Method for pulping and papermaking by utilizing sweet sorghum stalk vinasse

A technology for pulping and papermaking and sweet sorghum, which is applied in pulp beating methods, pulp beating/refining methods, and papermaking, etc., can solve the problems of poor economic benefits of enterprises, technical difficulties in wastewater, and high consumption costs, and achieve good economic benefits. , the effect of forest protection, cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

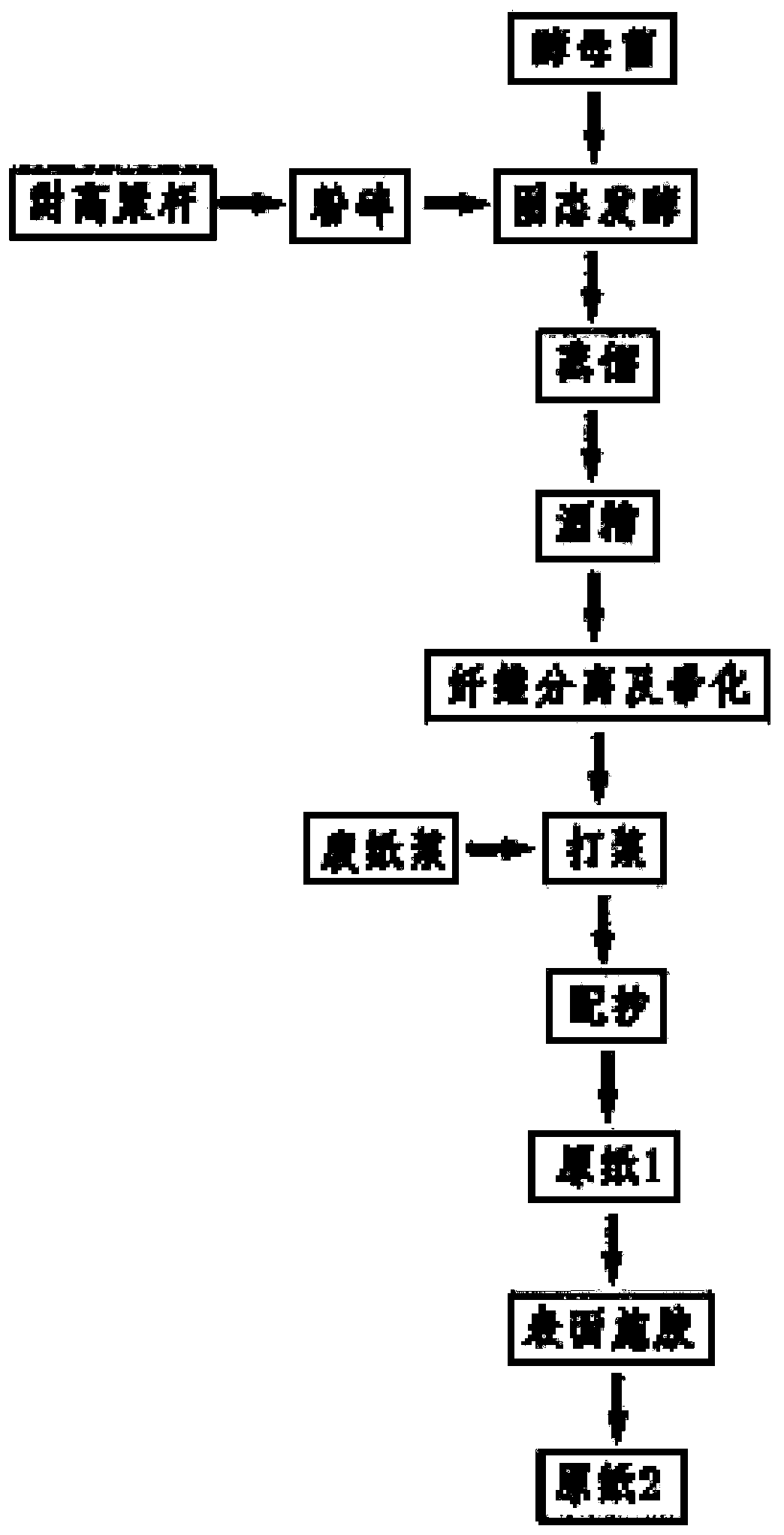

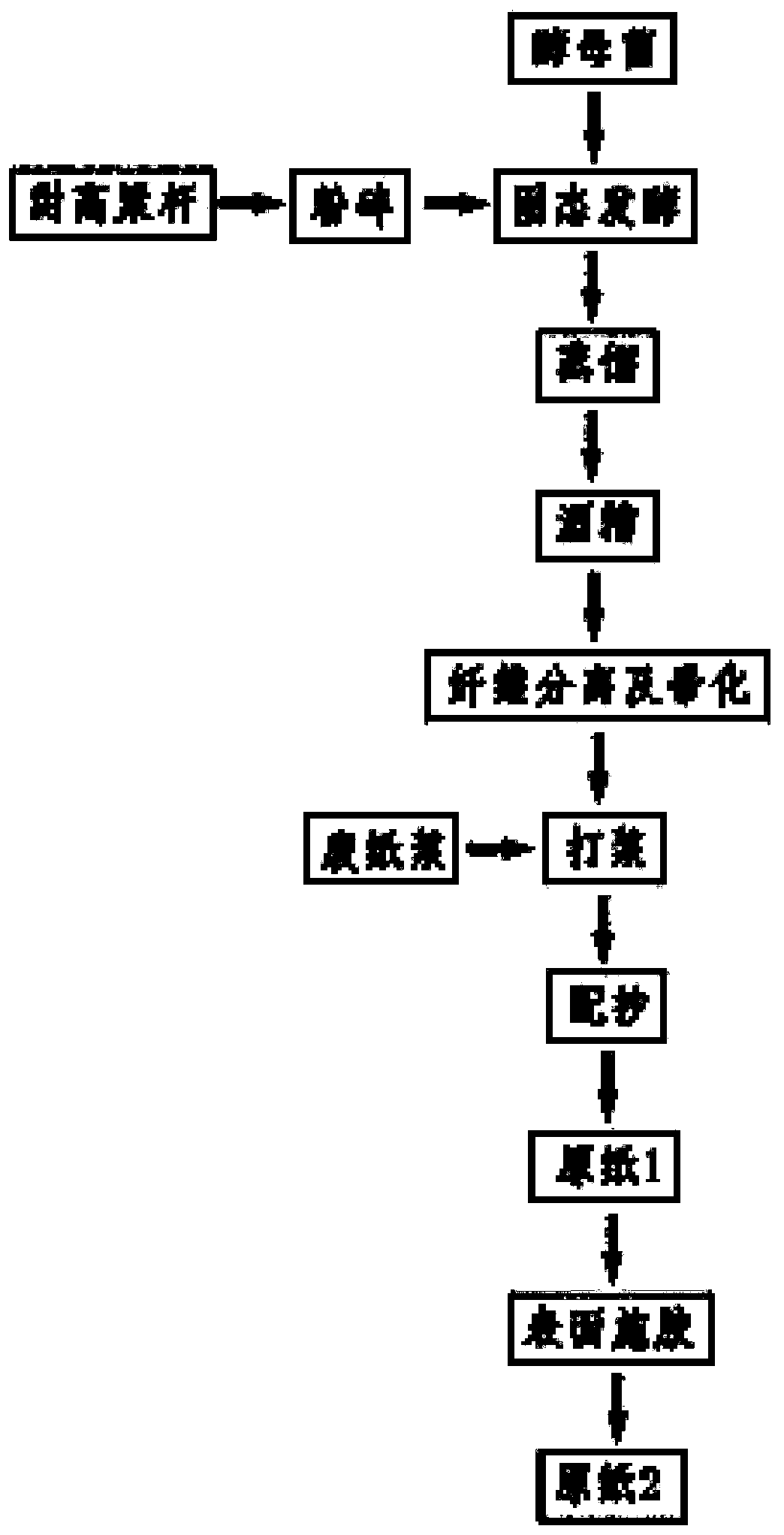

Image

Examples

Embodiment 1

[0022] A method for making pulp and paper using distiller's grains from sweet sorghum stalks. The method includes four steps. The first step is ethanol fermentation and distillation: take 16 tons of sweet sorghum stalks with a water content of 70%, grind them through a pulverizer, and grind them at a rate of 15% (v / The ratio of m) is added to the cultivated yeast seed liquid, and the ethanol fermentation and distillation are carried out to obtain 1 ton of ethanol with a mass fraction of 95% and 16 tons of hot distiller's grains with a water content of 80%. The temperature of the hot distiller's grains is 94°C; It is directly sent to the disc refiner for fiber separation and broomification, the disc refiner spacing is 0.002m, the refining concentration is 20% (w / w), and 14 tons of pulp with a water content of 85% are obtained; the third step is to take 2.1 tons of waste After the pulp board is decomposed by the defiberizer, it is sent to the Valley beater for beating to 36oSR t...

Embodiment 2

[0024] In the method of pulping and papermaking with distiller's grains from sweet sorghum stalks described in Example 1, the resulting base paper has a fracture length of 2.65 km and a ring pressure index exceeding 8.15 N·m / g.

Embodiment 3

[0026] A method for making pulp and paper using distiller's grains from sweet sorghum stalks described in Example 1, the first to third steps are to process sweet sorghum stalks and waste paper pulp to obtain 14 tons of distiller's grain fiber pulp with a water content of 85% and 10.5 tons of waste paper pulp slurry with a water content of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com