Patents

Literature

54results about How to "Realize economic value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

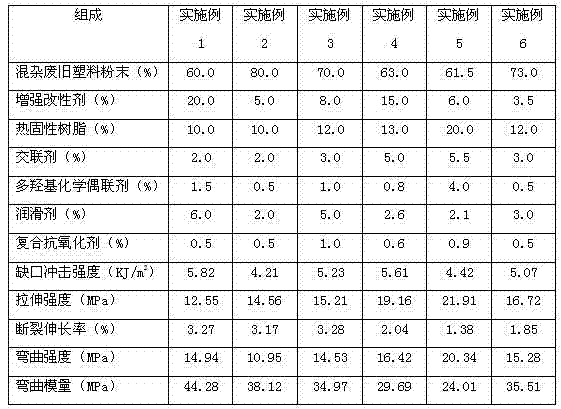

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

Intensive processing method for stalk articles or agricultural castoff

InactiveCN101492700AEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperature sterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

Method for producing xylose coupled cogeneration of propanone, butanol and ethanol using stalk

InactiveCN101358218AIncrease profitNot easy to useBiofuelsMicroorganism based processesSocial benefitsCellulose

The invention provides a method for producing xylose co-produced with acetone, butanol and ethanol by utilizing straws. The straws are hydrated by acid to be filtered to be divided into xylose hydrolysis fluid and xylose residue; the xylose residue is zymohydrolyzed, fermented and rectified to prepare the acetone, the butanol and the ethanol; the xylose hydrolysis fluid is used for preparing the xylose. The method of producing xylose co-produced with acetone, butanol and ethanol by utilizing straws of the invention realizes the maximization of the cellulose straw substances, not only the straw resources are fully utilized to realize changing waste into valuable and the added value of products is improved to realize the economic value of the straws, but also the new raw material source and methods for the production of the acetone and the ethanol are developed and more economic benefits and social benefits are brought to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

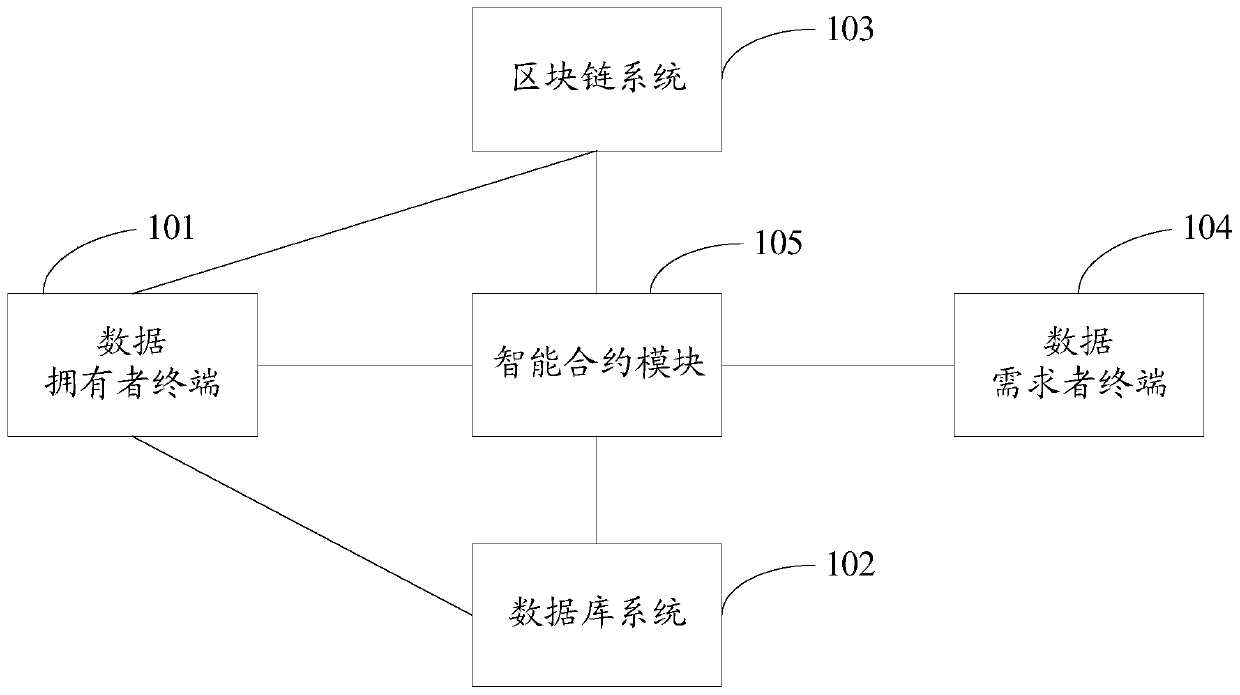

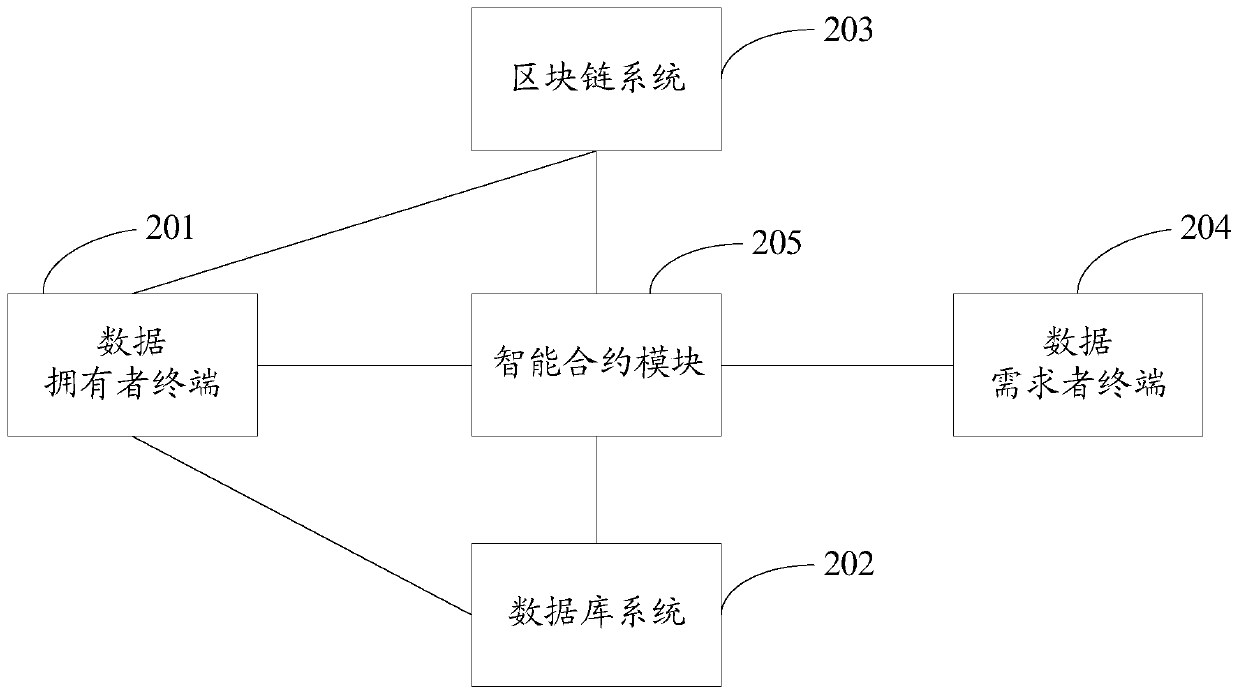

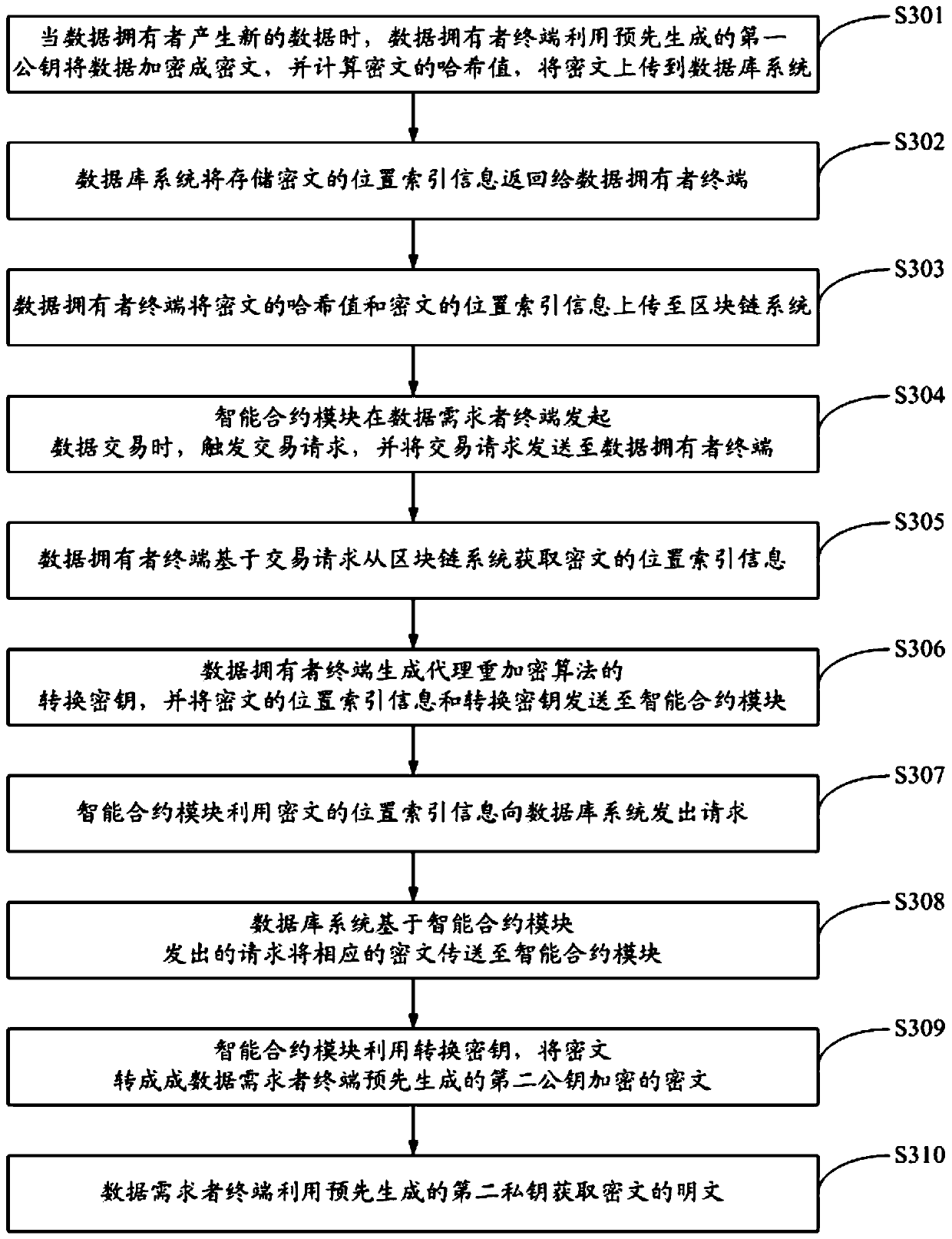

Blockchain data transaction system and method based on proxy re-encryption and smart contract

ActiveCN110430186AGuaranteed privacy and securityRealize economic valueKey distribution for secure communicationFinanceTransaction dataData needs

The invention discloses a blockchain data transaction system and a blockchain data transaction method based on proxy re-encryption and an intelligent contract. The system comprises a data owner terminal, a database system, a blockchain system, a data demander terminal and an intelligent contract module. According to the method, the security privacy of the transaction data can be ensured by using the proxy re-encryption technology, and the efficient and automatic execution of the data transaction can be realized by using the smart contract, so that the security privacy and efficiency problems of the blockchain data transaction are solved. The economic value of the data is realized, and the application value of the data is brought into full play.

Owner:STATE GRID E COMMERCE CO LTD +2

Method for predicting power load

InactiveCN101706778AOvercome incompletenessEffective predictionSpecial data processing applicationsAc network circuit arrangementsLoad forecastingAlgorithm

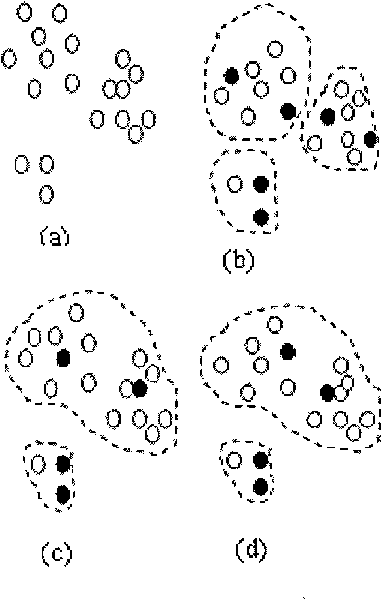

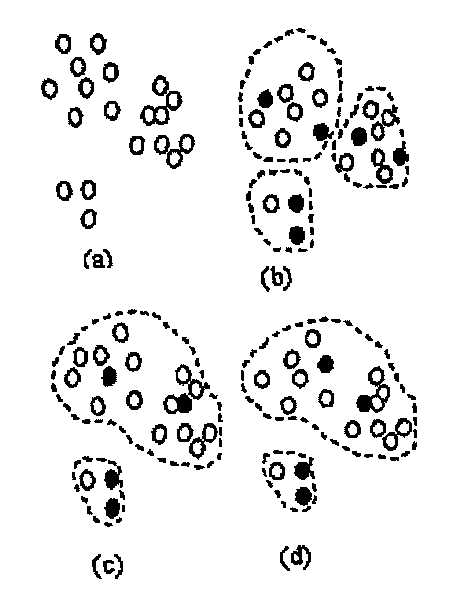

The invention relates to a method for predicting power load and provides the power load prediction method which can better solve the problem of low accuracy. The invention provides application thereof in load prediction based on CURE algorithm. Application of the CURE algorithm in the load prediction comprises the following steps: (1) extracting data sample from a historical database of load prediction; (2) adopting hierarchical algorithm to cluster each sub-region of the data sample; and (3) clustering all the data in the sample and inputting representative points only including clusters found when all sub-regions cluster independently.

