A kind of hydrophobic flame-retardant water-based curing agent and preparation method thereof

A water-based curing agent, flame-retardant technology, applied in the field of hydrophobic flame-retardant water-based curing agent and its preparation, can solve the problems of short pot life, poor aging resistance, high surface tension of water-based curing agent, etc., and achieve good storage stability , good corrosion resistance, excellent hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

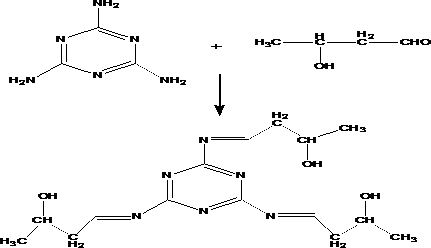

Method used

Image

Examples

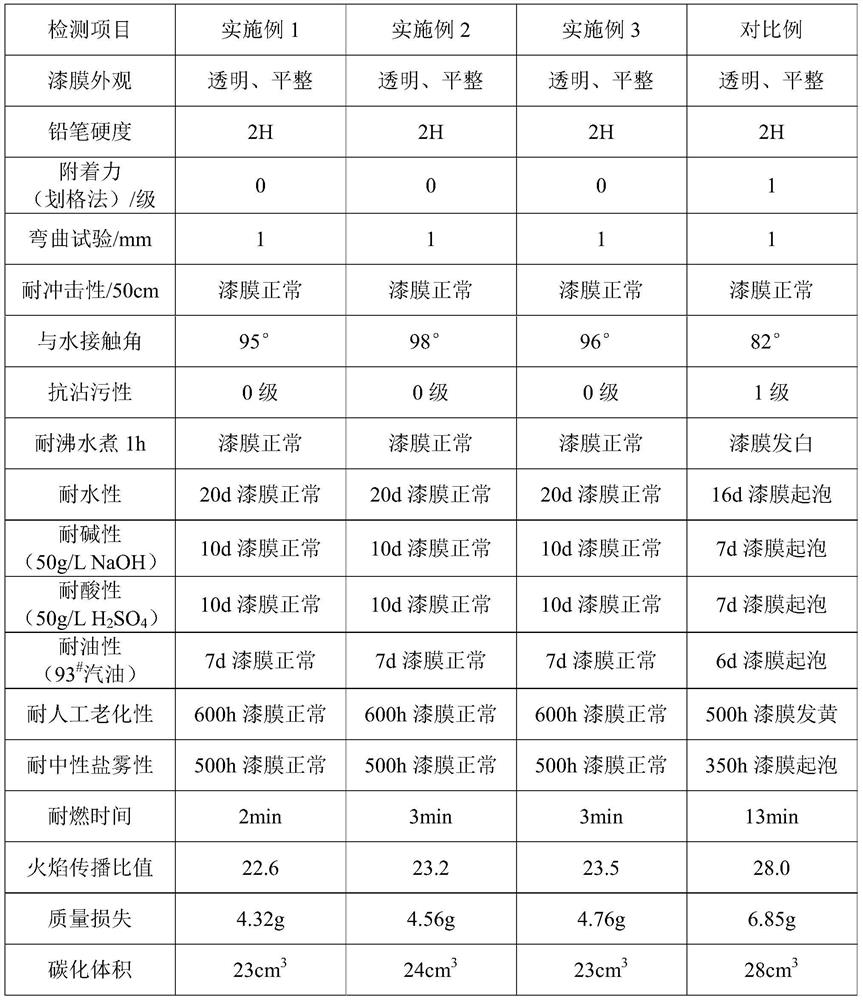

Embodiment 1

[0030] A kind of hydrophobic flame-retardant water-based curing agent, its preparation steps are as follows:

[0031] a), pre-dehydrating and drying oligomer polyols and solvents;

[0032] b), feed nitrogen into the reactor equipped with a thermometer, condenser, and stirrer to remove the air in the reactor, add 3.0 parts of dimethylol propionic acid, 8.0 parts of polytetrahydrofuran polyol, dilauric acid dilaurate 0.05 parts of butyl tin, 15.0 parts of hydroxyl-containing melamine derivatives, 9.85 parts of propylene glycol ethyl ether acetate, stir evenly and heat up to 60-70°C;

[0033] c), Slowly add 58.0 parts of hexamethylene diisocyanate dropwise, control the dropping time to 0.5~1h, then raise the temperature to 84~88°C and keep it warm for 2.0~3.0h, cool down to 70~75°C, add hexafluoroisocyanate 3.8 parts of propanol, keep the constant temperature reaction for 1.5~2.5h, start to detect the NCO value, stop the reaction when the detected NCO value is consistent with th...

Embodiment 2

[0035] A kind of hydrophobic flame-retardant water-based curing agent, its preparation steps are as follows:

[0036] a), pre-dehydrating and drying oligomer polyols and solvents;

[0037] b), feed nitrogen into the reactor equipped with a thermometer, condenser, and agitator to remove the air in the reactor, add 4.5 parts of dimethylol propionic acid, 6.0 parts of polyether glycol, dilauric acid 0.05 parts of dibutyltin, 15.5 parts of hydroxy-containing melamine derivatives, 13.05 parts of propylene glycol methyl ether acetate, stir evenly and heat up to 60-70°C;

[0038] c), Slowly add 55.0 parts of hexamethylene diisocyanate dropwise, control the dropping time to 0.5~1h, then raise the temperature to 84~88°C and keep it warm for 2.0~3.0h, cool down to 70~75°C, add hexafluoroisocyanate 2.5 parts of propanol, keep the constant temperature reaction for 1.5~2.5h, start to detect the NCO value, stop the reaction when the detected NCO value is consistent with the design value; l...

Embodiment 3

[0040] A kind of hydrophobic flame-retardant water-based curing agent, its preparation steps are as follows:

[0041] a), pre-dehydrating and drying oligomer polyols and solvents;

[0042]b), feed nitrogen into the reactor equipped with a thermometer, condenser, and stirrer to remove the air in the reactor, add 4.0 parts of dimethylolpropionic acid, 8.0 parts of polyethylene glycol, dilauric acid dilaurate according to the formula 0.05 parts of butyl tin, 16.5 parts of hydroxyl-containing melamine derivatives, 11.95 parts of propylene glycol ethyl ether acetate, stir evenly and heat up to 60-70°C;

[0043] c), Slowly add 52.0 parts of hexamethylene diisocyanate dropwise, control the dropping time to 0.5~1h, then raise the temperature to 84~88°C and keep it warm for 2.0~3.0h, cool down to 70~75°C, add hexafluoroisocyanate 4.5 parts of propanol, keep the constant temperature reaction for 1.5~2.5h, start to detect the NCO value, stop the reaction when the detected NCO value is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com