Patents

Literature

615results about How to "High quality and precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Movable laser cladding and repairing system

ActiveCN103074625AAchieve claddingAchieve fixMetallic material coating processesLaser scanningLaser sensor

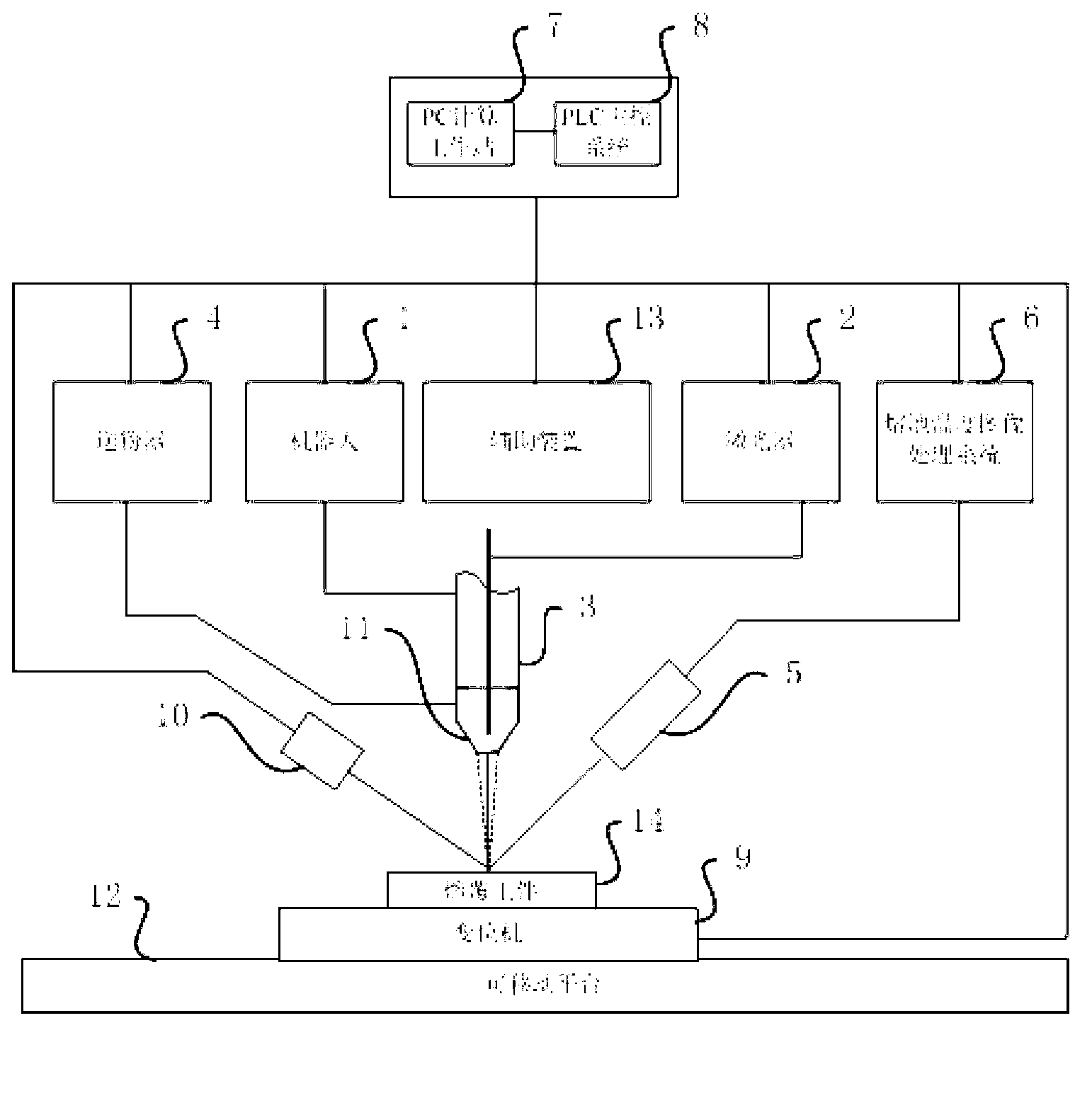

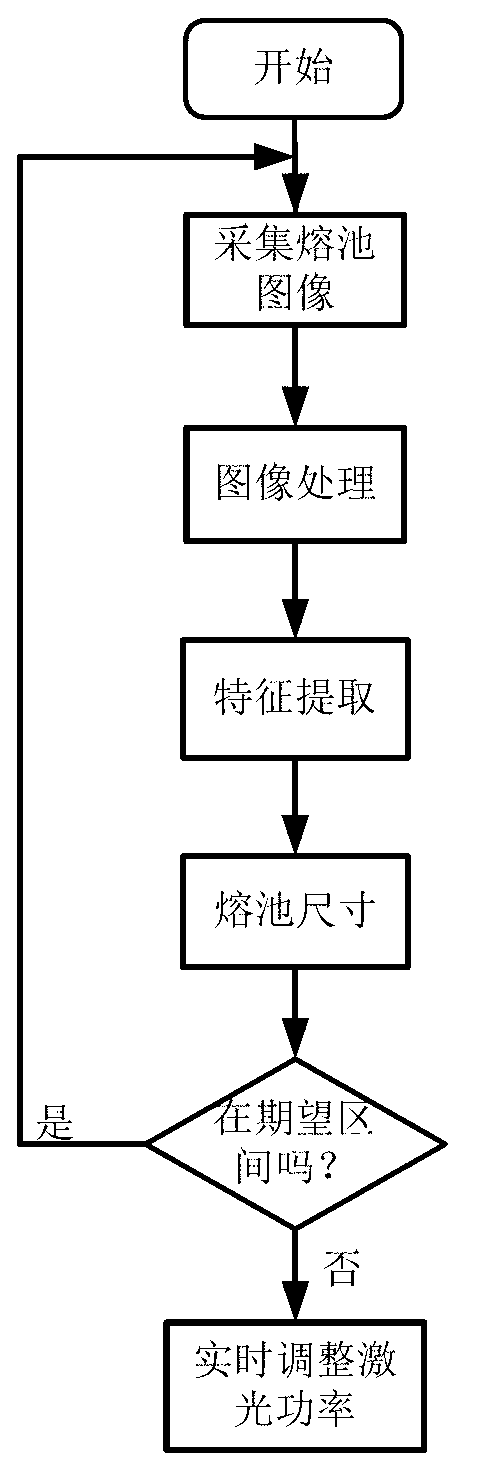

The invention provides a movable laser cladding and repairing system in the field of laser cladding and repairing. The movable laser cladding and repairing system comprises a movable platform, wherein a laser, a robot, a position changing machine, a powder feeder, an image processing system, a control system (comprises a PLC (programmable logic controller) main control system, a PC (personal computer) computing workstation), a video camera, a three-dimensional laser scanning sensor, a laser processing head and a coaxial powder feeding head are fixedly arranged on the movable platform. The movable laser cladding and repairing system takes the robot as a moving body, controls the clad pool size, the temperature and other information by using an image acquiring and processing system, and scans a workpiece to slice, stratify and automatically clad a three-dimensional workpiece model based on the three-dimensional laser sensor; the movable laser cladding and repairing system is convenient and flexible, simplifies a repairing process, achieves precision and self-adaptive control of a cladding process, effectively improves the cladding quality, and facilitates field application of a large component through the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

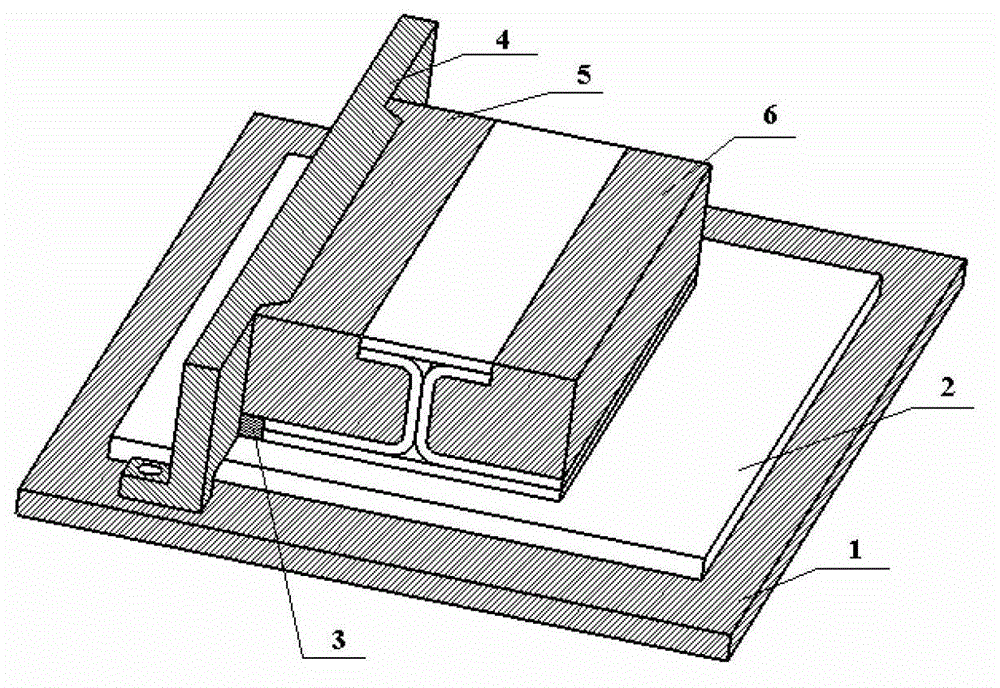

Method for forming control of long joist axial line of composite material stiffened wall panel

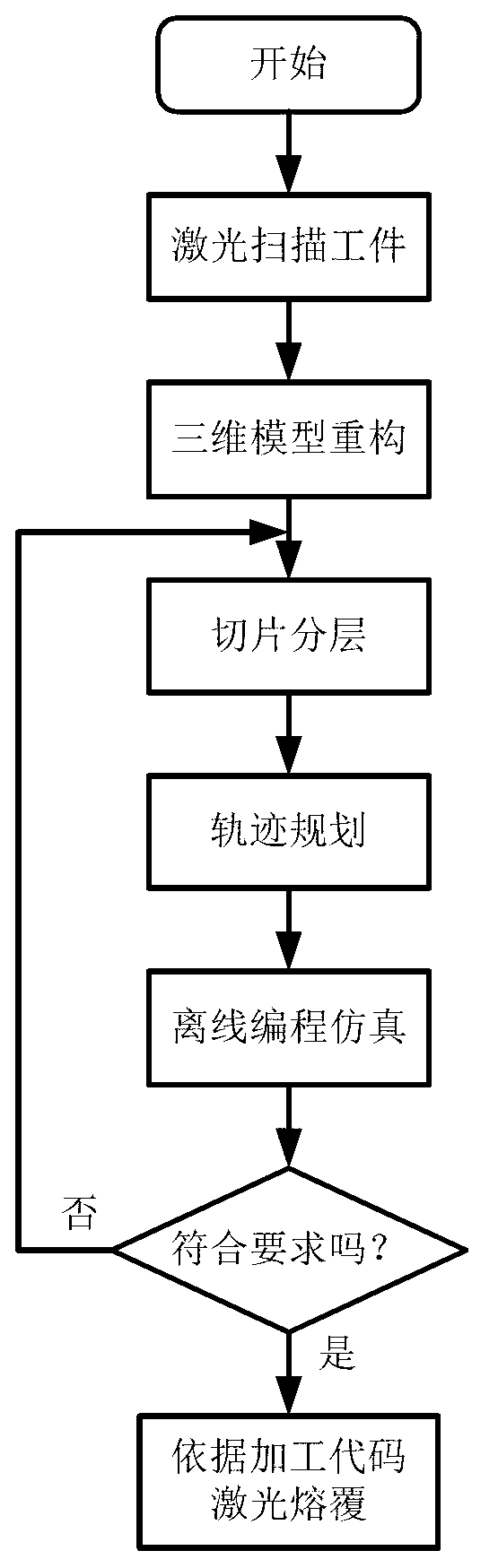

The invention belongs to technologies of composite material forming, and relates to a method for forming control of a long joist axial line of a composite material stiffened wall panel in an aviation aircraft. The method is a fixture method suitable for forming control of long joist axial lines of various types, such as a T shape, an I shape, a J shape and the like, of long joist composite material stiffened wall panels. A forming fixture mainly comprises a long joist forming mold A and a long joist forming mold B, a skinned curing mold, a cushion block and an axial line positioning mold. The two ends of the long joist forming mold A are designed to be dovetail-shaped and are closed matched with the axial line positioning mold to control the deviation of a long joist in the length direction of the axial line; and the axial line positioning mold is fixed on the skinned curing mold through positioning pins to control left and right deviations of the long joist axial line. By the forming fixture method, the molding surface quality and the position accuracy of a long joist product are effectively improved, and the long joist axial line is prevented from deviation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

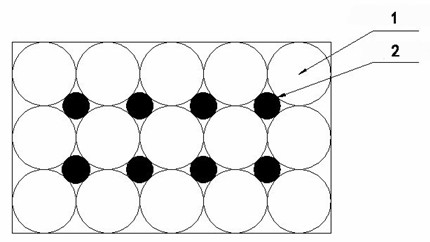

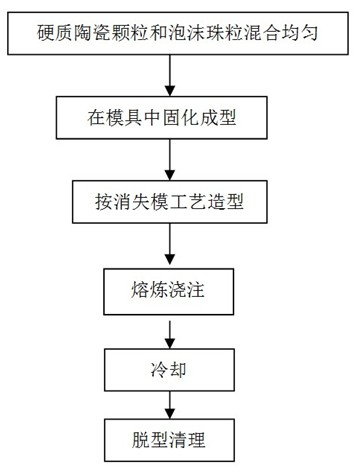

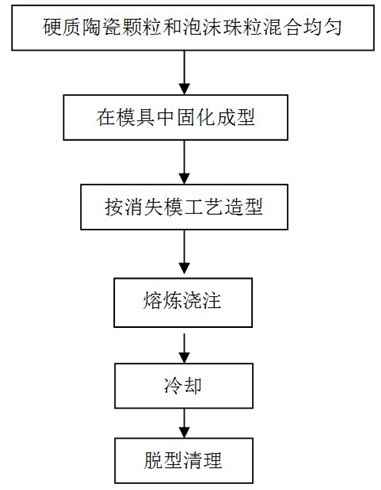

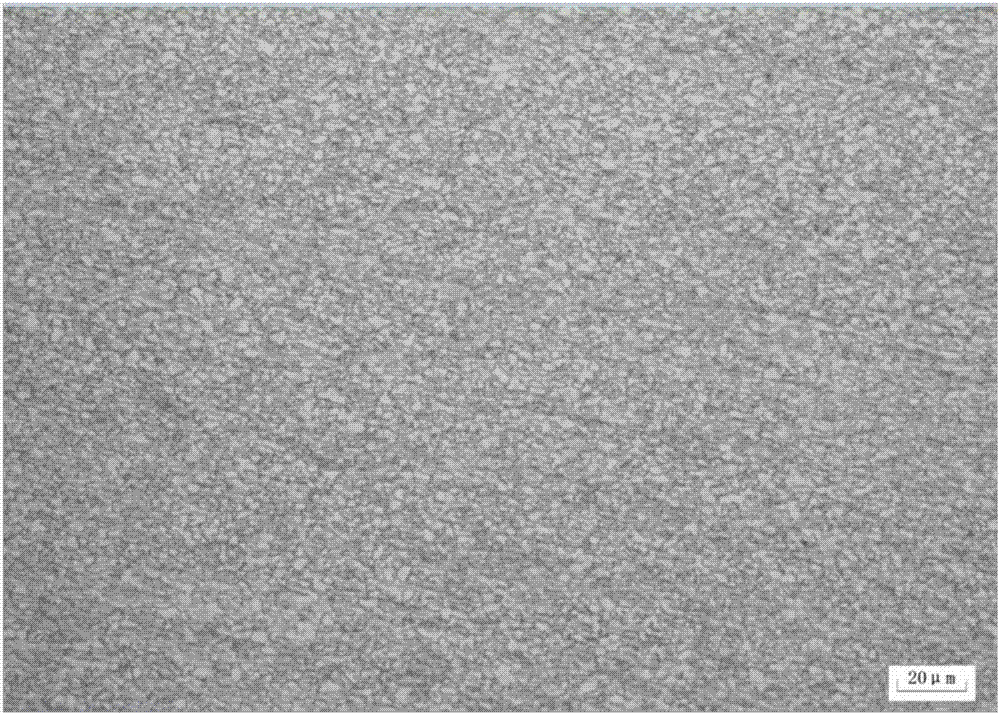

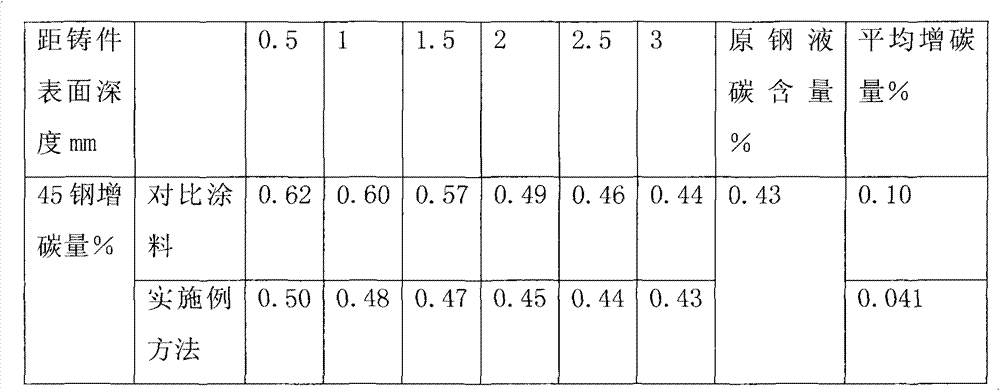

Method for preparing ceramic particle enhanced steel-base composite material cast by evaporative pattern casting die

