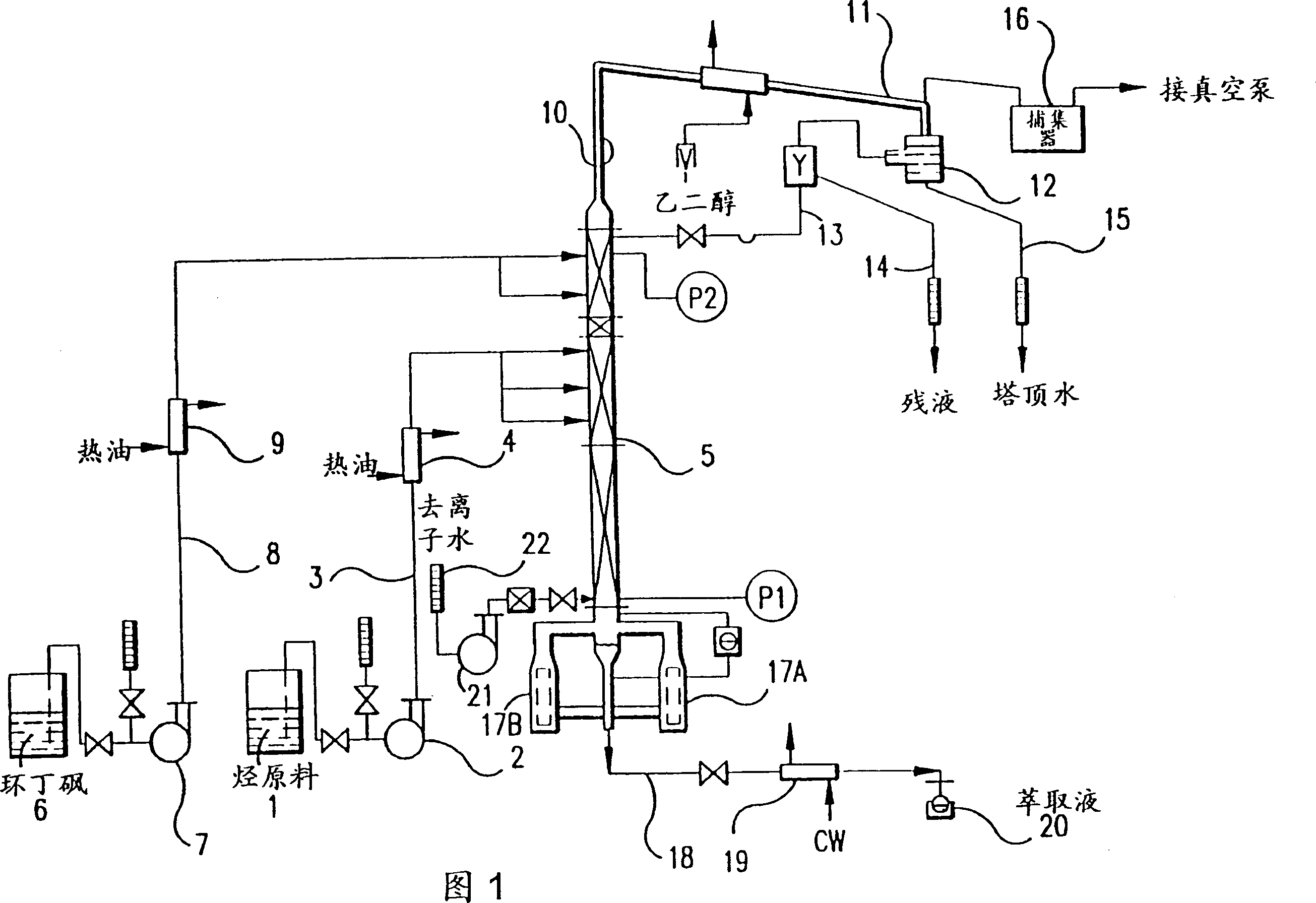

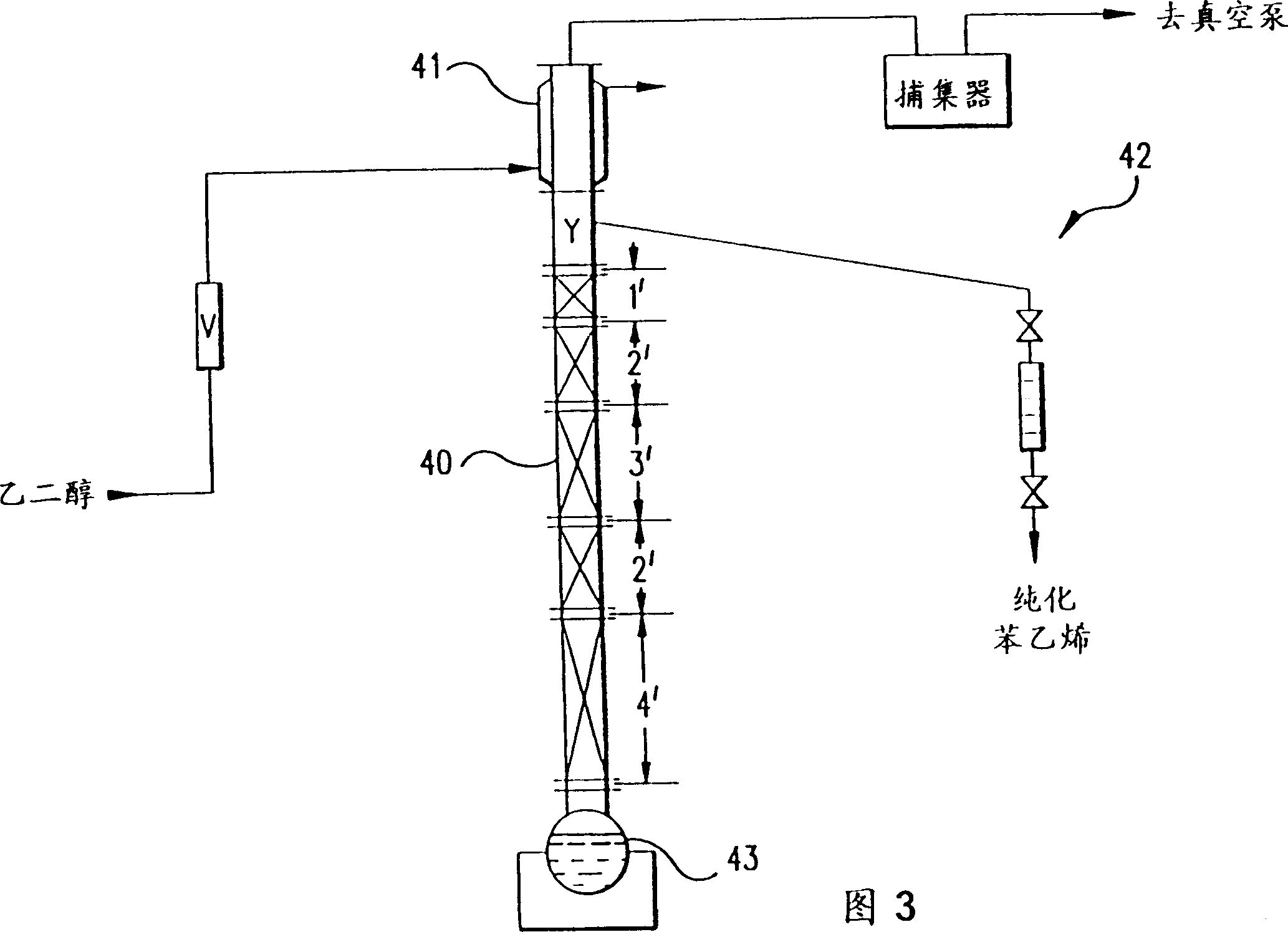

Device and method for separating rough styrene contained in pyrolysis gasoline

InactiveCN101723793AHydrocarbon distillationDistillation purification/separationMeasuring instrumentBuffer tank

