Patents

Literature

71results about How to "Enough heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil sand pyrolysis dry distillation method

InactiveCN103289715ALow ashHigh yieldLiquid hydrocarbon mixture productionSpecial form destructive distillationCoalFuel gas

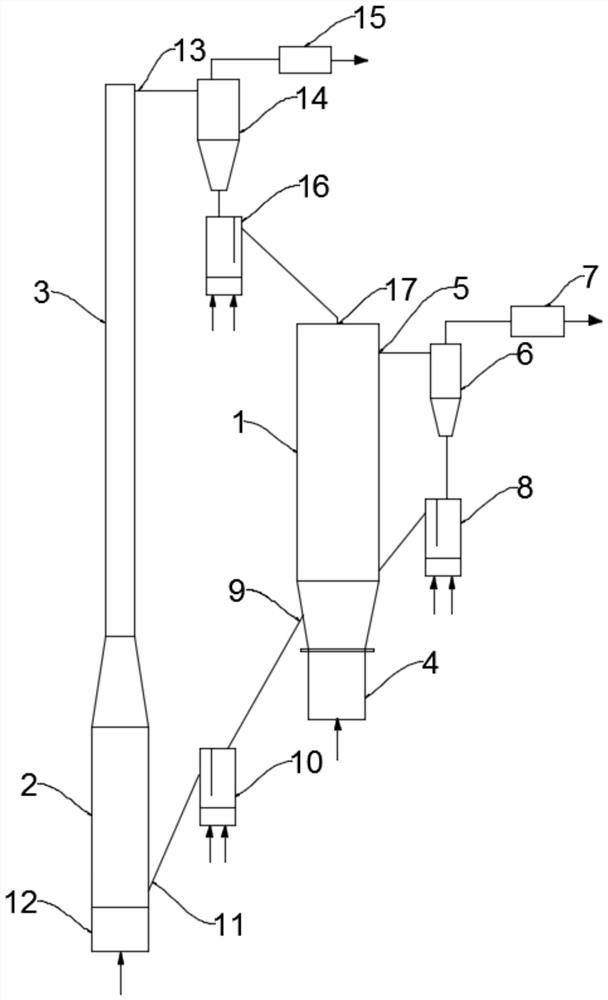

The invention provides an oil sand pyrolysis dry distillation method. The method comprises the following steps of: performing dry distillation by using oil sands and coal as raw materials to obtain dry distillation gas and semi-coke; and treating the dry distillation gas to obtain light oil, mixed oil and fuel gas. According to the oil sand pyrolysis dry distillation method provided by the invention, oil sands and coal are used as raw materials to perform a dry distillation reaction, so that the output of fuel gas can be increased; and the produced fuel gas is recycled in the dry distillation of oil sands and coal, so that enough heat can be obtained in the dry distillation process, and an extra heat source is not required.

Owner:庆华集团新疆和丰能源化工有限公司 +1

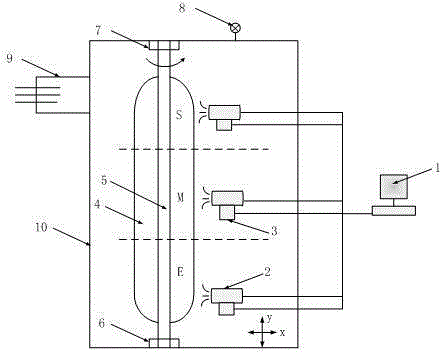

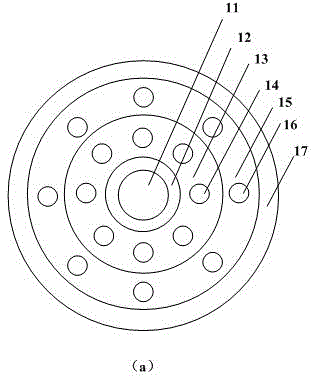

Preparing method of high purity quartz sleeve for large-size optical fiber preform

ActiveCN105330140AAvoid it happening againNo pollution in the processGlass shaping apparatusGlass productionAcid washingOxygen

The invention relates to a preparing method of a high purity quartz sleeve for a large-size optical fiber preform. The method comprises the steps of firstly, clamping a target rod or tube subjected to acid washing and drying on upper and lower chucks of an upright deposition device; adopting an upright sectional vapor deposition method, and introducing siloxane, oxygen, natural gas or methane or hydrogen gas, nitrogen gas as a raw material into a blowtorch, wherein after igniting, high temperature flame reacts to generate silicon dioxide powder with the particle size between 5-200nm, the powder is attached to the surface of the target rod or tube and finally achieves the set target rod size; then placing the silicon dioxide powder rod obtained by depositing into a graphite resistance furnace with the temperature being 1200-1600 DEG C, and introducing Cl2 and He with a flow ratio being (1-5) to (1-20) for vitrification sintering, thus obtaining a quartz sleeve preformed unit; performing mechanical cold machining on the quartz sleeve preformed unit to obtain the quartz sleeve; then adopting a weak base solution to wash, then repeatedly washing with deionized water, soaking with acid and finally washing with the deionized water and drying.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

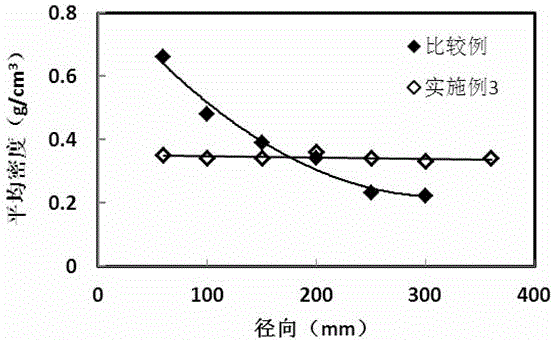

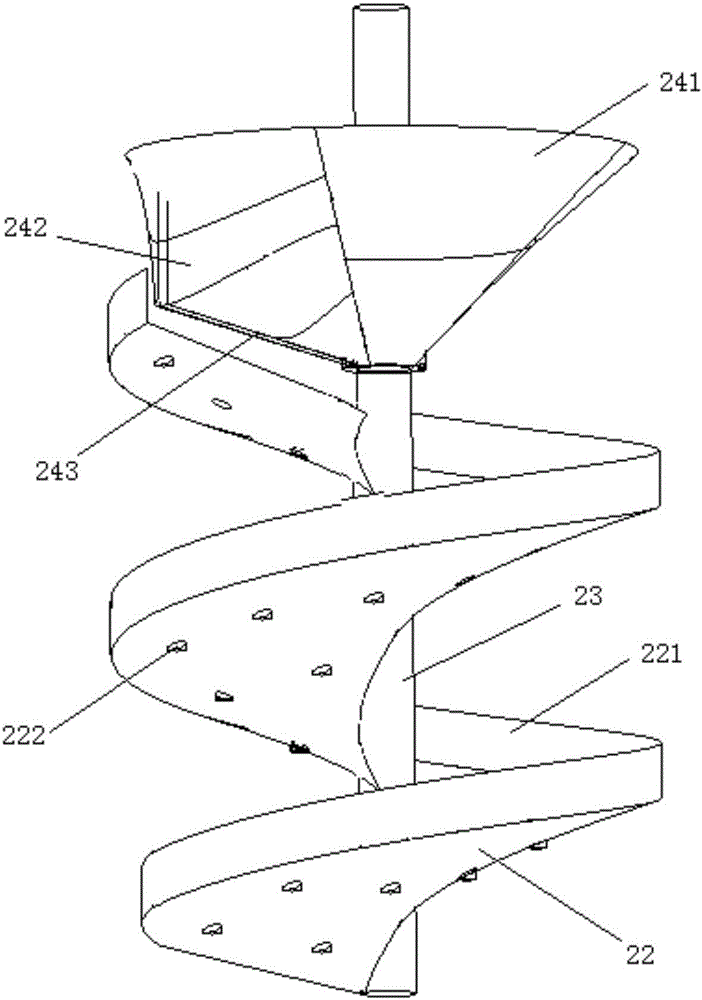

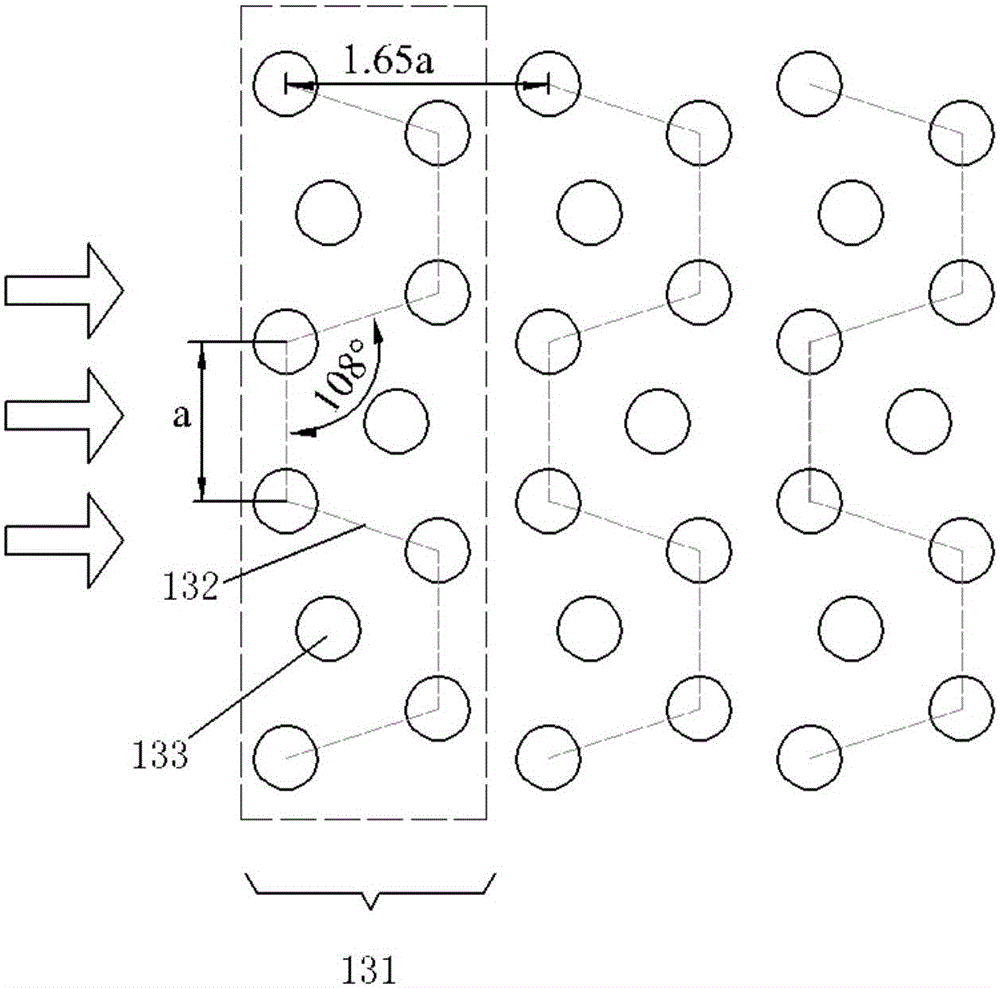

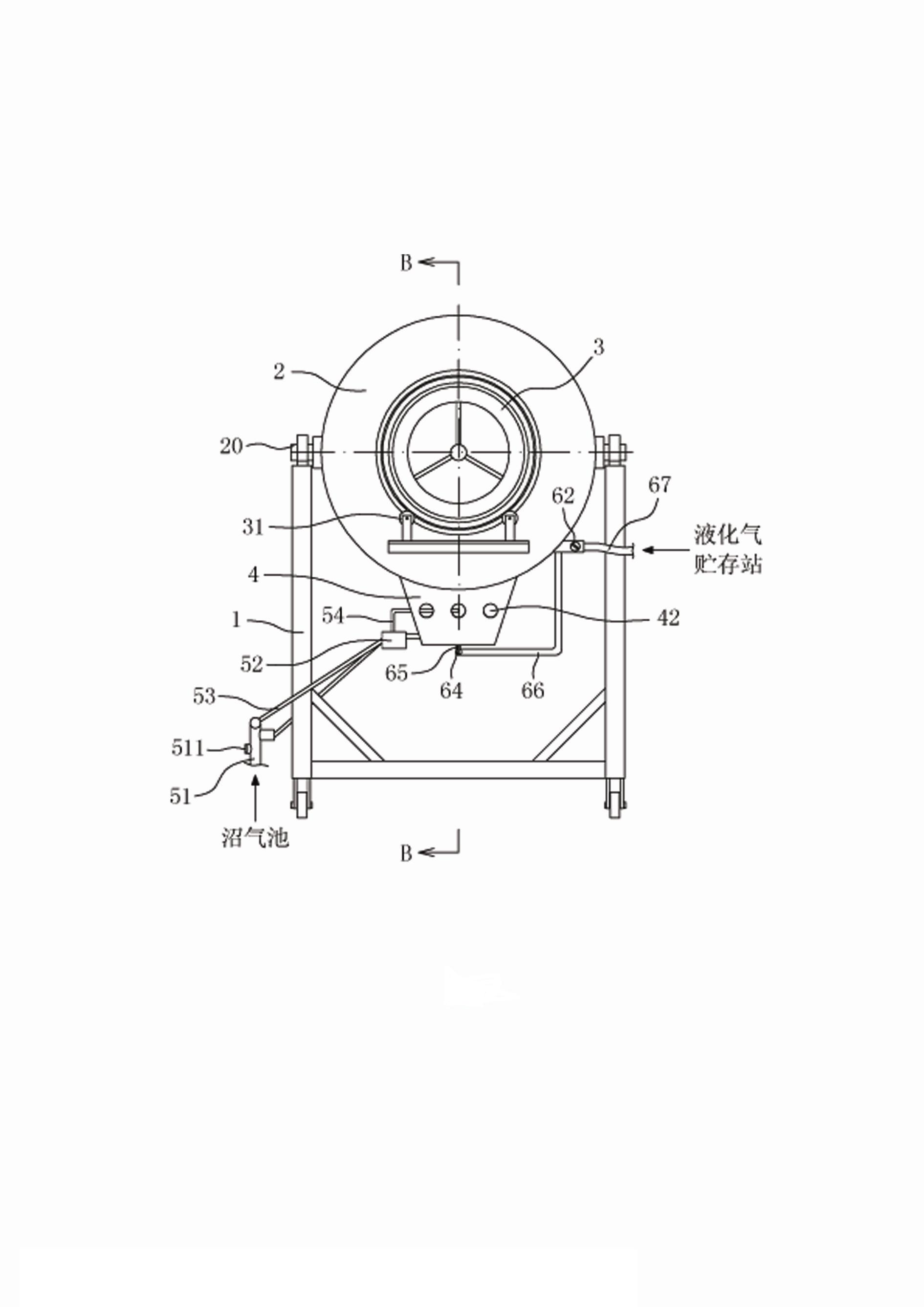

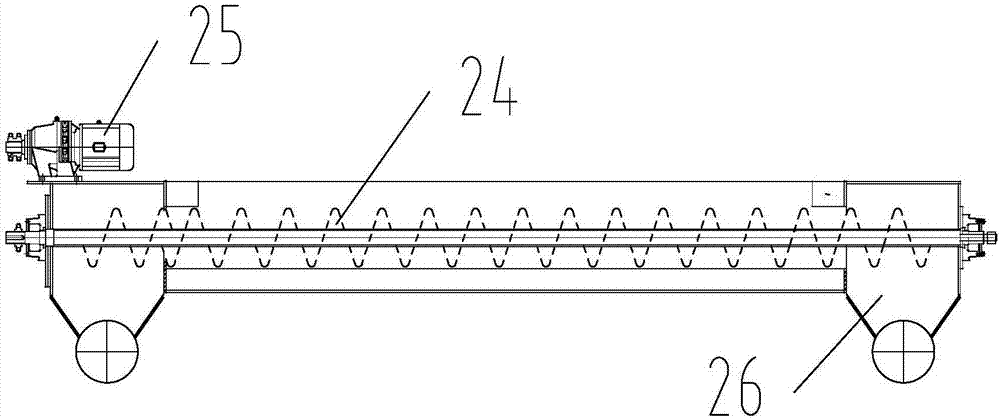

Grain drying device

ActiveCN107178987AExtended retention timeUniform qualityFood processingDrying gas arrangementsSpiral bladePorous medium

The invention discloses a grain drying device. The grain drying device comprises a hot-blast stove, an air blower and a drying tower, and is characterized in that a shaft rod is arranged in a tower body of the drying tower; spiral plates are arranged on the shaft rod; the spiral plates outwards extend from the surface of the shaft rod; two or more stages of spiral plates are arranged on the shaft rod; blowing holes are formed in the spiral plates, and penetrate through the surfaces of the spiral plates; and the hot-blast stove adopts the scheme of arranging heat exchange pipes in a pentagonal form and filling porous mediums in the heat exchange pipes. Compared with the prior art, the grain drying device has the following advantages: the drying speed can be adjusted through adjusting the rotating speed of a rotating shaft according to different grain characteristics; the overturning of materials is realized through multiple sections of spiral blades; the heat exchange efficiency is improved through arranging the heat exchange pipes in a pentagonal form and filling the porous mediums in the pipes; the problems of high production cost, energy consumption and low drying efficiency in the grain drying device can be effectively solved; and the grain drying device is used for drying grains, and reduces the drying cost, saves the energy, and improves the drying efficiency.