Owner:王阳

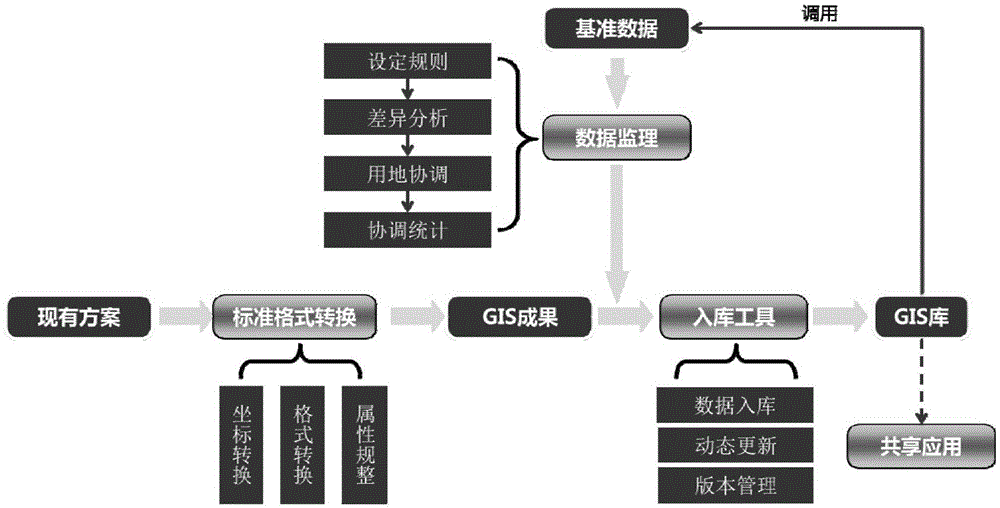

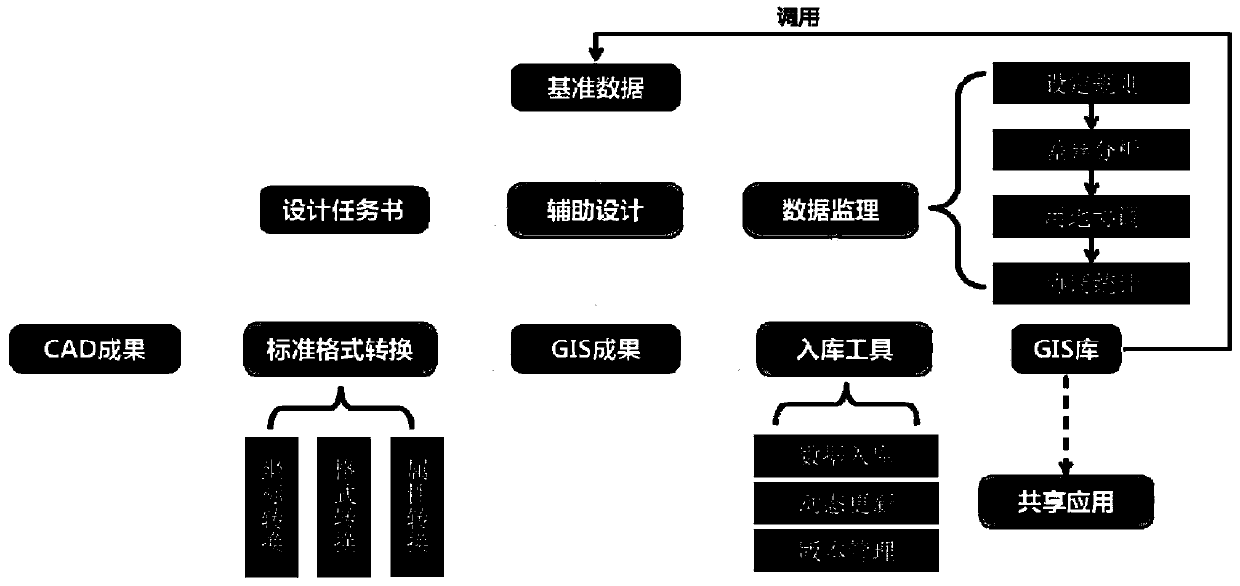

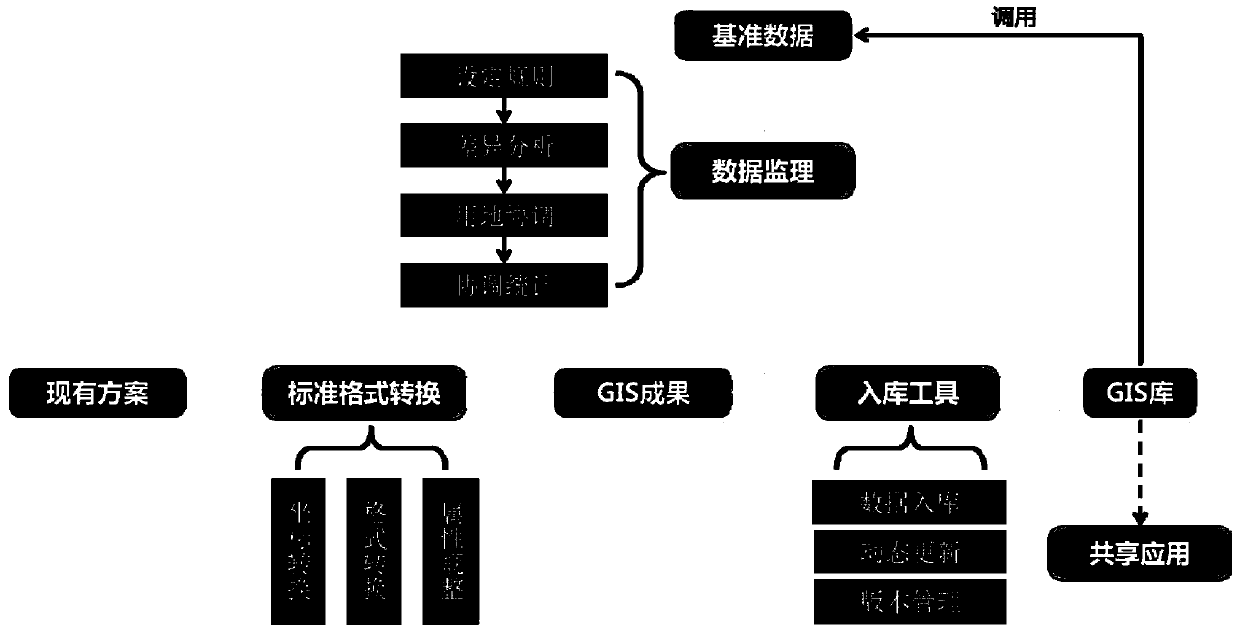

Method for realizing ''more rules one'' electronic approval of multi-type planning scheme

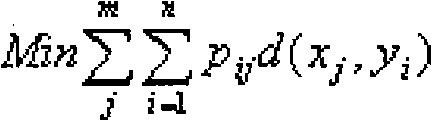

ActiveCN105354267ARealize full lifecycle managementEasy to implementOffice automationGeographical information databasesBaseline dataComputer science

The invention relates to a method for realizing ''more rules one'' electronic approval of multi-type planning schemes. The method comprises: presetting a GIS (Geographic Information System) database; extracting / reading reference data from the GIS database; creating or entering a space planning scheme for an electronic approval system; comparing the space planning scheme with the reference data, and coordinating a land block; and storing the coordinated / processed space planning scheme into the GIS database. According to the method disclosed by the invention, contradiction of the space planning scheme among various departments can be solved, administrative examination efficiency is improved, and economic values of construction land are realized to a maximum limit.

Owner:广东绘宇智能勘测科技有限公司

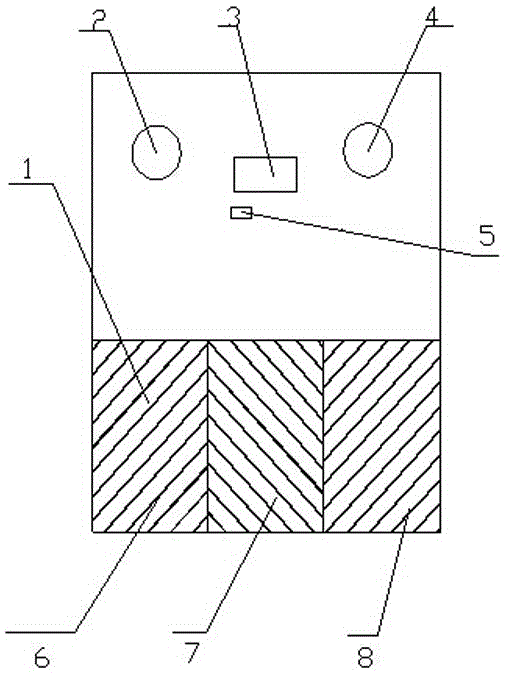

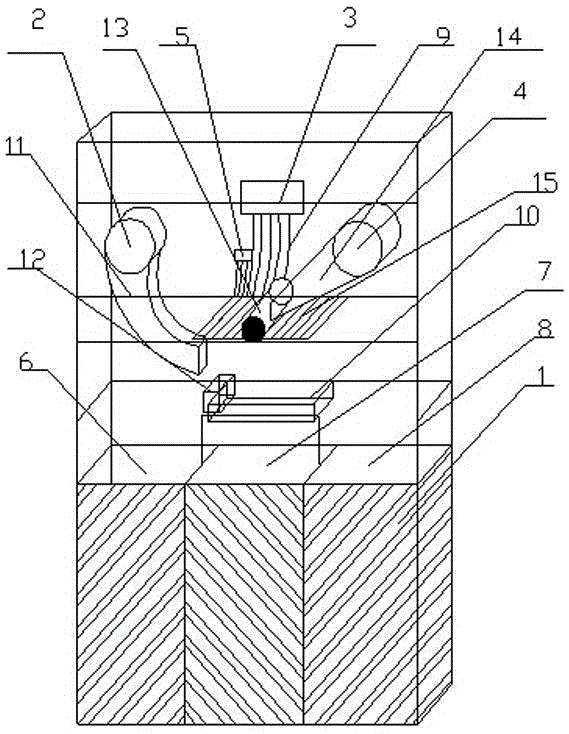

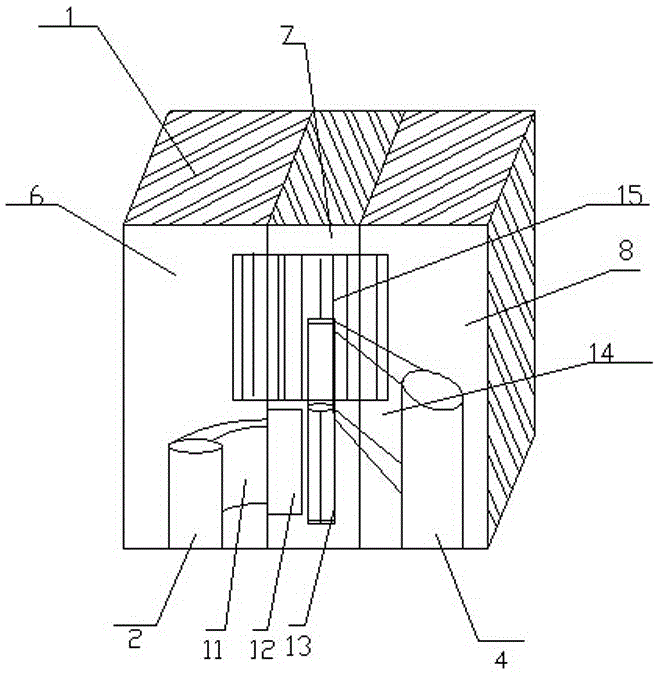

Beverage bottle paid recycling machine and using method thereof

InactiveCN105788073AMake recycling workExcellent mechanical propertiesGlass recyclingPlastic recyclingCompression deviceEngineering

The invention discloses a beverage bottle paid recycling machine and a using method thereof. The beverage bottle paid recycling machine comprises a machine body. The machine body is composed of an inlet device, a compression device, a classification device, a feedback charging system and a buffer system. The mechanical characteristics are obvious, the machine has the advantages of being easy to operate, low in power consumption and good in recycling effect, is placed at a place with dense population and can recycle beverage bottles, the recycling rate is greatly increased, and the environment-friendly value is obtained; a user can independently and selectively put beverage bottles according to the varieties of the beverage bottles, feedback is performed after recycling is completed to an IC card of the user for charging, paid recycling is achieved, and economic value is obtained; plastic, iron and aluminum beverage jars and bottles and glass bottles are automatically received, automatic feedback is performed after recycling is completed to the magnetic card of the user for charging, and therefore the problems that the garbage can recycling mode is single, no compression is performed, and the occupied space is large are solved.

Owner:BINZHOU UNIV

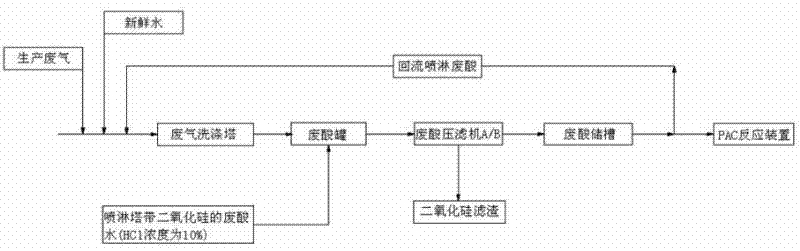

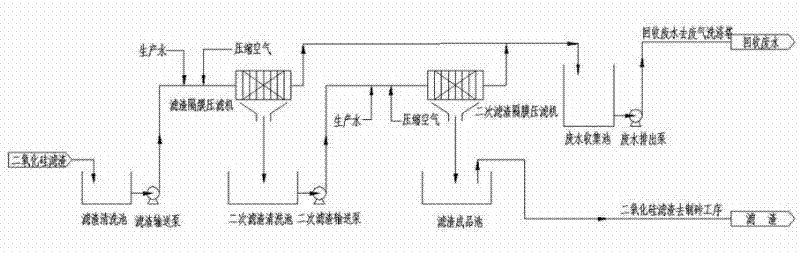

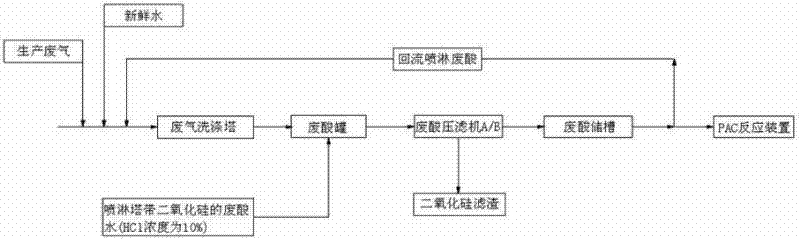

Baking-free brick and method for utilizing silicon sludge formed in polycrystalline silicon production to manufacture baking-free brick

The invention discloses a baking-free brick and a method for utilizing silicon sludge formed in polycrystalline silicon production to manufacture the baking-free brick and belongs to the technical field of treatment for the silicon sludge formed during the polycrystalline silicon production process. The method for utilizing silicon sludge formed in polycrystalline silicon production to manufacture the baking-free brick provided by the invention comprises the following steps of: 1) dechlorinating and filtering the silicon sludge; 2) adding aggregates and cement into the silicon sludge, and carrying out compression moulding; and 3) naturally maintaining. An environment-friendly application capable of generating economic value is supplied to the treatment for the silicon sludge; the recycling of the wastes of the silicon sludge is realized; and the environment is protected. The baking-free brick provided by the invention comprises the following components by weight percent: 30%-60% of silicon sludge, 6%-8% of cement and the balance aggregates, wherein the water content of the silicon sludge is 10%-35% and the grain size of the aggregates is 0.5mm-10mm. The baking-free brick provided by the invention is practicable to reuse the silicon sludge; the wastes are reused; the environmental pollution is reduced; the cost is low; and the baking-free brick is suitable for being popularized.

