Process of treating oil-bearing sewage for ternary combination flooding in oil field

A ternary composite, treatment process technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. Difficult to remove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the implementation method.

[0026] Take the oil containing less than 3000mgL -1 , The polymer content is 140-650mg / L, the surfactant content is 14-350mg / L, and the alkali content is 228-1500mg / L.

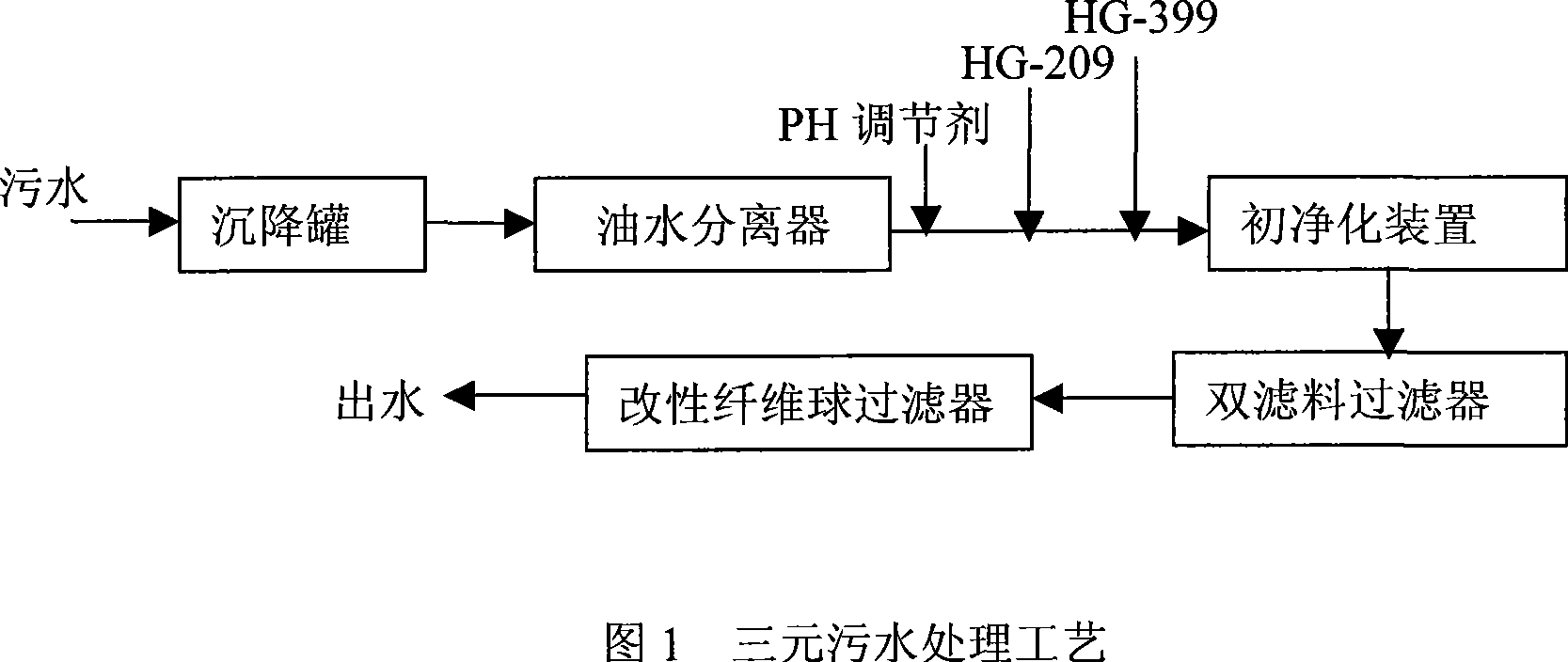

[0027] According to the oily sewage treatment process of oilfield three-element compound flooding of the present invention, firstly, the sewage is pretreated in the settling tank, and the sewage is stagnated in the settling tank for 7-8 hours, and most of the suspended matter in the sewage is removed by the principle of gravity settlement. oil; then, the sewage treated by gravity sedimentation is sent to the oil-water separator, and in the oil-water separator, the sewage is treated by a composite process combining cyclone and air flotation to remove the emulsified oil in the sewage and in the pretreatment When the slick oil is not removed, the oil content in the sewage is not more than 30mgL -1 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com