Owner:HEFEI UNIV OF TECH

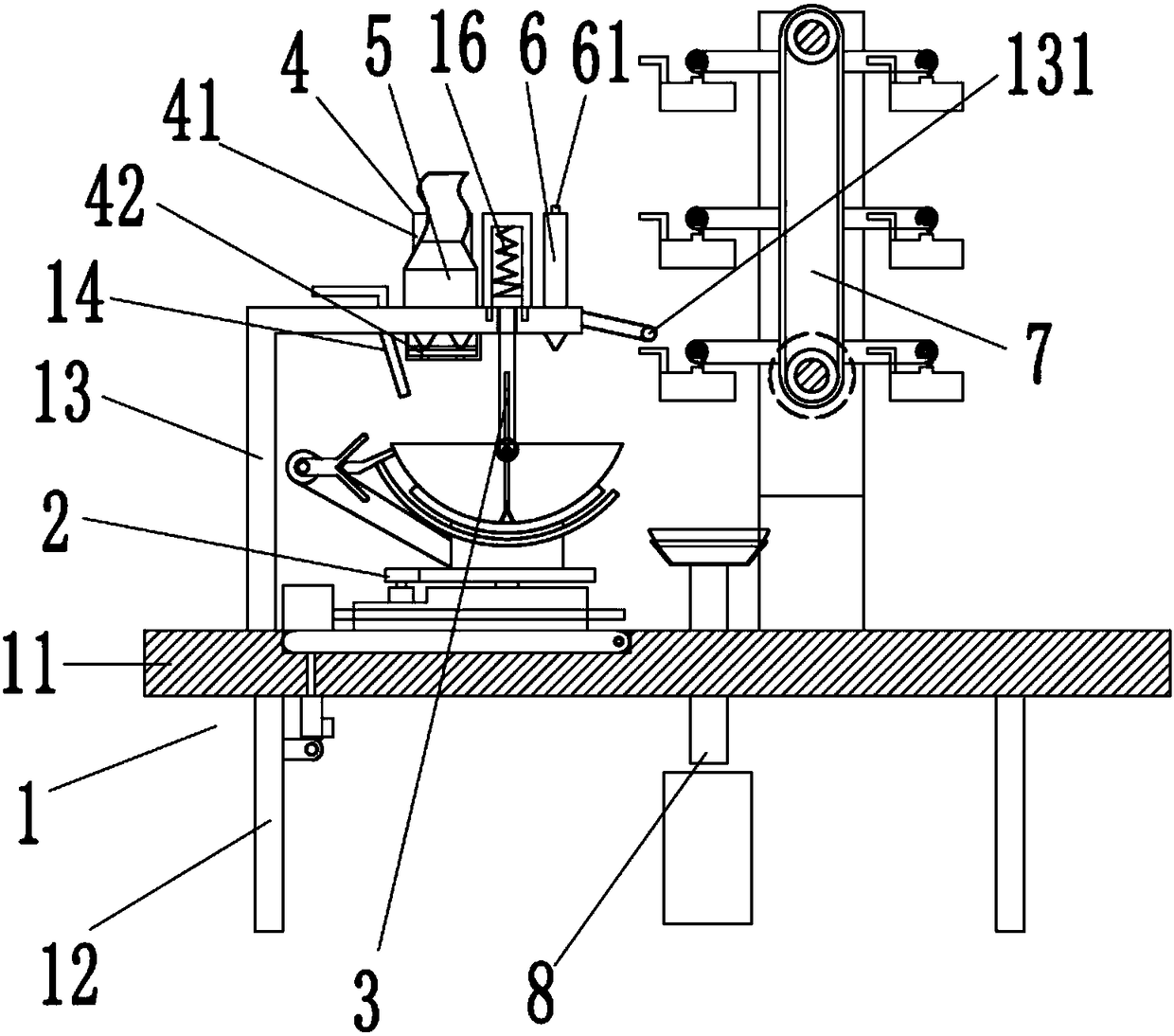

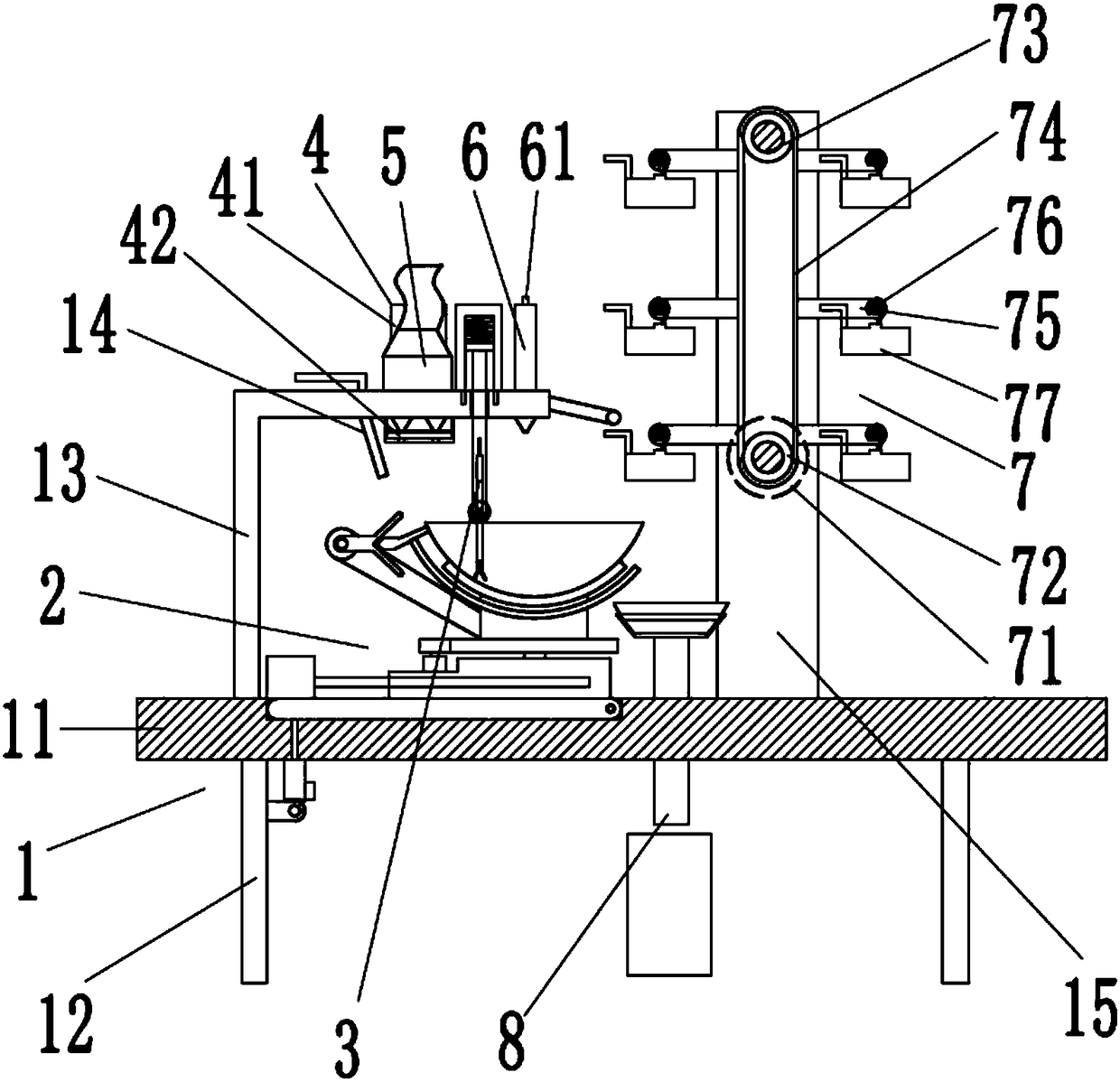

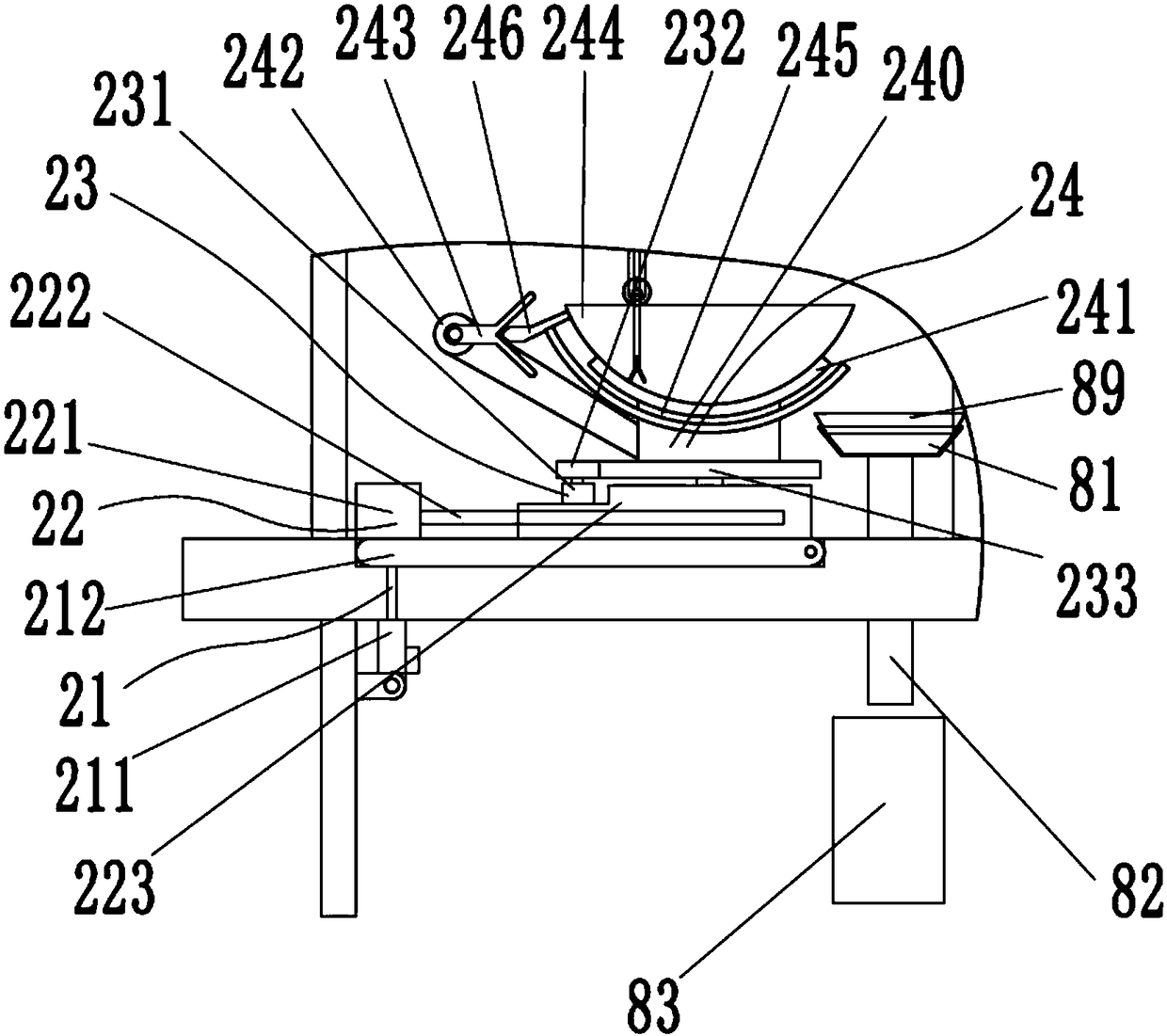

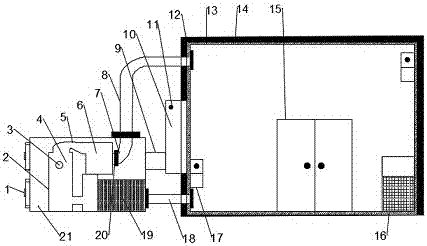

Automatic cooker

ActiveCN108420300AEnough heatGuaranteed qualityCooking vessel supportCooking vessel constructionsSolenoid valveCooking process

The invention discloses an automatic cooker, which comprises an underframe, and a cooking device, a stirring mechanism, a solid seasoning device, a liquid seasoning device, a vegetable sending deviceand a waste water recovery device which are arranged on the underframe; the cooking device comprises an overturning structure, a movement mechanism, a rotation mechanism and a stir-frying mechanism; the movement mechanism is arranged on the overturning structure; the rotation mechanism is arranged on the movement mechanism; the stir-frying mechanism is pivoted to the movement mechanism; the rotation mechanism is used for driving the stir-frying mechanism to rotate; the stirring mechanism comprises a truner and a fan-shaped brush, wherein the truner and the fan-shaped brush form an angle of 180degrees; the liquid seasoning device consists of a plurality of negative-pressure cylinders, wherein each negative-pressure cylinder is provided with a solenoid valve, and the solenoid valve can enable the negative-pressure cylinder to be communicated with outside; the vegetable sending device is positioned on one side of the cooking device; the waste water recovery device is arranged between thecooking device and the vegetable sending device. The automatic cooker has the advantages that stir-frying can be met, stirring frying also can be met, heating is even in a cooking process, a pot bodycan be cleaned in time in the cooking process and the like.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

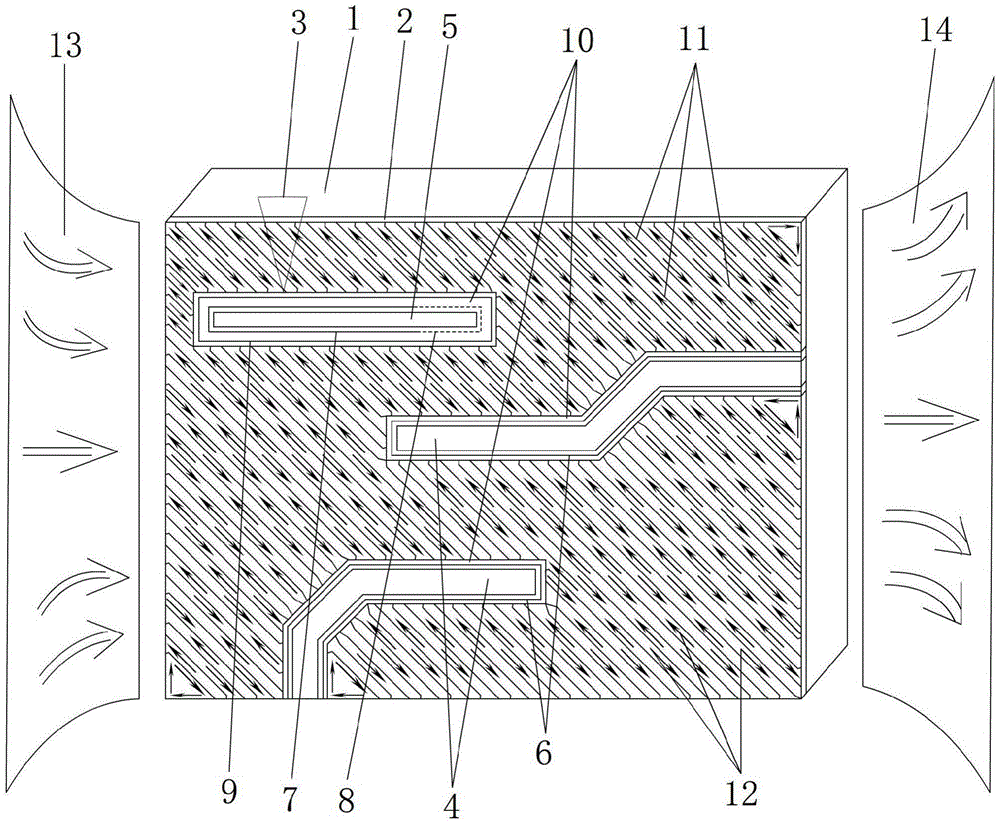

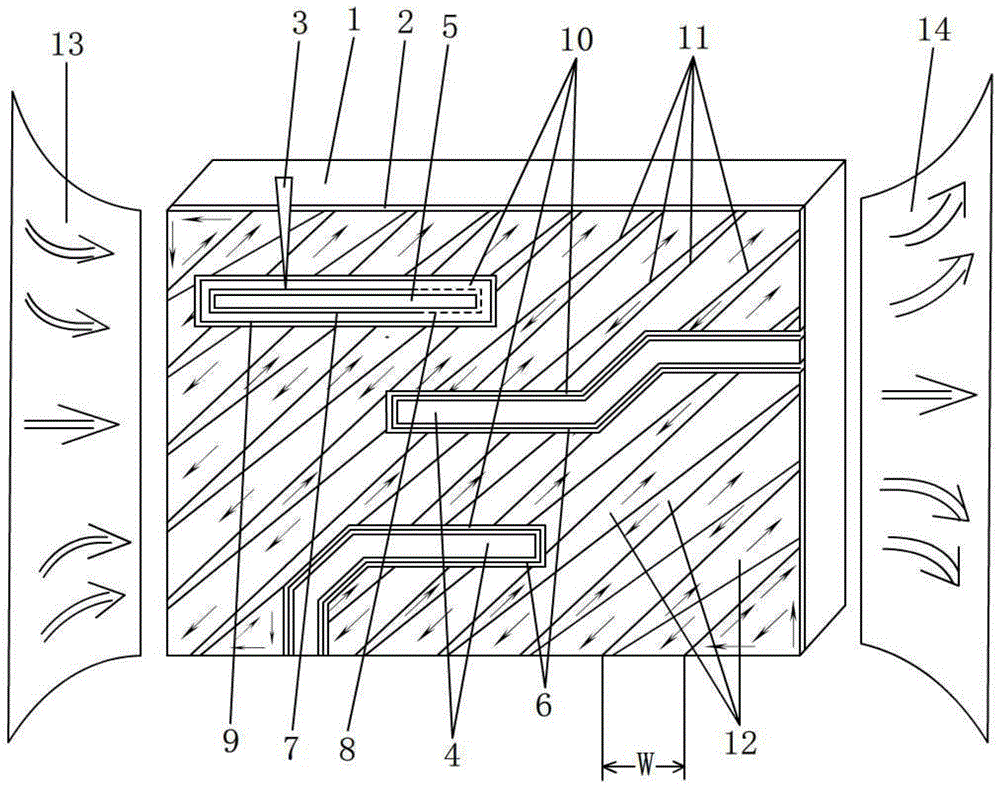

Method for selectively removing conductive layer on baseplate material

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

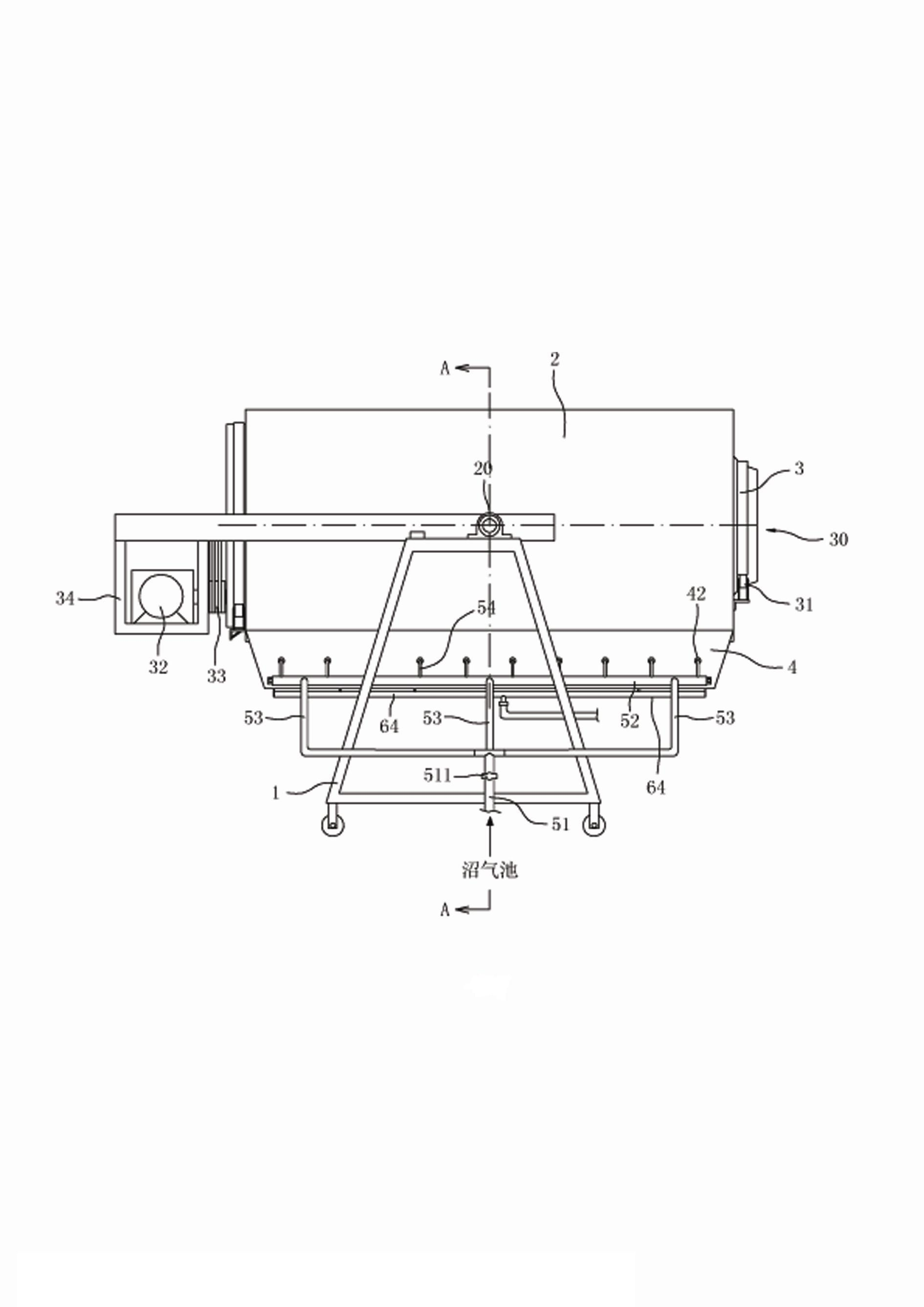

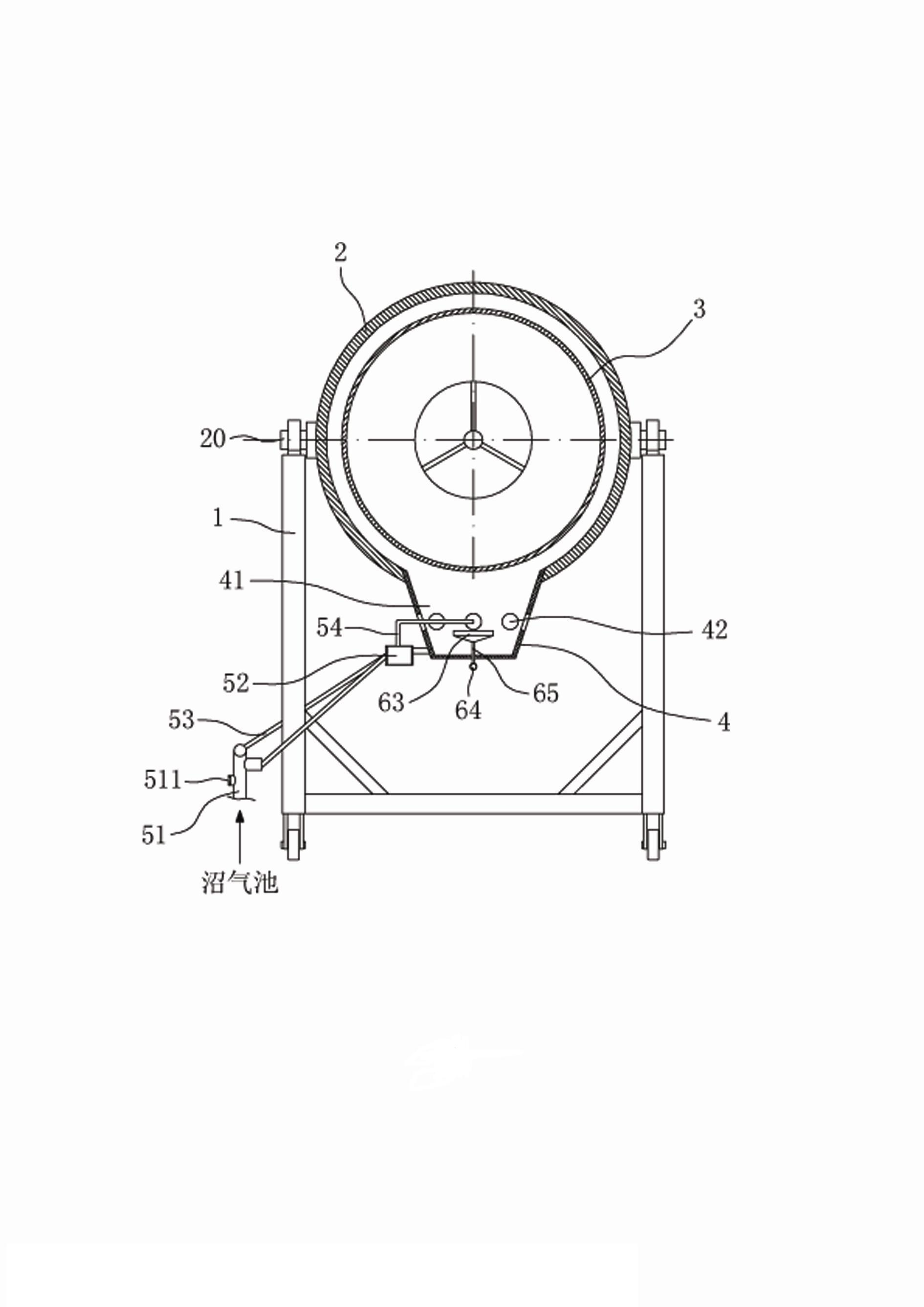

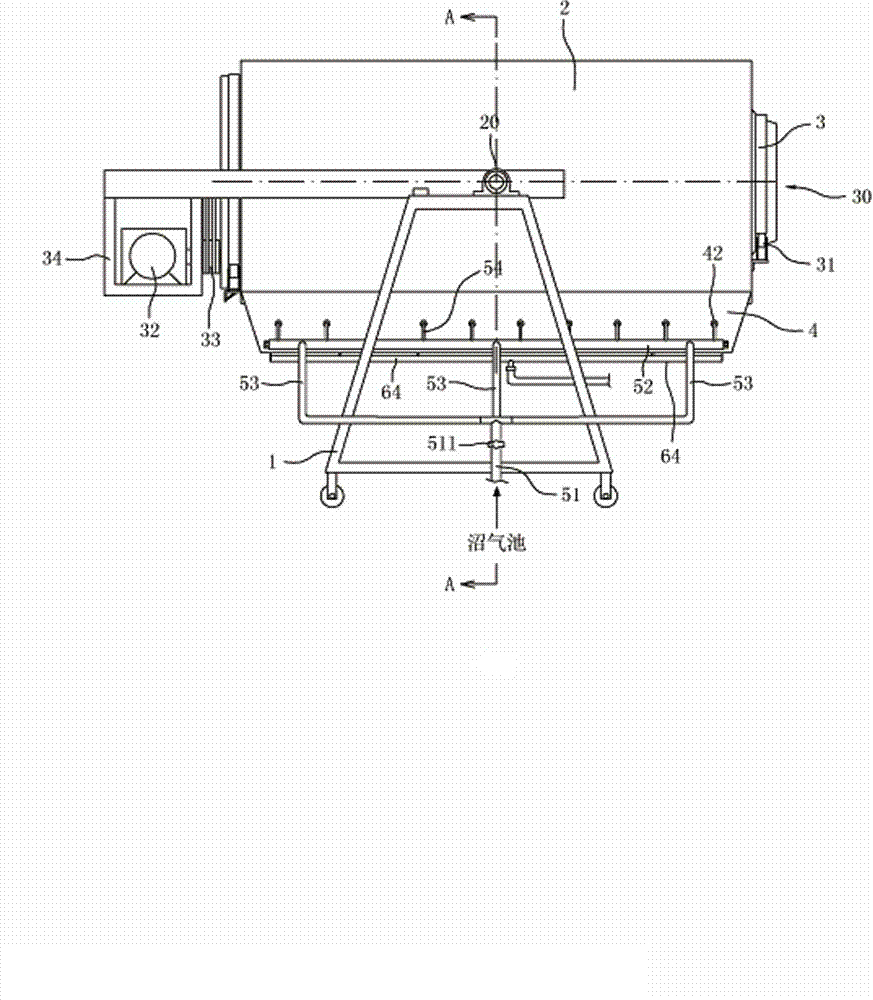

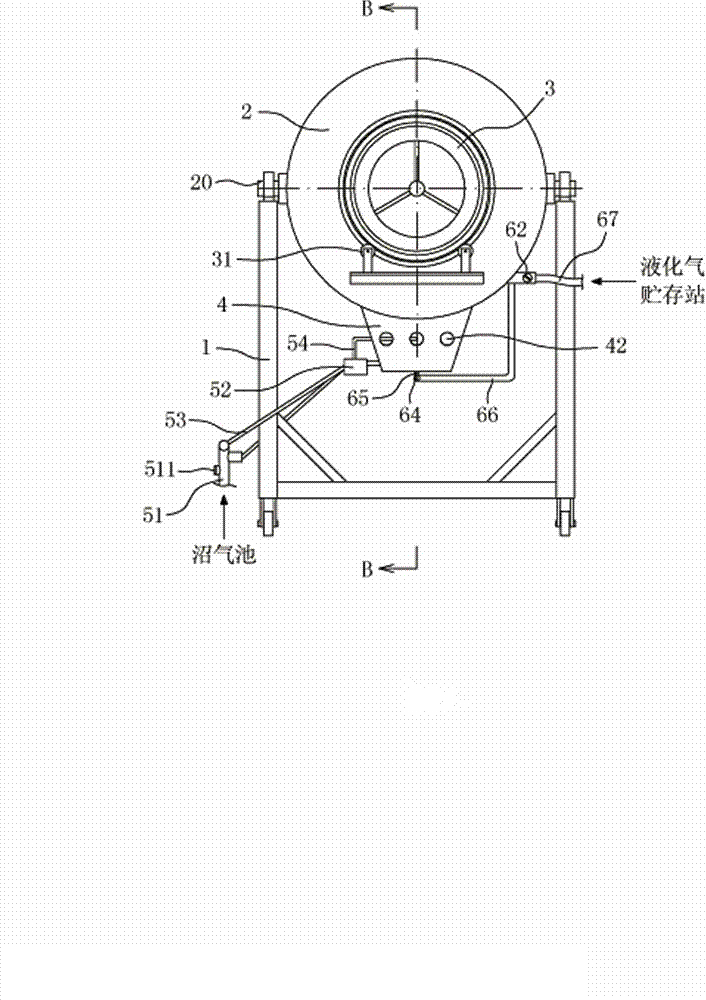

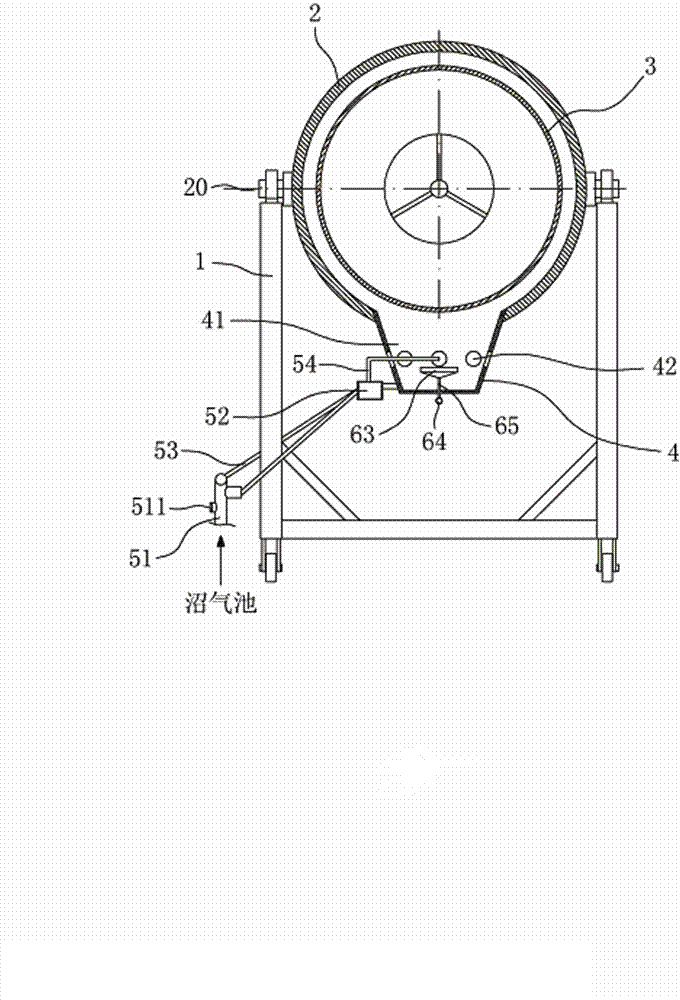

Biogas tea fixing machine

ActiveCN101933544ASmooth air supplySafe and reliable ignitionPre-extraction tea treatmentBiogasTracheid

The invention discloses a biogas tea fixing machine, which comprises a frame, a horizontal tea fixing roller arranged on the frame, a driving device driving the tea fixing roller to roll, and a heating device used for heating the tea fixing roller. The biogas tea fixing machine is characterized in that: the heating device comprises a stove and a biogas combustion device arranged under the tea fixing roller; the biogas combustion device comprises a biogas delivery pipeline which is connected with a biogas digester and provided with a valve, and a plurality of high temperature-resistant biogas ejectors connected with the output end of the delivery pipeline; the biogas ejectors pass through the side wall of the stove to extend into the hearth of the stove; and biogas nozzles of all the biogas ejectors are arranged at equal intervals along the length direction of the hearth. The fixing machine is provided with heat by the combustion of the biogas, and the combustion cost is lower, so the manufacturing cost of tea is reduced; the main component of the biogas is methane, and generates water and carbon dioxide after combustion, so the environment is protected; besides, the combustion value of the biogas is high, so the biogas provides enough heat for the fixing machine; therefore, the produced tea has higher quality.

