Patents

Literature

44results about How to "Energize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for changing restaurant and kitchen garbage into resource without environmental pollution

InactiveCN101274860AAvoid wastingEnergizeBio-organic fraction processingWaste processingThermal energyAnaerobic bacteria

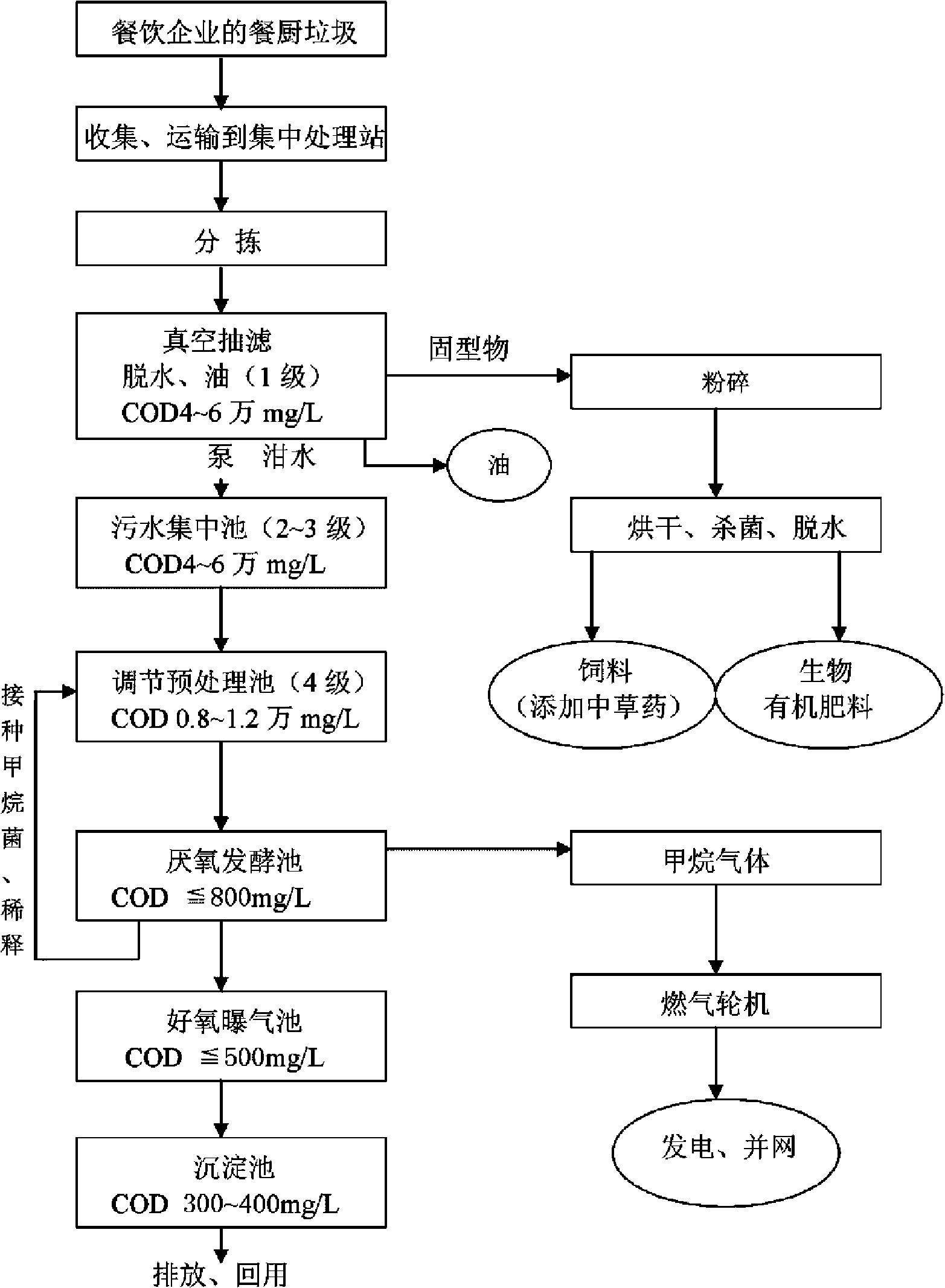

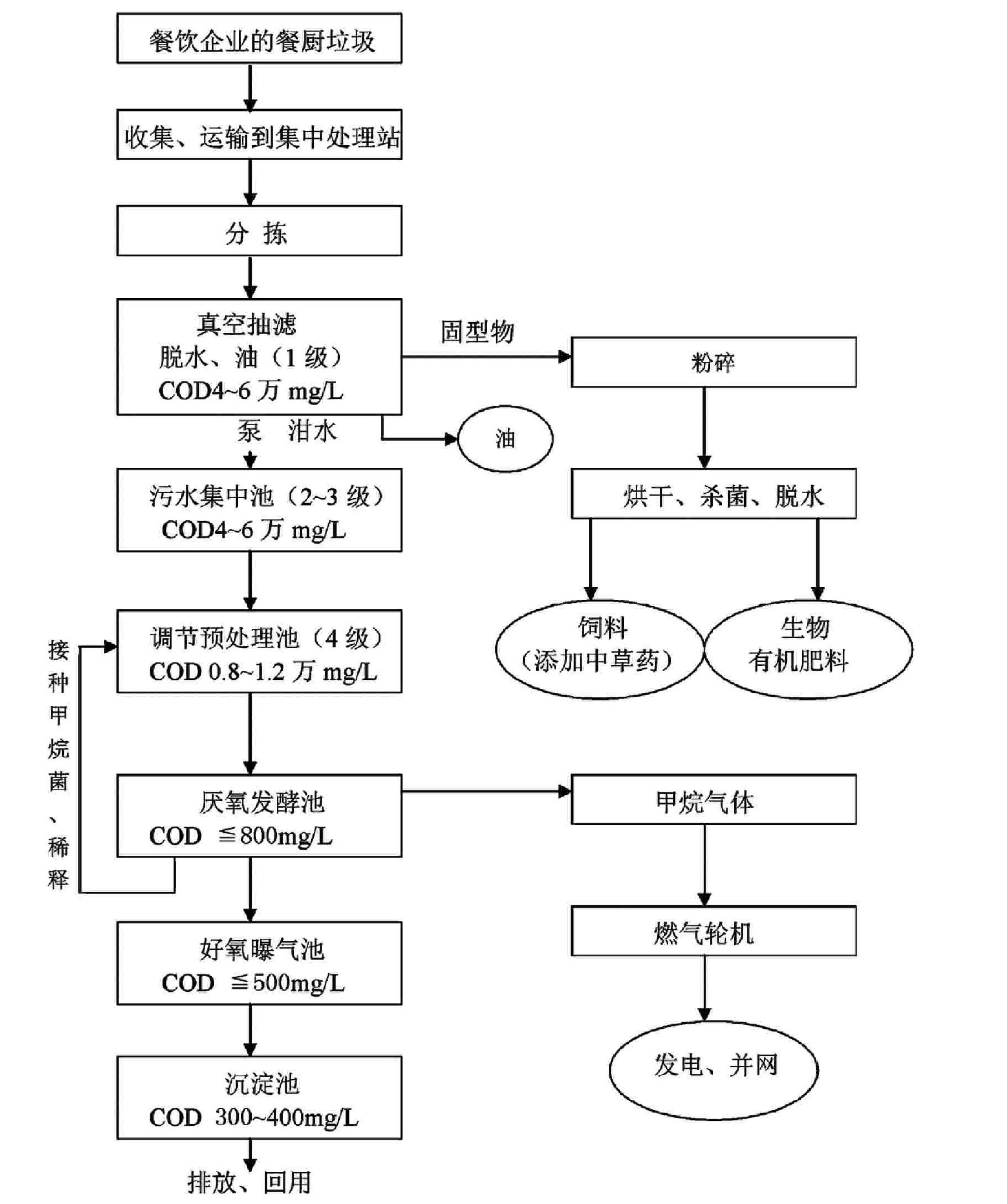

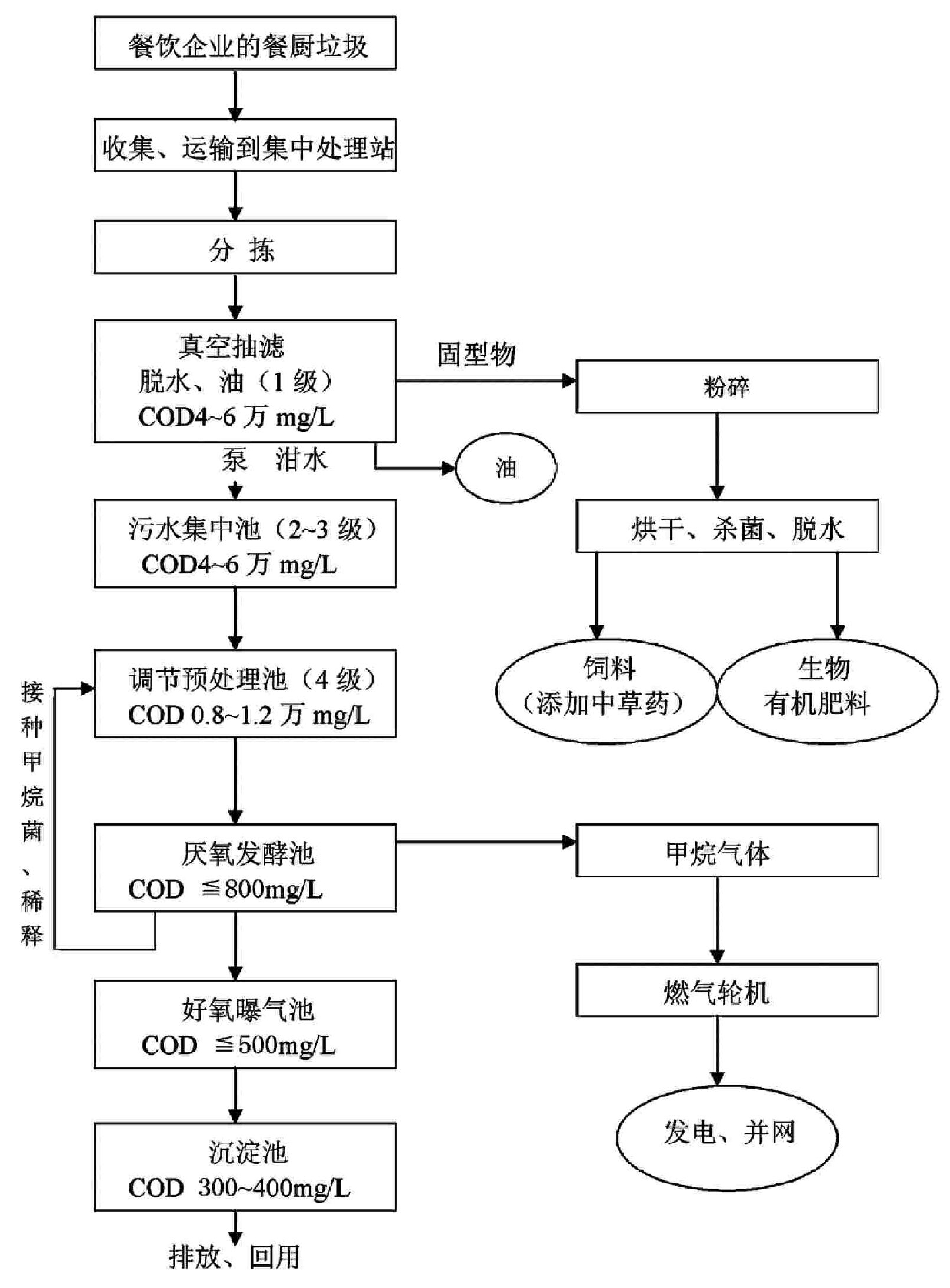

The invention relates to a treating method for energy regeneration, resource recovery and pollution free of restaurant garbage, which comprises the steps that separated liquid material is pumped into a swage concentrating pool; then the concentrated liquid material is discharged into a regulating and pretreating pool, in which methane bacteria are inoculated; the pretreated liquid material is discharged into an anaerobic fermentation pool, in which anaerobic bacteria groups are added so that methane gas is generated and the overflowing liquid material from the anaerobic fermentation pool is led to enter an aerobic aerated pool for aerobic reaction; the liquid material after the aerobic reaction is discharged into a sedimentation tank for sedimentation. In the comprehensive utilization of 'swill', the disposing method of the invention carries out anaerobic fermentation and aerobic aerated biochemical treatment to transform part of the energy in the swill into bio-energy which is then transformed into heat energy and finally into electrical energy that is connected with power grid for use. The separated solid material is smashed, dried, sterilized, dehydrated and then added with Chinese herbal medicine to be processed into Chinese herbal medicine compound feeds and fertilizers; meanwhile, the treatment of energy regeneration, resource recovery and pollution free of restaurant garbage for restaurant garbage is realized.

Owner:WUXI KELUN SCI & TECH DEV

Fuel cell and system, control method, control system and electrical apparatus

ActiveCN109159720AEnergizeExtended driving distanceElectric energy managementBattery/fuel cell control arrangementElectricityFuel cells

