Patents

Literature

65results about How to "Good preloading effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

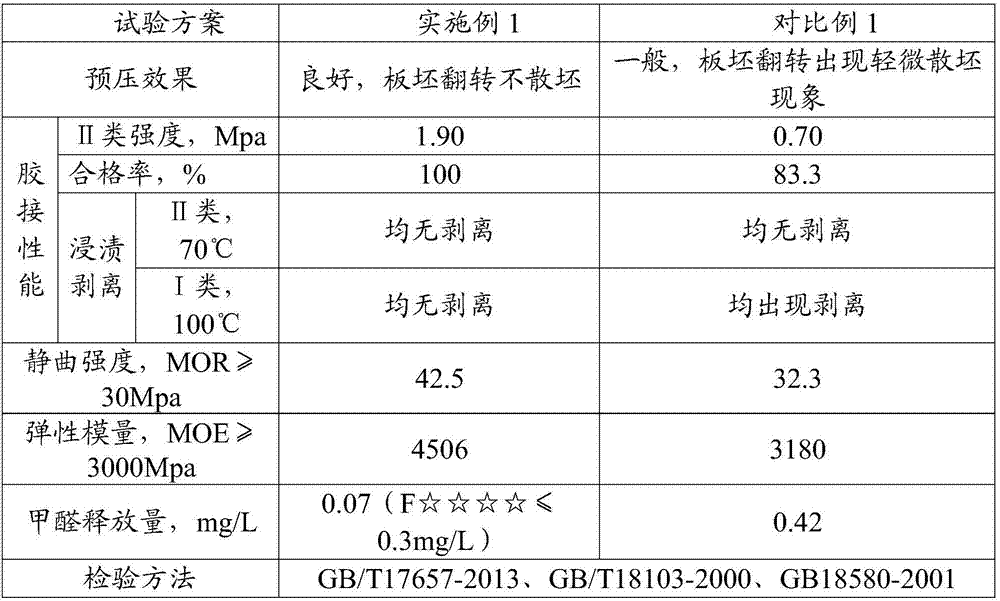

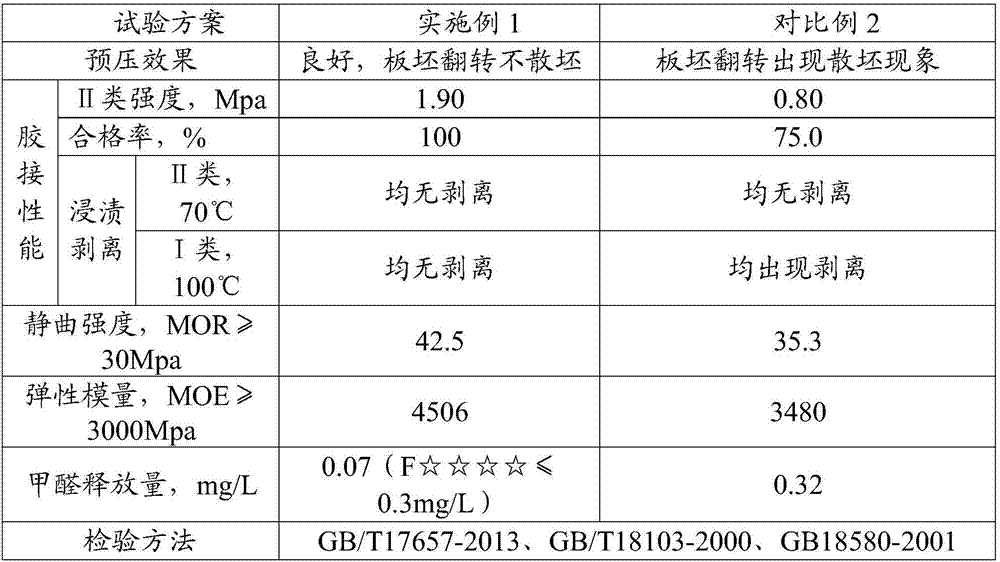

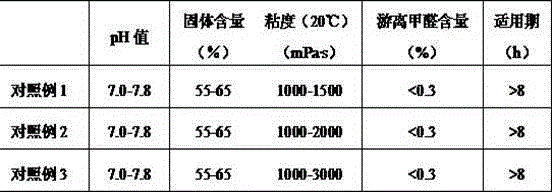

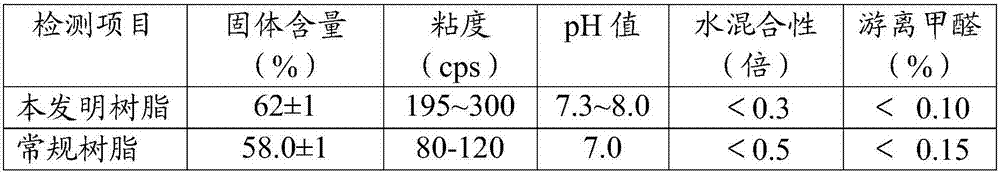

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

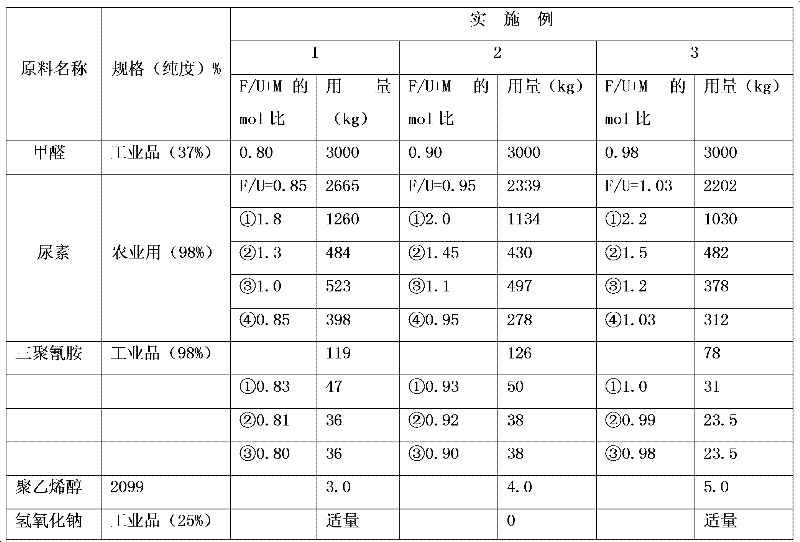

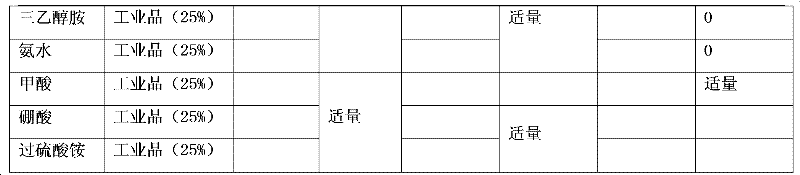

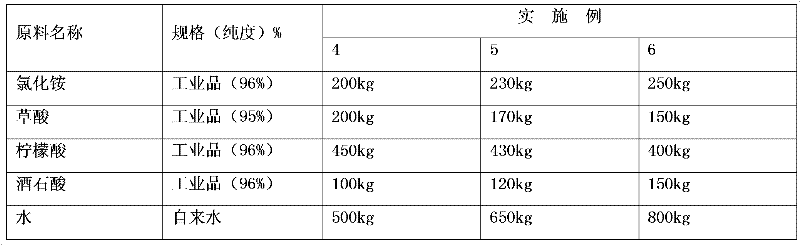

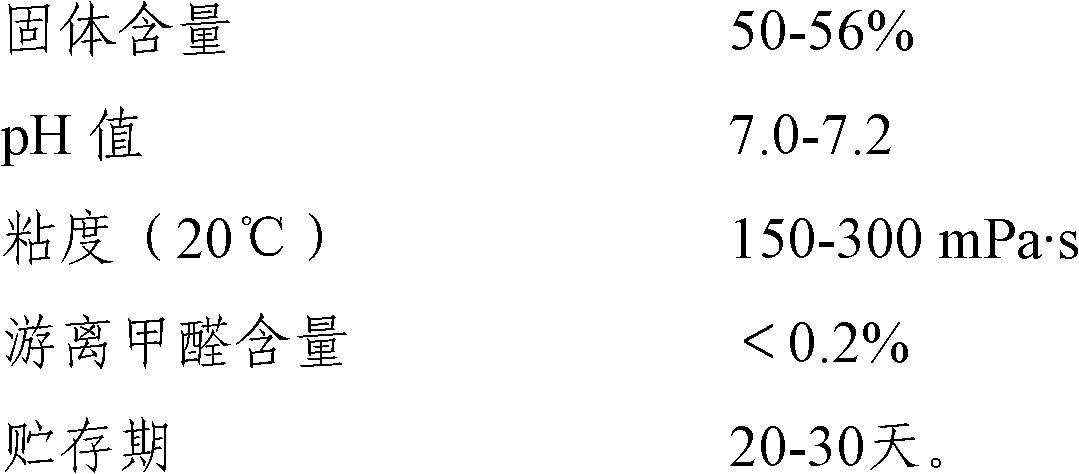

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

Environment-friendly urea resin for laminating plywoods from high water-content veneers and preparation and application thereof

ActiveCN102086257AThe polycondensation reaction is sufficientGood water solubilityAldehyde/ketone condensation polymer adhesivesHigh water contentUltimate tensile strength

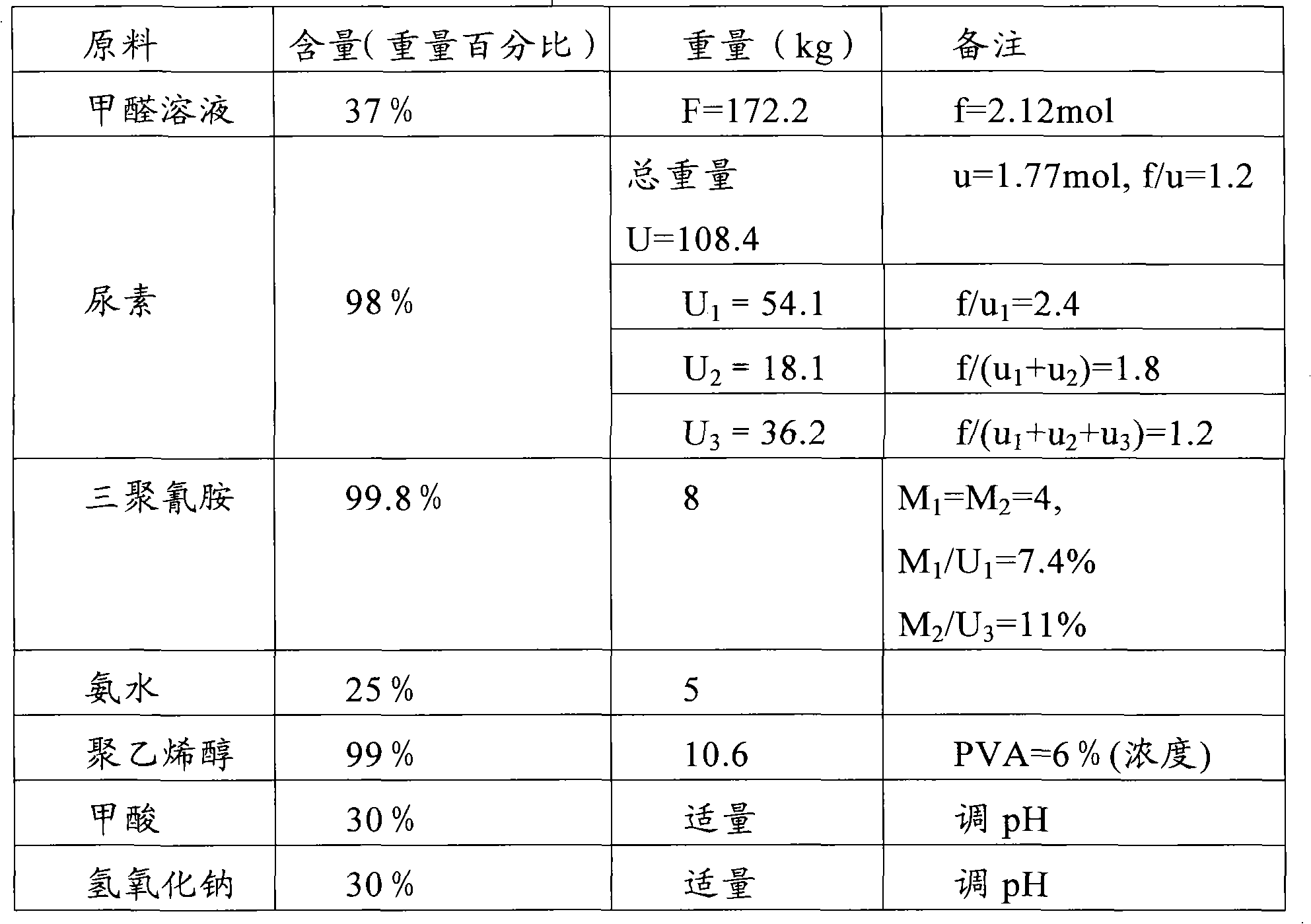

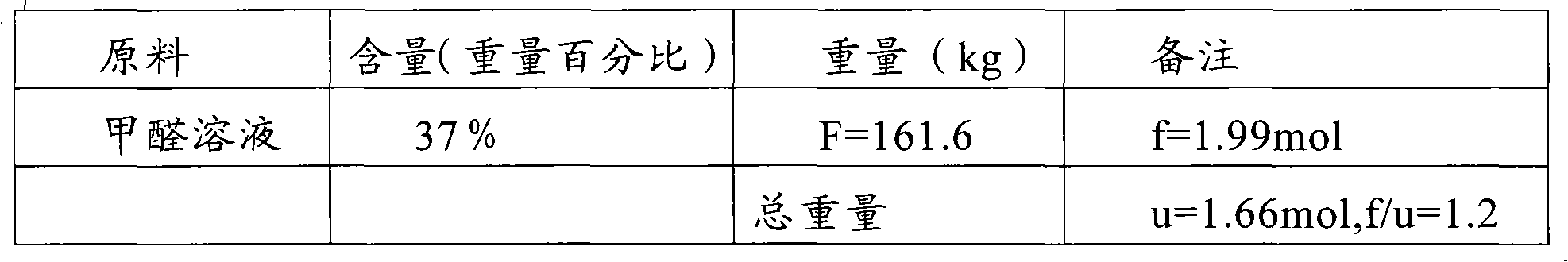

The invention relates to a preparation method and application of environment-friendly urea resin for laminating plywoods from high water-content veneers. The method for synthesizing the resin is simple, and low in cost; the laminated plywoods can meet the national E1 grade and even E0 grade environmental protection requirements; and the problems of low prepressing performance and water resistance when the high water-content veneers are laminated into the plywoods are mainly solved. In the synthesis of the urea resin, an acid-base-acid-base process is adopted, formaldehyde and polyvinyl alcohol are added at one time, urea is added by three batches, melamine is added by two times, and after ammonia water is added, the ammonia water, the urea, the formaldehyde and urea-form condensate are reacted to generate a series of triazine ring compounds, and the microstructure of the resin is improved. When the resin is cured, the crosslinking density is improved, wet shear strength of the plywoods is obviously improved and the formaldehyde emission is obviously reduced.