Owner:福建安溪历山茶仙茶业有限公司

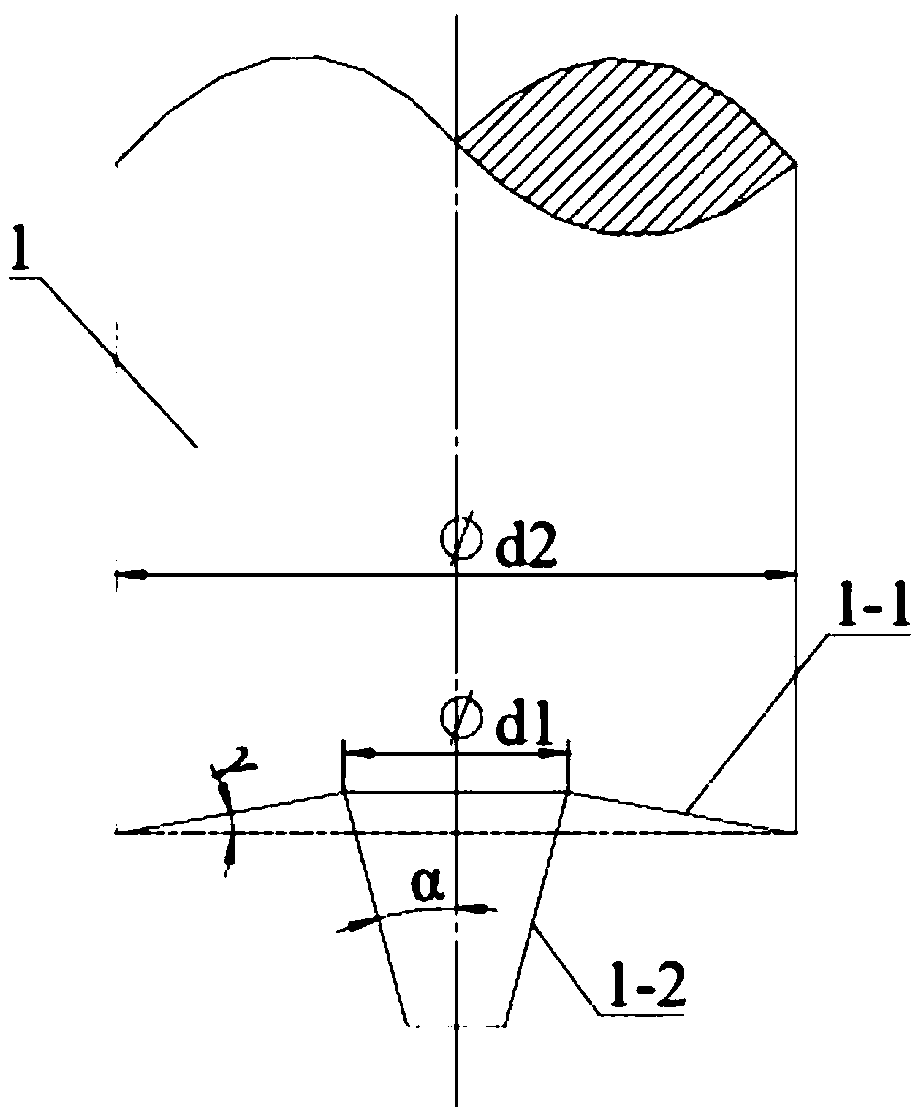

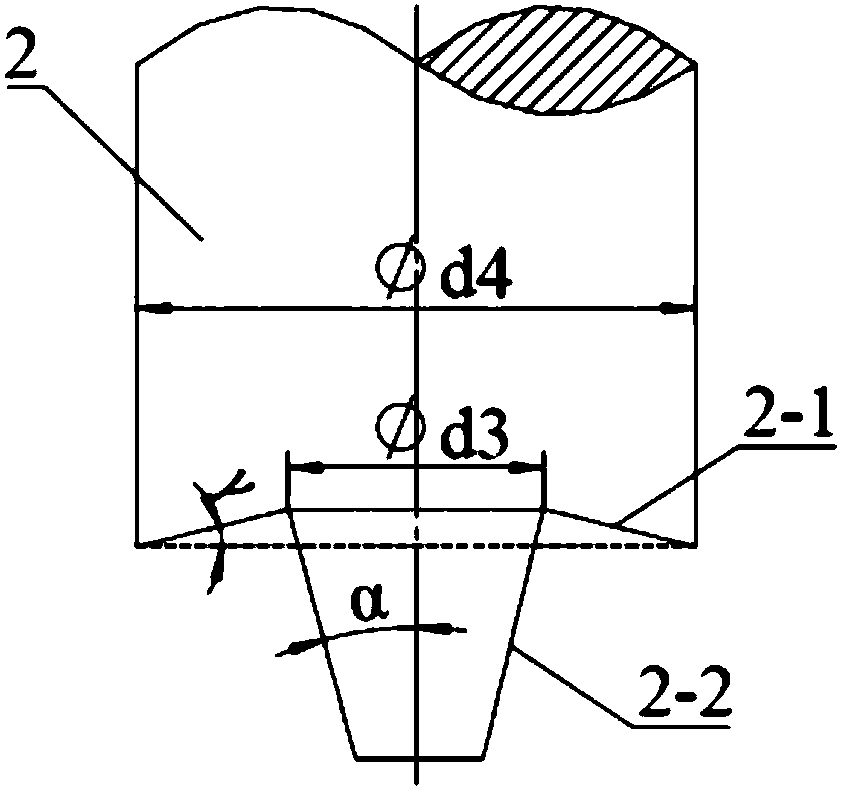

Double-way friction stir welding method for dissimilar material mismatching processing

ActiveCN108127244AReduce contact areaReduce frictional heat generationNon-electric welding apparatusButt jointCopper

The invention discloses a double-way friction stir welding method for dissimilar material mismatching processing. The problems are solved that in the butt joint and friction stir welding process of dissimilar metal such as aluminum / steel, aluminum / copper and magnesium / copper, the situations easily exist that a stirring head is abraded, formation of welding seams is poor due to a material glued tothe stirring head, and the defects exist in intermetallic compounds in the welding seams and exist in the welding seams. The method comprises the steps that 1, two parent materials to be welded are preprocessed, the thickness of a welding area is subjected to differentiation, and a mismatching connector is formed; 2, firstly, the parent materials to be welded are subjected to ultrasonic cleaning and preprocessing, and then acetone is used for wiping the surfaces of the parent materials; 3, the two parent materials to be welded are clamped and located; 4, the stirring head with a large-sized shaft shoulder is shifted to the sides of the low-melting-point parent materials, a small quantity of high-melting-point parent materials are inserted in the stirring head, and first-time welding is conducted; 5, the stirring head is replaced by a small-sized stirring head, the small-sized stirring head is further shifted to the sides of the low-melting-point parent materials, second-time repair welding is conducted, and accordingly the good-quality connection between dissimilar materials is formed. The double-way friction stir welding method is applied to butt joint and friction stir welding ofthe dissimilar metal such as aluminum / steel, aluminum / copper and magnesium / copper.

Owner:安徽万宇机械设备科技有限公司

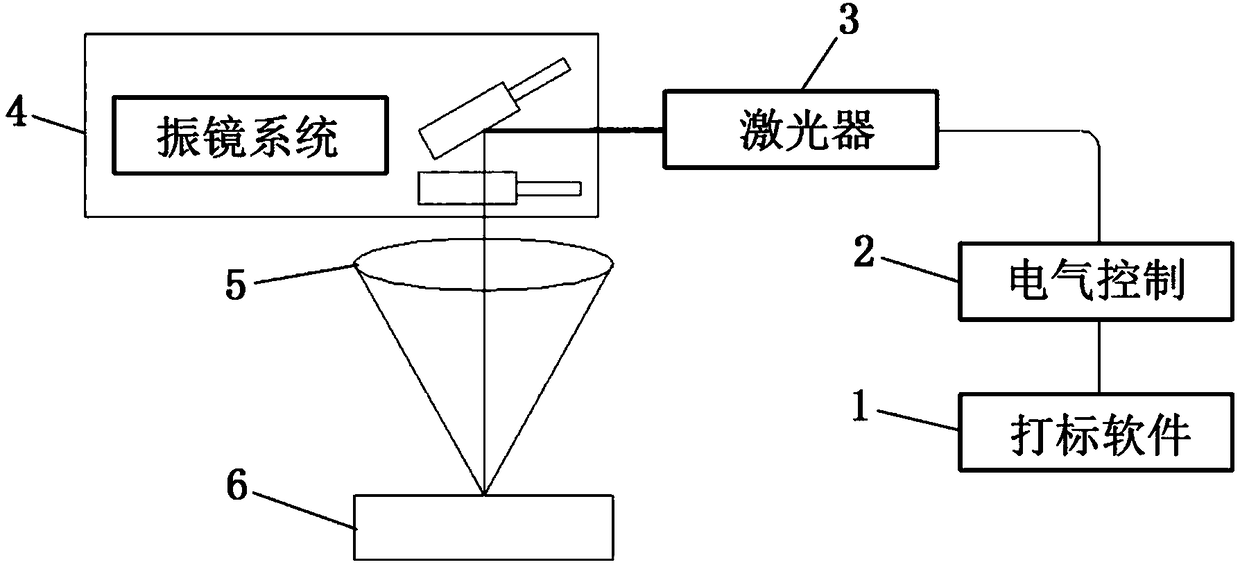

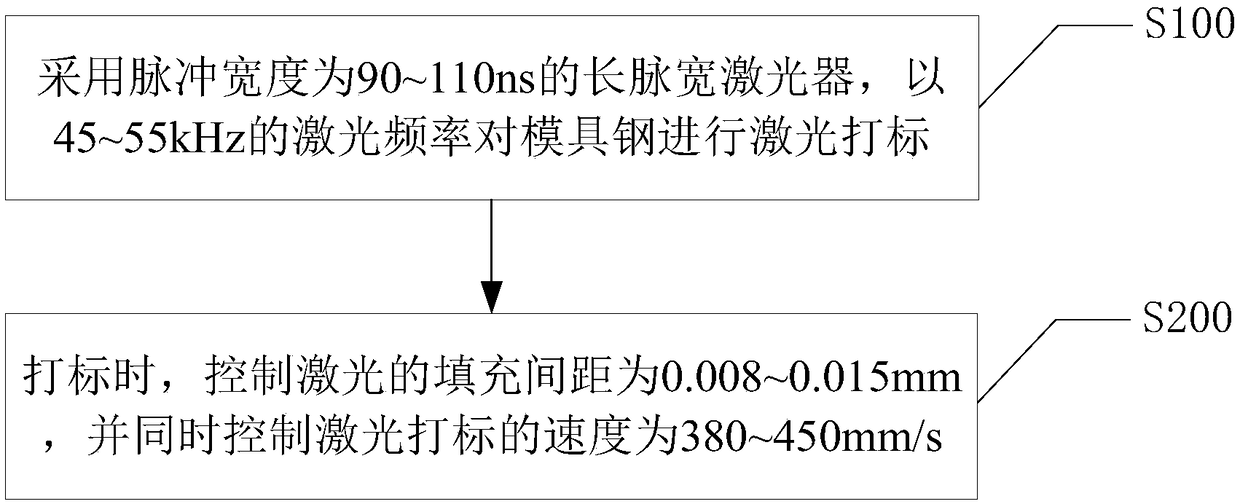

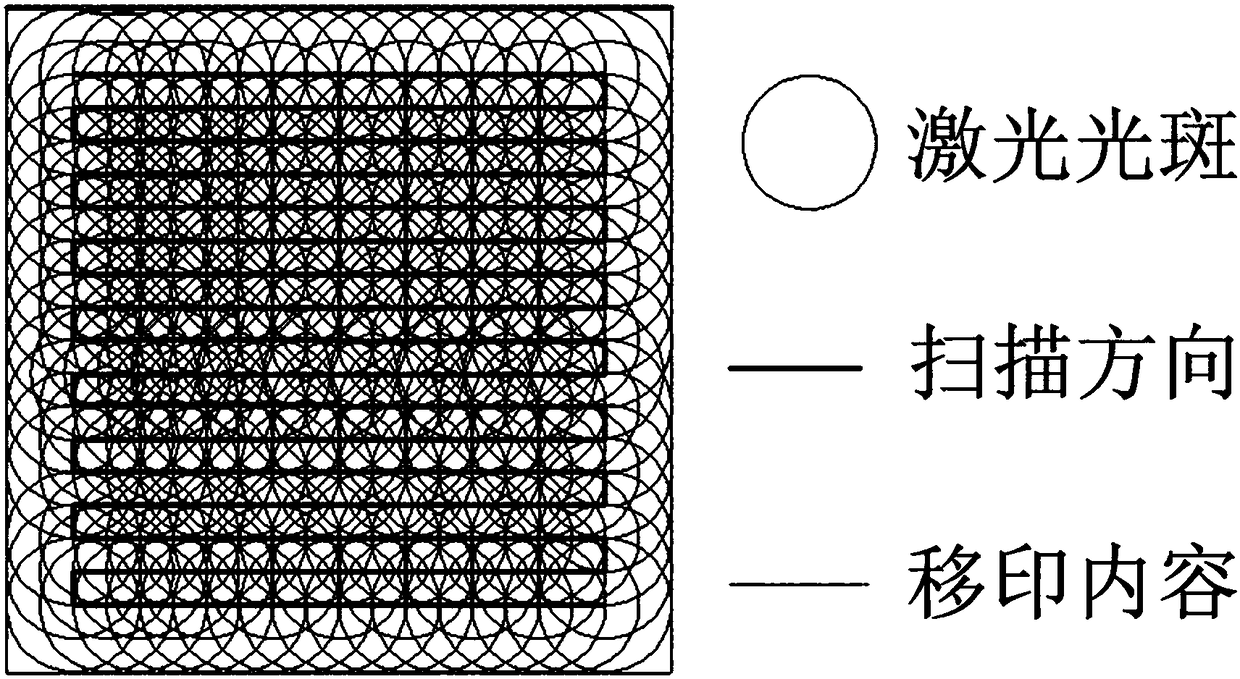

Laser marking method for die steel

ActiveCN108326435ARetain corrosion resistanceRetain wear-resistantWelding/soldering/cutting articlesLaser beam welding apparatusVaporizationOptoelectronics

The invention discloses a laser marking method of die steel. The method comprises the steps that a long pulse width laser with the pulse width of 90-110 ns is adopted, and laser marking is carried outon the die steel at the laser frequency of 45-55 kHz; and during marking, a filling distance of the laser is controlled to be 0.008-0.015 mm, and meanwhile, the laser marking speed is controlled to be 380-450 mm / s. According to the laser marking method, the laser with a long pulse width and a high frequency is adopted, marking machining is carried out on the die steel under the preferable fillingdensity and the low marking speed so that the instantaneous peak power can be guaranteed not to exist while enough heat can be guaranteed, and then the effect that steel on the surface of the die steel is removed through heating and vaporization and the bottom material is not damaged is achieved; and the shape of the part subjected to the steel removing and machining is consistent with the shapeof the unmachined part, the boundary is clear and straight, the surface is smooth, the hand feeling is free of depth and dirt resistance, the advantages of corrosion resistance and wear resistance ofthe die steel are perfectly reserved, and the machined die steel can be stored for a long time.

Owner:HANS LASER TECH IND GRP CO LTD

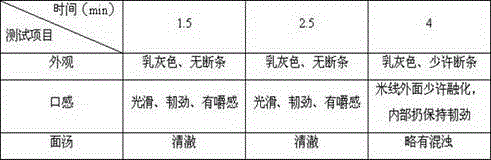

Food-therapy rice noodles and production method thereof

InactiveCN106036398AHigh nutritional valueIncrease elasticityFood ingredient functionsFood extrusionFood processingNutrient content

The invention discloses food-therapy rice noodles and belongs to fields of food and food processing. The food-therapy rice noodles comprises, by weight, 1000-2000 parts of brown rice flour, 300-500 parts of fresh rhizoma dioscoreae juice, 10-20 parts of maca powder, 10-20 parts of radix pueraiae powder, 10-20 parts of edible starch and 10-20 parts of lotus powder. The food-therapy rice noodles has the advantages that most of the nutritional value in brown rice is kept, the glue-like fresh rhizoma dioscoreae juice is used as the dry-wet juice for dough kneading, the nutritional components in the rhizoma dioscoreae can be obtained favorably, and the produced rice noodles is good in elasticity and air-holding capacity. The invention further provides a production method of the food-therapy rice noodles.

