Double induction and arc composite heating additive device and method for tungsten carbide powder core wire

A tungsten carbide powder and induction heating technology, applied in electrode support devices, additive processing, metal processing equipment, etc., can solve the problems of low overall density and poor coating surface forming, and improve melting characteristics and equipment costs. Low, additively efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

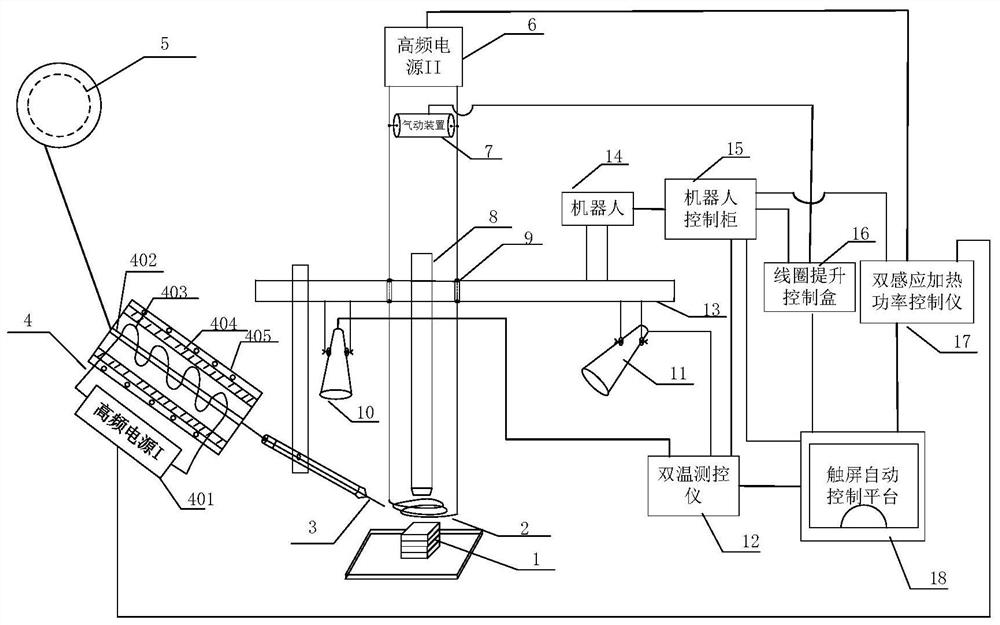

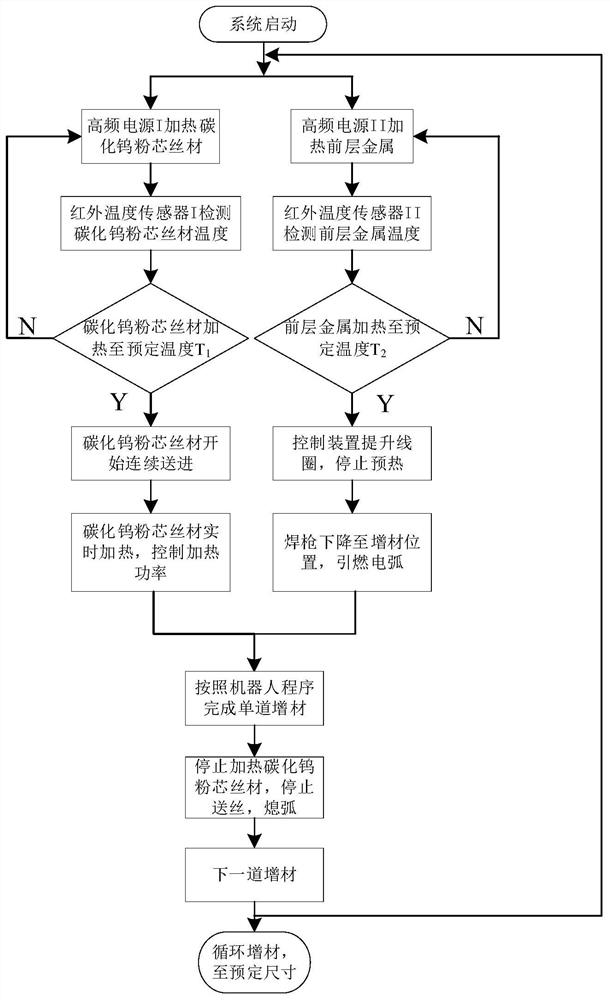

Method used

Image

Examples

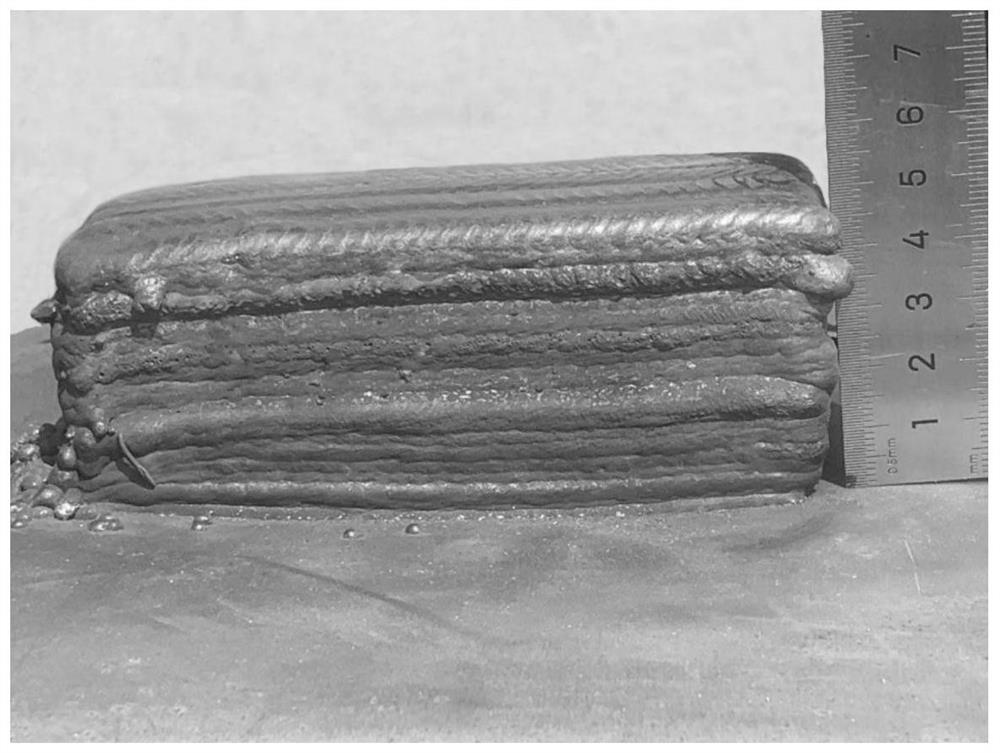

Embodiment 1

[0043] Using the device of the above invention to carry out the addition of tungsten carbide powder core wire with a diameter of 1.6mm and a tungsten carbide content of 10%, the specific steps are as follows:

[0044] Step 1: After selecting the plasma arc additive process parameters of the tungsten carbide powder core wire 3, the robot control cabinet 15 and the touch screen automatic control platform 18 are started;

[0045] Step 2: First, the touch-screen automatic control platform 18 sends a control signal through the robot control cabinet 15 connected to it, and the robot control cabinet 15 simultaneously activates the high-frequency power supply I401 and the high-frequency power supply II6 through the dual induction heating power controller 17, according to the setting tungsten carbide powder core wire induction heating frequency f 1 =90KHz, the induction heating current is I 1 = 80A, the induction heating frequency of the front layer metal is f 2 =200KHz, the inductio...

Embodiment 2

[0053] Using the device of the above invention to carry out the addition of tungsten carbide powder core wire with a diameter of 1.6mm and a tungsten carbide content of 20%, the specific steps are as follows:

[0054] Step 1: After selecting the plasma arc additive process parameters of the tungsten carbide powder core wire 3, the robot control cabinet 15 and the touch screen automatic control platform 18 are started;

[0055] Step 2: First, the touch-screen automatic control platform 18 sends a control signal through the robot control cabinet 15 connected to it, and the robot control cabinet 15 simultaneously activates the high-frequency power supply I401 and the high-frequency power supply II6 through the dual induction heating power controller 17, according to the setting tungsten carbide powder core wire induction heating frequency f 1 is 100KHz, and the induction heating current is I 1 is 90A, the front metal induction heating frequency f 2 =300KHz, the induction heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com