Bar stirring friction additive manufacturing device and method

An additive manufacturing and friction stir technology, used in manufacturing tools, additive processing, non-electric welding equipment, etc., can solve the problem of automatic continuous supply of bars, etc., to reduce the probability of additive defects and the quality of parts forming. Good, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art may better understand the present invention and can be implemented, but the embodiments given are not intended as a qualification of the present invention.

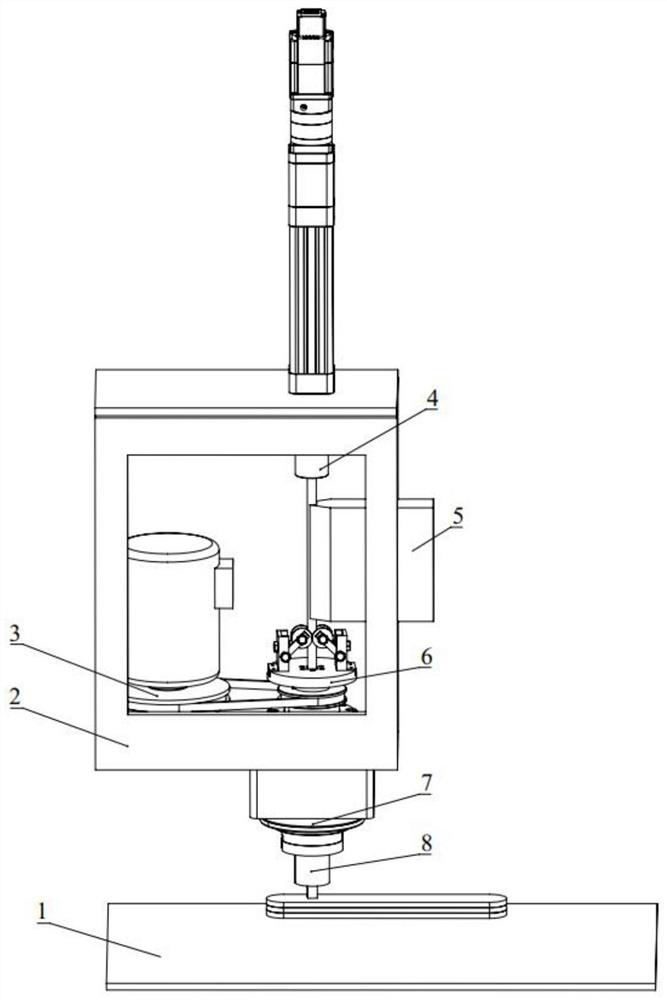

[0066] Reference Figure 1-Figure 8 As shown, one of the bar stocks of the present invention 501 stirring friction additive manufacturing apparatus, comprising:

[0067] Frame 2; Frame 2 is used to integrate the various parts together for easy connection to the machine tool, the machine tool controls the distance between the additive manufacturing device and the substrate 101 and its lateral movement.

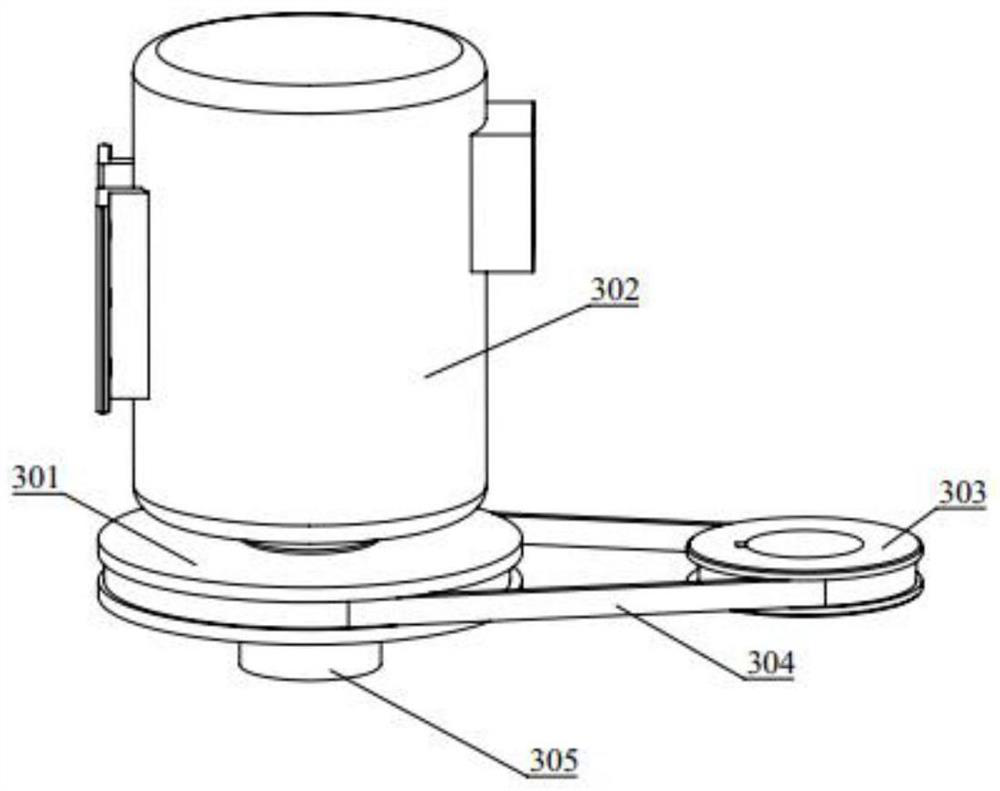

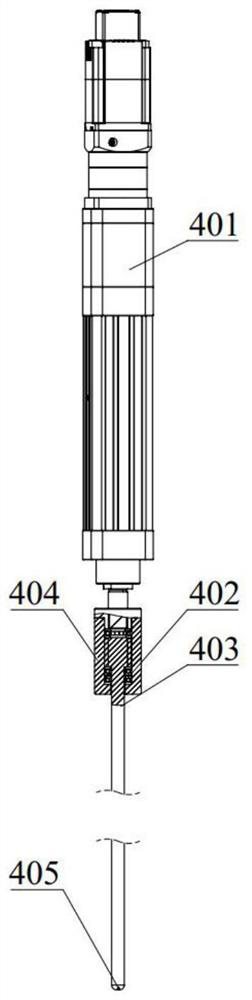

[0068]Stirring friction assembly, the stirred friction assembly comprises a transmission mechanism 3, a hollow shaft mechanism 7 and a forging sleeve 8, the hollow shaft mechanism 7 is provided with a penetrating shaft hole, the transmission mechanism 3 and the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com