InactiveCN102489686AHigh bonding strengthImproved dimensional accuracy and surface qualityFoundry mouldsFoundry coresCoalCeramic particle

The invention provides a method for preparing a ceramic particle enhanced steel-base composite material cast by an evaporative pattern casting die. The method comprises the following steps of: uniformly mixing hard ceramic particles and aged foam beads according to any proportion, and filling the mixture into a curing die cavity of the die for curing to manufacture a foam die in which enhancement bodies are uniformly distributed; and then shaping according to the conventional evaporative pattern casting method, putting the obtained foam die into the cavity, smelting a base metal material to pouring temperature, pouring the base metal material into the cavity, cooling and solidifying the base metal material at room temperature, and clearing sand away from the base metal material to obtain the ceramic particle enhanced steel-base composite material, of which the hard ceramic particles are dispersed in the base metal. The preparation method is easy to operate, high in whole performance and high in yield rate; furthermore, in spite of whole enhancement and partial enhancement, various metal-base composite material parts can be directly made without secondary processing; the method is suitable for large-scale industrial production, and can be widely applied to anti-abrasion fields, such as mines, power, metallurgy, coals, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

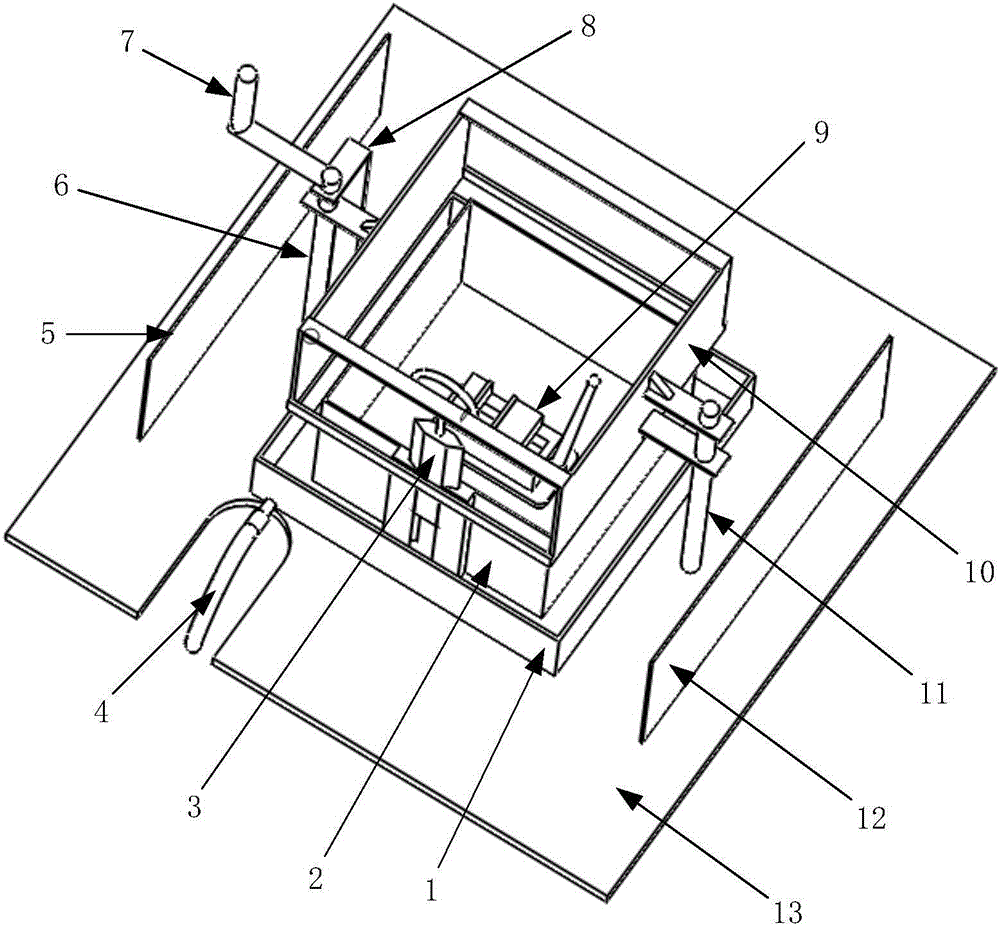

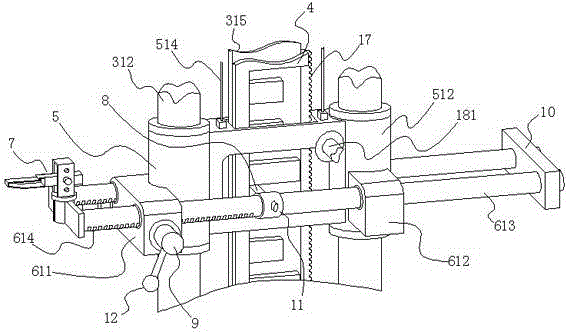

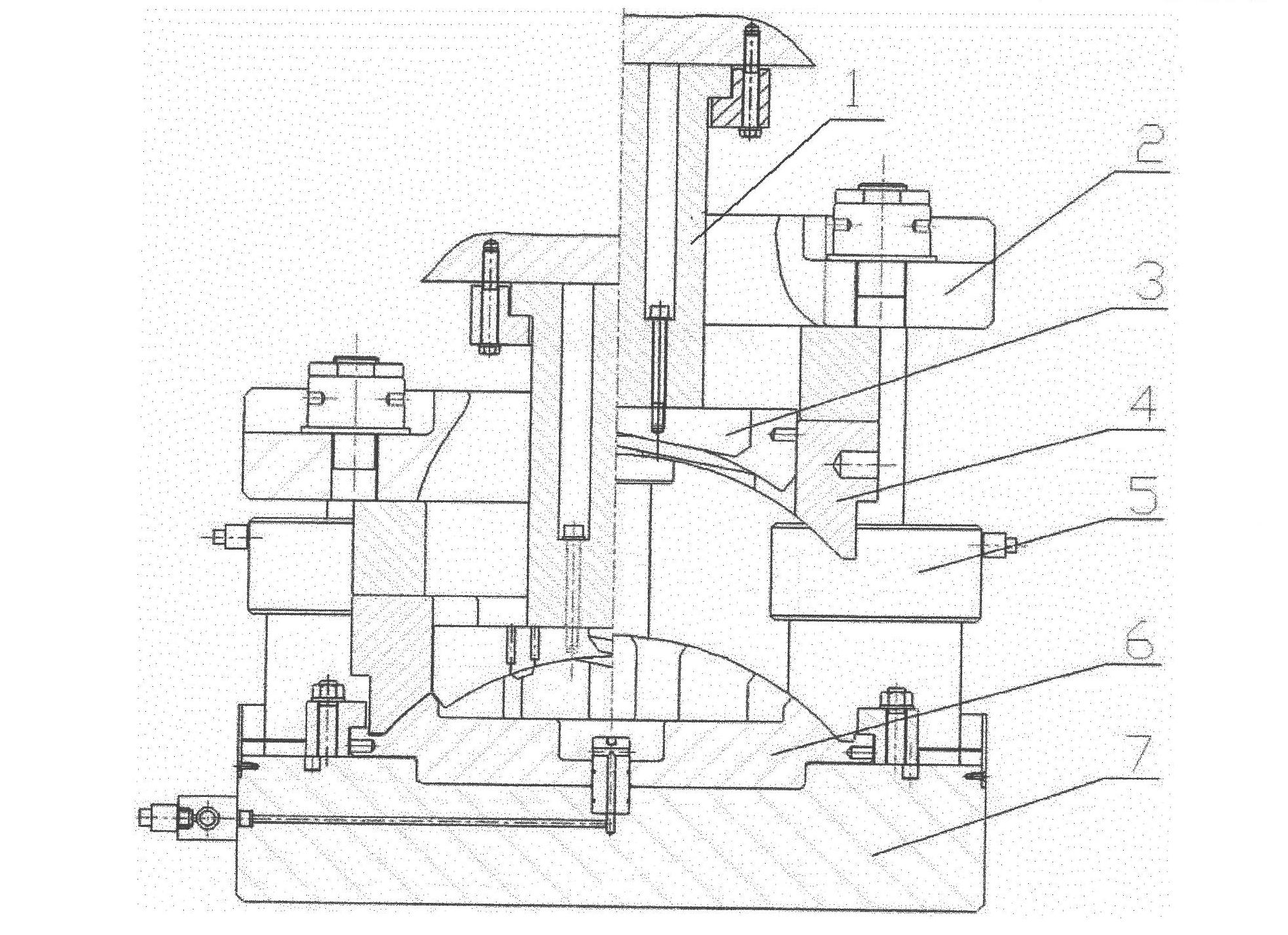

Flexible clamp for milling thin-walled workpiece with complex curved surface

ActiveCN106514369AEven by forceReduce processing deformationMilling equipment detailsPositioning apparatusMachining deformationMagnetorheological fluid

The invention discloses a flexible clamp for milling a thin-walled workpiece with a complex curved surface, and belongs to the field of machining. The flexible clamp comprises a vice clamp, a fluid carrying trough for accommodating a magnetorheological fluid, a magnetoresistive plate frame arranged at the upper part of the fluid carrying trough, and plate electrodes for providing a horizontal magnetic field, wherein the left side of the magnetoresistive plate frame is connected with a lead screw through threads; the right side of the magnetoresistive plate frame sleeves a supporting and positioning rod in a matching way; the upper end of the lead screw is connected with an operating crank; and the operating crank can drive the lead screw to rotate and drive the magnetoresistive plate frame to rise and fall. The flexible clamp provided by the invention can effectively reduce the machining deformation of the thin-walled workpiece with the curved surface, effectively restrains the vibration of the thin-walled workpiece with the curved surface during milling, lowers the machining noise, reduces the machining error, and guarantees high machining efficiency and high surface machining quality.

Owner:SHANDONG UNIV

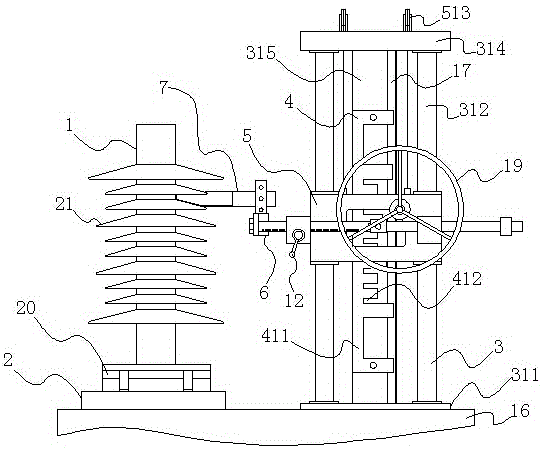

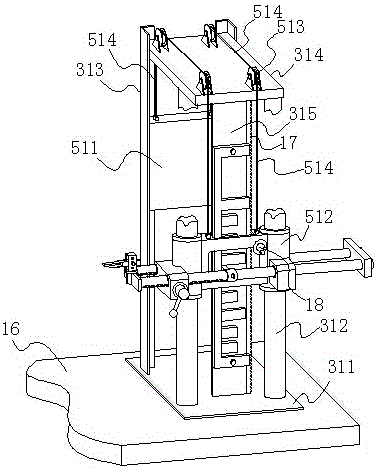

Elliptical porcelain insulator shape processing device and processing method thereof

The invention discloses an elliptical porcelain insulator shape processing device and a processing method thereof. The elliptical porcelain insulator shape processing device comprises a rotation mechanism and a porcelain insulator shape processing mechanism; the porcelain insulator shape processing mechanism comprises a rack, a positioning plate arranged on the rack, a lifting device capable of moving upwards and downwards along the rack and an expansion device capable of moving back and forth horizontally along the lifting device; a fettling knife is arranged on one end of the expansion device; the expansion device is also provided with a positioning rod which cooperates with the positioning plate; the expansion device can drive the fettling knife and the positioning rod to move back and forth horizontally; the lifting device and the expansion device control the positioning rod on the expansion device to cooperate with the positioning plate, so that the fettling knife on the end of the expansion device processes the shape of the insulator earthen brick along the positioning plate. The elliptical porcelain insulator shape processing device reduces production difficulty of the elliptical porcelain insulator, and increases product percent of pass.