Owner:广西鑫恒晶木业股份有限公司

Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

ActiveCN101314235ARealize green productionGood workmanshipPolyureas/polyurethane adhesivesFlat articlesWater basedVolatiles

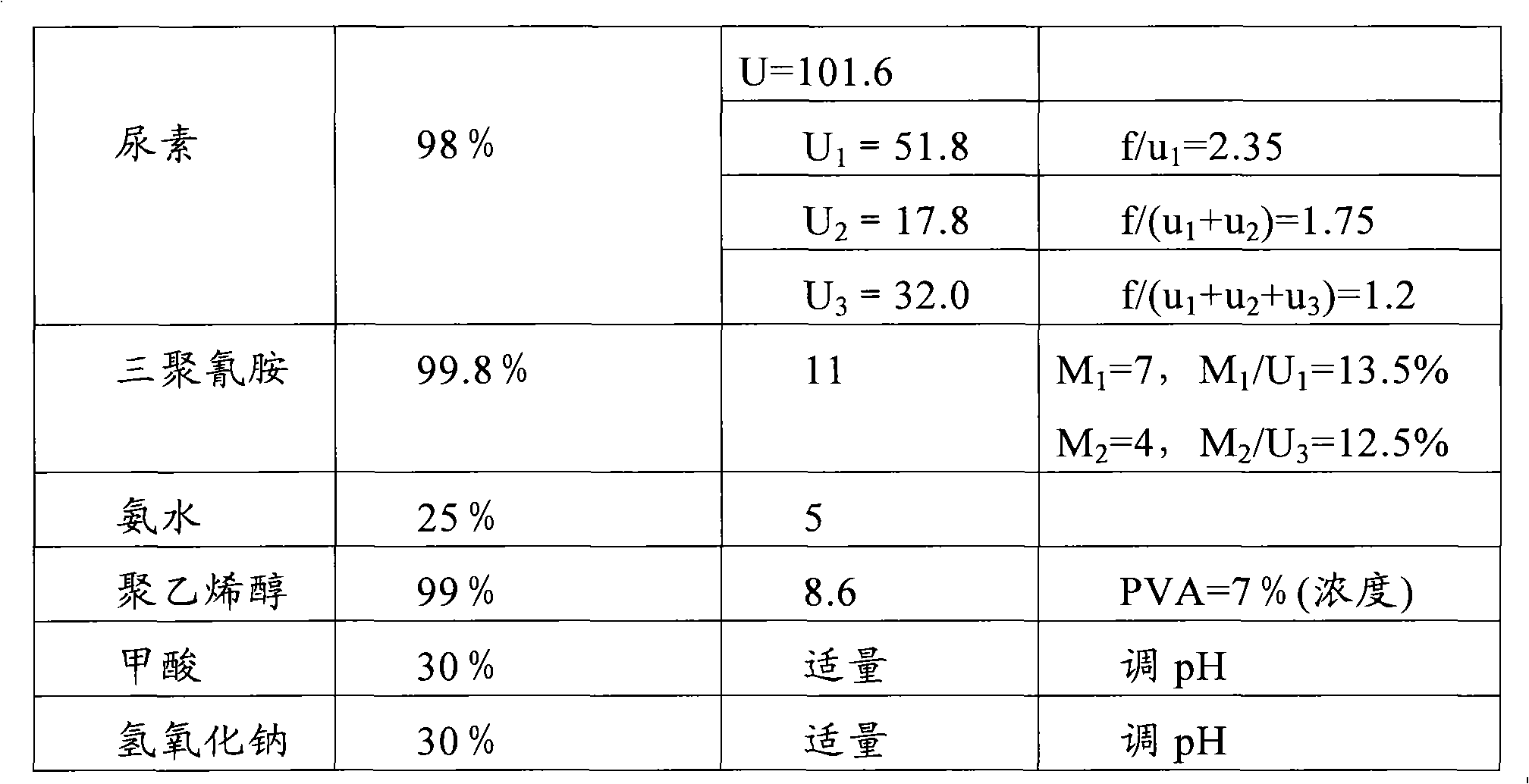

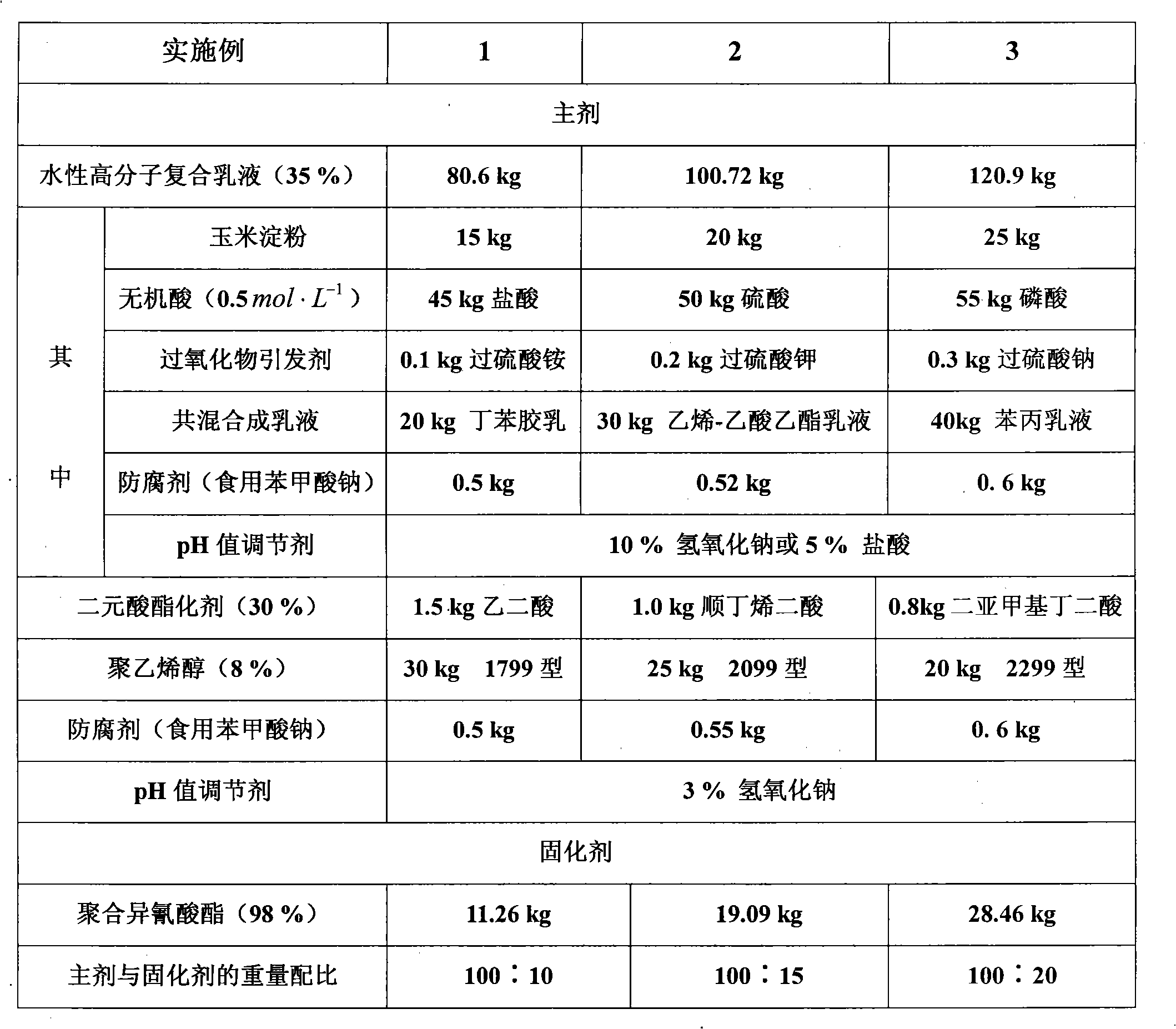

The invention relates to a water-based macromolecule-isocyanate straw hard board and a preparation method thereof. Straws of rice, wheat, corn or other crops, a water-based macromolecule-isocyanate adhesive and a straw interface performance modifying agent are used as raw materials, and the straws are treated by section cutting, kneading and modification, adhesive application and heat pressing to produce the water-based macromolecule-isocyanate straw hard board. A mixture ratio of the absolute dry straws to the water-based macromolecule-isocyanate adhesive to the straw interface performance modifying agent by weight is 100 to 10-16 to 0.05-0.15. The straw hard board uses the water-based macromolecule-isocyanate adhesive to replace a pure isocyanate adhesive, radically improves the problems of toxic organic volatiles, poor prepressing performance, adhesion on boards, etc., remarkably reduces cost and really realizes green production, and the raw materials after the treatment of kneading and modification have good prepressing and molding performances and high one-off qualified rate. The water-based macromolecule-isocyanate straw hard board has the characteristics of unique design, long active period, excellent aging, water and heat resisting performances, simple operation, easy availability of equipment, no environmental pollution, easy implementation, etc., and produces huge entironmental, social and economical benefits after the water-based macromolecule-isocyanate straw hard board is popularized.