The invention relates to a device for separating rough styrene contained in pyrolysis gasoline, comprising a rectifying tower, partition walls (7, 8), a liquid distributor, a condenser, a tower-top product buffer tank, liquid collectors (15, 16) and a reboiler, wherein the two partition walls (7, 8) divides the rectifying tower into six parts, i.e. a public rectifying area, a feeding area, a C6-C7 discharging area, a steam stripping area, a rough styrene discharging area and a public stripping area; a partition wall segment is from the top end of the partition wall (7) to the bottom end of the partition wall (8); the top of the public rectifying area is provided with a temperature measuring instrument, and light component C5 fractions are extracted in the public rectifying area; the left side of the partition wall (7) is provided with the feeding area, materials enter from the feeding area, the right side of the partition wall (7) is provided with the C6-C7 discharging area, and the C6-C7 fractions are extracted in the C6-C7 discharging area; the left side of the partition wall (8) is provided with the steam stripping area, and the right side of the partition wall (8) is provided with the rough styrene discharging area; heavy component C9 fractions are extracted in the bottom of the public stripping area, and the bottom of the public stripping area is also provided with the temperature measuring instrument. The invention saves two towers and corresponding accessory equipment due to the rectifying tower with the partition walls (7, 8) and saves the energy by more than 30 percent.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Catalyst for selective hydrogenation of petroleum hydrocarbon and preparation method and application thereof

InactiveCN101856613ACatalyst activation/preparationRefining by selective hydrogenationHydrogenation processAlkyne

The invention relates to a catalyst for selective hydrogenation of petroleum hydrocarbon, in particular to a catalyst for selective hydrogenation of cracked petroleum. The catalyst comprises a titanium oxide-aluminum oxide compound serving as a carrier and active ingredient metal nickel loaded on the compound carrier, wherein based on nickel atoms, the metal nickel accounts for 5 to 35 percent of the total weight of the catalyst; and the titanium oxide accounts for 5 to 40 percent of the weight of the titanium oxide-aluminum oxide compound carrier. Compared with a conventional catalyst of the same type, the catalyst has high low-temperature hydrogenation activity and is suitable for the selective hydrogenation process of a diolefin-containing fraction, particularly C6-C8 fractions, C8 fraction, C9 fraction and whole fraction of cracked petroleum. Moreover, the invention also relates to a preparation method and application of the catalyst. The catalyst can also be used for selective hydrogenation of alkynes or diolefins of other petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP

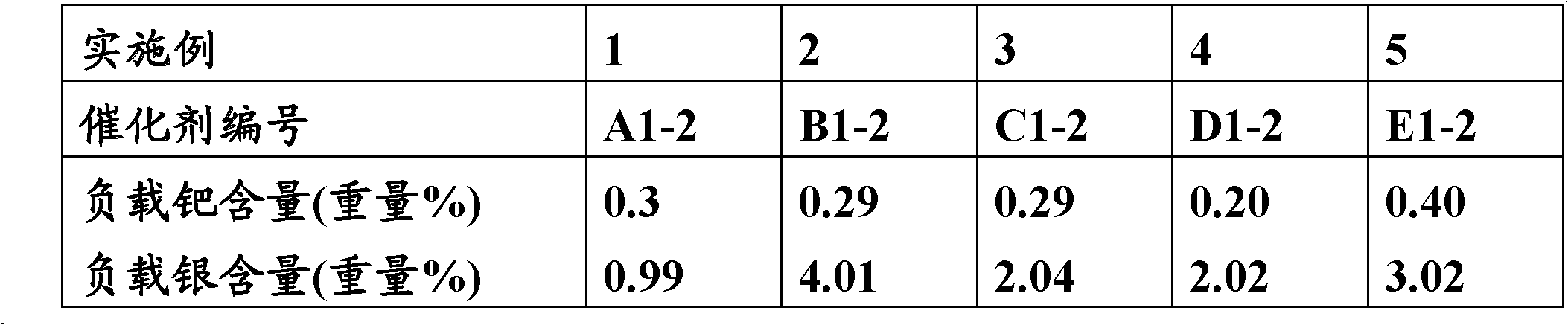

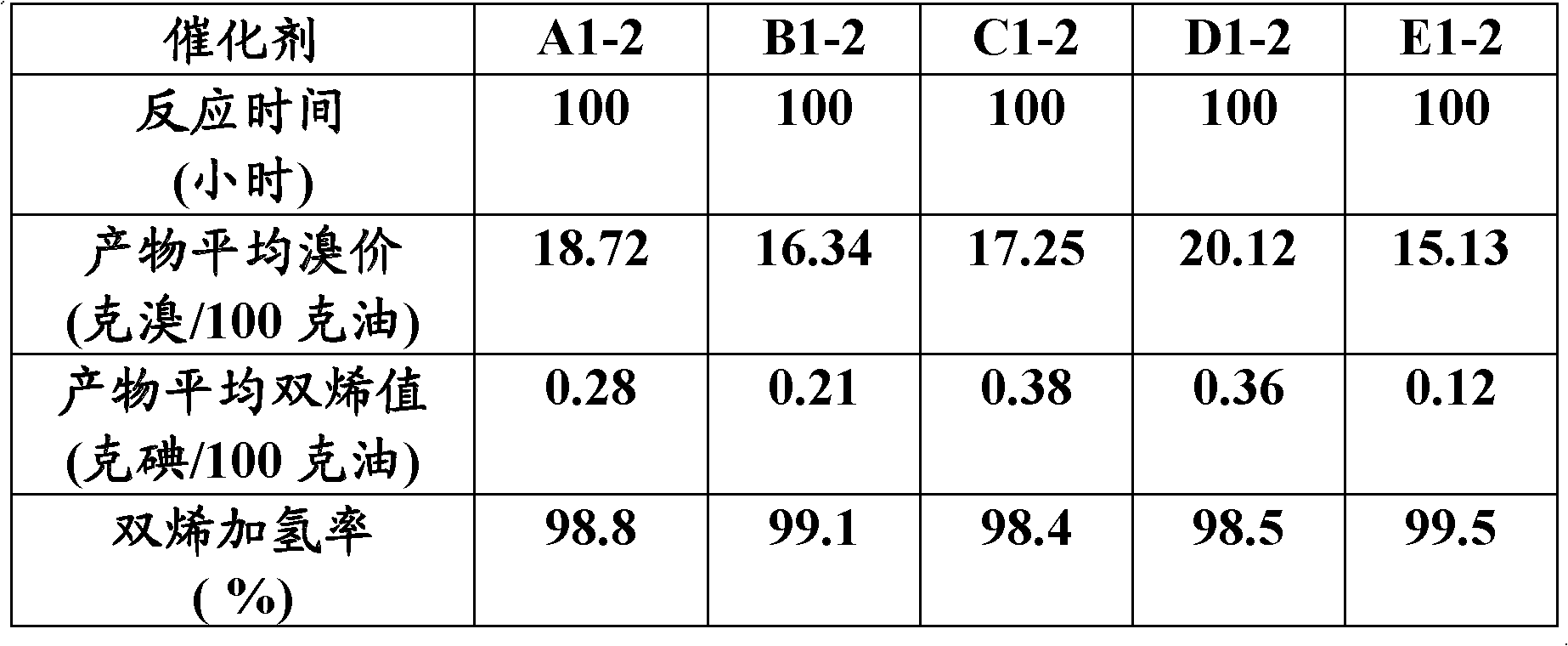

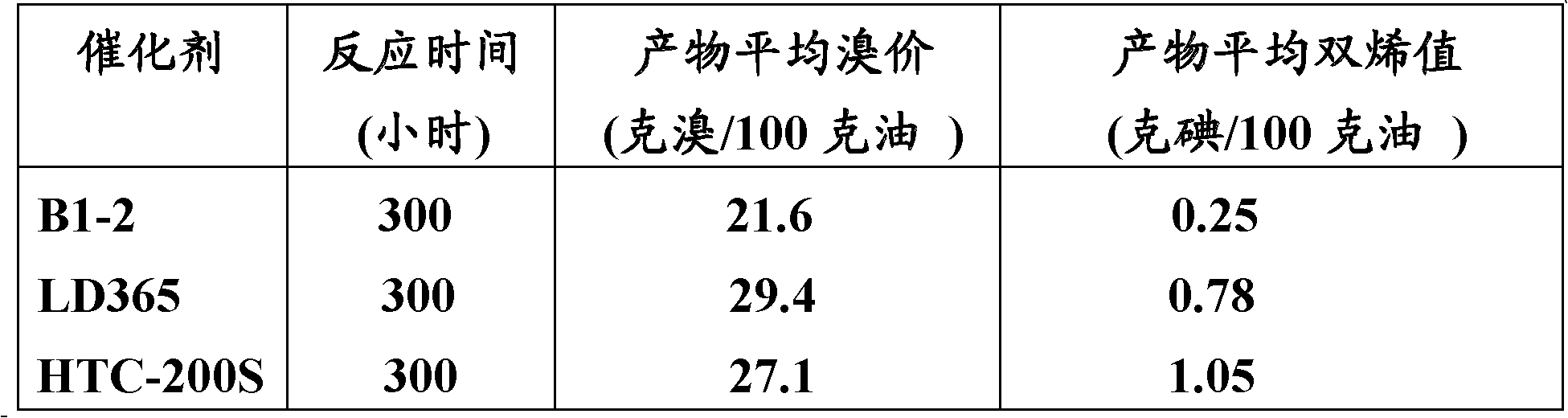

Pd-Ag/Al2O3-TiO2 catalyst for selective hydrogenation of cracked gasoline or its fractions, and preparation method thereof

ActiveCN102728351ALow temperature hydrogenation activity is highImprove performanceRefining by selective hydrogenationMetal/metal-oxides/metal-hydroxide catalystsActive componentAlkyne formation

The invention relates to a Pd-Ag / Al2O3-TiO2 catalyst for selective hydrogenation of cracked gasoline or its fractions. The catalyst comprises an Al2O3-TiO2 composite as a carrier, and active components of Pd and Ag loaded on the carrier, wherein the Pd content accounts for 0.15-0.5wt% of the total weight of the catalyst, and the Ag content accounts for 0.8-4.5wt% of the total weight of the catalyst. Compared with same catalysts, the catalyst for the hydrogenation of the cracked gasoline or its fractions of the invention has the advantages of high hydrogenation selectivity at a low temperature, strong As impurity resistance, large charging capacity and stable activity. In addition, the invention also relates to a preparation method of the catalyst. The catalyst of the invention can also be used for the selective hydrogenation of alkynes and / or diolefins of other petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation catalyst for pyrolysis gasoline

ActiveCN101121136AReduce acidityApertureHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsActive componentGram