Owner:ZHUZHOU DINGSHUN NEW MATERIAL TECH CO LTD

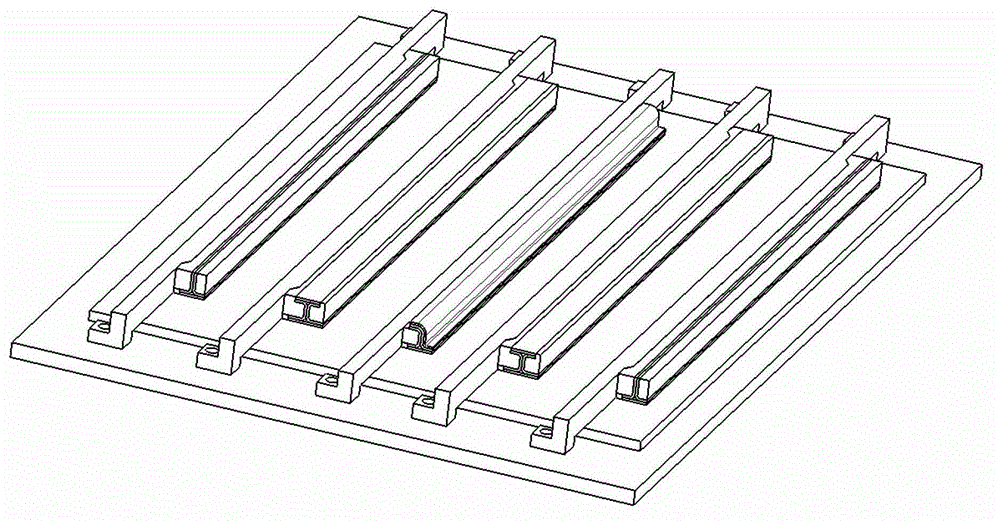

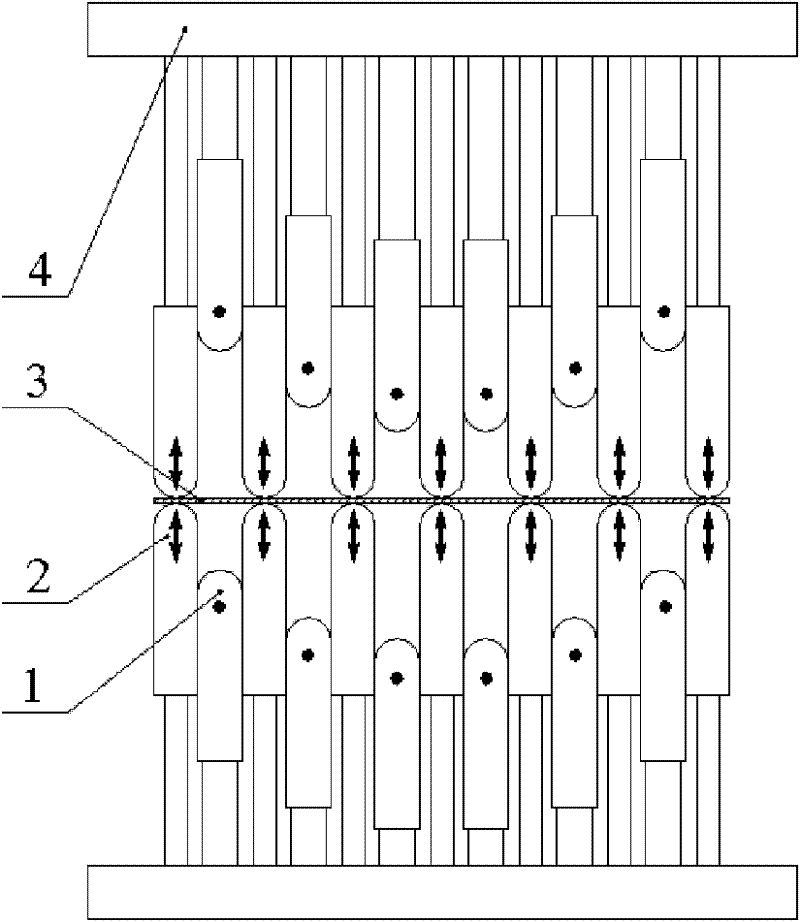

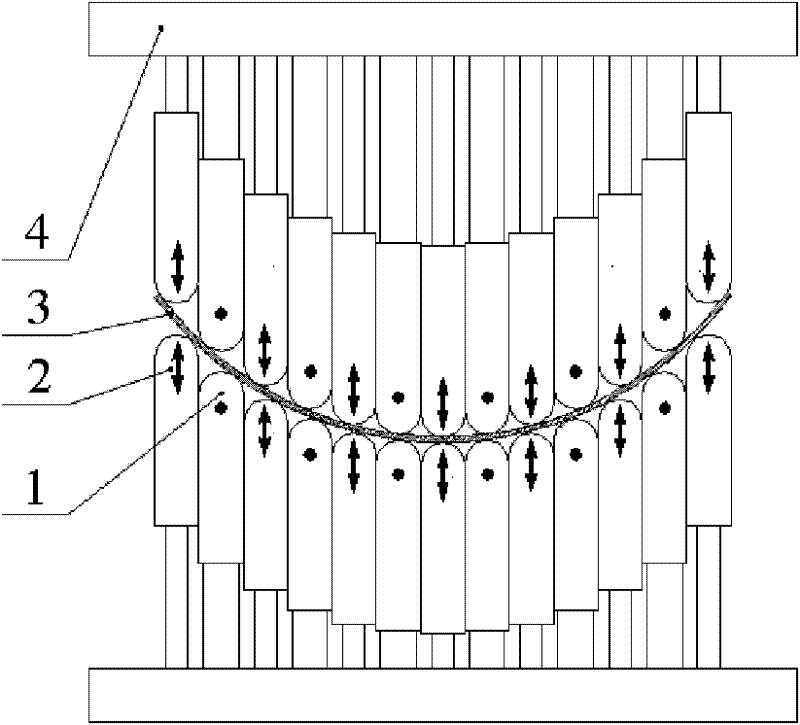

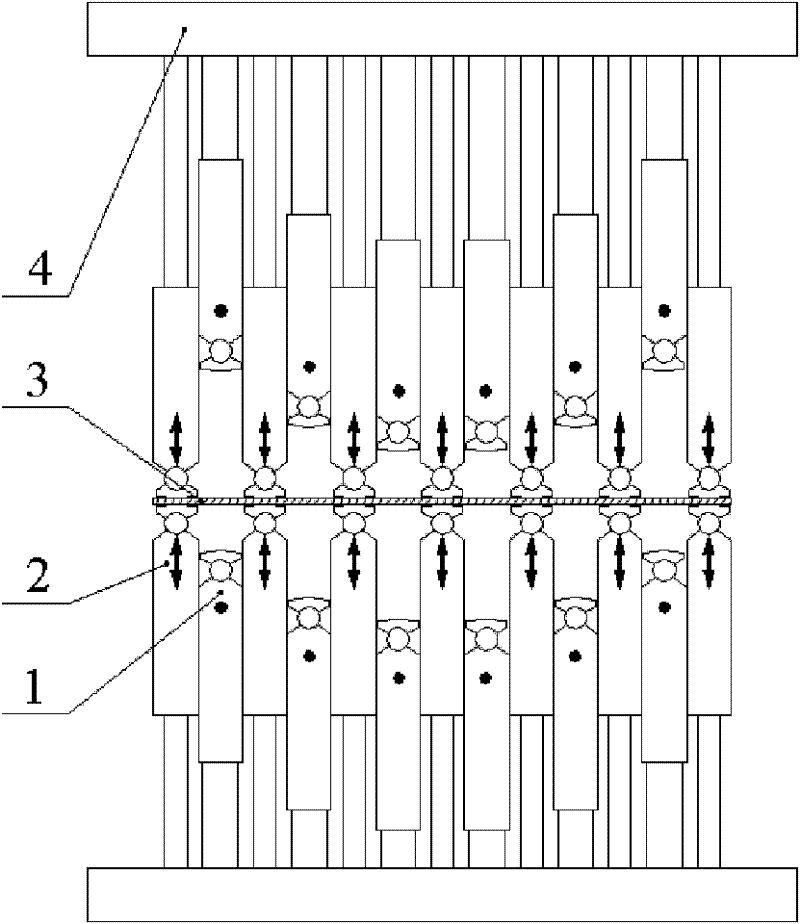

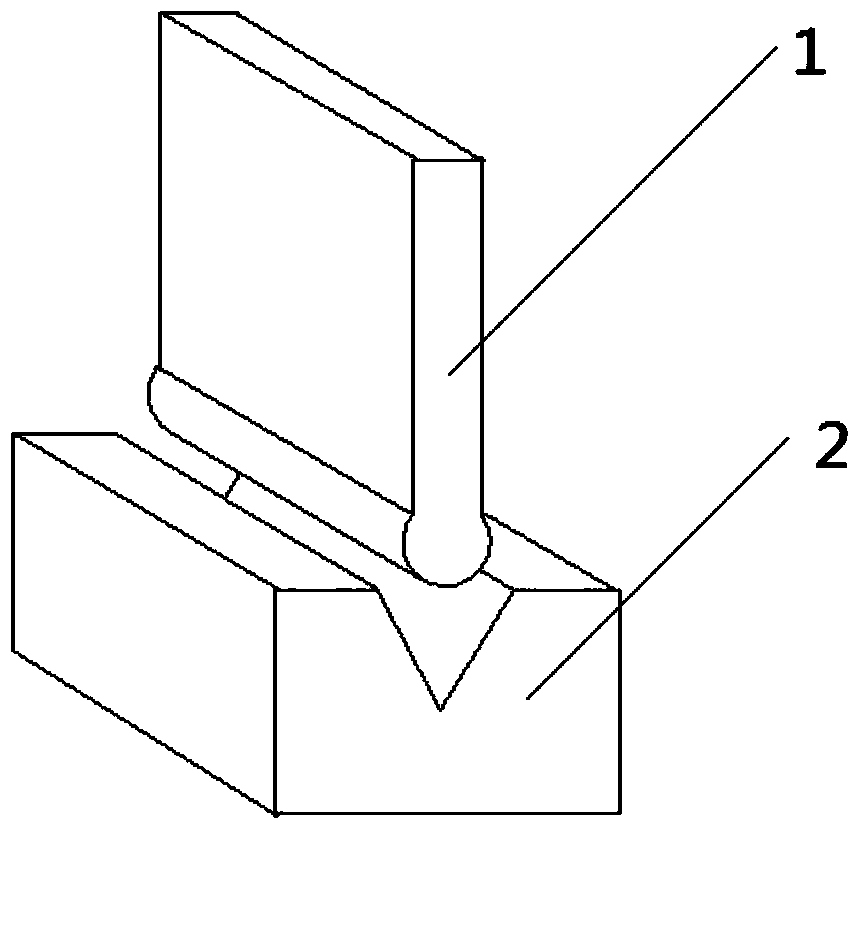

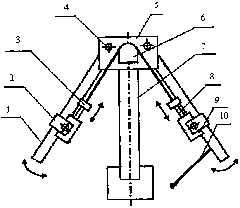

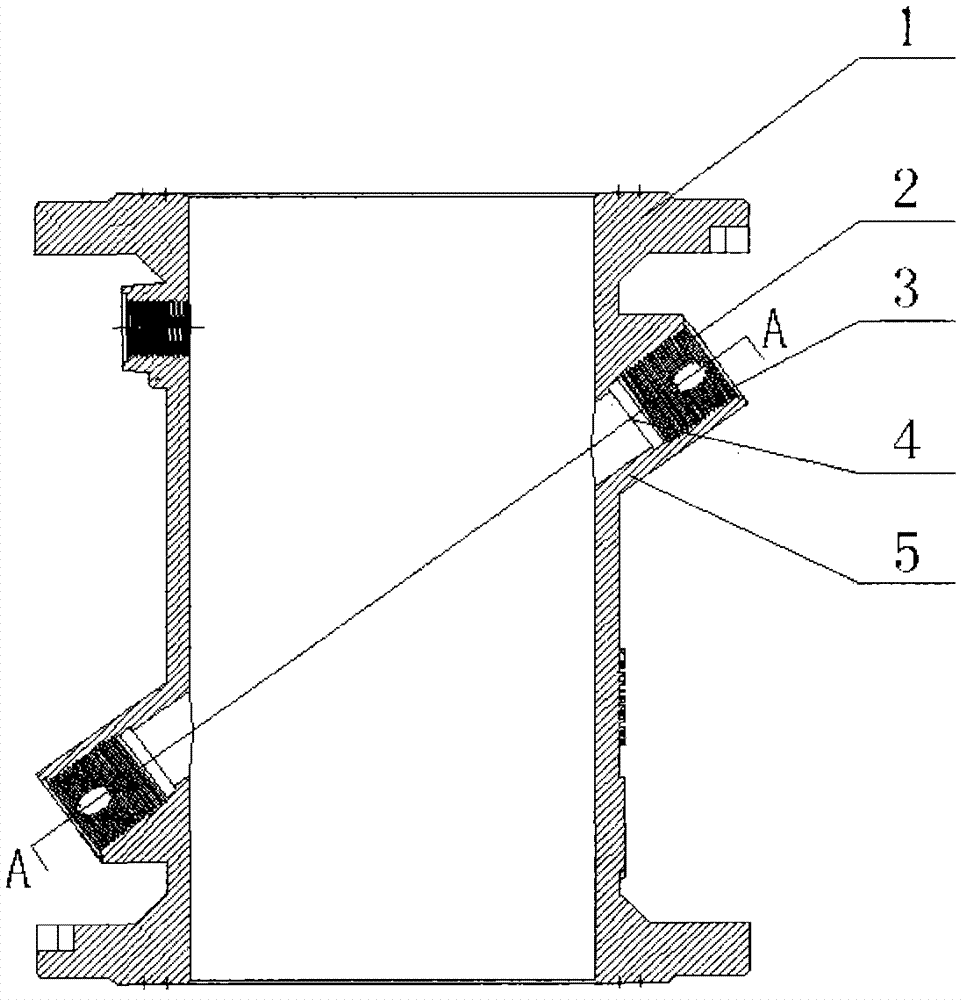

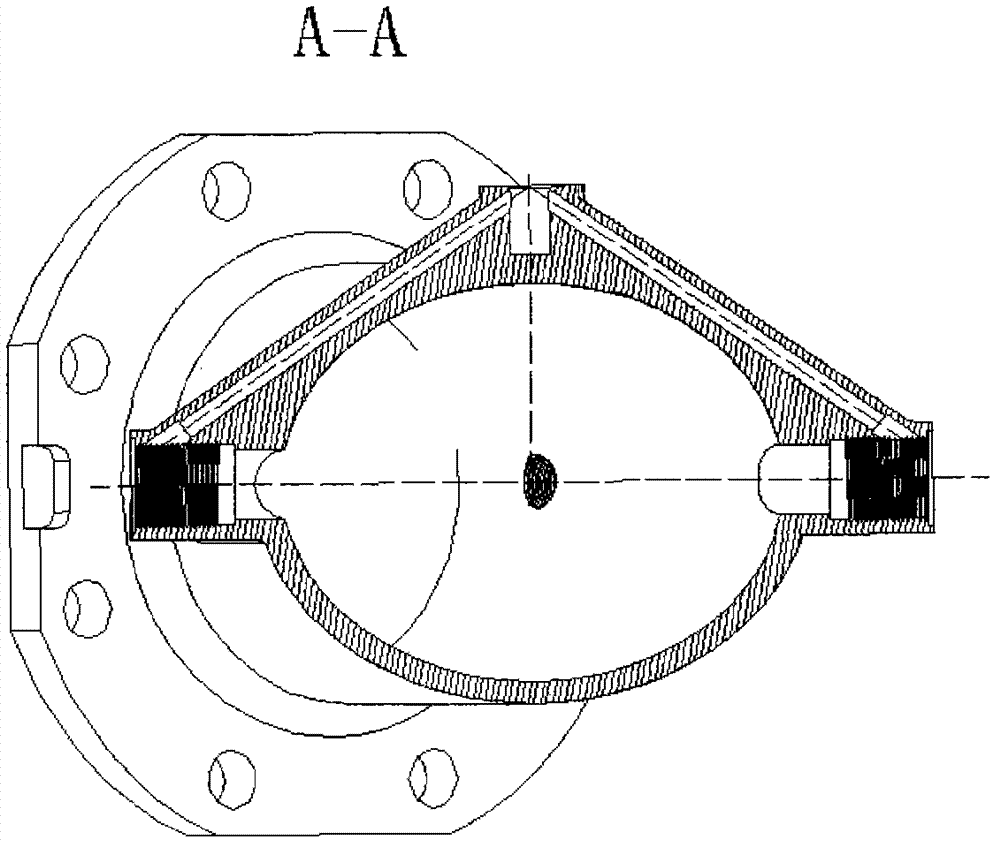

Plate multipoint forming device with crease resistant functions

ActiveCN102248053AReduce designAchieve moldless formingShaping toolsBiomedical engineeringEquipment use

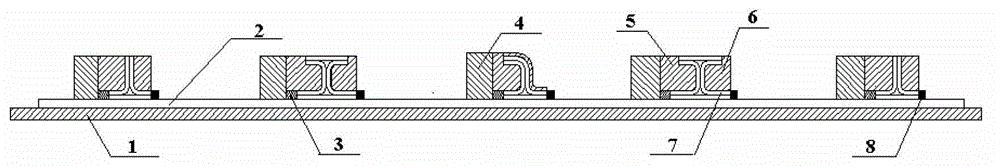

The invention discloses a plate multipoint forming device with crease resistant functions, relating to plastic processing equipment used for plate curved surface forming and belonging to the field of mechanical engineering. The device mainly comprises shape-adjusting units (1), clamping units (2), a unit fixing plate (4) and a loading mechanism and is characterized in that the shape-adjusting units (1) and the clamping units (2) are arranged in a staggering manner; enveloping surface shapes of the plurality of shape-adjusting units (1) with adjustable heights can be changed through a shape-adjusting mechanism; the traditional entity die is replaced; and the plurality of clamping units (2) which are shifted passively are used for clamping a plate through back pressure effects to replace a side-pressing mechanism. The device can be used for inhibiting creases and rebound when the plate is formed and used for forming complex outline curved surface members with different sizes, therefore, the step of cutting sides after forming is omitted, and the utilization rate of the plate is improved.