Owner:BEIHUA UNIV

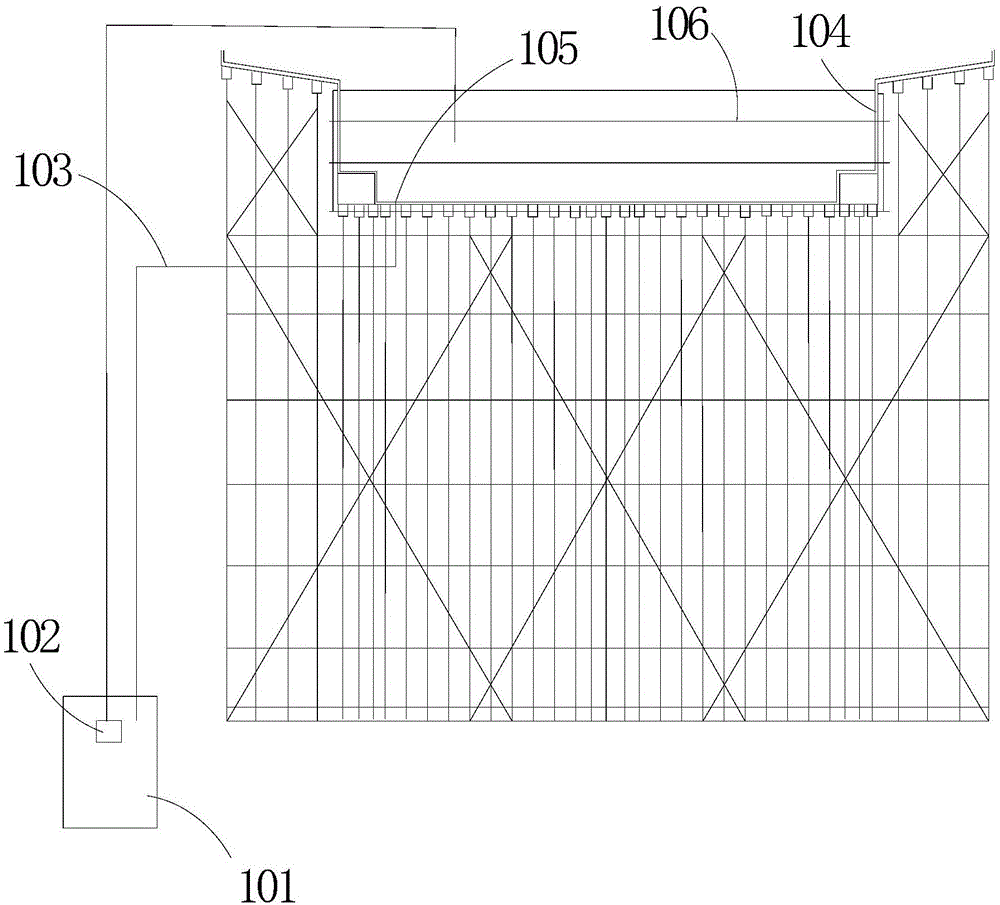

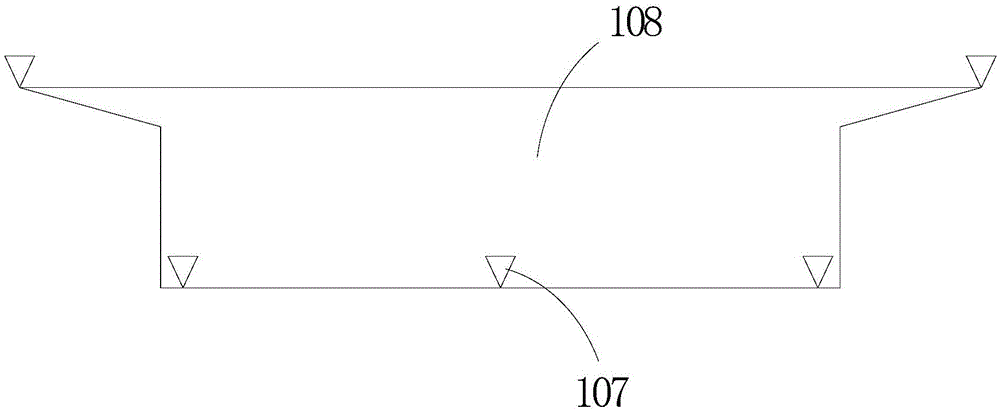

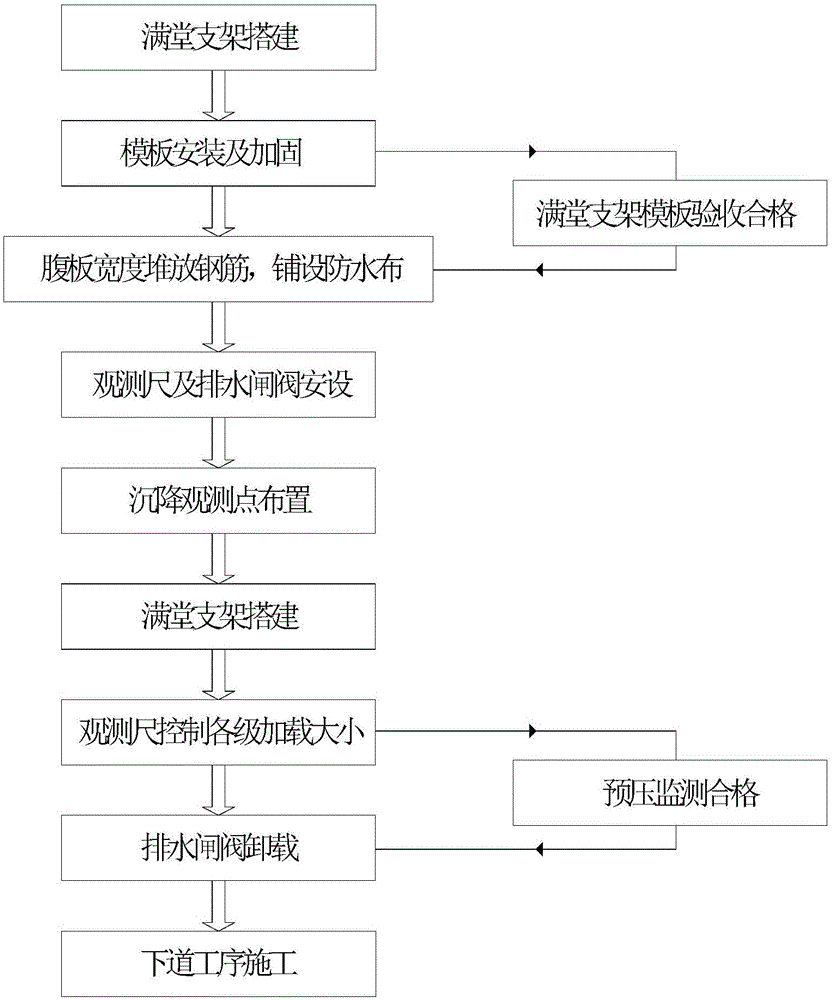

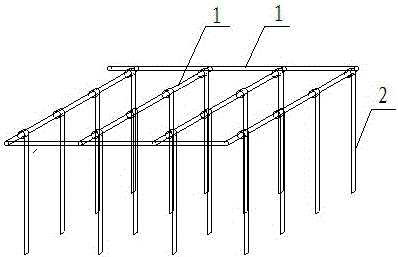

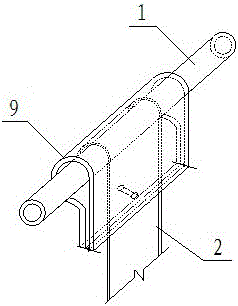

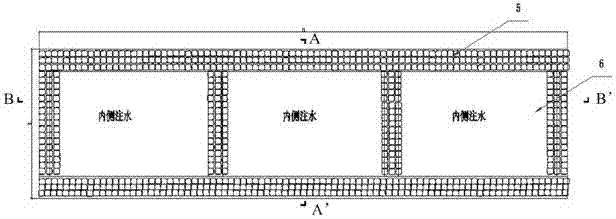

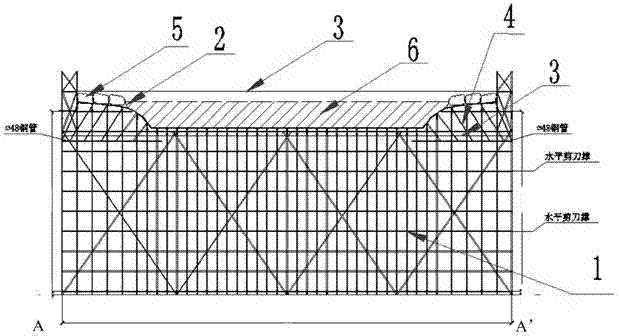

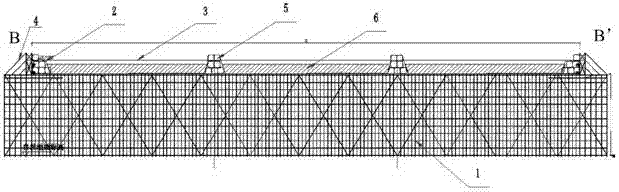

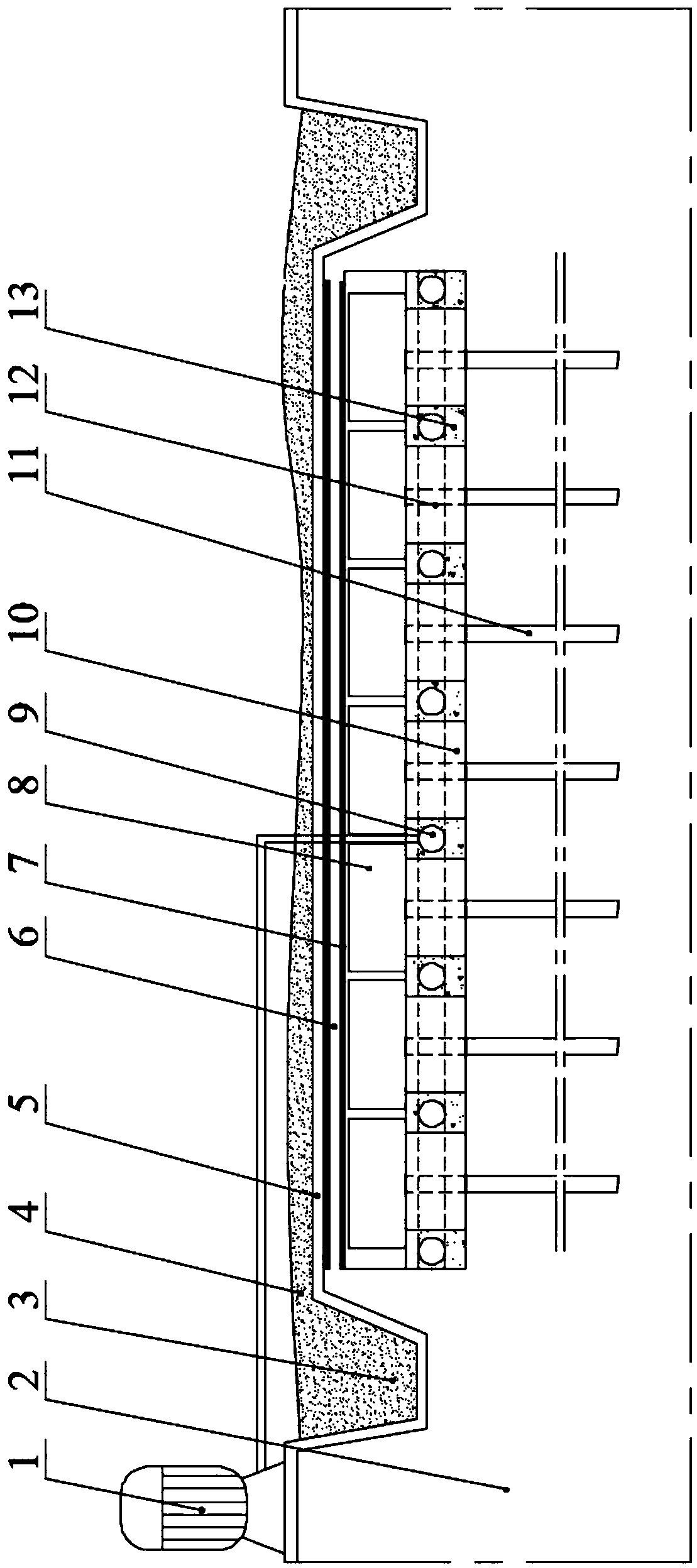

Fluid analogue simulation preloading construction method of full framing

InactiveCN105155425AAvoid deformationSave materialBridge erection/assemblyHorizontal forceSupporting system

The invention relates to the technical field of fluid analogue simulation preloading of full framings, and discloses a fluid analogue simulation preloading method of a full framing. The method comprises the following construction steps: 1) laying bottom templates, web templates and end templates on the full framing; 2) stacking steel bar materials on the web templates; 3) covering the bottom templates, the web templates, the concrete-iron materials and the end templates by utilizing waterproof cloth so as to form a water-tank structure; 4) injecting water in the water-tank structure, and performing preloading monitoring; and 5) after finishing preloading monitoring, draining water in the water-tank structure. The fluid analogue simulation preloading construction method of a full framing, provided by the invention, has the advantages that materials are saved, and the construction cost is reduced; the construction time is shortened, and other equipment materials are saved; vertical loads are applied on the full framing, and horizontal force generated to a supporting system during concrete pouring is simulated, so that the web templates are prevented from deforming and bursting during concrete pouring, and a uniform preloading effect can be reached.

Owner:SHENZHEN MUNICIPAL ENG

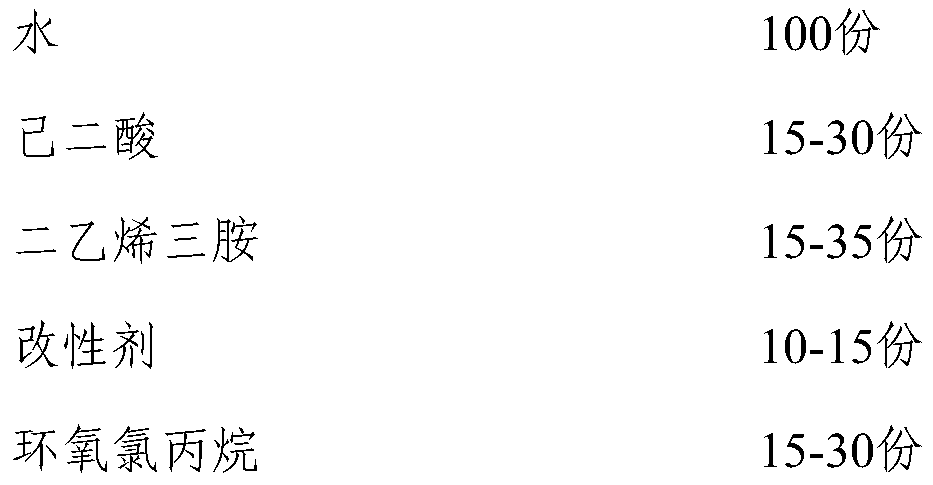

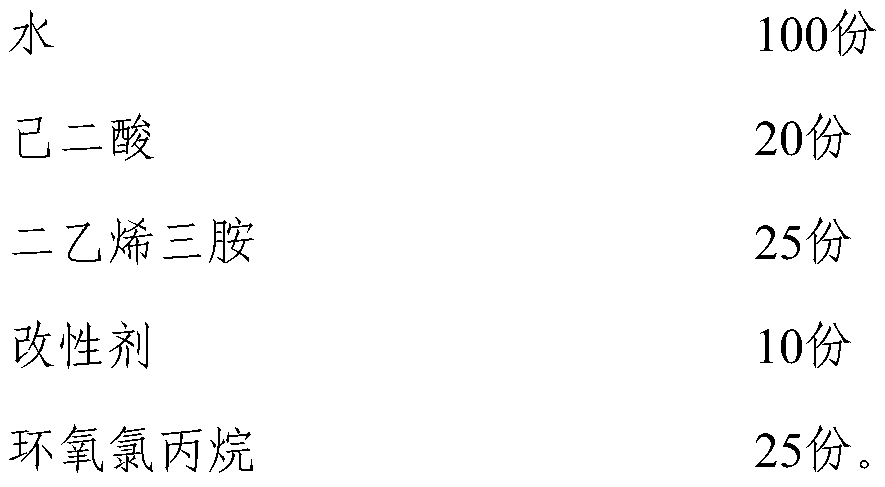

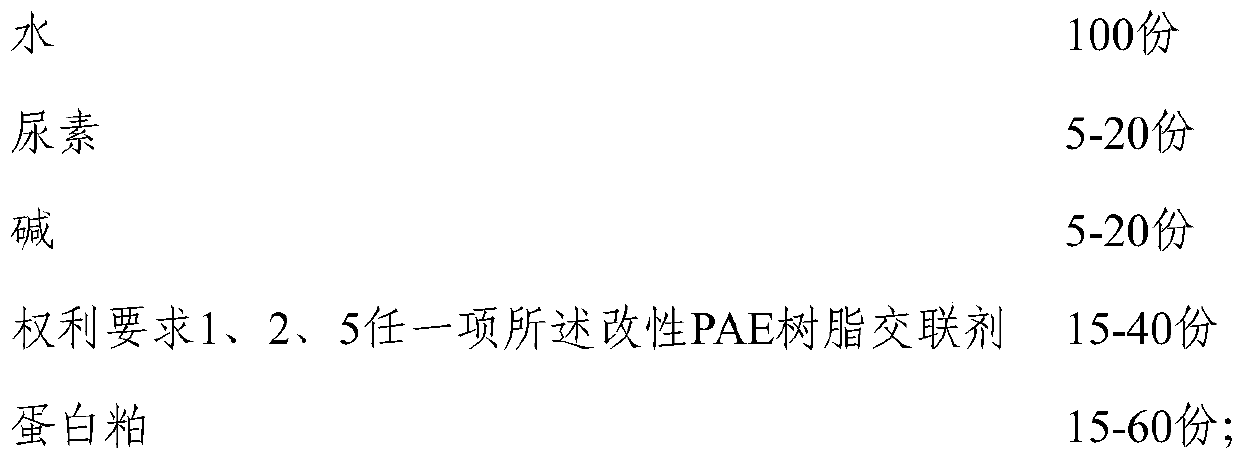

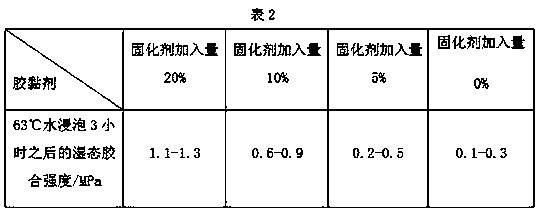

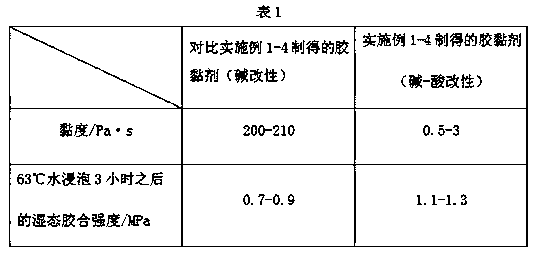

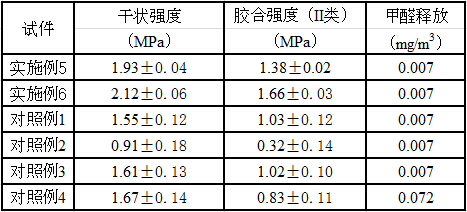

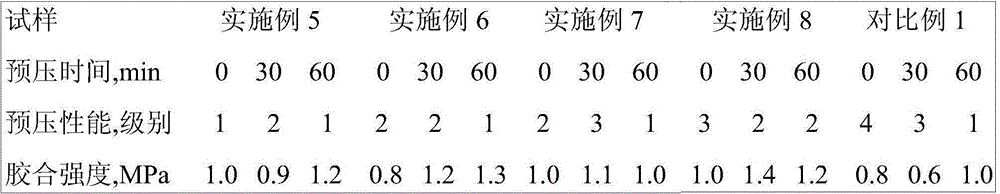

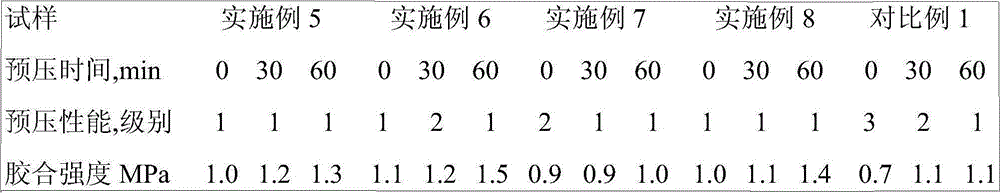

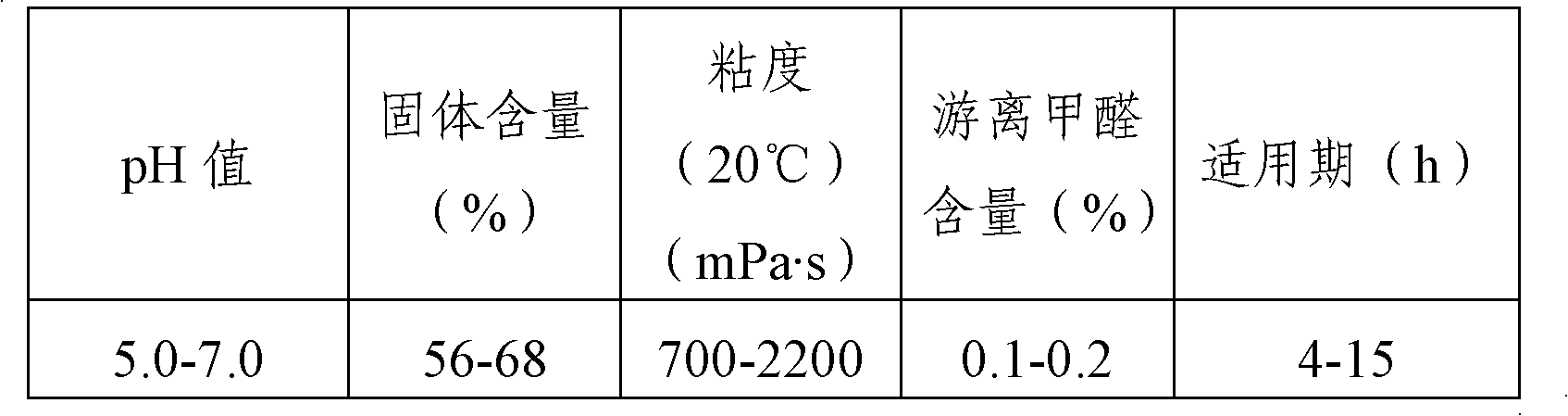

Modified PAE resin cross-linking agent, modified adhesive and application

ActiveCN111171314AFulfil requirementsGood preloading effectProtein adhesivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a modified PAE resin cross-linking agent, a modified adhesive and application. The modified PAE resin cross-linking agent is prepared from water, adipic acid, diethylenetriamine, a modifier and epoxy chloropropane. The embodiment of the invention provides a modified PAE resin cross-linking agent, wherein the main chain of the cross-linking agent is grafted with a catecholgroup with an adhesion function. It is accidentally found that by grafting catechol functional groups to the main chain of PAE and adopting the high-activity crosslinking technology, so that the initial viscosity of the prepared protein adhesive is remarkably improved, the pre-pressing forming time is greatly shortened, the water-resistant bonding strength is improved, and the national standard requirements are met.

