Friction material adding device and friction material adding method

A friction shaft and friction part technology, applied in the field of solid-phase additive, can solve the problems of coarse grains, large deformation, low additive efficiency, etc., and achieve excellent organizational properties, small deformation, and high additive efficiency of the additive layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

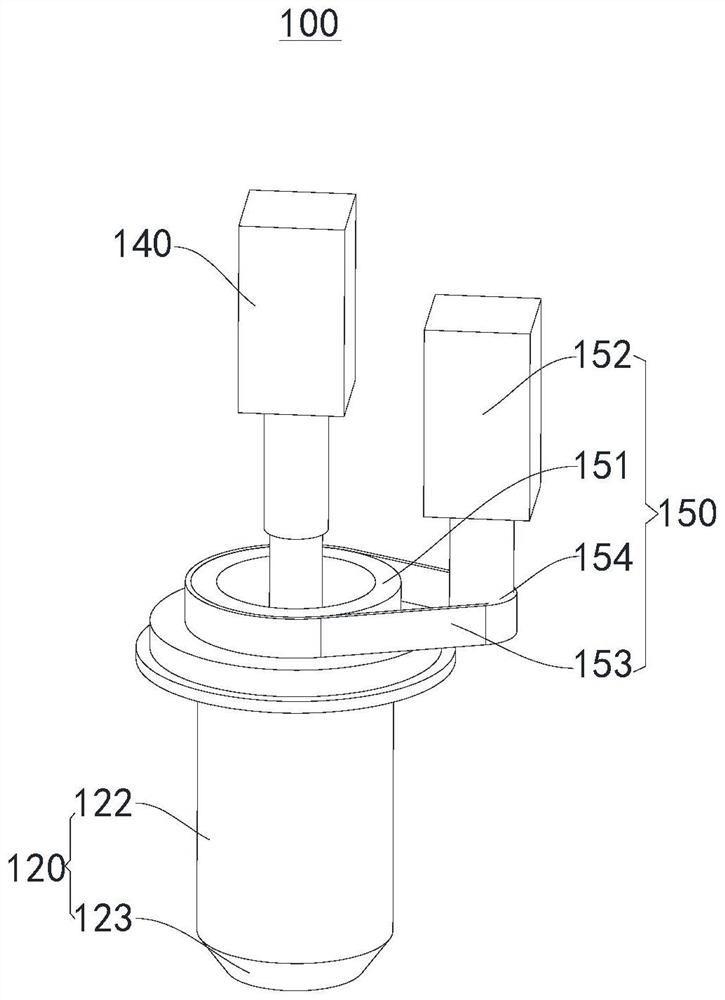

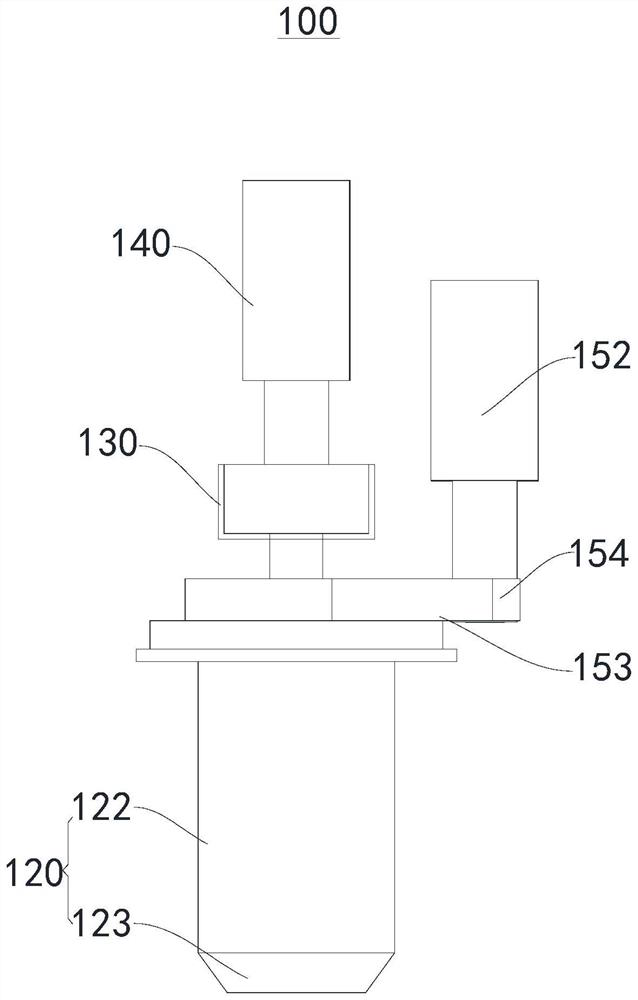

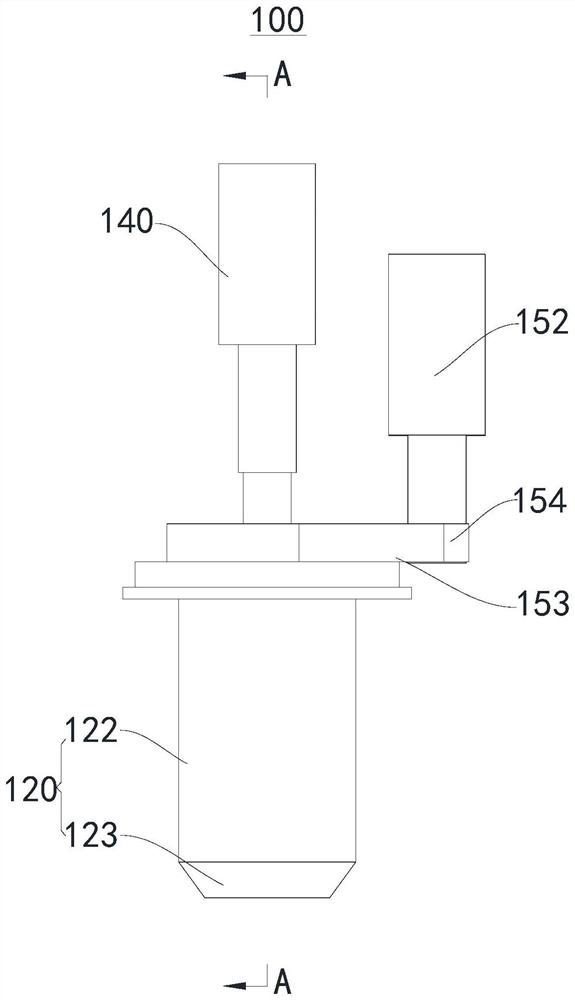

[0034] see Figure 1-Figure 4 , the present invention provides a friction additive device 100 , including a friction shaft 110 , a friction shaft sleeve 120 , a pushing mechanism 130 , a first driving mechanism 140 and a second driving mechanism 150 .

[0035] Please refer to figure 1 and Figure 4 , in this application, the friction shaft 110 is used as the main stirring shaft, which includes a clamping part 111, a friction part 112 and a material guiding part 113 connected in sequence from top to bottom. The driving mechanism 140 is connected, the diameter of the friction part 112 is larger than the diameter of the clamping part 111 and gradually increases along the direction from the clamping part 111 to the guide part 113 to form a trapezoidal structure in cross section, and the diameter of the guide part 113 is along the clamping part 113. The direction from the portion 111 to the material guide portion 113 is gradually reduced to form an inverted trapezoidal structure ...

Embodiment 2

[0042] The present embodiment provides a friction additive method, which includes using the friction additive device 100 provided in Embodiment 1 to perform friction additive on a substrate, using 6061 aluminum alloy as a raw material for additive additive, and realizing three or more layers of additive additive. material effect.