The present invention relates to a selective hydrogenation catalyst of pyrolysis gasoline which mainly solves the technical problem in the prior art that the selective hydrogenation catalyst of pyrolysis gasoline which has a high activity in low temperature, a strong anti-interference ability, a high glue capacity, the good stability and well resistant ability towards free water is difficult to prepare. The present invention solves the problem well by a technical proposal which includes that (a) 0.01 percent to 0.5 percent of active component of palladium or an oxide of the palladium; (b) 0.01 percent to 2.0 percent of at least one element which is selected from IA or II A in an element periodic table or the oxide of the element; (c) 0.01 percent to 20.0 percent of at least one element which is selected from IVA or VA in the element periodic table or the oxide of the element; (d) an alumina carrier, which are accounted by a weight proportion of the alumina carrier, and in which, a specific surface of the alumina carrier is 40 square meters per gram to 160 square meters per gram; a total pore volume is 0.3ml / g to 1.2ml / g; the pore volume that a pore diameter of which is less than 30nm is 5 percent to 60 percent of the total pore volume; the pore volume that the pore diameter of which is between 30nm to 60nm is 20 percent to 75 percent of the total pore volume; the pore volume that the pore diameter of which is more than 60nm is 20 percent to 60 percent of the total pore volume. The present invention can be used for the industrial production of the selective hydrogenation of pyrolysis gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Process for Producing Olefins Using Aromatic Saturation