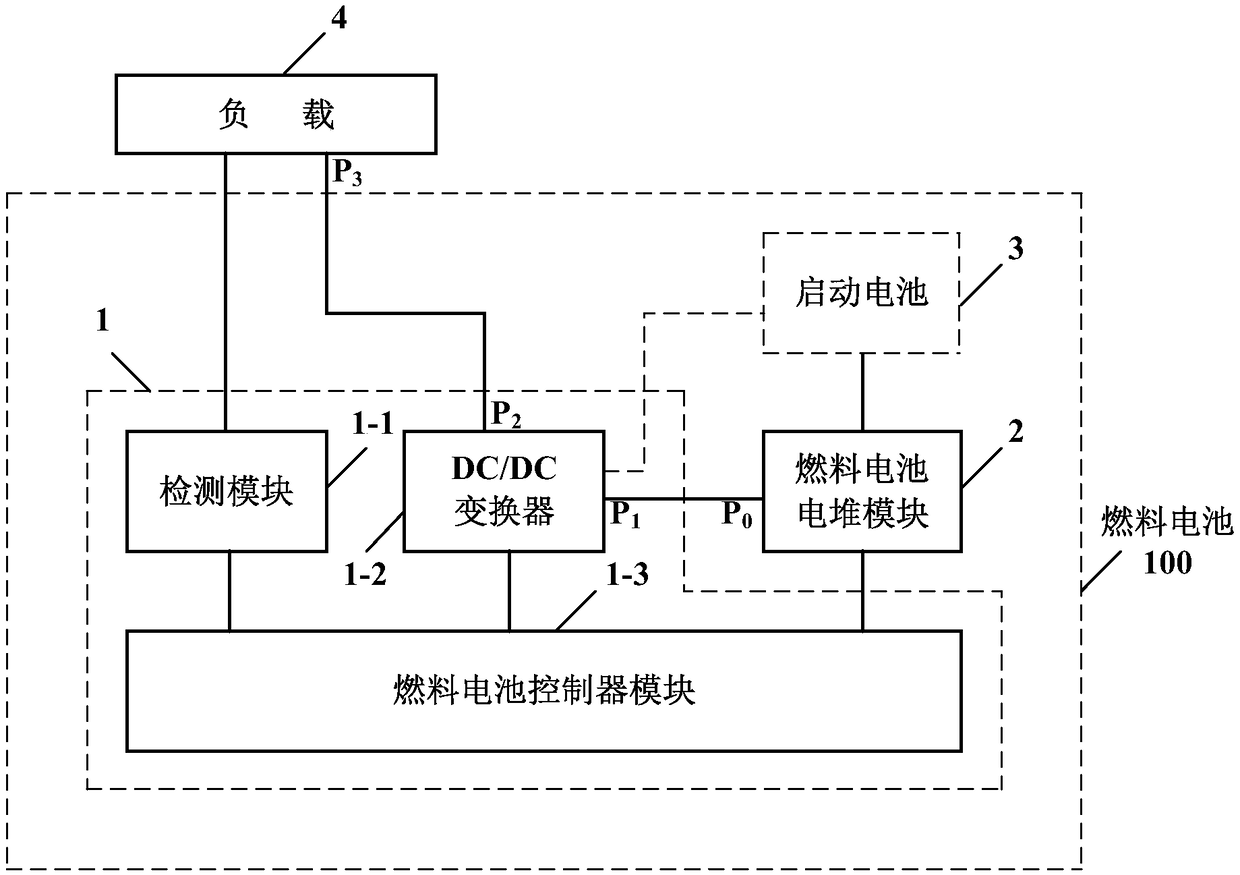

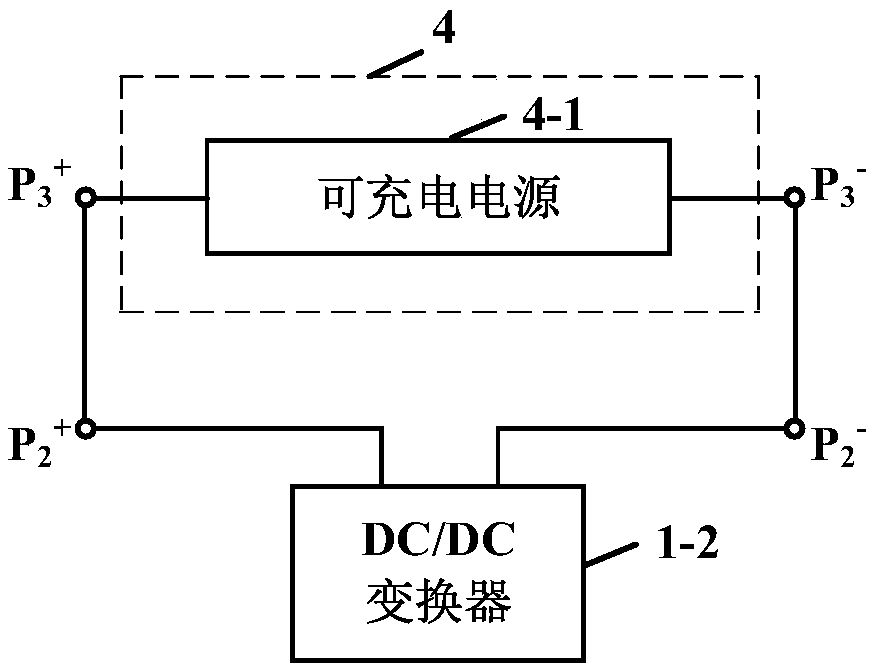

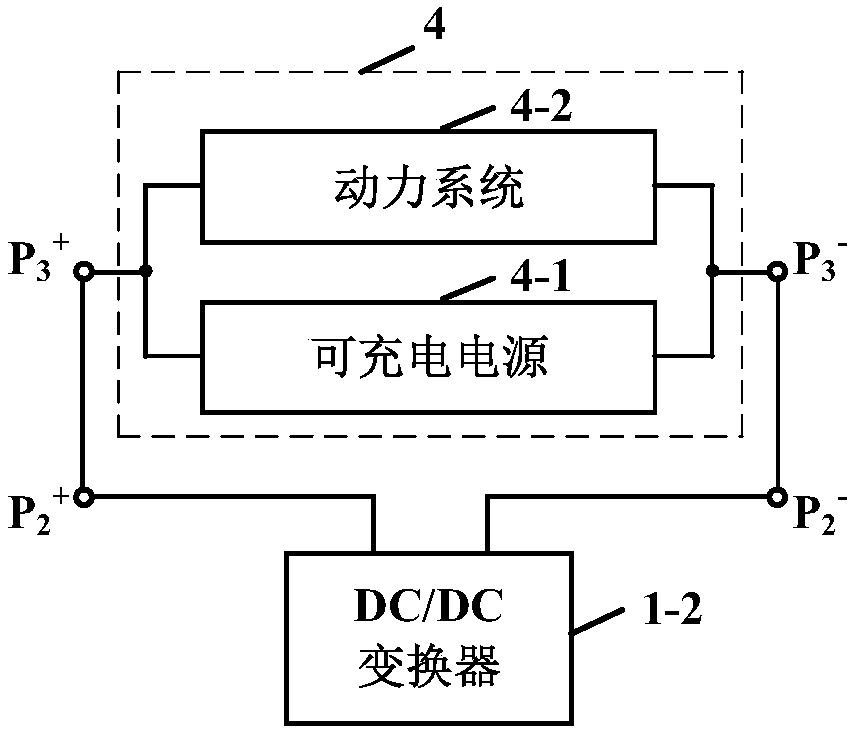

Embodiments of the present invention provide a fuel cell and system, a control method, a control system, and an electric device, wherein the fuel cell is configured to be connected to a load comprising at least a rechargeable power source, and the fuel cell comprises a fuel cell stack module. The control system comprises a detection module adapted to detect the remaining power of the rechargeablepower supply in real time; DC / DC converter of fuel cell; The fuel cell controller module is adapted to control the DC / DC converter to output constant power to the terminal of the load according to thepreset power corresponding to the remaining power. By using this control system, the power supply of the equipment can be increased without destroying the internal structure of the original power supply system of the existing equipment. When combined with the multi-power platform, the idle standby state and / or the variation time of the off-load condition can be prolonged, the starting times and / or the frequent off-load operation state can be reduced, thereby prolonging the service life of the battery.

Owner:北京汇通有利能源科技有限公司

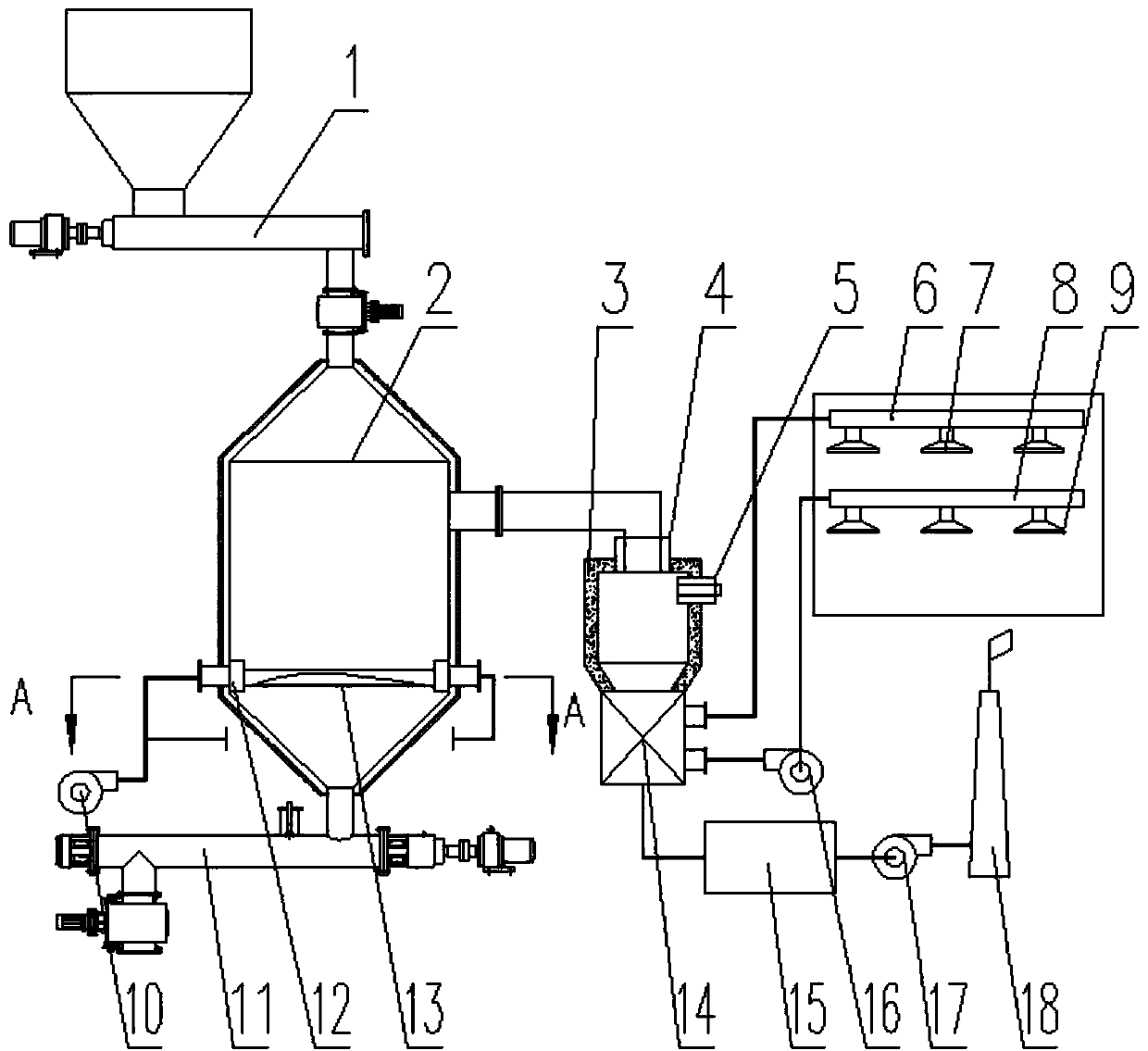

Novel medical waste disposal method and novel medical waste disposal device

InactiveCN104475429AReduce emissionsReduce concentrationSolid waste disposalBiofuelsRefuse-derived fuelMedical treatment

The invention discloses a novel medical waste disposal method and a novel medical waste disposal device. After the medical waste is disposed by the method, the aims of disinfection and sterilization are achieved and a refuse-derived fuel is also produced so as to realize volume reduction, quantity reduction, energy regeneration and harmlessness; the device comprises a feed bin, wherein the feed bin is sequentially connected with a large storage bin, a material crusher, a material dryer, a conveyor, a small storage bin and an extrusion forming machine; a lime tank is arranged on the side surface of the conveyor; and multiple levels of conveying mechanisms are arranged at the lower part and side surface of the extrusion forming machine. According to the method and the device, the medical waste can be made into the refuse-derived fuel to achieve the aims of harmlessness, volume reduction, quantity reduction and energy regeneration in the medical waste disposal; and moreover, the discharge of HCL can be reduced during combustion, and the concentration of doxin is reduced so as to reduce environmental pollution while the value of medical waste in energy regeneration is improved.

Owner:杭州运邦环保技术有限公司

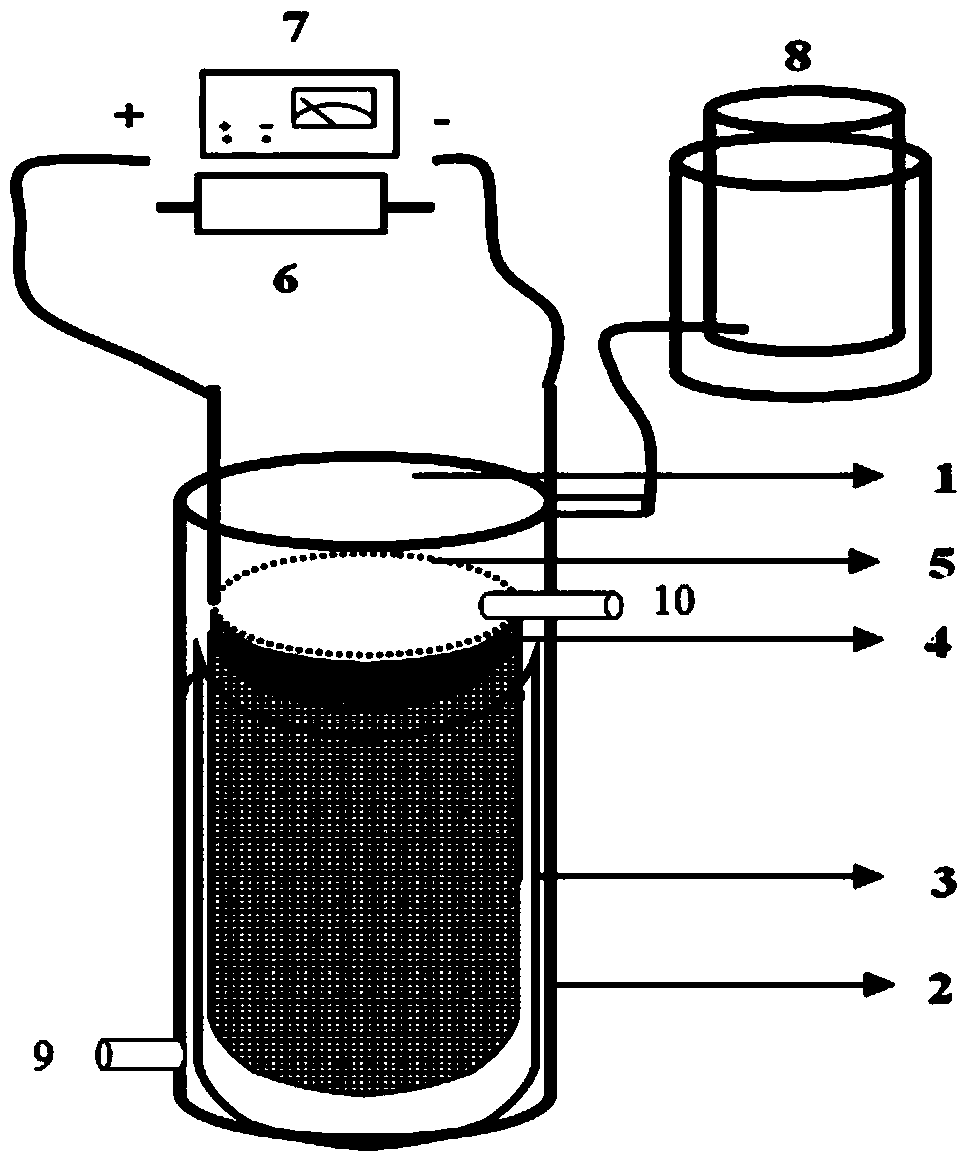

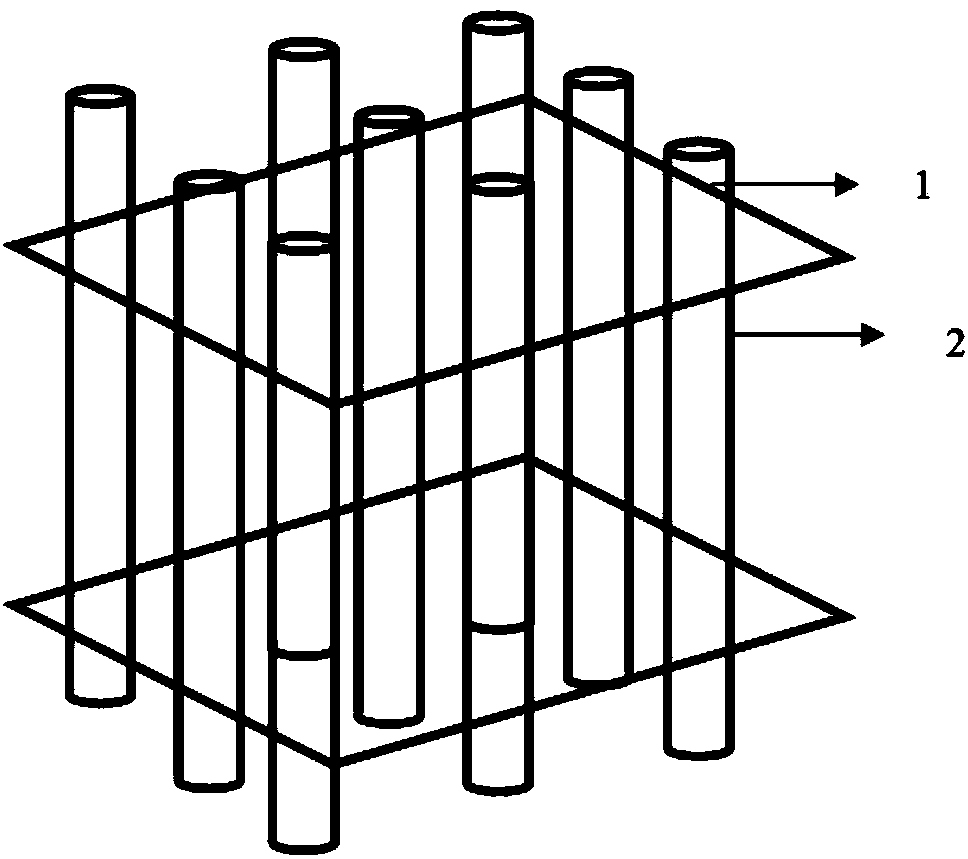

Bioelectrochemistry device and bioelectrochemistry method for extracting reducing energy from waste and wastewater

ActiveCN103811791AImplement resourcesEnergizeTreatment with anaerobic digestion processesBiochemical fuel cellsBiofuel CellsWastewater

The invention relates to a bioelectrochemistry device and a bioelectrochemistry method for extracting reducing energy from waste and wastewater. The device comprises a positive electrode chamber serving as a reactor, a conductor wall, a membrane, a positive electrode, an external circuit and a load or an external power supply, wherein the conductor wall is a negative electrode of the reactor; the negative electrode serving as a reactor main body structure or an independent negative electrode is embedded into the positive electrode chamber. A plurality of the devices can be connected in parallel or in series to form an integrated device, so that the treatment capability is improved. The device can work under a biological fuel battery or biological electrolytic tank mode or alternately runs in the two modes; the pH value of the wastewater is controlled to be 4-9 in a working process.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

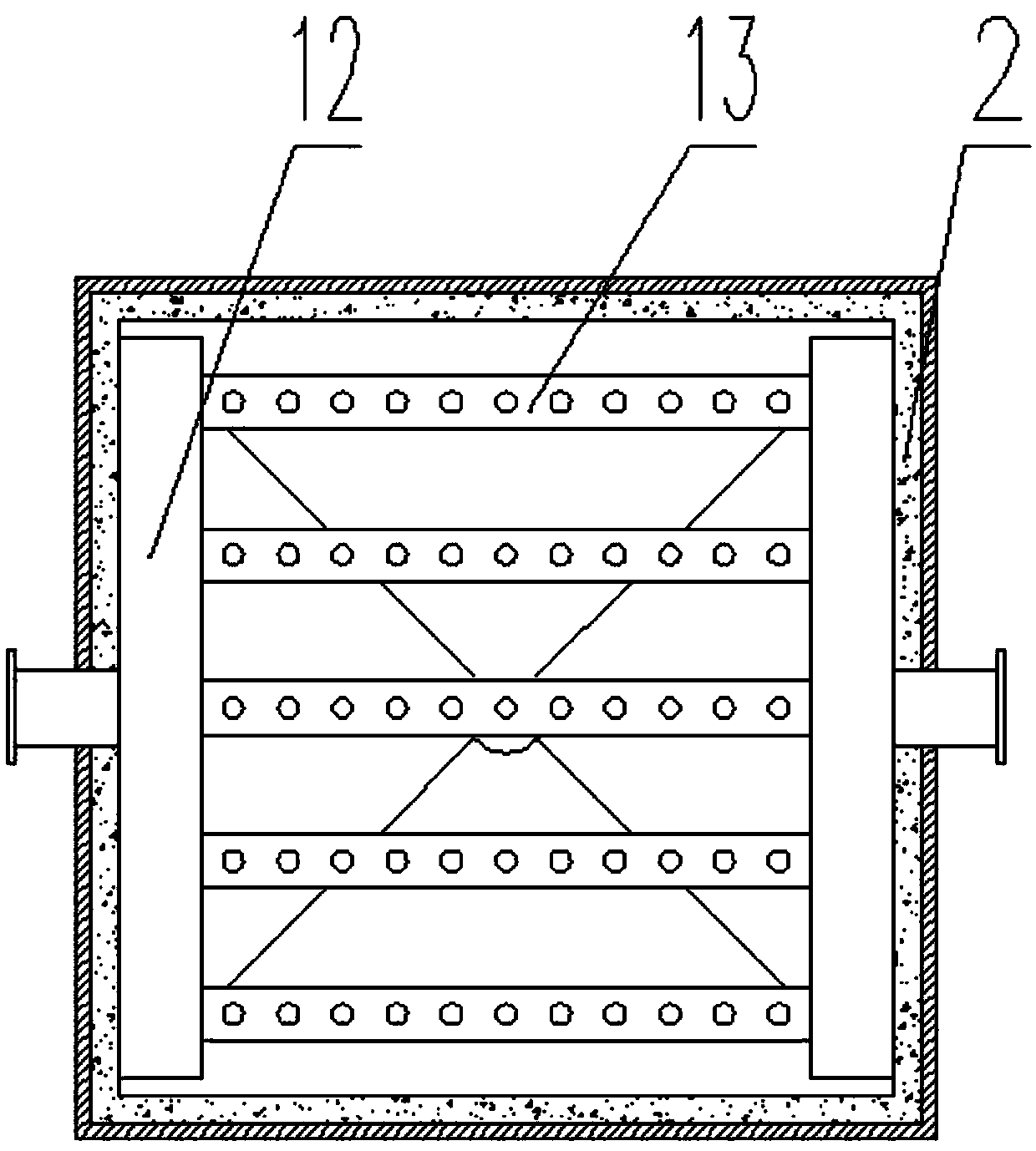

Method for achieving deep sludge dehydration and energy utilization on plate-and-frame filter press

InactiveCN104445863ASimple processEasy to operateSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCombustionSludge

The invention discloses a method for achieving deep sludge dehydration and energy utilization on a plate-and-frame filter press. The method includes the following steps that firstly, filter aid suspension liquid is prepared, a filter aid and water are mixed in proportion, and the filter aid suspension liquid is prepared; secondly, the filter aid suspension liquid prepared in the first step is conveyed to a filter medium of the plate-and-frame filter press, and a precoat is formed; thirdly, sludge on which dehydration needs to be conducted is doped with the filter aid in the first step, and the use amount of the filter aid is larger than the weight of absolutely-dry sludge in the sludge on which dehydration needs to be conducted by 20 percent; fourthly, the sludge doped with the filter aid is conveyed into the plate-and-frame filter press, filter-pressing dehydrating is conducted on the sludge, and pressing dehydrating is conducted on the sludge after filter-pressing dehydrating. According to the method for achieving deep sludge dehydration and energy utilization, deep dehydrating of the sludge is achieved, automatic discharging can be achieved, efficiency is obviously improved, the operation cost is obviously reduced, conditions are created for energy utilization of the sludge, and an obtained filter cake can be used as the raw materials for combustion of plants or other incinerators to be incinerated or used as the raw material of cement plants to be co-processed.