Owner:JILIN UNIV

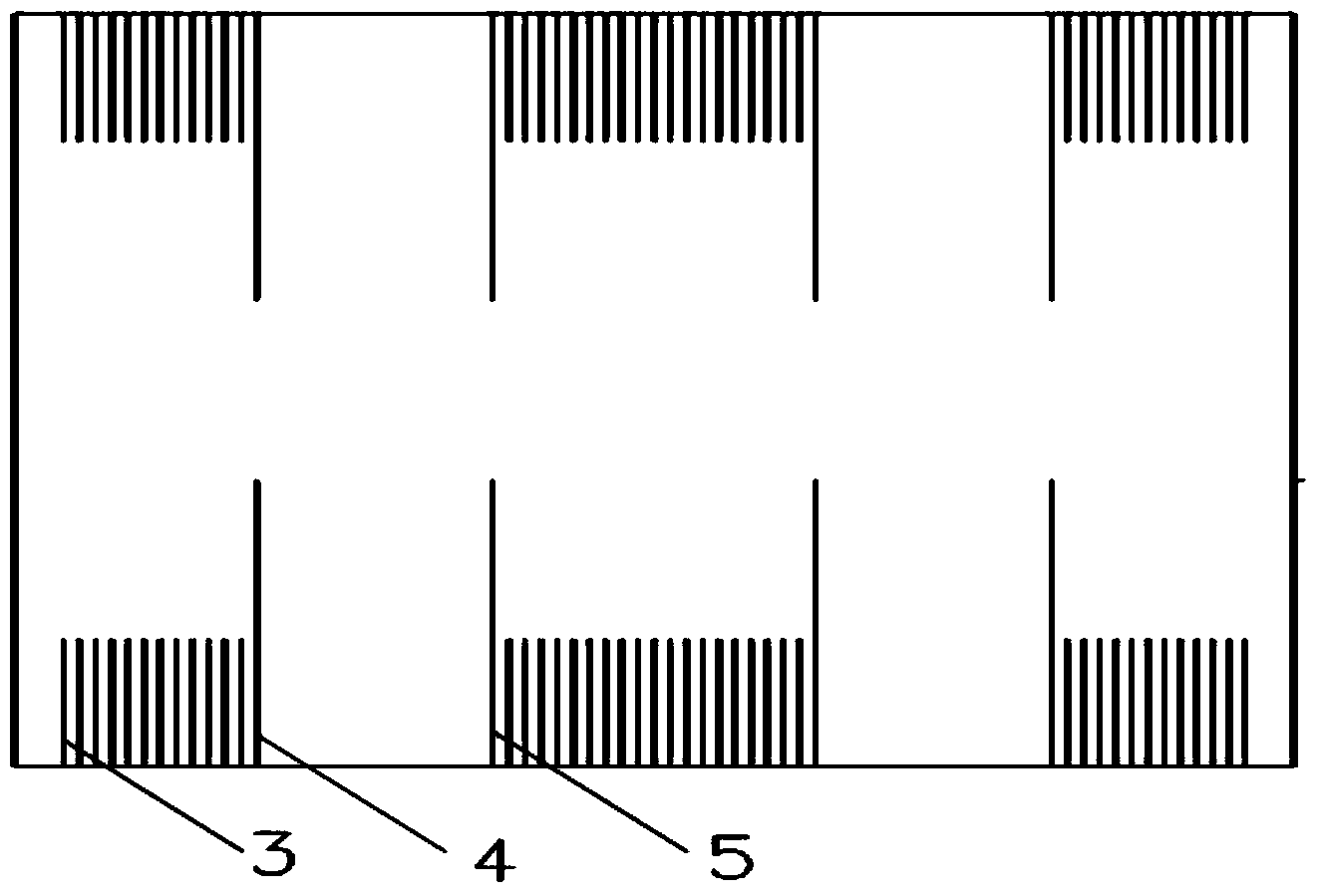

Full-automatic wood door lock, hinge groove and hole processor

InactiveCN101279454ASolve processing problemsImprove processing efficiencyDrilling machinesWood mortising machinesMilling cutterEngineering

The invention relates to a wood processing device, in particular to a full-automatic lock for wooden door, the groove of a hinge and a hole processing machine, which comprises a frame. The invention is characterized in that: a working table which is controlled by a motor to move horizontally and used for placing a wooden door forms a sliding fitting with the frame, and a clamping device for wooden door is arranged at the side edge of the frame; an electric milling cutter device for hinge which can horizontally move along the X direction relative to the frame is arranged at the front side of the frame, an electric drilling and milling device for fade lockhole which can move in the Y direction is arranged at the rear side of the frame and an electric drilling and milling device for door side lock groove which can move along the Y direction is arranged below the electric drilling and milling device for fade lockhole. Various motors and cylinders of the wood processing device are controlled by a computer chip controller, thus ensuring that the drills, and milling knives lift and prone automatically according to the program or simultaneously sequentially complete a plurality of cutting and manufacturing of holes and grooves required for arrangement of locks or hinges on the fade or at the side of a door. The problem of processing the inclined plane groove is solved, and the processing efficiency, the slotting quality and the processing precision are significantly enhanced. Furthermore, the wood processing device can process an inclined plane groove, thus solving the problems of processing of inclined plane grooves and significantly enhancing the processing efficiency, the grooving quality and the processing precision.

Owner:TAIZHOU EVOK MASCH CO LTD

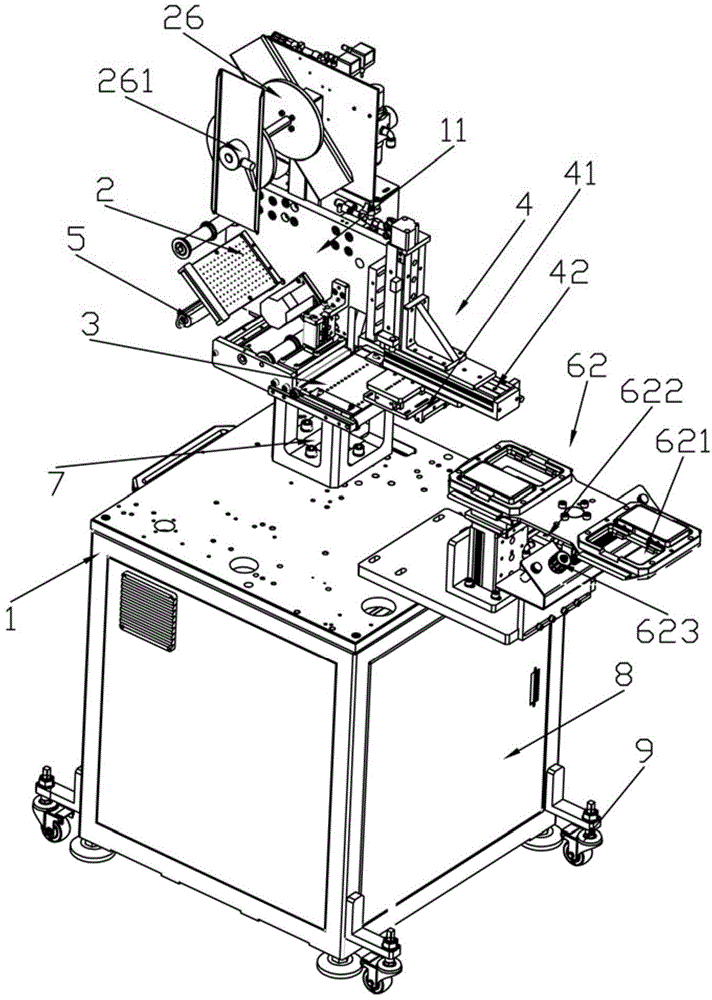

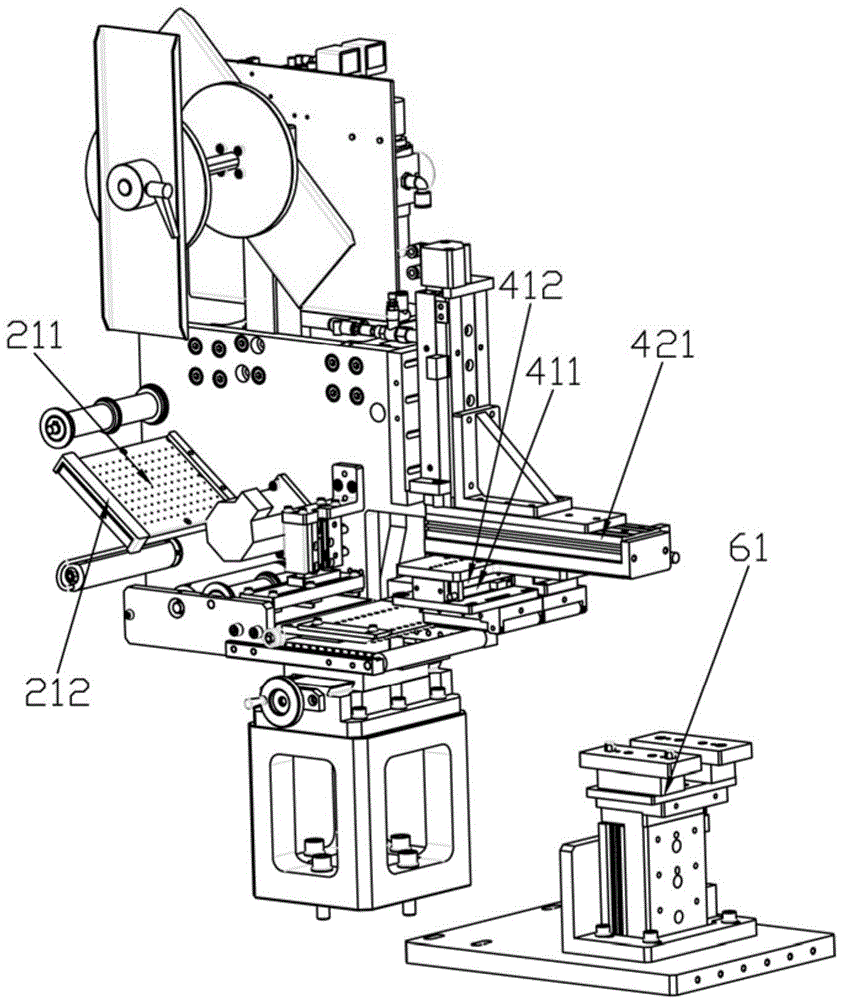

Semi-automatic pad pasting machine

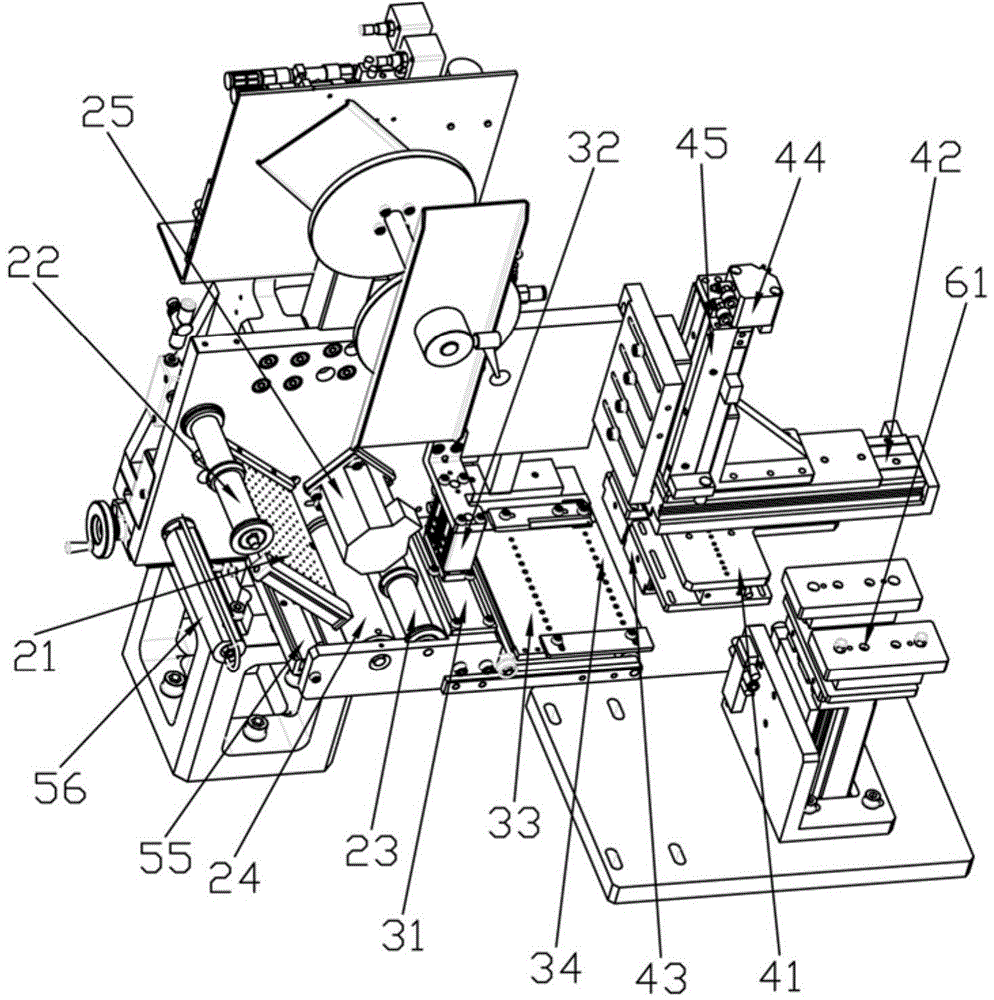

InactiveCN104828283AReduce labor costsImprove film quality and film precisionPackagingManipulatorOne-time pad

The invention relates to the field of pad pasting, in particular to a semi-automatic pad pasting machine. The semi-automatic pad pasting machine comprises a frame. A feeding mechanism is arranged on the frame. A stripping mechanism is arranged at the portion, located at the output end of the feeding mechanism, of the frame. A waste recycling mechanism is further arranged at the portion, located at the output end of the stripping mechanism, of the frame. A mechanical arm mechanism is arranged at the portion, located at the output end of the stripping mechanism, of the frame and comprises a suction cup assembly used for sucking a to-be-pasted pad, an unfolding assembly used for unfolding the to-be-pasted pad during pad pasting and a bubble removing assembly used for removing bubbles generated during pad pasting, wherein the suction cup assembly, the unfolding assembly and the bubble removing assembly are arranged at the bottom of the mechanical arm mechanism. A pad pasting station is further arranged on the frame and located on the transferring path of the mechanical arm mechanism. According to the semi-automatic pad pasting machine, as the feeding mechanism, the stripping mechanism and the mechanical arm mechanism are arranged to be matched, a user only needs to hang the pad on a hanging roller, the to-be-pasted pad is transferred and pasted through the mechanical arm mechanism, then the waste recycling mechanism carries out assisting to recycle waste, a one-time pad pasting process is completed, and the pad pasting quality and the pad pasting accuracy can be improved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