Owner:重庆中笃食品有限公司

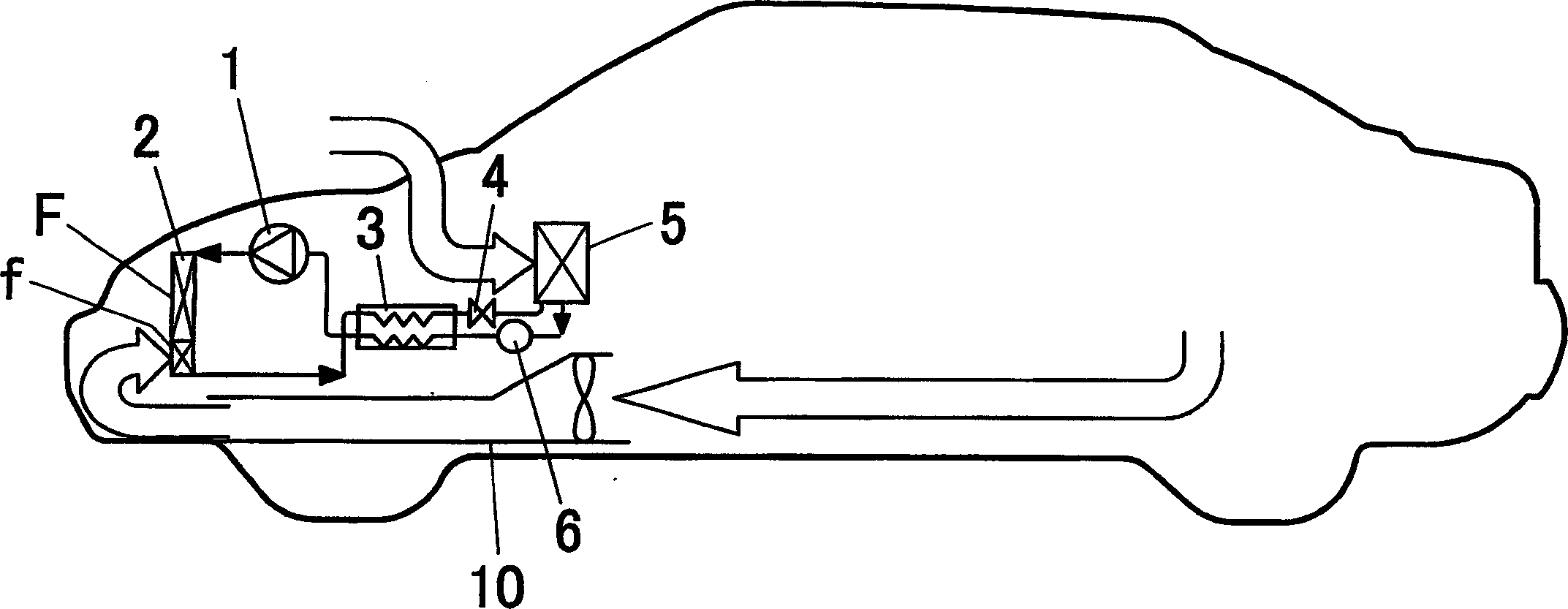

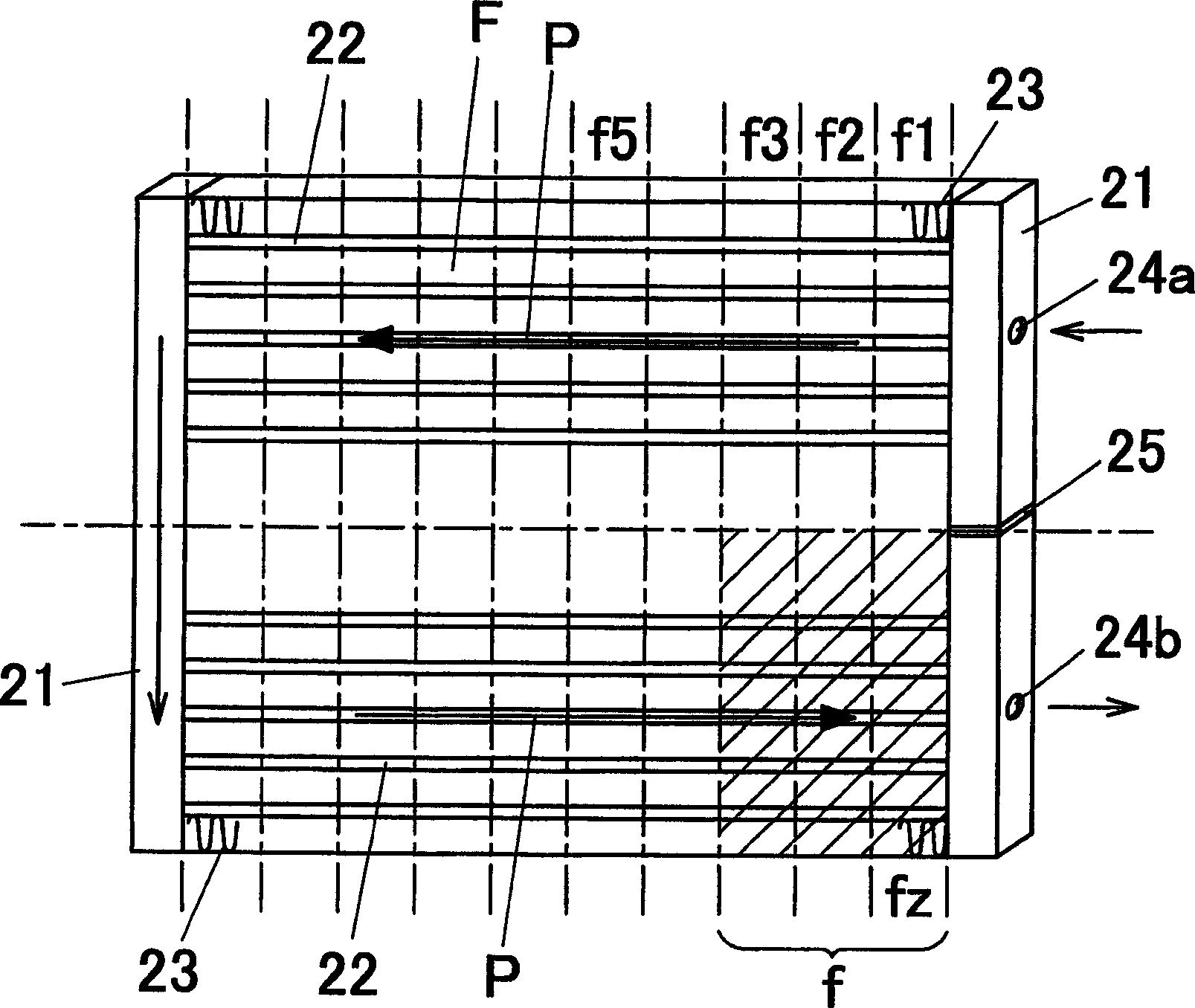

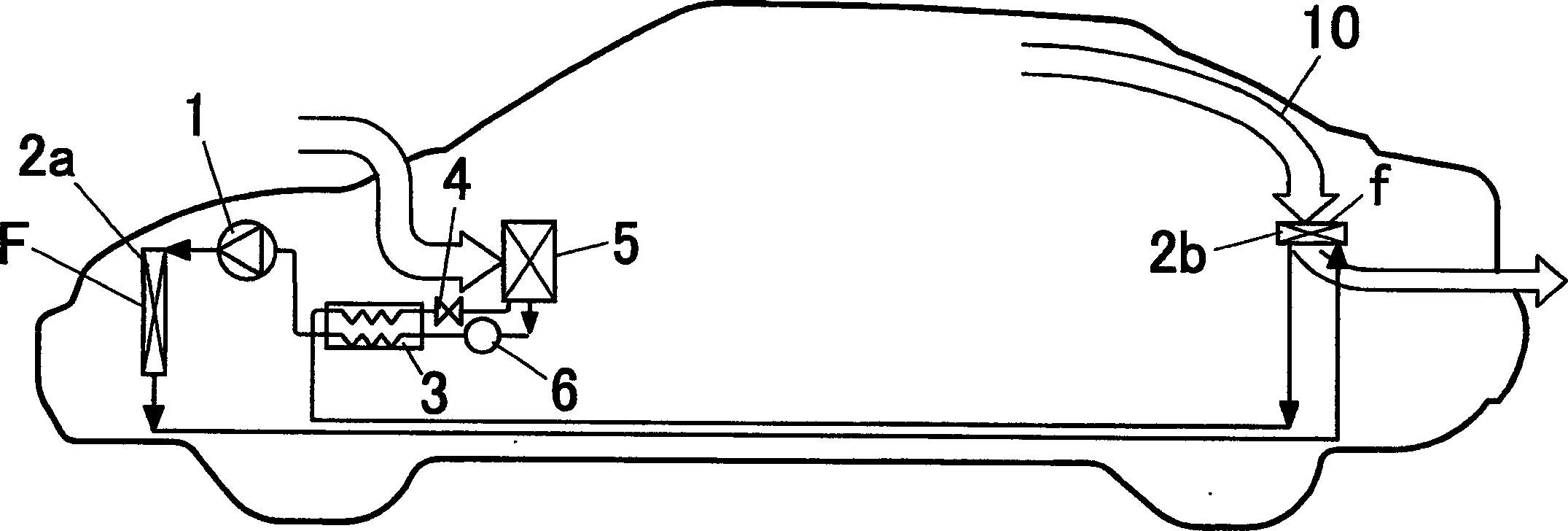

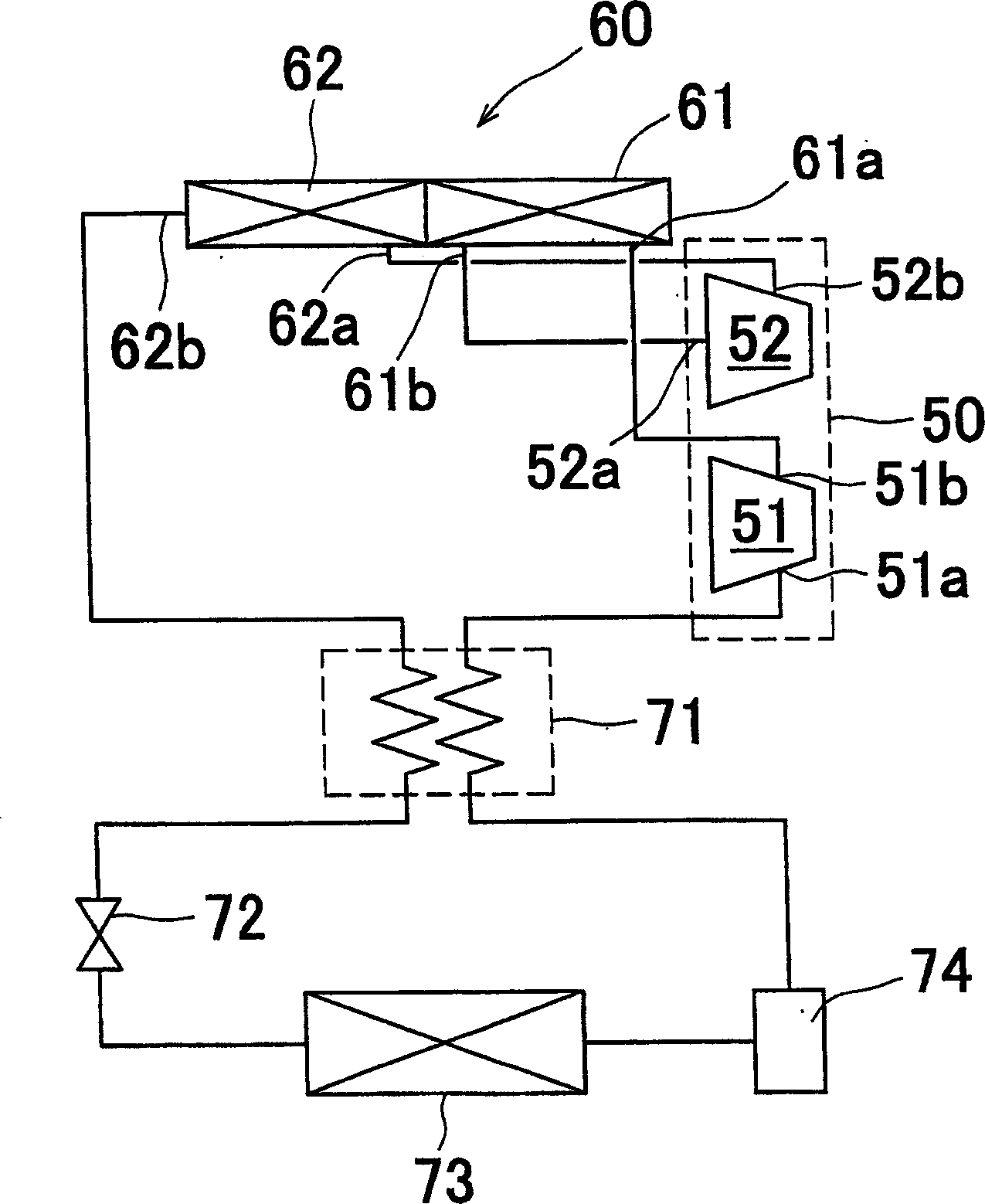

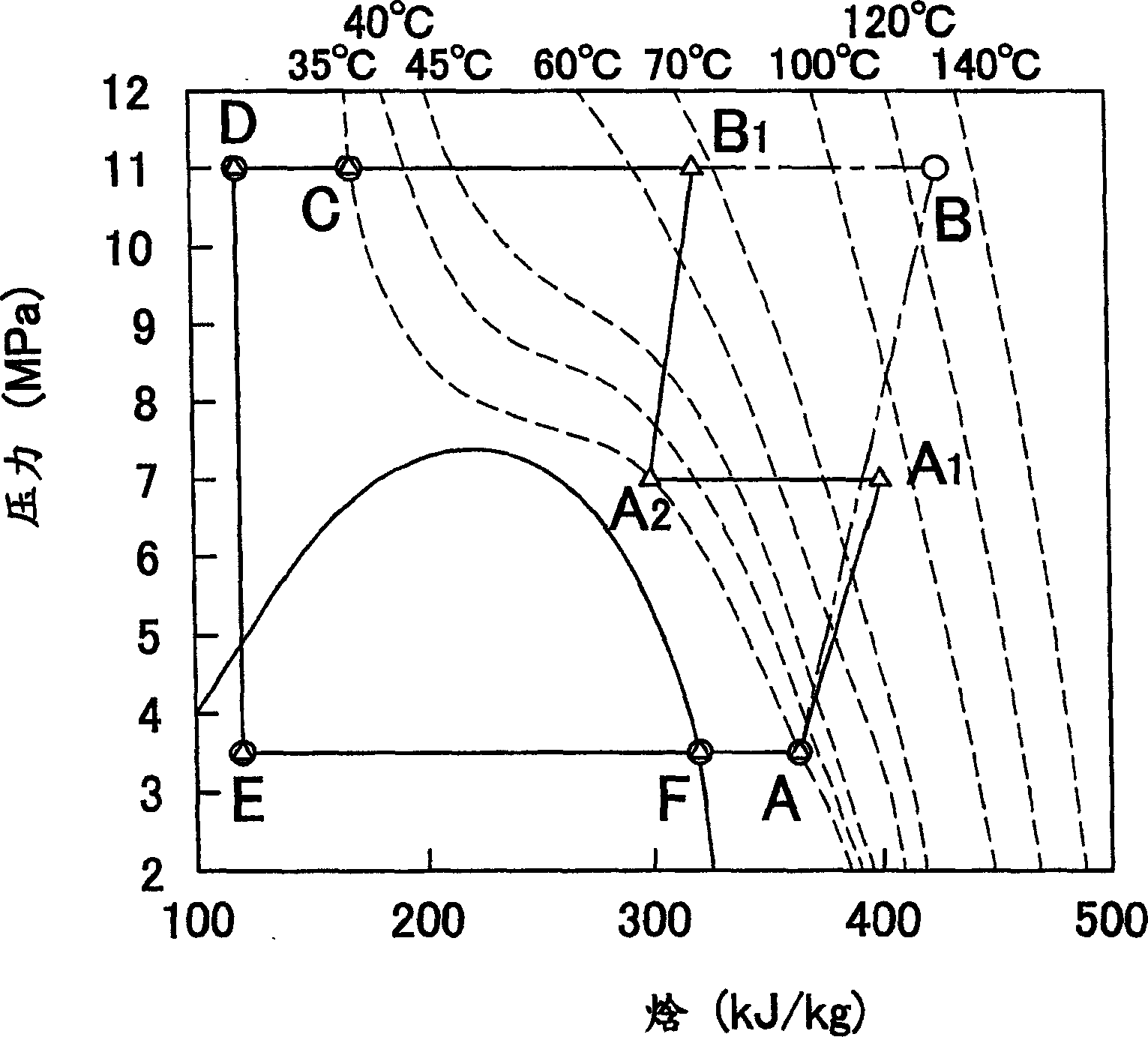

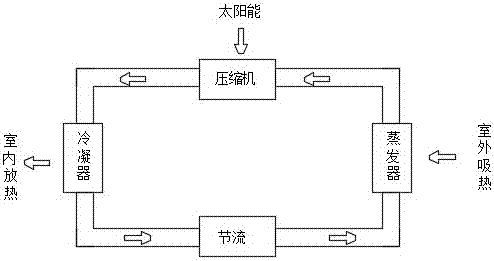

Vehicle air-conditioning related technique having refrigetation cycle of supercritical refrigerant

InactiveCN1914054ARealize the function/effectEnough heatAir-treating devicesCompression machines with non-reversible cycleEngineeringAir conditioning

The invention is directed to a vehicle air-conditioning apparatus in which supercritical refrigerant passing through a refrigerant heat releasing passage P of a heat releasing device 2 exchanges heat with refrigerant cooling air introduced from an air introduction surface F of a heat releasing device 2 to be cooled, and the cooled refrigerant exchanges heat with air to be introduced into a passenger compartment by an evaporator 5. Since at least a part of discharge air discharged from an inside of a passenger compartment is introduced from an air introduction surface F of the heat releasing device 2 as a ventilation loss utilizing air, ventilation loss utilizing air can be used as a part of refrigerant cooling air. It is constituted such that the ventilation loss utilizing air is introduced to the downstream side area f of the refrigerant heat releasing passage P in an air introduction surface F of the heat releasing device 2. Thus, in a vehicle air-conditioning apparatus having a supercritical refrigerant refrigeration cycle, ventilation loss can be reduced while improving refrigeration performance.

Owner:SHOWA DENKO KK

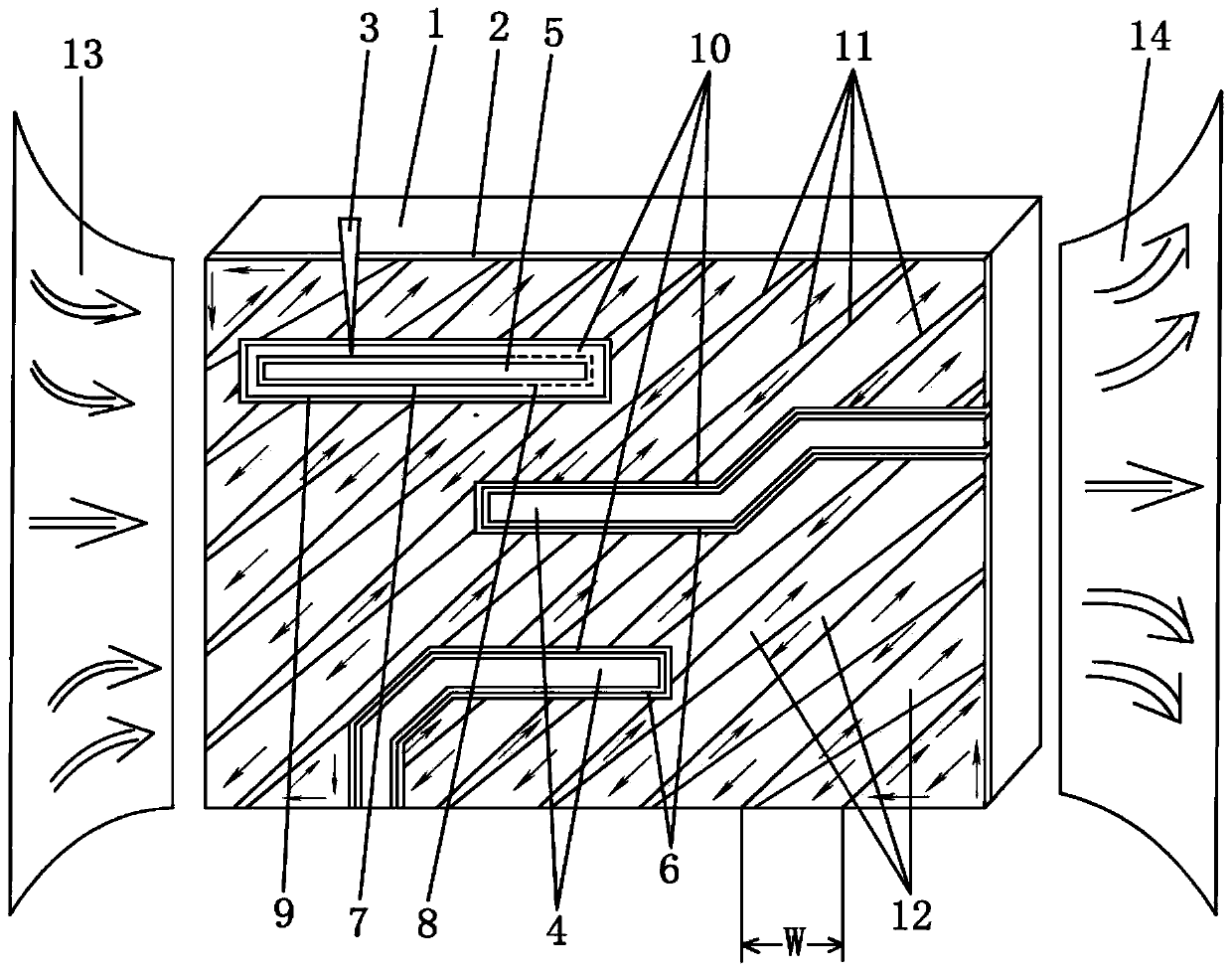

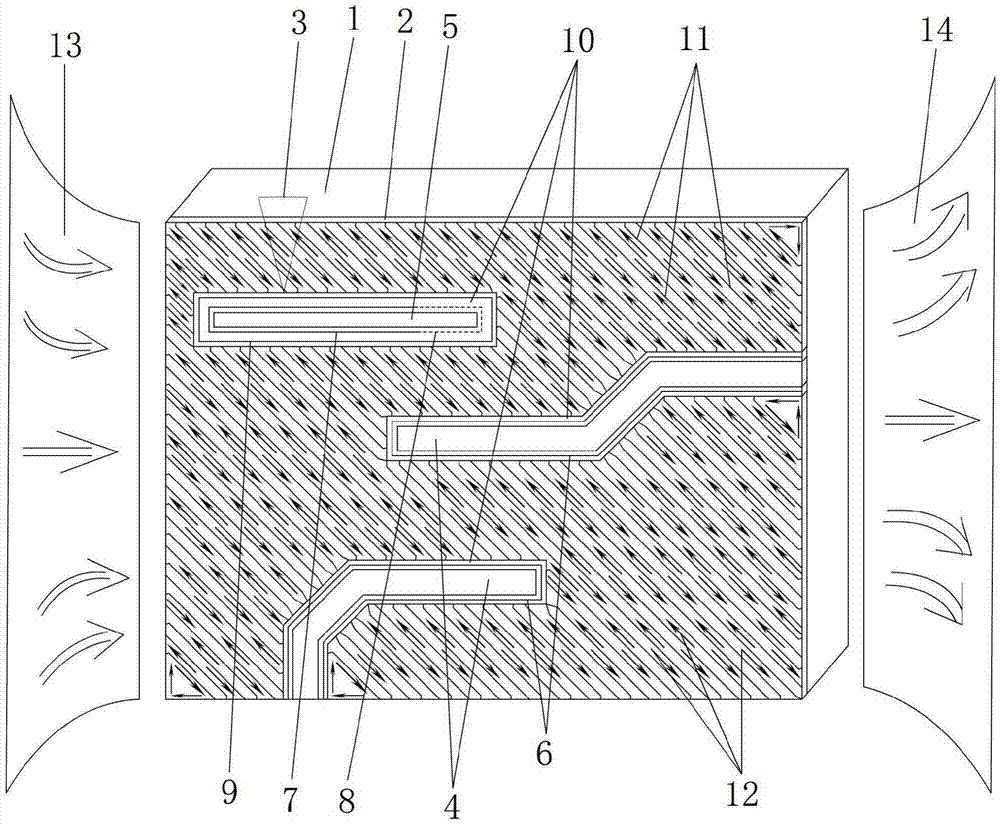

Method for making electric conduction patterns on metal-foil-clad insulating substrate

ActiveCN103769749AInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilLaser beams