Owner:BEIJING FORESTRY UNIVERSITY

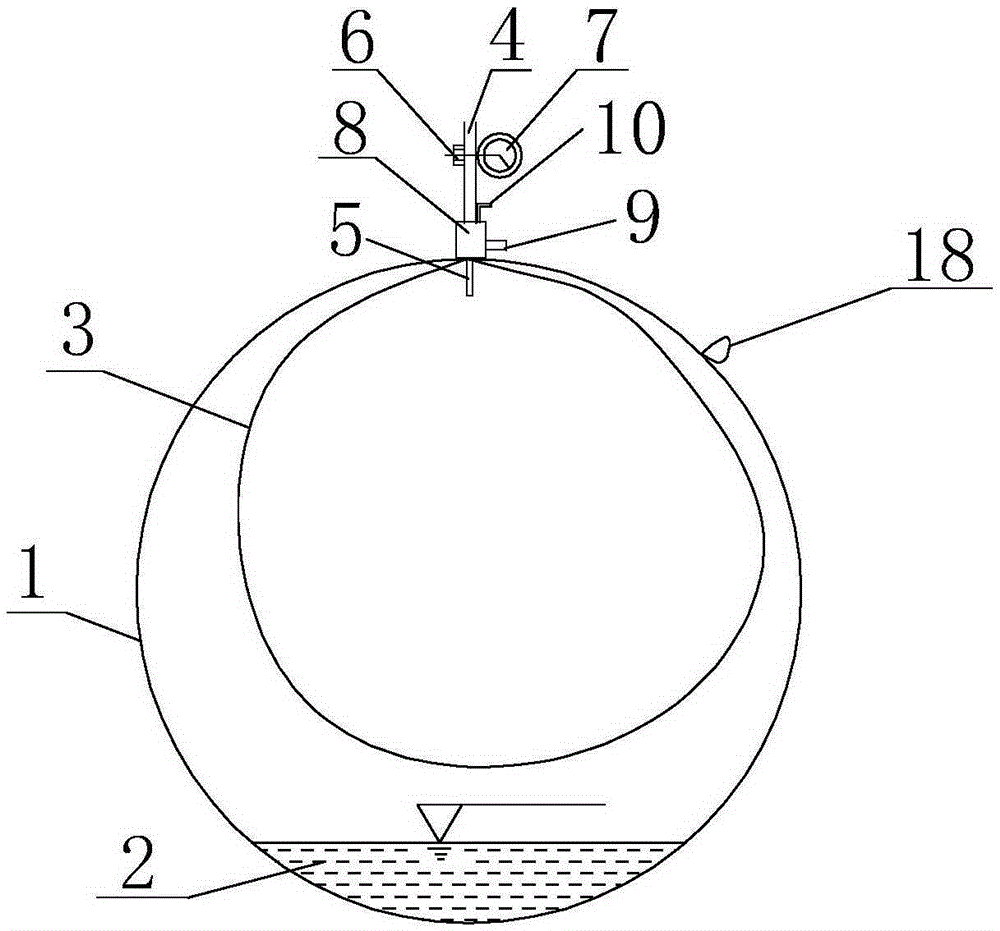

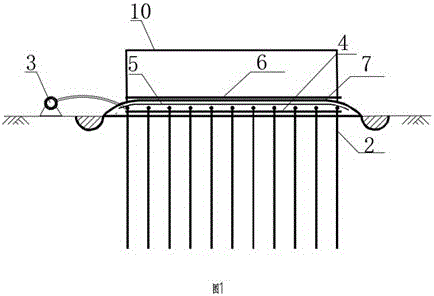

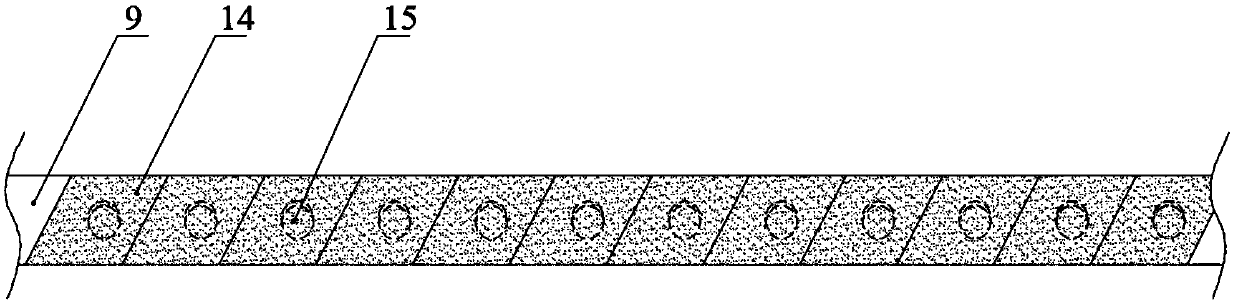

Border dike water bag strip, water storing border dike, and method for performing water bag strip pile-loading and prepressing

The invention relates to the technical field of civil engineering and construction, and in particular relates to and discloses a border dike water bag strip, a water storing border dike, and a method for performing water bag strip pile-loading and prepressing. The border dike water bag strip comprises a water bag strip body at an outer layer, wherein water is poured in the water bag strip to form a water pouring layer; an air bag strip is also arranged in the water bag strip body; the volume of water in the water pouring layer is in balance with the air pressure in the air bag strip, so as to keep the water bag strip body full and in a great shape. The water storing border dike comprises two transverse isolation dikes and a longitudinal base, wherein the border dike water bag strip is horizontally positioned on the base and is in sealing connection with the isolation dikes to encircle a rectangular structure; at least one waterproof film layer is paved at the bottom part of the rectangular structure and forms a sealed water storing groove with the rectangular structure. A method for performing the water bag strip pile-loading and prepressing ca perform the pile-loading and prepressing for an embankment through the aforementioned water storing border dike. According to the border dike water bag strip, the water storing border dike, and the method for performing water bag strip pile-loading and prepressing, the prepressing water load is sufficient, so that the prepressing effect is good; the settlement and deformation can be easily monitored; the advantages of safety, environmental protection, economy, high operability and recyclability are achieved.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of formaldehyde-free soybean meal-based wood adhesive for artificial boards

ActiveCN109880586ALow costLow priceNon-macromolecular adhesive additivesProtein adhesivesEpoxyChemical reaction

The invention relates to a preparation method of a formaldehyde-free soybean meal-based wood adhesive for artificial boards, and belongs to the technical field of adhesives. According to the invention, renewable resources, namely soybean meal, are used as raw materials, a water phase is selected as a solvent, and a process step of an alkali-acid two-step method is adopted. Epoxy resin, dicyandiamide, low-molecular-weight polyamide and soybean protein are combined for modification, a chemical reaction is carried out at the same time, and therefore the formaldehyde-free soybean meal-based wood adhesive with very high water resistance and bonding strength is prepared; the adhesive has the advantages of no formaldehyde, low viscosity, good cold pressing performance, low cost, high adhesive strength and the like; the adhesive does not volatilize formaldehyde, phenol or other harmful substances, has the characteristic of no formaldehyde, and is safe and environment-friendly, and the preparedsoybean meal-based wood adhesive is low in viscosity, convenient for applying, good in coating and pre-pressing performance, easy to spray and apply, convenient for repairing of plywood and capable of preventing a shaving board from being scattered, and the problems that a soybean adhesive is high in viscosity and difficult to spray are solved.

Owner:GUANGXI UNIV

Sand-bed-free vacuum preloading and water bag heaped loading combined reinforcing device and method for soft soil foundation

InactiveCN105780754AGuarantee stabilityShorten the construction periodSoil preservationCut and fillSecondary layer

The invention discloses a sand-bed-free vacuum preloading and water bag heaped loading combined reinforcing device for a soft soil foundation. The device comprises plastic drainage plates vertically instead into the soft soil foundation, a first non-woven geotechnical cloth layer laid on the surface of the soft soil foundation, water-permeable hoses flatly laid on the first non-woven geotechnical cloth layer and peripherally covered with medium sand, plastic drainage plates connected to the water-permeable hoses, a vacuumizing device connected to the water-permeable hoses, a second non-woven geotechnical cloth layer laid on the plastic drainage plates, a sealing film laid on the second non-woven geotechnical cloth layer, a third non-woven geotechnical cloth layer laid on the sealing film, and a covering piece placed on the sealing film. According to the sand-bed-free vacuum preloading and water bag heaped loading combined reinforcing device and method for the soft soil foundation, a sand bed can be omitted, the construction speed can be increased, and construction cost can be reduced; and in addition, water bag loading is used for replacing filling loading, and the reinforcing effect of a vacuum preloading method can be further improved in regions with limited filling resources.

Owner:HOHAI UNIV

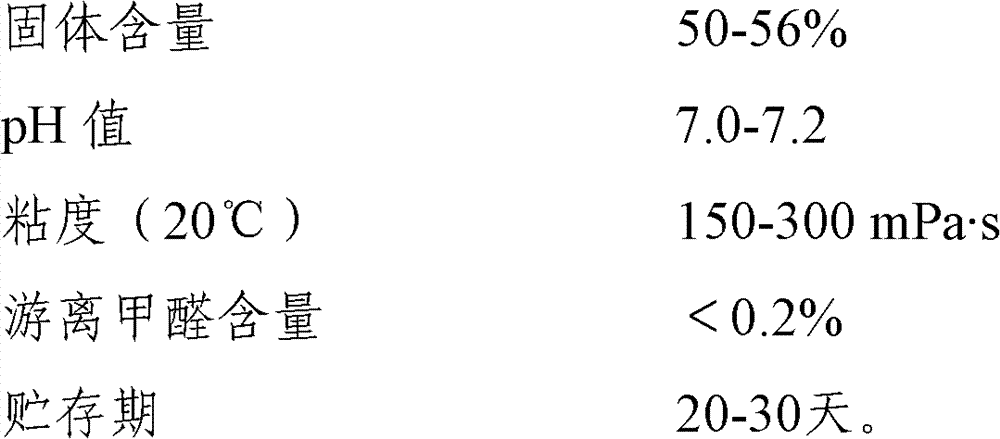

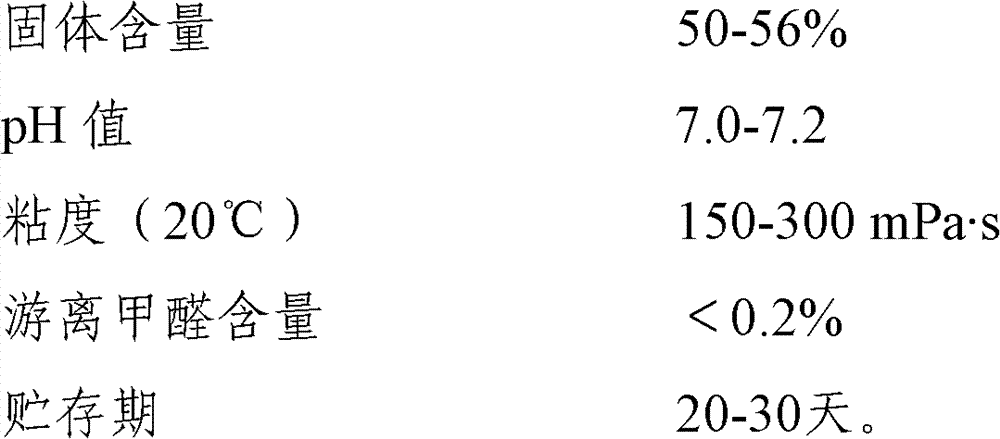

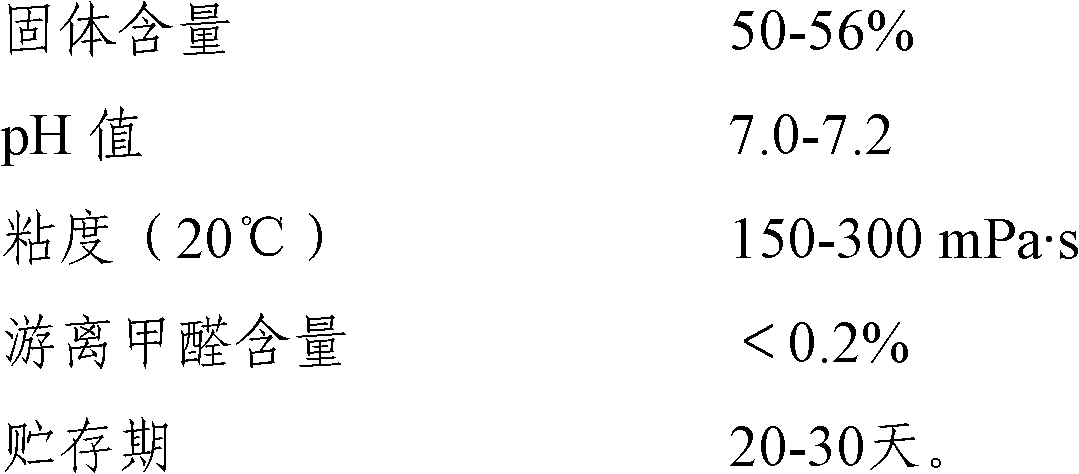

E0-level melamine modified urea formaldehyde resin adhesive

ActiveCN106883366AImprove water resistanceReduce free formaldehydeNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveParquetina

The invention discloses a preparation method of E0-level melamine modified urea formaldehyde resin. The E0-level melamine modified urea formaldehyde resin is prepared by the following steps of feeding urea by three batches, and feeding melamine by three batches. The invention also discloses the E0-level melamine modified urea formaldehyde resin and an E0-level melamine modified urea formaldehyde resin adhesive. The method has the advantages that the distribution of the internal molecular structure of the urea formaldehyde resin is changed by the multi-batch feeding type, the prepared resin is added into an adhesive mixer, a formaldehyde removing agent, a reinforcing agent, an acid curing agent and industrial flour are stirred until all the components are uniformly mixed, so as to obtain a mixed adhesive, and the obtained mixed adhesive is applied into the production of parquets; the hot pressing cycle can be shortened, the hot pressing time is shortened from conventional 70-79s / mm to 30-35s / mm under the condition of no change of pressure and temperature parameters, and the utilization rate and production efficiency of a hot press are greatly improved; the release amount of formaldehyde in the prepared plate reaches superE0 level.

Owner:广州市长安粘胶制造有限公司

High-altitude water injection surcharge load system for bridge support prepressing

The invention provides a high-altitude water injection surcharge load system for bridge support prepressing. The high-altitude water injection surcharge load system comprises a support formwork system, steel tube inclined struts, construction steel ropes, sand bags and waterproof cloth. The steel tube inclined struts are arranged at the two ends of the top of a support formwork; the construction steel ropes are divided into an upper layer and a lower layer and arranged below the bottom face of the top of the support formwork and on a water surface respectively in a transversely-and-oppositely-pulled mode; the sand bags are arranged on flange plates and cross beams of the support formwork; the waterproof cloth is laid on the top of the support formwork and the surfaces of the sand bags. The high-altitude water injection surcharge load system for bridge support prepressing is used high-altitude water injection type prepressing construction combined with sand bag surcharge load conducted for prepressing activities of detection of the overall stability of a framed bent in bridge support erection, the high-altitude water injection surcharge load system for bridge support prepressing can be widely applied to box girder framed bent construction and bridge floor pressing operation of girder bridges, major bridges and the like, and the high-altitude water injection surcharge load system for bridge support prepressing is simple in structure, easy and convenient to operate, capable of saving cost and safe in use.

Owner:SHANGHAI NO 7 CONSTR

Environment-friendly urea-formaldehyde resin adhesive, preparation method and application thereof

ActiveCN110330614AFully curedLow costAldehyde/ketone condensation polymer adhesivesThioureaRoom temperature

The invention belongs to the field of adhesives, and discloses an environment-friendly urea-formaldehyde resin adhesive, a preparation method and application thereof. The preparation method comprisesthe following steps: heating a formaldehyde solution to be 30 to 40 DEG C, adding urea to perform reaction for 2 to 10min, heating the solution to be 45 to 65 DEG C, then adjusting the pH value of a system to be 6.5 to 8 through alkali liquor, adding urea to perform reaction for 20 to 40min, heating the system to be 85 to 95 DEG C, then stopping heating, adding ammonium chloride in four lots at the temperature, so as to perform curing reaction, then adjusting the pH value to be 6.5 to 8 through alkali liquor and ammonia, adding urea to reduce the temperature to be 78 to 85 DEG C, performing reaction for 30 to 50min, starting to heat up when the temperature is reduced to 72 to 76 DEG C, adding melamine when the temperature is increased to be 82 to 88 DEG C, and performing thermal reaction for 20 to 40min; adding thiourea when the temperature is reduced to be 73 to 78 DEG C, and performing thermal reaction for 5 to 15min; adjusting the pH value to be 9 plus or minus 0.3 through alkali liquor when the temperature is reduced to be 68 to 72 DEG C; adding urea when the temperature is reduced to be 63 to 67 DEG C, performing reaction for 20 to 40min, and cooling the system to be room temperature. The environment-friendly urea-formaldehyde resin adhesive is low in the content of free formaldehyde and high in strength.