Owner:SICHUAN RENESOLA SILICON MATERIAL

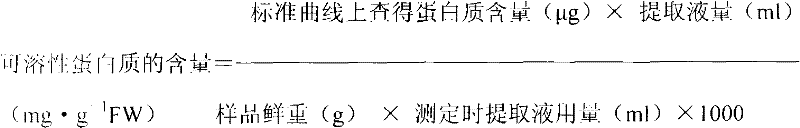

Method for substituting for flaveria bidentis by utilizing grain amaranth

InactiveCN101743836AReduced germination rateLower average plant heightWeed killersHorticultureFlaveria bidentisPasture

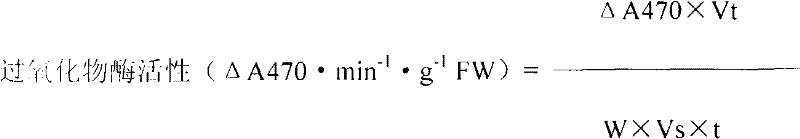

The invention provides a method for substituting for flaveria bidentis by utilizing grain amaranth; in the method, the grain amaranth is adopted to carry out biological substitution to the flaveria bidentis; the method can lead the germination rate of the flaveria bidentis to be reduced by 80.43 percent, the average plant height is reduced by 77.30 percent, the average single plant branches are reduced by 98.96 percent, the average single plant leaves are reduced by 99.14 percent, the average single plant biomass liveweight is reduced by 92.54 percent, the average soluble protein content is reduced by 52.99 percent, and the method has remarkable control function to the foreign invasion of the flaveria bidentis; the grain amaranth is a common plant, the seed is easy to obtain, the planting method is simple, and the operation is easy; the grain amaranth is pasture with good quality, while controlling the population quantity of the flaveria bidentis, the grain amaranth has a certain economical value.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

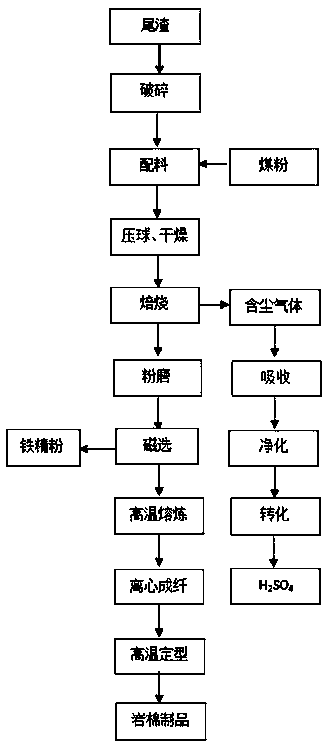

Method for comprehensively utilizing residual tailings after extracting precious metals from acid pickling sludge

InactiveCN103725878ARealize economic valueEasy to operateRotary drum furnacesSulfur compoundsSludgeTailings

The invention particularly relates to a method for comprehensively utilizing residual tailings after extracting precious metals from acid pickling sludge. The method is suitable for processing the residual tailings after recycling the precious metals from the acid pickling sludge through an acid leaching method. The method disclosed by the invention has the advantages that the residual tailings after extracting the precious metals from the acid pickling sludge can be comprehensively recycled to be prepared into powdered iron, rock wool products and sulfuric acid, so that the economic value is effectively realized; the method is simple in operation process, popular in raw material, low in production cost and remarkable in economic effect; the residual tailings are effectively and comprehensively utilized by means of the method disclosed by the invention, so that the discharge of the tailings is reduced, the land is saved and the environment is effectively protected.

Owner:王洪

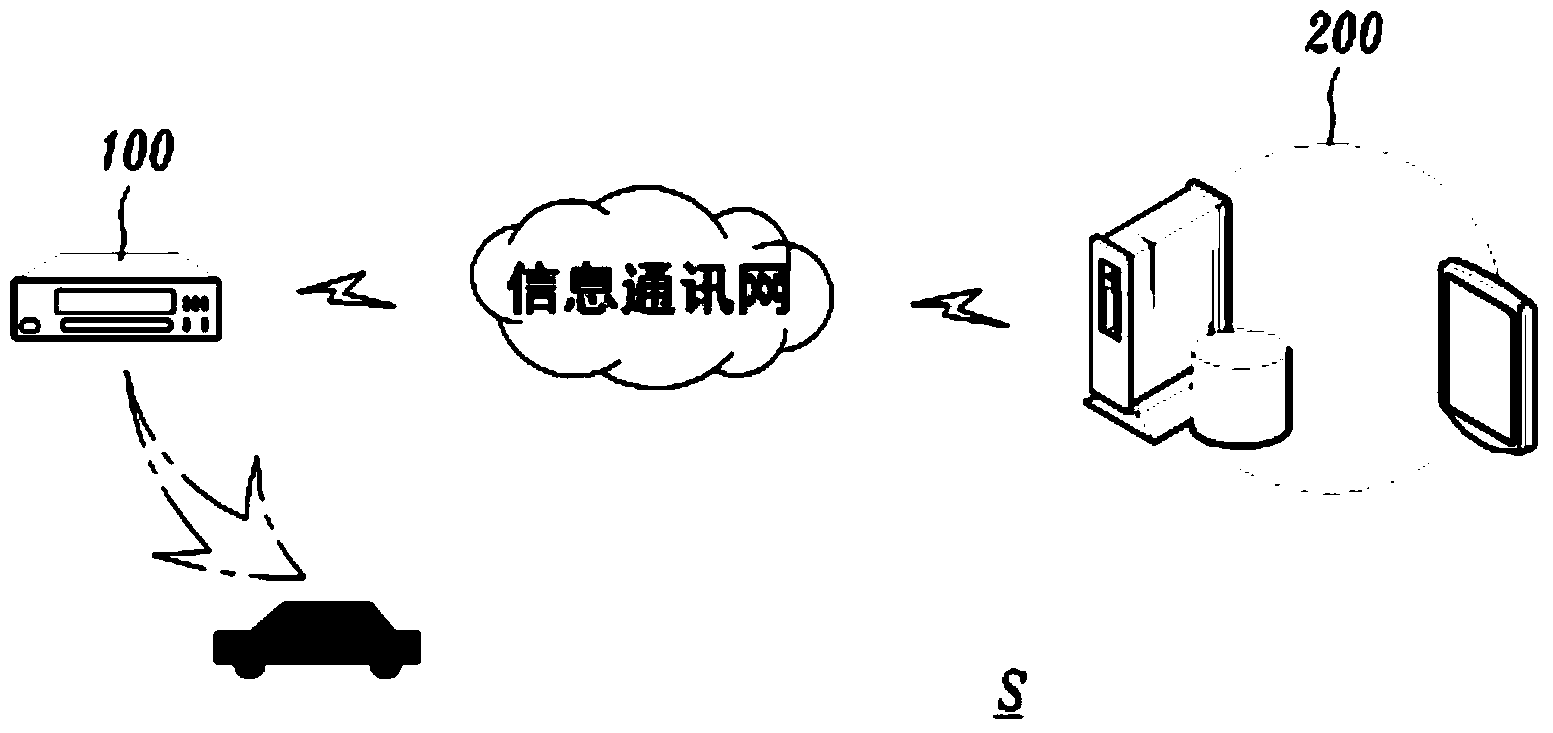

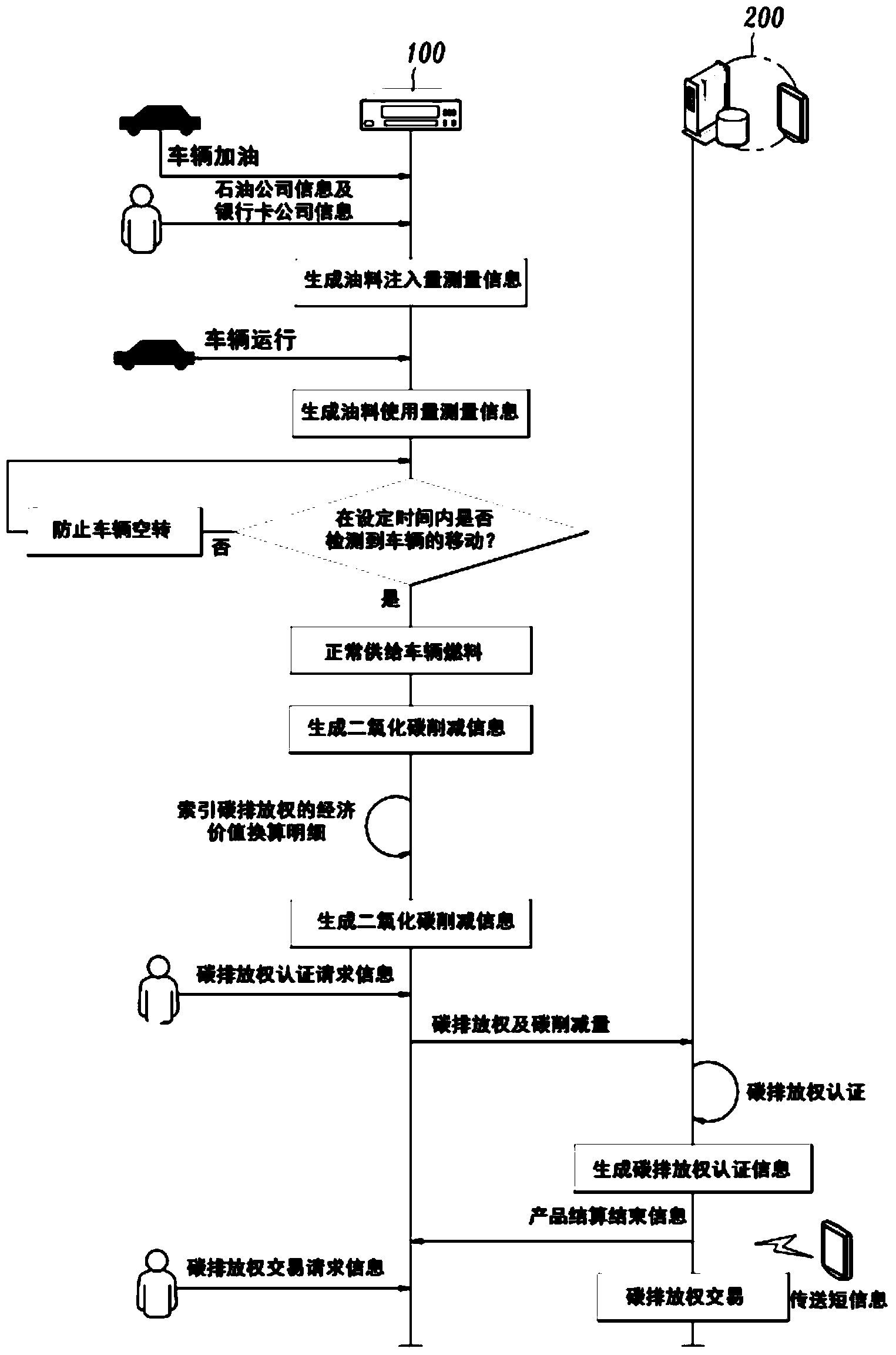

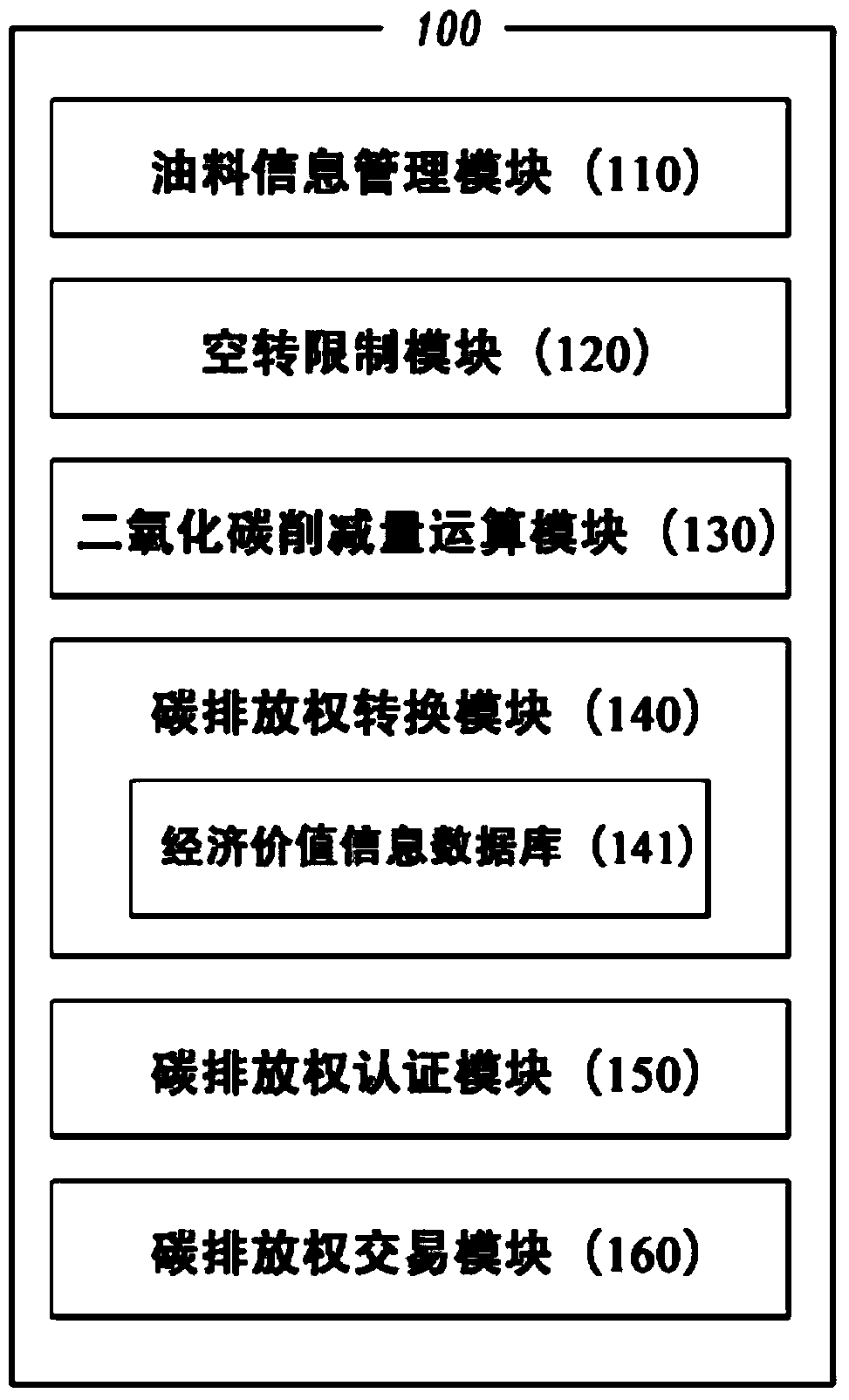

System for converting greenhouse gas emissions to carbon credit and method for same

InactiveCN103635919ATackling warmingRealize economic valueRegistering/indicating working of vehiclesTechnology managementCarbon creditEconomic benefits

The present invention relates to a system for converting greenhouse gas emissions to carbon credit and a method for the same. The system for converting the greenhouse gas emissions to carbon credit includes a carbon emission reduction device which detects an amount of fuel filled in a vehicle and an amount of fuel used by the vehicle, minimizes the supply of fuel to the engine of the vehicle to prevent excessive fuel consumption and limit carbon emissions when the vehicle does not move within a preset time, supplies fuel to the engine of the vehicle in a normal manner when the vehicle is moved according to detection of the acceleration pedal of the vehicle, generates carbon dioxide reduction information by adding or subtracting an emitted amount of carbon dioxide that is limited during an idling prevention time to or from the emitted amount of carbon dioxide of the vehicle, and converts the carbon dioxide reduction information to carbon credit which includes a generated economic value upon reduction of a ton of carbon emissions. According to the present invention, a greenhouse gas reference emission amount for the vehicle may be reduced, and the greenhouse gas reduction amount for the vehicle may be converted into carbon credit that includes an economic value through the carbon emission reduction device so as to induce active participation by individuals for the reduction of greenhouse gas. Thus, the country, companies, and also individuals may play a role in resolving the problem of global warming, and the economic value of carbon credit generated by reducing the greenhouse gas from the vehicle may be sold or transferred to or acquired from the country or companies to provide economic benefit to the individual and stable growth for the companies.