Owner:梁毅 +2

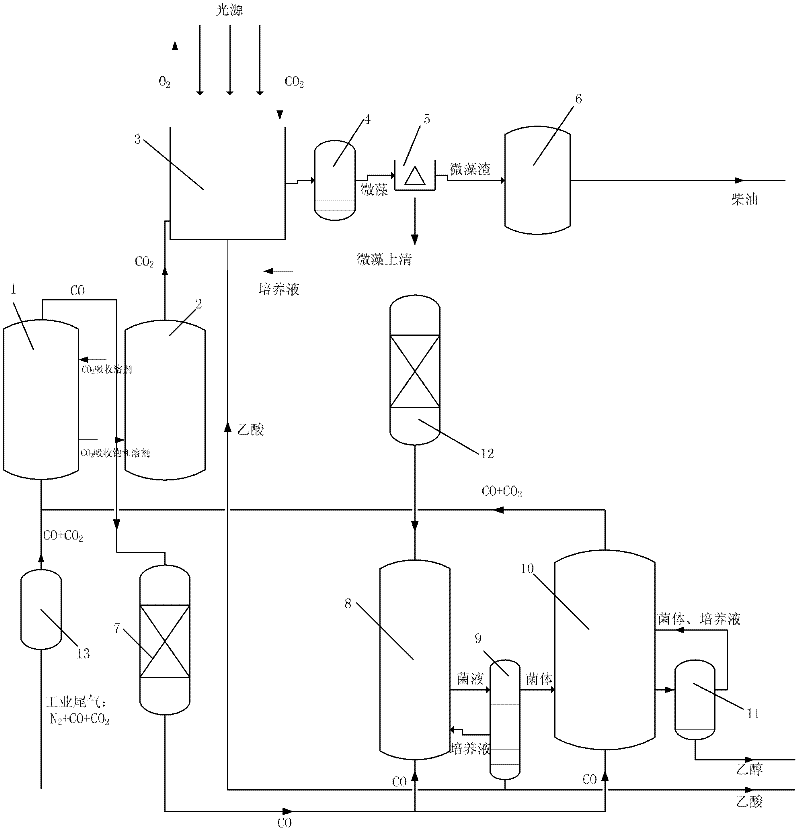

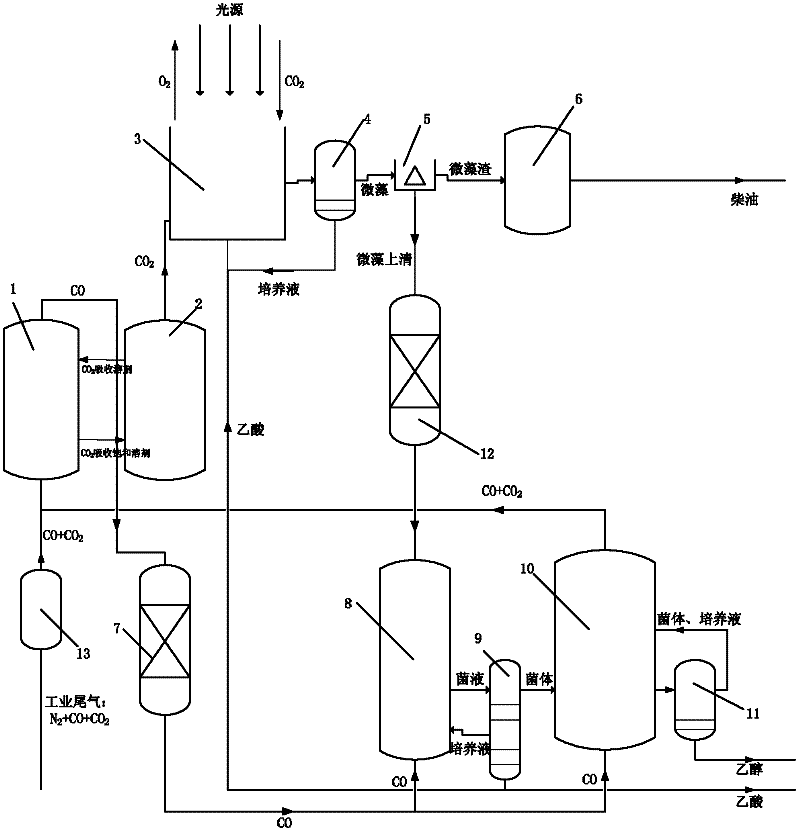

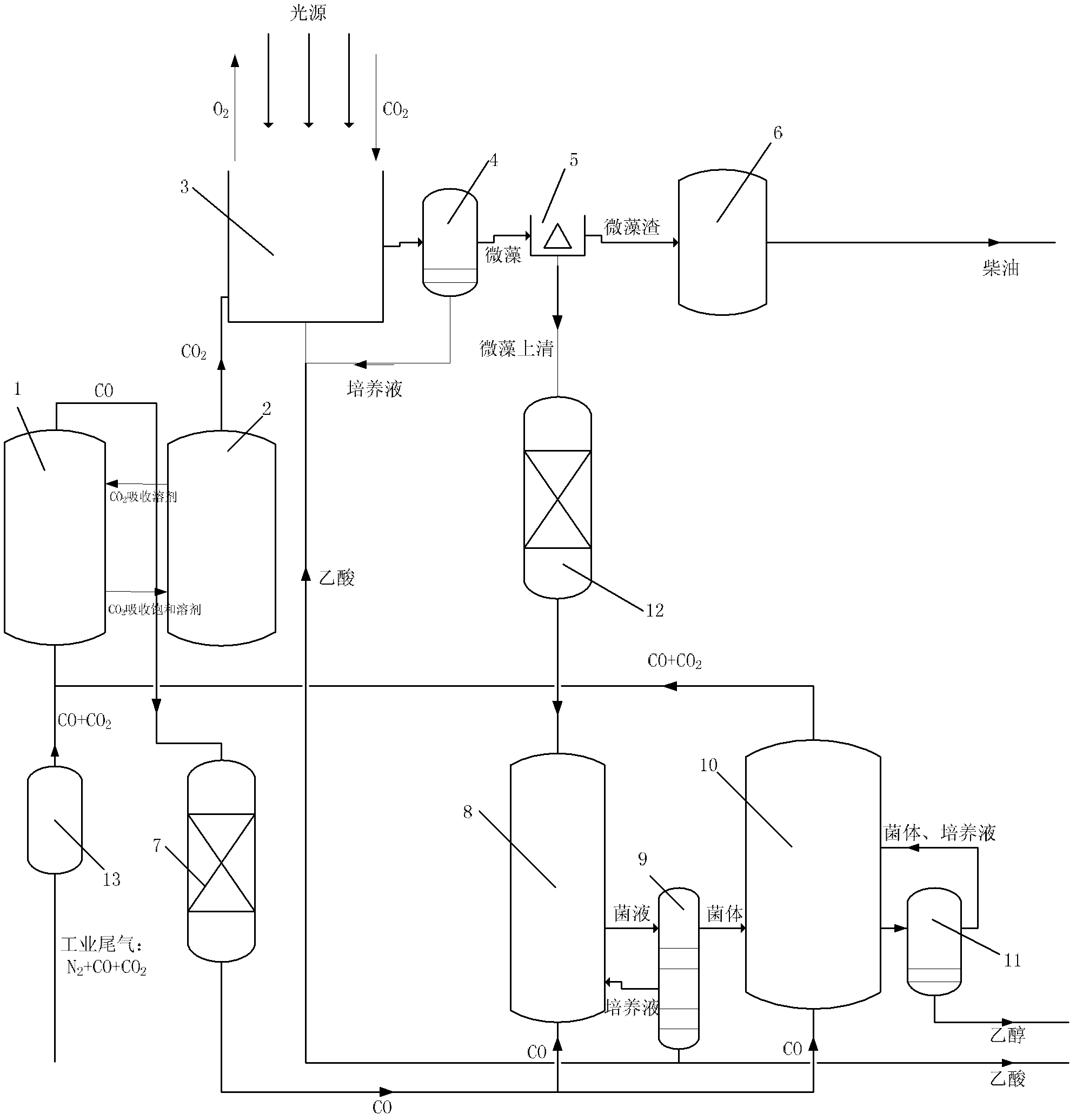

An industrial tail gas energy conversion system

ActiveCN102266719ASolve the discontinuous supplyImportant use valueBiofuelsMicroorganism based processesChemistryOil production

The invention discloses an industrial tail gas recycling system. In the industrial tail gas recycling system, a microalgae oil production device is organically coupled with a synthesis gas fermentation strain growth tank and a synthesis gas fermentation strain fermentation tank. By the industrial tail gas recycling system, CO2 and CO in the tail gas can be recycled effectively, so that two types of clean energy, namely ethanol and diesel, and a few of acetic acid by-products can be obtained. Thus, components of the industrial tail gas can be treated fully through a biologic mode, energy is recycled; therefore, pollution of industrial tail gas emission to the environment can be relieved; and the industrial tail gas energy recycling system has significant use value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

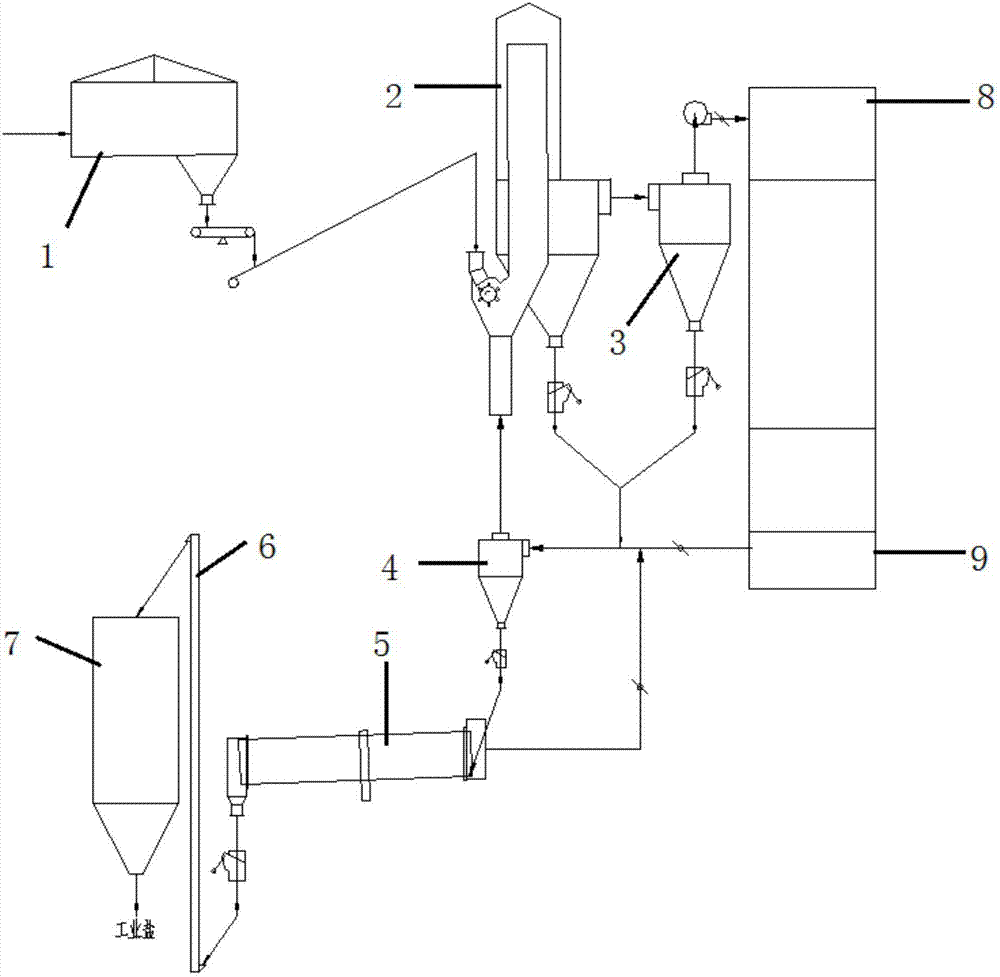

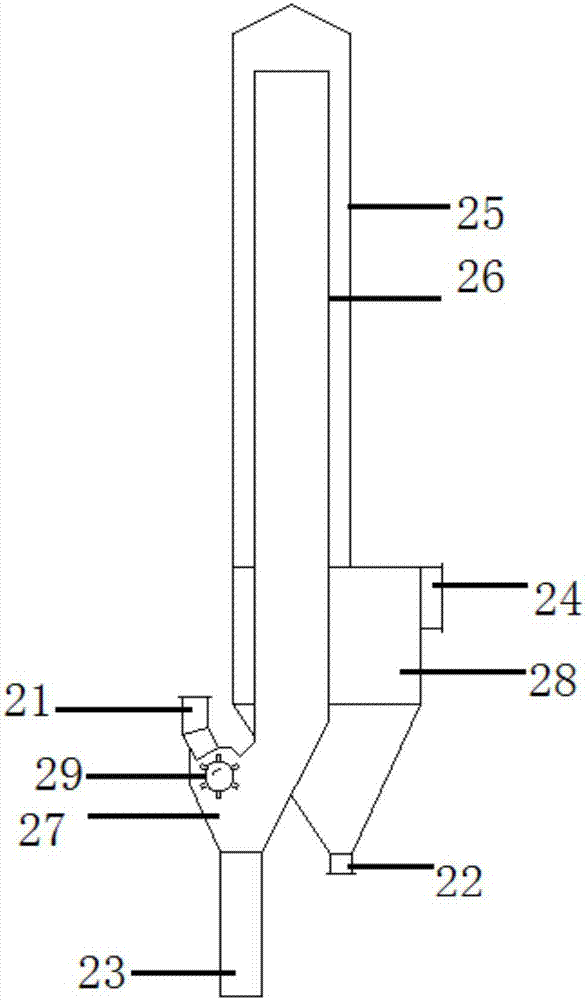

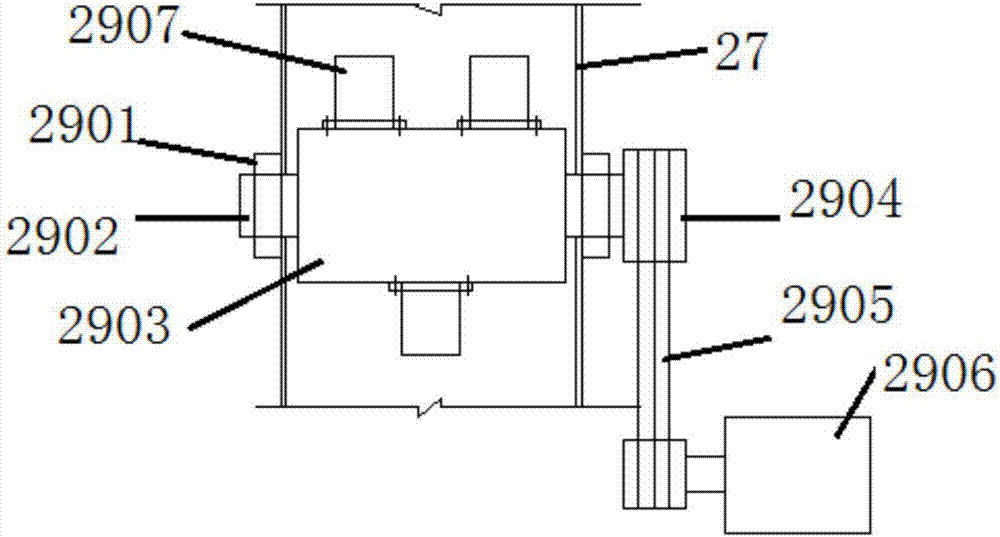

Method and system for cooperatively treating organic waste salt and high-salt organic wastewater by cement kiln

PendingCN107990320AEliminate secondary pollutionHarmlessWater contaminantsMultistage water/sewage treatmentFlue gasEvaporation

The invention provides a method and a system for cooperatively treating organic waste salt and high-salt organic wastewater by a cement kiln. According to the method and the system, low-temperature evaporation and dehydration is carried out on the high-salt organic wastewater by utilizing waste flue gas waste heat of the cement kiln to prepare a concentrated solution with low water content, then the high-temperature flue gas of the cement kiln is used for carrying out twice incineration on organic matters in the concentrated solution or organic matters in the organic waste salt to generate clean industrial salt, waste gas generated in the process enters a cement kiln system for high-temperature strong alkalization treatment so that secondary pollution of the organic waste salt and the high-salt organic wastewater can be thoroughly eliminated, harmless, reclamation, the energy-saving effect and the low-cost treatment of the organic waste salt and the high-salt organic wastewater are realized, and the friendly environment and safe production is ensured.