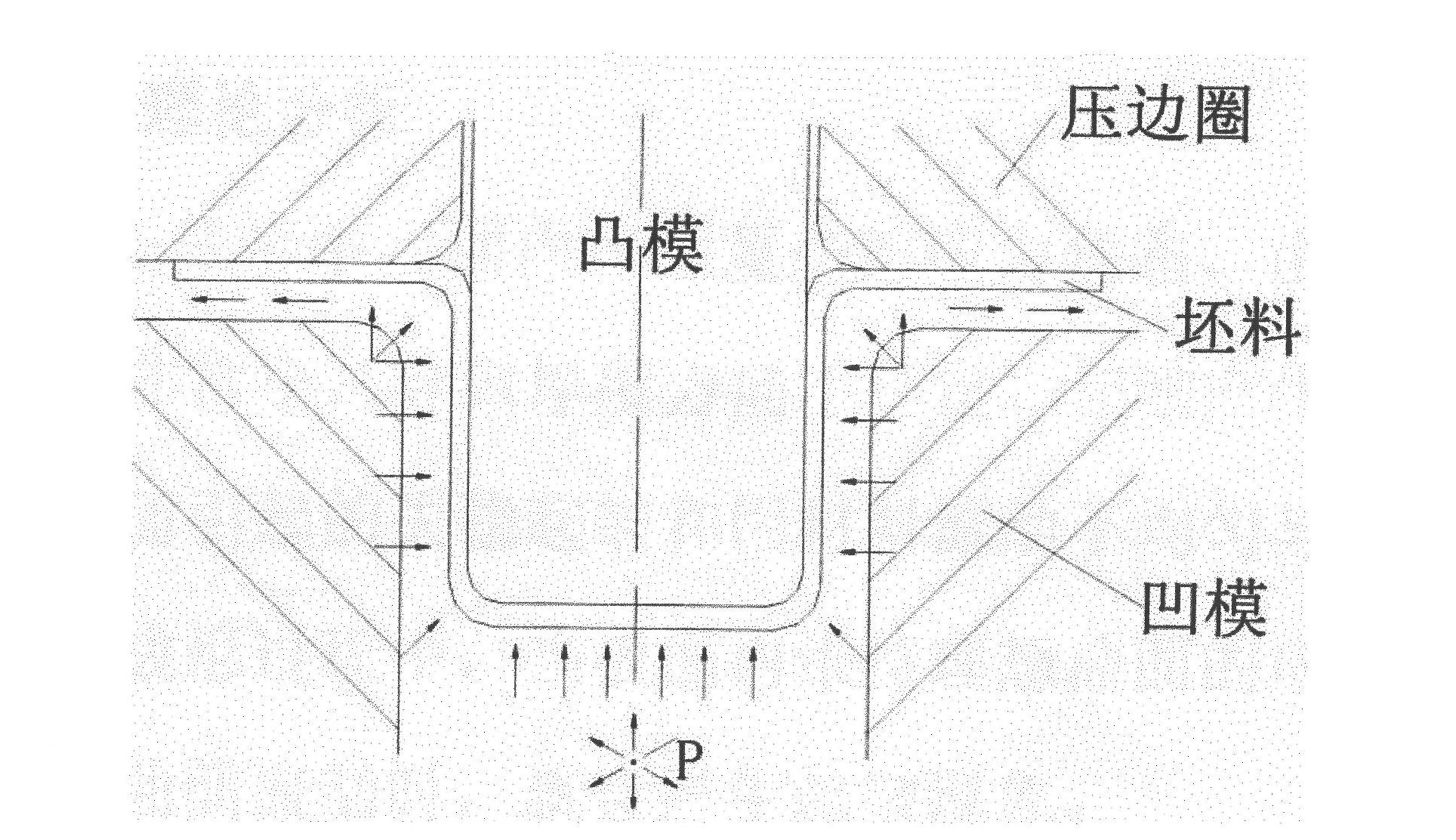

Method for forming thin-walled parts through stamping and drawing

The invention discloses a method for forming thin-walled parts through stamping and drawing, which is used for reducing the thicknesses (0.4-2mm) of raw materials to 50-100% of the original thicknesses the raw materials; the raw materials comprise magnesium alloys, aluminum alloys, titanium alloys, high temperature alloys and complex splice-welded plates; and the method specifically comprises the following steps that: a flexible forming technique is adopted with the aid of moulds and a hydraulic machine, wherein the moulds are in concave-convex fit with the hydraulic machine; upper and lower blank holders and concave and convex moulds are respectively subjected to hydraulic pressure exertion control; the nominal pressure of a main hydraulic cylinder exerted on the concave and convex moulds is 25000-4500 KN, and the nominal pressure of a side-pressing hydraulic cylinder accounts for 50-67% of the nominal pressure of the main hydraulic cylinder; and the maximum operating pressure of a liquid chamber is 150MPa. By using the method disclosed by the invention, an expected effect is obtained, and the qualification rates and efficiencies of parts are obviously improved; and meanwhile, the hydroforming technology fills in the gaps in industry application, and lays a solid foundation for the thorough solving of technical bottlenecks existing in actuating cylinder cover forming and the research and preparation of future novel thin-wall parts and sheet metal forming parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

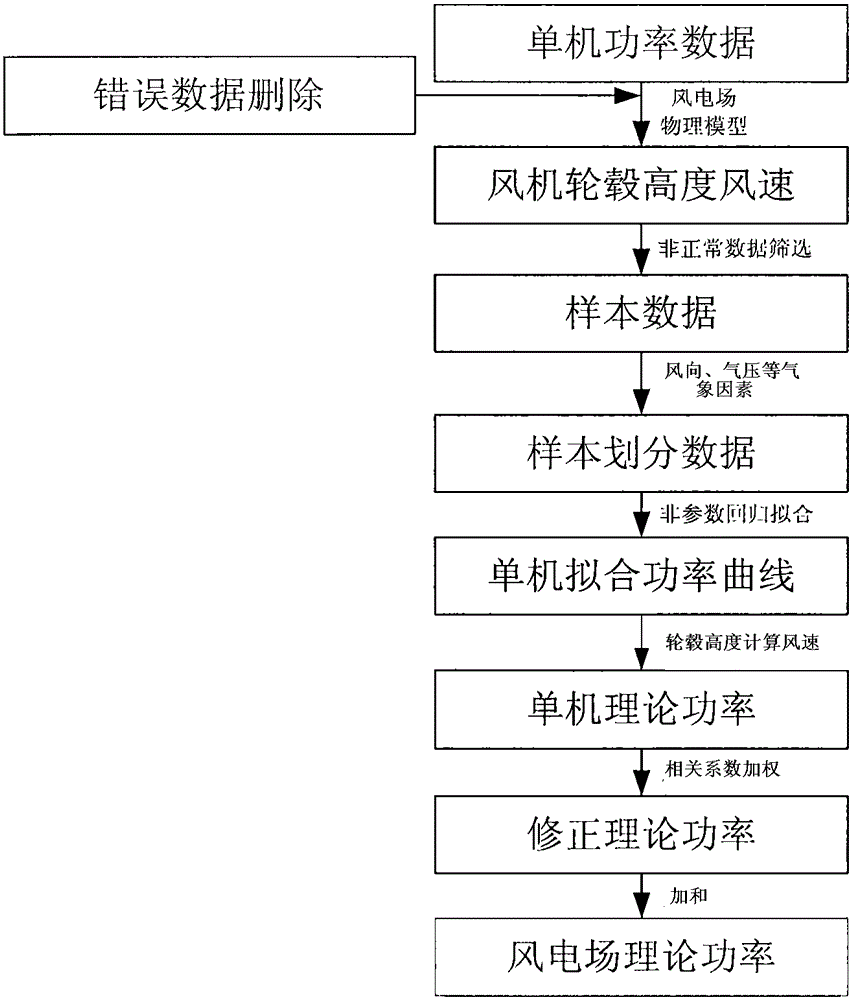

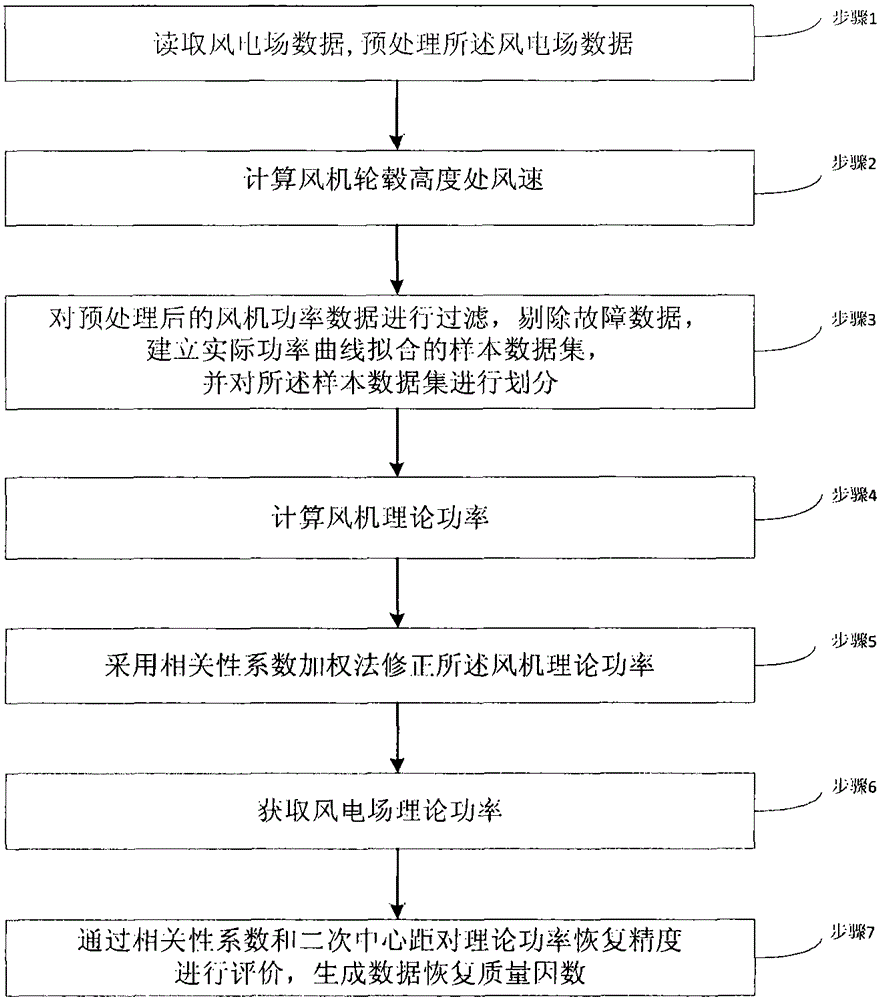

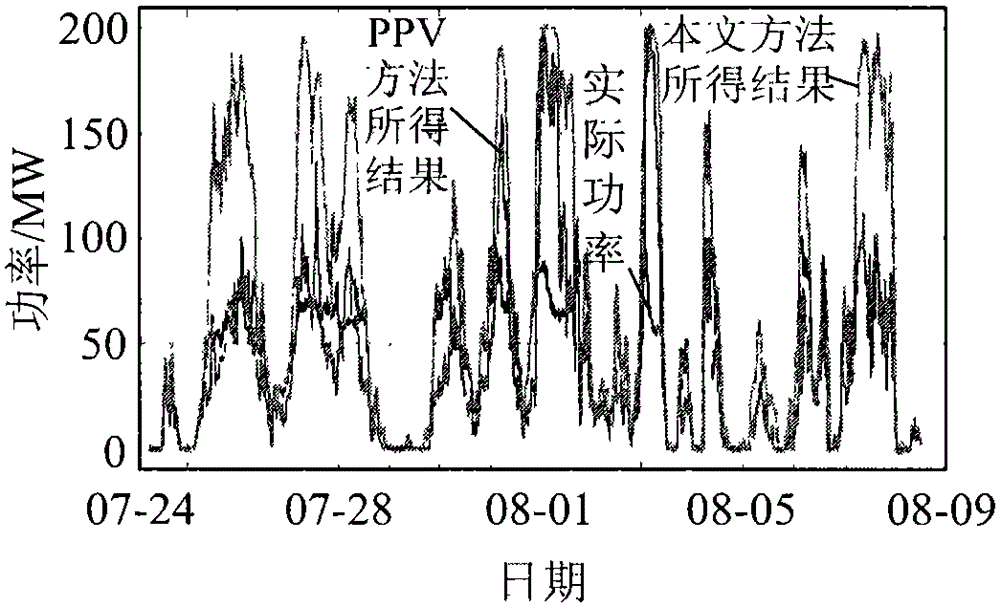

Actual power curve fitting based theoretical power determination method for wind power plant

ActiveCN105160060AGrasp the real operation statusPromote rational formulationData processing applicationsSpecial data processing applicationsElectric fieldEngineering

An actual power curve fitting based theoretical power determination method for a wind power plant comprises: reading wind power plant data; preprocessing the wind power plant data; calculating wind speed at the height of a wheel hub of a fan; filtering preprocessed fan power data to remove fault data, establishing a sample data set for actual power curve fitting, and dividing the sample data set; calculating theoretical power of the fan; adopting a correlation coefficient weighting method for correcting the theoretical power of the fan; obtaining theoretical power of the wind power plant; and evaluating theoretical power recovery precision through a correlation coefficient and a secondary center distance, and generating a data recovery quality factor. With the method, the theoretical power recovery precision is high and the tedious and complicated calculation is avoided; and the method is simple to operate, easy to realize and high in applicability.

Owner:CHINA ELECTRIC POWER RES INST +2

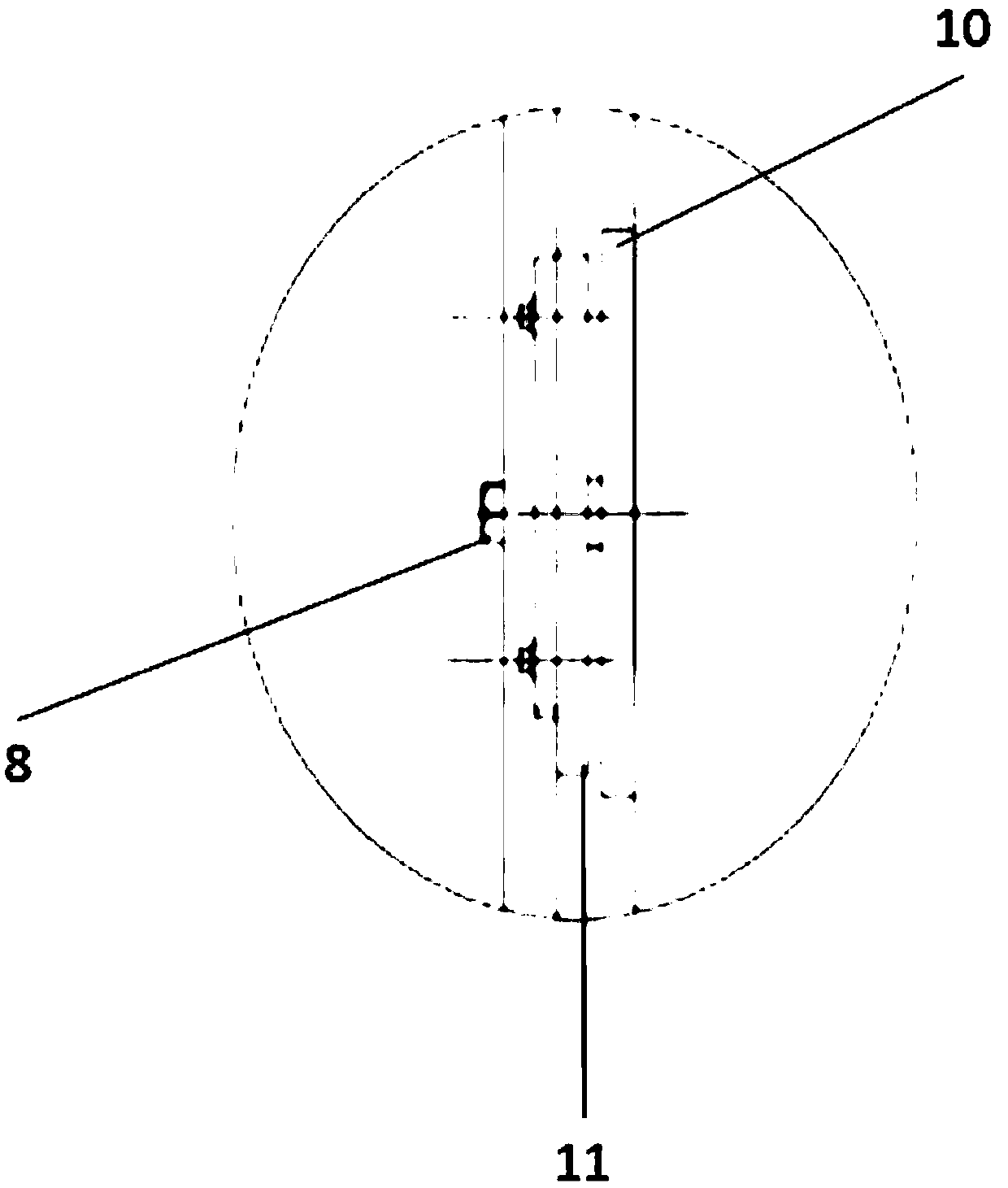

Remote laser radar calibration system and method

ActiveCN107678013AAchieve a high degree of unityRealize synchronous acquisitionWave based measurement systemsRead throughLaser

The invention discloses a remote laser radar calibration system. The calibration is carried out between a laser radar and a calibration device, and the calibration device is provided with a support, acalibration panel, and an adjustment device. The calibration panel is disposed on the support, and the adjustment device is used for adjusting the height and angle of the calibration panel. The adjustment device comprises a support which is provided with an upper part and a lower part, wherein the upper part is provided with a plurality of adjustment holes at different heights, and the lower partand a folding device are fixed through a connecting device. The adjustment device also comprises an inner rotating control device and an outer rotating control device, wherein the outer rotating control device is disposed between the inner rotating control device and the support, and the inner and outer rotating control devices have the same center. The scale position is read through the mutual rotation of the inner and outer rotating control devices, and the angle is adjusted. In addition, a fixed device can pass through the calibration panel, is disposed on the adjustment holes of the support in a bulged manner, and is fixed on the adjustment holes through a spiral fixing part.