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

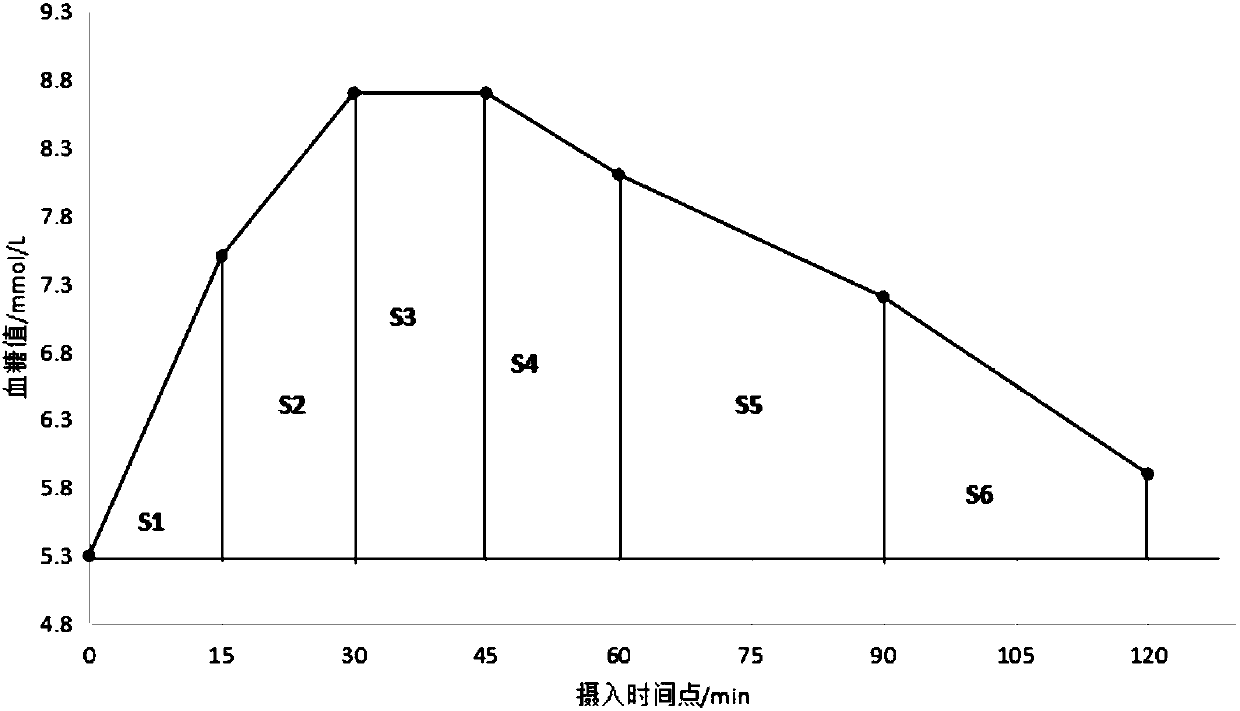

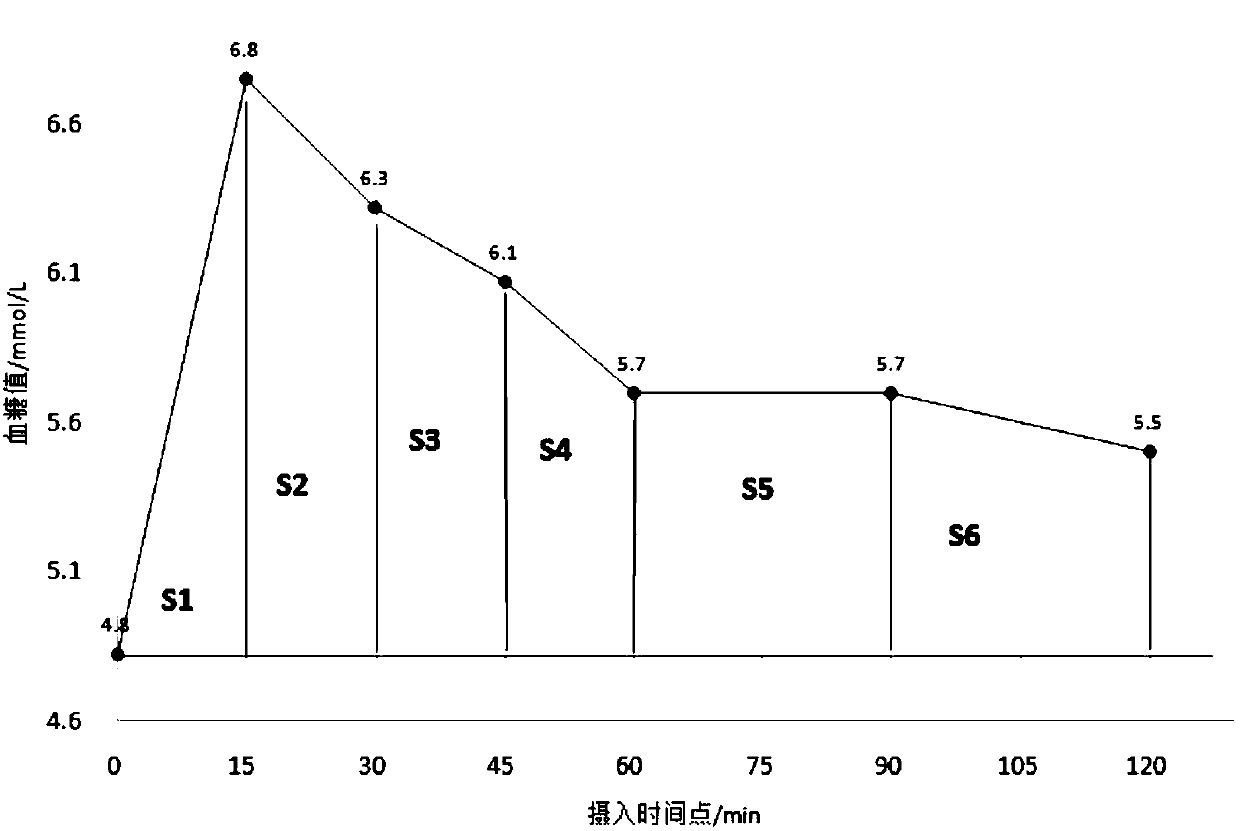

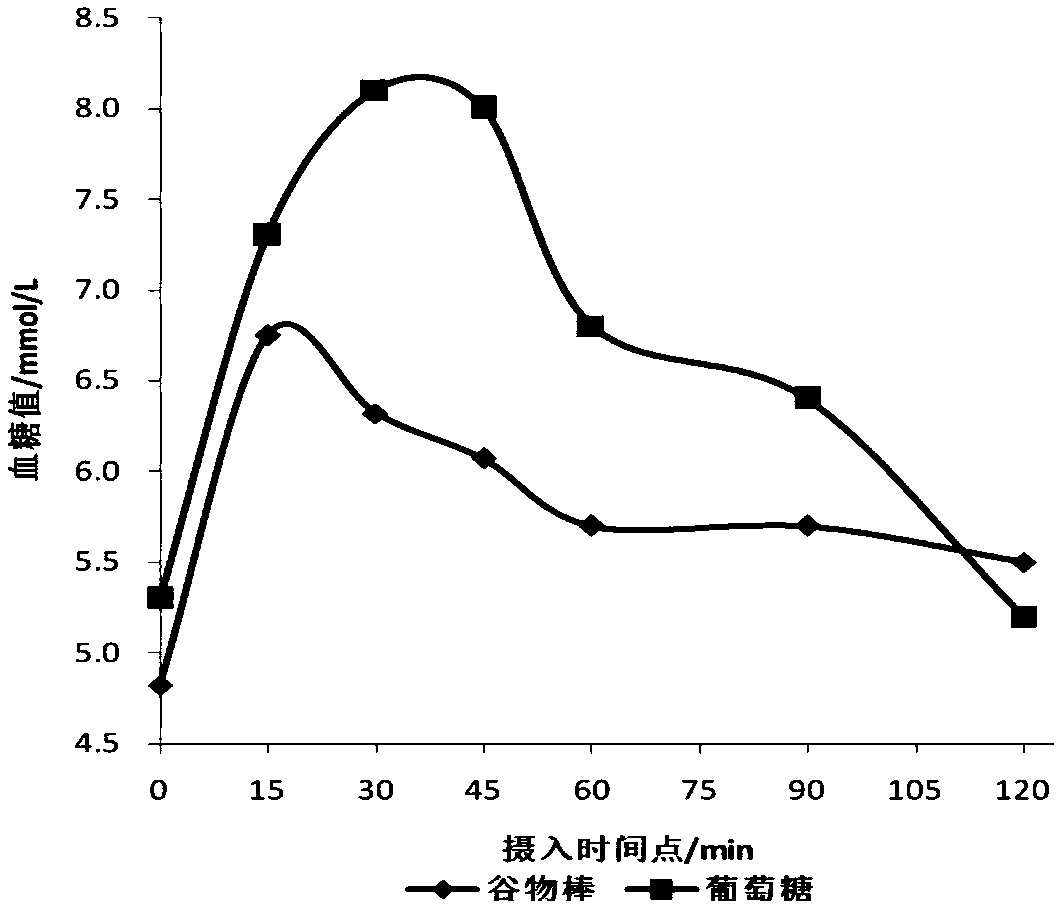

Low-GI cereal bars and preparation method thereof

PendingCN108041116AHigh protein contentMeet intakeDough treatmentBakery productsAmerican cranberryWhey protein powder

The invention discloses low-GI cereal bars and a preparation method thereof. The low-GI cereal bars are prepared from almonds, crisp red beans, compound syrup, dried cranberries and concentrated wheyprotein powder. The low-GI cereal bars provided by the invention are verified by performing testing experiments on people. The raw material components selected by the preparation method realize the beneficial effects of low-GI and smooth postprandial blood sugar by mutual collaboration. The low-GI cereal bars provided by the invention provide sufficient calories, protein and dietary fibers while generating satiety easily, provide a low-GI staple food capable of maintaining smooth postprandial blood sugar for diabetic patients and ensure nutrient intake of the diabetic patients while avoiding suffering from hunger.

Owner:美安康质量检测技术(上海)有限公司

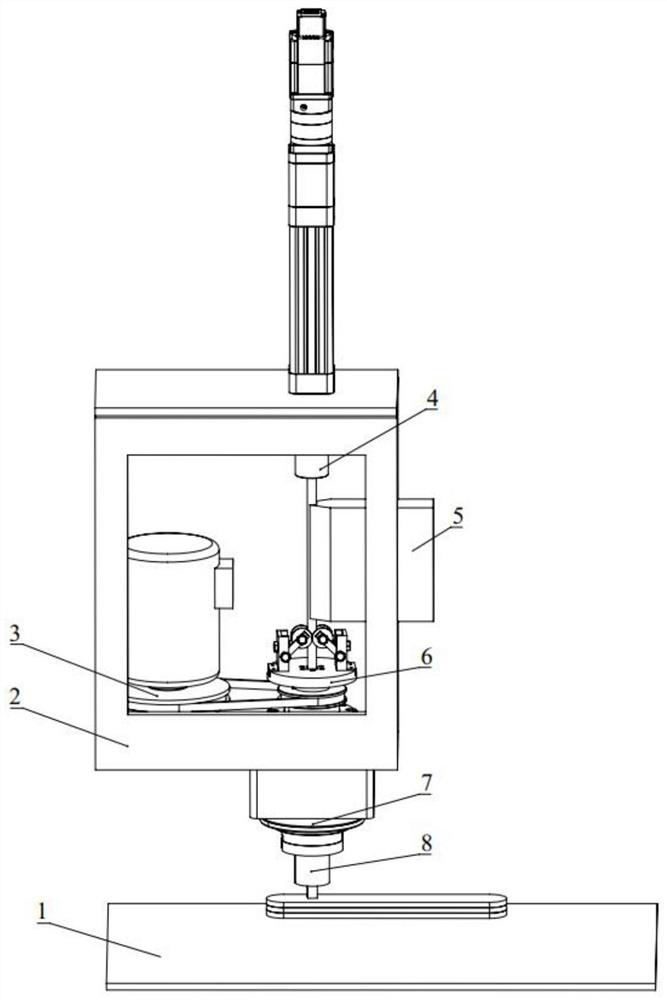

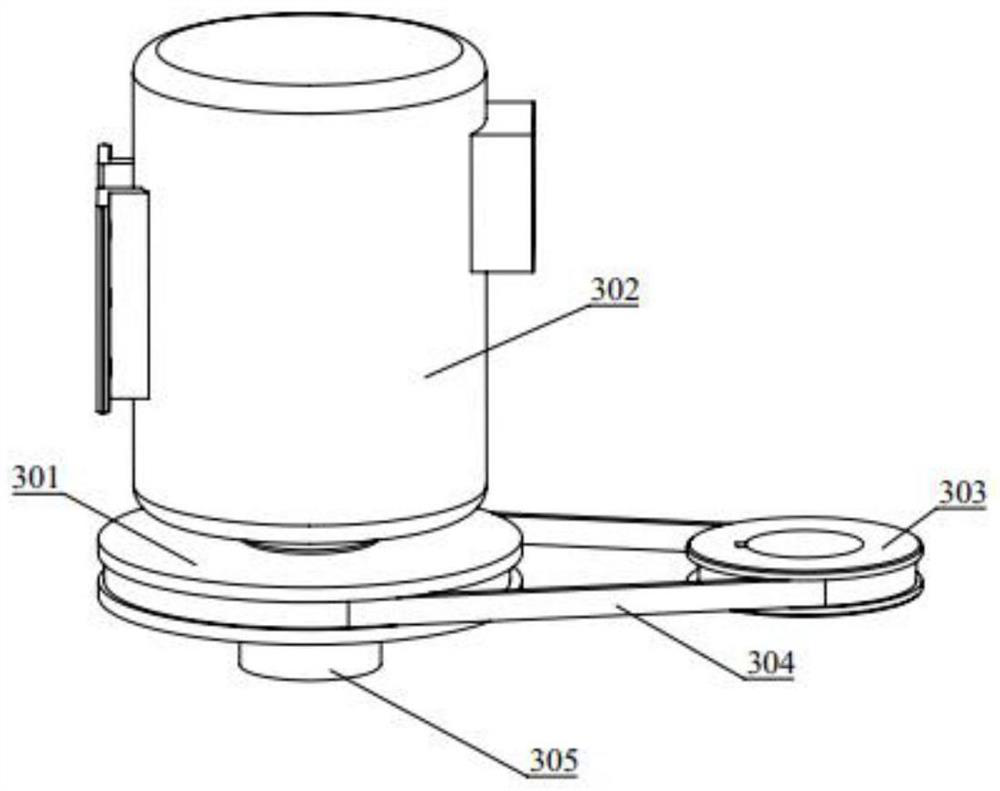

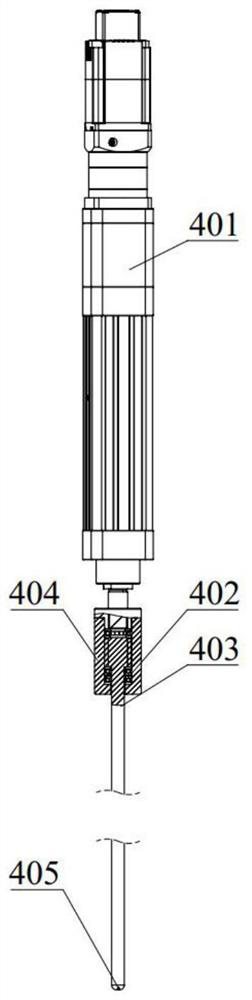

Bar stirring friction additive manufacturing device and method

PendingCN114523189AEnabling Friction Stir Deposition Additive ManufacturingImprove additive efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyPlasticultureBar stock

The invention relates to a bar stirring friction additive manufacturing device and method. The bar stirring friction additive manufacturing device comprises a frame. The stirring friction assembly comprises a transmission mechanism, a hollow rotating shaft mechanism and a forging sleeve, a penetrating shaft hole is formed in the hollow rotating shaft mechanism, the transmission mechanism and the hollow rotating shaft mechanism are installed on the frame, the transmission mechanism drives the hollow rotating shaft mechanism to rotate relative to the frame, and the end, extending out of the frame, of the hollow rotating shaft mechanism is connected with the forging sleeve. The feeding assembly comprises an ejector rod mechanism and a loading mechanism, the ejector rod mechanism is installed on the frame relative to the hollow rotating shaft mechanism, the loading mechanism is arranged between the ejector rod mechanism and the hollow rotating shaft mechanism, a through discharging port is formed in the loading mechanism, the loading mechanism comprises a pushing part arranged corresponding to the discharging port, and the ejector rod mechanism, the discharging port and the shaft hole are coaxially arranged. The bar is used as an additive medium, plasticizing is fast, plasticized materials are easy to control, continuous feeding of the bar is achieved, operation is easy and convenient, reliability is high, the additive efficiency is high, and the effect is good.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

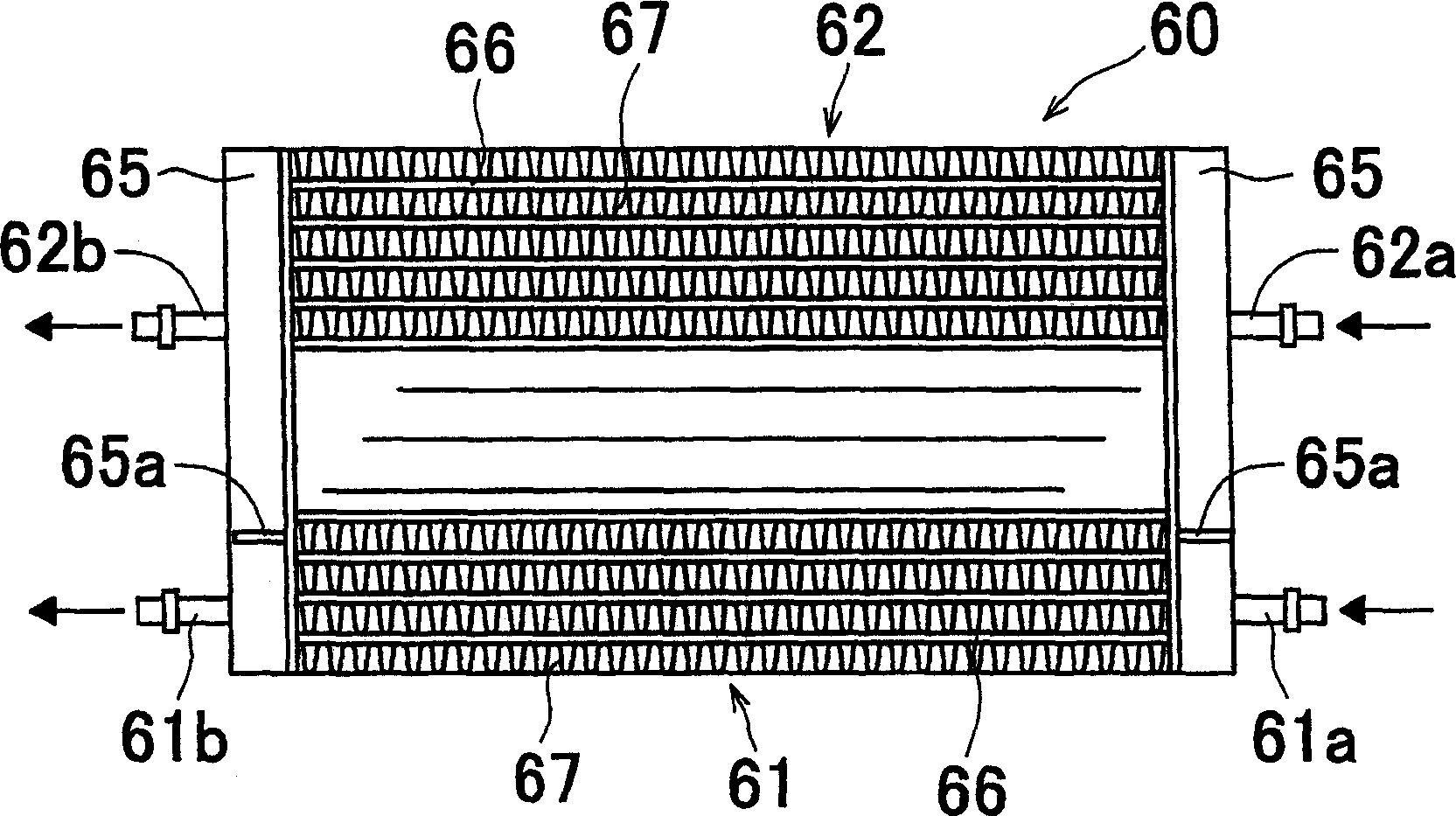

Refrigeration system, compressing and heat-releasing apparatus and heat-releasing device

InactiveCN1708663AReduce the temperatureAvoid defectsCompression machines with non-reversible cycleGas cycle refrigeration machinesRefrigerantChiller

Owner:SHOWA DENKO KK

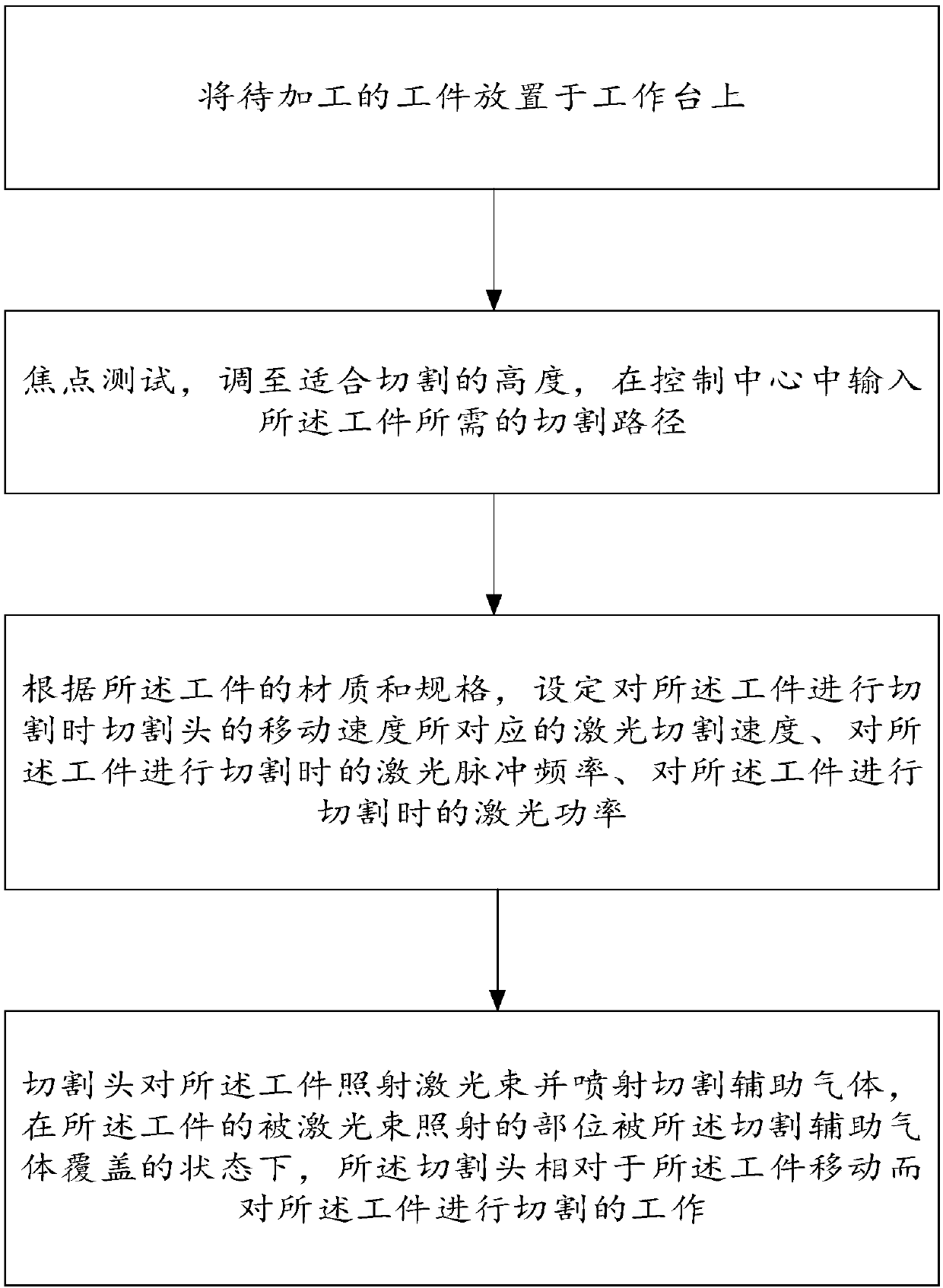

Laser cutting method and device

ActiveCN111195779AImprove efficiencyQuality improvementLaser beam welding apparatusLaser processingEngineering

The embodiment of the invention belongs to the technical field of laser processing, and particularly relates to a laser cutting method and device. The method comprises the following steps that a workpiece to be processed is placed on a workbench; focus testing is performed, the workpiece is adjusted to the height suitable for being cut, and a cutting path needed by a workpiece is input to a control center; according to the material and specification of the workpiece, the laser cutting speed corresponding to the moving speed of a cutting head when the workpiece is cut, the laser pulse frequencyduring workpiece cutting and the laser power during workpiece cutting are set; the cutting head irradiates laser beams to the workpiece and sprays cutting auxiliary gas, in the state that the portion, irradiated by the laser beams, of the workpiece is covered with the cutting auxiliary gas, the cutting head is moved relative to the workpiece, the cutting work is performed on the workpiece, processing can be performed under the high cutting speed state, it is ensured that enough heat is produced to cut through the workpiece, and meanwhile it is ensured that no or few material melting phenomenawere caused.

Owner:HANS LASER TECH IND GRP CO LTD

A method of making conductive patterns on metal foil-clad insulating substrates

ActiveCN103769749BInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilPhysical approach