[0043] Specifically, the friction additive method provided in this embodiment includes the following steps:

[0044] Step 1: Fix the 6061 aluminum alloy substrate on the worktable, set the friction additive device 100 and the substrate at an angle of 3°, move the pushing mechanism 130 to be separated from the accommodating cavity 121, and move the friction additive device 100 above the substrate 3mm.

[0045] Step 2: Fill the 6061 aluminum alloy particles into the accommodating cavity 121. After the filling is completed, the pushing mechanism 130 is driven to push the material downward, and the first driving mechanism 140 and the second driving mec...

Embodiment 3

[0050] This embodiment provides a friction additive method, which includes using the friction additive device 100 provided in Example 1 to perform friction additive on a substrate, using T2 red copper as a raw material for additive, and realizing more than 5 layers of additive Effect.

[0051] Specifically, the friction additive method provided in this embodiment includes the following steps:

[0052] Step 1: Fix the 6061 aluminum alloy substrate on the worktable, set the friction additive device 100 and the substrate at an angle of 3°, move the pushing mechanism 130 to be separated from the accommodating cavity 121, and move the friction additive device 100 above the substrate 5mm.

[0053] Step 2: Fill the T2 copper particles into the accommodating cavity 121. After the filling is completed, the pushing mechanism 130 is driven to push the material downward, and the first driving mechanism 140 and the second driving mechanism 150 are activated respectively, and the rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com