Owner:TONGJI UNIV +1

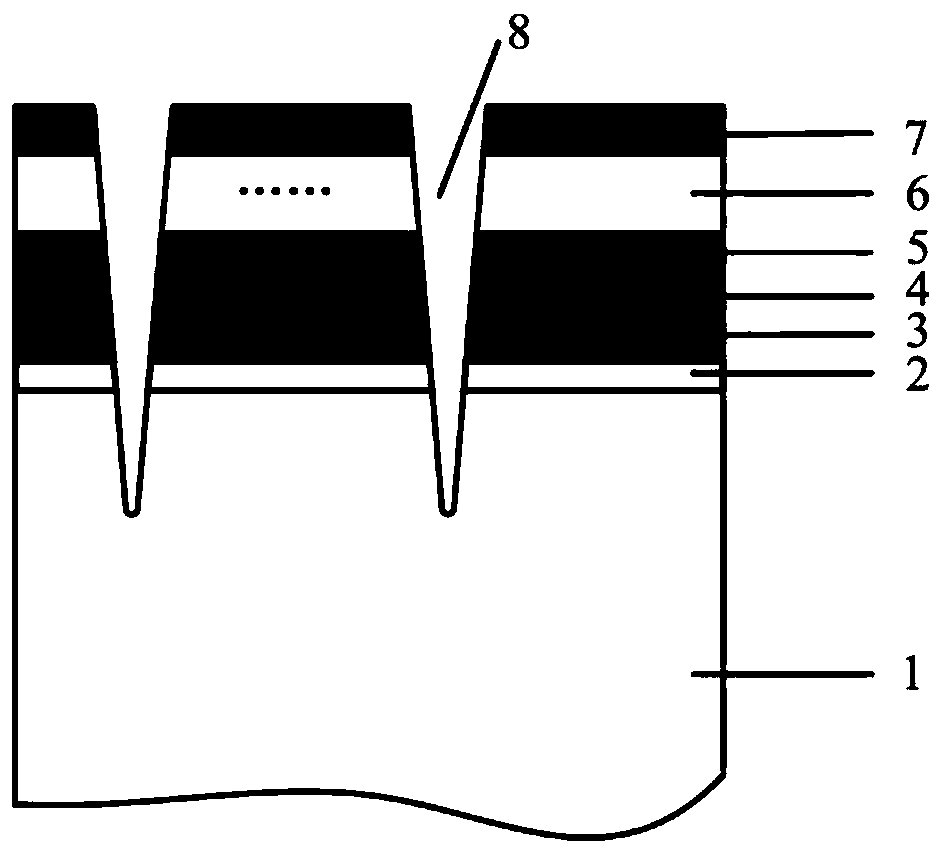

Cutting tool with micro textures and gradient coatings as well as preparation method of cutting tool

ActiveCN110016642AHigh hardnessGood self-lubricating performanceVacuum evaporation coatingSputtering coatingPlasma technologyHardness

The invention discloses a cutting tool with micro textures and gradient coatings as well as a preparation method of the cutting tool. The base material of the cutting tool is high-speed steel, hard alloy or ceramic. Firstly, a laser-induced plasma technology is used to form micro textures of different patterns and sizes on the front and back surfaces of the cutting tool; and a method of multi-arcion plating and medium-frequency magnetron sputtering co-deposition is used to prepare Zr+ZrN transition layers, nano laminated layers consisting of alternating ZrVCN+TiSiNbC hard coatings and a WBSesoft coating on the surfaces of the cutting tool. The cutting tool has the advantages of the micro textures, the hard coatings, the soft coating, the nano layers and the laminated structure, and thushas high hardness and good self-lubricating property. During dry cutting, effective continuous lubricating films can be formed on the surfaces of the cutting tool, and the micro textures on the surfaces can perform the functions of reducing friction and collecting wear debris; and the nano laminated coating layers increase the binding force between the coating layers and reduce the internal stressof the coating layers. The cutting tool can be widely used in dry cutting and the cutting of difficult-to-machine materials.

