Femto-second laser ture three-D micro-nano-processing center

A femtosecond laser and micro-nano processing technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve limitations and other problems and achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

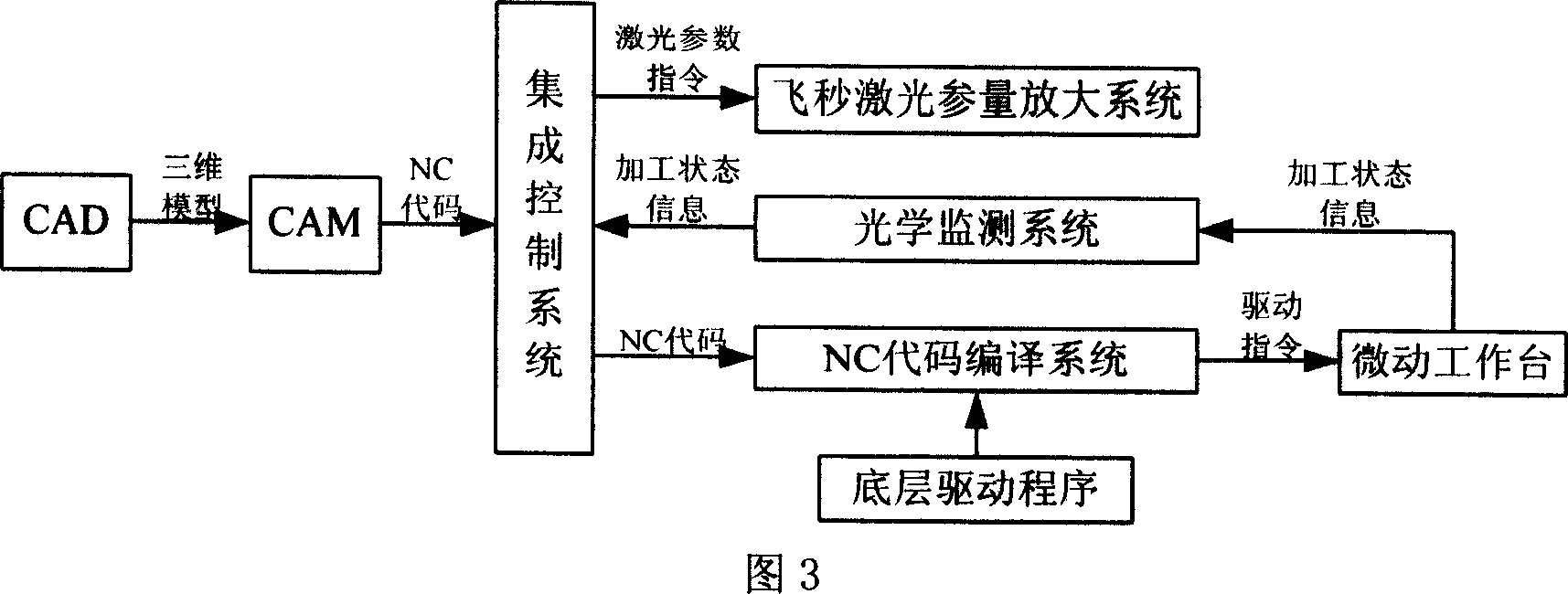

[0022] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

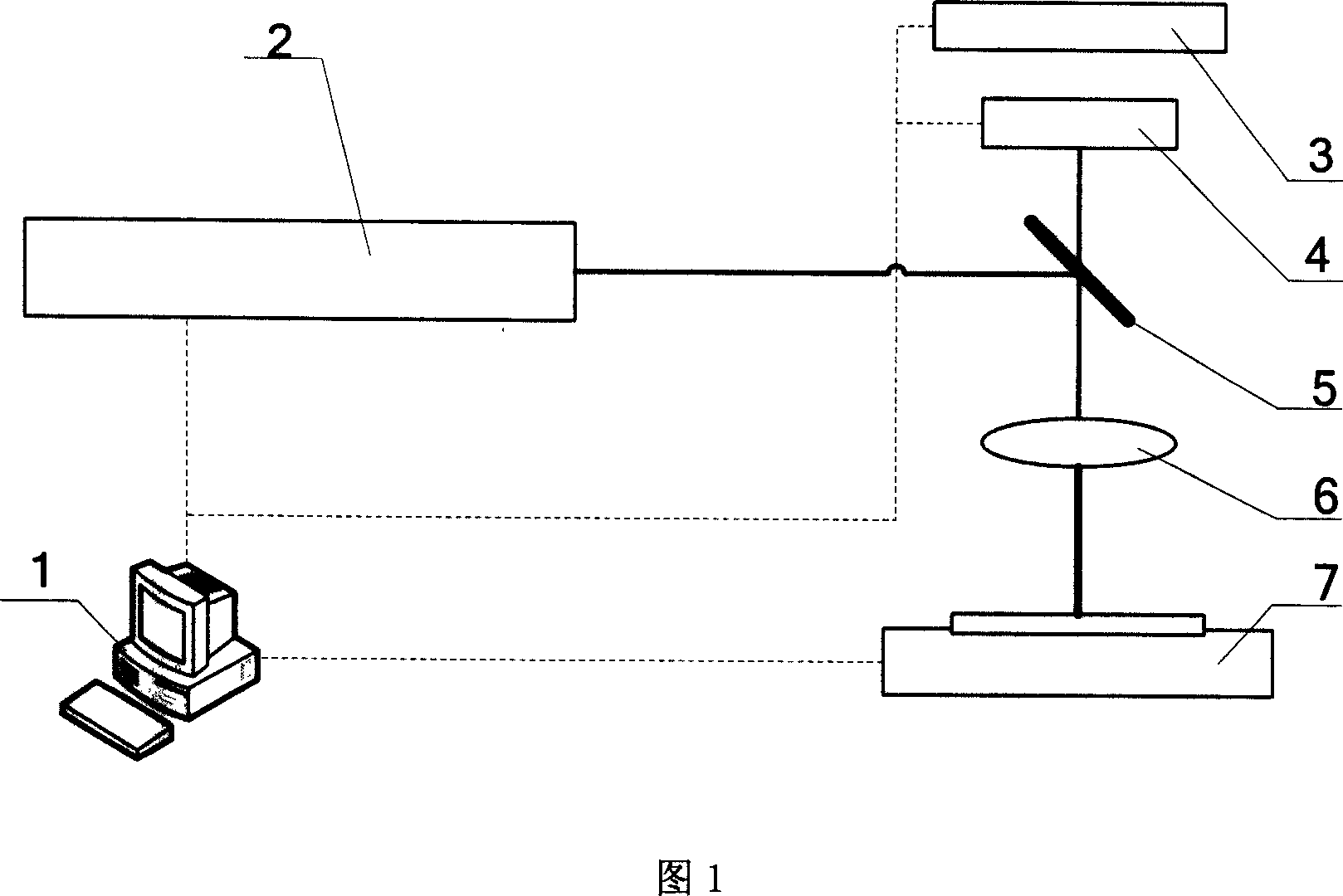

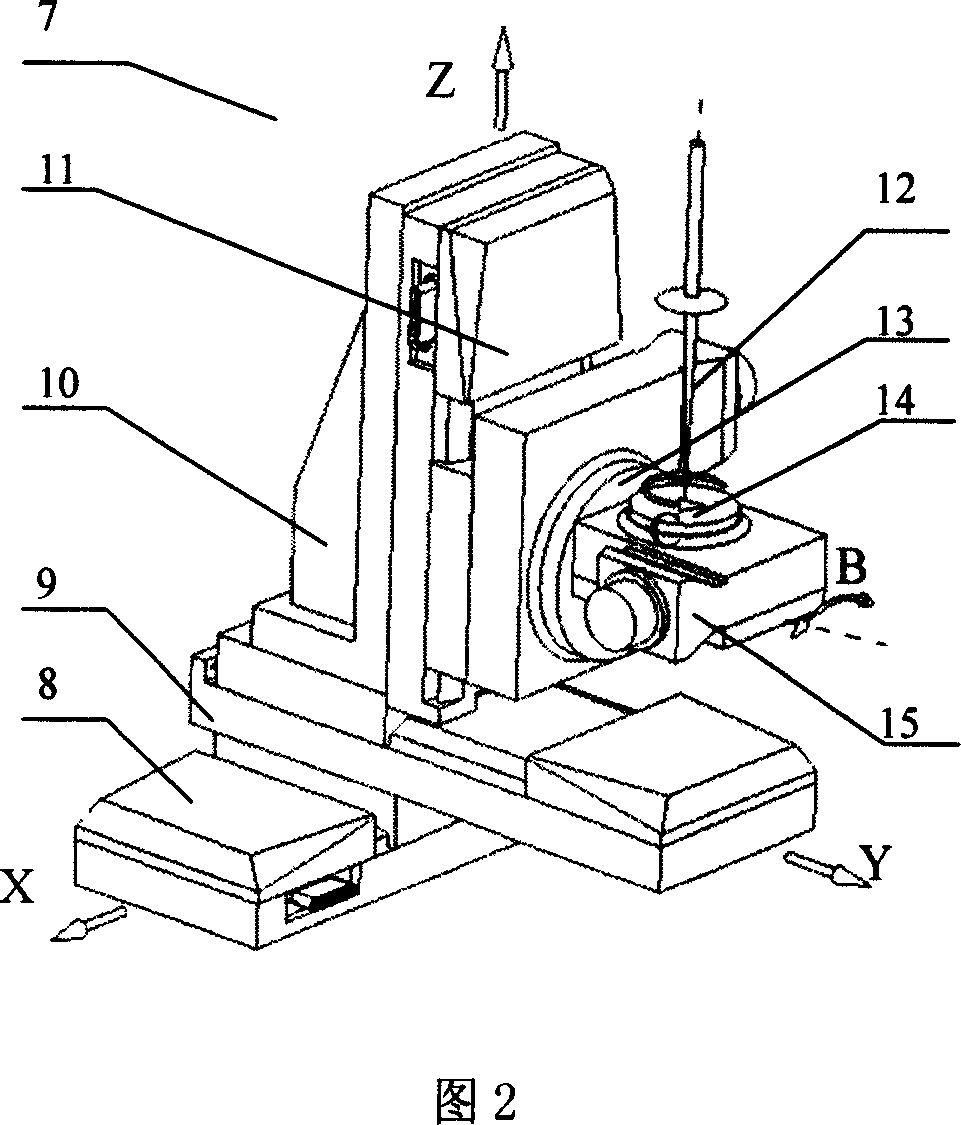

[0023] With reference to shown in Fig. 1, the present invention is provided with reflecting mirror 5 along the output beam direction of femtosecond laser generation amplifying system 2, and the negative included angle of reflecting mirror 5 and output beam is 45 °, along the optical axis direction after reflection in reflection A multi-axis linkage micro-motion workbench 7 is set under the mirror 5, a focusing lens 6 is set in the direction of the optical axis between the mirror 5 and the multi-axis linkage micro-motion workbench 7, and a CCD sensor 4 is set above the reflection mirror 5, femtosecond The laser generation and amplification system 2 , the multi-axis linkage micro-motion workbench 7 , the CCD sensor 4 and the LCD monitor 3 are connected to the industrial computer 1 .

[0024] Femtosecond laser generation amplification system 2, mirror 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com