Owner:长沙中硅环保科技有限公司 +1

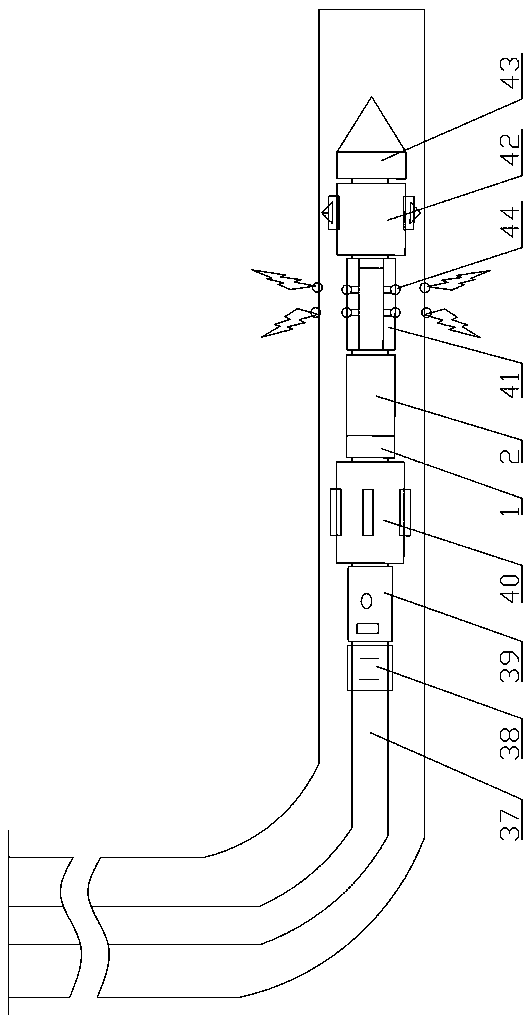

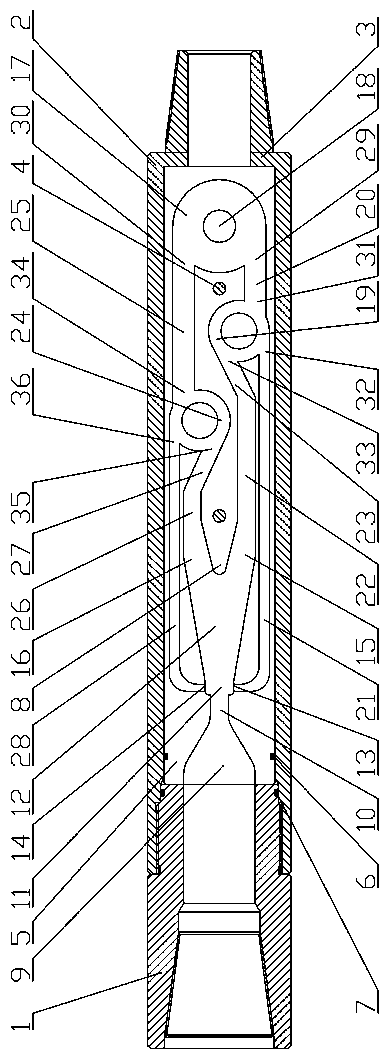

Pulse horizontal well volume fracturing device and horizontal well volume fracturing method

ActiveCN111577234ARapid crackingEnergizeGeothermal energy generationFluid removalHorizontal wellsCoiled tubing

The invention relates to the technical field of oil and gas field exploitation, and provides a pulse horizontal well volume fracturing device and a horizontal well volume fracturing method. The devicecomprises a coiled tubing, a horizontal section of the coiled tubing is sequentially connected with a connector, a motor head assembly, a centralizer, a pulse tool, an ejector, a positioner and a guide shoe, and the pulse tool, the ejector, the positioner and the guide shoe can generate a high-pressure fluid body. The method comprises the following step of (1) drilling down and determining a perforation position. According to the device and the method, the structure is reasonable and compact, the use is facilitated, through the arrangement, the disassembled and assembled can be quickly achieved, the construction cost can be reduced, a pulse fluid body can be generated by the pulse tool, the pulse fluid body can improve the perforation efficiency during volume fracturing through a nozzle,the generation of micro-cracks in a perforation hole eyelet can be increased, the energy increasing in the perforation hole eyelet is realized, cracks is quickly formed on stratum, the construction pressure is reduced, and the device and the method solve the problem that a traditional volume fracturing reforming technology is relatively limited in a method of reforming a target layer section whenformation fracture pressure is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

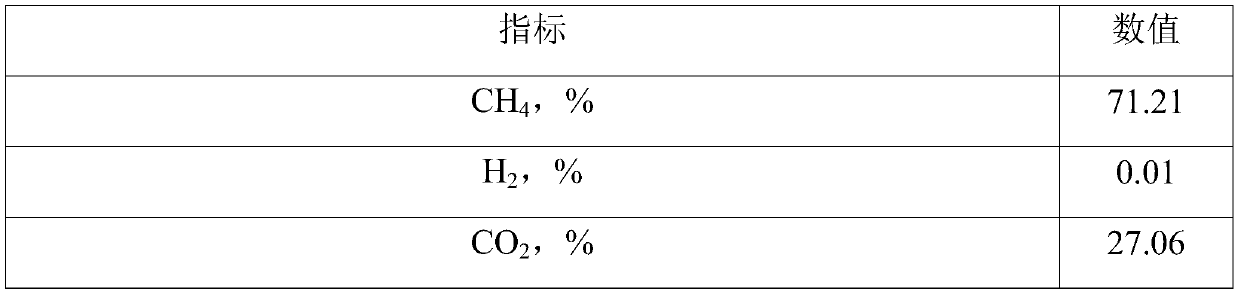

Method for improving characteristics of marsh gas produced through anaerobic fermentation of chicken manure

InactiveCN107935344AEasy to operateImprove controllabilityBiological sludge treatmentProduction rateResource utilization

The invention discloses a method for improving the characteristics of marsh gas produced through anaerobic fermentation of chicken manure. The production of marsh gas is promoted through anaerobic fermentation of chicken manure by taking zeolite as an external source additive. According to the method, efficient and stable production of marsh gas by using chicken manure is realized, the method hasthe characteristics of large fermentation gas production rate, stable gas production and high content of methane in the produced gas, the problem that the system is easy to collapse, which is caused by ammonia nitrogen inhibition in the anaerobic digestion process of chicken manure, is solved, and theoretical foundation and data support are provided for energy and resource utilization of chicken manure.

Owner:SHANGHAI JIAO TONG UNIV

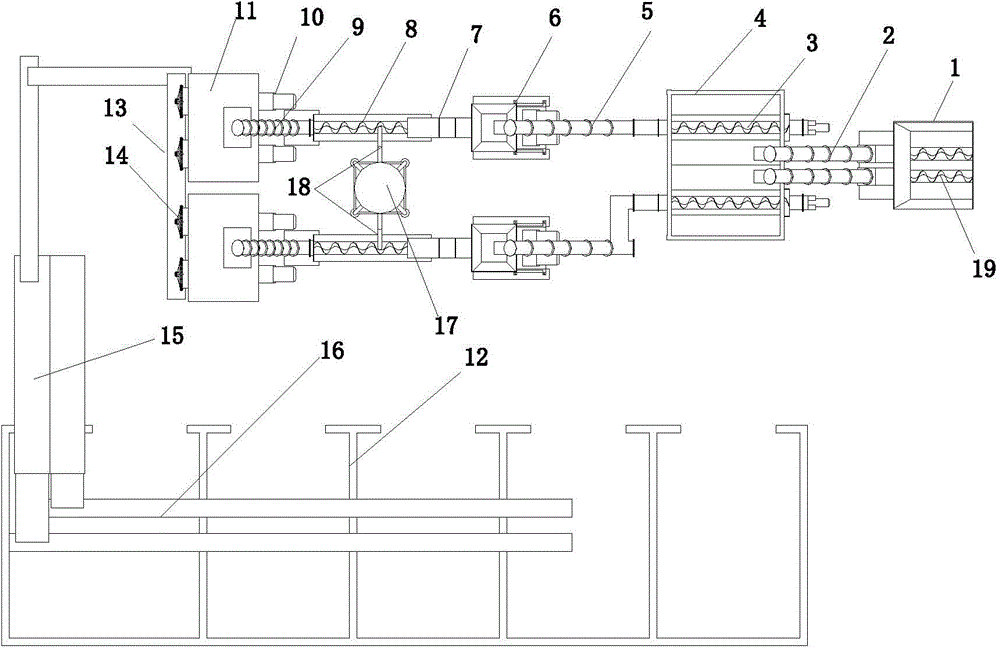

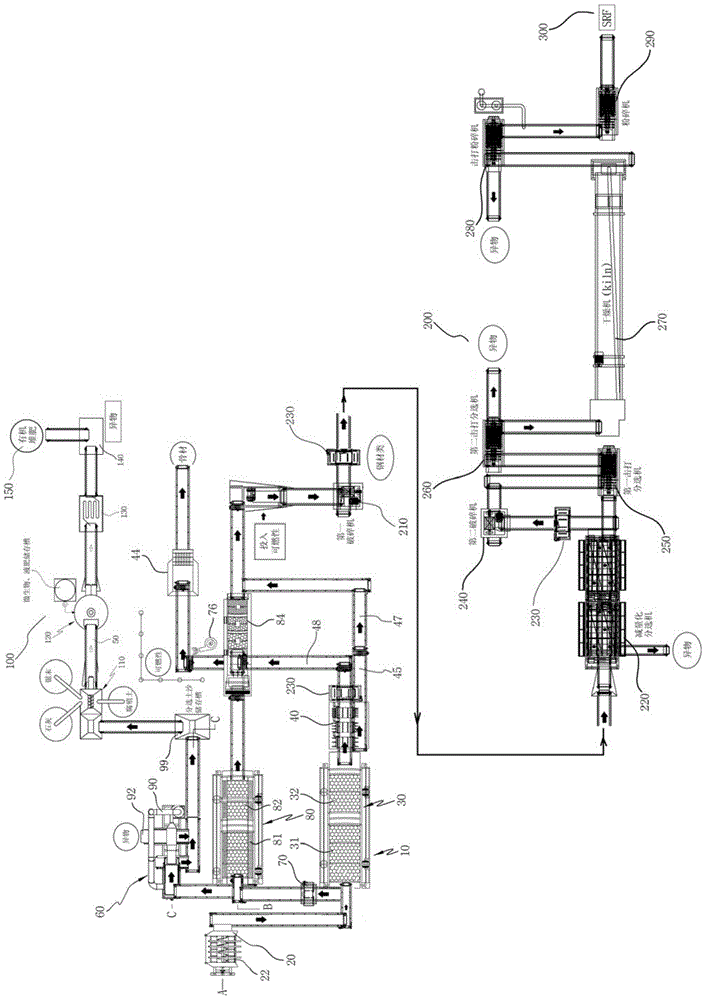

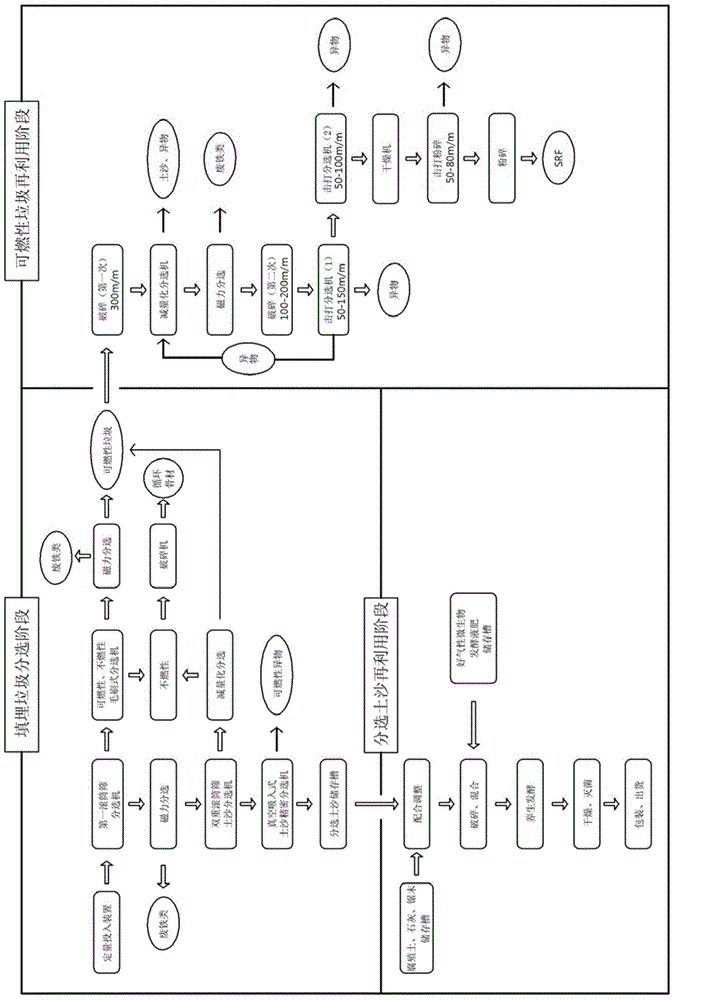

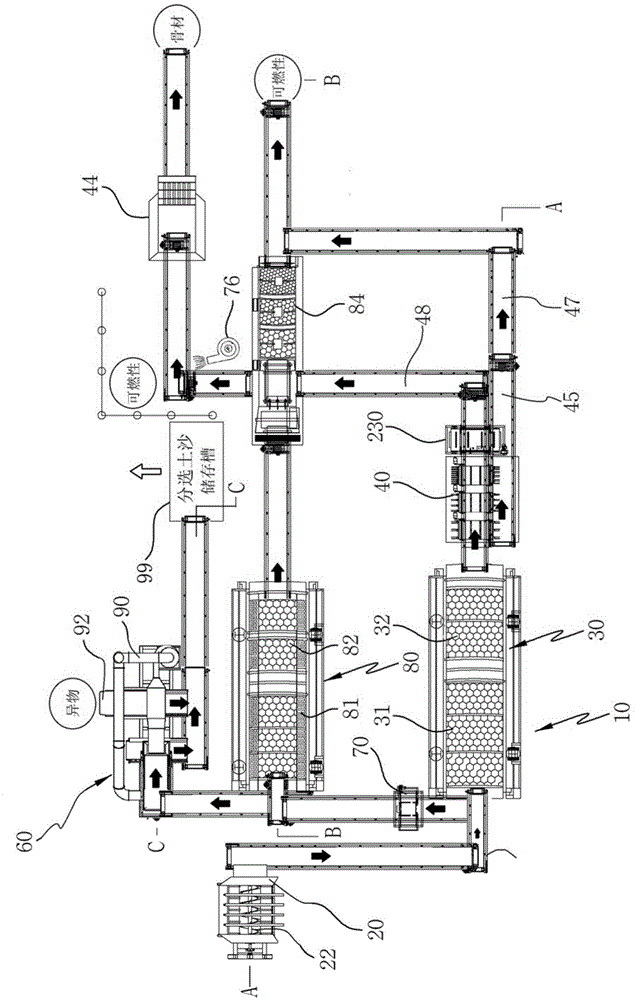

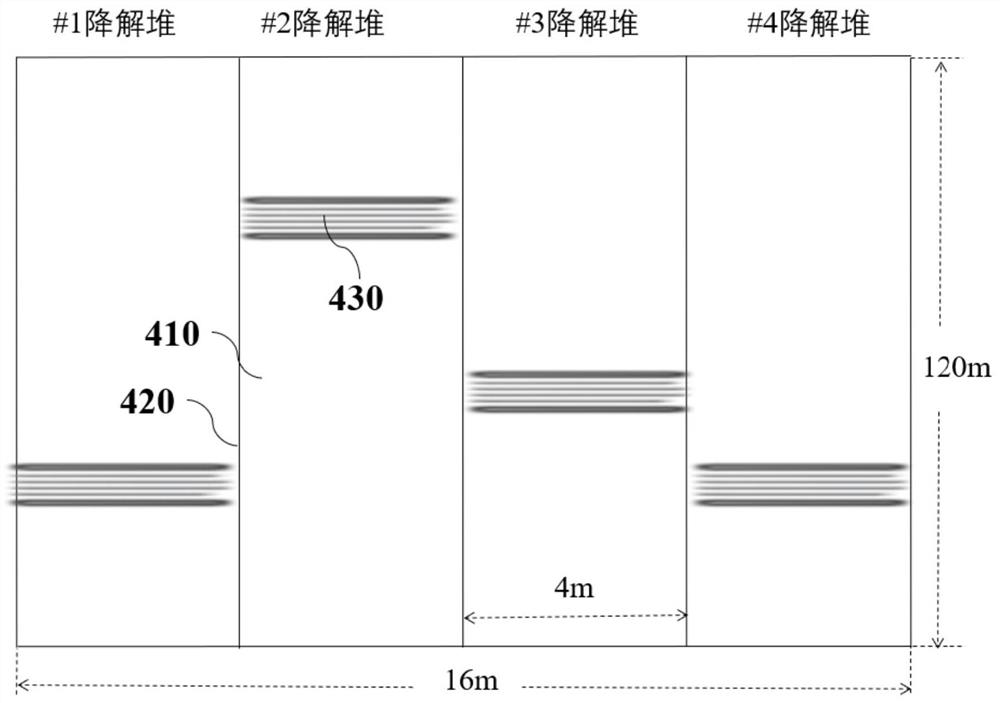

Mechanical sorting and recycling method and device for landfill waste

InactiveCN104624606AFacilitate subsequent processing and reuseEnergizeSolid waste disposalClimate change adaptationLitterEnergy regeneration

The invention discloses a mechanical sorting and recycling method and device for landfill waste. The mechanical sorting and recycling method comprises the following procedures: sorting the landfill waste; sorting separated soil and sand; recycling the sorted soil and sand; and recycling combustible waste. The mechanical sorting and recycling method disclosed by the invention is used for treating a large amount of landfill waste per day, and distinguishing and recycling various kinds of waste, an organic fertilizer can be prepared by recycling the soil and sand, fuel can be prepared by recycling the combustible waste, the energy regeneration of the waste can be fully achieved, resources are saved and the waste is utilized.