Owner:SOUTHEAST UNIV

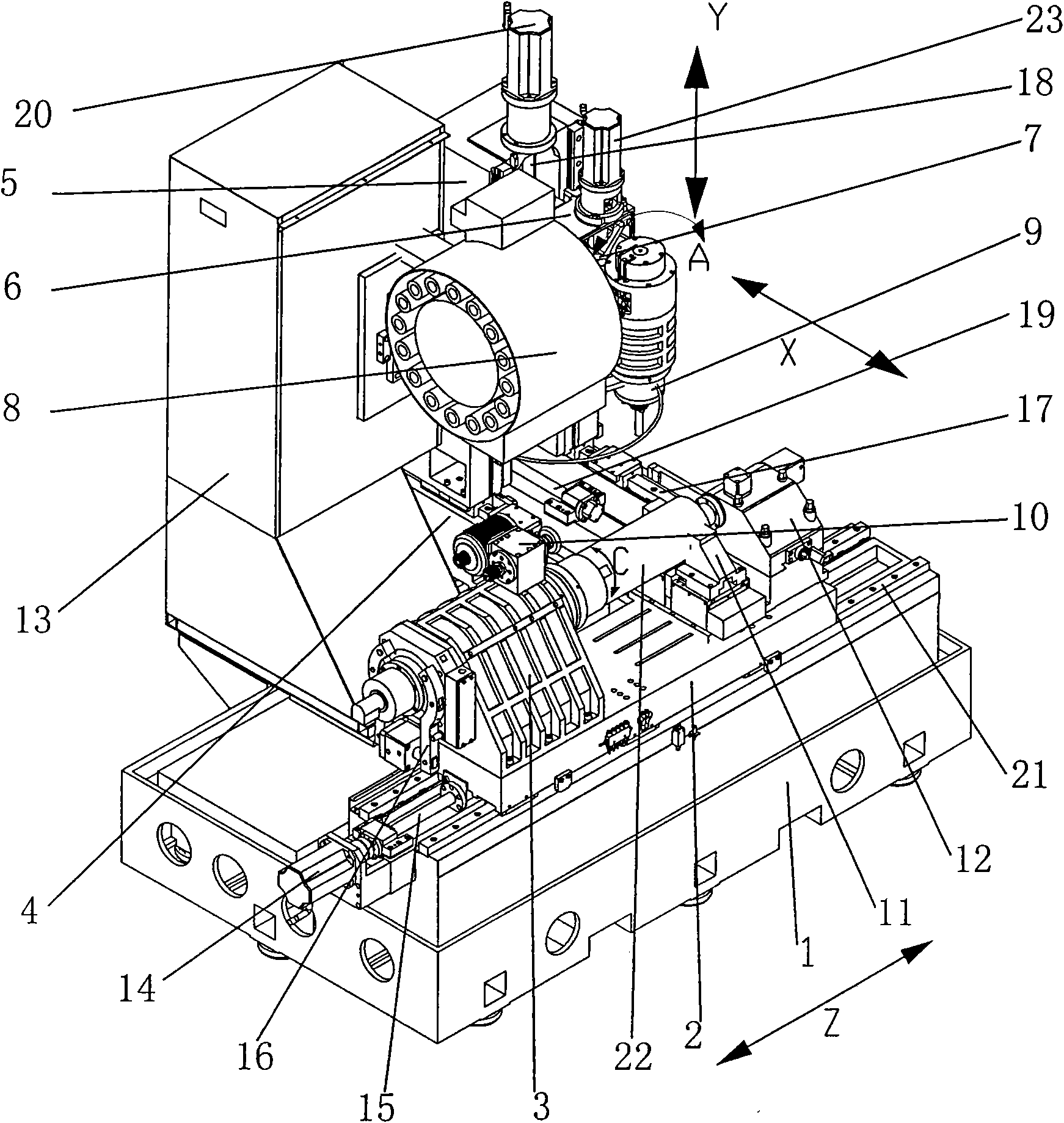

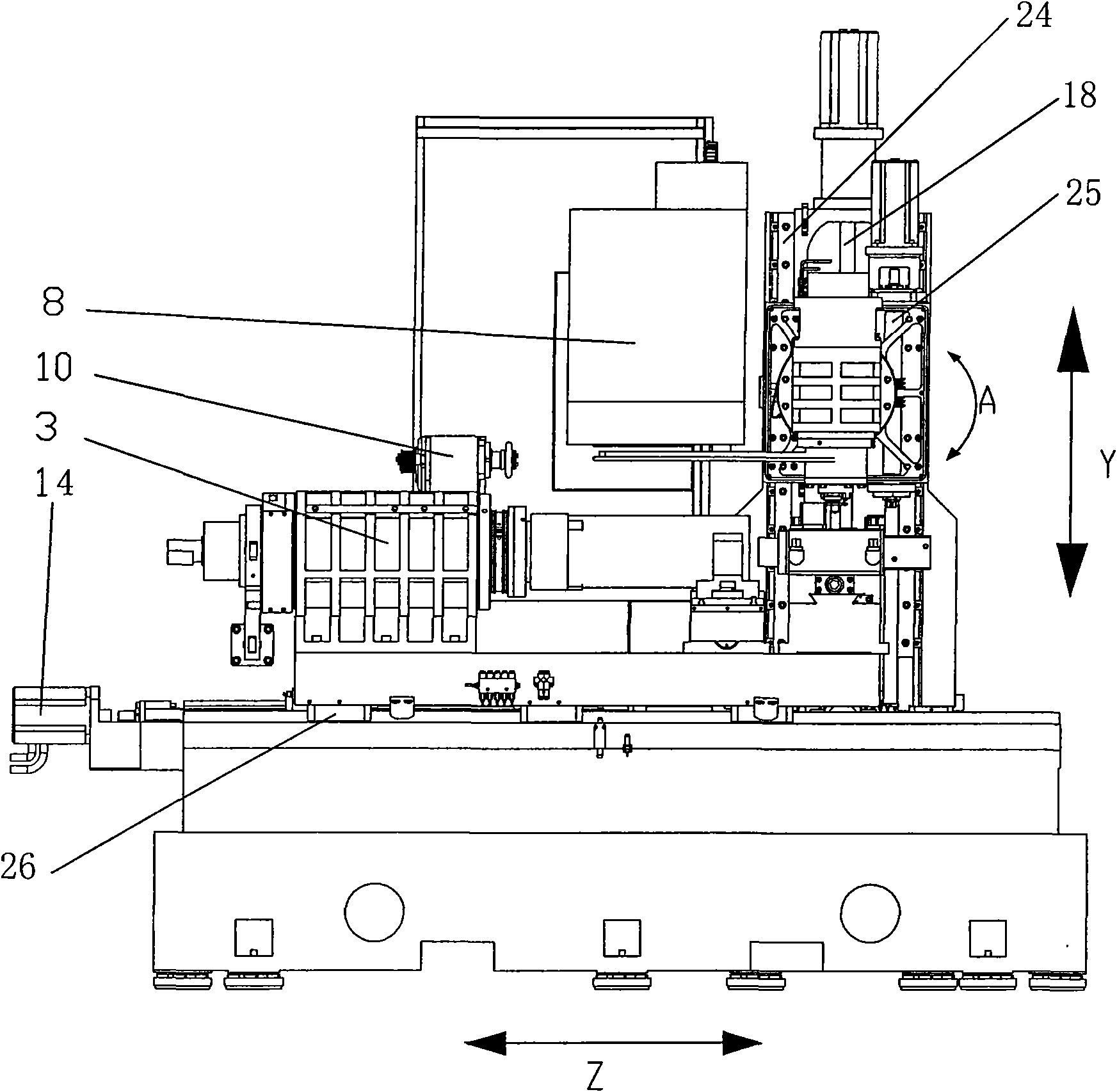

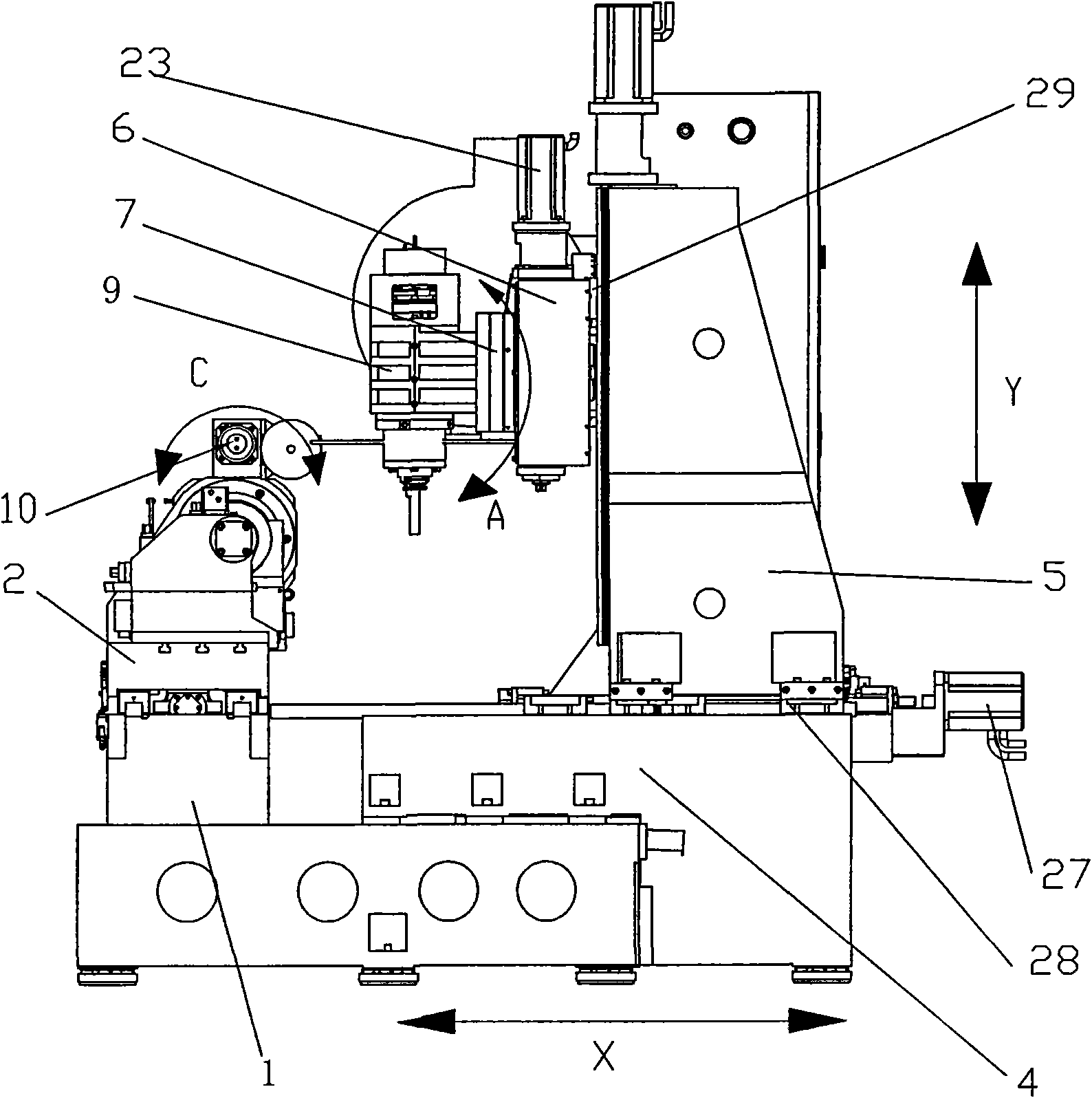

Five-axis multi-functional thread grinding machining center

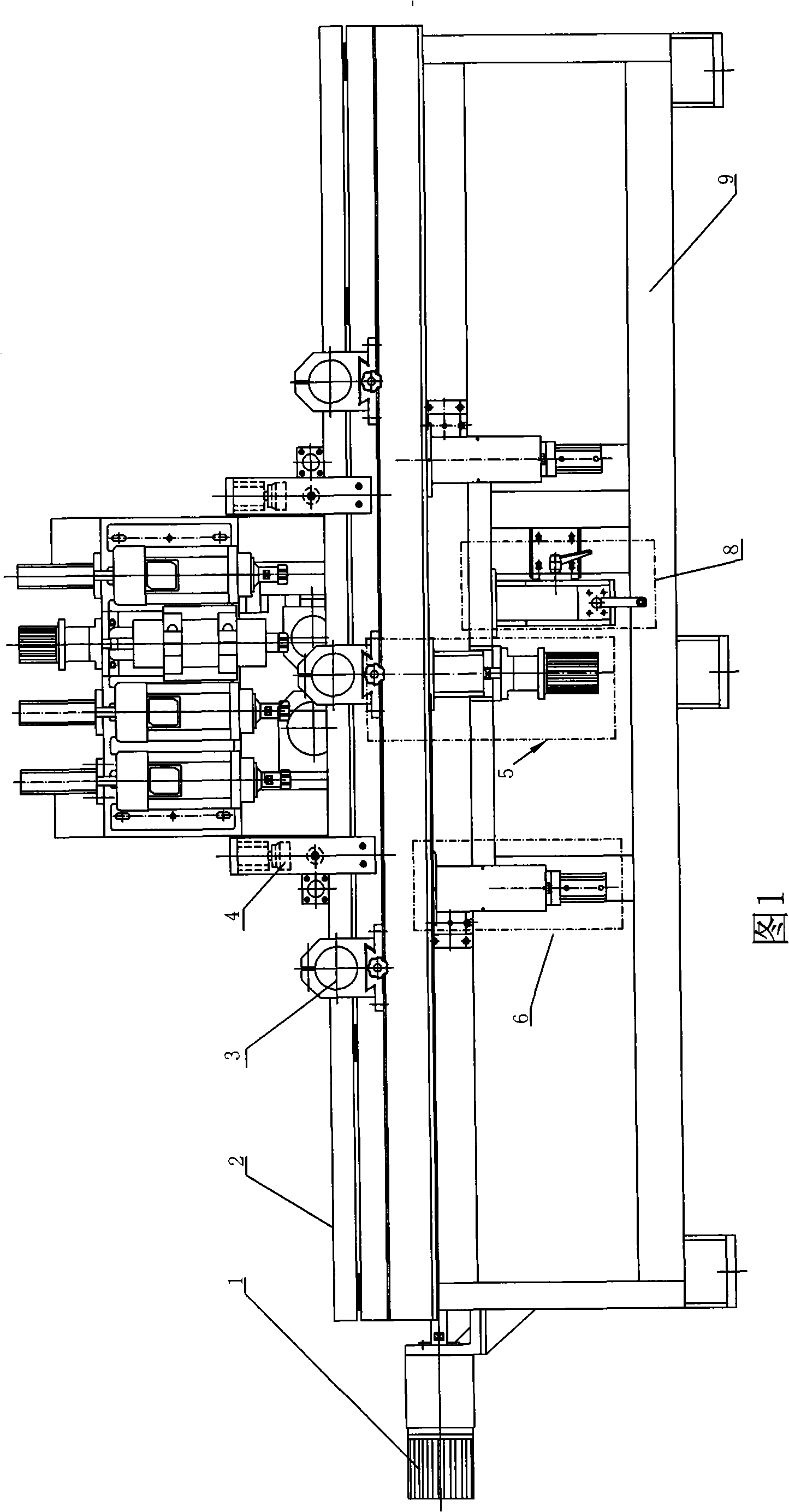

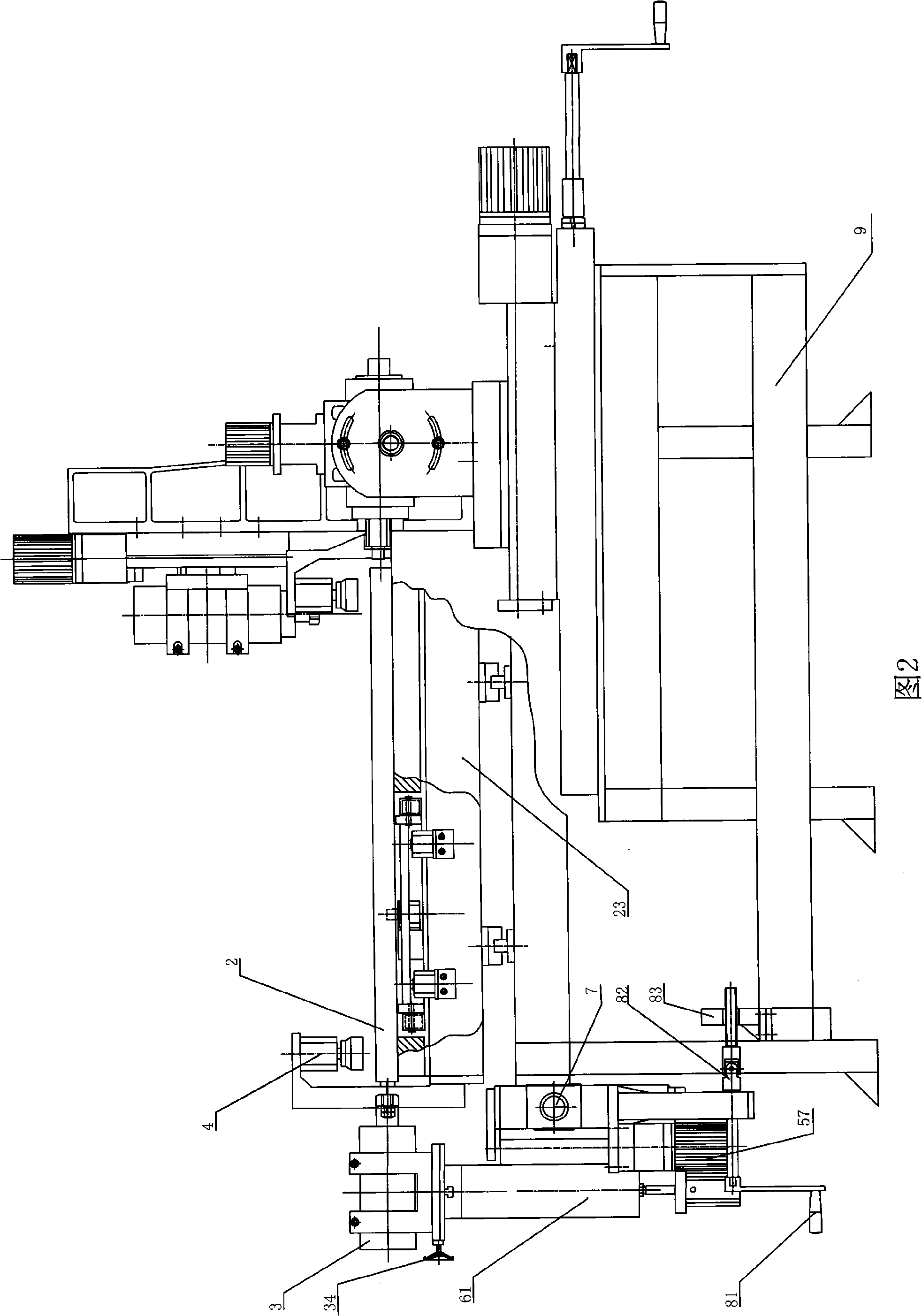

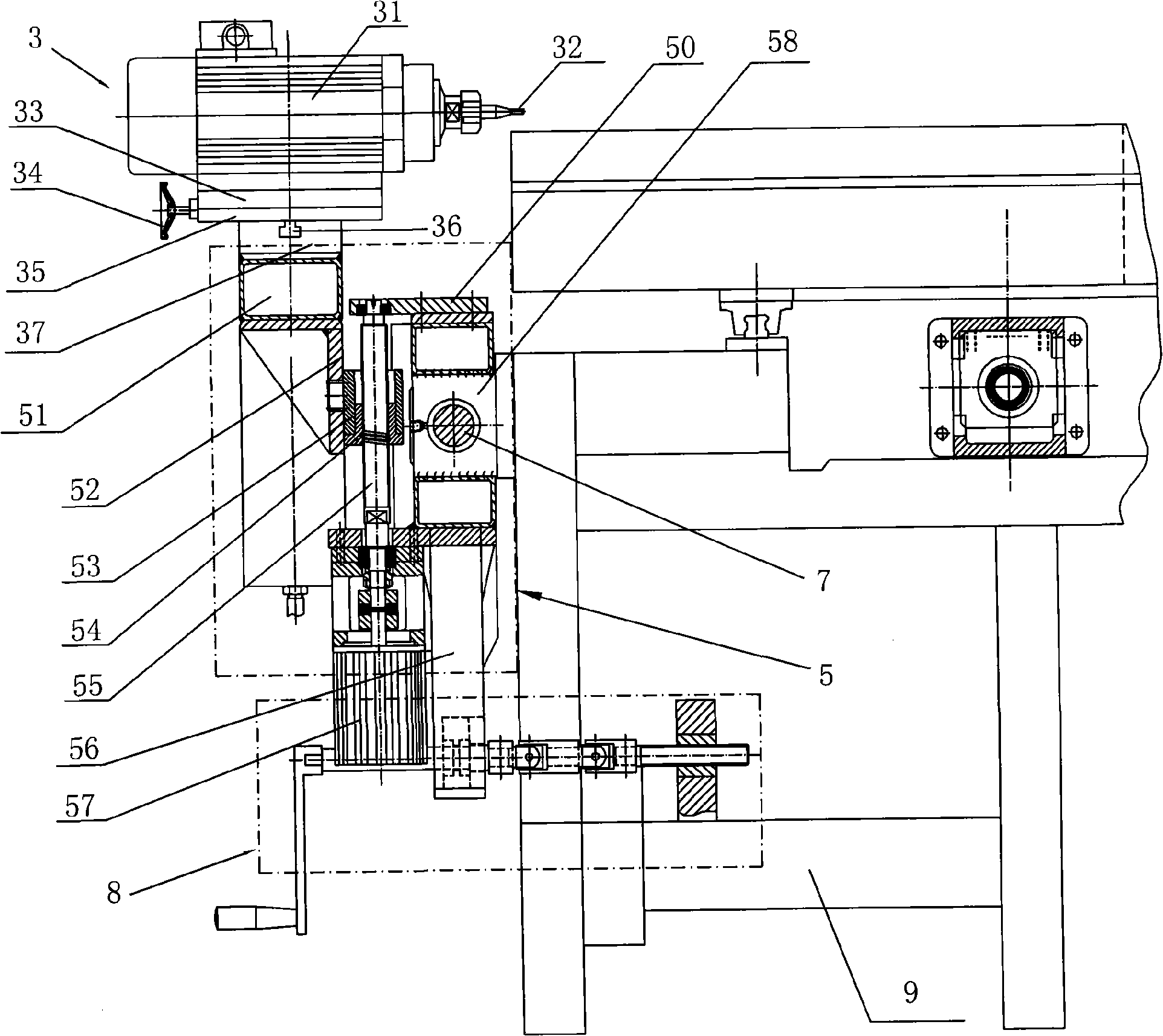

ActiveCN101513686AImplement fixesSimple structureThread cutting machinesManufacturing cost reductionNumerical control

A five-axis multi-functional thread grinding machining center belongs to the numerically controlled machine tool field. The five-axis multi-functional thread grinding machining center consists of a machine tool body, a Z-direction slide plate, a workpiece electric spindle, a X-direction base plate, a post, a Y-direction slide plate, an A-axis turntable and a grinding electric spindle. A Z-direction servomotor drives a Z-direction lead screw to drive the Z- direction slide plate to perform Z-direction movement, the post is arranged on a X- direction guide rail slider, a X-direction servomotor drives an X-direction lead screw to drive the post to perform X-direction movement, a Y-direction guide rail is fixedly arranged on the post, the Y-direction slide plate is positioned on a Y-direction guide rail slider, a Y-direction servomotor drives a Y-direction lead screw to drive the Y-direction slide plate to perform Y-direction movement, the Z-direction slide plate is provided with the workpiece electric spindle, the A-axis turntable is arranged on the Y-direction slide plate and is connected with an A-axis servomotor, and the grinding electric spindle is fixed on the A-axis turntable by bolt fastening. The five-axis structure is adopted in the grinding machining center, thus simplifying machine tool structure, realizing grinding of super-long nuts, enlarging applicability of the machine tool and lowering manufacturing cost.

