Livestock and poultry waste circulating system based on organic padding and operation method of livestock and poultry waste circulating system

A technology of livestock and poultry waste and operation method, which is applied in the field of breeding waste treatment, can solve the problems of increasing the risk of livestock and poultry infection, complicated operation, and bad smell in breeding warehouses, so as to reduce the number of equipment and plant area, and reduce the number of livestock and poultry. Poultry infection rate and the effect of avoiding malodor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

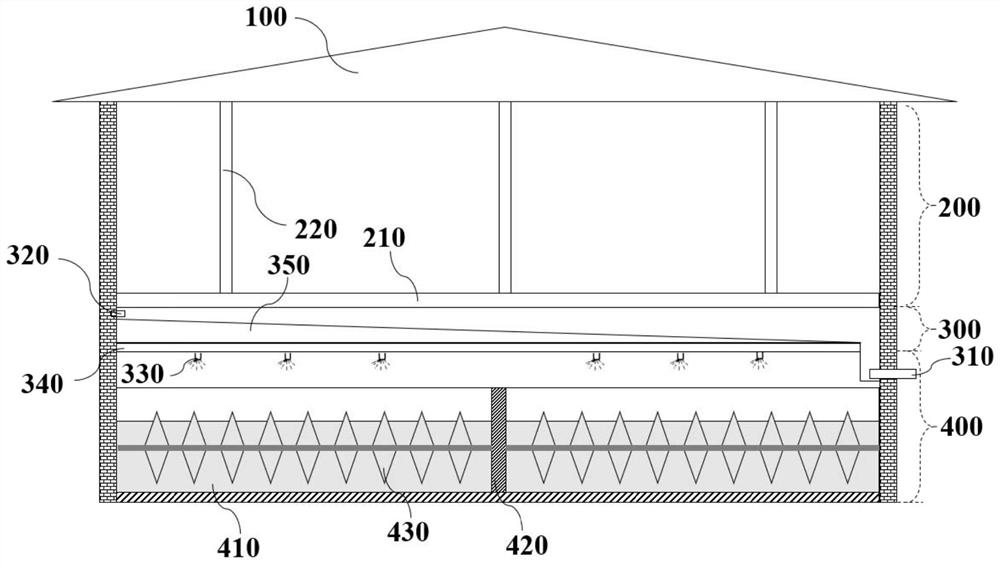

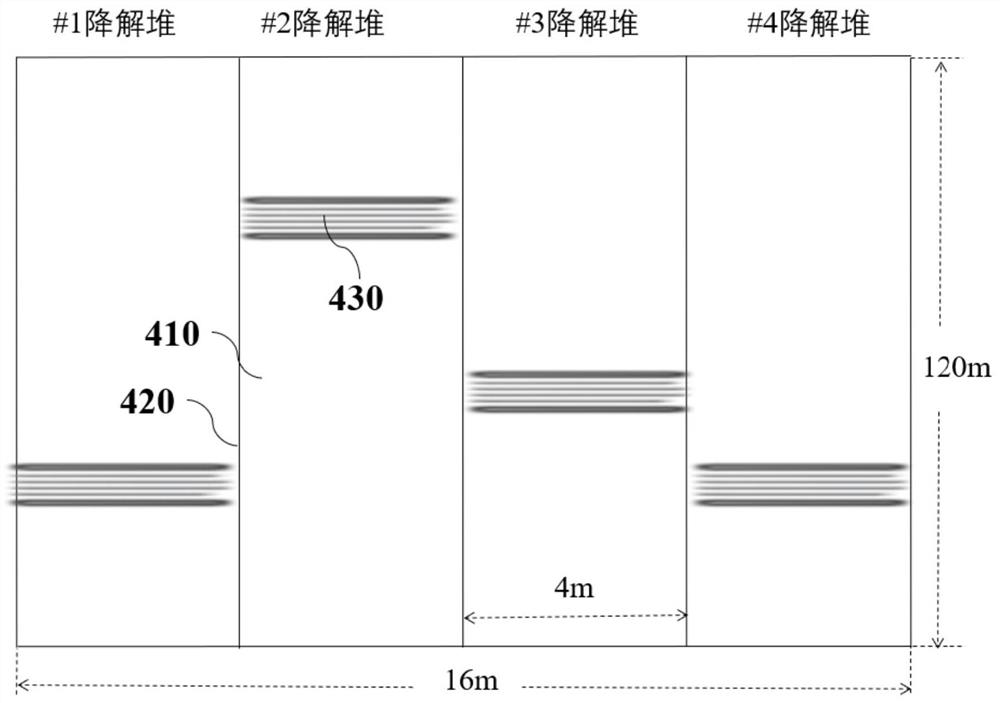

Embodiment 1

[0058] About 12 tons of high-concentration organic wastewater and manure are discharged from a pig farm in a certain base every day, and about 8 tons of wastewater are sprayed by the spray unit to the fermentation pile. The hog breeding period is 6 months. After the hogs are slaughtered, the organic litter is transferred to the fermentation pile, and the elevated mesh bed 210 is washed. Pig farm sewage mainly includes pig urine and a small amount of flushing water. Its main characteristics are: high concentration of organic matter, high suspended solids, deep color, and a large number of bacteria. Due to the large amount of animal excrement, NH 3 - High N concentration (300mg / L). Pollutants in sewage mainly exist in the form of dissolved carbohydrates, which make the sewage show a high BOD 5 (3600mg / L), COD cr (8000mg / L) and chromaticity, etc. The pollutants have good biodegradability. In addition, the sewage contains a large amount of nutrients such as N and P. The TP conce...

Embodiment 2

[0064] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that: in this embodiment, no machine bedding material is laid on the elevated net bed 210, and the excrement of livestock and poultry falls from the elevated net bed 210 to the collection unit 300, and then Realize solid-liquid separation. The feces of the collection unit 300 are collected to the fermentation layer 400 by a manure hanging machine, and the solid waste of livestock and poultry is composted in the fermentation layer 400, and at the same time, the fermentation liquid of the fermentation device is sprayed on the feces. When cultivating for 30 days, foul smell appeared in the cultivating area 200 domain of the elevated net bed 210.

Embodiment 3

[0066] The basic content of this embodiment is the same as that of Embodiment 1, the difference being that: in this embodiment, the elevated net bed 210 is laid with machine padding, and the laying thickness is 20 cm. No water collection unit is provided between the elevated net bed 210 and the fermentation layer 400 , that is, the culture wastewater almost all leaks down to the fermentation layer 400 . Because domestic pigs have the habit of fixed-point excretion, the breeding wastewater is concentrated in a certain area of the fermentation layer 400, resulting in excessive logistics humidity in this area, which affects fermentation; at the same time, the fermentation of materials in other areas of the fermentation layer 400 is not complete, affecting the overall fermentation efficiency .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com