Titanium oxide-aluminum oxide compound as well as preparation method and application thereof

A composite and titanium oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that the pore distribution is difficult to control and cannot be obtained, and achieve low temperature High activity, extended activity period, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

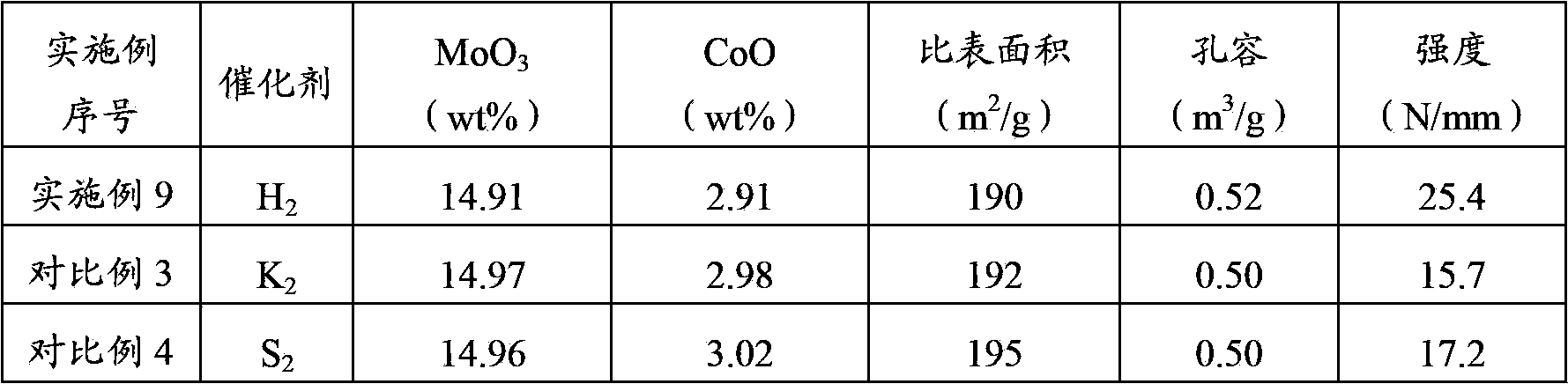

Examples

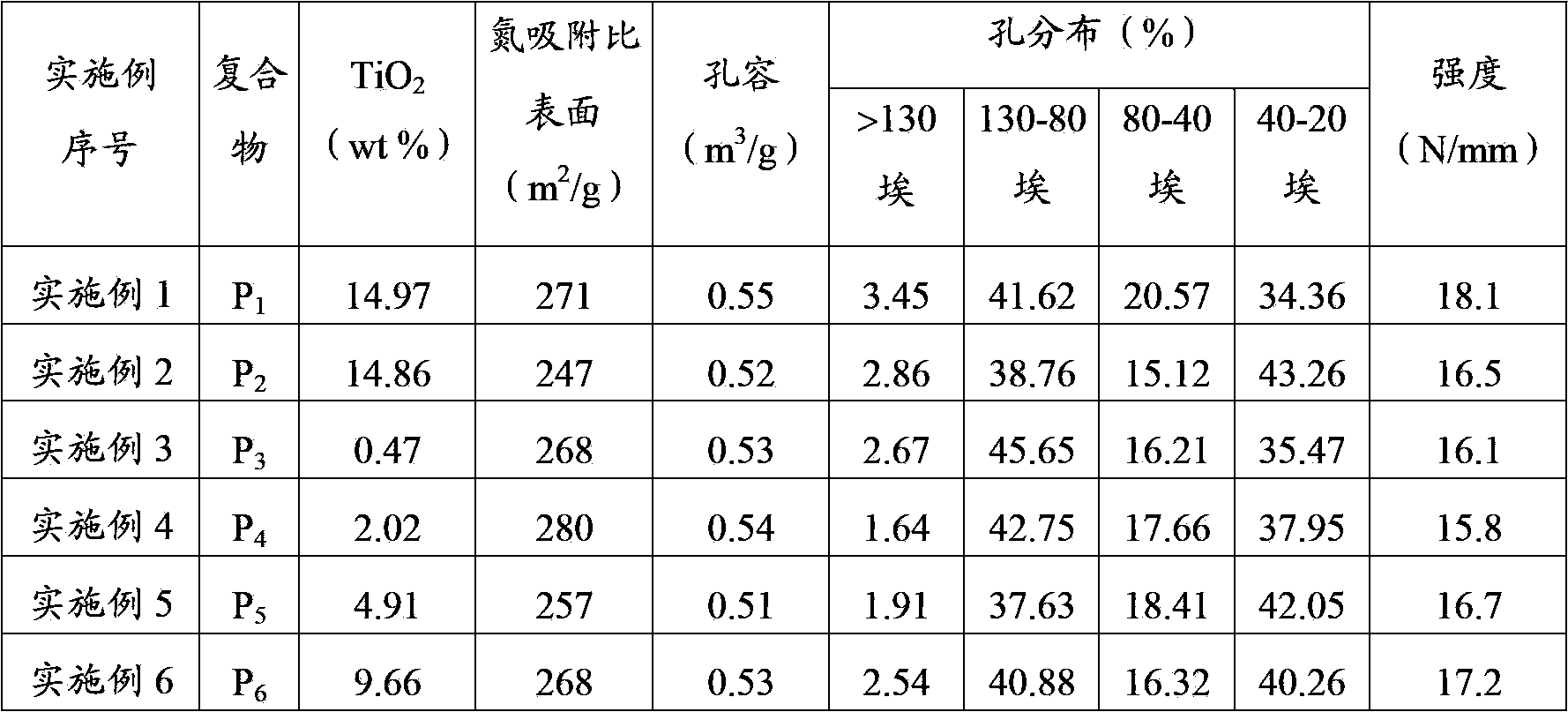

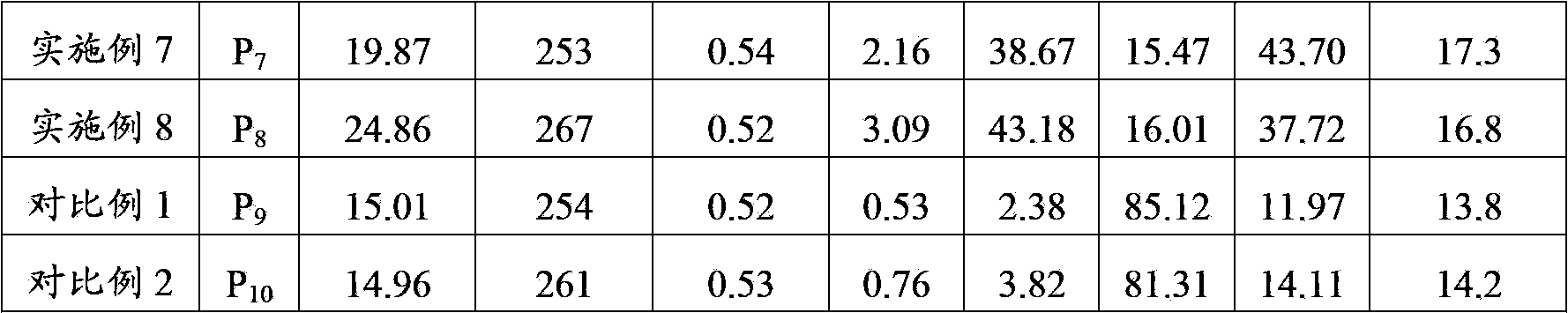

Embodiment 1

[0036] Take analytically pure AlCl 3 ·6H 2 O 201.3g, dissolved in 1000ml of deionized water to prepare solution A 1 ; Take chemically pure Ti(SO 4 ) 2 22.5g, dissolved in 500ml of deionized water to prepare solution B 1 ; Take analytically pure NH 4 HCO 318g, dissolve in 600ml of deionized water, add 250ml of ammonia water with a concentration of 24-28wt%, stir and mix evenly, then add deionized water to prepare 1000ml of solution C 1 .

[0037] Under the condition of normal pressure and temperature of 70-75℃, A 1 , B 1 and C 1 The three solutions were co-precipitated in parallel. control solution C 1 flow rate, keep the pH value of the precipitate in the range of 5.0-6.0 for 8 minutes, then increase the solution C 1 flow rate, keep the pH value of the mixed solution in the range of 8.5-9.5 for 8 minutes, then reduce the solution C 1 flow rate, keep the pH value of the mixed solution in the range of 5.0-6.0 for 8 minutes, then increase the solution C 1 flow, so t...

Embodiment 2

[0039] Repeat the experimental process in Example 1, the difference is, get analytically pure Al 2 (SO 4 ) 3 18H 2 O sample 277.6g was dissolved in 1000ml deionized water to obtain solution A 2 , to replace A in Example 1 1 . As a result, 48.6 g of titanium oxide-alumina composite P 2 , and its structure and performance results are shown in Table 1.

Embodiment 3

[0041] Repeat the experimental process in embodiment 1, difference is, get analytical pure AlCl 3 ·6H 2 O2 35.7g, dissolved in 1000ml deionized water to obtain solution A 3 , to replace A in Example 1 1 ; Take chemically pure Ti(SO 4 ) 2 0.75g, dissolved in 300ml deionized water to obtain solution B 3 , to replace B in Example 1 1 . As a result, 48.8 g of titanium oxide-alumina composite P 3 , and its structure and performance results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com