Owner:鹰潭佰伦包装有限公司

Soybean meal adhesive for blockboards, and preparation method thereof

ActiveCN111675998AImprove bonding performanceReduce usageNon-macromolecular adhesive additivesProtein adhesivesPhosphoric acidPlasma treatment

The invention discloses a soybean meal adhesive for blockboards, and a preparation method thereof. The adhesive comprises, by mass, 22-26 parts of soybean meal powder, 86 parts of a dispersing agent,2-3 parts of trypsin, 1-2 parts of a composite viscosity regulator, 2-3 parts of a branched polymer cross-linking agent and 0.04-0.04 part of calcium phosphate. The preparation method comprises the following steps: K1, performing plasma treatment on the soybean meal powder in a nitrogen atmosphere, then adding calcium chloride and the dispersing agent, performing ultrasonic treatment, adding trypsin, performing treatment at 50-60 DEG C for 20 minutes, cooling, adding phosphoric acid, and performing uniform stirring to obtain a first mixture; and K2, adding calcium phosphate and the branched polymer cross-linking agent into the first mixture, uniformly stirring, adding the composite viscosity regulator, mixing, and regulating the pH value to 9.0 to obtain the soybean meal adhesive for the blockboards. The adhesive is good in water-resistant adhesive property, and ensures the practical performance of the adhesive and the durability of the blockboards.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

Adhesive for indoor plywood

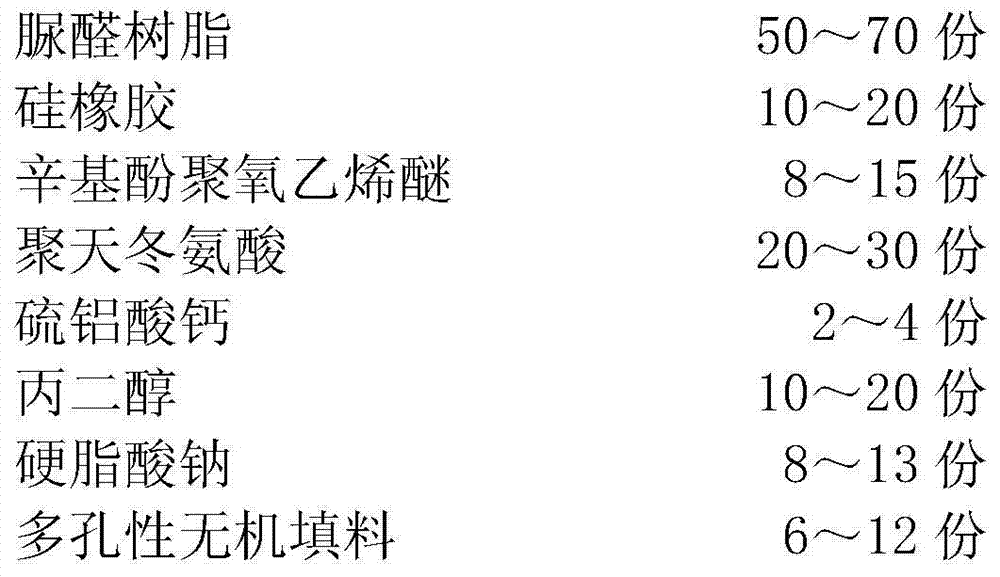

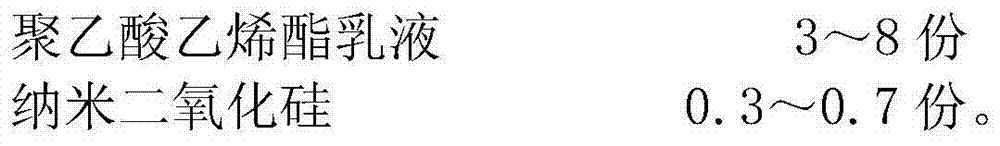

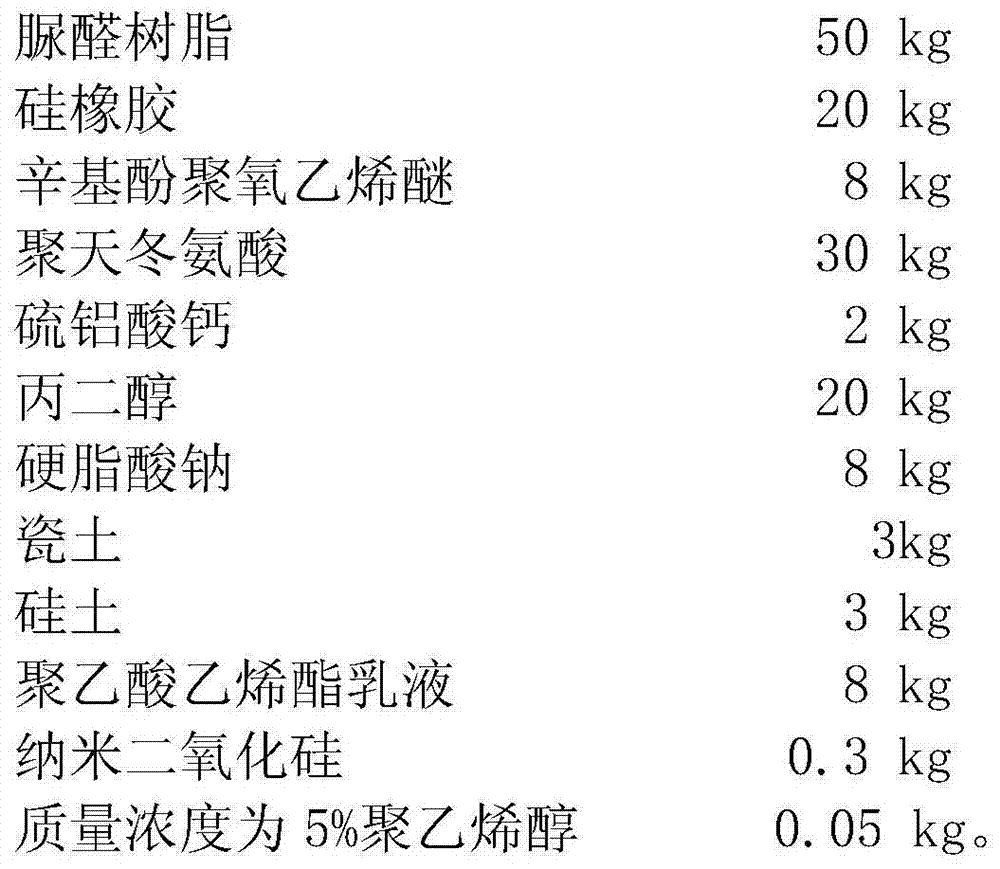

InactiveCN104762039AIncrease productivityReduce formaldehydeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium stearateAdhesive

The invention relates to the technical field of adhesive, in particular to adhesive for indoor plywood. The adhesive comprises, by weight, 50-70 parts of urea resin, 10-20 parts of silicone rubber, 8-15 parts of octyl phenol polyoxyethylene ether, 20-30 parts of polyaspartic acid, 2-4 parts of calcium sulphoaluminate, 10-20 parts of propylene glycol, 8-13 parts of sodium stearate, 6-12 parts of porous inorganic filler, 3-8 parts of polyvinyl acetate emulsion, 1-5 parts of nano-silica and 5-10 parts of water. The adhesive for the indoor plywood is good in viscosity, has the antiseptic and anti-static functions and contains lower formaldehyde, the water resistance and aging resistance of the adhesive are improved greatly, and the service life of the adhesive is prolonged by half a year to one year. The adhesive is mainly applied to bonding of the inner plywood.

Owner:黄琳

Additive of urea-formaldehyde resin adhesive for artificial board and preparation method of adhesive

InactiveCN105985746AWell mixedGood preloading effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesCassava (food)Resin adhesive

Provided are an additive of a urea-formaldehyde resin adhesive for an artificial board and a preparation method of the adhesive. The additive is prepared from, by weight, 50-70 parts of sepiolite powder, 100 parts of carboxymethyl sweet potato residues, 20-40 parts of cassava residues, corncob residues and 5-20 parts of oat waste; the raw materials are mixed to be uniform according to the above-mentioned proportions, and a urea-formaldehyde resin additive is obtained; the urea-formaldehyde resin additive and urea-formaldehyde resin are mixed to be uniform according to the weight part ratio of (20-30):100, and the urea-formaldehyde resin adhesive is obtained. According to the additive of the urea-formaldehyde resin adhesive for the artificial board and the preparation method of the adhesive, the preparation method is simple, the additive and the urea-formaldehyde resin adhesive have good miscibility, a good prepressing property can be given to the urea-formaldehyde resin, and the production efficiency of plywood and blockboard is guaranteed; the additive can react with formaldehyde produced in artificial board production, and formaldehyde emission of the artificial board is reduced.

Owner:尤殿凯

Flour composition for urea resin and preparation method and application thereof

InactiveCN105062392AGood compatibilitySave foodNon-macromolecular adhesive additivesStarch adhesivesFiberHydrolysis

The invention discloses a flour composition for urea resin and a preparation method and application thereof. The flour composition is prepared from, by weight parts, 100 parts of mixed plant fiber powder having undergone EM bacterium solid fermentation hydrolysis treatment, 0.15-0.25 part of sodium carboxymethyl cellulose, 4-7 parts of calcium carbonate powder and 8-12 parts of flour. The mixed plant fiber powder having undergone the EM bacterium solid fermentation hydrolysis treatment is prepared according to the following method: matching raw materials which are, by weight parts, 50-60 parts of wood powder, 20-35 parts of corn stalk and 10-20 parts of cassava residue powder, placing the three kinds of powder in a stirring mixer, performing spraying to add EM bacterium liquid with stirring, performing stirring evenly, enabling the number of effective bacterium in the materials to be 0.5-1*10<10> CUF / kg, enabling the moisture content to be 40-50 wt%, and performing fermentation until the measured pH of a sample is 4.0-4.5. The flour composition for urea resin is used for plywood production, can save plenty of grains and have good prepressing performance, the adhesive strength and water resistance of a plywood product are improved compared with the use of wheat flour, and the formaldehyde emission is reduced.

Owner:广州市北林林产工业有限公司

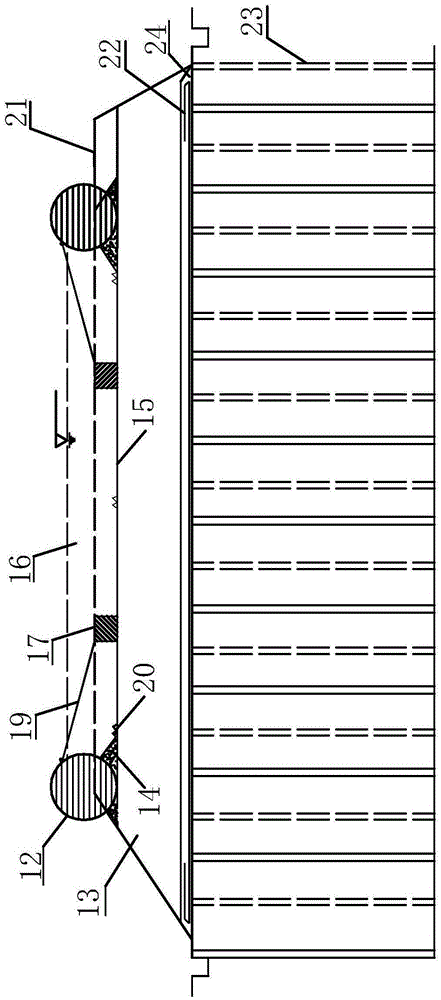

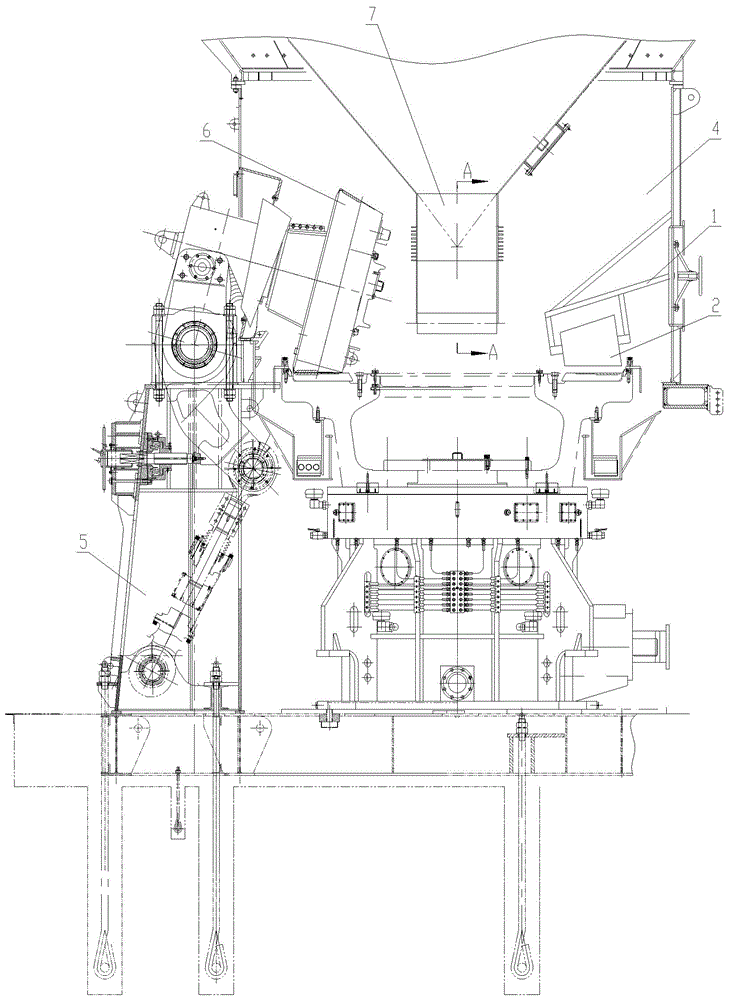

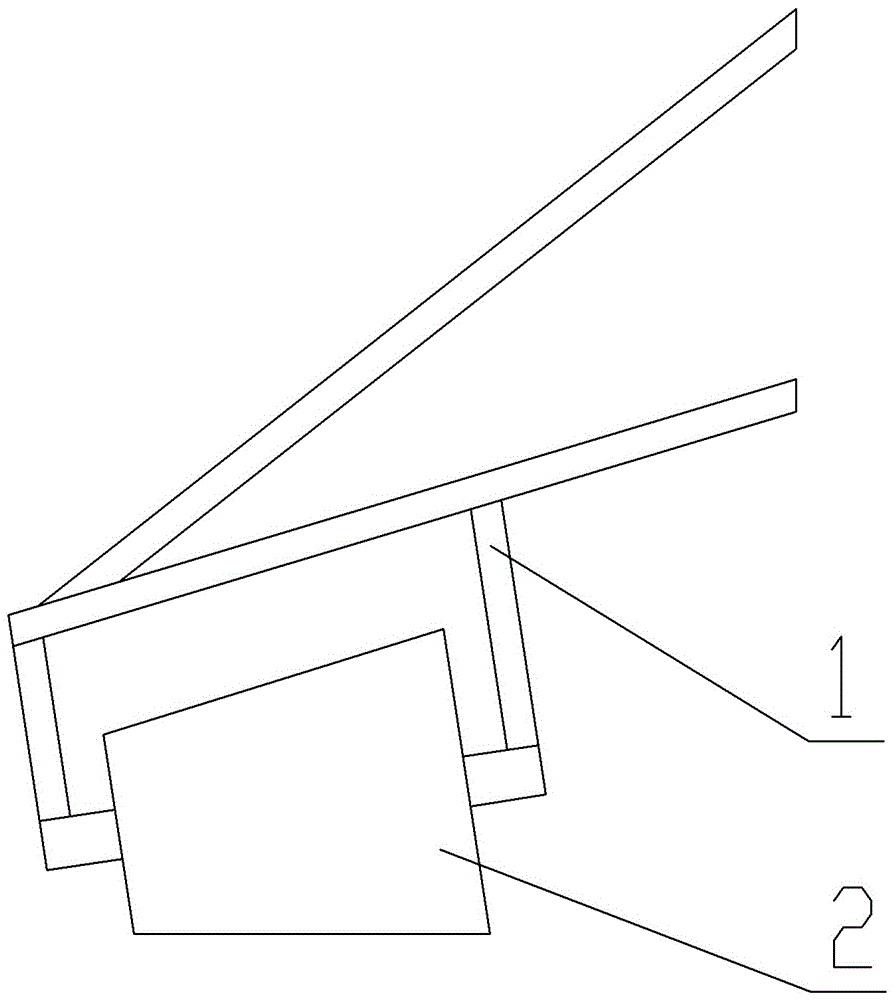

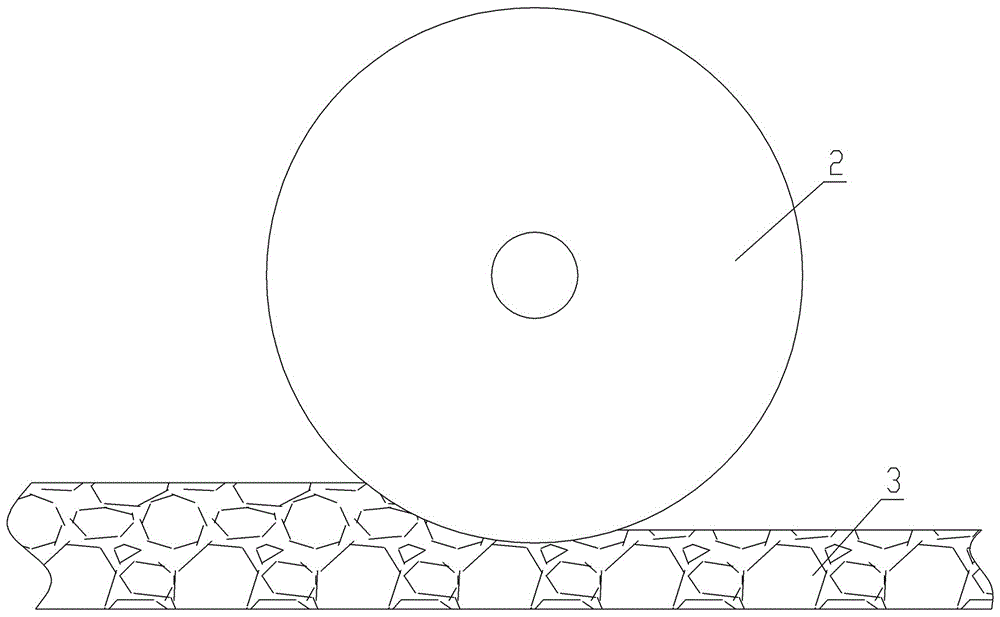

Vertical roller mill with material prepressing and positioned blanking and vertical roller milling method

The invention discloses a vertical roller mill with material prepressing and positioned blanking and a vertical roller milling method. A material layer prepressing device and a concentrated blanking device are arranged in an inner cavity of a mill body; the material layer prepressing device includes a grinding roller; rotating shafts are arranged at two ends of the grinding roller, and are connected with connecting rods through bearings and bearing bases; the connecting rods are connected with a support frame; the support frame is fixed on the wall of the inner cavity of the mill body, and is positioned two adjacent grinding rollers in the inner cavity of the mill body; the upper end of an extension pipe of the concentrated blanking device is connected with the lower end of a blanking inner cone hopper; the lower part of a fixed plate at the lower part of an inner cavity of the extension pipe is connected with the upper part of a connecting plate; the lower part of the connecting plate is connected with a scraper; and a gap is formed between the lower end surface of the scraper and the upper end surface of a milling disc. The vertical roller mill is reasonable in design, accurate in blanking point and excellent in material paving and prepressing effects, and can improve the powder milling quality.