ActiveUS20190055483A1Treatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneNaphtha

A process for increasing olefin production from refinery that processes hydrocarbon streams that are rich in aromatic compounds and includes steam cracking and hydrotreating an aromatically rich feedstock to produce a hydrotreated pyrolysis gasoline stream and light pyrolysis oil byproduct, saturating at least one additional naphtha / hydrocarbon stream together with the hydrotreated pyrolysis gasoline stream or together with the light pyrolysis oil byproducts to form a first naphthene stream, and steam cracking the first naphthene stream to produce olefins.

Owner:SABIC GLOBAL TECH BV

Catalyst for catalytic cracking mixed waste plastic and preparation method thereof

InactiveCN101284235AGood technical effectVersatilityMolecular sieve catalystsLiquid hydrocarbon mixture productionCatalytic pyrolysisCatalytic reforming

The invention discloses a catalyst for manufacturing fuel oil through catalytic pyrolysis of mixed-waste plastics, and a preparation method thereof, and relates to catalytic thermal cracking for manufacturing the fuel oil through waste plastic cracking and a second stage catalyst in thermal cracking catalytic reforming. A first stage catalyst comprises a metallic oxide of 2.0wt percent to 30.0wt percent and carclazyte or montmorillonite of 70.0wt percent to 98.0wt percent; the first stage catalyst is innoxious and cheap, increases the reaction velocity of plastic cracking, reduces the temperature in the scission reaction, improves the selectivity of decomposition products, and is dechlorinated and transformed into innocuous substances. The second stage catalyst is composed of ferric oxide, molybdenum oxide, zinc oxide, cerium oxide, lanthana, nickel oxide or copper oxide, and ZSM-5, MCM-22, USY, REY, Beta or MOR molecular sieves; the second stage catalyst performs the second catalytic pyrolysis and isomerization and the aromatization reversion reactions on pyrolysis gas in the first stage, to increase the distillate rate of pyrolysis gasoline and gas oil. The catalyst and the preparation method thereof have good selectivity, and the raw material does not need classification, washing and drying; the operation is flexible, and the running cost is low; the method is particularly applied to the fuel oil manufacture through the cracking of the mixed-waste plastics in the urban and rural domestic refuse, the composition is complicated; the oil yield of the qualified fuel oil can reach up to more than 70 percent calculated on the basis of the waste plastic.

Owner:TONGJI UNIV

Method for selective hydrogenation through cracking of C5-C9 distillate

InactiveCN107159283AAperture size adjustableGood adhesive performancePhysical/chemical process catalystsRefining by selective hydrogenationPtru catalystHydrogenation reaction

The present invention relates to a method for selective hydrogenation through cracking of a C5-C9 distillate. According to the method, the catalyst comprises an alumina carrier having a macroporous structure and metal active components comprising nickel and tungsten and supported on the carrier, the nickel oxide content is 12-22 wt% based on the total weight of the catalyst, the tungsten oxide is 1.5-8 wt% based on the total weight of the catalyst, and the hydrogenation reaction process conditions are that the reaction inlet temperature is 40-55 DEG C, the reaction pressure is 2.0-3.5 MPa, the hydrogen oil volume ratio is 60-150, and the liquid volume space velocity is 3.0-5.5 h<-1>. According to the present invention, the catalyst has characteristics of good glue capacity, strong arsenic resistance, strong sulfur resistance, strong coking inhibition and low temperature activity; and the method provides strong adaptability for the cracking gasoline raw materials having different arsenic contents and different sulfur contents.