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

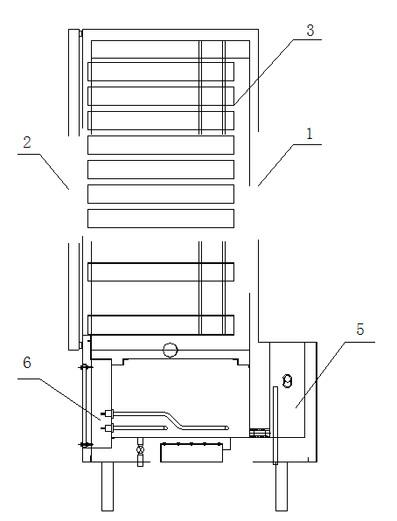

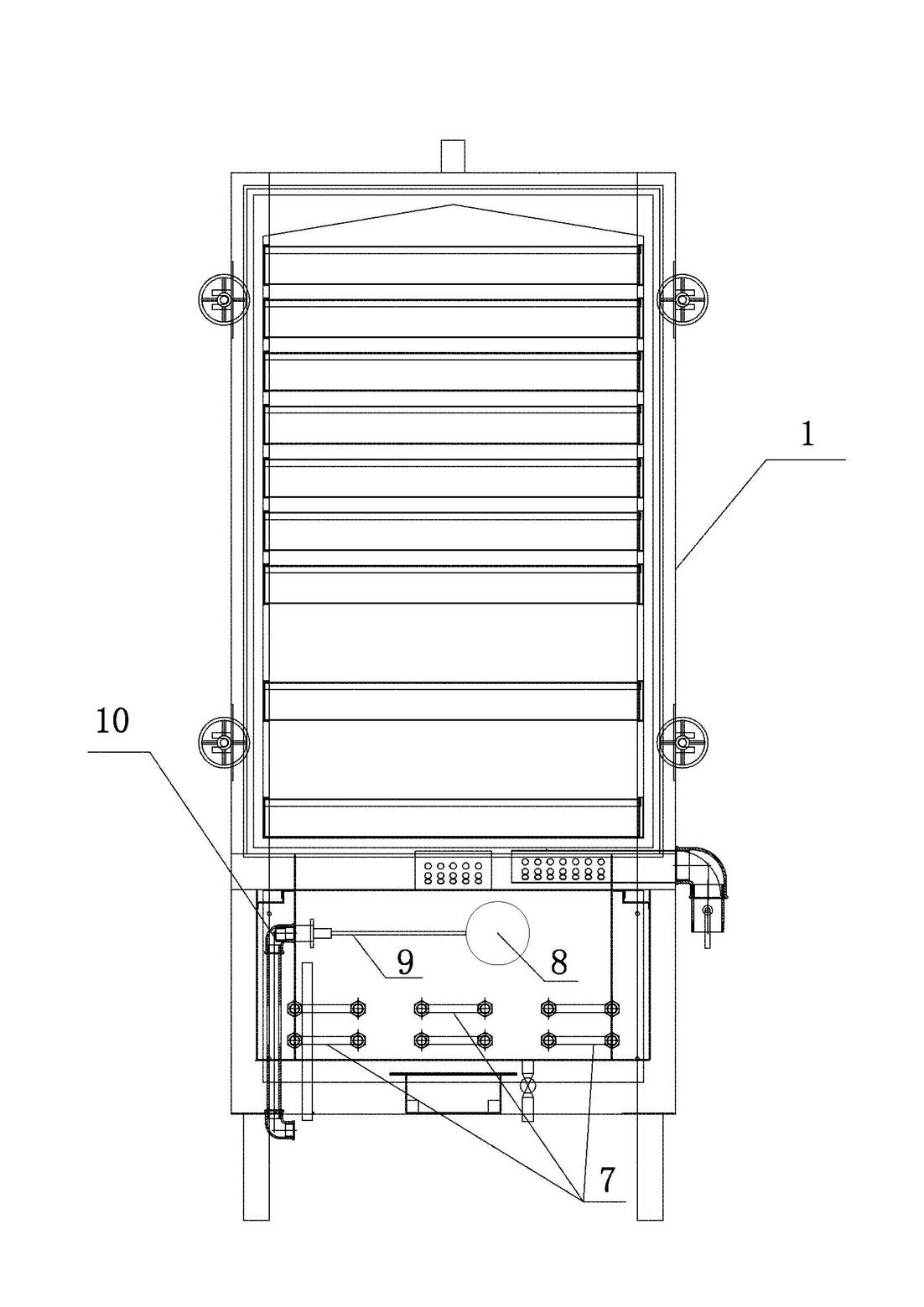

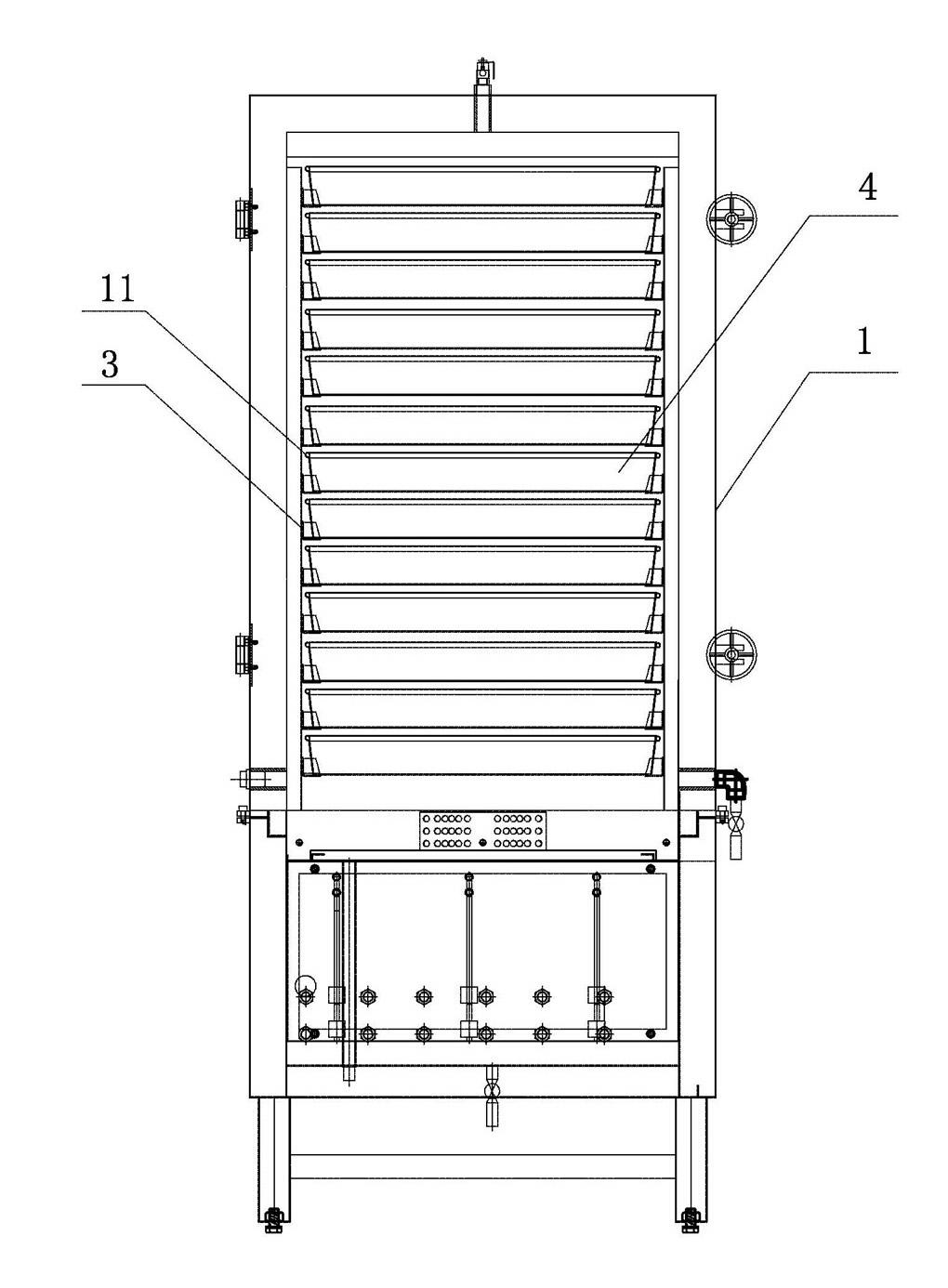

Rice steaming cabinet

The invention relates to a rice steaming cabinet comprising a cabinet body, internal devices, a control circuit and pipeline layout, wherein the cabinet body comprises a shell and a door; the internal devices include a tray, a bracket, a tube bag, a steam generating device, a water tank, eight electric heating tubes and the like; the liquid level in the water tank is controlled by a floater; among the eight electric heating tubes, six are main electric heating tubes and two are spare electric heating tubes; the main electric heating tubes are arranged at the bottom of a steam generating liquid surface in two lines, in three rows and in a plane, and the main electric heating tubes at two sides are connected with a thermocouple; and the control circuit is internally provided with an alternate-current solid-sate relay as well as a normally-opened auxiliary contact and a normally-closed auxiliary contact which are connected with the electric heating tubes to form a coil so as to control the electric heating tubes to be communicated or to be shut off. Under the swinging state, such as on a ship, the rice steaming cabinet can be used stably and safely, so that rice can be prevented frombeing half-cooked and not edible due to insufficient water supply, and electrical equipment can be prevented from ageing due to dry heating, therefore, the rice steaming cabinet provides food security for seamen and other personnel working under the unstable states, is simple to manufacture and has wide market prospect.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY +1

A method for selectively removing a conductive layer on a substrate material

ActiveCN103747626BInhibit sheddingFinely craftedPrinted circuit manufacturePhysicsElectrical and Electronics engineering

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

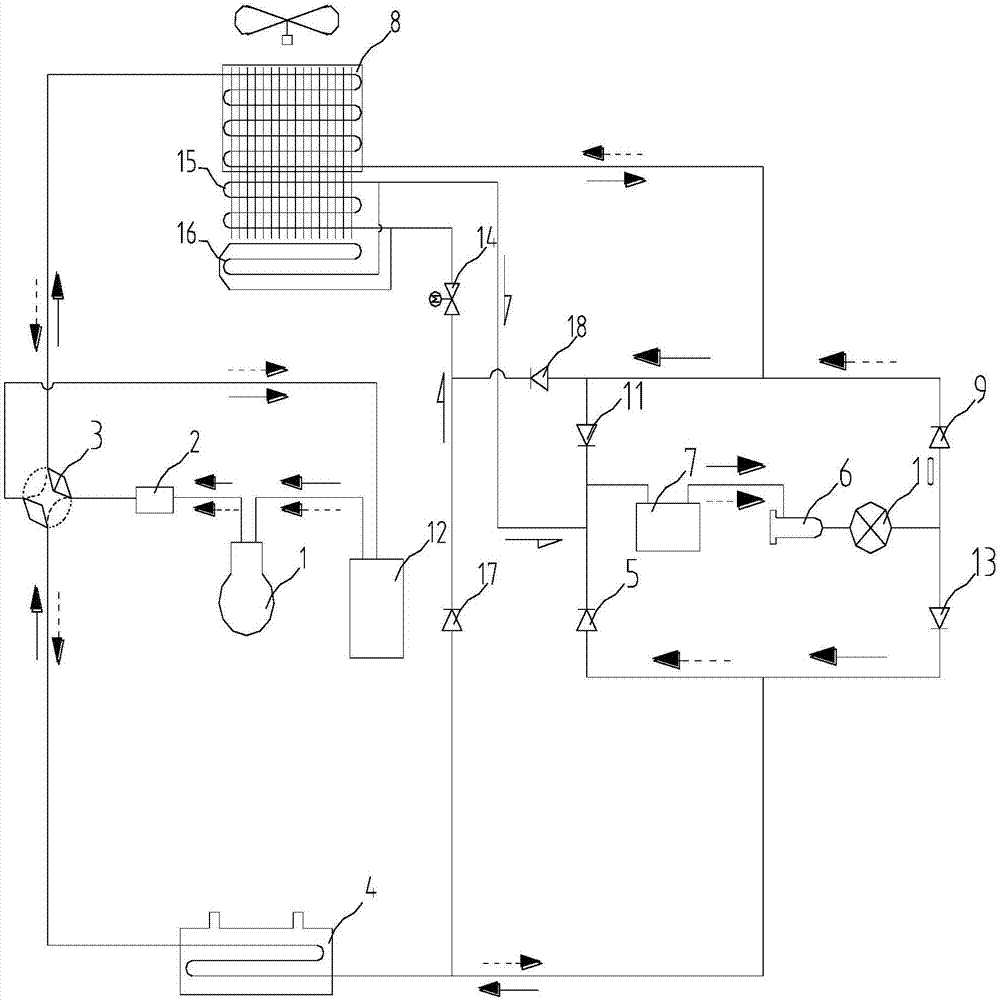

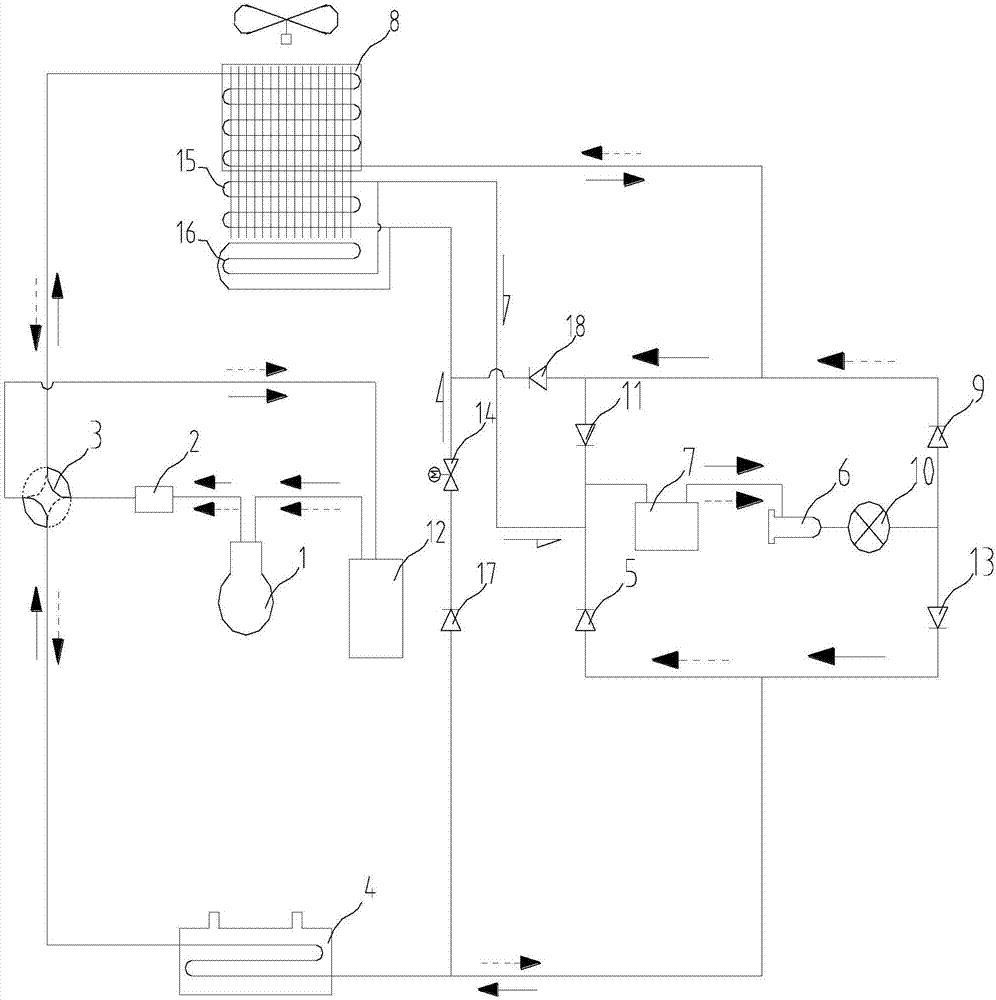

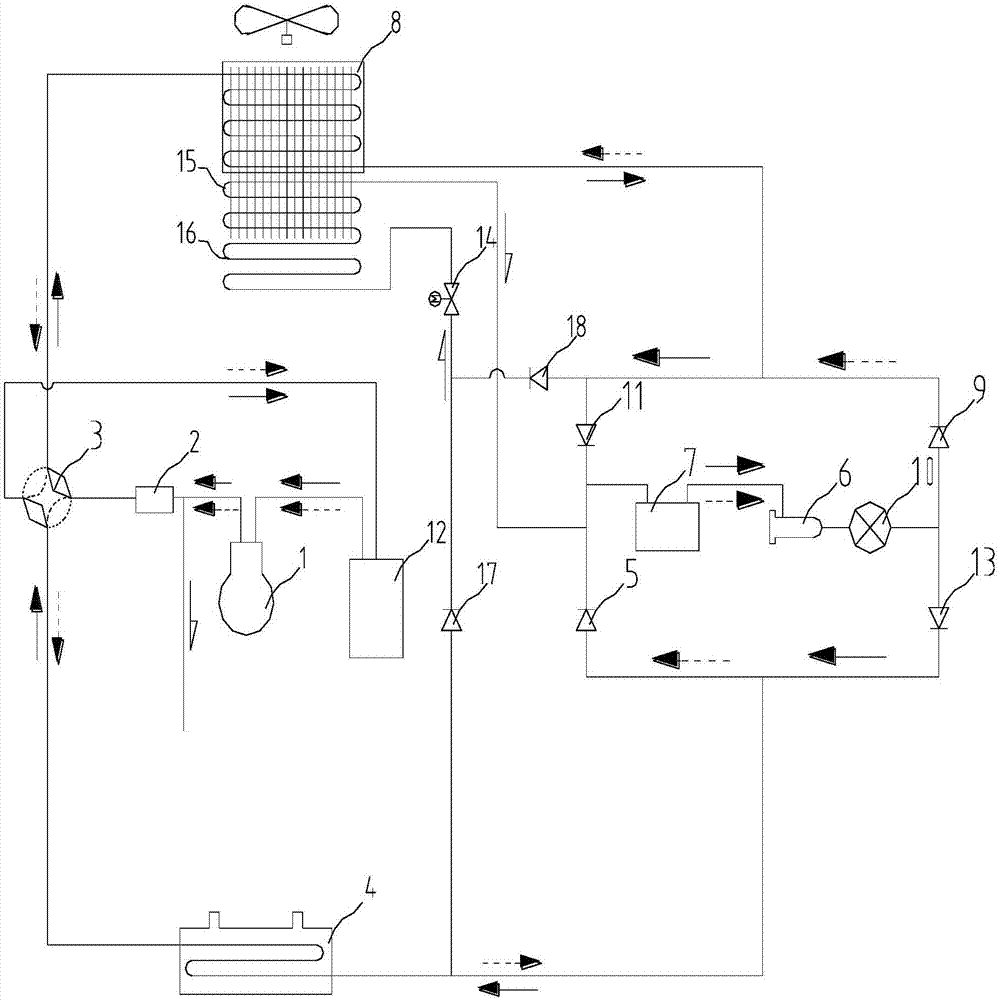

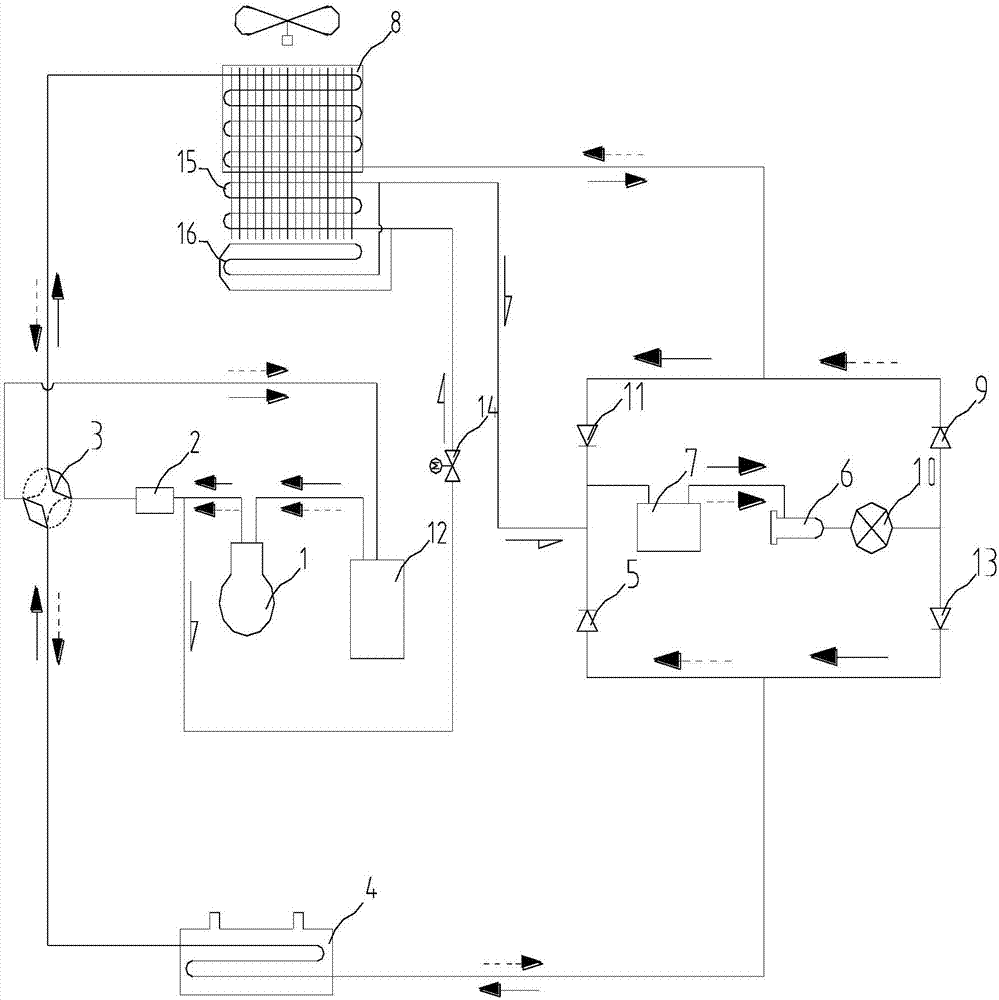

Heat pump unit

PendingCN107965944ASwitch as soon as possibleMeet heating needsHeat pumpsCorrosion preventionEngineeringEnergy consumption

The invention discloses a heat pump unit. The heat pump unit comprises a first heat exchange part, a second heat exchange part, an expansion valve and a water pan, wherein the first heat exchange partserves as a condenser under a heating mode, and the second heat exchange part serves as an evaporator under the heating mode. The heat pump unit further comprises a defroster arranged on the second heat exchange part. The defroster comprises an inlet end and an outlet end. The inlet end of the defroster communicates with an outlet pipe section of the first heat exchange part and an outlet pipe section of the second heat exchange part. The heat pump unit further comprises an ice breaker arranged on the water pan. The ice breaker also comprises an inlet end and an outlet end. The inlet end of the ice breaker also communicates with the outlet pipe section of the first heat exchange part and the outlet pipe section of the second heat exchange part. Under the heating mode, a refrigerating medium flowing out of the first heat exchange part supplies heat to the defroster and the ice breaker, under the refrigerating mode, a refrigerating medium flowing out of the second heat exchange part supplies heat to the defroster and the ice breaker, defrosting and ice breaking are thoroughly conducted on the second heat exchange part and the water pan, and the energy consumption of the heat pump unit is not increased.

