Starch-based aqueous macromolecule-isocyanate wood adhesive and preparation method thereof

A water-based polymer, wood adhesive technology, applied in the direction of adhesive, adhesive type, graft polymer adhesive, etc., can solve the problems of poor bonding, loss of polymerized isocyanate, fast drying speed of adhesive film, etc., to achieve good stability properties, improving water loss and drying, and good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

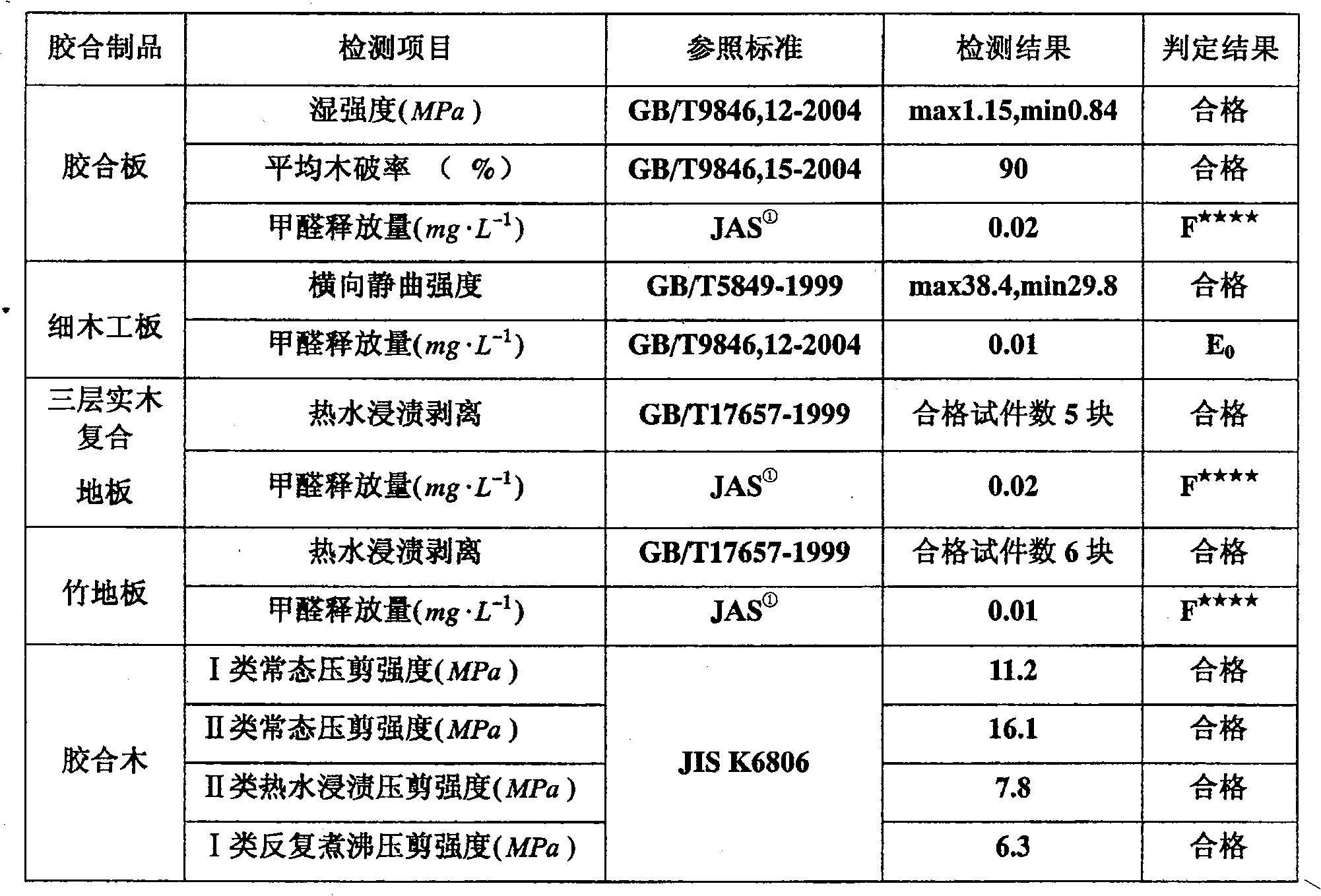

Examples

Embodiment 1-3

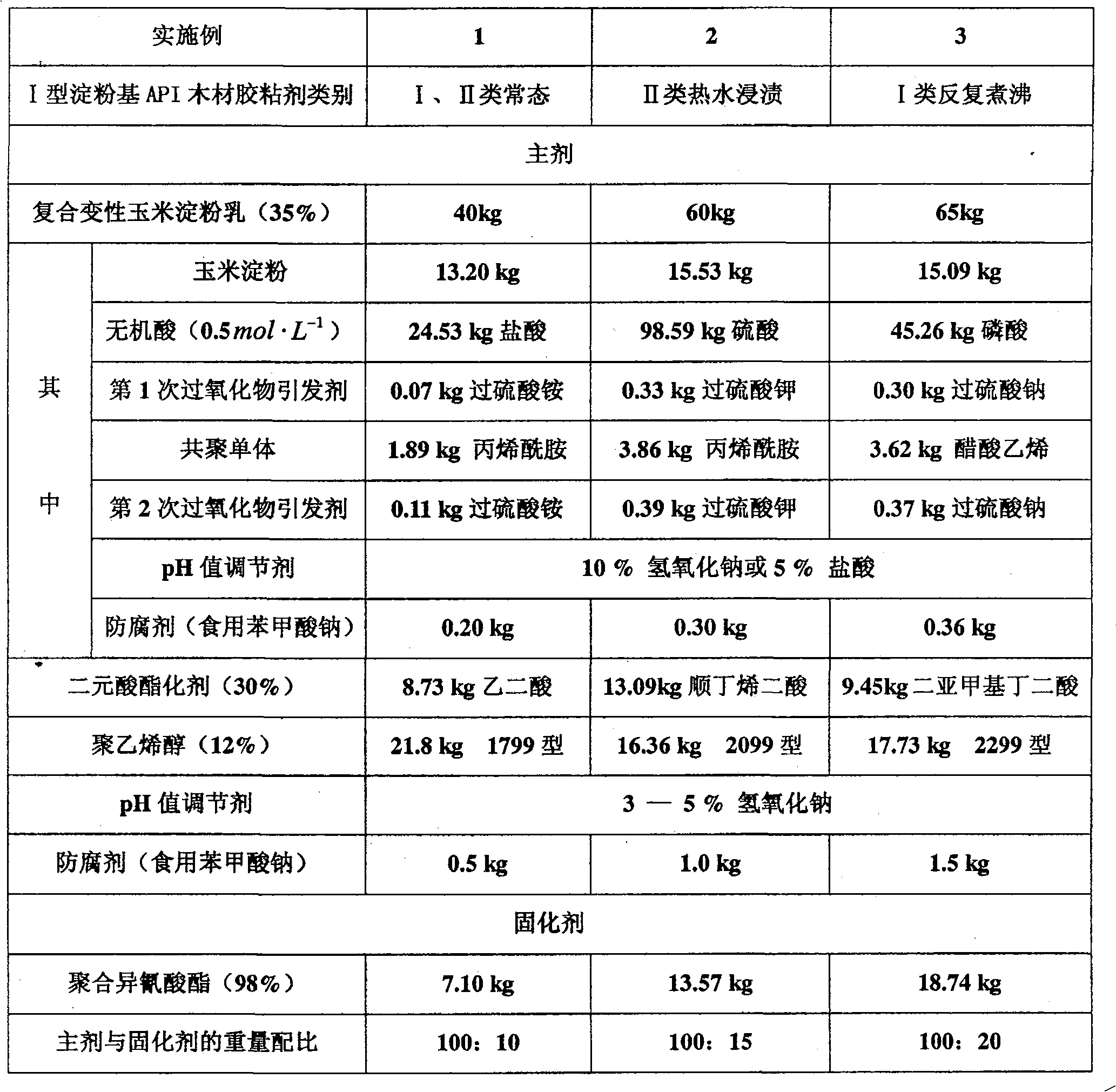

[0027] Embodiment 1-3: the preparation of type I starch-based water-based polymer-isocyanate wood adhesives of different compressive shear strengths of the present invention

[0028] The weight ratio of each raw material in each embodiment is shown in Table 1.

[0029] Preparation method: (taking Example 1 as an example, other examples are basically the same as Example 1 except that the amount of raw materials is different)

[0030] (1) Dilute the concentration to 0.5mol·L -1 Add 24.53kg of hydrochloric acid solution into the reaction kettle with agitator and condenser, slowly add 13.20kg of cornstarch into the hydrochloric acid solution, stir vigorously to prepare cornstarch milk with a concentration of 35%, heat it to 55°C and keep it warm. Add 0.07kg of ammonium persulfate to cornstarch milk for the first time, stir evenly, acidolysis and oxidation at 55°C, and pre-initiate for 30 minutes at the same time, adjust the pH value to 7 with 10% sodium hydroxide to obtain primar...