Owner:ECONURI +2

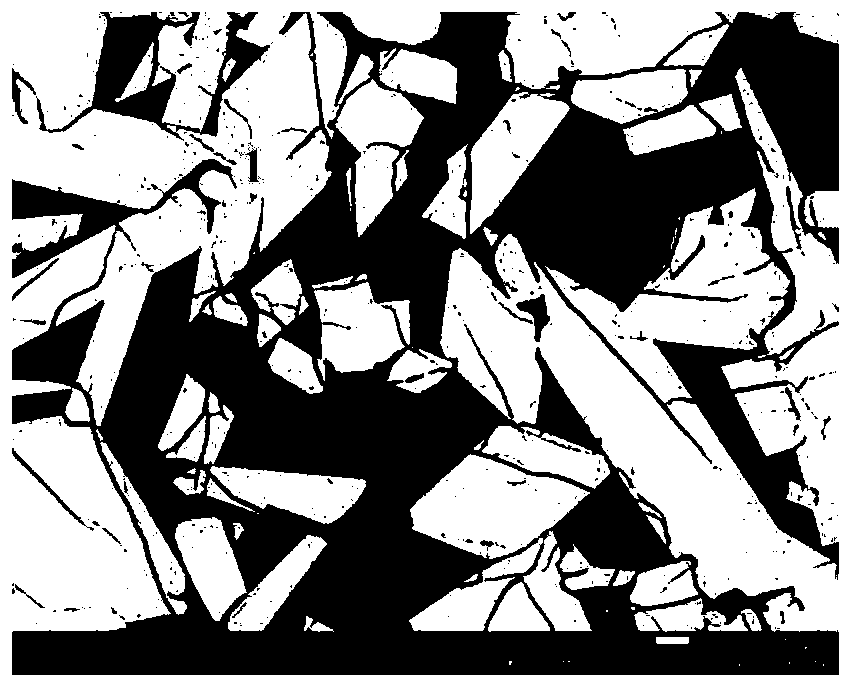

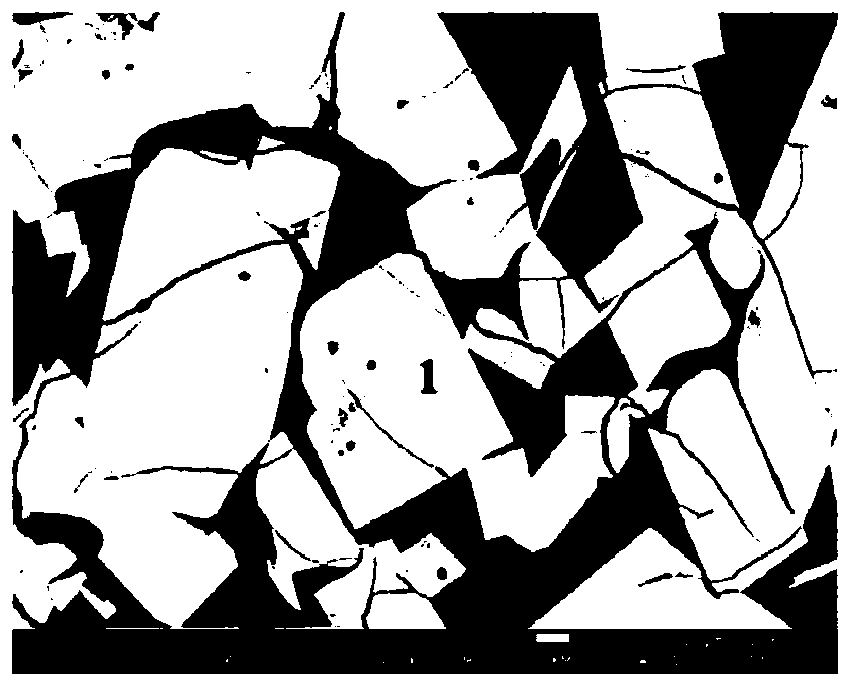

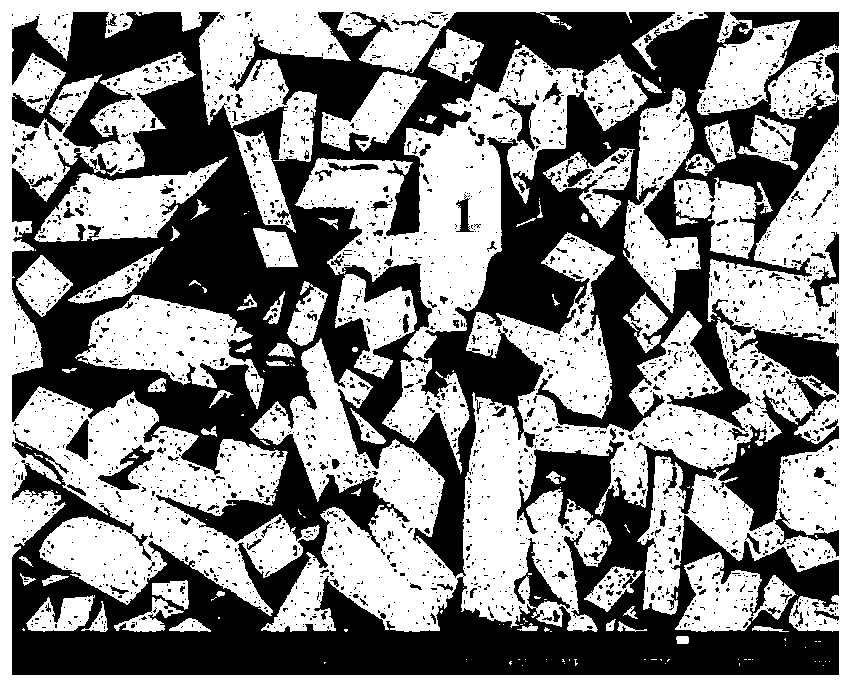

A method for controlling the crystallization phase of molten titanium slag

ActiveCN107653380BPromote crystallizationRaise the gradeProcess efficiency improvementSulfateReducer

The invention relates to a method for adjusting and controlling a melt separation titanium slag crystallization phase. According to the method, the components of titanium slag are adjusted and controlled to comprise, by weight, 40-70% of TiO2, 4-18% of MgO, 4-18% of Al2O3 and a reducer, wherein the weight ratio of the reducer to TiO2 is 0.01-0.15; and the titanium slag is heated to be melted, after complete reacting, the temperature is decreased to be 1300-1500 DEG C at the speed rate of 0.1-20 DEG C / min for quenching treatment so as to obtain the melt separation titanium slag. According to the method for adjusting and controlling the melt separation titanium slag crystallization phase, through adjusting and controlling over the components and controlling over the crystallization process,anosovite becomes a sole precipitated phase of the melt separation titanium slag, the TiO2 grade of an anosovite titanium-rich phase in the melt separation titanium slag is high, the grain size is large, the mineral phase structure is compact, the single separation degree is high, and after subsequent treatment, the high-grade titanium slag with the TiO2 grade being 76% or above can be obtained. According to the method for adjusting and controlling the melt separation titanium slag crystallization phase, the requirement of a sulfate process titanium dioxide technique for the titanium slag grade is met, and the method is suitable for industrialized application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