Owner:HANRUN UNITED HIGH TECH DEV BEIJING CO LTD

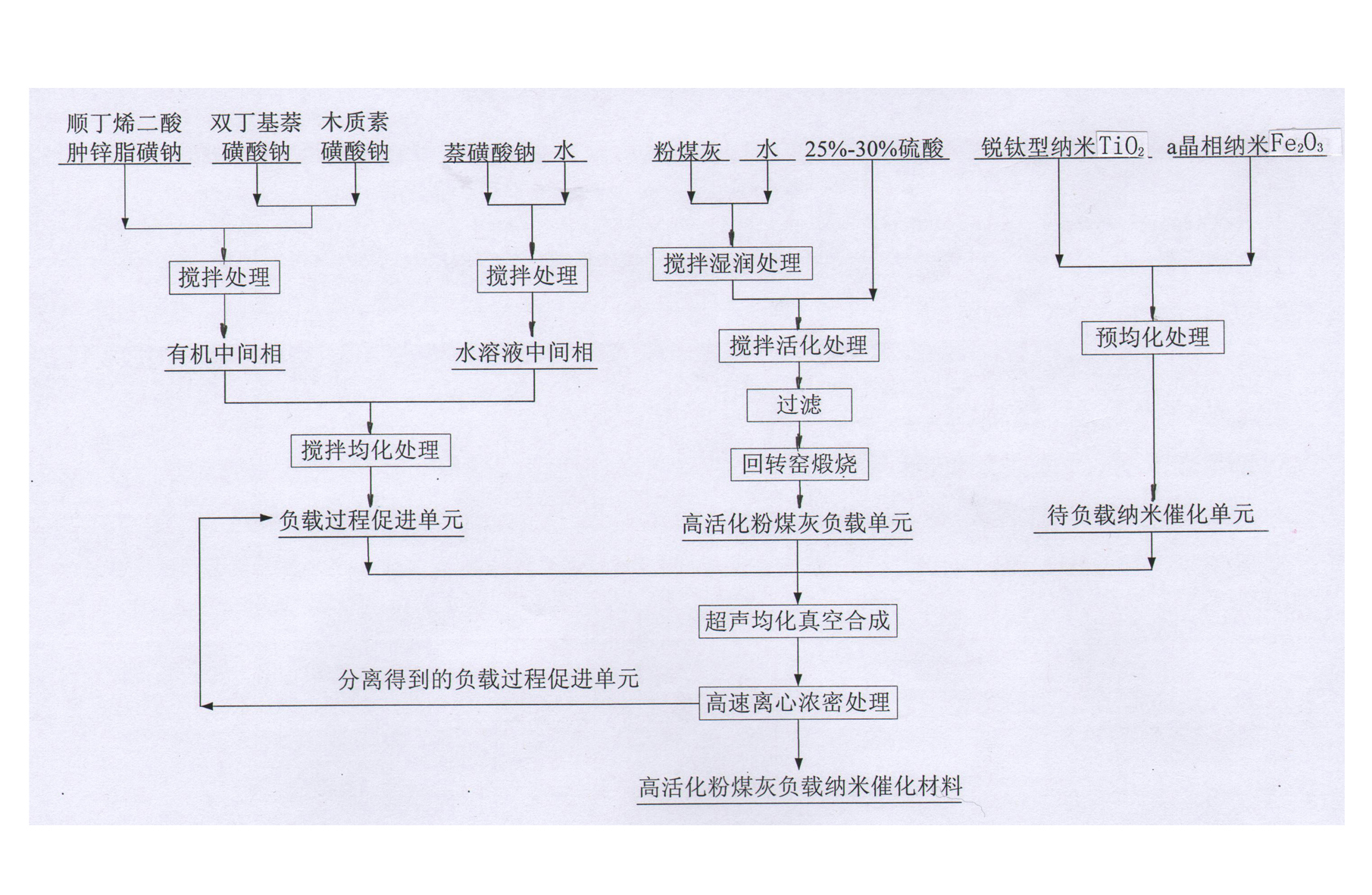

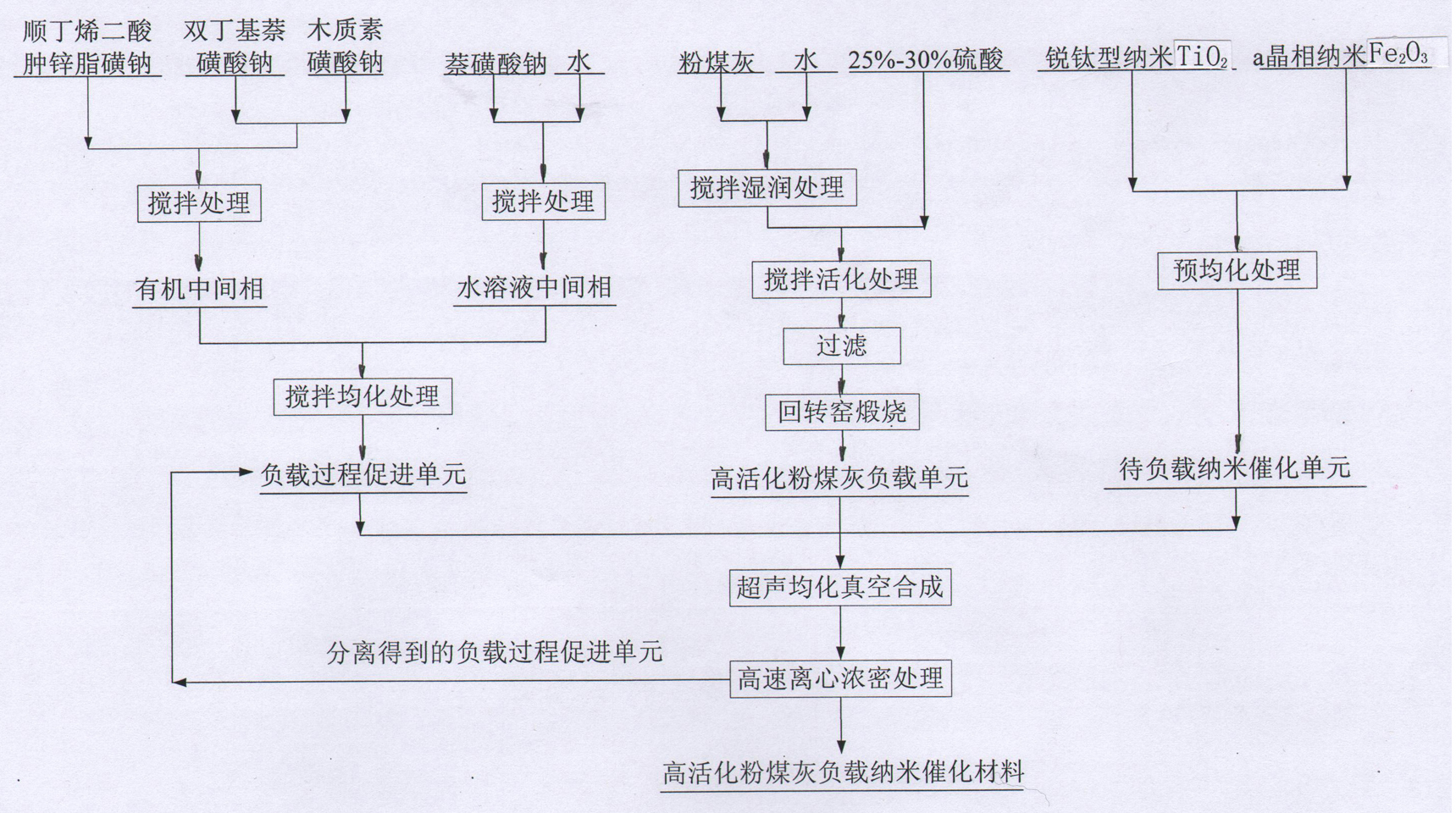

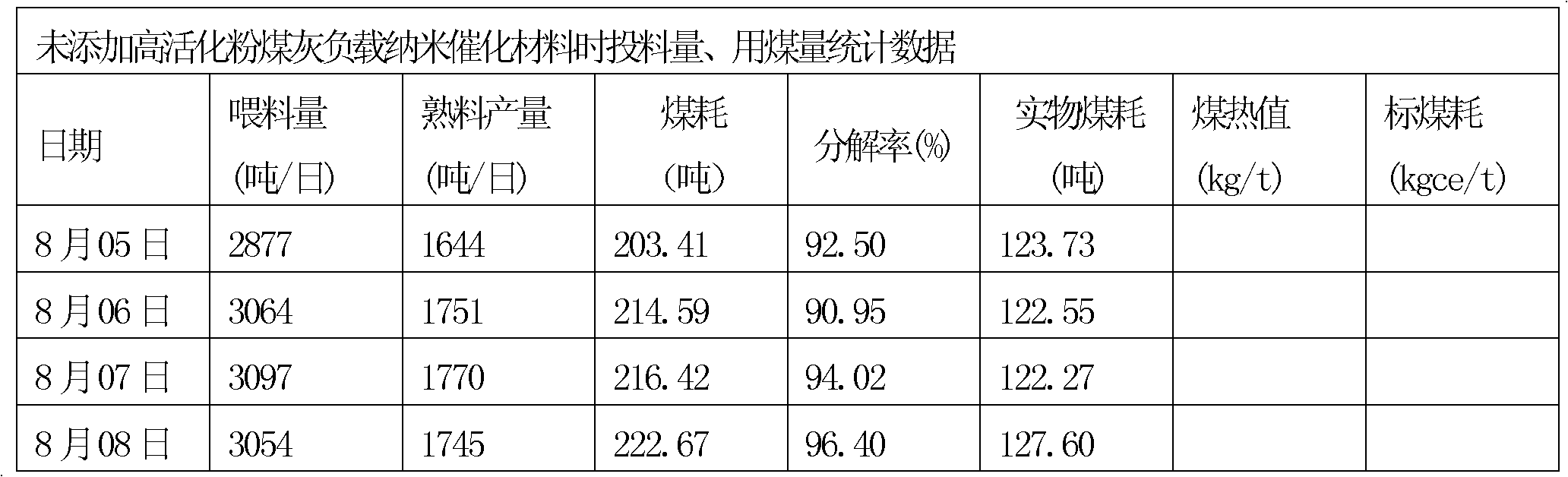

High-activation coal ash loaded nano catalytic material and synthetic process

InactiveCN102614932AHigh strengthImprove thermal powerOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsLow activityCoal

The invention discloses a high-activation coal ash loaded nano catalytic material for improving the combustion efficiency of coal and a synthetic process. The high-activation coal ash loaded nano catalytic material is synthesized by 37.5 to 50 weight percent of high-activation coal ash loaded unit, 7.5 to 12.5 weight percent of nano catalytic unit to be loaded and 37.5 to 55 weight percent of load process promotion unit. The high-activation coal ash loaded nano catalytic material can be directly used for multiple industrial kilns, so that 'energy conservation and environment friendliness' arerealized effectively. In addition, the combustion of low-activity fuel such as inferior coal and the like is facilitated particularly, so local inferior fuel can be adopted to promote the reasonable utilization of energy and improve the utilization efficiency of resources, one-time air volume is small, and an energy-saving effect is obvious.

Owner:YUNNAN ZENENG TECH

Mayonnaise and making method thereof

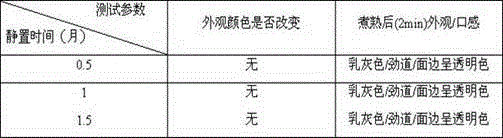

The invention discloses mayonnaise and a making method thereof. The mayonnaise is characterized by comprising yolk, as well as components in percentage by mass of the yolk of 9-11% of honey, 2-3% of lemon juice and 0.5-1% of table salt. The mayonnaise is prepared through the following steps of cleaning fresh poultry eggs with running water, performing drying by airing, performing shell removal, and performing separation of beaten eggs so as to obtain the yolk; adding the honey, the lemon juice and the table salt to the yolk, performing uniform stirring, and performing homogenizing so as to obtain mayonnaise mixed liquid; and loading the mayonnaise mixed liquid in a superhigh pressure special bag, and performing superhigh pressure treatment at 300-600Mpa for 5-10min so as to obtain the mayonnaise. The mayonnaise has the advantages that a superhigh pressure technology is adopted for making the mayonnaise, so that under the condition that fat is not added additionally, the mayonnaise hasfavorable texture and stability; besides, the superhigh pressure technology has the effect of sterilization; based on smooth and rich mouth feel of conventional mayonnaise, the mayonnaise has the characteristics of being safe and nutritive, reducing energy absorption and the like; and the superhigh pressure technology is a good substitute of a making and thermization manner of the conventional mayonnaise.

Owner:NINGBO ACAD OF AGRI SCI +1

Biogas tea fixing machine

ActiveCN101933544BSmooth air supplySafe and reliable ignitionPre-extraction tea treatmentCombustionMethane

The invention discloses a biogas tea fixing machine, which comprises a frame, a horizontal tea fixing roller arranged on the frame, a driving device driving the tea fixing roller to roll, and a heating device used for heating the tea fixing roller. The biogas tea fixing machine is characterized in that: the heating device comprises a stove and a biogas combustion device arranged under the tea fixing roller; the biogas combustion device comprises a biogas delivery pipeline which is connected with a biogas digester and provided with a valve, and a plurality of high temperature-resistant biogas ejectors connected with the output end of the delivery pipeline; the biogas ejectors pass through the side wall of the stove to extend into the hearth of the stove; and biogas nozzles of all the biogas ejectors are arranged at equal intervals along the length direction of the hearth. The fixing machine is provided with heat by the combustion of the biogas, and the combustion cost is lower, so the manufacturing cost of tea is reduced; the main component of the biogas is methane, and generates water and carbon dioxide after combustion, so the environment is protected; besides, the combustion value of the biogas is high, so the biogas provides enough heat for the fixing machine; therefore, the produced tea has higher quality.

Owner:福建安溪历山茶仙茶业有限公司

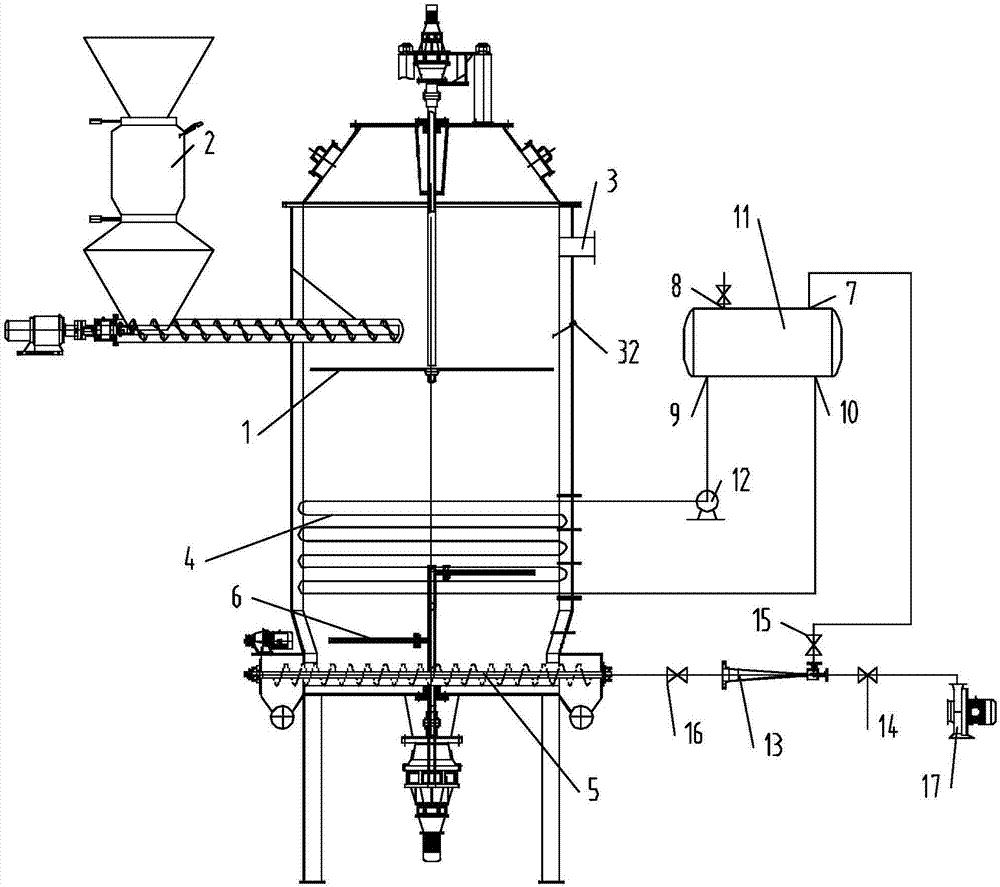

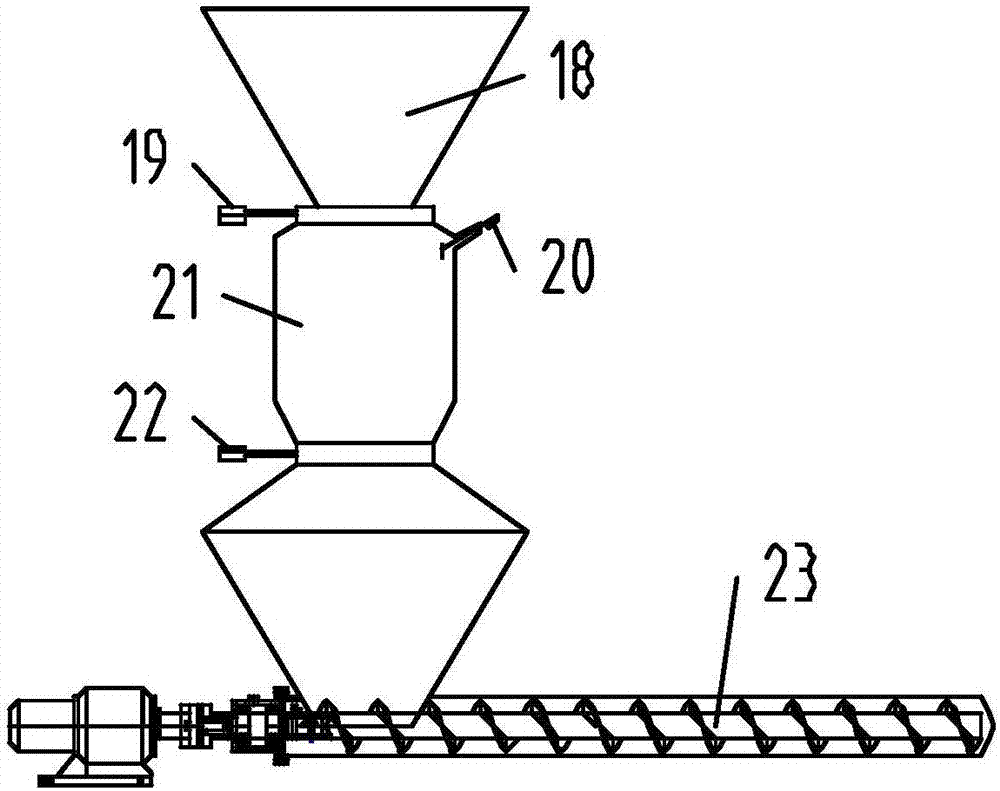

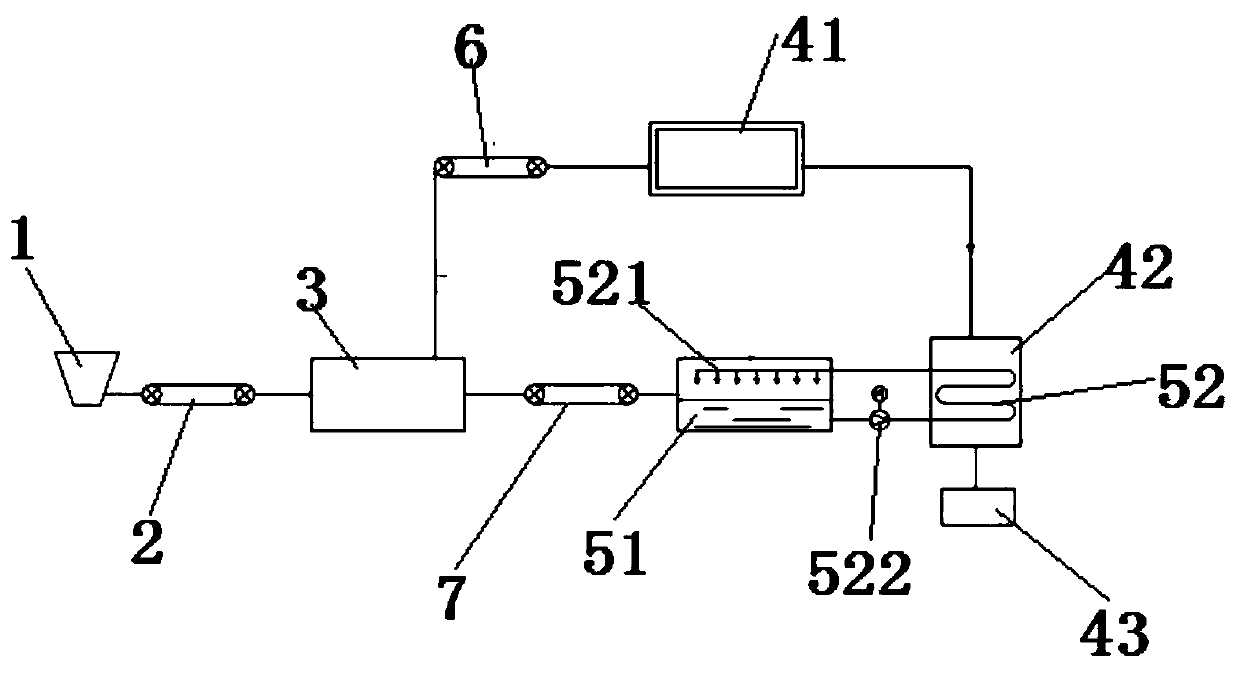

Gasification unit for preparing biomass medium-heating value fuel gas

ActiveCN107163988AInto the uniformUniform dischargeCombustible gas productionWater vaporSpiral blade

The invention provides a gasification unit for preparing biomass medium-heating value fuel gas, which can improve the heating value of gasified combustible gas on the basis of not additional investment of big production devices and guarantee of stable running. The gasification unit comprises a gasification furnace and a steam generation air inlet system; the bottom part of the gasification furnace is provided with a spiral discharging gas distribution device, and a spiral shaft rotated in the spiral discharging gas distribution device is a hollow shaft of which periphery is provided with a spiral blade; an air outlet is arranged on the hollow shaft; the steam generation air inlet system comprises a steam pocket, a circular hot water pump, a heating coil arranged at the middle lower part of the gasification furnace, a mixer, a blower and a valve; a heating coil outlet is connected with a water inlet of the steam pocket through the circular hot water pump, and the water outlet of the steam pocket is connected with the heating coil inlet; a vapor outlet of the steam pocket is connected to an inlet of the mixer through the valve; a blower outlet is connected to the inlet of the mixer through the valve; the mixer outlet is connected with one end of the spiral shaft through a rotating joint.

Owner:NANJING FORESTRY UNIV

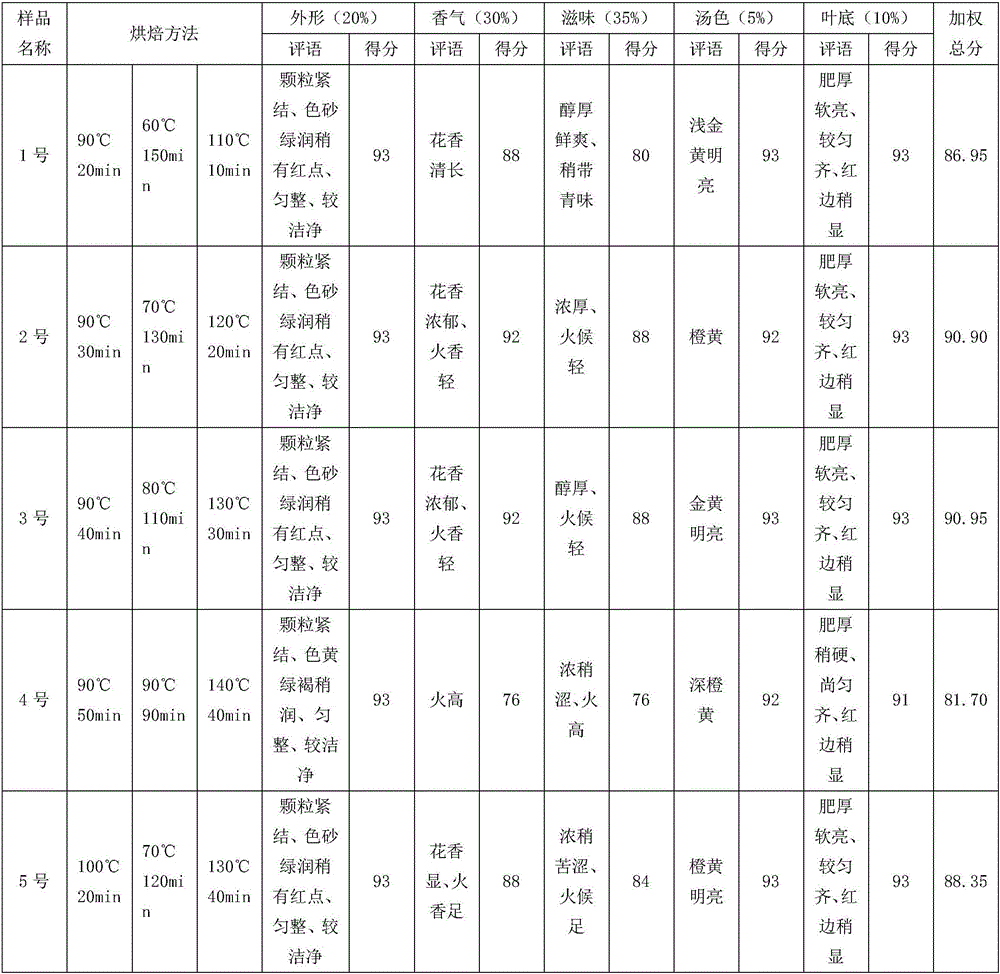

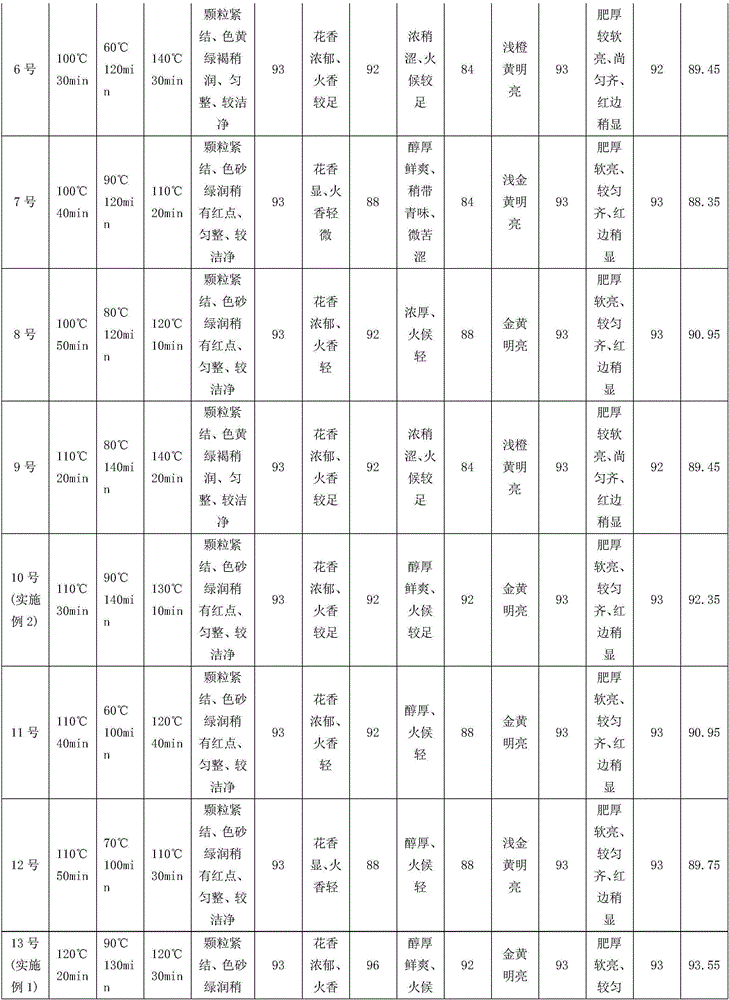

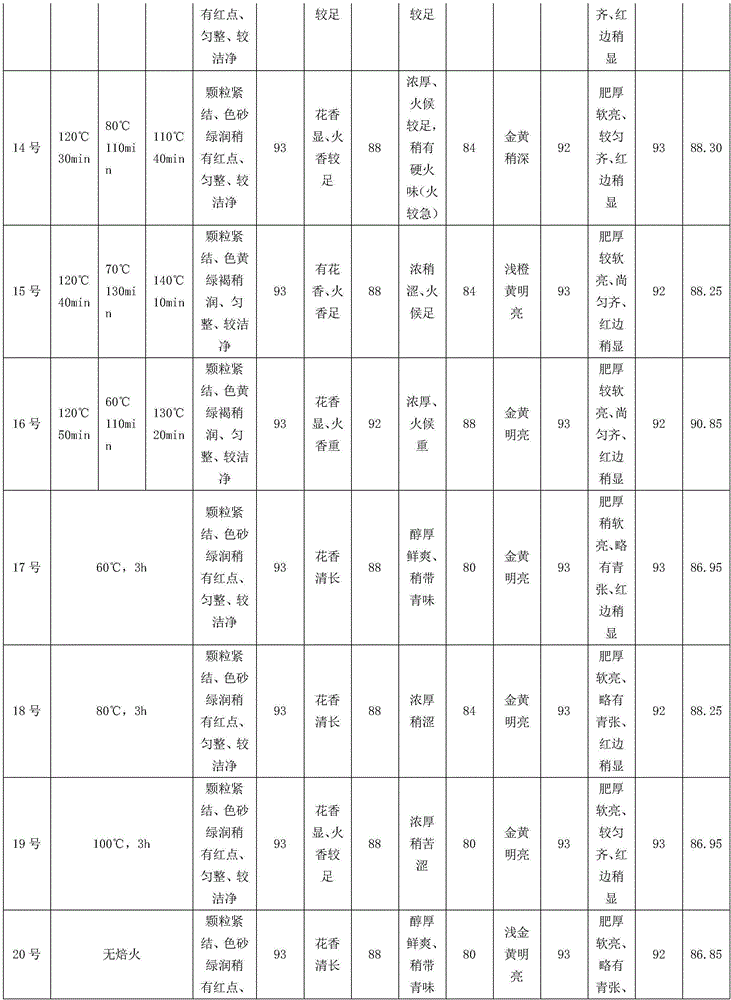

Temperature-changeable baking method of orange osmanthus oolong tea

The invention provides a temperature-changeable baking method of orange osmanthus oolong tea, and belongs to the technical field of tea leaf baking. The orange osmanthus oolong tea is granular orange osmanthus oolong tea which is obtained by removing stems and bracts after refining; the temperature-changeable baking method of the orange osmanthus oolong tea comprises the following steps: (1) removing impurities at high temperature, wherein the temperature is 110 DEG C to 120 DEG C and the lasting time is 20min to 30min; turning and stirring for one time during the process; (2) slowly baking at low temperature, wherein the temperature is 90 DEG C and the lasting time is 130min to 140min; turning and stirring for 1 to 2 times during the process; (3) improving the aroma at high temperature, wherein the temperature is 120 DEG C to 130 DEG C and the lasting time is 10min to 30min; turning and stirring for one time during the process. The method provided by the invention has the advantages that (1) the baked orange osmanthus oolong tea has relatively low water content, the aroma of tea leaves is improved, and the bitter and green tastes of the tea leaves are reduced; (2) baked tea grains are tight, have rich flower aroma, have mellow and fresh taste and have thick, soft and bright leaves after being brewed.