Owner:李奎范 +3

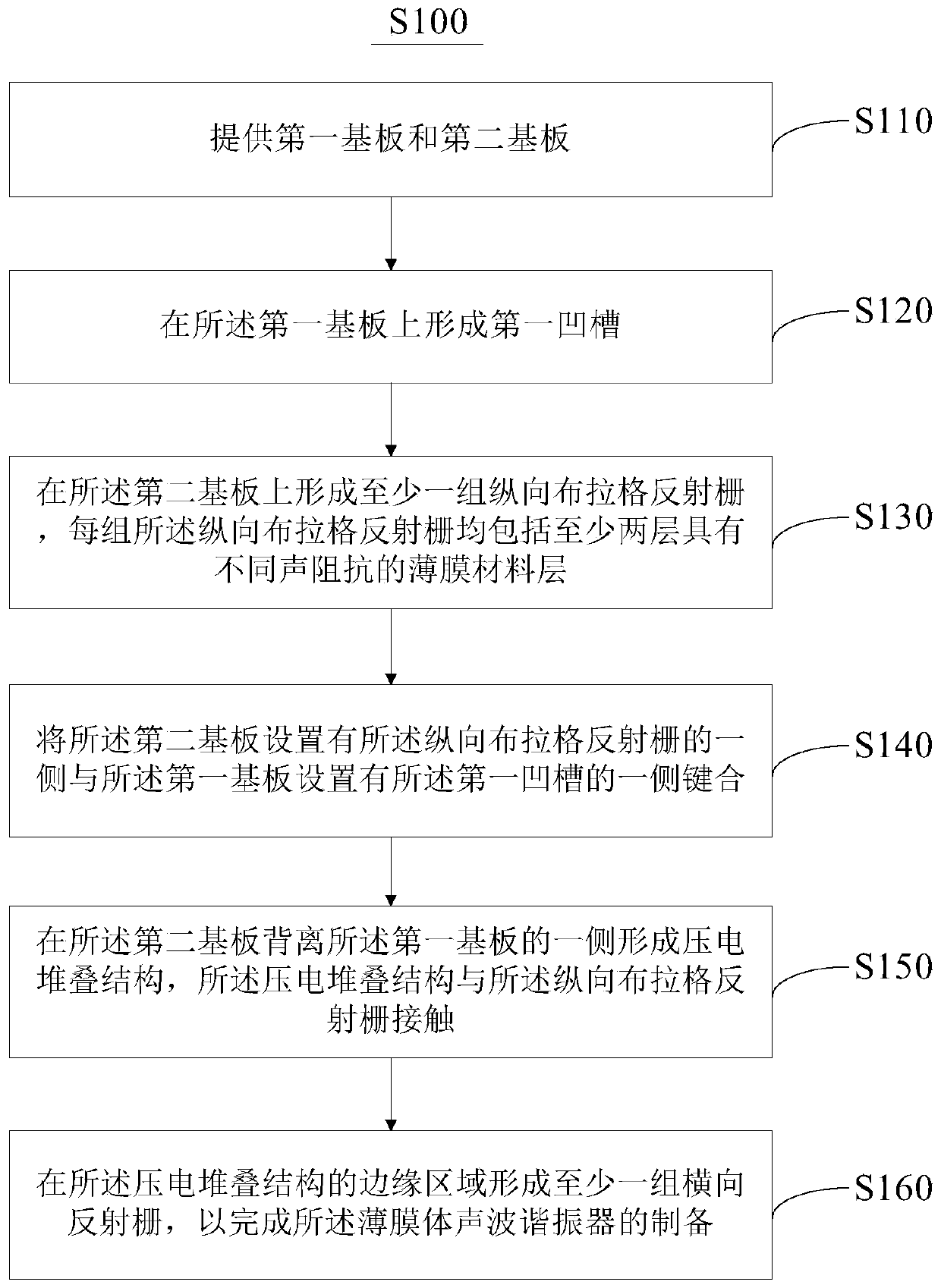

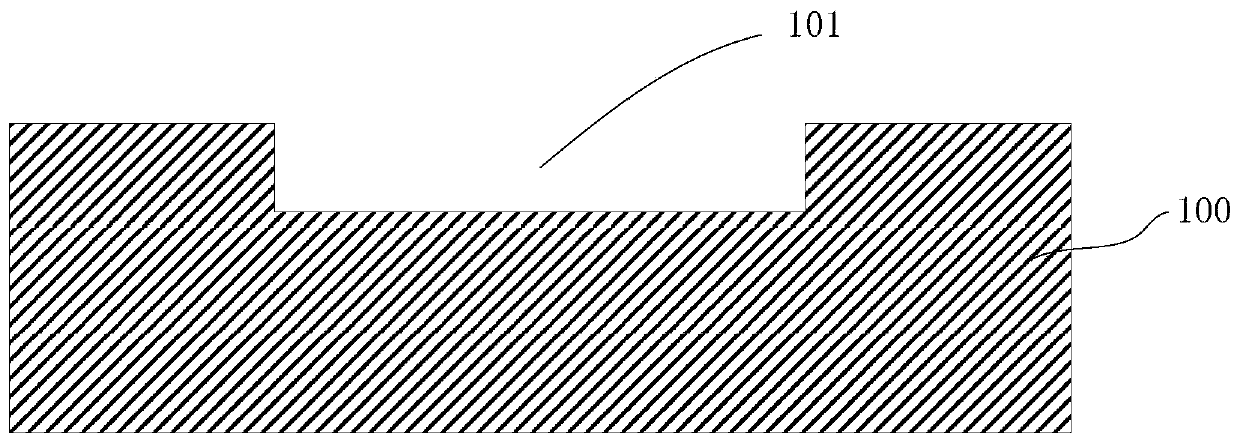

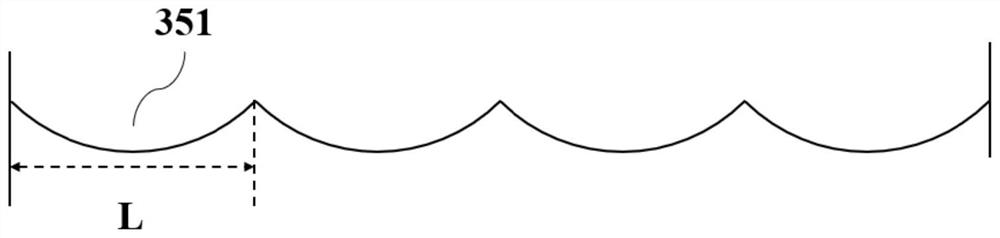

Film bulk acoustic resonator and preparation method thereof

PendingCN110311643AImprove frequency stabilityReduce lossImpedence networksThin-film bulk acoustic resonatorGrating

The invention provides a film bulk acoustic resonator and a preparation method thereof. The preparation method comprises the following steps: providing a first substrate and a second substrate; forming a first groove in the first substrate; forming at least one group of longitudinal Bragg reflection gratings on the second substrate, wherein each group of longitudinal Bragg reflection gratings comprises at least two thin film material layers with different acoustic impedances; bonding the side, provided with the longitudinal Bragg reflection grating, of the second substrate with the side, provided with the first groove, of the first substrate; forming a piezoelectric stacking structure on one side, deviating from the first substrate, of the second substrate; and forming at least one group of transverse reflection grids in the edge area of the piezoelectric stack structure to complete the preparation of the film bulk acoustic wave resonator. The prepared film bulk acoustic resonator is provided with reflecting gates in the transverse direction and the longitudinal direction, acoustic energy can be limited in an effective area of a device, the energy trapping effect can be achieved, the Q value of the device can be further improved, and therefore the resonator has high frequency stability.

Owner:HANGZHOU SAPPLAND MICROELECTRONICS TECH CO LTD

Method for producing biomass fuel by utilizing paper-making sludge and domestic sludge

The invention relates to a method for producing a biomass fuel by utilizing paper-making sludge and domestic sludge. The invention aims at enabling the provided method to have the characteristics of simple process flow, convenience and safety in operation and capability of reducing environmental pollution and enabling the prepared fuel to be high in combustion value and be capable of replacing coal. The technical scheme is as follows: the method for producing the biomass fuel by utilizing the paper-making sludge and the domestic sludge sequentially comprises the following steps of: 1) firstly adding 0.5-2 parts by weight of acid into the sludge and uniformly stirring; 2) then adding 8-12 parts by weight of coalification agent, 3-5 parts by weight of water-reducing agent and 0.1-0.5 part by weight of biomass enzyme and uniformly stirring; and 3) aging and curing for at least 24h, and then performing granulation.

Owner:杭州临安屹晨生物科技有限公司

Moisturizing red wine serum

InactiveCN106511247AEasy to makeKeep healthyCosmetic preparationsToilet preparationsEvening Primrose OilSkin elasticity

The invention discloses a moisturizing red wine serum which is prepared from the following components in parts by weight: 25-35 parts of red wine, 5-7 parts of lavender essential oil, 2-4 parts of rose extracting solution, 1-3 parts of pansy flower extractive, 4-6 parts of evening primrose oil, 0.2-0.4 parts of essence, 10-20 parts of apricot kernel meal, 5-10 parts of honey, 10-15 parts of yoghourt, 0.5-0.7 part of collagen, 0.8-1 part of xanthan gum, 0.3-0.5 part of hydroxyethyl cellulose, 1-3 parts of sodium hyaluronate, 5-7 parts of glycerinum and 50-70 parts of deionized water. The moisturizing red wine serum disclosed by the invention can be absorbed by the skin within seconds and has the effects of creating transparent and bright skin, tightening the skin, forming a moisture-holding protective screen on the skin, smoothing and pulling the skin, stimulating the fibroblast proliferation, activating skin, recovering skin elasticity, keeping young, keeping skin healthy and invigorating the skin.

