Straw smoldering and rapid humification combined use method and humic fertilizer product of straws

A humification and smoldering technology, applied in the direction of chemical fertilizer treatment control, application, organic fertilizer, etc., can solve the problems of severe influence of phenological factors, non-point source pollution, slow humification process of straw, etc., to eliminate particle pollution and reduce Effects on Energy Consumption and Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

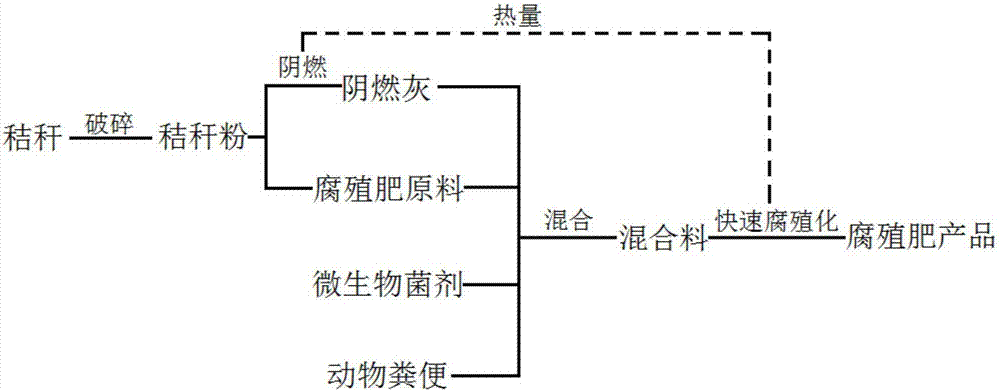

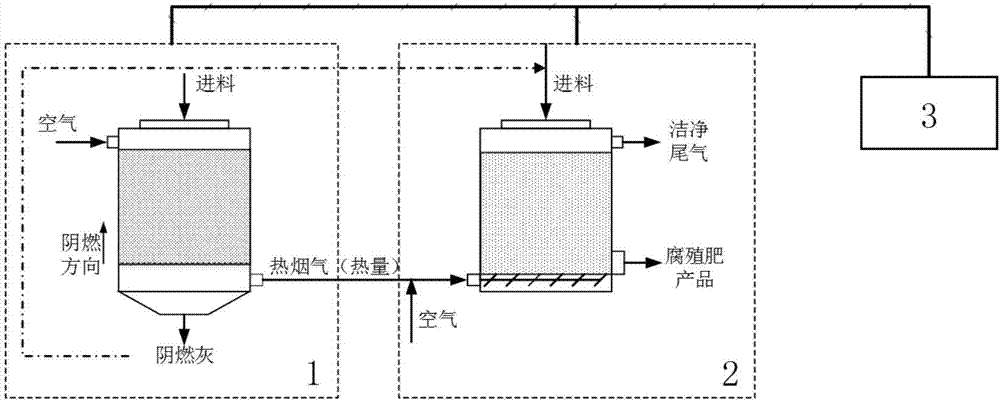

[0039] Such as figure 1 As shown, the straw powder is firstly crushed to obtain straw powder. The particle size of the crushed straw powder is 40-100 mesh; A part of straw powder is mixed with smoldering ash, microbial agent and animal manure to form a mixture. Such as figure 2 As shown, the straw powder in the smoldering furnace is electrically heated and ignited to generate hot flue gas. The hot flue gas mixed with air enters the silo-type composting reactor, and the humification system 2 starts to work. The operation process of the smoldering system 1 and the humification system 2 is controlled by the control system 3, which monitors and adjusts the air velocity, oxygen concentration in the smoldering system 1 and the temperature and ventilation in the humification system 2 in real time, so as to keep the smoldering System 1 and humification system 2 run stably.

Embodiment 2

[0041] A combined utilization method of straw smoldering and rapid humification, the method specifically includes the following steps:

[0042] (1) Crushing the straw to obtain straw powder, the particle size of the straw powder is 40-100 mesh;

[0043] (2) Use part of the straw powder as smoldering straw powder, control the mass percentage of moisture in the smoldering straw powder to 20%, and then place it in the smoldering furnace to ensure that the bulk density of the smoldering straw powder is 45kg / m 3 , into the air, adopt the reverse smoldering mode, ignite by electric heating, and keep the air flux on the smoldering surface at 7.0L / (m 2 s), the volume fraction of oxygen in the air is 0.6%, and smoldering ash and hot smoke are obtained after smoldering;

[0044](3) Another part of straw powder is used as humus fertilizer raw material, mixed evenly with smoldering ash, microbial agent and animal manure, and placed in a silo-type composting reactor, wherein the humus fer...

Embodiment 3

[0047] A combined utilization method of straw smoldering and rapid humification, the method specifically includes the following steps:

[0048] (1) Crushing the straw to obtain straw powder, the particle size of the straw powder is 100-160 mesh;

[0049] (2) Use part of the straw powder as smoldering straw powder, control the mass percentage of moisture in the smoldering straw powder to 25%, and then place it in the smoldering furnace to ensure that the bulk density of the smoldering straw powder is 40kg / m 3 , into the air, adopt the reverse smoldering mode, ignite by electric heating, and keep the air flux on the smoldering surface at 8.0L / (m 2 s), the volume fraction of oxygen in the air is 0.5%, and smoldering ash and hot smoke are obtained after smoldering;

[0050] (3) Another part of straw powder is used as humus fertilizer raw material, mixed evenly with smoldering ash, microbial agent and animal manure, and placed in a silo-type composting reactor, wherein the humus f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com