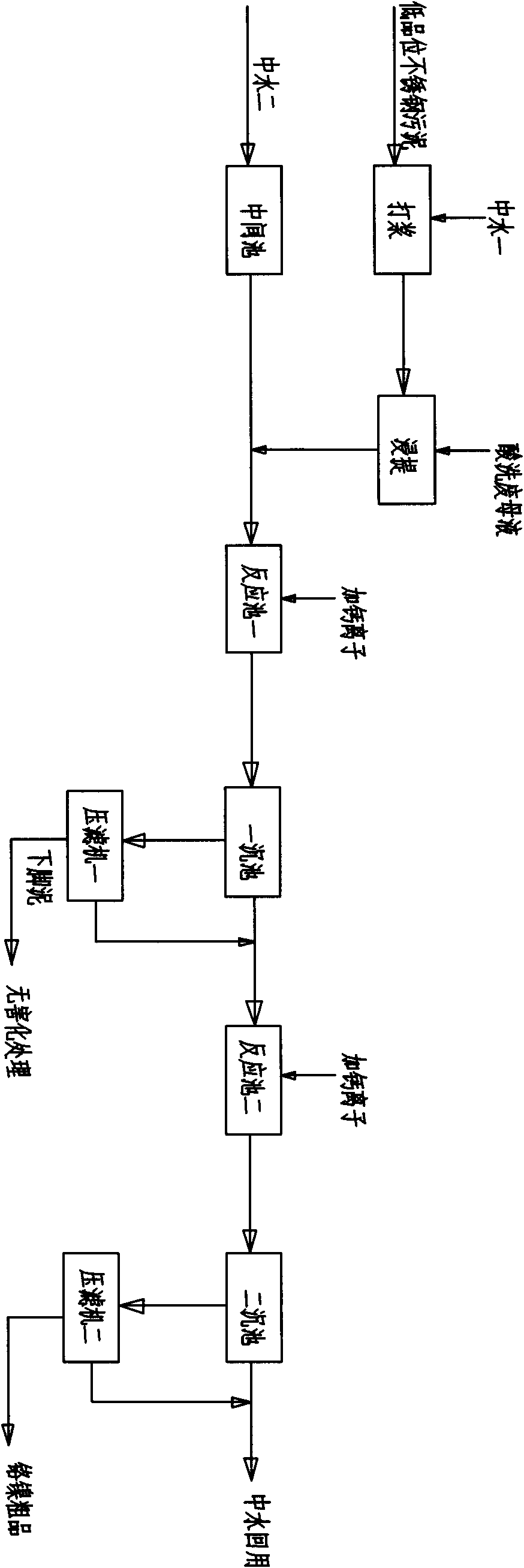

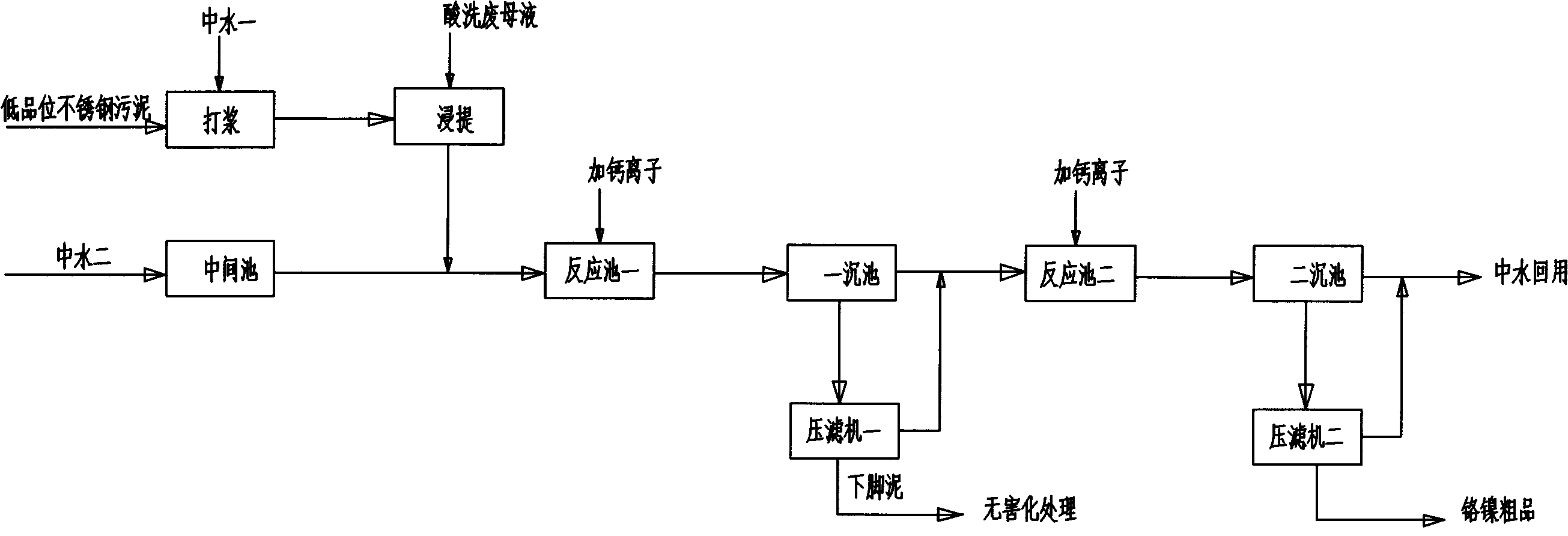

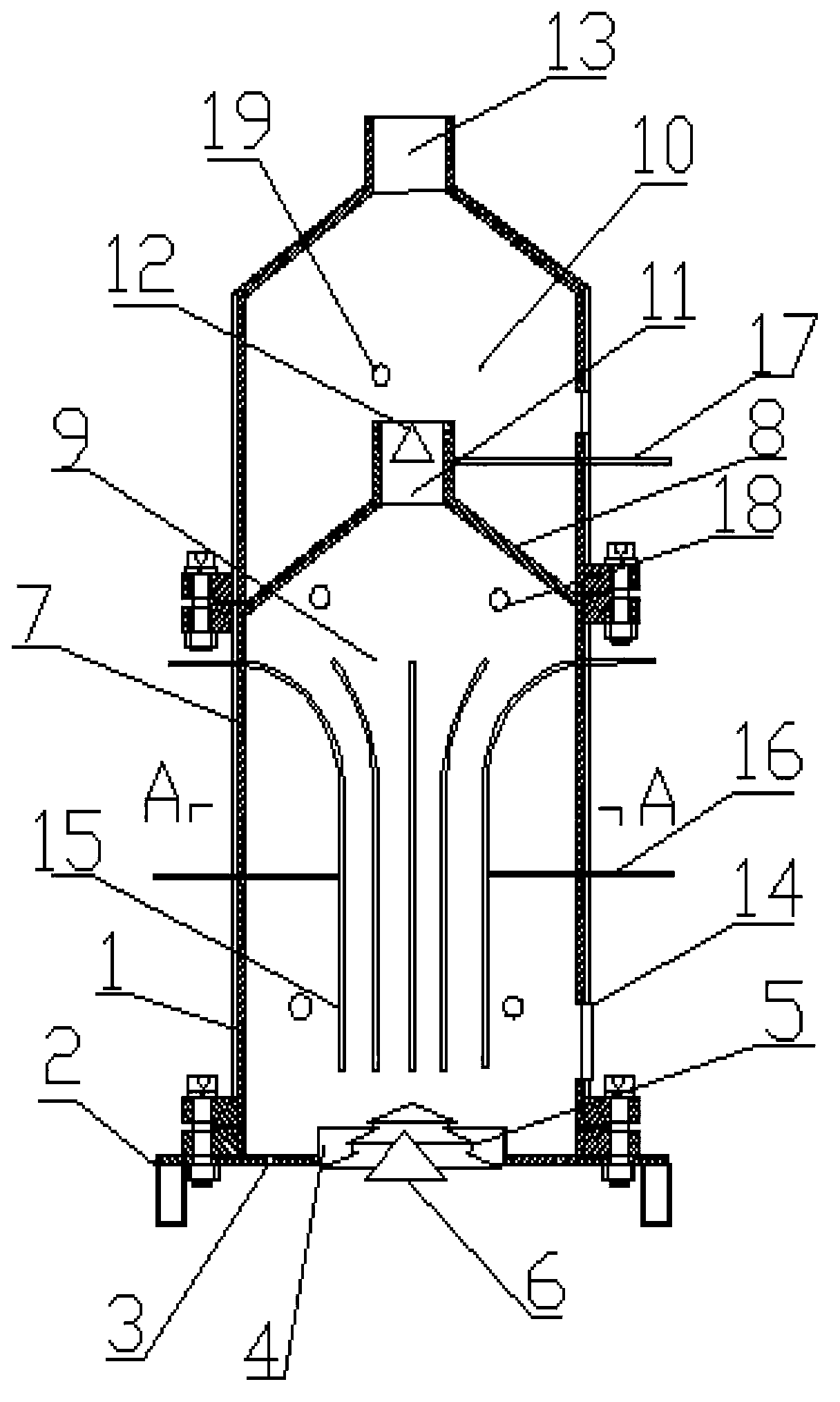

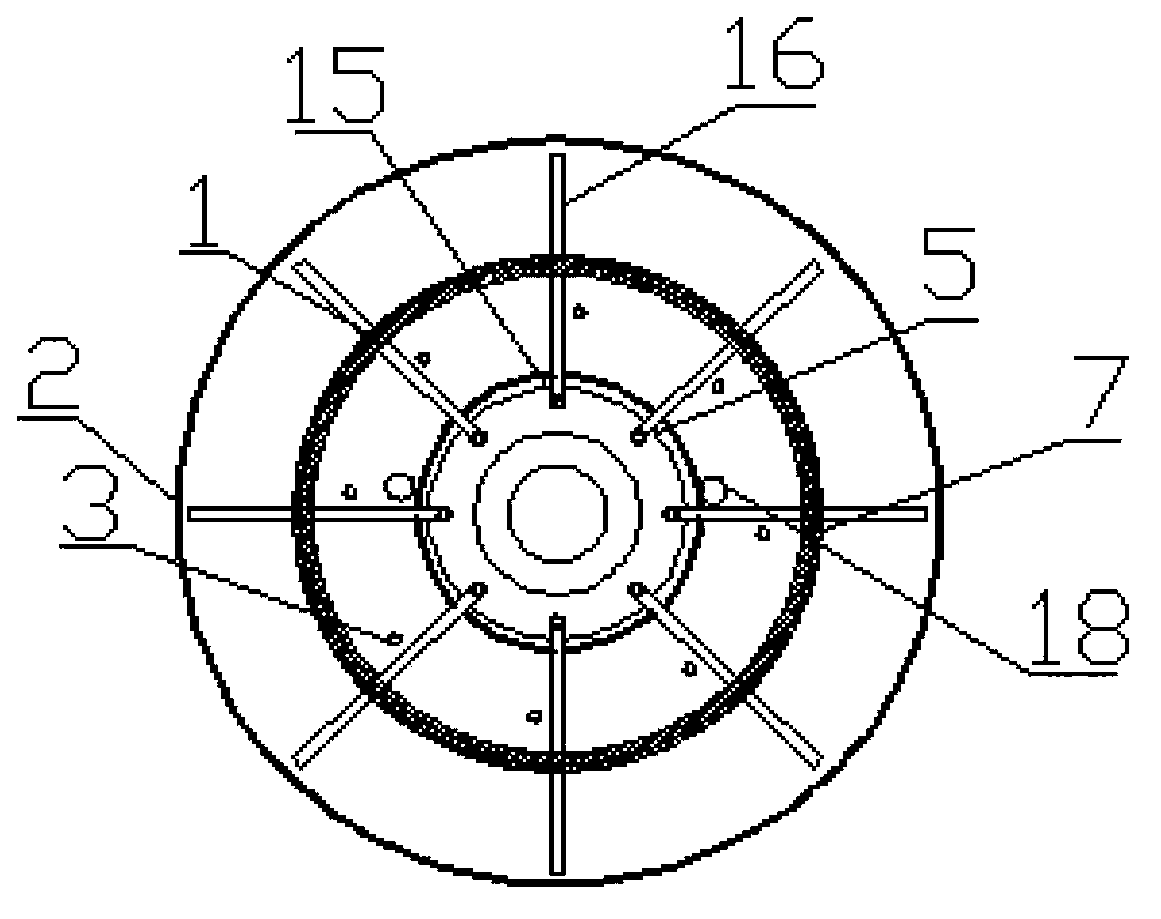

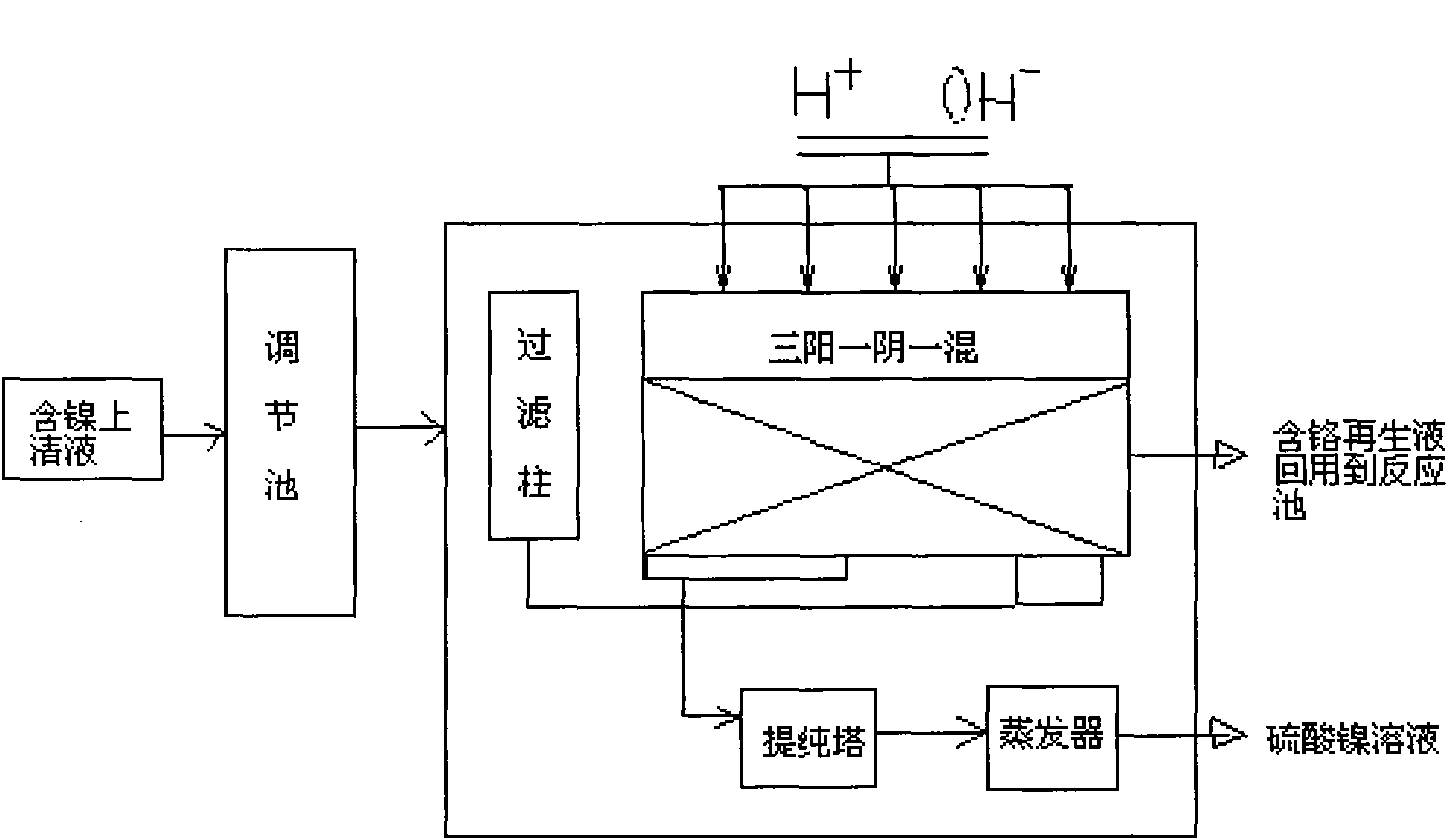

Method for extracting chromated nickel from low-grade stainless steel sludge by using stainless steel acid-washing waste mother liquor

ActiveCN102181647ARealize economic valueEasy to operateProcess efficiency improvementCalcium hydroxideLow graded

The invention discloses a chemical processing method, in particular to a method for extracting chromated nickel from low-grade stainless steel sludge by using stainless steel acid-washing waste mother liquor. By the method, low-grade nickel oxide ores are converted into high-grade nickel oxide ores. The method comprises the following steps of: making slurry of low-grade nickel and chromium sludge from stainless steel manufacturing enterprises by using recycled water; regulating the pH value by using the acid-washing waste mother liquor, and regulating the pH value by using calcium hydroxide or calcium oxide sectionally; discarding sludge in a reaction tank I, and reserving materials in a reaction tank II; and recycling active ingredients in a mechanical filtering mode. The method has the advantages that the operation is simple, equipment investment is small, raw materials are popularized, environmental pollution can be reduced, and the economic benefit is obvious. The method can be widely applied to a large number of stainless steel manufacturing enterprises or low-grade nickel ores.

Owner:陈宇青

Remediation method for remediating heavy metal contaminated soil around mining area through plant intercropping

PendingCN112427452ATo achieve the goal of "repair while producing"Realize economic valueContaminated soil reclamationCultivating equipmentsContaminated soilsSoil science

The invention relates to a remediation method for remediating heavy metal contaminated soil around a mining area through plant intercropping, which comprises the following steps of planting hyperaccumulator and ornamental plants in heavy metal contaminated cultivated land soil according to the natural growth period in an intercropping manner, conducting conventional cultivation, continuously transplanting the hyperaccumulator to expand the remediation area in the harvesting period, andtransplanting the ornamental plants as economic plants after being cultivated. According to the ecological restoration mode, one year serves as a restoration period, hyperaccumulator plants are planted in one season or multiple seasons, ornamental plants are intercropped, and the restoration efficiency of thecontaminated farmland soil can be improved through simultaneous restoration operation of the hyperaccumulator plants and the ornamental plants; meanwhile, the polluted cultivated land is used as an economic plant seedling raising area, considerable economic value is obtained, and an ecological restoration mode of restoring while producing is achieved.

Owner:江苏萤火虫环境科技有限公司 +2

Energy-saving two-section type thermal treatment furnace for organic chemical industrial effluent

InactiveCN102829478BSimple structureEasy to operateIncinerator apparatusLiquid wasteCombustion chamber