Owner:谢桂斌

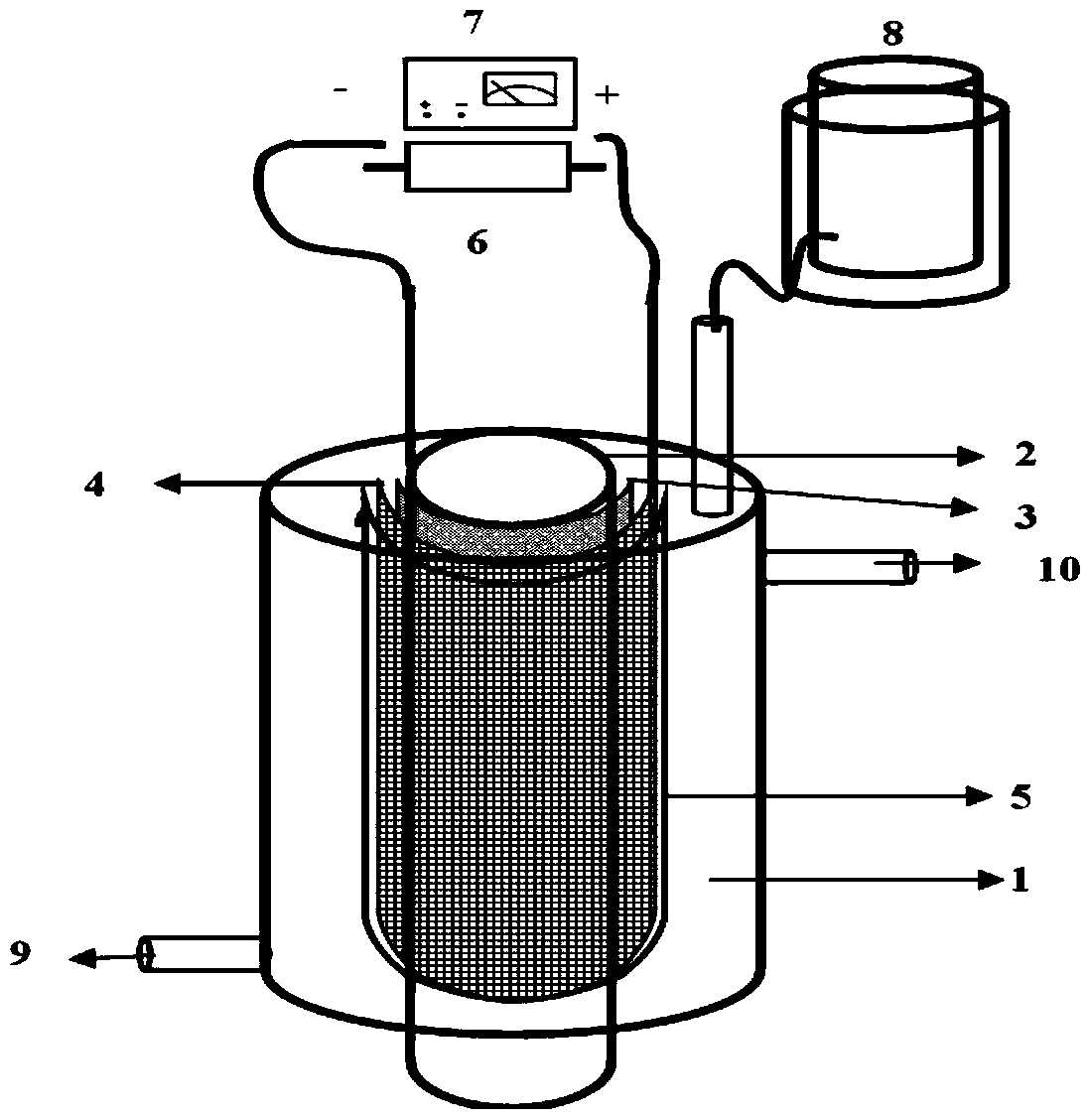

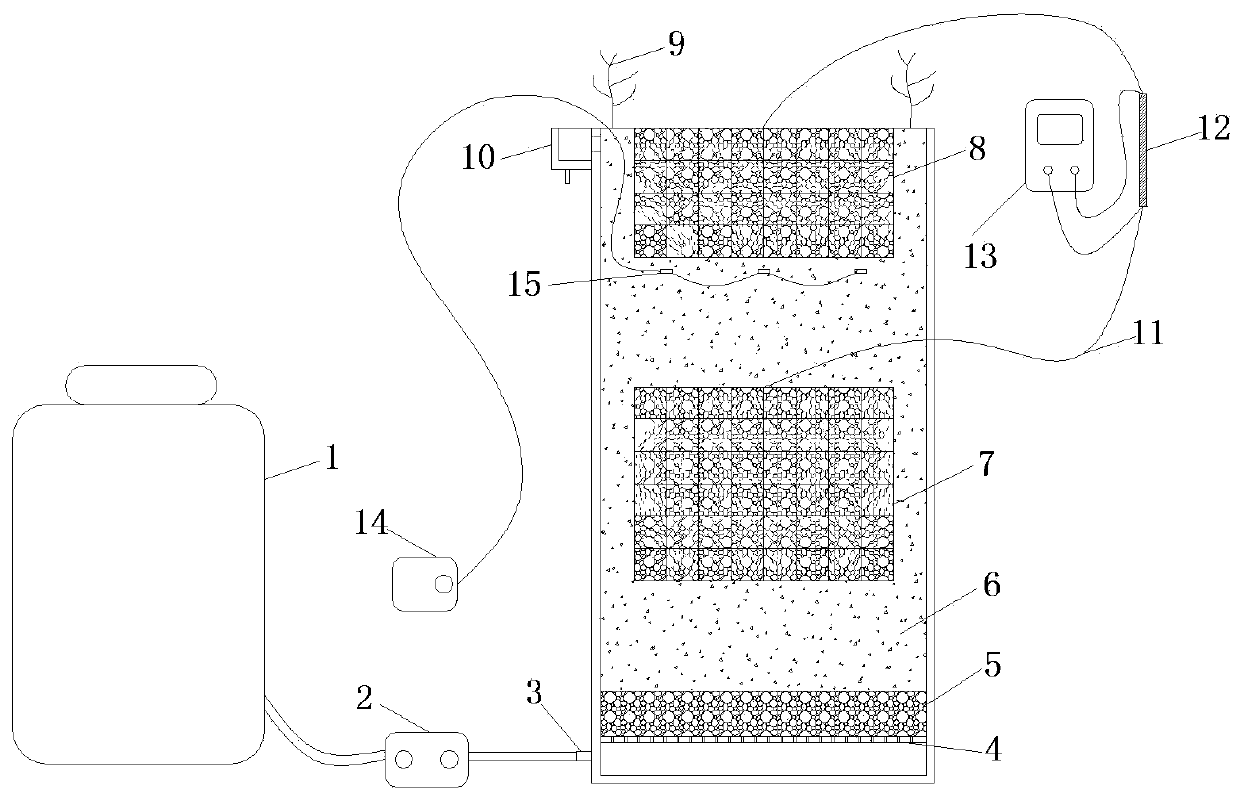

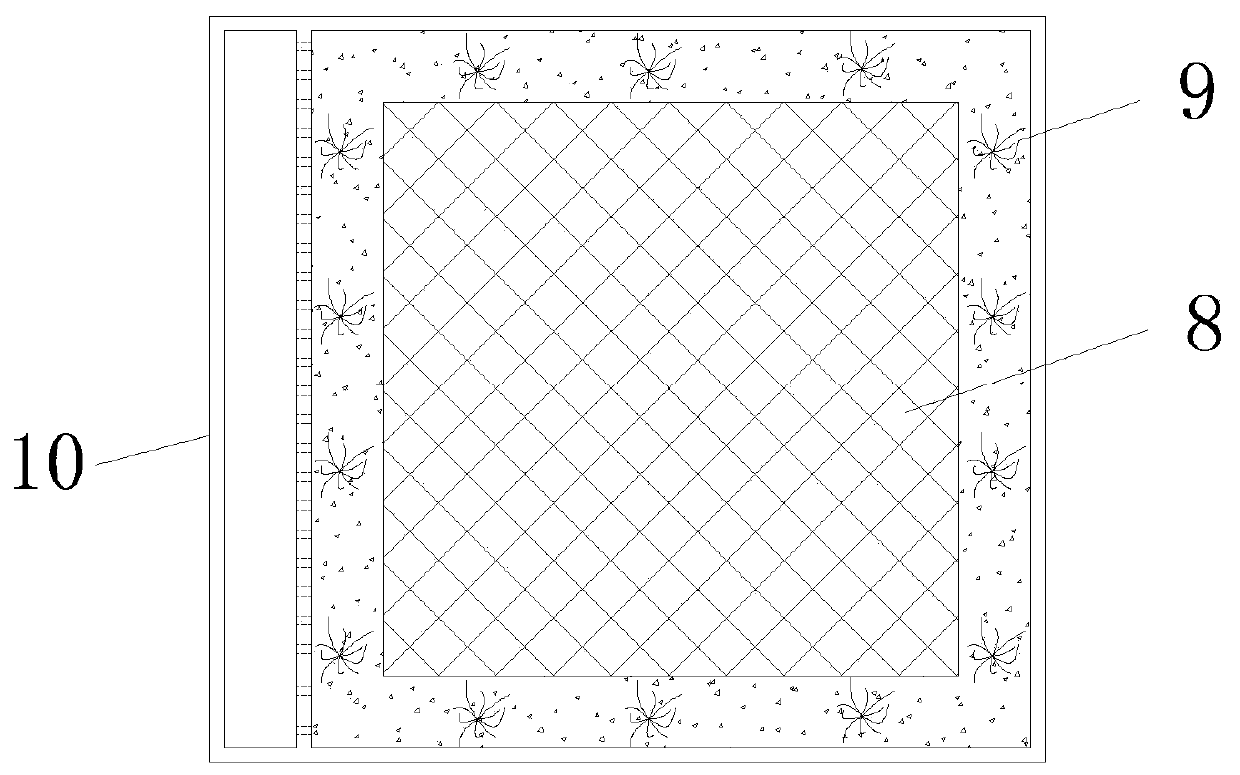

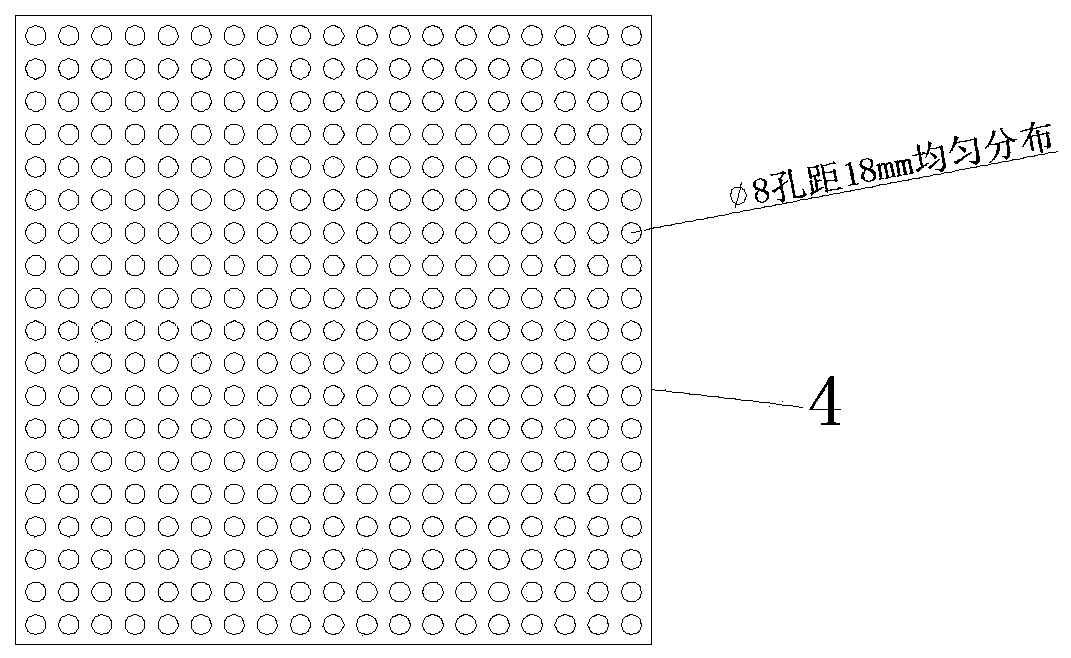

Wastewater purification apparatus of artificial wetland coupled with microbial fuel cell

InactiveCN109851035AGood economic costSimple operation and maintenanceWater contaminantsBiological water/sewage treatmentDual effectChemical energy

The invention discloses a waste water purification apparatus of an artificial wetland coupled with a microbial fuel cell. On the basis of the artificial wetland, electrodes are arranged, a cathode andan anode are connected with an external resistor through conducting wires, and a multimeter is connected with the external resistor to measure the output voltage. The apparatus can be reconstructed on the basis of an original artificial wetland to achieve dual effects of purifying water quality and improving production capacity. The energy is extracted from wastewater, the transformation of chemical energy to biological energy to electric energy is realized, and the waste comprehensive utilization is achieved. According to the apparatus, pollutants in water can be benignly circulated, and atthe same time the energy utilization of resources can be realized. The apparatus has relatively good economic cost, simple operation and maintenance, and simple and easy and feasible electrode form, and the inherent defect that expensive electrodes are needed to be used in the microbial fuel cell is directly avoided, so that the apparatus has the advantage of practical engineering popularization.

Owner:XIAN UNIV OF SCI & TECH

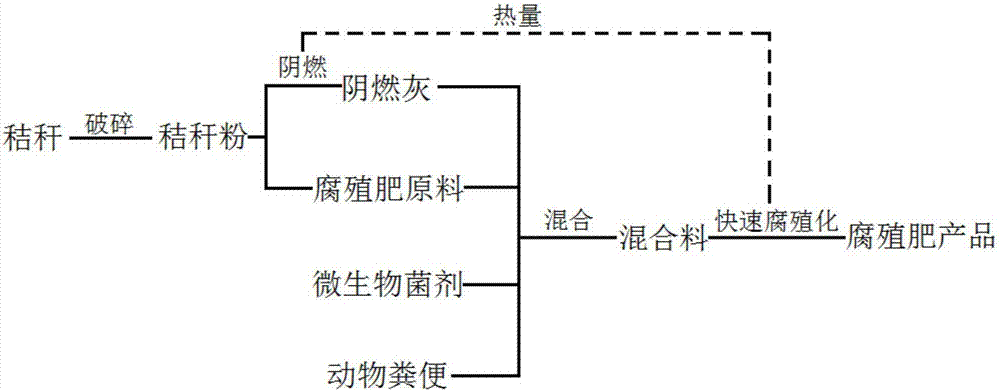

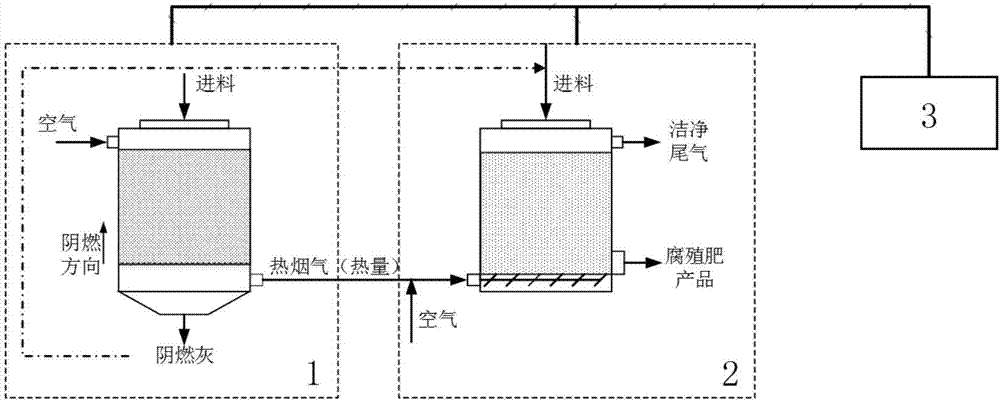

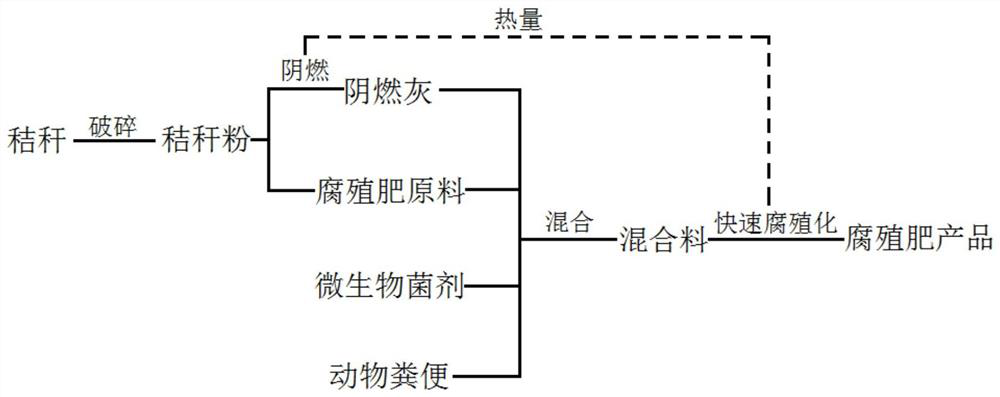

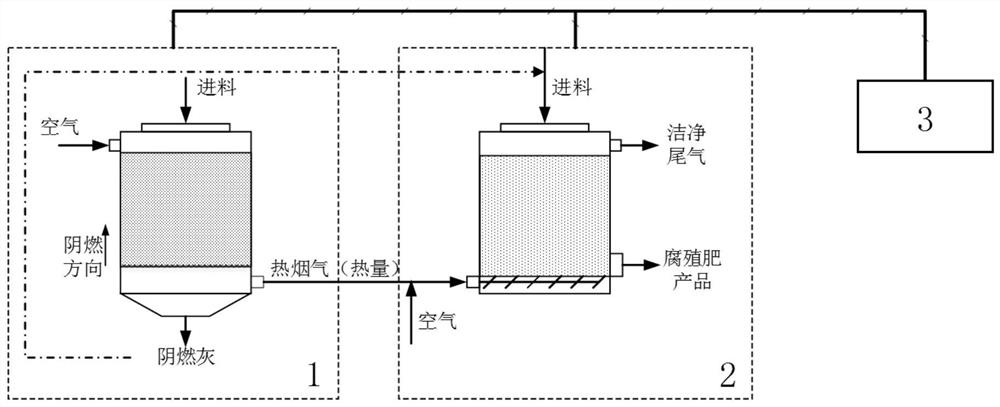

Straw smoldering and rapid humification combined use method and humic fertilizer product of straws

ActiveCN106905072ASynchronous smoldering processSimultaneous rapid humificationBio-organic fraction processingExcrement fertilisersResource utilizationFlue gas

The invention relates to a straw smoldering and rapid humification combined use method and a humic fertilizer product of straws. The combined use method specifically comprises the following steps: (1) crushing the straws, thereby obtaining straw powder; (2) putting part of the straw powder serving as smoldering straw powder into a smoldering furnace, and feeding air for smoldering, thereby obtaining smoldered ash and hot flue gas; (3) uniformly mixing the other part of the straw powder, which serves as a humic fertilizer raw material, with the smoldered ash and an auxiliary material, and putting the mixture into a humification reactor; (4) mixing the hot flue gas with the air, and feeding the hot flue gas and air mixture into the humification reactor to enable the humic fertilizer raw material to be rapidly humified, thereby obtaining the humic fertilizer product. Compared with the prior art, the straw smoldering and rapid humification combined use method has the advantages that the straws which are crops are subjected to smoldering and rapid humification for combined use, and the smoldered ash and the hot flue gas which are produced in the smoldering process are fully used in a rapid humification process, so that rapid and efficient in-situ harmless use of the straws is realized, the environmental pollution is low, and the resource utilization rate is high.

Owner:TONGJI UNIV

Rose essence emulsion for removing beverage and whitening skin

InactiveCN107412113AKeep healthyPromote proliferationCosmetic preparationsToilet preparationsEmulsionFiber cell

The invention discloses a freckle-removing and whitening rose essence emulsion, which is mainly prepared from the following components in proportions by weight: 2-4 parts of rose extract, 1-3 parts of pansy flower extract, and 4 parts of evening primrose oil ‑6 parts, 5‑7 parts of pearl powder, 0.2‑0.4 parts of essence, 1‑2 parts of lemon essential oil, 4‑8 parts of white clove, 2‑4 parts of white aconite, 3‑5 parts of Angelica dahurica, 0.5‑0.7 parts of hyaluronic acid, 2‑4 parts of polyglycerol esters, 0.4‑0.6 parts of phenoxyethanol, 2‑3 parts of glycerin, 0.6‑1 parts of hydrolyzed zein, 2‑4 parts of sorbitol, 0.1‑0.3 parts of caprylyl glycol, 5‑7 parts of collagen 100‑120 parts of deionized water. It can be quickly absorbed by the skin, making the skin bright and firm, and has the effect of removing freckles and whitening, forming a water-retaining barrier on the skin, smoothing and lifting the skin, stimulating the proliferation of fibroblasts, activating the skin, restoring the elasticity of the skin and maintaining youthfulness, and keeping the skin healthy. vitality.

Owner:赵宏耀

Preparation method of sludge active carbon

InactiveCN110078071AAvoid sludge dewatering processReduce energy consumptionCarbon compoundsOther chemical processesActivated carbonSolid product

The invention relates to a preparation method of sludge active carbon. The preparation method specifically comprises the following steps: (1) after mixing sludge with a calcium-based additive, heating, keeping warm, and cooling to a room temperature to obtain a solid-liquid mixture; (2) after centrifugal separation of the solid-liquid mixture prepared and obtained in the step (1), obtaining a water-containing solid; (3) heating the water-containing solid obtained in the step (2), keeping warm, and cooling to a room temperature to obtain a solid product; and (4) carrying out acid pickling and water washing on the solid product obtained in the step (3), and drying to obtain the sludge active carbon. Compared with the prior art, physical and chemical activation of sludge pyrolytic carbon is realized while harmless and energy sludge is realized, the sludge active carbon with large holes and low cost can be prepared, and the preparation method has the characteristics of simple technology, low preparation energy consumption, wide product adaptation and the like.

Owner:TONGJI UNIV

Industrial tail gas recycling system

ActiveCN102266719BSolving the problem of discontinuous supplyStable biological reaction environmentBiofuelsMicroorganism based processesOil productionClean energy

The invention discloses an industrial tail gas recycling system. In the industrial tail gas recycling system, a microalgae oil production device is organically coupled with a synthesis gas fermentation strain growth tank and a synthesis gas fermentation strain fermentation tank. By the industrial tail gas recycling system, CO2 and CO in the tail gas can be recycled effectively, so that two types of clean energy, namely ethanol and diesel, and a few of acetic acid by-products can be obtained. Thus, components of the industrial tail gas can be treated fully through a biologic mode, energy is recycled; therefore, pollution of industrial tail gas emission to the environment can be relieved; and the industrial tail gas energy recycling system has significant use value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

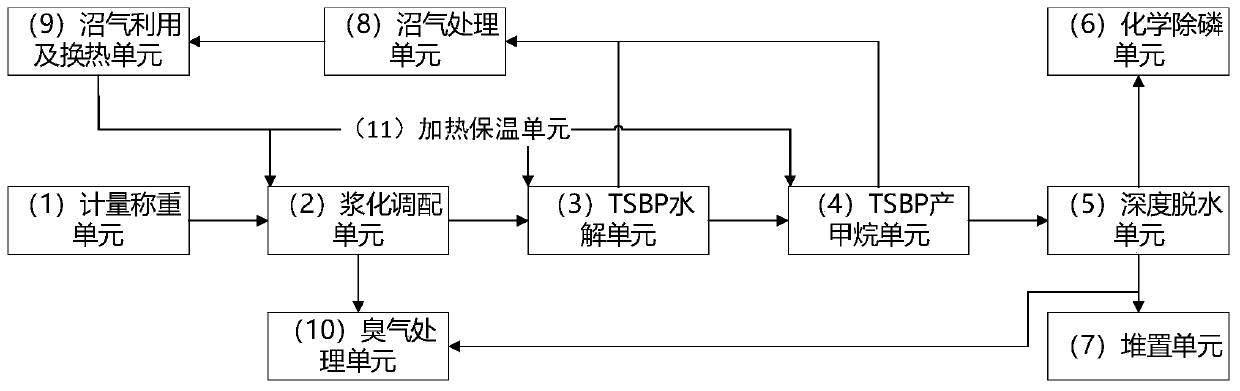

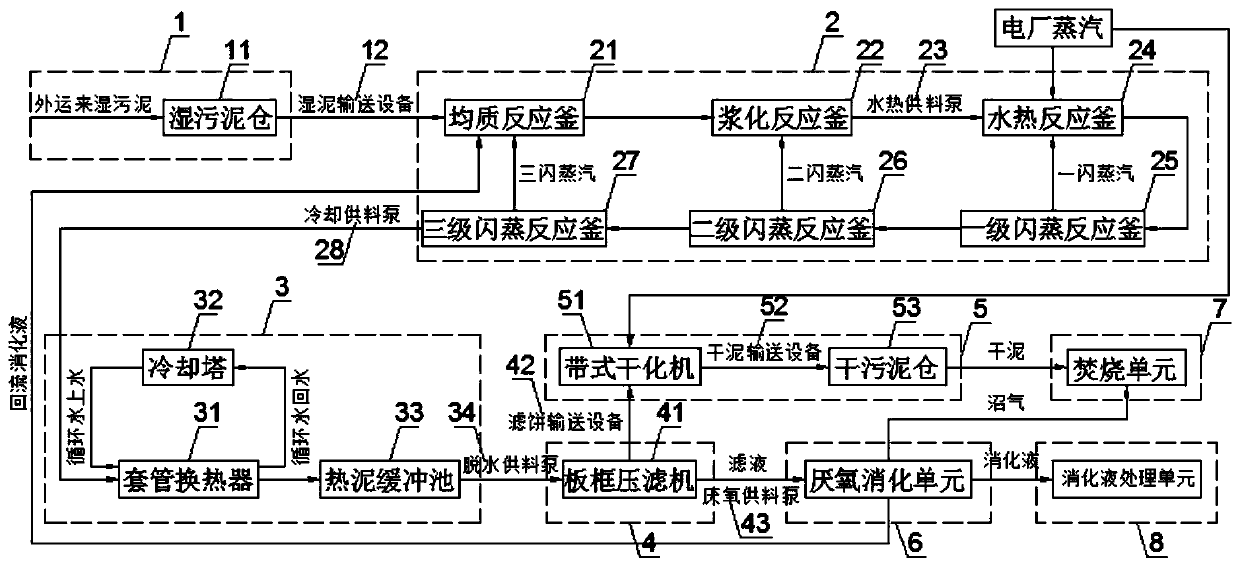

System for treating sludge by two-phase anaerobic digestion and method

PendingCN111484219AAchieve reductionHarmlessSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesMethanogenesisMethane production

The invention relates to a system for treating sludge by two-phase anaerobic digestion, which comprises a metering and weighing unit, a slurrying and blending unit, a TSBP hydrolysis unit, a TSBP methanogenesis unit, a deep dehydration unit, a stacking unit, a chemical phosphorus removal unit, a biogas treatment unit, a biogas utilization and heat exchange unit, a heating and heat preservation unit and an odor treatment unit. The sludge enters the slurrying and blending unit through the metering and weighing unit for moisture content blending, then enters the TSBP hydrolysis unit firstly, is subjected to rapid wall breaking at a high temperature, degrades macromolecular organic matters into micromolecular organic acids, and then is conveyed to the TSBP methane production unit, and the volatile organic acids are converted into biogas in a medium-temperature environment. The biogas is subjected to desulfurization and moisture removal treatment and then is used for power generation, and power generation waste heat is used for heating and heat preservation of the hydrolysis unit and the methanogenesis unit; the digested sludge is subjected to deep dehydration and then is subjected to subsequent treatment and utilization; according to the invention, the sludge capacity can be realized, and the digested sludge and the biogas slurry are treated at the same time, so that the influenceon the environment is prevented.