Owner:TEA RES INST OF FUJIAN ACADEMY OF AGRI SCI

Heat pump unit

PendingCN107965943AShorten the timeConducive to long-term stable operationHeat pumpsCorrosion preventionEvaporatorEngineering

The invention discloses a heat pump unit. The heat pump unit comprises a compressor, a second heat exchange part, an expansion valve and a water pan, wherein the second heat exchange part serves as anevaporator under a heating mode. The heat pump unit further comprises a defroster arranged on the second heat exchange part. The defroster comprises an inlet end and an outlet end. The inlet end of the defroster communicates with an outlet pipe section of the compressor. A refrigerating medium flowing out of an outlet of the compressor supplies heat to the defroster. The heat pump unit further comprises an ice breaker arranged on the water pan. The ice breaker also comprises an inlet end and an outlet end. The inlet end of the ice breaker also communicates with the outlet pipe section of thecompressor. The refrigerating medium flowing out of the outlet of the compressor supplies heat to the ice breaker. According to the heat pump unit disclosed by the invention, whether the heat pump unit is under the heating mode or the defrosting mode (refrigerating mode), the refrigerating medium flowing out of the outlet of the compressor can supply heat to the defroster and the ice breaker, andin this way, defrosting and ice breaking can be thoroughly conducted on the second heat exchange part and the water pan.

Owner:HANRUN UNITED HIGH TECH DEV BEIJING CO LTD

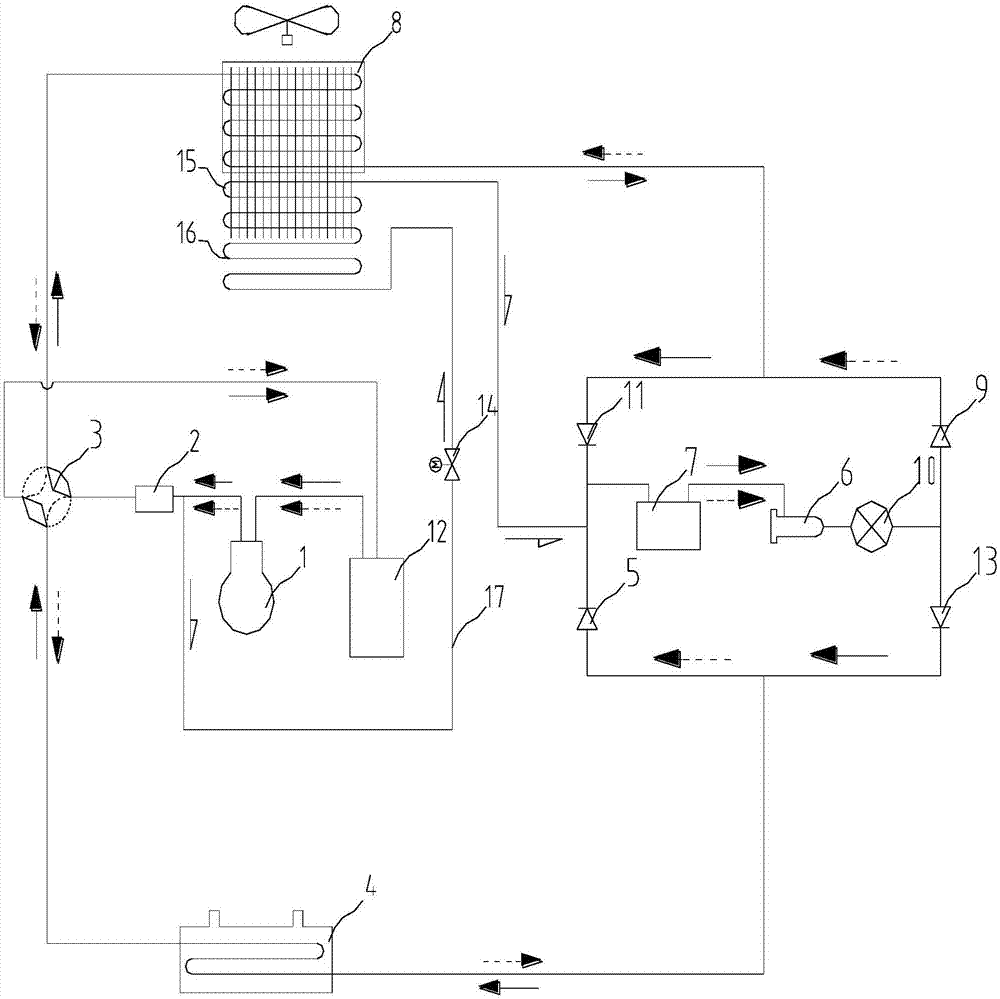

Solar photovoltaic heat pump dryer

InactiveCN107218772AImprove utilizationEnough heatHeat pumpsDrying gas arrangementsAir dryingElectrical and Electronics engineering

The invention discloses a solar photovoltaic heat pump dryer, which comprises a box body and an air-drying box. Four photovoltaic modules are arranged on the top of the box body, and a control box is arranged on the left side of the box body. There is a sliding door on the front, and a radiant heat pipe is arranged inside the door, a heat pump unit is arranged on the right side of the radiant heat pipe, and six battery boxes are arranged on the upper part of the heat pump unit; Air outlet, and an air outlet is provided on the right side of the air-drying box, and a temperature sensor is installed on the upper surface of the air outlet, and a heat dissipation pipe is provided inside the air-drying box. Since the photovoltaic module can provide power, the set The auxiliary heat pipe can provide auxiliary heat for the heat pump unit. At this time, the heat pump unit raises the heat and transports it to the heat dissipation pipe. At this time, the temperature sensor detects the temperature and starts the supplementary heat pipe, so that the high-temperature gas flows out from the air outlet, and the objects at the air outlet are dried. The object is dried, so the device is worth popularizing.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

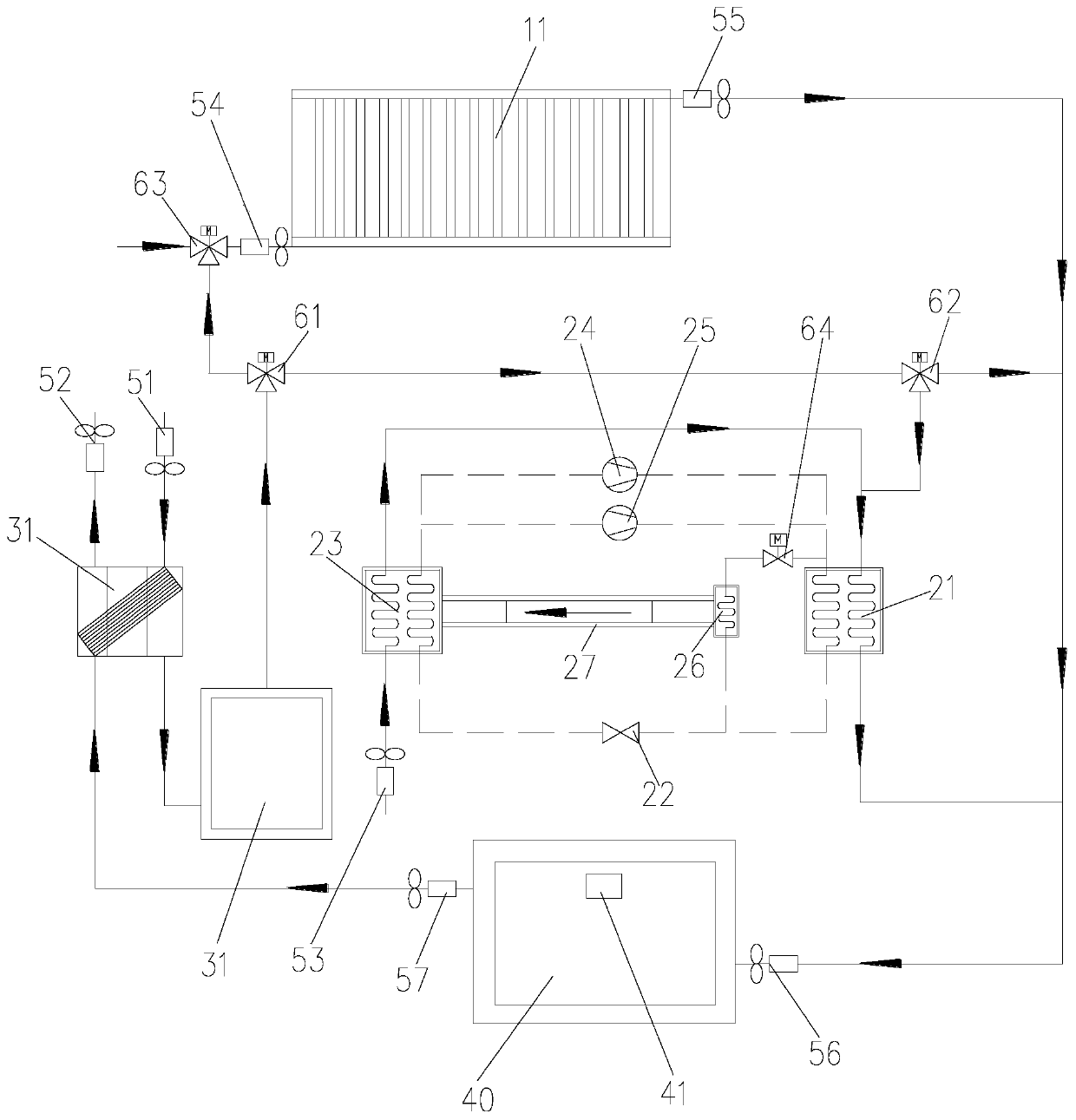

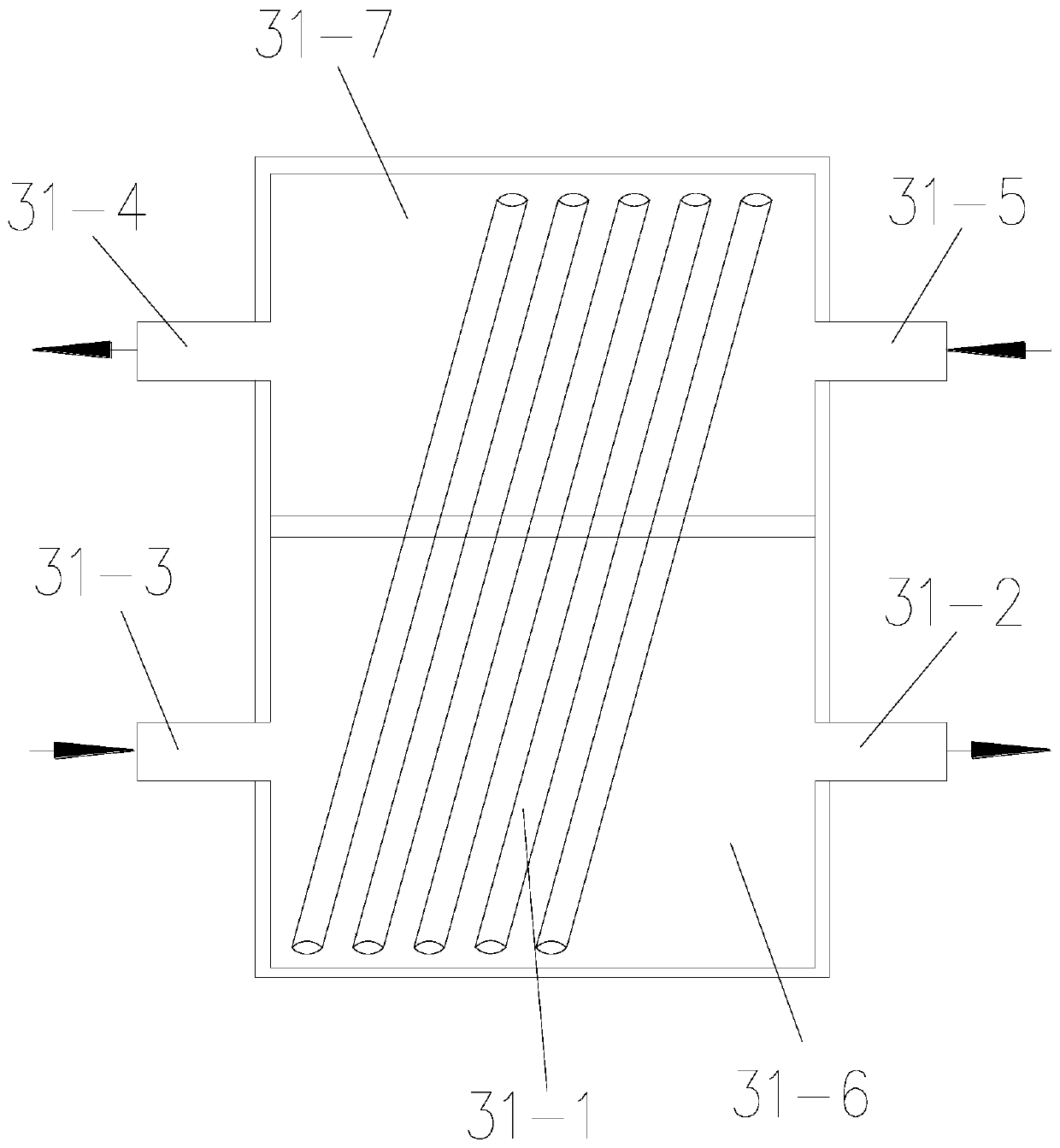

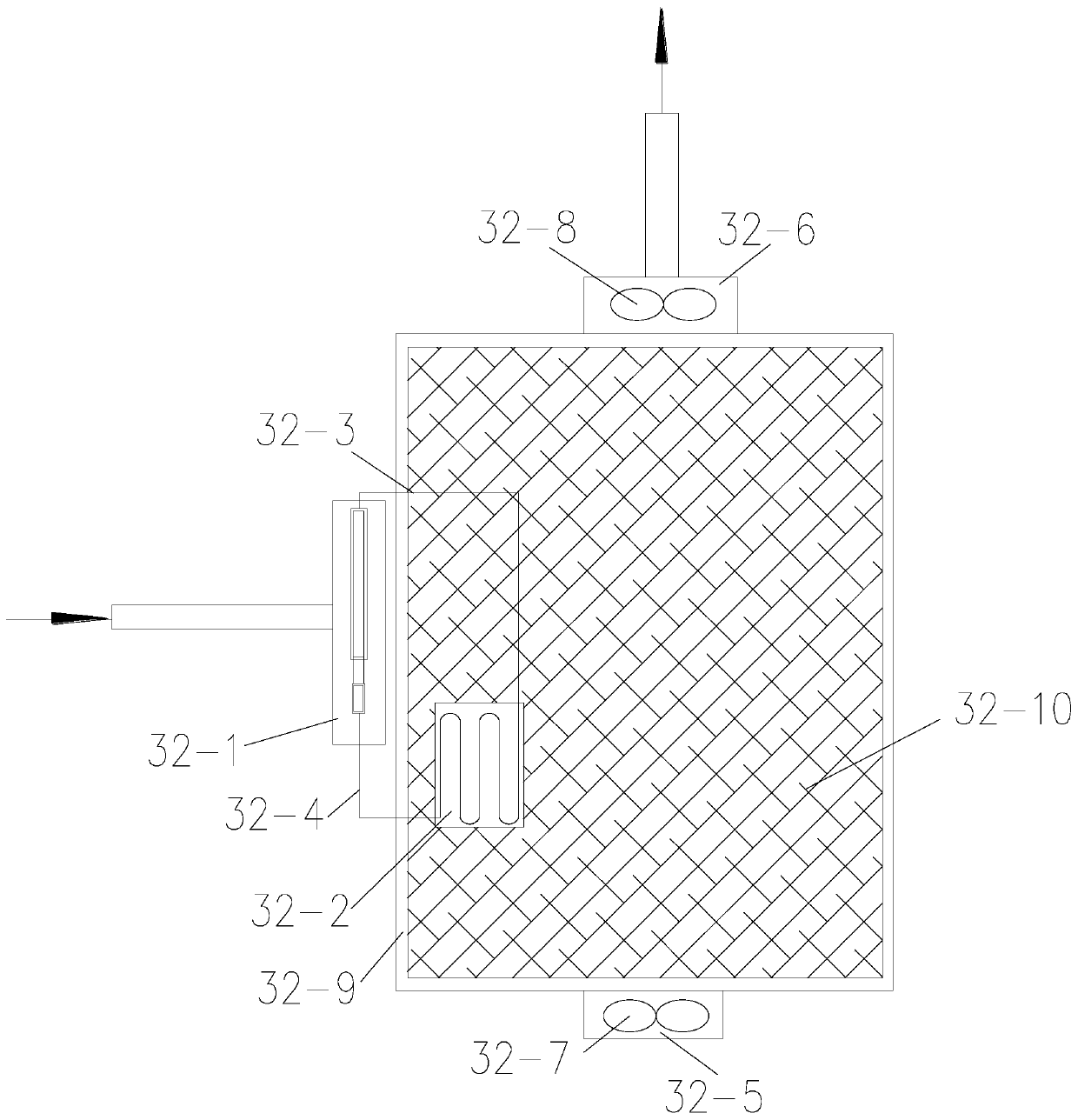

Solar assisted heat pump drying system

ActiveCN110145901AGuaranteed heating efficiencyRealize multi-directional controlSolar heating energyMechanical apparatusEngineeringPosition control

The invention discloses a solar assisted heat pump drying system. The solar assisted heat pump drying system comprises a drying chamber, a two-stage compression type heat pump system and a solar vacuum heat pipe heat collecting system; the two-stage compression type heat pump system is connected with the drying camber and is used for supplying heat energy required for drying to the drying chamberthrough a drying medium; the solar vacuum heat pipe heat collecting system is connected with the drying chamber and is used for supplying the heat energy required for drying to the drying chamber through the drying medium; and the solar vacuum heat pipe heat collecting system is also connected with the two-stage compression type heat pump system and is used for preheating the drying medium which enters the two-stage compression type heat pump system. According to the heat pump system disclosed by the invention, two compressors are arranged in parallel, so that enough heat energy can be supplied to the system; a condenser and a secondary condenser are connected in parallel; multi-position control of the temperature of the drying medium can be realized; and the heating efficiency of the heatpump system can be ensured through the heat exchange of the secondary condenser and the condenser.

Owner:XIAN UNIV OF SCI & TECH

Domestic rubbish disposal device and disposal method

InactiveCN110153151ACoping with variable compositionTo achieve the purpose of thorough mixingSolid waste disposalTransportation and packagingSelf consumptionLitter

The invention provides a domestic rubbish disposal device which comprises a rubbish receiving system, a rubbish conveying system, a sorting system, a pyrolysis system and an anaerobic fermentation system. The sorting system is connected with the rubbish receiving system through the rubbish conveying system. The pyrolysis system is connected with the sorting system through an inorganic conveying belt. The anaerobic fermentation system is connected with the sorting system through an organic conveying belt. The pyrolysis system and the anaerobic fermentation system are coupled, and inorganic matter and organic matter in domestic rubbish are treated separately; through improvement and connection to the pyrolysis system and the anaerobic fermentation system, heat generated in the systems is basically completely recycled for self use, no percolate is generated, and secondary pollution is avoided; and in-situ self consumption of the domestic rubbish is achieved, and the high environmental protection application value is achieved.

Owner:BEIJING CHANGXIN TAIHE ENERGY SAVING TECH CO LTD +1

Device and method for autothermal production of high-purity hydrogen by catalytic cracking of methane

ActiveCN108328573BThe reaction device is simpleRealize self-heating operationHydrogen productionHydrogen/synthetic gas productionSyngasPtru catalyst

The invention discloses a device and method for autothermally producing high-purity hydrogen by catalytic cracking of methane. The device mainly includes a cracking reactor, a regeneration reactor, a riser, a cyclone separator, a filter device and a flow sealing valve; the method includes: Methane goes backwards with the catalyst in the cracking reactor and undergoes a catalytic cracking reaction to obtain hydrogen and deactivated catalyst. After impurity removal and separation, high-purity hydrogen is obtained. The catalyst carries carbon deposits into the regeneration reactor for regeneration to generate syngas and regenerated catalyst. The regenerated catalyst is transported to the cyclone separator through the riser, and then re-enters the cracking reactor for recycling after removing impurities. The present invention can not only fully recover the catalytic activity of the deactivated catalyst, produce high-purity hydrogen, but also use the heat released by the combustion of carbon deposits on the deactivated catalyst to provide heat for the regeneration reactor, and use the heat carried by the regenerated catalyst to provide heat for the cracking reactor. Heat, so that the system runs by self-heating, reducing energy consumption and saving costs.

Owner:CHINA UNIV OF MINING & TECH

Ironing therapy agent for pains, and preparation method thereof,

The present invention relates to the technical field of Chinese herbs, particularly to an ironing therapy agent for pains, and preparation method thereof, wherein the ironing therapy agent comprises, by weight, 25-35 parts of sarcandra glabra, 8-12 parts of safflower, 8-12 parts of frankincense, 8-12 parts of myrrh, 25-35 parts of schefflera arboricola hayata, 19-25 parts of punctate ardisia herb, 12-17 parts of the root of thunbergia grandiflora, 25-35 parts of zanthoxylum nitidum, 25-35 parts of schefflera octophylla harms, 25-35 parts of kadsura coccinea, 4-6 parts of processed radix aconiti, and 4-6 parts of processed radix aconiti kusnezoffii. The ironing therapy agent of the present invention has effects of wind evil removing, pain stopping, blood circulation activation and blood stasis removing, can effectively release various rheumatic pains, and provides good treatment effects on pains, arthritis, shoulder and neck pain, and rheumatoid arthritis.

Owner:宁家平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com