Owner:QINZHOU UNIV

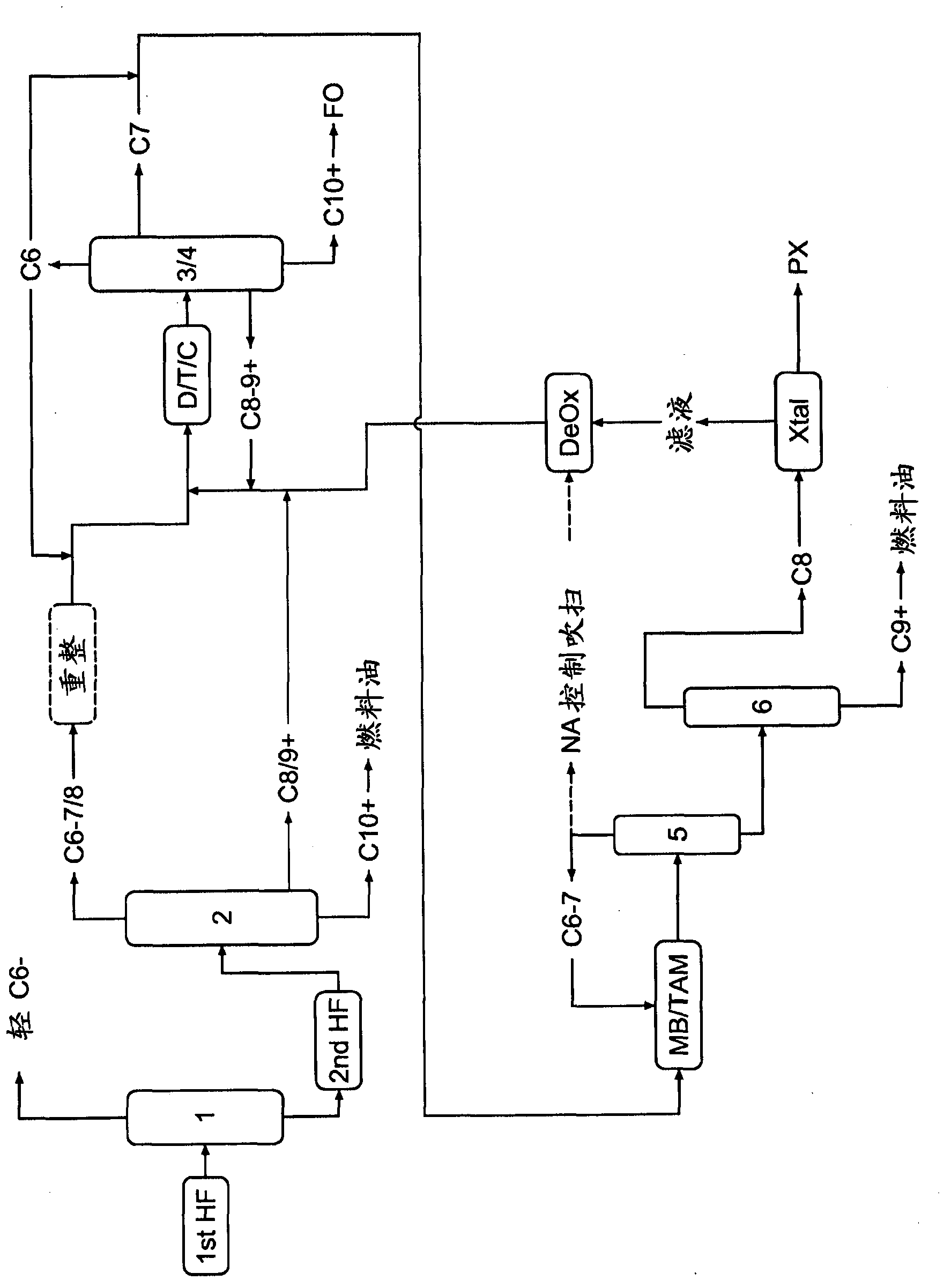

Method and apparatus for obtaining aromatics from diverse feedstock

ActiveCN103261124ATreatment with plural serial stages onlyHydrocarbons from unsaturated hydrocarbon additionBenzeneNaphtha