Owner:NANKAI UNIV

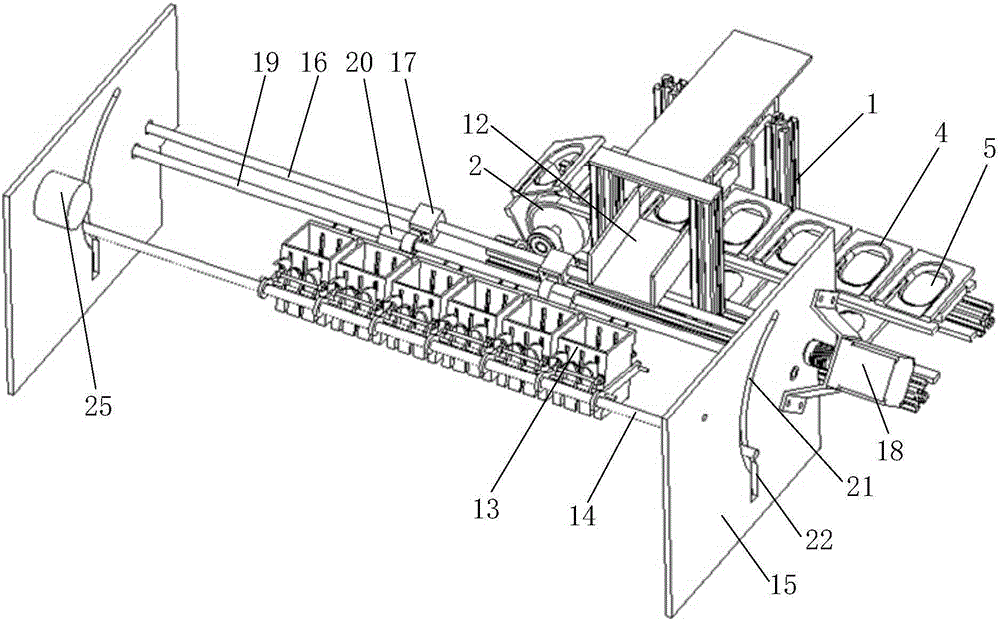

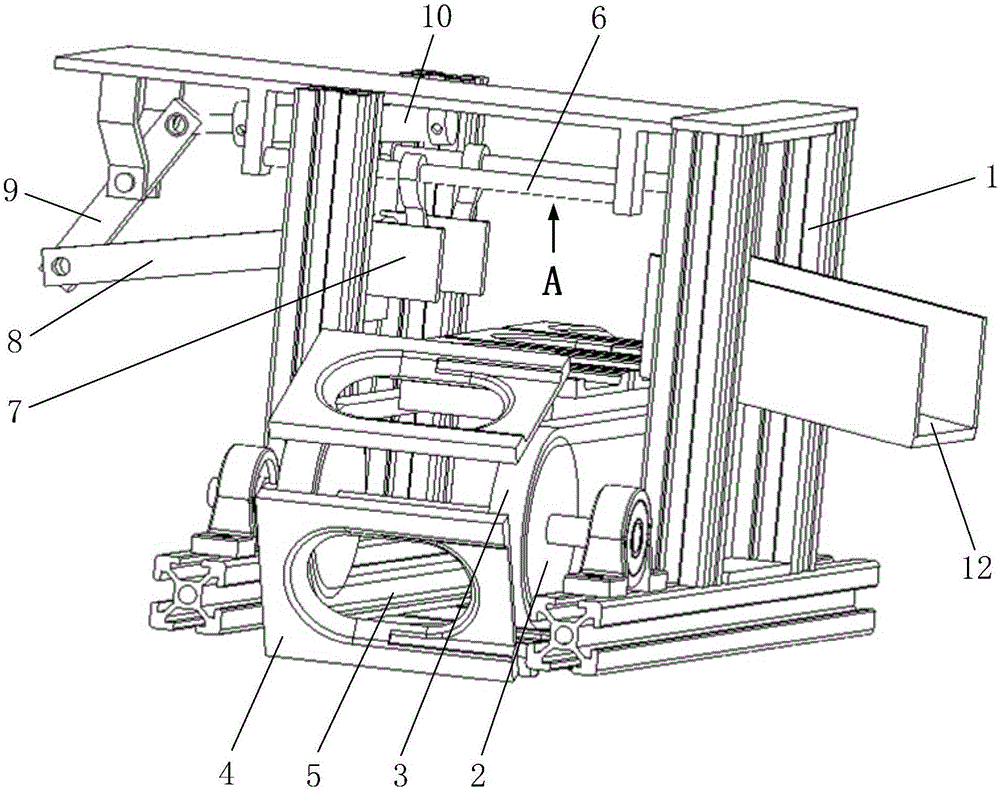

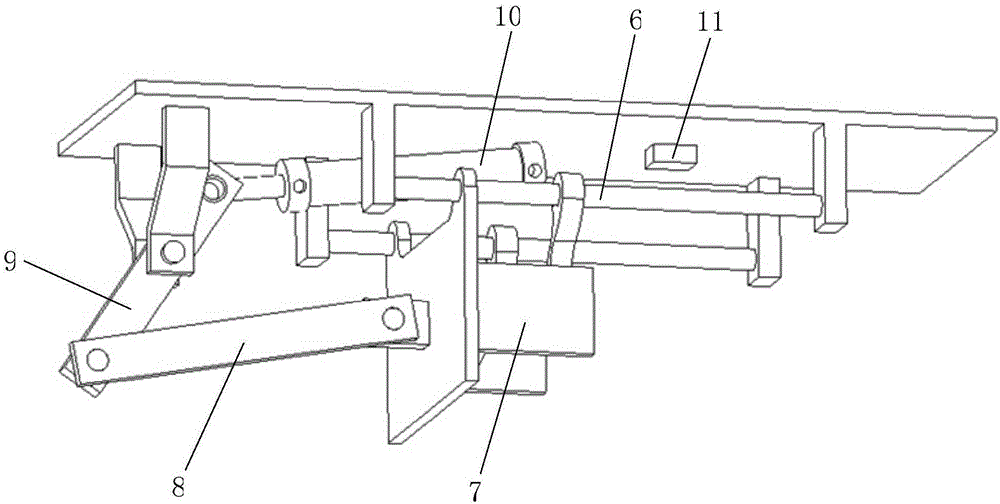

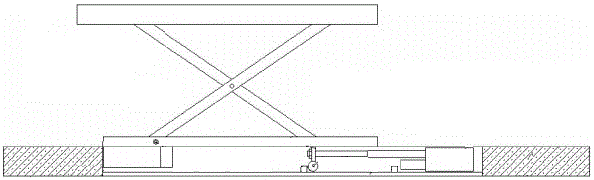

Pneumatic propelling encasing device for poultry eggs

InactiveCN106240887ARealize automatic packingReduce time, manpower and material resourcesPackaging eggsAutomatic controlAssembly line

The invention provides a pneumatic propelling encasing device for poultry eggs. The device comprises an egg conveying mechanism, a pneumatic egg propelling mechanism and an egg encasing mechanism. The poultry eggs are continuously conveyed to an egg propelling position through egg conveying plates, and an air cylinder drives an egg propelling rack to move so as to push the poultry eggs from the egg conveying plates to a transitional tank and slip into egg encasing boxes; a screw block on a lead screw is controlled through a stepping motor to move transversely to drive the egg encasing boxes to move, so that a plurality of poultry eggs are successively loaded in the egg boxes and are finally loaded in egg trays so as to realize automatic encasement of the poultry eggs; by virtue of automatic control of the air cylinder and the stepping motor and the like, automation of a poultry encasing process is realized, so that the workload of workers is alleviated, the production cost is lowered, and the production efficiency is improved; time, manpower and material resources consumed by conveying the poultry eggs can be reduced by assembly line work, so that the speed that the poultry eggs enter the market is accelerated, and the economical value of the poultry eggs is realized.

Owner:LIAONING TECHNICAL UNIVERSITY

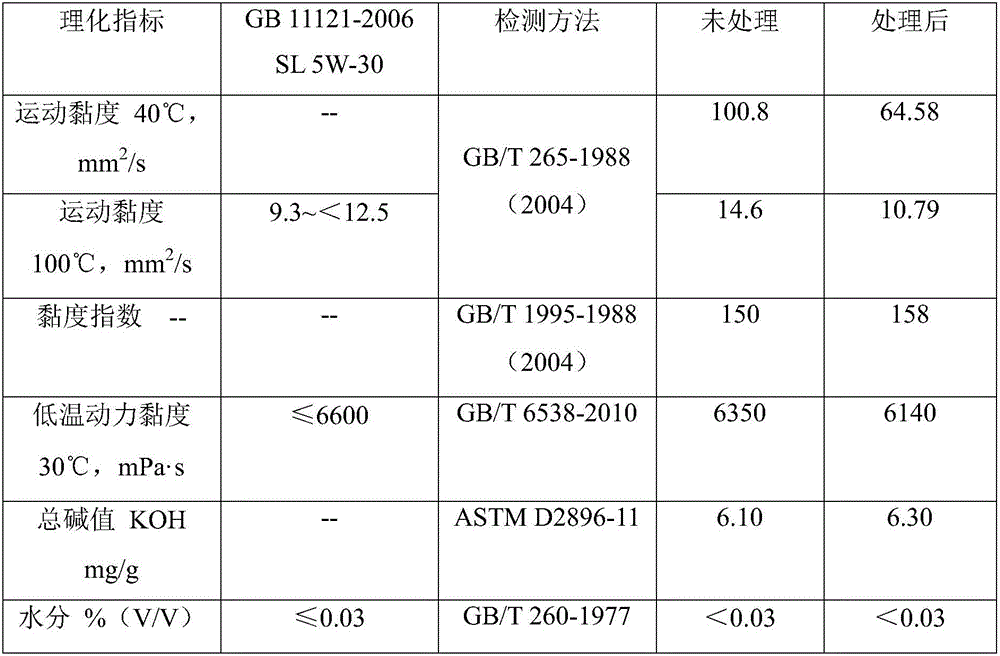

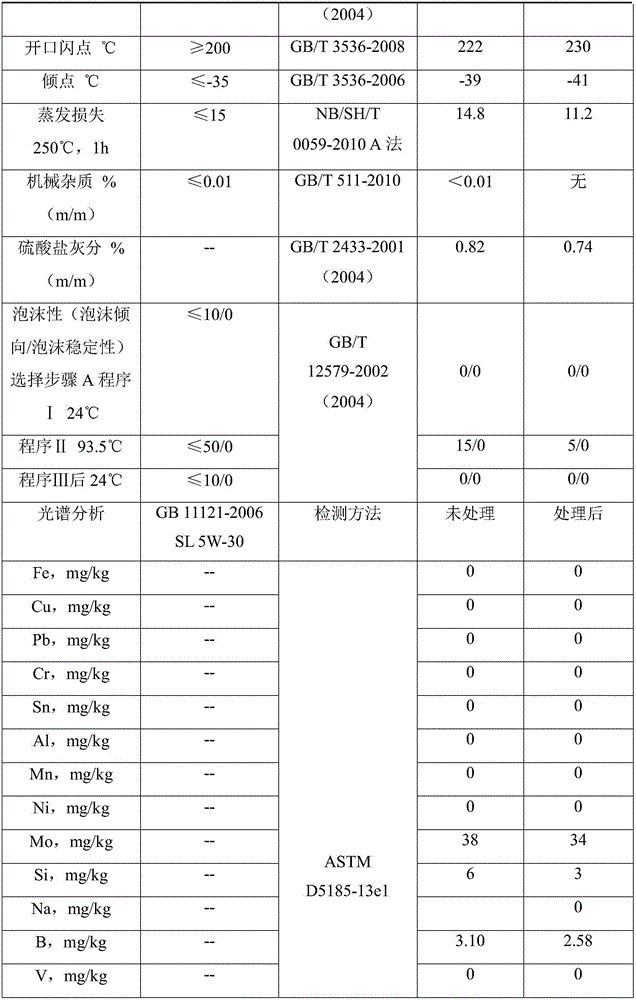

Treating method of automobile engine lubrication oil

InactiveCN106147893AChange other propertiesPromote absorptionLiquid carbonaceous fuelsMicrometerLength wave

The invention discloses a treating method of automobile engine lubrication oil. The treating method comprises the following steps that firstly, a pleurotus eryngii cultivation material obtained after harvesting is smashed, water is added to carry out oscillation, and supernate is taken; secondly, Tween 80 is added in the supernate and mixed evenly; thirdly, THz waves with the wavelength of 10-120 micrometers and the frequency of 0.5-2.5 THz are adopted for irradiation; fourthly, polymethacrylate is added in the mixture irradiated in the third step and mixed evenly; fifthly, THz waves with the wavelength of 10-120 micrometers and the frequency of 0.5-2.5 THz are adopted for irradiation; sixthly, THz waves are used for irradiating the automobile engine lubrication oil; seventhly, the substance obtained in the fifth step is added into the irradiated automobile engine lubrication oil, and the mixture continues to be irradiated with THz waves. By means of the method, the lubricity of the automobile engine lubrication oil can be improved; meanwhile, the automobile power can be improved, and oil saving and emission reduction can be achieved.

Owner:SICHUAN FULI ENVIRONMENTAL PROTECTION TECH CO LTD

Method for planting small yellow ginger under walnut forest

PendingCN114365666ARealize economic valueImprove land utilizationFertilising methodsCultivating equipmentsWalnut NutIntercropping

The invention discloses a method for planting small yellow ginger under a walnut forest, which realizes intercropping of walnuts and small yellow ginger, the planting time of the small yellow ginger is from the middle ten days of March to the end of April, the harvesting time is from the beginning of December to the next February, and the growth cycle is eight months. According to the method for planting the small yellow ginger under the walnut forest, idle land under the walnut forest is fully utilized, the economic value of the small yellow ginger is achieved, and the land utilization rate is increased.

Owner:普洱鸿星食品有限公司

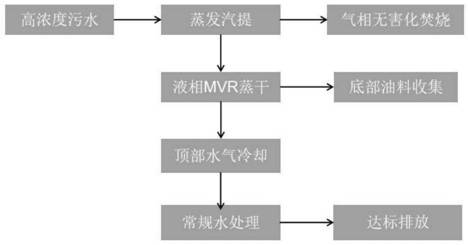

Method for treating high-concentration sewage generated in waste oil regeneration process

PendingCN112978825AReduce CoD valueBoost Bod5/CodFatty/oily/floating substances removal devicesWater contaminantsSewage treatmentSewage

The invention provides a method for treating high-concentration sewage generated in a traditional waste oil regeneration process. According to the method, steam stripping evaporation and MVR (mechanical vapor recompression) low-energy-consumption evaporation drying are conducted on the high-concentration sewage generated in a regenerated oil distillation link with extremely high CoD (more than 200,000) and extremely low Bod5 / Codgt (lower than 0.3), oil materials in the sewage are collected, the CoD of the sewage is greatly reduced to 10,000 or below, and the Bod5 / Cod is greater than 0.6. The wastewater is converted into common wastewater which is easy to treat, the wastewater is treated by a conventional wastewater treatment system, and the wastewater is discharged after reaching the standard.

Owner:湖北大江润业再生资源有限公司

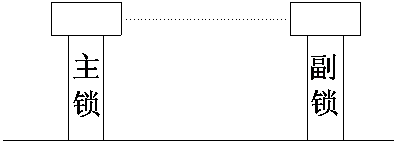

Responsive type master-slave unattended operation self-service parking place lock

ActiveCN105908652APrevent parking spacesRealize economic valueProgramme controlComputer controlInternet of ThingsParking space

The invention provides a responsive type master-slave unattended operation self-service parking place lock. The responsive type master-slave unattended operation self-service parking place lock comprises a master lock body and a slave lock body. The master lock body state is obtained, and the state of the slave lock body is synchronized with the master lock body state; and the master lock body and the slave lock body are two independent units, and the master lock body responds to a command for adjusting the lock state. According to the creatively-provided parking place lock, the master lock body and the slave lock body are locked at the same time and arranged in a parking place, and the phenomenon that a small vehicle occupies the special parking place, and consequently normal parking and vehicle taking of a vehicle owner are affected is prevented; the situation that a vehicle driven out of the parking place collides with the parking place lock in the backing up process is prevented, and the parking place lock is intelligently prevented from colliding; a two-dimensional code is used for unlocking, an APP setting terminal scans the two-dimensional code and directly communicates with the parking place lock, and therefore unlocking can be achieved; unlocking can be achieved through communication of an APP terminal and a cloud; when it is necessary, unlocking can be achieved through a key, great convenience is brought for parking and vehicle taking, and meanwhile other vehicles are effectively prevented from occupying the parking place; and meanwhile the parking place lock can further be applied to the Internet of Things, and the economic value is achieved.

Owner:GUANGDONG CYBERWAY INFORMATION TECH CO LTD

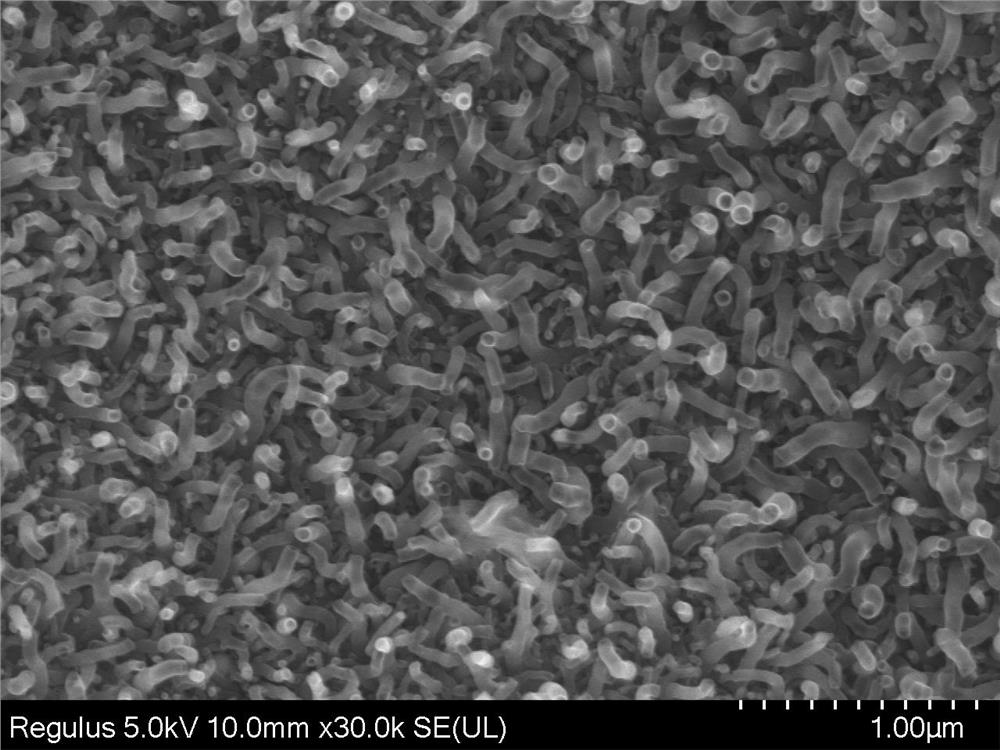

Method for jointly preparing carbon nanotube/porous carbon material and hydrogen-rich synthesis gas through biomass pyrolysis

ActiveCN113148983AIncrease added valueImprove qualityCarbon compoundsHydrogen productionCarbon compositesCalcium hydroxide

The invention discloses a method for jointly preparing a carbon nanotube / porous carbon material and hydrogen-rich synthesis gas through biomass pyrolysis, which comprises the following steps: (1) washing and drying corn straw powder to remove redundant impurities for later use; (2) dipping the obtained corn straw powder in a mixed aqueous solution of NiCl2 and CaCl2, fully stirring to enable the corn straw powder to be fully contacted with the mixed aqueous solution of NiCl2 and CaCl2, and drying to obtain a Ni-Ca loaded dry material; and (3) in a nitrogen atmosphere, heating and pyrolyzing the Ni-Ca loaded dry material in an inert atmosphere to obtain the carbon nanotube / porous carbon composite material. The gas generated by pyrolysis is purified with a calcium hydroxide solution to obtain hydrogen-rich synthetic gas. According to the method, the carbon nanotube / porous carbon material and the hydrogen-rich synthesis gas can be obtained at the same time, the comprehensive utilization efficiency of biomass pyrolysis products is improved, and a new way is provided for high-value utilization of biomass resources.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

A method to realize the "multi-plan integration" electronic approval of multi-type planning schemes

ActiveCN105354267BRealize full lifecycle managementEasy to implementOffice automationGeographical information databasesComputer scienceInformation system

The invention relates to a method for realizing ''more rules one'' electronic approval of multi-type planning schemes. The method comprises: presetting a GIS (Geographic Information System) database; extracting / reading reference data from the GIS database; creating or entering a space planning scheme for an electronic approval system; comparing the space planning scheme with the reference data, and coordinating a land block; and storing the coordinated / processed space planning scheme into the GIS database. According to the method disclosed by the invention, contradiction of the space planning scheme among various departments can be solved, administrative examination efficiency is improved, and economic values of construction land are realized to a maximum limit.

