Modified PAE resin cross-linking agent, modified adhesive and application

A technology of resin cross-linking agent and modifier, applied in the direction of adhesive additives, polymer adhesive additives, adhesives, etc. Social benefits, simple and easy process, high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

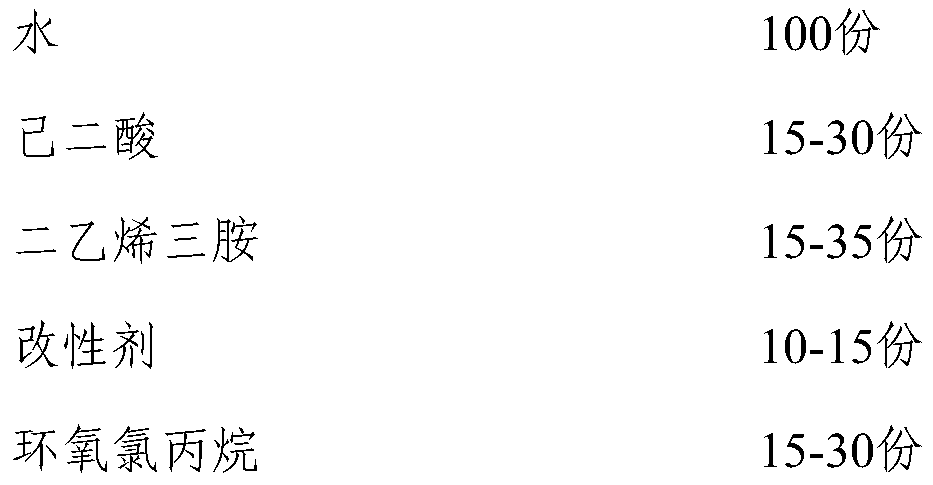

[0058] 1. This embodiment provides a modified PAE resin crosslinking agent, which is made of the following raw materials in parts by weight:

[0059]

[0060] The present embodiment also provides the preparation method of this modified PAE resin crosslinking agent, comprising:

[0061] (1) Preparation of polyamide polyamine intermediate. Add 15kg of adipic acid and 10kg of diethylenetriamine into the reaction kettle, and stir for 30 minutes after the raw materials are completely mixed. Raise the temperature to the predetermined reaction temperature, begin to evaporate the water in the solution, and keep the temperature for 5 hours. After the water is evaporated to dryness, stop heating immediately, add a certain proportion of water to adjust the solid content to 30wt% when the temperature is lowered to below 120°C, and stop stirring after stirring until homogeneous. The whole process was protected by nitrogen gas.

[0062] (2) Preparation of grafted catechol group prepol...

Embodiment 2

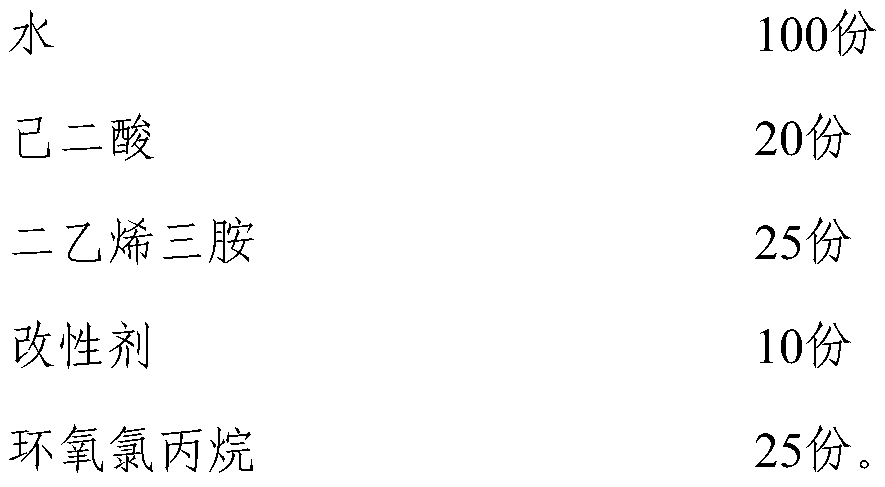

[0077] 1. This embodiment provides a modified PAE resin crosslinking agent, which is made of the following raw materials in parts by weight:

[0078]

[0079] The present embodiment also provides the preparation method of this modified PAE resin crosslinking agent, comprising:

[0080] (1) Preparation of polyamide polyamine intermediate. Add 15kg of adipic acid and 10kg of diethylenetriamine into the reaction kettle, and stir for 30 minutes after the raw materials are completely mixed. Raise the temperature to the predetermined reaction temperature, begin to evaporate the water in the solution, and keep the temperature for 5 hours. After the water is evaporated to dryness, stop heating immediately, add a certain proportion of water to adjust the solid content to 30wt% when the temperature is lowered to below 120°C, and stop stirring after stirring until homogeneous. The whole process was protected by nitrogen gas.

[0081] (2) Preparation of grafted catechol group prepol...

Embodiment 3

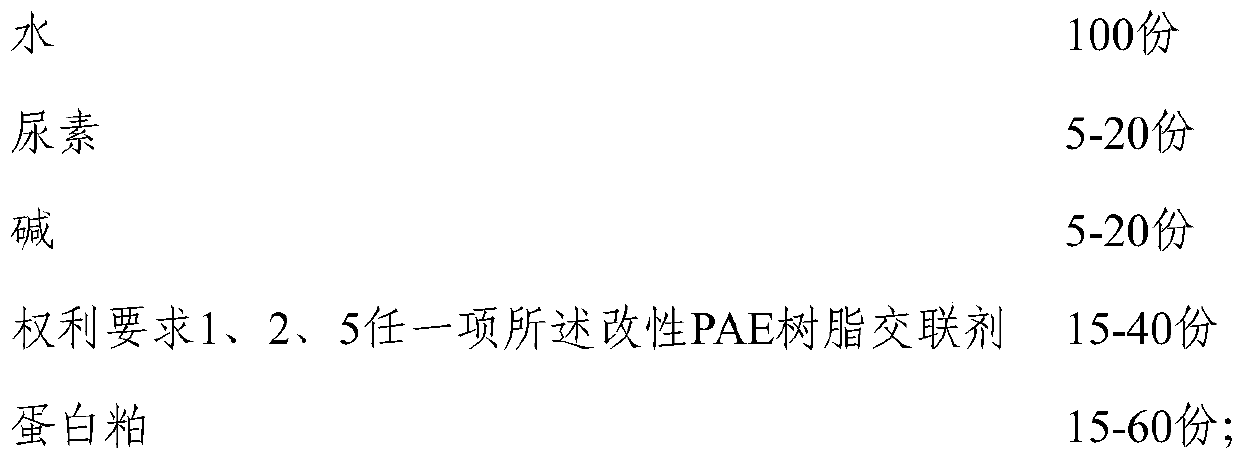

[0095] 1. This embodiment provides a modified PAE resin crosslinking agent, which is made of the following raw materials in parts by weight:

[0096]

[0097] The present embodiment also provides the preparation method of this modified PAE resin crosslinking agent, comprising:

[0098] (1) Preparation of polyamide polyamine intermediate. Add 15kg of adipic acid and 10kg of diethylenetriamine into the reaction kettle, and stir for 30 minutes after the raw materials are completely mixed. Raise the temperature to the predetermined reaction temperature, begin to evaporate the water in the solution, and keep the temperature for 5 hours. After the water is evaporated to dryness, stop heating immediately, add a certain proportion of water to adjust the solid content to 30wt% when the temperature is lowered to below 120°C, and stop stirring after stirring until homogeneous. The whole process was protected by nitrogen gas.

[0099] (2) Preparation of grafted catechol group prepol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com