Owner:新乡市长城机械有限公司

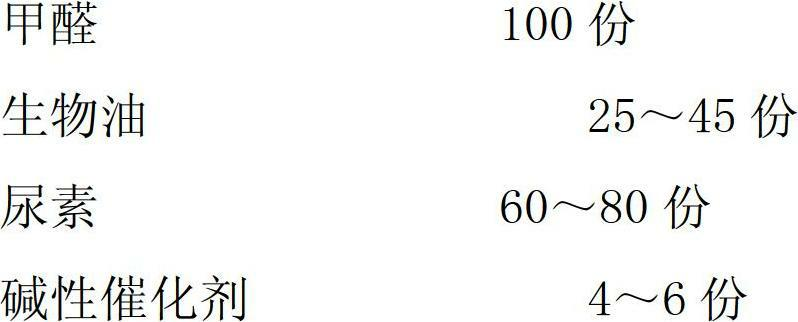

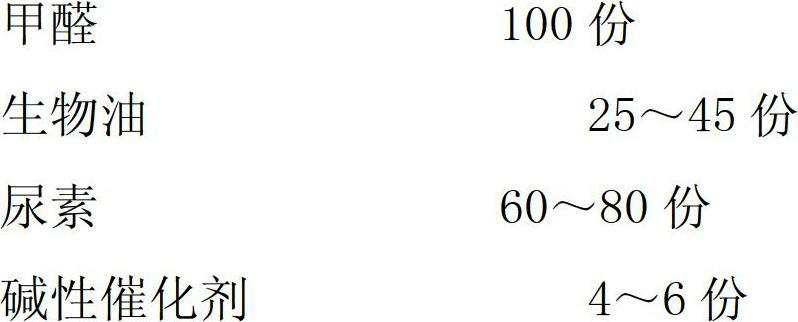

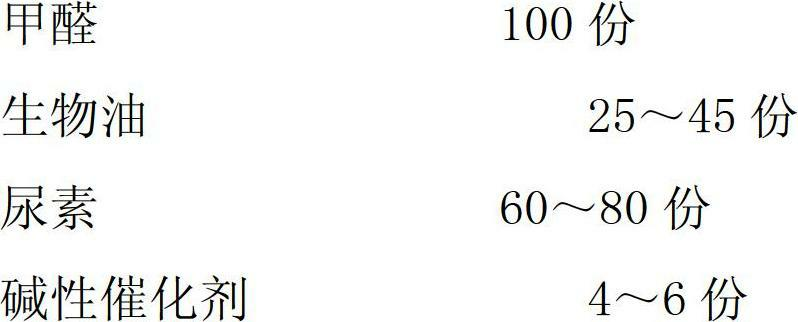

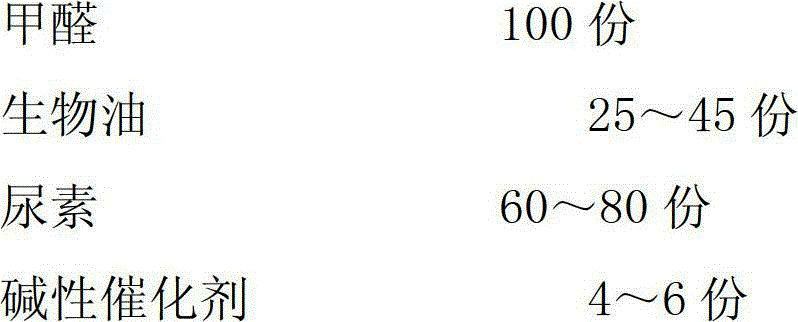

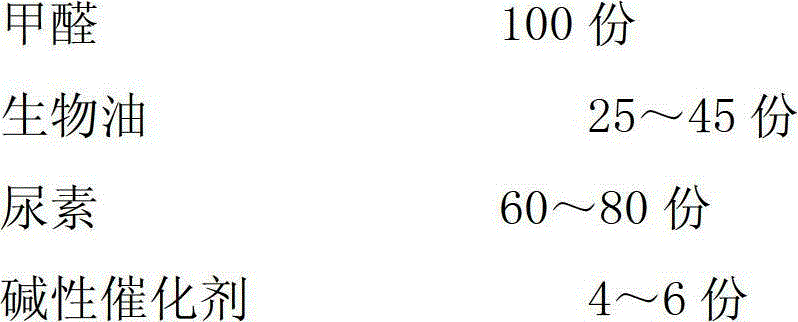

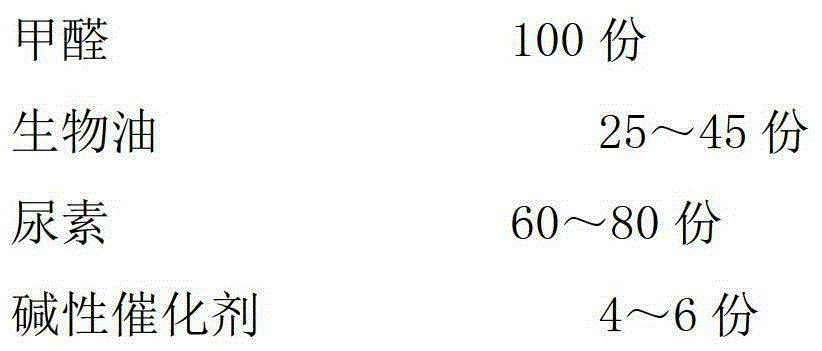

Method for preparing biological oil modified urea resin adhesive

InactiveCN102633970AChange skeleton structureImprove water resistanceAldehyde/ketone condensation polymer adhesivesAging resistanceResin adhesive

The invention relates to a method for preparing biological oil modified urea resin, belonging to the technical field of wood adhesive. The method comprises the following steps of: adding formaldehyde, biological oil and basic catalyst into a reaction container according to specified mass part for reaction so as to obtain hydroxymethylation biological oil; adding 75% of urea in specified mass part into the reaction container, adjusting pH of a reaction system in the reaction container to be 7.5-8.5 by using an acidic pH adjusting agent, and keeping warm; and adjusting pH of the reaction system in the reaction container to be 4.8-5.2 by using the acidic pH adjusting agent, adding 25% of urea in specified mass part; controlling the temperature of the reaction system in the reaction container to be 90 2 DEG C, after the extracted reaction system is dropped into clear water to form white mist and cannot disperse, adjusting pH to 8.0 by using an alkaline pH adjusting agent, and keeping warm to obtain the biological oil modified urea resin. The method disclosed by the invention is capable of improving water resistance, ageing resistance of the urea resin, increasing stability and reducing formaldehyde release amount.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of weatherproof preservative plywood

InactiveCN107443521AImprove water retentionPreventing the problem of over agingRadiation/waves wood treatmentPressure wood treatmentAdditive ingredientAdhesive

The invention belongs to the technical field of processing anti-corrosion plywood, and in particular relates to a preparation method of weather-resistant anti-corrosion plywood, including a veneer anti-corrosion treatment method of vacuum immersion in anti-corrosion liquid, a method of drying anti-corrosion veneer by electromagnetic wave drying and an adhesive preparation. Compared with the prior art, the present invention has the following advantages: the antiseptic liquid in the present invention is friendly to the environment and has good resistance to various microorganisms. Through the cooperation of vacuum conditions, the antiseptic liquid has good permeability in the veneer and can Uniform, and then use electromagnetic wave sealing treatment, which can make the ingredients in the antiseptic solution better combined in the veneer, which can effectively reduce the loss of active ingredients and improve the durability of the antiseptic effect; the adhesive can avoid the problem of excessive aging and avoid After hot pressing, the glue is opened, so that the obtained plywood has a stable structure, good weather resistance, effective and long-lasting anti-corrosion effect, and remarkable economic benefits.

Owner:含山县茂盛胶合板厂

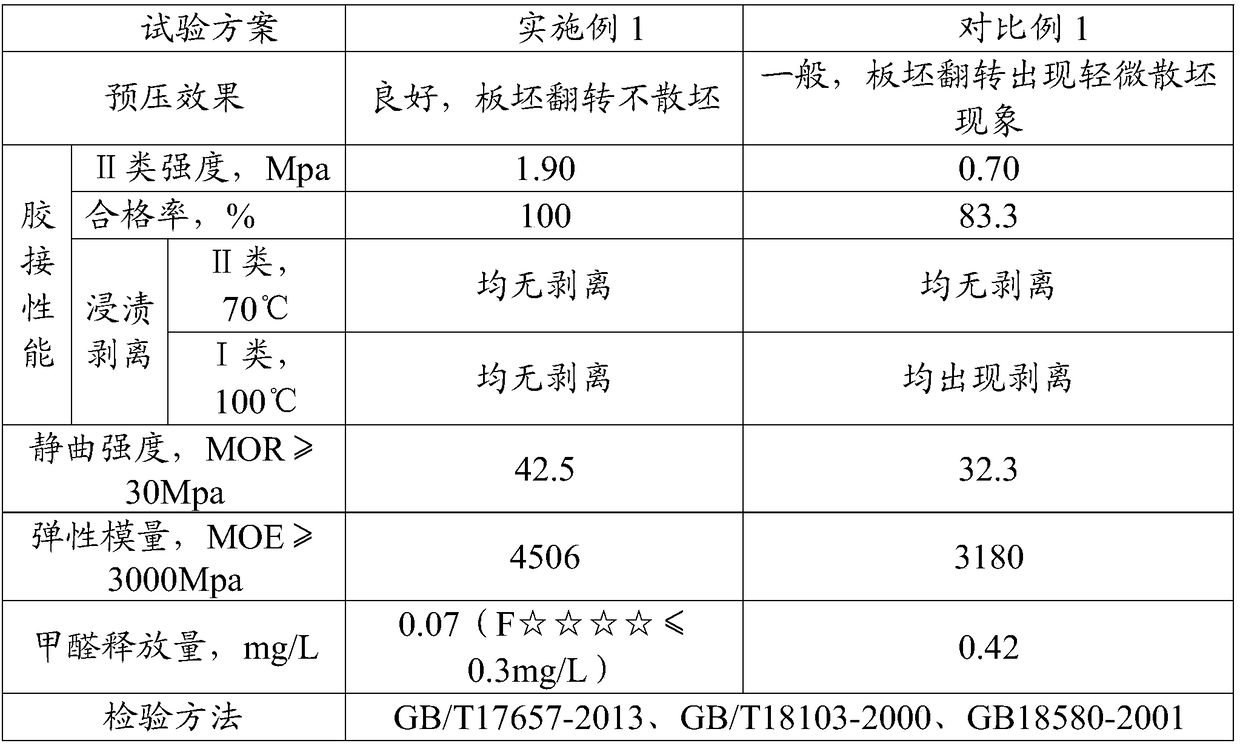

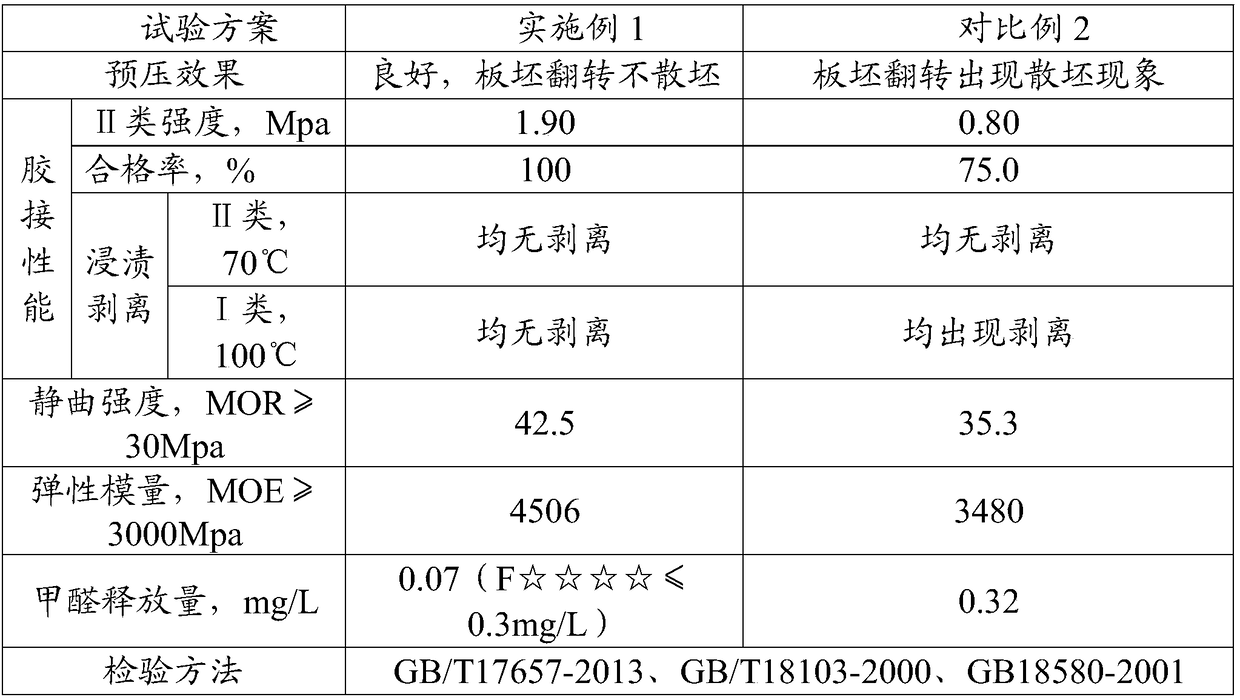

A kind of e0 grade melamine modified urea-formaldehyde resin adhesive

ActiveCN106883366BWell mixedIncrease profitNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveParquetina

The invention discloses a preparation method of E0-level melamine modified urea formaldehyde resin. The E0-level melamine modified urea formaldehyde resin is prepared by the following steps of feeding urea by three batches, and feeding melamine by three batches. The invention also discloses the E0-level melamine modified urea formaldehyde resin and an E0-level melamine modified urea formaldehyde resin adhesive. The method has the advantages that the distribution of the internal molecular structure of the urea formaldehyde resin is changed by the multi-batch feeding type, the prepared resin is added into an adhesive mixer, a formaldehyde removing agent, a reinforcing agent, an acid curing agent and industrial flour are stirred until all the components are uniformly mixed, so as to obtain a mixed adhesive, and the obtained mixed adhesive is applied into the production of parquets; the hot pressing cycle can be shortened, the hot pressing time is shortened from conventional 70-79s / mm to 30-35s / mm under the condition of no change of pressure and temperature parameters, and the utilization rate and production efficiency of a hot press are greatly improved; the release amount of formaldehyde in the prepared plate reaches superE0 level.