The process relates to the use of any naphtha-range stream containing a portion of C8+ aromatics combined with benzene, toluene, and other non-aromatics in the same boiling range to produce toluene. By feeding the A8+ containing stream to a dealkylation / transalkylation / cracking reactor to increase the concentration of toluene in the stream, a more suitable feedstock for the methylation reaction can be produced. This stream can be obtained from a variety of sources, including the pygas stream from a steam cracker, "cat naphtha" from a fluid catalytic cracker, or the heavier portion of reformate.

Owner:EXXONMOBIL CHEM PAT INC

Scale inhibitor used in cracked gasoline hydrogenation system

ActiveCN102071061AAdaptableStrong targetingTreatment apparatus corrosion/fouling inhibitionOrganic solventScavenger

The invention relates to a scale inhibitor used in a cracked gasoline hydrogenation system. The scale inhibitor can solve the technical problems, thus the scale inhibitor can well adapt to the complicated operating conditions of the cracked gasoline hydrogenation system, the generation of scale in the cracked gasoline hydrogenation system can be effectively inhibited, the scale adhered to the surface of the equipment can be dispersed in the material, the life of the hydrogenation catalyst can be prolonged and the operational cycle of the cracked gasoline hydrogenation equipment can be prolonged. The scale inhibitor of the invention comprises the following components by weight percent: 5-25% of metal-ion deactivator, 5-30% of antioxidant, 5-30% of radical scavenger, 5-35% of dispersant and35-60% of organic solvent. The preparation method of the scale inhibitor comprises the following steps: heating the raw materials, stirring, fully dissolving and mixing, and cooling.

Owner:浙江杭化科技股份有限公司

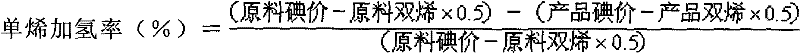

Selective hydrogenation catalyst and its preparation method and application

InactiveCN102441374ALarge theoretical specific surface areaGood dispersionMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionBULK ACTIVE INGREDIENT

The invention relates to a selective hydrogenation catalyst and its preparation method and application. The catalyst comprises a catalyst carrier and metal active ingredients, prepared by the following steps: pickling graphene and then washing the pickled graphene with water to neutral, then immersing the neutral graphene in weak ammonia and drying at a high temperature to obtain the catalyst carrier, preparing active metal into a precursor solution of the active metal, then steeping or spraying the precursor solution on the catalyst carrier to obtain a supported graphene catalyst precursor precursor, drying and then reducing to obtain a product. The catalyst can be used in selective hydrogenation catalytic reaction. Compared with the prior art, the catalyst can be used for a one-stage selective hydrogenation reaction of cracked gasoline and can be simultaneously used for a selective hydrogenation reaction of C2-C4. The catalyst has the advantages of high hydrogenation activity and good diolefin hydrogenation selectivity, and is beneficial for prolonging the regeneration period of the catalyst.

Owner:上海欣年石化助剂有限公司

Recovery of styrene from pyrolysis gasoline by extractive distillation

InactiveCN1077560CDistillation purification/separationHydrocarbonsBoiling pointExtractive distillation

An extractive distillation process for separating at least one substituted unsaturated aromatic from a pyrolysis gasoline mixture, containing said aromatic and at least one close-boiling aromatic or non-aromatic hydrocarbon, employing a two part extractive solvent: (a) sulfolane (tetramethylene sulfone), and (b) portion consisting of water.

Owner:苏尔寿际特(北京)技术有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com