Embodiment 4-6

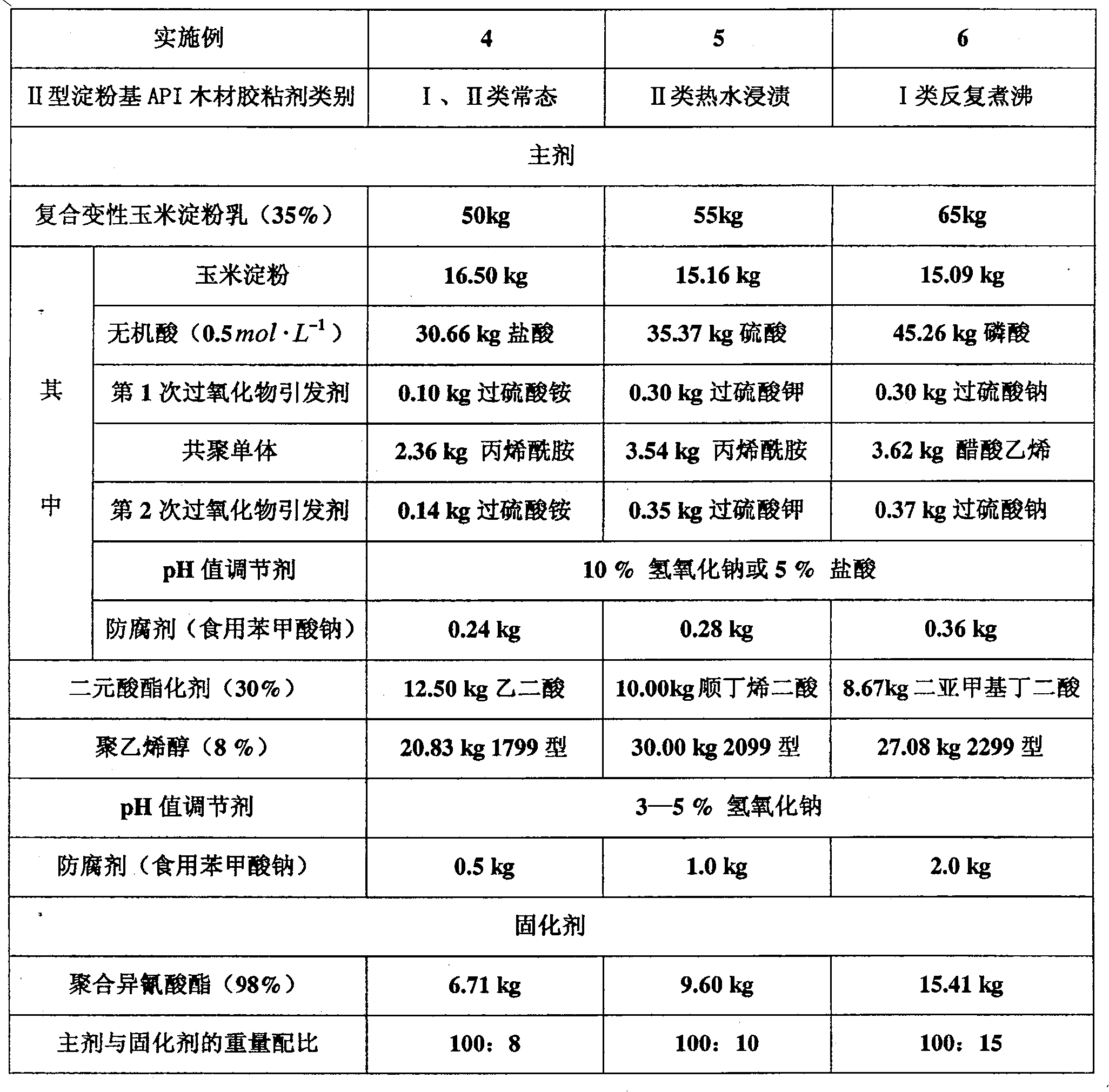

[0036] Embodiment 4-6: the preparation of type II starch-based water-based polymer-isocyanate wood adhesives of different compressive shear strengths of the present invention

[0037] The weight ratio of each raw material in each embodiment is shown in Table 2.

[0038] Table 2

[0039]

[0040] Preparation method: (taking Example 4 as an example, other examples are basically the same as Example 4 except that the amount of raw materials is different)

[0041] (1) Dilute the concentration to 0.5mol·L -1 Add 30.66kg of hydrochloric acid solution into the reaction kettle with agitator and condenser, slowly add 16.50kg of cornstarch into the hydrochloric acid solution, stir vigorously to prepare cornstarch milk with a concentration of 35%, heat it to 55°C and keep it warm. Add 0.10 kg of ammonium persulfate to cornstarch milk for the first time, stir evenly, acidolysis and oxidation at 55°C, and pre-initiate for 30 minutes at the same time, adjust the pH value to 7 with 10% sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com