Owner:广州市长安粘胶制造有限公司

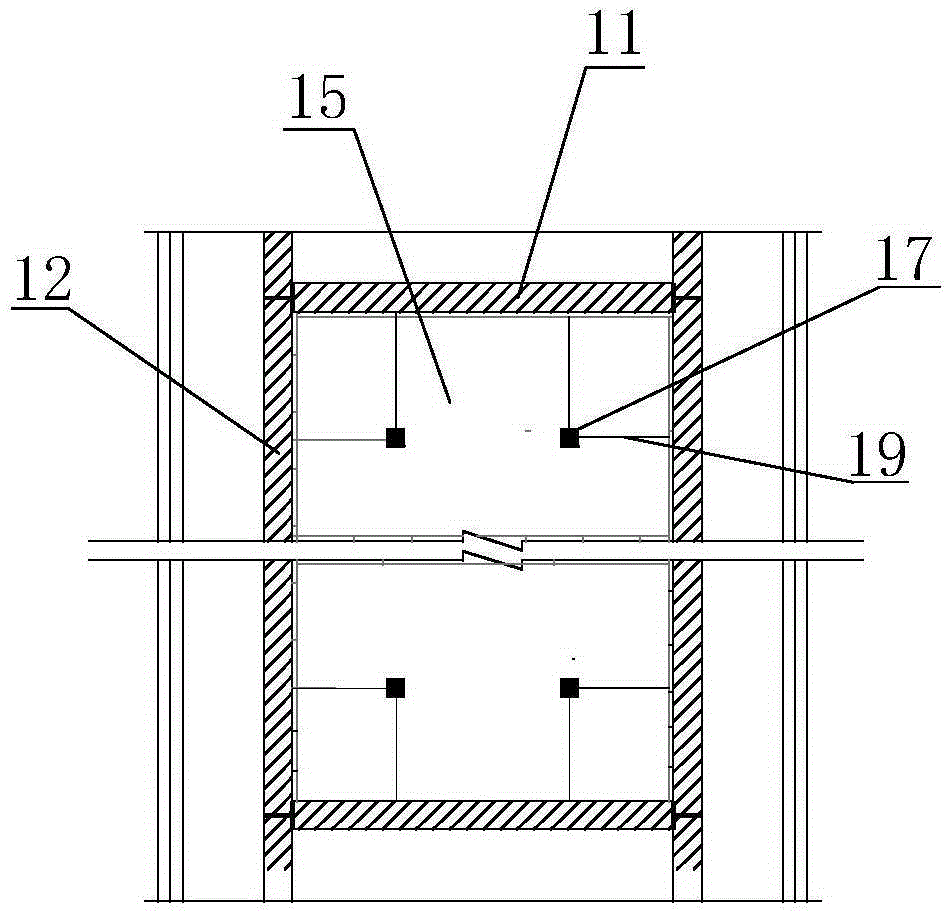

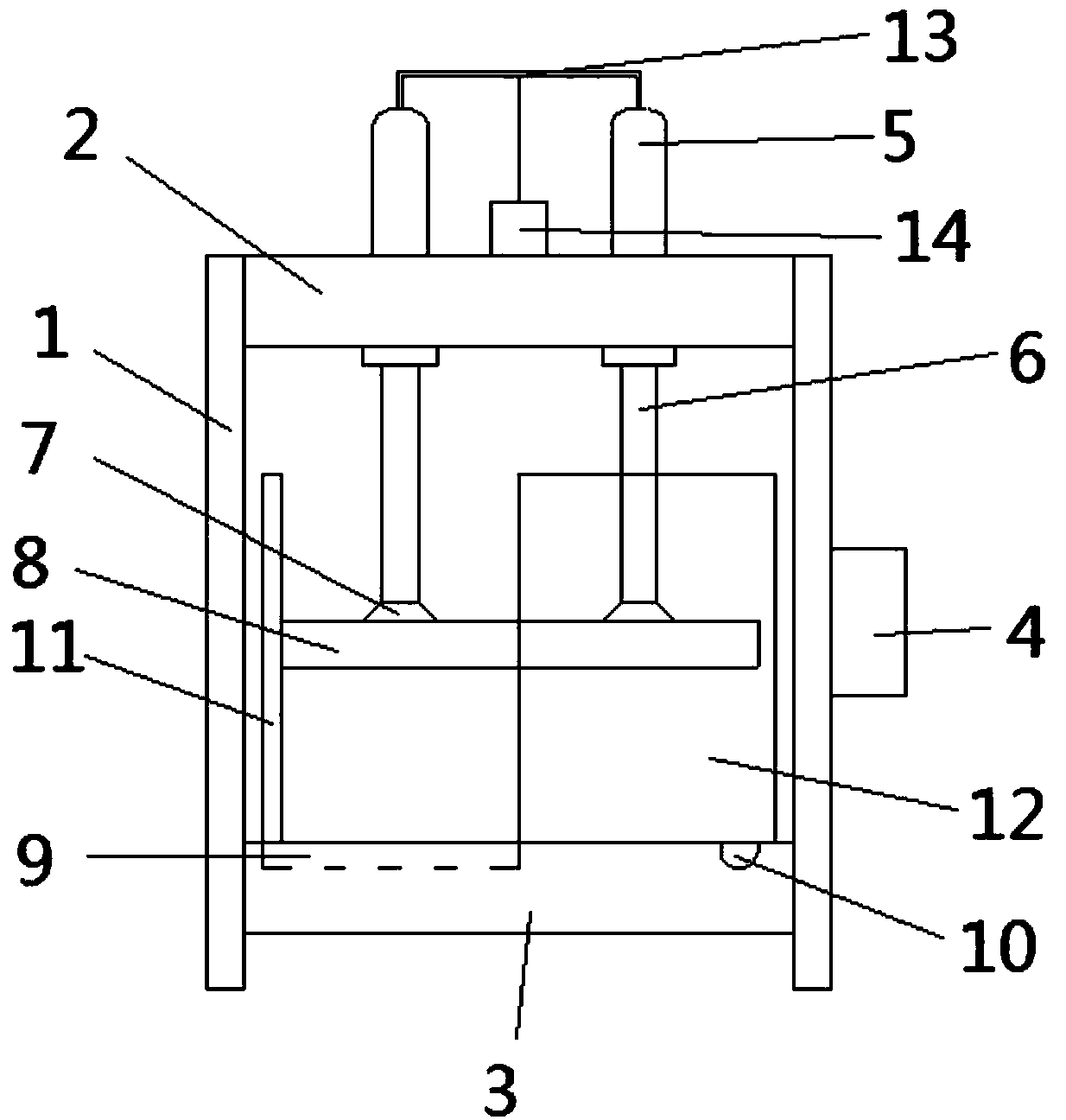

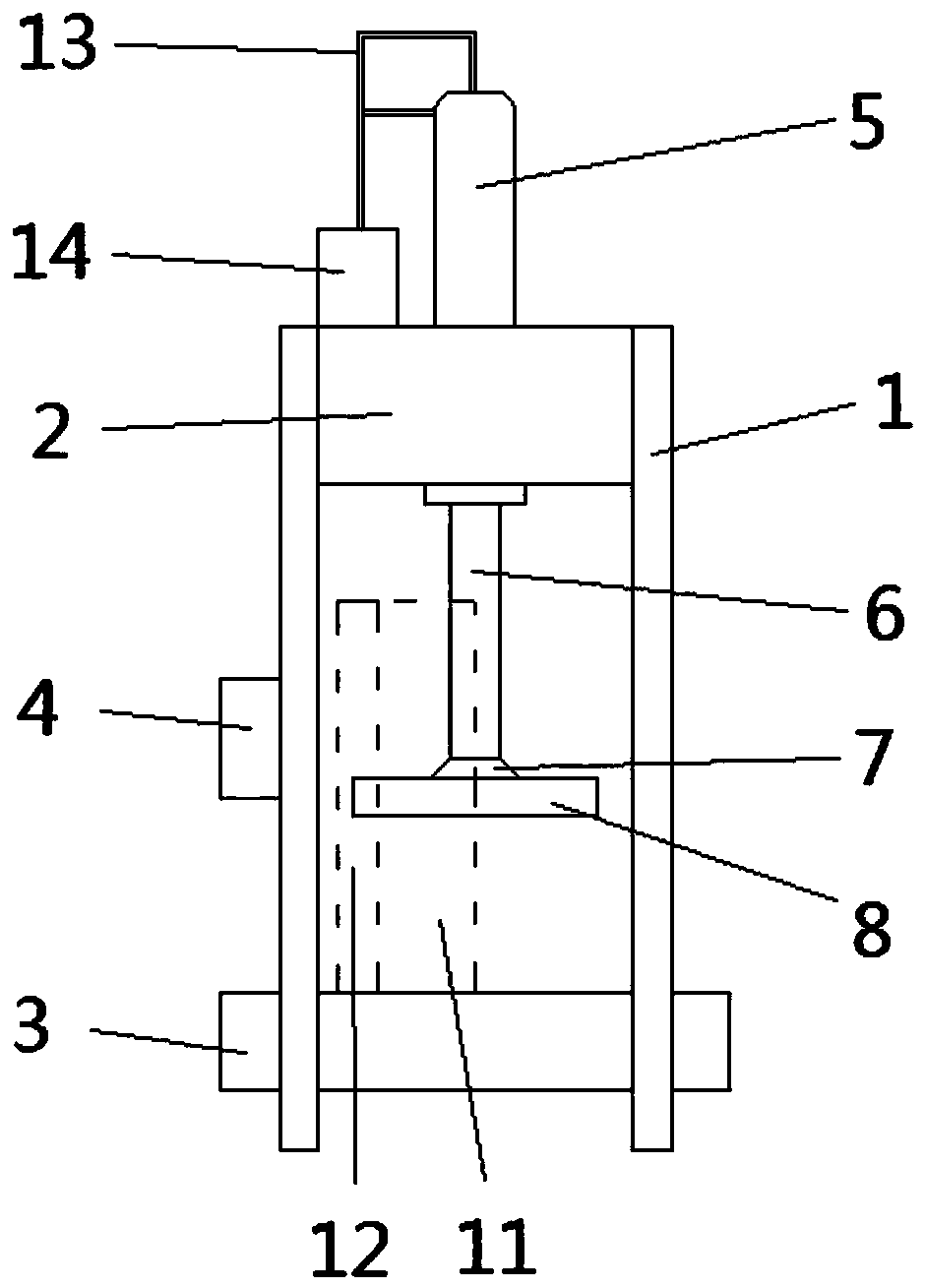

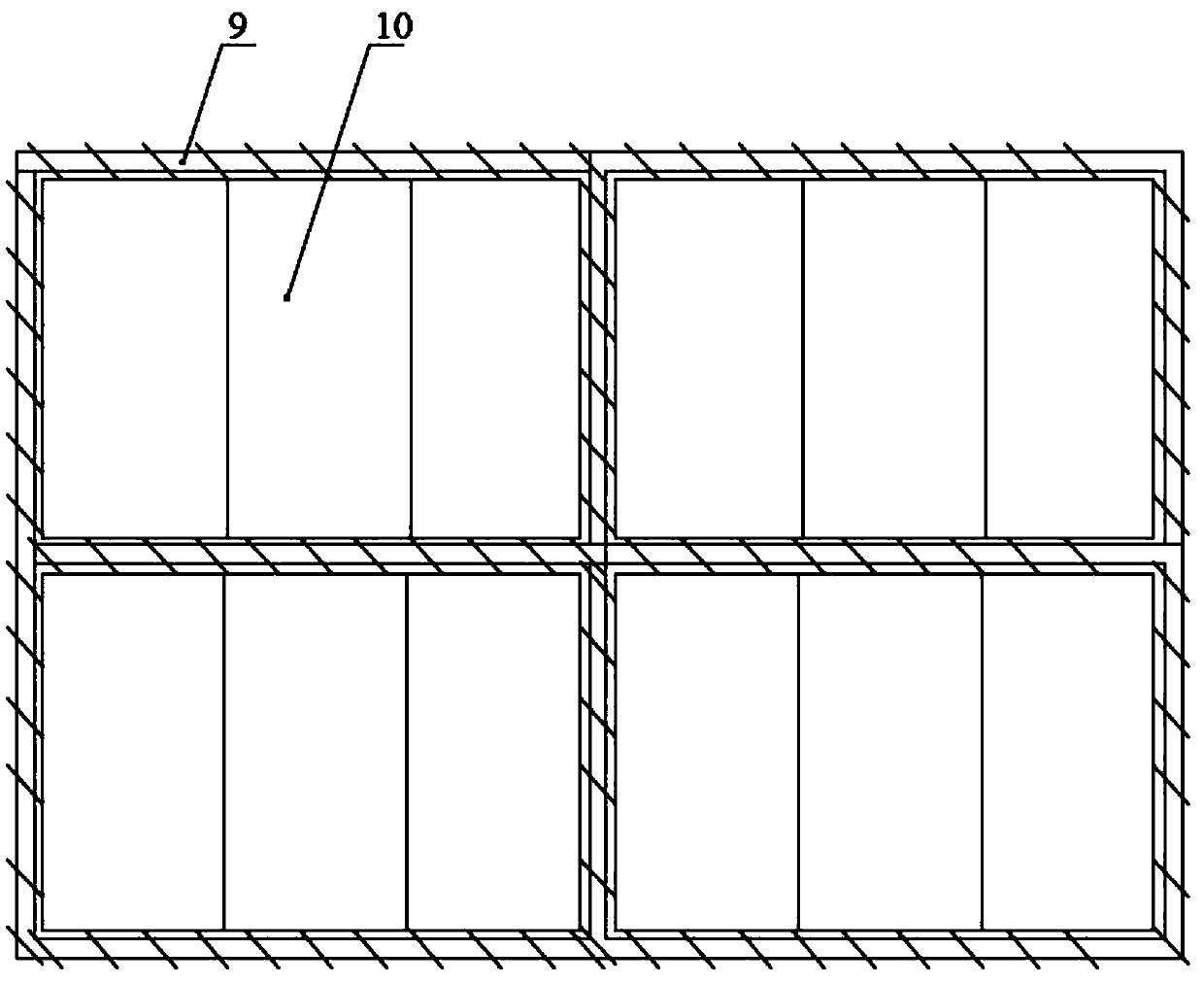

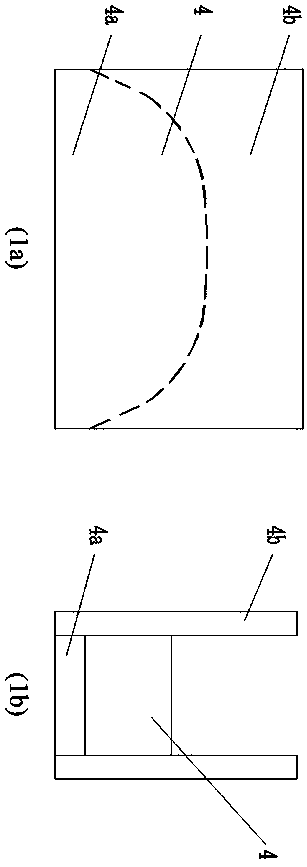

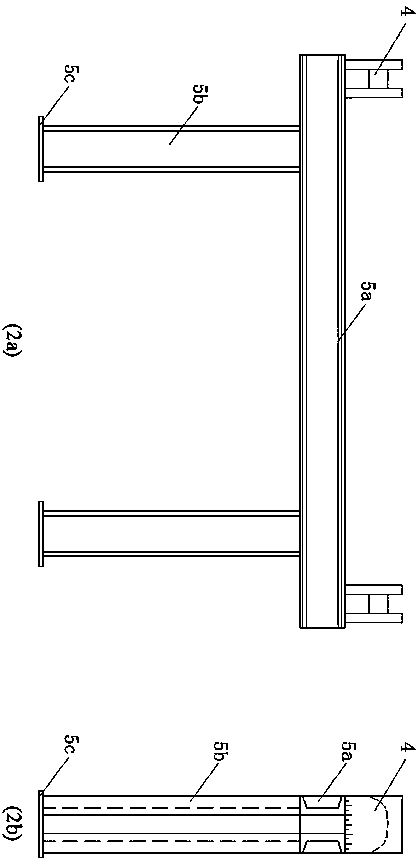

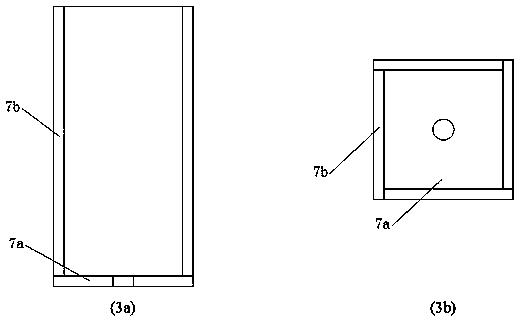

Cold press with plate positioning function

InactiveCN107627411APrecise positioningNeatly stackedPlywood pressesLaminationHydraulic cylinderEngineering

The invention discloses a cold press with a plate positioning function. The cold press comprises a pair of stand columns. An upper top plate and a lower bottom plate are correspondingly arranged between the stand columns. Each stand column is provided with an electric control cabinet. A pair of hydraulic cylinders is fixed in the upper top plate. A piston rod is connected with the lower portions of the hydraulic cylinders. The bottom of the piston rod is connected with a downward pressing plate through a pressing block. The surface of the lower bottom plate is provided with a first slideway and a second slideway which are perpendicular to each other. A first baffle plate is arranged in the first slideway. A second baffle plate is arranged in the second slideway. The cold press has the advantages that a plate can be accurately positioned during plate feeding, and the plate can be neatly stacked.