Owner:广东绘宇智能勘测科技有限公司

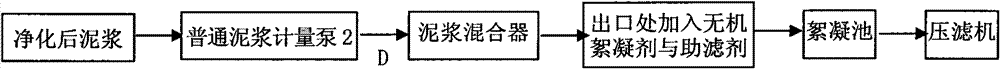

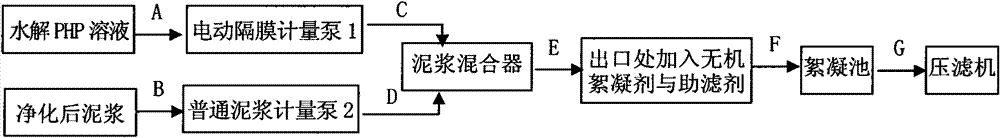

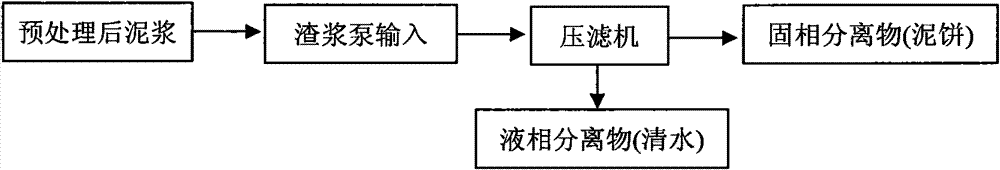

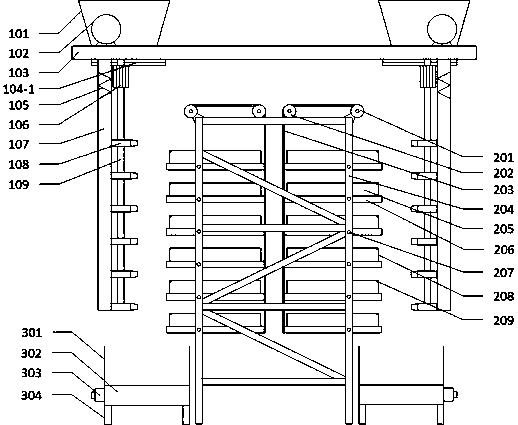

Solid-liquid separation process for drilled pile waste mud

InactiveCN101863608BAccurate processingLow costSludge treatment by de-watering/drying/thickeningFlocculationFiltration

The invention discloses a solid-liquid separation process for drilled pile waste mud. The method comprises the following steps of: A, collecting and purifying the drilled pile waste mud; B, flocculating the purified mud; C, performing filtration aid treatment on the flocculated mud by taking quicklime powder as a filter aid; and D, performing solid-liquid separation on the mud after filtration aid treatment. Through the process, the waste mud can be treated at the construction site thoroughly and is prevented from discharging to the environment at source; and the available parts in the mud can be well recycled.

Owner:骆嘉成

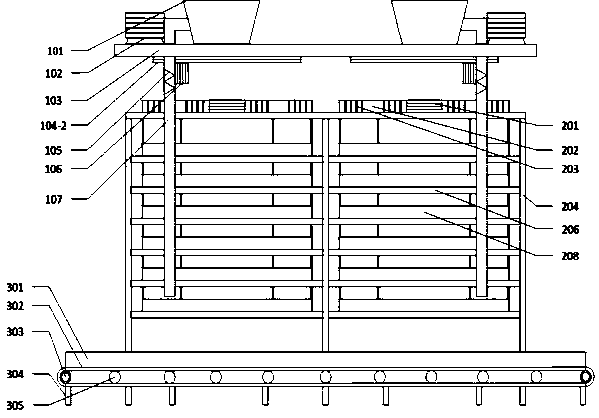

Automated material feeding and collecting device for hermetia illucens breeding, and use method

PendingCN111418556AExpand production scaleReduce human resource costsStorage devicesAnimal husbandryTraction motorEngineering

The invention relates to an automated material feeding and collecting device for hermetia illucens breeding. The automated material feeding and collecting device for hermetia illucens breeding comprises a feeding system, a breeding frame and a material collecting system, wherein the feeding system comprises feeding tanks, material pumps, a supporting platform, moving sliding chutes, feeding brackets, moving motors, conveying pipelines, flexible expanding and contracting regions and feeding guns; the breeding frame comprises traction motors, traction steel wires, traction rollers, breeding frameworks, trays, breeding framework moving plugs, tray moving plugs and a breeding frame bracket; and the material collecting system comprises belt motors, material collecting brackets, rolling wheels,belts and partition boards. At first, materials are uniformly conveyed into the conveying pipelines from the feeding tanks through the material pumps, then the materials are quantitatively conveyed into the breeding frameworks of the breeding frame through the feeding guns, after breeding and cultivation are completed in the breeding frames, the traction motors are started, the breeding trays andthe breeding frameworks are raised up, materials can be movably and automatically poured out from the breeding frameworks to enter the belts of the material collecting systems, the belts are driven bythe belt motors, and the materials are conveyed to subsequent technological steps. Through the steps, efficient stable automated feeding and material collecting operations of hermetia illucens breeding can be realized.

Owner:源创环境科技有限公司

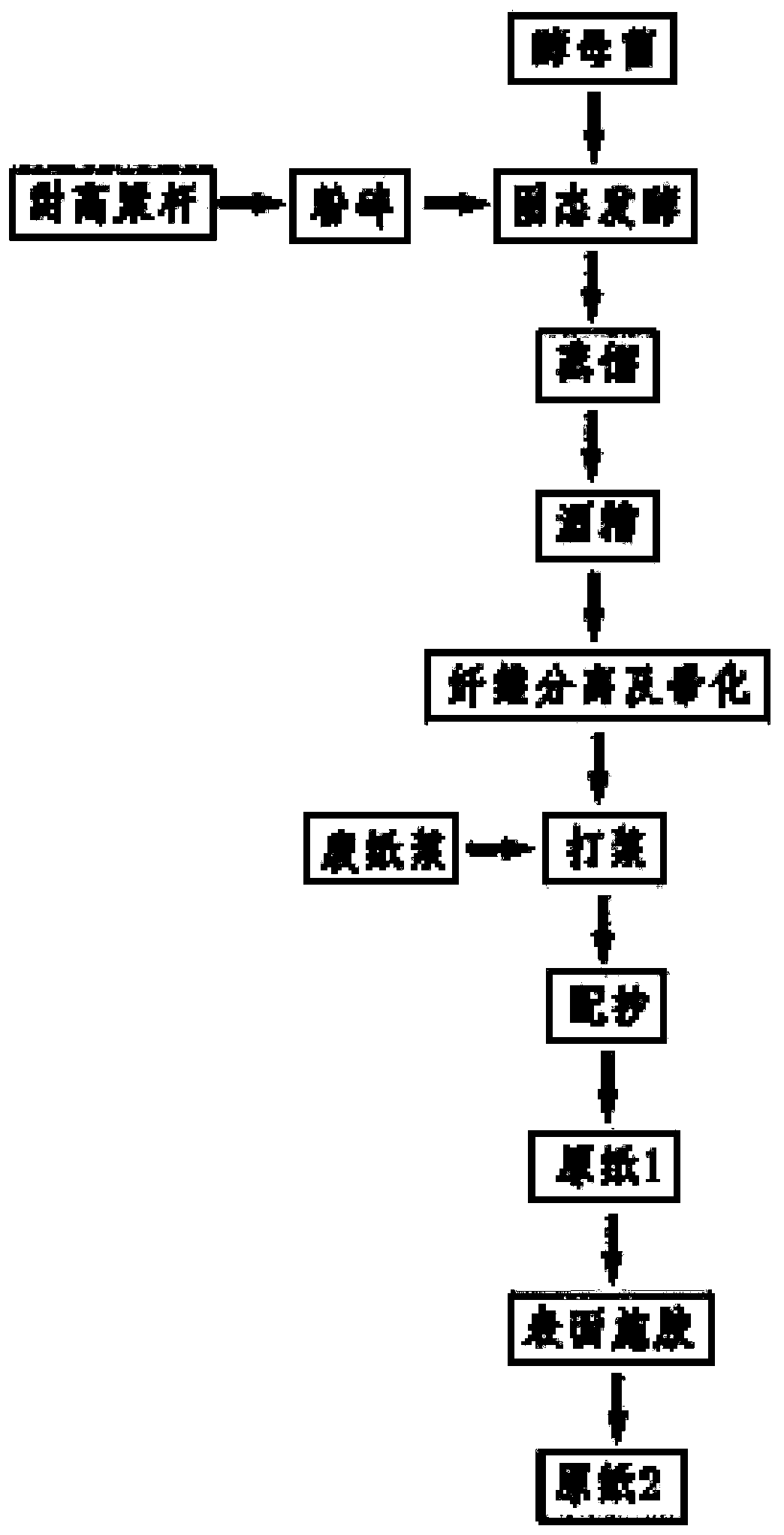

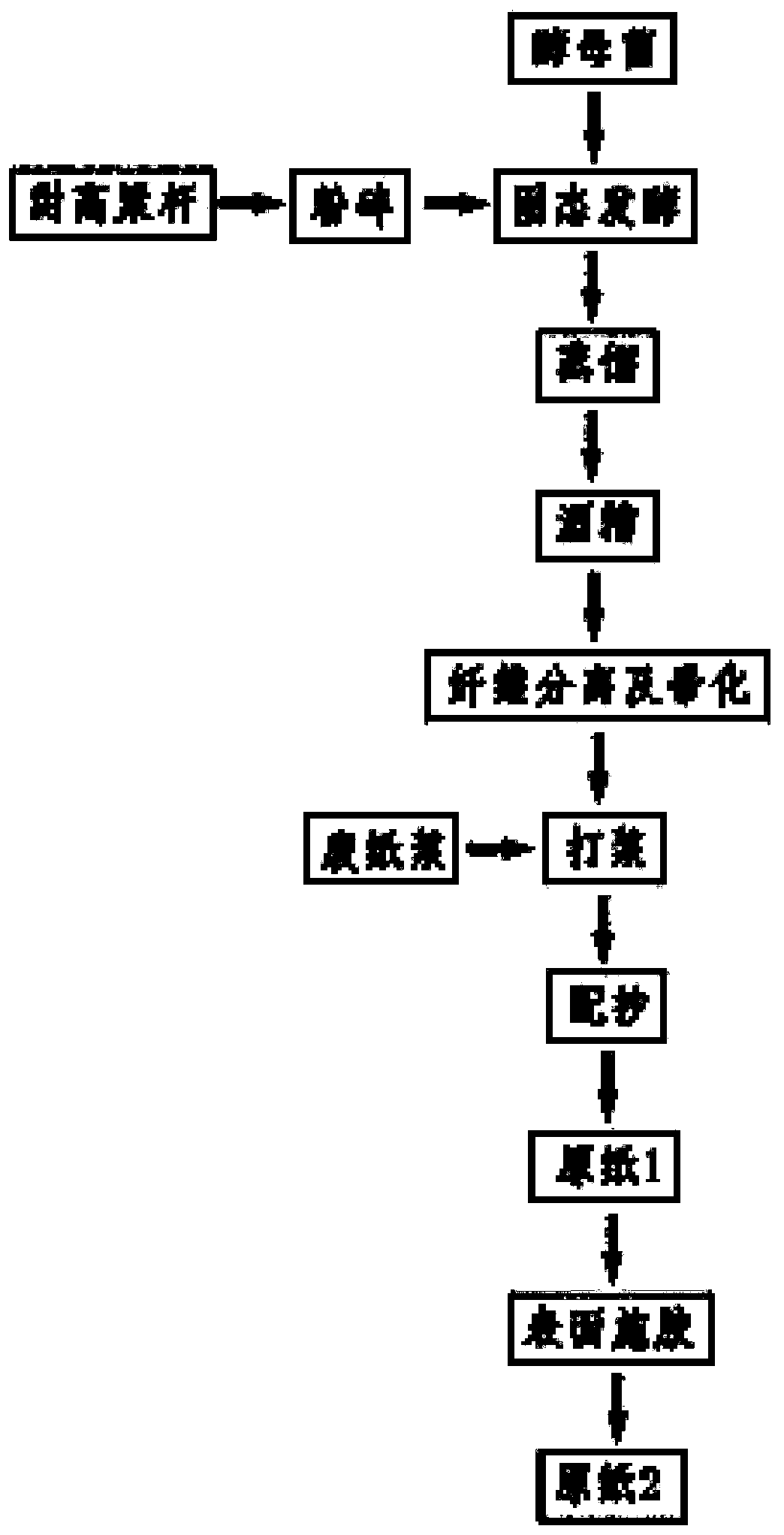

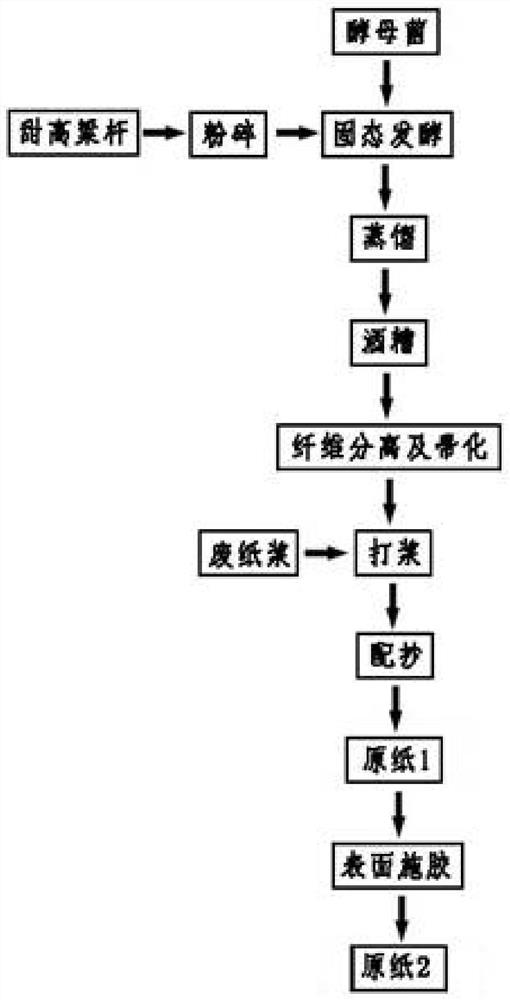

Method for pulping and papermaking by utilizing sweet sorghum stalk vinasse

ActiveCN111118943ARealize economic valueExtend the industrial chainPulp beating methodsSecondary cellulose fibresFiberAlcohol ethyl

