Oily wastewater recycling and wastewater treatment system and treatment method thereof

A wastewater treatment system and resource utilization technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as difficult and effective oil-water separation and resource utilization, and achieve energy and resource utilization to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

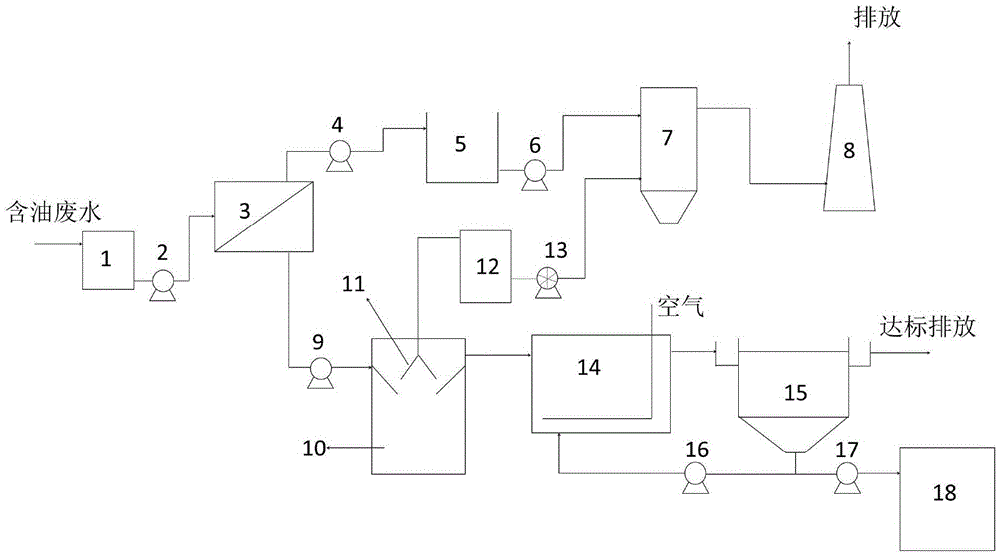

[0033] Such as figure 1 As shown, an oily wastewater recycling and wastewater treatment system in this embodiment includes a raw water conditioning tank 1, an ultrafiltration separation unit 3, an oil storage tank 5, an incinerator 7, a flue gas discharge tower 8, and a biogas storage tank 12 , anaerobic reactor 10, three-phase separator 11, aerobic reactor 14, sedimentation tank 15, sludge thickening tank 18; described raw water adjustment tank 1 and ultrafiltration separation unit 3 pass waste water delivery pump 2 and pipeline Connected, the ultrafiltration separation unit 3 and the oil storage tank 5 are connected to each other through the membrane dope delivery pump 4 and the pipeline, and the oil storage tank 5 and the incinerator 7 are connected to each other through the incinerator oil delivery pump 6 and the pipeline, so Described incinerator 7 is connected with flue gas discharge tower 8 by pipeline; Described ultrafiltration separation unit 3 and anaerobic reactor 1...

Embodiment 2

[0037] The basic structure is the same as in Example 1, wherein the ultrafiltration membrane used in the ultrafiltration separation unit 3 is an organic-inorganic composite ultrafiltration membrane, and the membrane has good oil-water separation performance. The membrane is backwashed regularly, and the backwash water flows into the Raw water adjustment pool 1.

Embodiment 3

[0039] The basic structure is the same as in Embodiment 1, wherein the pumps used in the ultrafiltration separation unit 3 to the incinerator 7 are anti-stick screw pumps or gear pumps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com