Owner:ANJI HENGSHENG BAMBOO WOOD

Method for preparing biological oil modified urea resin adhesive

InactiveCN102633970BChange skeleton structureImprove water resistanceAldehyde/ketone condensation polymer adhesivesAging resistanceResin adhesive

The invention relates to a method for preparing biological oil modified urea resin, belonging to the technical field of wood adhesive. The method comprises the following steps of: adding formaldehyde, biological oil and basic catalyst into a reaction container according to specified mass part for reaction so as to obtain hydroxymethylation biological oil; adding 75% of urea in specified mass part into the reaction container, adjusting PH of a reaction system in the reaction container to be 7.5-8.5 by using an acidic PH adjusting agent, and keeping warm; and adjusting PH of the reaction system in the reaction container to be 4.8-5.2 by using the acidic PH adjusting agent, adding 25% of urea in specified mass part; controlling the temperature of the reaction system in the reaction container to be 90 + / - 2 DEG C, after the extracted reaction system is dropped into clear water to form white mist and cannot disperse, adjusting PH to 8.0 by using an alkaline PH adjusting agent, and keeping warm to obtain the biological oil modified urea resin. The method disclosed by the invention is capable of improving water resistance, ageing resistance of the urea resin, increasing stability and reducing formaldehyde release amount.

Owner:BEIJING FORESTRY UNIVERSITY

Additive of urea formaldehyde resin adhesive and preparation method thereof

InactiveCN102408848BWell mixedGood preloading effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer scienceResin adhesive

Owner:BEIJING FORESTRY UNIVERSITY

Additive agent of urea-formaldehyde resin adhesive and preparation method thereof

InactiveCN102321439BSolve the problem of size reductionGood preloading effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesResin adhesiveMechanical property

The invention provides an additive agent of urea-formaldehyde resin adhesive and a preparation method thereof. The additive agent of the urea-formaldehyde resin adhesive is prepared from the following components in parts by weight: 100 parts of modified starch, 1-5 parts of polymer compound, 300-500 parts of desulfurization gypsum, and 0.1-2 parts of swelling agent which are mixed uniformly to obtain the additive agent. The additive agent of the urea-formaldehyde resin can replace flour to be added into urea-formaldehyde resin, the adhesive is endowed with favorable prepressing when artificial plates are prepared, the high production efficiency of the artificial plates is ensured, simultaneously the formaldehyde emission of the artificial plates can be reduced effectively, the problem of volume reduction in the process of preparing the urea-formaldehyde resin adhesive is solved, and the physical mechanical property of the artificial plates is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Vacuum preloading device with sandbag cushion layer, and construction method thereof

Disclosed are a vacuum preloading device with a sandbag cushion layer, and a construction method thereof. The vacuum preloading device comprises a vacuum pump, a vertical sandbag layer, a horizontal sandbag layer, geotextile, a clay sealing layer, a polyethylene sealing film and a split water sealing layer. The vertical sandbag layer, the horizontal sandbag layer, the geotextile, the clay sealinglayer, the polyethylene sealing film and the split water sealing layer are sequentially laid on the soil surface from bottom to top. A plurality of vacuum tubes communicated with the vacuum pump are embedded in sandbag gaps of the longitudinal sandbag layer, and a plurality of plastic drainage plates are fixedly inserted into the bottoms of sandbags of the vertical sandbag layer; the polyethylenesealing film is hermetically laid on the upper surfaces of the clay sealing layer and a film pressing groove; the split water sealing layer is arranged on the upper surface of the polyethylene sealingfilm. The vacuum preloading device and the construction method thereof have the advantages that the arrangement mode of conventional horizontal drainage bodies is changed, the flexible water-permeable and sand-permeable sandbags position the vacuum tubes and the plastic drainage plates and apply a certain downward pressure on the soil surface, and the plastic drainage plates, the sandbags and thevacuum tubes are assembled integrally; the vacuum preloading device has the advantages of stable shape, capability of not being affected by sedimentation and convenience in construction.

Owner:TIANJIN CHENGJIAN UNIV

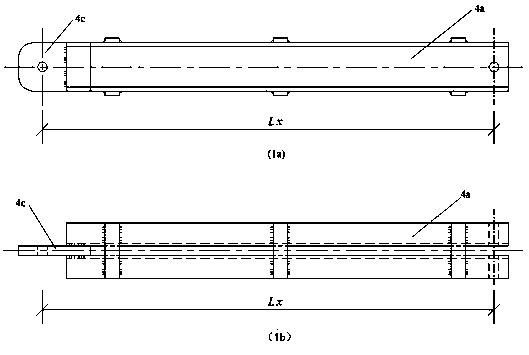

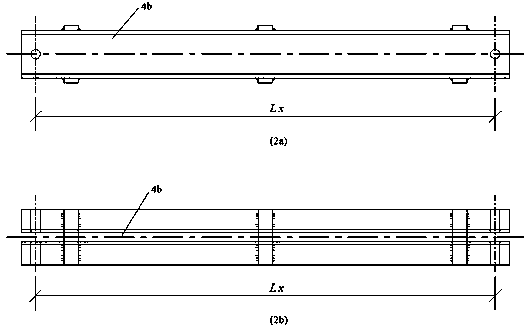

Preloading operation method of a high-altitude tower column crossbeam support

ActiveCN109252447ATo achieve the effect of "four or two to pull a thousand catties"Good preloading effectBridge erection/assemblyPull forceCable stayed

The invention relates to the field of bridge engineering and discloses a preloading operation method of a high-altitude tower column crossbeam support, which is suitable for cable-stayed bridges, suspension bridges and the like. The method comprises the following steps: S1, a hinged preloading force transmission structure is manufactured. The hinged preloading force transmission structure is formed by a hinged diagonal brace A and a hinged diagonal brace B. The force transmission bracket is connected with a steel pin correspondingly; S2, construction is carried out on that tower column and a support is erected, wherein the tower column is provided with a tower column reserve hole for pas steel wire rope, the horizontal included angle of the tower column reserve hole is 0 DEG, and the bracket legs of the support are embedded in advance and the upper frame bracket legs are embedded in the tower column during construction. After the bracket corbel is finished, the bracket is erected on the bracket corbel, and the upper bracket is erected between the upper bracket corbel. S3, hinged preloading force transmission structure is installed, one end of that steel wire rope is connected withthe articulated preloading force transmission structure, and one end passes through a pre-reserved hole of a tower column; S4, the jack is installed, using the pulling force F (i) n ( / i) exerted on the wire rope by the jack; S5, the hinged preload transfer structure and the jack are removed to complete the preload of the bracket.

Owner:DONGGUAN UNIV OF TECH

Construction method for high-efficient preloading of tower column cross beam support

ActiveCN109235268ASolve the high-altitude operation of preloading technologyAvoid working at heightsBridge erection/assemblyBridge engineeringArchitectural engineering

The invention relates to the field of bridge engineering, and discloses a construction method the high-efficient preloading of a tower column cross beam support. The method comprises the following steps: S1 making a saddle, a support frame and a tensioning steel cushion; S2, a tower column and a support are built, wherein the tower column is embedded with bracket brackets for supporting the support, and the bracket brackets are supported and erected on the bracket brackets; 3, weld that saddle above the two ends of the horizontal bar, weld the bottom steel plate and the top of the bracket, andwelding the tensioning steel pad at the bottom of the two ends of the bracket; S4, a steel strand is used to pass through a hole reserved in a tensioning steel cushion anchor lower plate, and is overlapped on a saddle seat and sandwiched between side plates of the saddle, and then the steel strand is pulled by a jack to realize preloading of the bracket; S5 Remove the saddle, support frame, tension steel pad, steel strand, jack and other structures, complete the pre-compression of the bracket. The device of the invention has the advantages of simple preparation, ingenious structure, convenient operation, convenient construction and high-altitude operation, and solves the defects of traditional high-altitude operation of preloading technology and large workload of conveying materials up and down.

Owner:DONGGUAN UNIV OF TECH

Method of fluidifying peanut shell and producing adhesion agent modifier

InactiveCN101130673AGood preloading effectImprove water resistanceAldehyde/ketone condensation polymer adhesivesForeign matterMethyl aldehyde

The invention discloses a preparing method of earthnut shell liquidation and adhesive modifier, which comprises the following steps: removing soil and foreign matter on the surface of earthnut; drying; disintegrating; mixing the earthnut shell powder and alcohol evenly; adding into inorganic middle strong acid or organic strong acid; reacting for 1. 0-4. 0 h with temperature at 120-160 deg. c; adding into caustic soda solution; adjusting pH value to neutral; decreasing the temperature below 40 deg. c; putting into material; getting the alcohol of earthnut shell powder or carbinol liquefied product; getting lumber adhesive agent modifier for glued board in room; increasing water resistance of gummed product; decreasing methyl aldehyde delivery quantity; producing glued board with urea-formaldehyde glue. This adhesive possesses distinctive prepressing effect, which bonding strength at 1. 3MPa and formaldehyde delivery quantity at 4. 5mg / L.

Owner:北京光纪国际生物科技服务有限公司

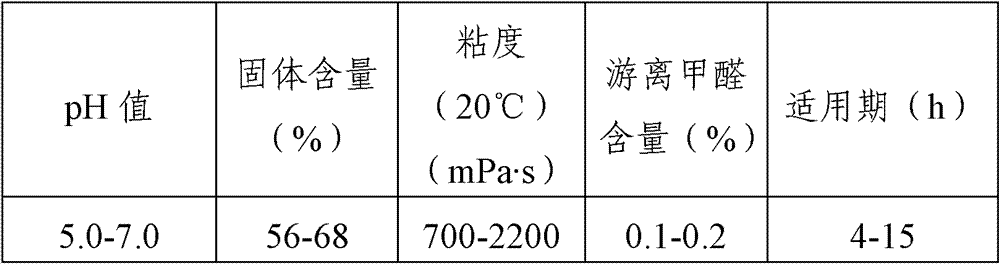

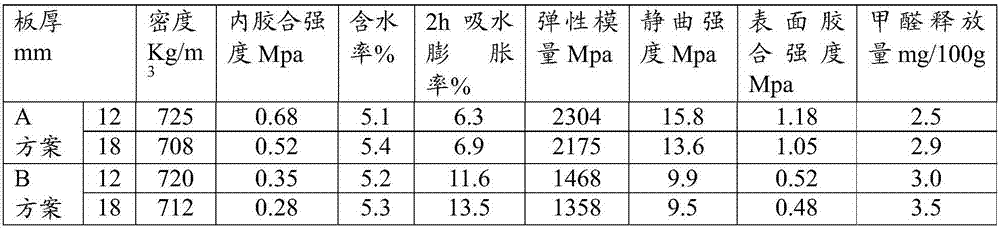

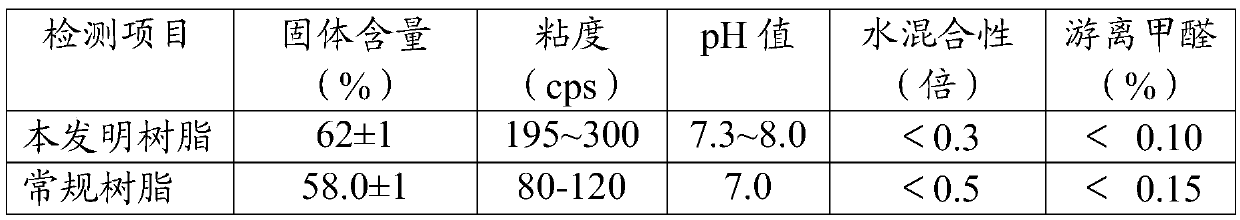

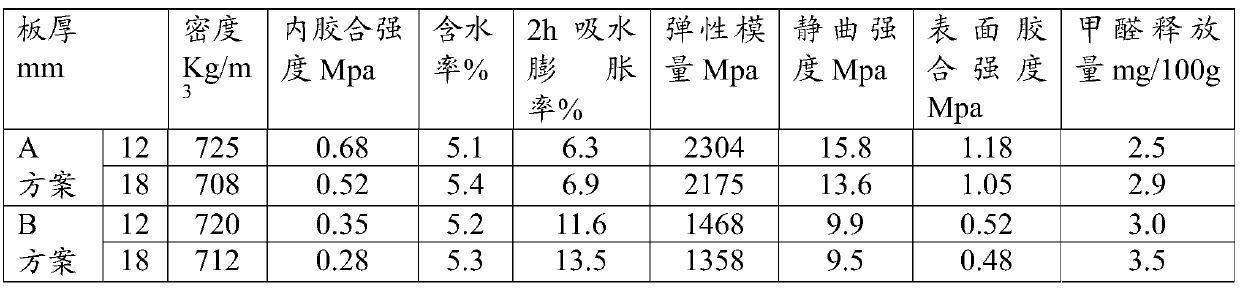

E0-level environment-friendly modified urea formaldehyde resin for shaving board and preparation method thereof

The invention discloses E0-level environment-friendly modified urea formaldehyde resin for a shaving board. In addition, the invention also discloses a preparation method of the E0-level environment-friendly modified urea formaldehyde resin for the shaving board. The preparation method is characterized by adopting high-concentration formaldehyde and urea which are low in molar ratio as raw materials and modifying urea formaldehyde resin by adding polyvinyl alcohol, melamine and a reinforcing agent. Through accurate control of a synthesis technology, a vacuum dewatering technological process is omitted, and the prepared urea formaldehyde resin is low in formaldehyde content, good in pre-pressing property, high in internal binding strength and surface binding strength and low in cost.

Owner:广州市长安粘胶制造有限公司

Urea-formaldehyde resin adhesive with ultra-low formaldehyde release and preparation process thereof

ActiveCN104629662BReduce volatilityStable in natureNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberPolyvinyl alcohol

The invention relates to an ultralow-formaldehyde-release urea-formaldehyde resin adhesive and a preparation process thereof. The preparation process comprises the following steps: adjusting the pH value of a formaldehyde solution by using sodium hydroxide; then adding urea for reaction, and dropwise adding formic acid during the reaction to control the reaction pH value; then under a certain viscosity, adjusting the pH value by using sodium hydroxide; adding hydroxyl methyl cellulose, and adding aluminum sulfate for reaction; adjusting the pH value by using formic acid; adding polyvinyl alcohol and pure water for reaction; and cooling to room temperature to obtain the ultralow-formaldehyde-release urea-formaldehyde resin adhesive. According to the ultralow-formaldehyde-release urea-formaldehyde resin adhesive and the preparation process provided by the invention, the obtained urea-formaldehyde resin adhesive has the characteristics of low formaldehyde release quantity, good pre-pressing property, long opening depositing time, strong initial viscosity and the like, and meanwhile, the solid content is greatly improved, so that the urea-formaldehyde resin adhesive is suitable for production of veneers, shaving boards, fiber boards and ecological boards.

Owner:BEIHUA UNIV

A kind of e0 grade environment-friendly modified urea-formaldehyde resin for particleboard and preparation method thereof

The invention discloses E0-level environment-friendly modified urea formaldehyde resin for a shaving board. In addition, the invention also discloses a preparation method of the E0-level environment-friendly modified urea formaldehyde resin for the shaving board. The preparation method is characterized by adopting high-concentration formaldehyde and urea which are low in molar ratio as raw materials and modifying urea formaldehyde resin by adding polyvinyl alcohol, melamine and a reinforcing agent. Through accurate control of a synthesis technology, a vacuum dewatering technological process is omitted, and the prepared urea formaldehyde resin is low in formaldehyde content, good in pre-pressing property, high in internal binding strength and surface binding strength and low in cost.

Owner:广州市长安粘胶制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com