Method for jointly preparing carbon nanotube/porous carbon material and hydrogen-rich synthesis gas through biomass pyrolysis

A biomass pyrolysis and porous carbon material technology is applied in the field of biomass pyrolysis combined preparation of carbon nanotubes/porous carbon materials and hydrogen-rich synthesis gas, which can solve the problems of high equipment requirements, high reaction temperature, and increased utilization costs. , to achieve the effect of improving solubility, enhancing interaction and realizing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

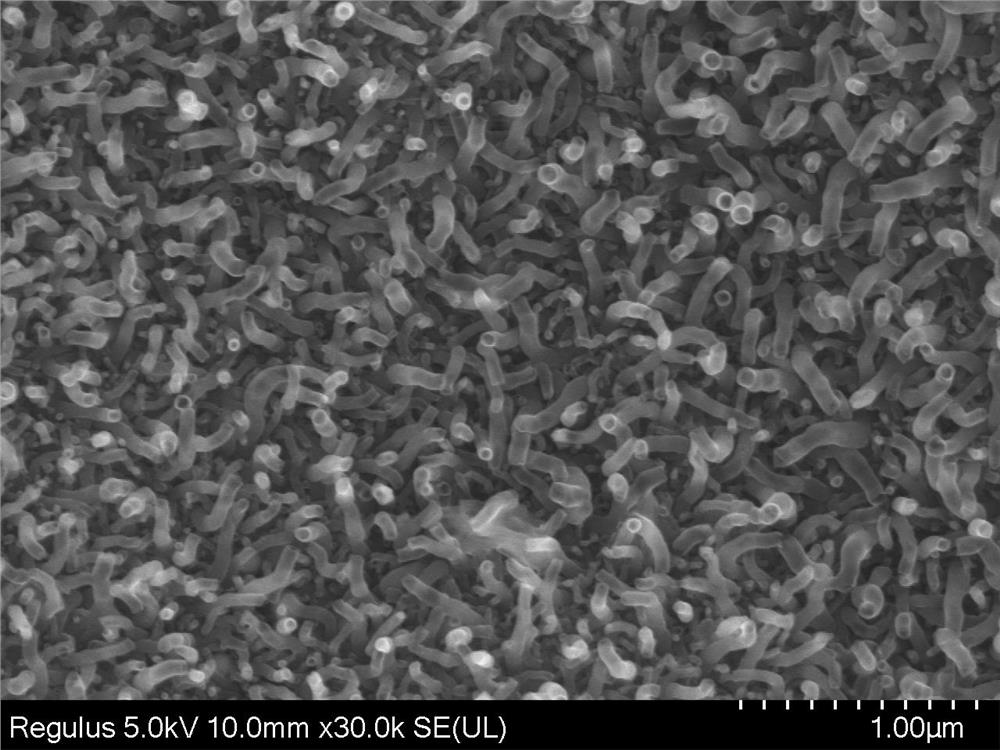

[0023] The experiment used corn stalk powder as raw material. Corn straw particles with a particle size of 50 mesh were selected, washed with deionized water, and dried at 105 °C for 24 h. The dried material was collected in a sample bag for later use. Take 0.01 mol NiCl 2 ﹒ 6H 2 O with 0.01 mol CaCl 2 ﹒ 2H 2 O was dissolved in 1500mL of water, and then 10.0 g of dry corn stover powder was impregnated in the above NiCl 2 and CaCl 2 In the mixed solution of corn stalk powder and NiCl 2 and CaCl 2 The mixed solution was fully contacted, and then dried in a drying oven at 105 °C for 24 h to obtain a Ni-Ca-loaded dry material. Take 5.0 g of the obtained Ni-Ca-loaded dry material and heat it on a fixed bed at 800 °C for 60 min under an inert atmosphere with a nitrogen flow rate of 150 ml / min. The solid product obtained by pyrolysis is carbon nanotube / porous carbon material, and its SEM image is as follows figure 1 shown. The gas obtained by pyrolysis is purified by ...

Embodiment 2

[0026] The experiment used corn stalk powder as raw material. Corn straw particles with a particle size of 50 mesh were selected, washed with deionized water, and dried at 105 °C for 48 h. The dried material was collected in a sample bag for later use. Take 0.03 mol NiCl 2 ﹒ 6H 2 O with 0.03 mol CaCl 2 ﹒ 2H 2 O was dissolved in 3000mL of water, and then 10.0 g of dry corn stover powder was impregnated in the above NiCl 2 and CaCl 2 In the mixed solution of corn stalk powder and NiCl 2 and CaCl 2 The mixed solution was fully contacted, and then dried in a drying oven at 105 °C for 48 h to obtain a Ni-Ca-loaded dry material. Take 5.0 g of the obtained Ni-Ca-loaded dry material and heat it on a fixed bed at 800 °C for 60 min under an inert atmosphere with a nitrogen flow rate of 150 ml / min. The solid product obtained by pyrolysis is carbon nanotube / porous carbon material. The gas obtained by pyrolysis is purified by 3000 ml of 0.005g / ml calcium hydroxide solution (t...

Embodiment 3

[0028] The experiment used corn stalk powder as raw material. Corn straw particles with a particle size of 50 mesh were selected, washed with deionized water, and dried at 105 °C for 24 h. The dried material was collected in a sample bag for later use. Take 0.05 mol NiCl 2 ﹒ 6H 2 O with 0.05 mol CaCl 2 ﹒ 2H 2 O was dissolved in 5000mL of water, and then 10.0 g of dry corn stover powder was impregnated in the above NiCl 2 and CaCl 2 In the mixed solution of corn stalk powder and NiCl 2 and CaCl 2The mixed solution was fully contacted, and then dried in a drying oven at 105 °C for 24 h to obtain a Ni-Ca-loaded dry material. Take 5.0 g of the obtained Ni-Ca-loaded dry material and heat it on a fixed bed at 800 °C for 60 min under an inert atmosphere with a nitrogen flow rate of 150 ml / min. The solid product obtained by pyrolysis is carbon nanotube / porous carbon material. The gas obtained by pyrolysis is purified by 5000 ml of 0.002g / ml calcium hydroxide solution (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com