Method for preparing biological oil modified urea resin adhesive

A urea-formaldehyde resin and bio-oil technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of poor water resistance, poor aging resistance and high free formaldehyde release of urea-formaldehyde resin adhesives , to achieve the effect of reducing formaldehyde emission, improving resin performance, and broadening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of bio-oil modified urea-formaldehyde resin that the present invention proposes is described in detail as follows in conjunction with embodiment:

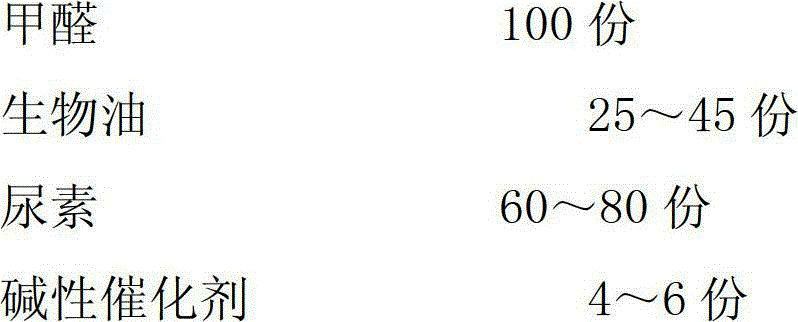

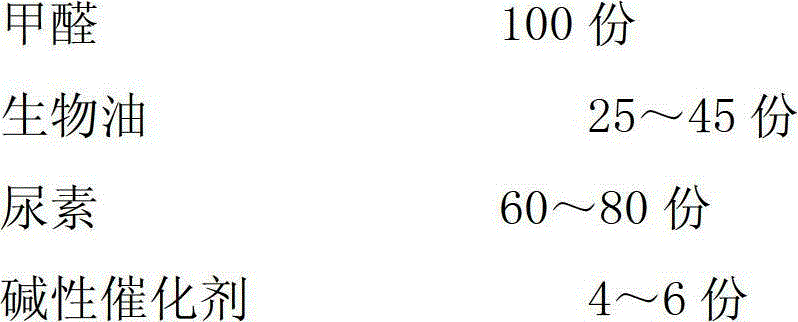

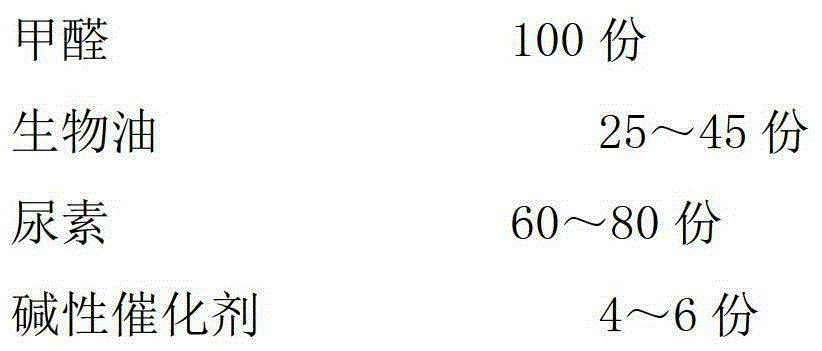

[0019] The preparation method of bio-oil modified urea-formaldehyde resin that the present invention proposes, the mass parts of each component in the raw material used are as follows:

[0020]

[0021] The preparation method comprises the following steps:

[0022] (1) Add formaldehyde, bio-oil and basic catalyst in the same mass parts as above into the reaction vessel, and react at 65-75°C for 20-30 minutes to obtain hydroxymethylated bio-oil;

[0023] (2) Add 75% of the urea according to the above ratio into the reaction vessel, raise the temperature to 85°C, use an acidic pH regulator to adjust the pH of the reaction body in the reaction vessel to 7.5-8.5, and keep warm for 60-90°C. minute;

[0024] (3) Adjust the pH of the reaction system in the reaction vessel to 4.8 to 5.2 with an acidic pH ...

Embodiment 1

[0029] (1) Add 100g of formaldehyde, 25g of bio-oil and 4g of sodium hydroxide into an aqueous solution with a mass concentration of 20% into the reaction vessel, and react at 65°C for 30 minutes to obtain hydroxymethylated bio-oil;

[0030] (2) Add 45g of urea to the above-mentioned hydroxymethylated bio-oil, raise the temperature to 85°C, adjust the pH to 7.5-8.0 with phosphoric acid with a mass concentration of 4%, and keep it warm for 60 minutes;

[0031] (3) Use phosphoric acid with a mass concentration of 4% to adjust the pH to 4.8-5.0, then add 15g of urea, and control the temperature of the system at 90±2°C. Within 60 minutes of the reaction, when the resin is dripped into clean water, it will become white mist and not After dispersing, adjust the pH to 8.0 with 8% sodium hydroxide within 5 minutes, and keep it warm for 10 minutes to obtain bio-oil modified urea-formaldehyde resin.

Embodiment 2

[0033] (1) Add 100g of formaldehyde, 30g of bio-oil and 6g of sodium hydroxide into an aqueous solution with a mass concentration of 30% into the reaction vessel, and react at 70°C for 30 minutes to obtain hydroxymethylated bio-oil;

[0034] (2) Add 48.75g of urea to the above-mentioned hydroxymethylated bio-oil, raise the temperature to 85°C, adjust the pH to 7.5-8.0 with formic acid with a mass concentration of 4%, and keep it warm for 70 minutes;

[0035] (3) Use formic acid with a mass concentration of 4% to adjust the pH to 4.8-5.0, then add 16.25g of urea, and control the system temperature at 90±2°C. Within 60 minutes of the reaction, when the resin is dripped into clear water, it will become white mist and After not dispersing, within 5 minutes, use 8% sodium hydroxide to adjust the pH to 8.0, and keep it warm for 20 minutes to obtain bio-oil modified urea-formaldehyde resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com