Owner:TSINGHUA UNIV

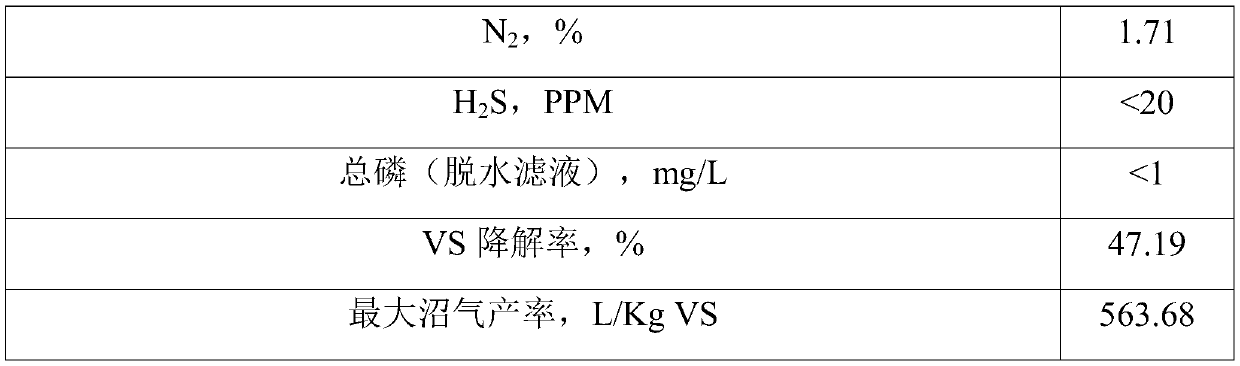

System and method suitable for sludge coupling fire coal burning disposal

InactiveCN110526543AIncrease heat to power ratioLow costSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCooling UnitsThermal treatment

The invention discloses a system and a method suitable for sludge coupling fire coal burning disposal. The system comprises a hydrothermal unit, a cooling unit, a dewatering unit, a drying unit, an incineration unit and a water treatment unit, wherein the sludge outlet of the hydrothermal unit is connected with the cooling unit, and the sludge outlet of the cooling unit is connected with the dewatering unit; the sludge outlet of the dewatering unit is connected with the drying unit; the filtrate outlet of the dewatering unit is connected with the water treatment unit; and the sludge outlet ofthe drying unit is connected with the incineration unit. According to the system, a hydro-thermal treatment technology is coupled with a fire coal thermal power generating unit, so that the final treatment of the sludge is rapidly and thoroughly realized, the energy utilization of the sludge is also realized, the coal consumption of the power plant is reduced, and the system plays an important role in cracking the sludge treatment problem and improving the energy structure.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

Livestock and poultry waste circulating system based on organic padding and operation method of livestock and poultry waste circulating system

ActiveCN113826565AAvoid the stenchReduce infection rateBio-organic fraction processingClimate change adaptationSewage treatmentWaste treatment

The invention belongs to the field of breeding waste treatment, and particularly relates to a livestock and poultry waste circulating system based on organic padding and an operation method of the livestock and poultry waste circulating system. A breeding bin of the fermentation system comprises an elevated net bed, a fermentation layer and a sewage blending layer, wherein organic padding is arranged on the elevated net bed, and the elevated net bed is used for providing a living space for livestock and poultry; the fermentation layer is used for fermenting solid wastes generated by the elevated net bed; a collecting unit of the sewage blending layer is located below the elevated net bed and used for collecting breeding wastewater and conveying the breeding wastewater to a fermentation device through a pipeline; a spraying unit is connected with the fermentation device through a spraying pipe, and the spraying unit is positioned right above the fermentation layer and can spray the fermentation layer. Breeding, solid-liquid separation, sewage treatment and solid waste treatment are integrated, so that the number of equipment and the occupied area of a plant are greatly reduced, the disease infection rate of livestock and poultry is reduced, and reduction, recycling and energy regeneration of livestock and poultry wastes are achieved.

Owner:青岛万慧源环保科技有限公司

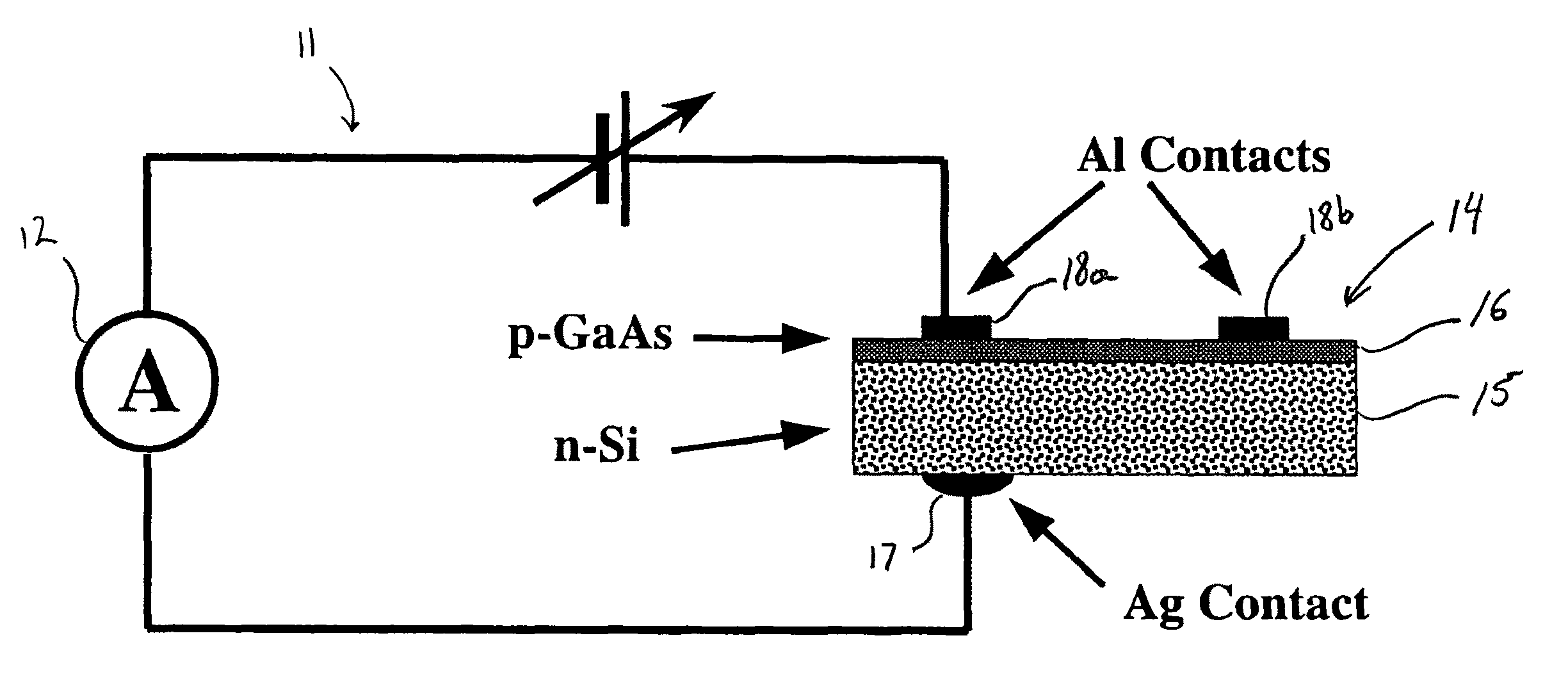

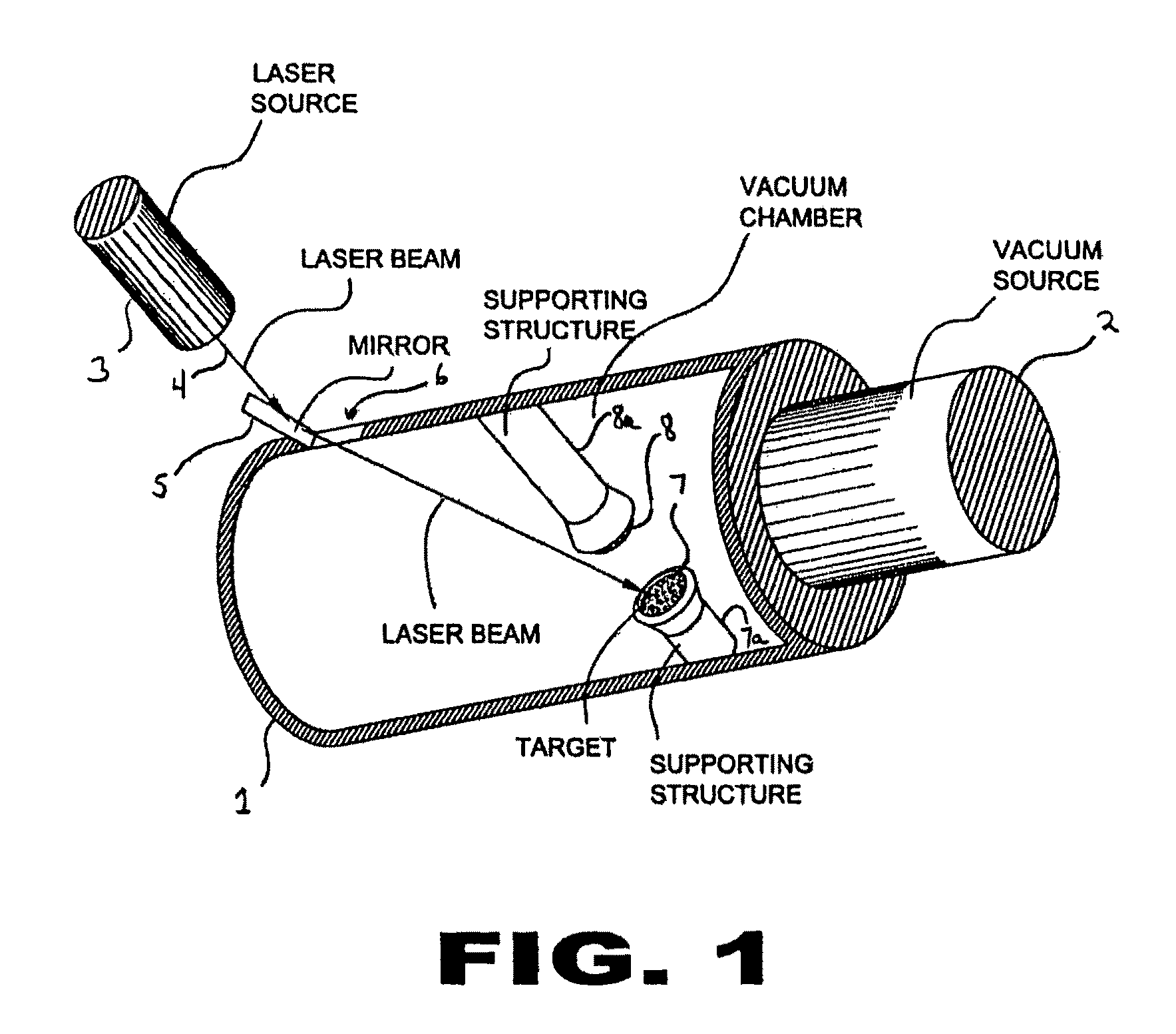

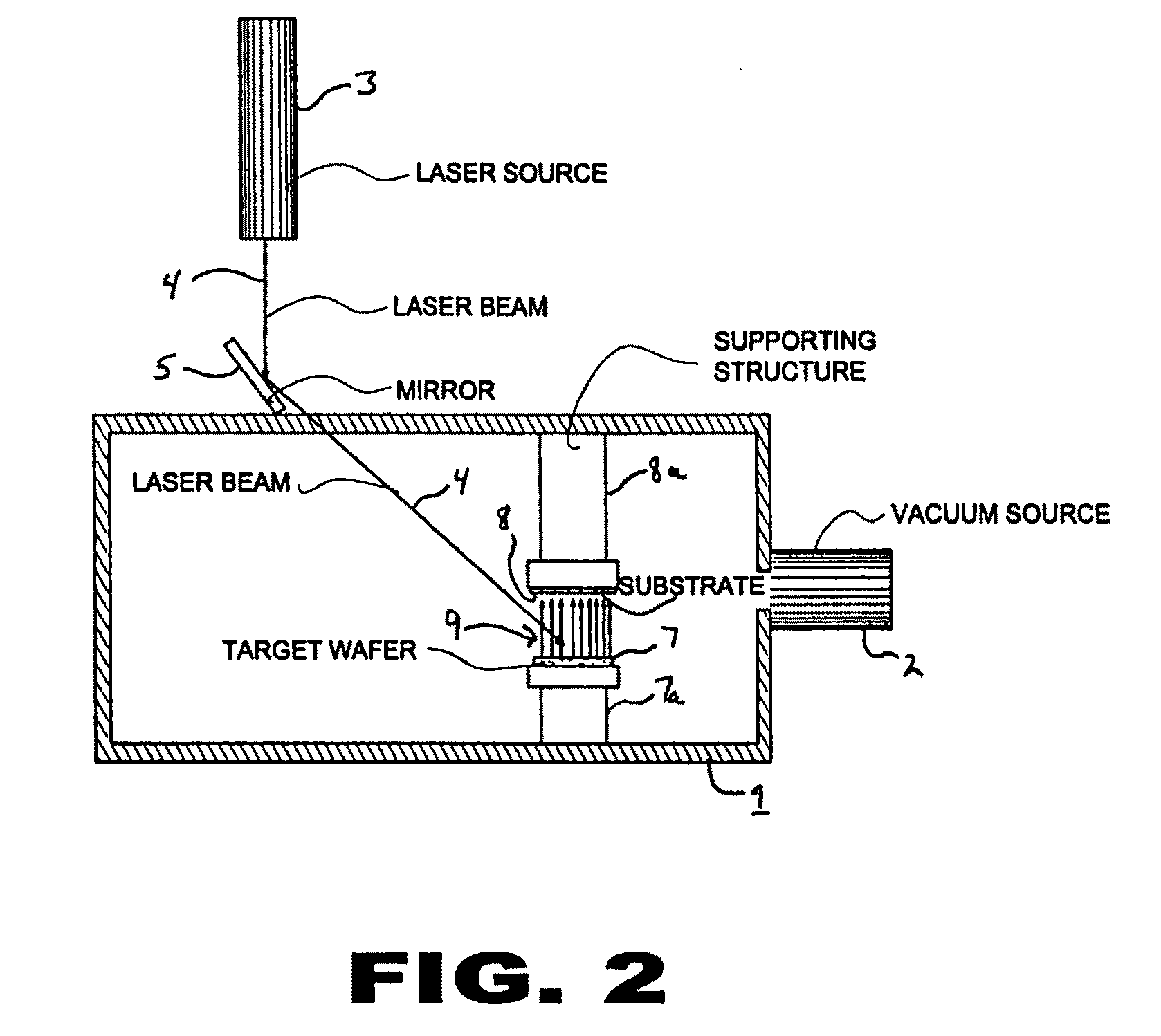

Method and apparatus for producing gallium arsenide and silicon composites and devices incorporating same

InactiveUS7923758B1Excels in qualityEnergizePolycrystalline material growthSolid-state devicesPolymer scienceSilicon

Owner:BOWLING GREEN STATE UNIV

Processing method for changing restaurant and kitchen garbage into resource without environmental pollution

InactiveCN101274860BAvoid wastingEnergizeBio-organic fraction processingWaste processingOxygenMethane gas

The invention relates to a treating method for energy regeneration, resource recovery and pollution free of restaurant garbage, which comprises the steps that separated liquid material is pumped into a swage concentrating pool; then the concentrated liquid material is discharged into a regulating and pretreating pool, in which methane bacteria are inoculated; the pretreated liquid material is discharged into an anaerobic fermentation pool, in which anaerobic bacteria groups are added so that methane gas is generated and the overflowing liquid material from the anaerobic fermentation pool is led to enter an aerobic aerated pool for aerobic reaction; the liquid material after the aerobic reaction is discharged into a sedimentation tank for sedimentation. In the comprehensive utilization of 'swill', the disposing method of the invention carries out anaerobic fermentation and aerobic aerated biochemical treatment to transform part of the energy in the swill into bio-energy which is then transformed into heat energy and finally into electrical energy that is connected with power grid for use. The separated solid material is smashed, dried, sterilized, dehydrated and then added with Chinese herbal medicine to be processed into Chinese herbal medicine compound feeds and fertilizers; meanwhile, the treatment of energy regeneration, resource recovery and pollution free of restaurant garbage for restaurant garbage is realized.