The invention discloses a method for pulping and papermaking by utilizing sweet sorghum stalk vinasse. The method comprises the following four steps: step 1, carrying out alcohol fermentation and distillation, namely crushing 16 tons of sweet sorghum stalks with a water content of 70% through a pulverizer, adding cultured yeast seed liquid according to a proportion of 15% (v / m), and carrying out alcohol fermentation and distillation to obtain 1 ton of ethyl alcohol with a mass fraction of 95% and 16 tons of hot vinasse with a water content of 80% and a temperature of 94 DEG C; step 2, directlyfeeding the hot vinasse into a millstone mill pulping machine for fiber separation and brooming with a disc milling interval being 0.002 m and a pulping concentration being 20% (w / w) so as to obtain14 tons of pulp with a water content of 85%; step 3, weighing 2.1 tons of waste paper pulp boards, defibering the waste paper pulp boards by using a defibering device, and then feeding the defiberingwaste paper pulp boards into a Valley beater for beating to a beating degree of 36 oSR so as to obtain 10.5 tons of pulp with a water content of 80%; and step 4, blending the vinasse fiber paper pulpobtained in the step 2 and the waste paper pulp obtained in the step 3 according to a ratio of 1: 1, and carrying out papermaking to obtain 4.2 tons of raw paper. The method is used for pulping and papermaking by utilizing the sweet sorghum stalk vinasse.

Owner:东营市弘力生物科技有限责任公司

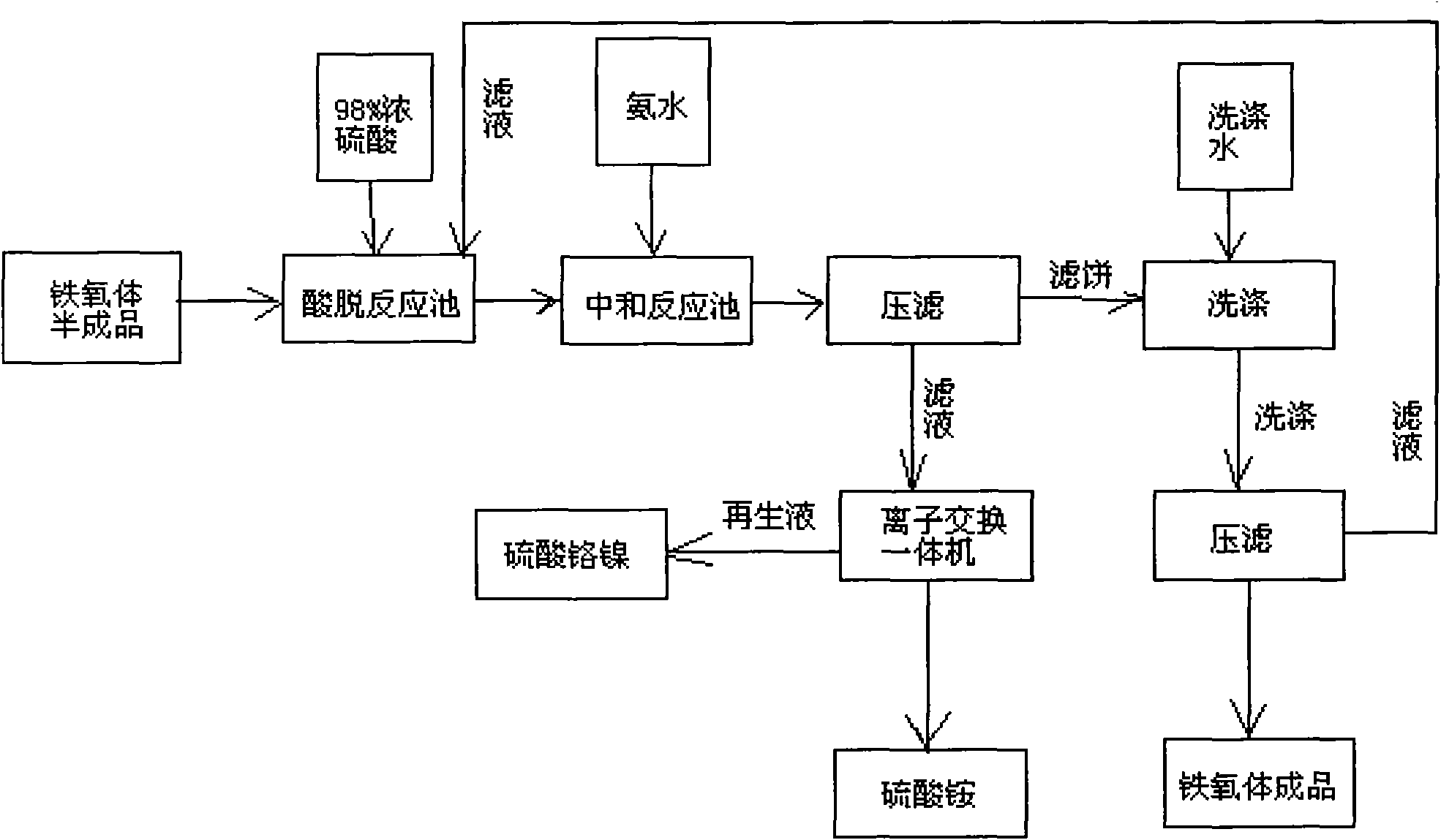

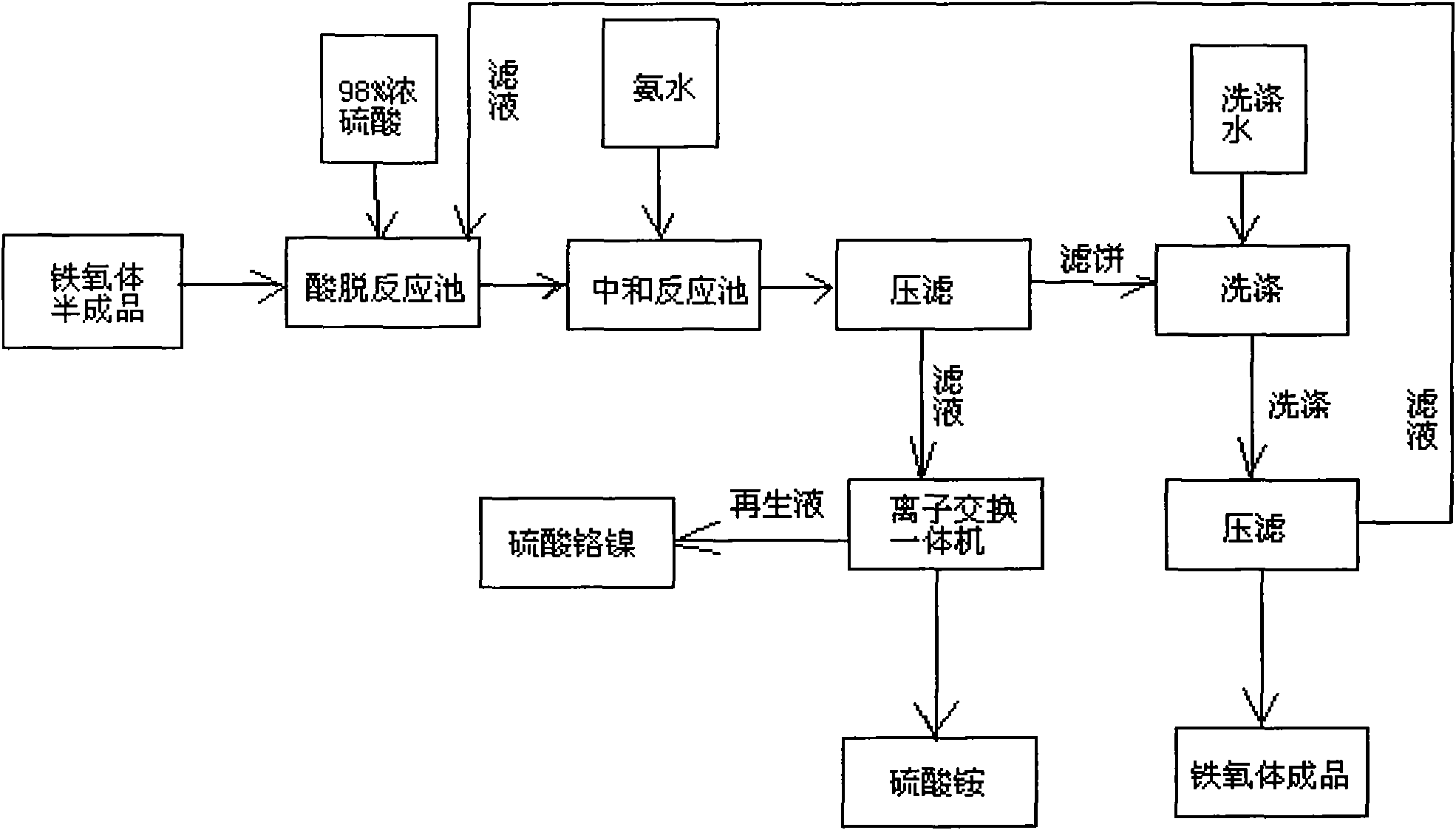

Purification method of semi-finished ferrite product containing chromium and nickel

The invention relates to a chemical purification method, in particular to a method for recovering heavy metal ions in an environmental protection process. The method comprises the following steps of: adding 98% concentrated sulfuric acid into an acid leaching reactor; adjusting a pH value to 2.5-2.8; them, carrying out a neutralization reaction with ammonia until the pH value of the solution is 4.3; and carrying out the processes of filtering, washing, filter pressing and the like to obtain a finished ferrite product. Byproducts can be processed by an all-in-one ion exchanging machine to obtain chromium sulfate, nickel sulfate and ammonium sulfate for different purposes. The invention has little production energy consumption, not only can change waste into valuables to achieve economic benefit, but also can eliminate environmental pollution caused by heavy metals in mud. The invention can be widely applied to enterprises of producing stainless steel to improve economic benefits and social benefits.

Owner:松阳县环境监测站

Clean fuel prepared from traditional Chinese medicine residues

The invention relates to a clean fuel prepared from traditional Chinese medicine residues, which comprises the following components in percentage by weight: 10-15 parts of coal gangue, 5-15 parts of jacobsite slag, 25-30 parts of industrial salt slurry, 1-5 parts of blast furnace slag, 30-40 parts of traditional Chinese medicine residue, 1-5 parts of combustion improver and 0.5-3 parts of synergist. The preparation process of the clean fuel comprises the following steps: baking the traditional Chinese medicine residues at high temperature to lower the water content to 1-4% below; and mixing and pulverizing the components, and finally, carrying out compression forming on the components by a forming machine. The clean fuel is simple in technique, provides a convenient environment-friendly treatment mode for traditional Chinese medicine residues discharged by the current enterprises, and converts the traditional Chinese medicine residues into energies, resources and harmless substances. After the traditional Chinese medicine residues and industrial solid waste are prepared into the clean fuel, the environmental pollution is reduced, and the economic value can be implemented.

Owner:TIANJIN SHENNONG ENVIRONMENTAL PROTECTION TECH CO LTD

Intensive processing method for stalk articles or agricultural castoff

InactiveCN101492700BEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperaturesterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

A method for pulping and papermaking using distiller's grains from sweet sorghum stalks

ActiveCN111118943BRealize economic valueExtend the industrial chainPulp beating methodsSecondary cellulose fibresFiberAlcohol ethyl

The invention discloses a method for making pulp and paper by using distiller's grains from sweet sorghum stalks. This method includes four steps. The first step is ethanol fermentation and distillation: take 16 tons of sweet sorghum stalks with a water content of 70%, grind them through a grinder, add the cultured yeast seed liquid at a ratio of 15% (v / m), and carry out Ethanol fermentation and distillation to obtain 1 ton of ethanol with a mass fraction of 95% and 16 tons of hot distiller's grains with a water content of 80% at a temperature of 94°C; in the second step, the hot distiller's grains are directly sent to a disc refiner for fiber separation and broom 14 tons of slurry with a water content of 85% are obtained, the disc grinding distance is 0.002m, and the refining concentration is 20% (w / w). In the third step, 2.1 tons of waste paper pulp boards are decomposed by a fiber decomposer and then sent to the Valley beater Beat the pulp to 36oSR to obtain 10.5 tons of slurry with a water content of 80%. In the fourth step, the distiller's grain fiber pulp obtained in the second step and the waste paper pulp obtained in the third step are mixed in a ratio of 1:1 to make paper to obtain 4.2 tons of base paper. The invention is used for the pulping and papermaking of distiller's grains from sweet sorghum stalks.

Owner:东营市弘力生物科技有限责任公司

Method for recycling nickel and chromium in stainless steel

InactiveCN106498171AReduce pollutionReduce manufacturing costProcess efficiency improvementSludgeIon exchange

The invention relates to a method for recycling nickel and chromium in stainless steel. The method comprises the following steps: treating nickel and chromium in stainless steel to generate sludge containing heavy metal chromium and nickel, feeding the sludge into a slurry pool, adding water, and pulping for 1.5 hours; pumping coarse raw material pulp obtained after pulping into an acid soluble pool, and adding concentrated HCl to adjust the pH value; adding distilled water in the coarse raw material pulp soaked in acid, injecting obtained waste water into a solid-liquid separation device for solid-liquid separation, and forming sediments by iron ions and chromium ions in the waste water in the solid-liquid separation device; pouring liquid out, and adjusting the pH value to obtain reaction liquid; filtering the sediments in the reaction liquid, taking the liquid and then injecting the liquid into an ion exchange unit for ion exchange to extract the nickel; and returning liquid outputted through ion exchange to a storage tank. Compared with the prior art, the method realizes resource recycling of precious metal in sludge and has comprehensive benefits including economic benefit, environmental benefit and social benefit.

Owner:张圆圆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com