Increment agent for urea-formaldehyde resin, preparing method thereof and urea-formaldehyde resin adhesive

A technology of urea-formaldehyde resin and extender, which is applied in the field of urea-formaldehyde resin glue and extender of urea-formaldehyde resin, which can solve the problems such as the decrease of bond strength between particleboard and fiberboard and wood-based panels, and reduce the molar ratio of urea-formaldehyde resin, etc., and achieve physical Improvement of mechanical properties, improvement of internal bonding strength, and reduction of formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

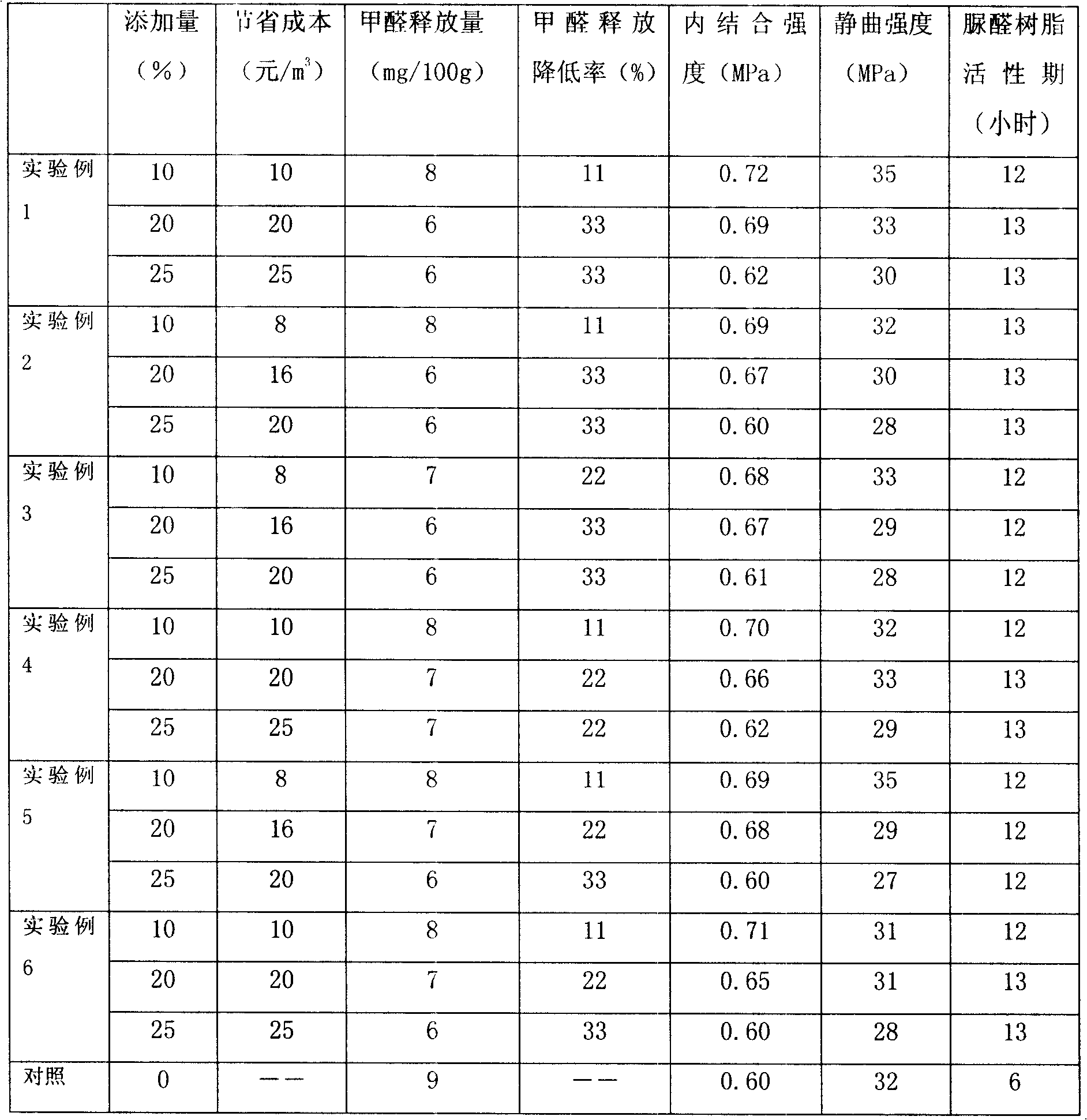

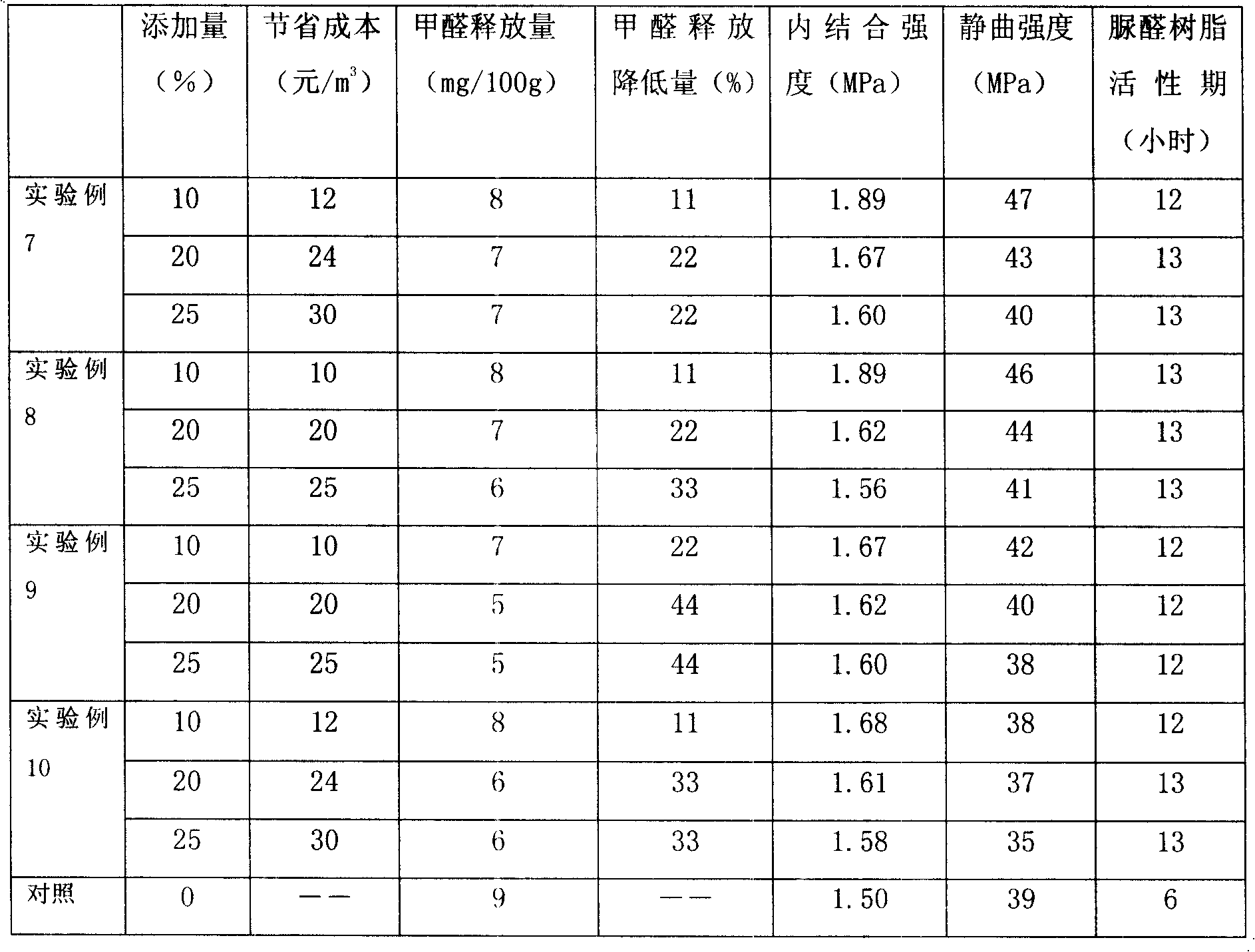

Examples

Embodiment 1

[0024] 1. Prepare raw materials according to the following weight ratio:

[0025] Formaldehyde (concentration 37%): 200kg

[0026] Urea: 150kg

[0027] Wheat flour: 100kg

[0028] Sodium phosphate: 0.2kg

[0029] Borax: 2kg

[0030] Water: 500kg

[0031] Sodium hydroxide solution (concentration is 30%): appropriate amount

[0032] 2. Add formaldehyde to the reaction kettle, start stirring, adjust the pH value to 6.5-7.0 with sodium hydroxide solution, add water and stir;

[0033] 3. Add wheat flour and sodium phosphate, stir until all are miscible, control the temperature at 20-25°C, measure the pH value, and control the pH value at 7.5-8.0 with sodium hydroxide solution;

[0034] 4. Add borax, control pH=8.5-9.0, temperature at 20-25°C, and react for 12 minutes;

[0035] 5. Add urea, stir until completely dissolved, control the temperature at 20±2°C, and control the pH at 8.0-8.5 with sodium hydroxide solution;

[0036] 6. Transfer the finished product to an aging tan...

Embodiment 2

[0046] Carry out raw material preparation according to the following weight ratio:

[0047] Formaldehyde (concentration 37%): 200kg

[0048] Urea: 150kg

[0049] Wheat flour: 120kg

[0050] Sodium phosphate: 0.3kg

[0051] Borax: 2kg

[0052] Water: 230kg

[0053] Sodium hydroxide solution (concentration is 30%): appropriate amount

[0054] In addition to step 2), the pH value is adjusted to 5.0-5.5 with sodium hydroxide solution; the temperature in step 3) is 15-20 ° C, and the pH is 6.0-6.5; the pH in step 4) is 8.0-8.5, and the temperature is 15 -20°C, the reaction time is 15 minutes; the temperature control in step 5) is 10±2°C, and the pH is 7.0-8.8; except that the pH in step 6) is 7.0-8.8, the rest are the same as in Example 1.

[0055] Product technical indicators:

[0056] Solid content 40-50%

[0057] Viscosity (Tu-4 cups) 15-18 (25°C, S),

[0058] pH 7.0-8.8

[0059] Density 1.10-1.20g / cm 3

[0060] Storage period ≥60 days

Embodiment 3

[0062] Carry out raw material preparation according to the following weight ratio:

[0063] Formaldehyde (concentration 37%): 200kg

[0064] Urea: 200kg

[0065] Calcium carbonate: 100kg

[0066] Sodium metaphosphate: 0.5kg

[0067] Acrylamide: 0.5kg

[0068] Water: 300kg

[0069] Sodium hydroxide solution (concentration is 30%): appropriate amount

[0070] Formic acid solution (concentration is 30%): appropriate amount

[0071] In addition to step 2), use formic acid solution to adjust the pH value to 3.5-4.0; the temperature in step 3) is 25-30 ° C, and the pH is 5.0-5.5; the pH in step 4) is 7.0-7.5, and the temperature is 25-30 ℃, the reaction time is 10 minutes, except that the pH is 8.0-8.8 in step 5) and step 6), the rest are the same as in Example 1.

[0072] Product technical indicators:

[0073] Solid content 40-50%

[0074] Viscosity (Tu-4 cups) 15-18 (25°C, S),

[0075] pH 8.0-8.8

[0076] Density 1.10-1.20g / cm 3

[0077] Storage period ≥60 days

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com