Owner:WUXI KELUN SCI & TECH DEV

Clean fuel prepared from traditional Chinese medicine residues

The invention relates to a clean fuel prepared from traditional Chinese medicine residues, which comprises the following components in percentage by weight: 10-15 parts of coal gangue, 5-15 parts of jacobsite slag, 25-30 parts of industrial salt slurry, 1-5 parts of blast furnace slag, 30-40 parts of traditional Chinese medicine residue, 1-5 parts of combustion improver and 0.5-3 parts of synergist. The preparation process of the clean fuel comprises the following steps: baking the traditional Chinese medicine residues at high temperature to lower the water content to 1-4% below; and mixing and pulverizing the components, and finally, carrying out compression forming on the components by a forming machine. The clean fuel is simple in technique, provides a convenient environment-friendly treatment mode for traditional Chinese medicine residues discharged by the current enterprises, and converts the traditional Chinese medicine residues into energies, resources and harmless substances. After the traditional Chinese medicine residues and industrial solid waste are prepared into the clean fuel, the environmental pollution is reduced, and the economic value can be implemented.

Owner:TIANJIN SHENNONG ENVIRONMENTAL PROTECTION TECH CO LTD

Pigpen heating system with feces as fuel

The invention discloses a pigpen heating system with feces as a fuel. A gas burner is installed at the front portion of a combustion chamber, the rear portion of the combustion chamber is connected with a flue gas inlet of a heat exchanger, a cold air inlet of the heat exchanger is connected with an outlet of a circulating fan, an inlet of the circulating fan is connected with an outlet of a return air duct, the return air duct is communicated with a return air hood, a hot air outlet of the heat exchanger is connected with an air supply duct, the air supply duct is connected to an air supply hood, the air supply hood and the air return hood are both installed in a pigpen, the gas burner is connected to a gas outlet of a gasifier, a horizontal air tube is disposed in an inner cavity of thelower portion of the gasifier, a gap for ash discharge is formed in an air tube, a plurality of through holes are formed in the lower portion of the air tube, and both ends of the air tube are connected to an air collecting box; the system has the advantages of being clean and environmentally friendly, and can achieve the energy regeneration, harmlessness and resource utilization of the feces.

Owner:潘礼斌

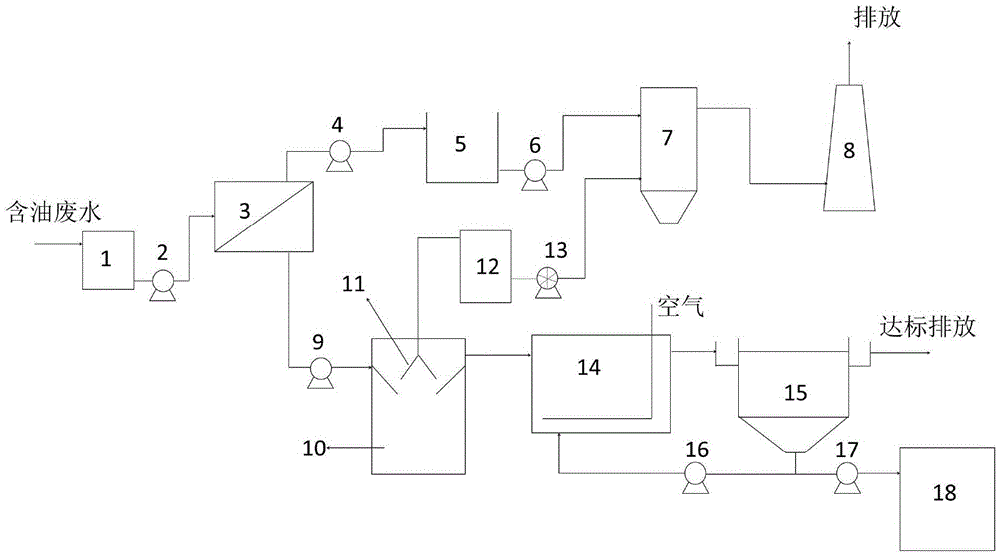

Oily wastewater recycling and wastewater treatment system and treatment method thereof

InactiveCN105645679ASolve the shortcomings of large load impactGuaranteed uptimeFatty/oily/floating substances removal devicesTreatment using aerobic processesUltrafiltrationAnaerobic reactor

The invention discloses an oily wastewater recycling and wastewater treatment system and a treatment method thereof, belonging to the field of oily wastewater treatment. The system mainly comprises a raw water regulating tank, an ultrafiltration separation unit, an oil storage tank, an incinerator, a fume emission tower, a biogas storage tank, an anaerobic reactor, a three-phase separator, an aerobic reactor, a precipitation tank and a sludge concentration tank. The ultrafiltration separation unit adopts an organic-inorganic composite ultrafiltration membrane, can effectively utilize oil substances in the oily wastewater, implements waste recycling, and ensures the treated oily wastewater to be stably discharged after reaching the standard. The complete production system has the characteristics of energy saving, consumption reduction, pollution reduction and effect enhancement.

Owner:NANJING UNIV

A combined utilization method of straw smoldering and rapid humification and its humus fertilizer product

ActiveCN106905072BEnergizeImplement resourcesBio-organic fraction processingExcrement fertilisersFlue gasAgricultural engineering

The invention relates to a combined utilization method of straw smoldering and rapid humification and a humic fertilizer product thereof. The combined utilization method specifically comprises the following steps: (1) crushing the straw to obtain straw powder; (2) crushing a part of the straw powder As smoldering straw powder, put it in a smoldering furnace, and smoldering will occur after the air is introduced to obtain smoldering ash and hot flue gas; Mix evenly together, and place in the humification reactor; (4) After mixing the hot flue gas and air, pass them into the humification reactor together, so that the humic fertilizer raw materials undergo rapid humification to obtain humic fertilizer fertilizer products. Compared with the prior art, the present invention combines the use of crop straw through smoldering and rapid humification, fully utilizes the smoldering ash and hot flue gas generated in the smoldering process in the rapid humification process, and realizes The rapid and efficient in-situ harmless utilization of straw is achieved, with little environmental pollution and high resource utilization.

Owner:TONGJI UNIV

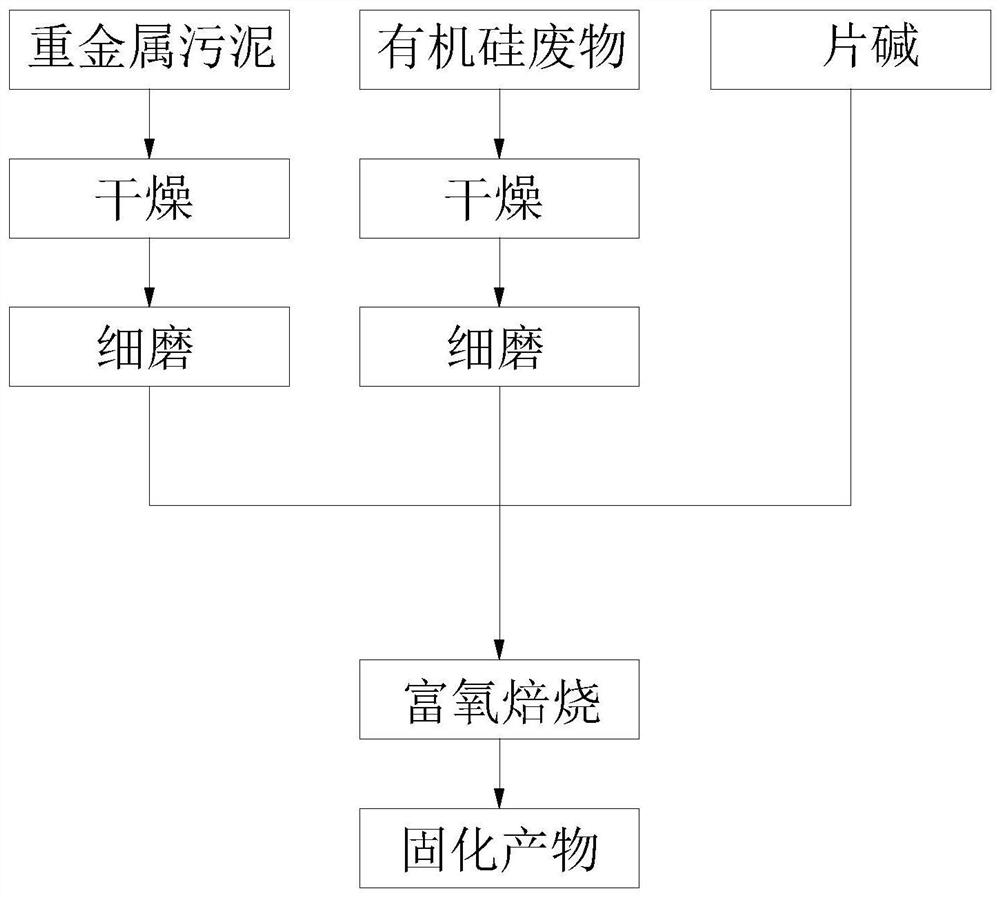

A method for harmless co-processing of heavy metal sludge and organic silicon waste

ActiveCN109368952BRealize the co-processing effectEnergizeSludge treatment by de-watering/drying/thickeningFixation/solidifcation sludge treatmentVitrificationSludge

The invention discloses a method for harmless co-processing of heavy metal sludge and organosilicon waste. The method comprises: (1) first drying the heavy metal sludge and organosilicon waste, and then grinding the metal sludge and organosilicon waste separately crushed until the particle size is less than 0.55mm; (2) mix fine-grained heavy metal sludge, organic silicon waste and caustic soda evenly according to the proportioning ratio, and obtain a high-temperature solidified vitrified mixed material; (3) mix the obtained mixed material in a rich Carry out high-temperature curing under an oxygen atmosphere to obtain a cured body stabilized by heavy metals. Starting from the components and characteristics of the waste itself, the present invention makes full use of the hydrocarbon organic matter and silicon components in the organosilicon waste, which not only realizes the energy conversion of the hydrocarbon organic matter in the waste, but also reduces the operating cost of the high-temperature solidification disposal process; at the same time It provides silicon components for the high-temperature solidification vitrification of heavy metal sludge, and obtains silicon-based glass materials with resource potential, realizes the co-processing effect of waste, and achieves the purpose of energy saving and environmental protection.

Owner:浙江金泰莱环保科技有限公司 +1

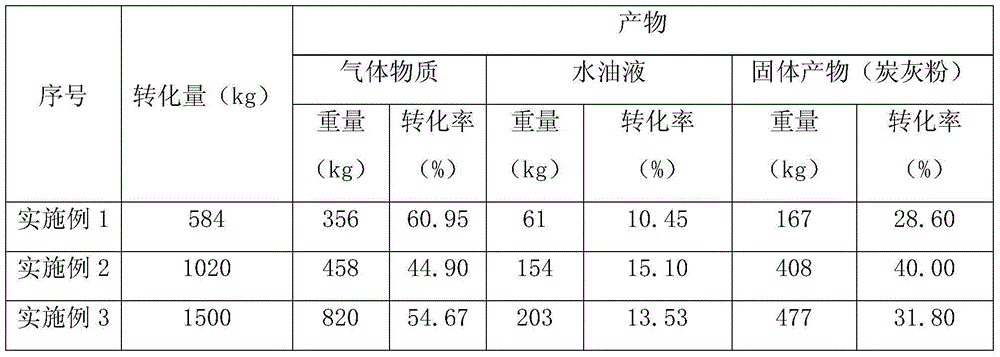

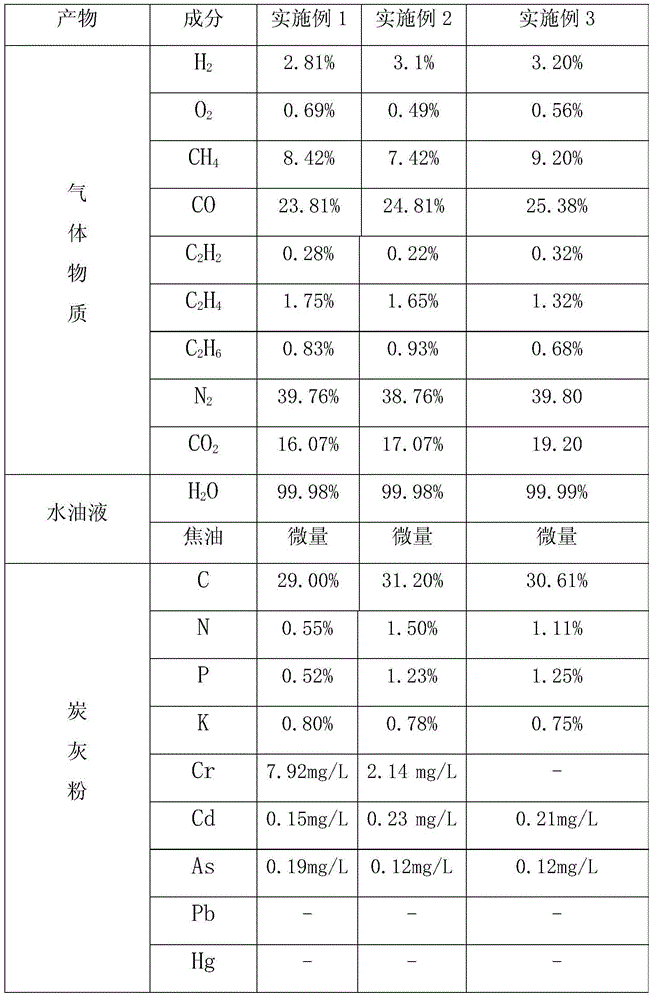

Friction-dragging thermal cracking treatment method of household garbage

ActiveCN103396837BZero emissionHarmlessSolid waste disposalLiquid hydrocarbon mixture productionProduct gasDomestic waste

The invention discloses a friction-dragging thermal cracking treatment method of household garbage. The friction-dragging thermal cracking treatment method comprises the following steps of: S1, filling the household garbage into a sealed friction thermal cracking device; S2, carrying out frication dragging on the household garbage through the rotation of a rotor of a rotor friction-dragging unit to generate friction heat and friction dragging force, so that the household garbage is thermally cracked by friction-dragging to obtain a product mixture; S3, carrying out settling treatment on the product mixture for separating out solid product in the product mixture to obtain the solid product; and S4, carrying out gas-liquid separation treatment on the rest of the product mixture to obtain gas substance and water oil liquor. The friction-dragging thermal cracking treatment method of the household garbage is simple to operate, capable of carrying out friction-dragging thermal cracking conversion for converting the household garbage into products including the gas substance, the water oil liquor, the charcoal ash powder and the like for recycling, so that the zero-residue, zero-emission, resource-recycling, energy-resource-recycling and industrial conversion utilization of the garbage is realized, and therefore, the friction-dragging thermal cracking treatment method is environment-friendly.

Owner:东莞市华港新能环保科技有限公司

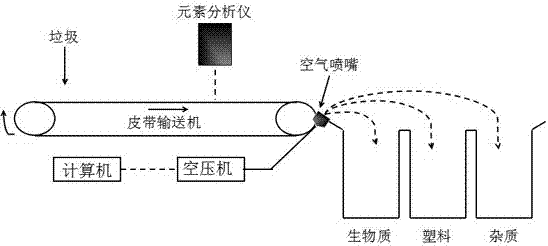

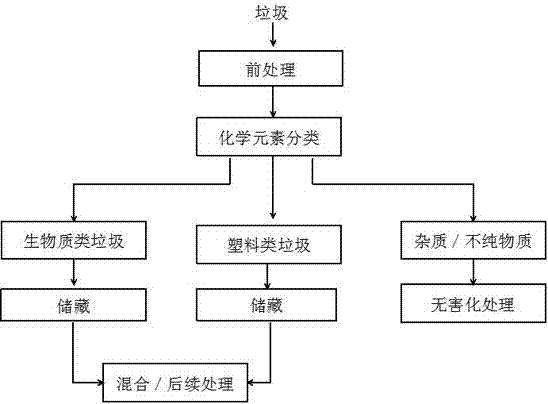

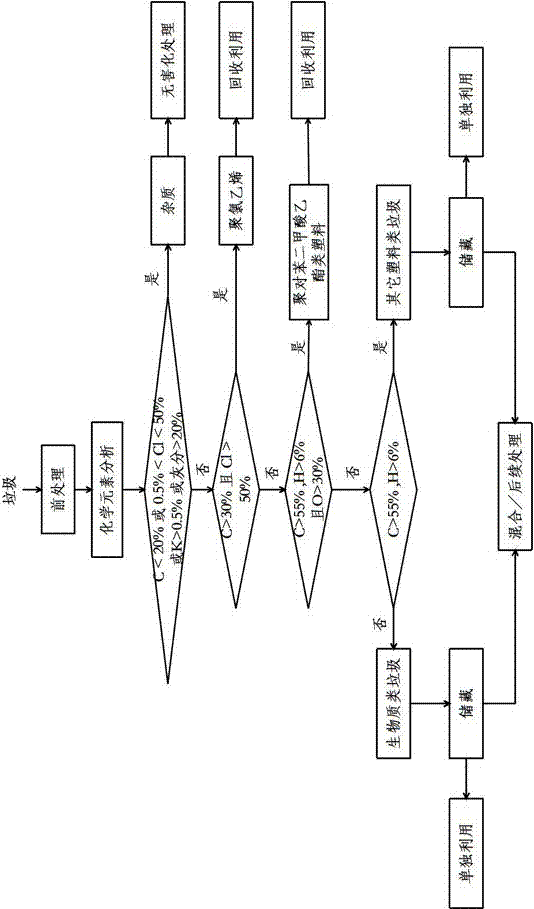

Garbage classification equipment, method and application based on chemical element characteristics

ActiveCN104722554BClassification operations are simplifiedEasy to operateSolid waste disposalComputer control systemChemical element

Owner:WUXI RONGBO ENERGY ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com