Owner:GUANGZHOU CITY AGILE MFG

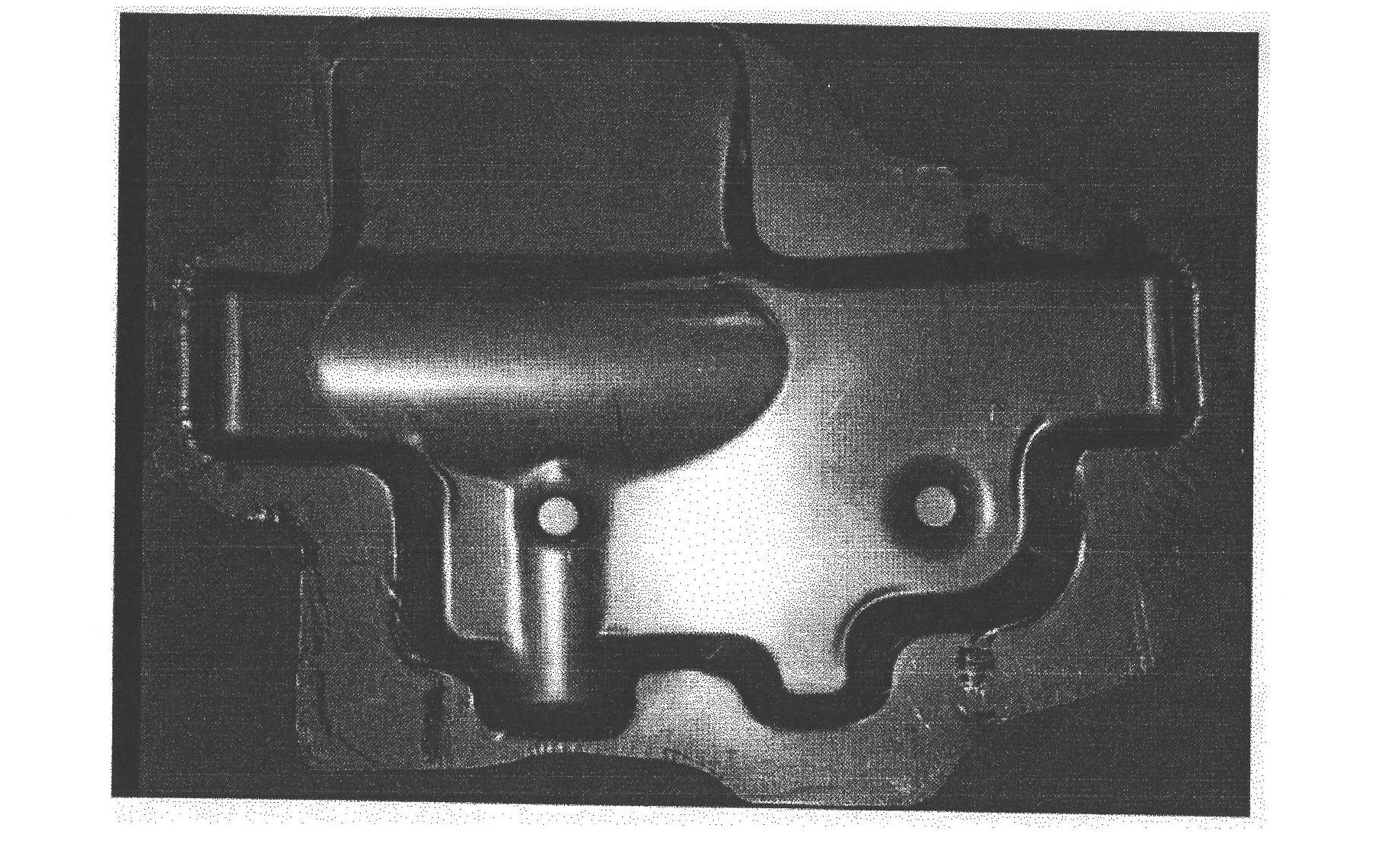

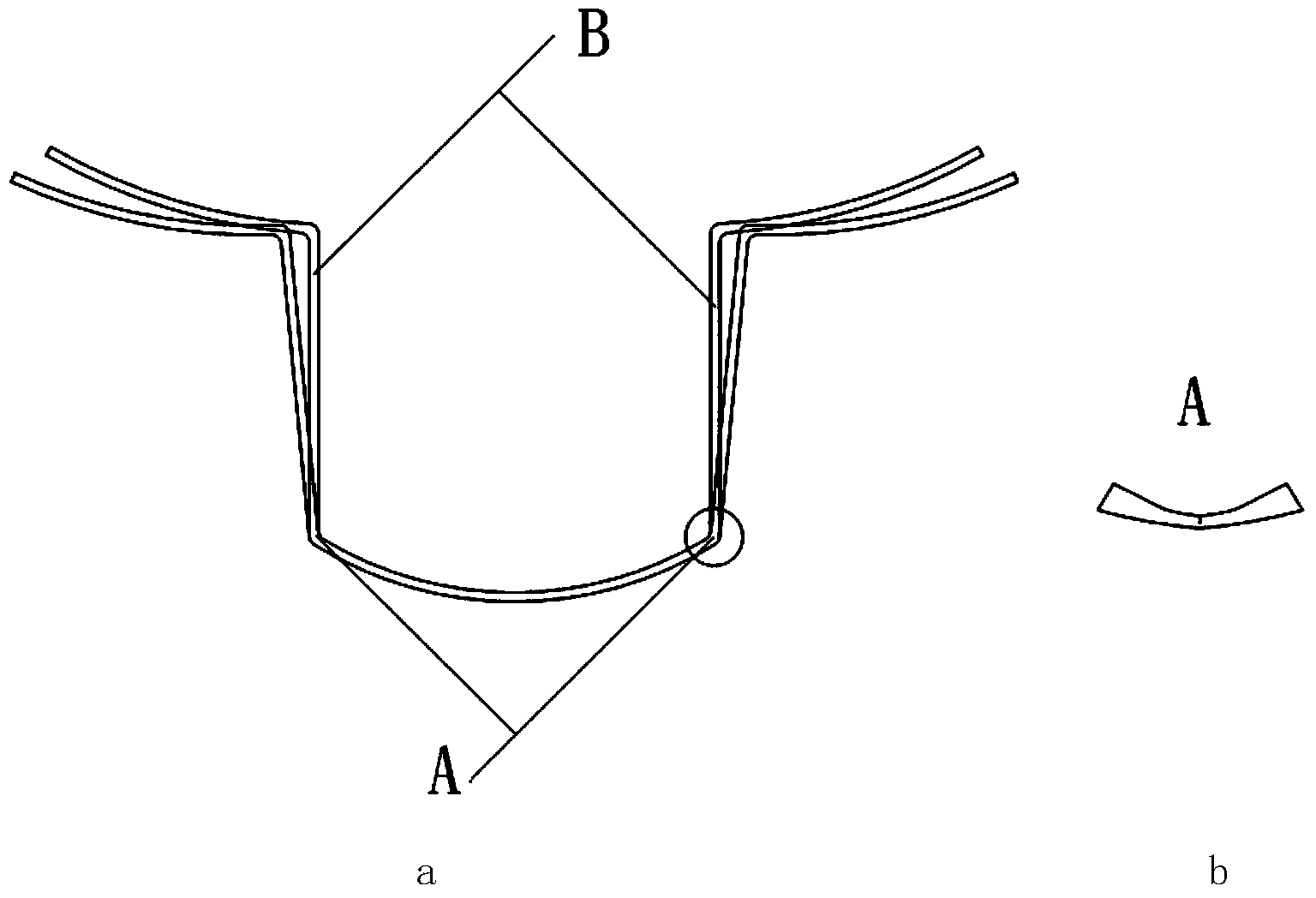

Incremental bending and forming method of hat-shaped member

InactiveCN103480704AHigh quality and precisionHigh forming precisionShaping toolsPunchingEngineering

Disclosed is an incremental bending and forming method of a hat-shaped member. Complex hat-shaped member with multi-arcs is formed through a simple mold matching with a plant bending machine. The method includes unfolding each arc of the complex hat-shaped member with the multi-arcs into a plane to determine the size of the plane blank; establishing a three-dimensional model according to the size of the plane blank, and dividing areas by adopting arcs as standards; performing numerical simulation on the forming process complex hat-shaped member with the multi-arcs, incremental bending arcs on two sides, then bending a central arcs, and finally bending boundaries of the areas; determining feeding amount of the plate blanks and downward punching amount of each step during the bending process according to the simulation result. By the aid of the method, the thickness of each part of a formed hat-shaped member is consistent basically, and surface quality and forming accuracy of the formed member can be guaranteed well; the process of controlling deformation is simple, and the method has the advantages of low cost and short period.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

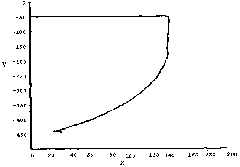

Stretch-bending molding process of angle steel component of vehicle body

ActiveCN101823092AHigh quality and precisionImprove manufacturing precisionPull forceMathematical model

The invention relates to a stretch-bending molding process of an angle steel component of a vehicle body and mainly aims to scientifically and rationally overcome the defects of overlarge rebound modulus and section bending deflection of workpieces and the like during the stretch-bending molding of the angle steel component of the vehicle body. The process realizes the emulation of pretension and post-tension corresponding to the minimum rebound modulus, provides a computing formula for the initial length of profiles and a trajectory model of a clamp, improves the forming quality, precision and work efficiency of a stretch-bending workpiece and the manufacturing quality of vehicle steel structure, reduces the manufacturing and maintenance cost, overcomes stretch-bending defects and provides basis for the stretch-bending molding precision control of profile parts. The process initially establishes a mathematical model for length rebound modulus of a multi-curvature profile, can precisely determine the initial length of a blank profile of parts, determines the optimal pretension and post-tension by a simulation method and precisely determines the trajectory of the clamp by establishing a multi-curvature profile stretch-bending module, thereby obtaining the ideal forming quality of the formed profile.

Owner:白城市瑞程汽车部件有限公司

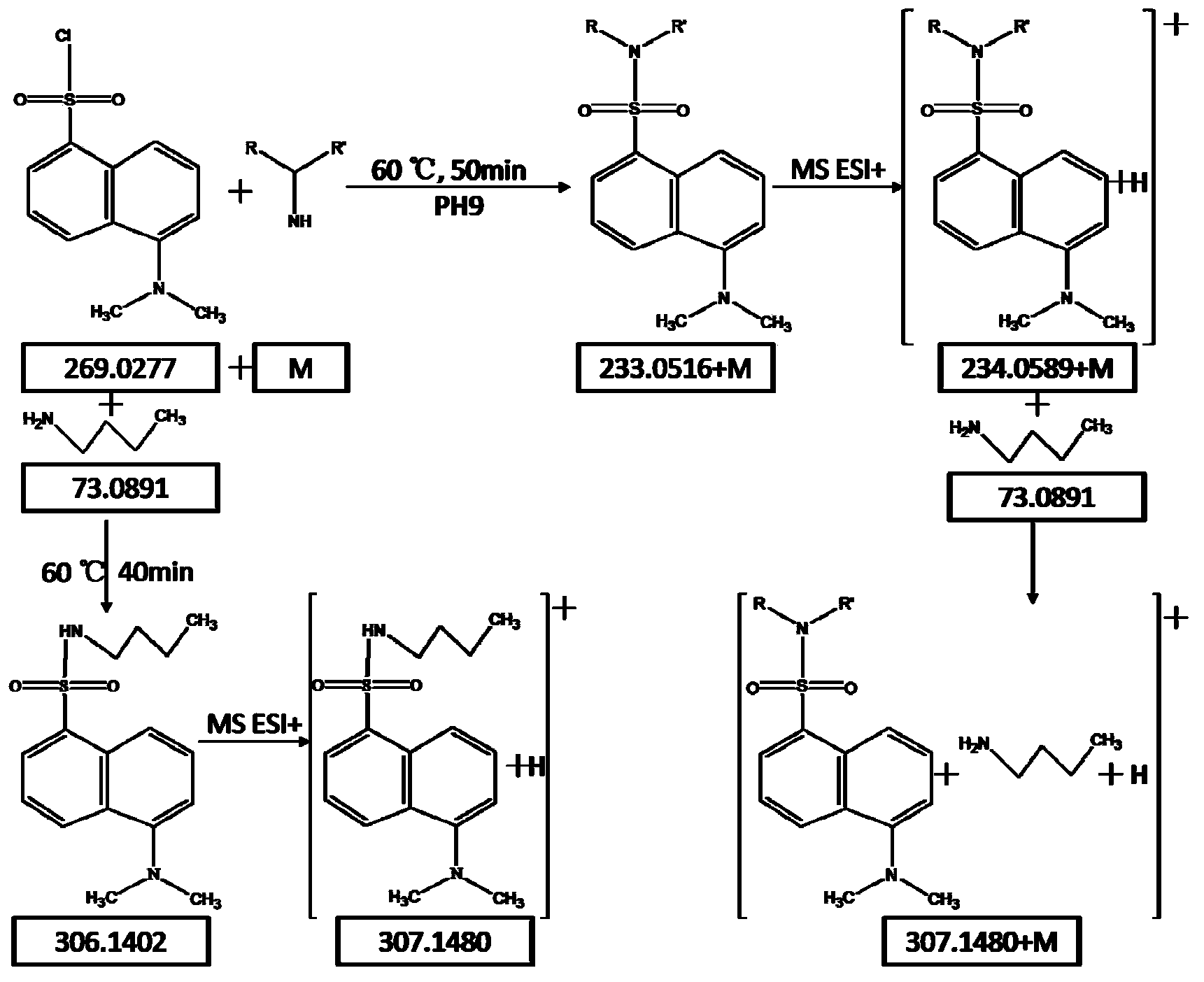

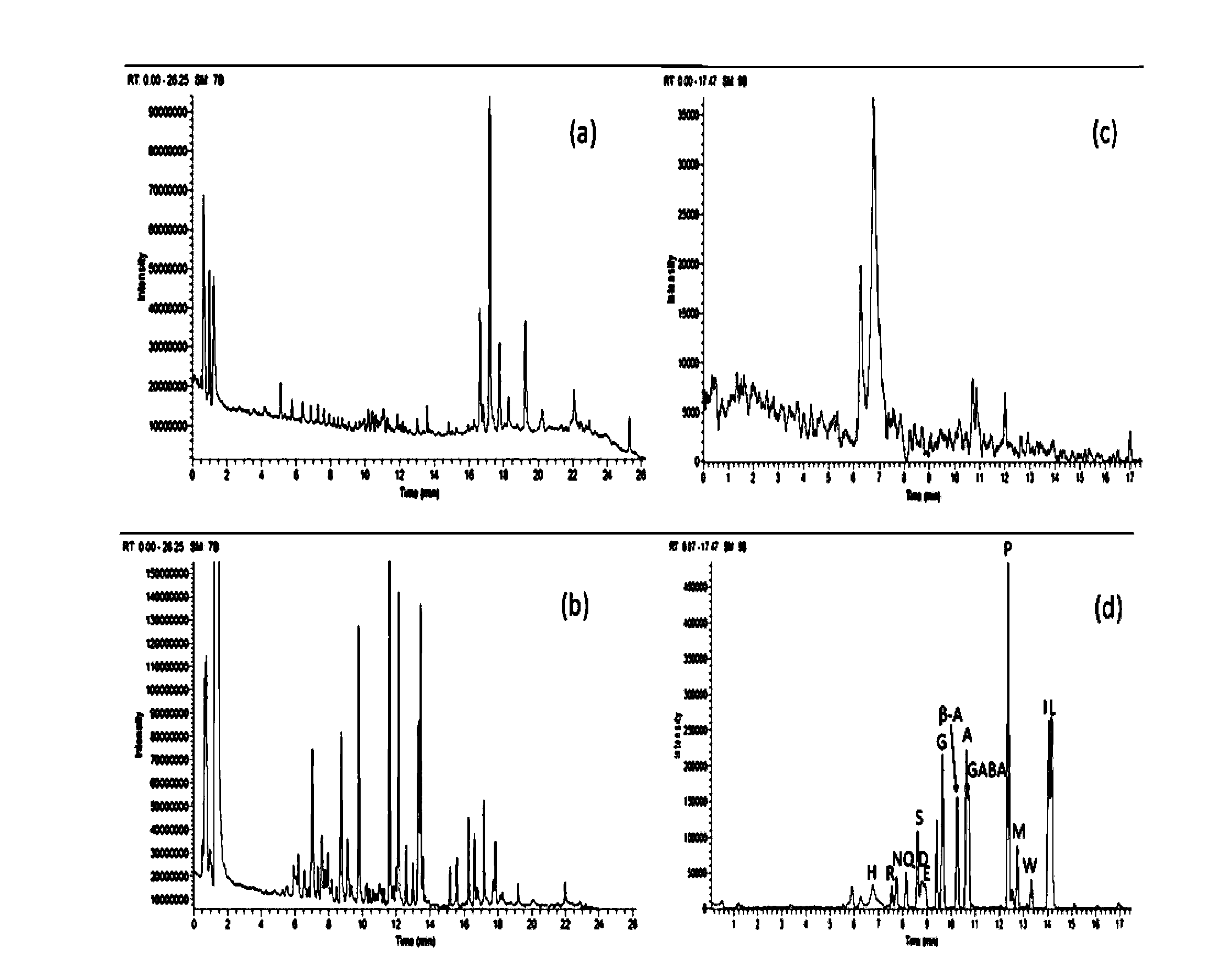

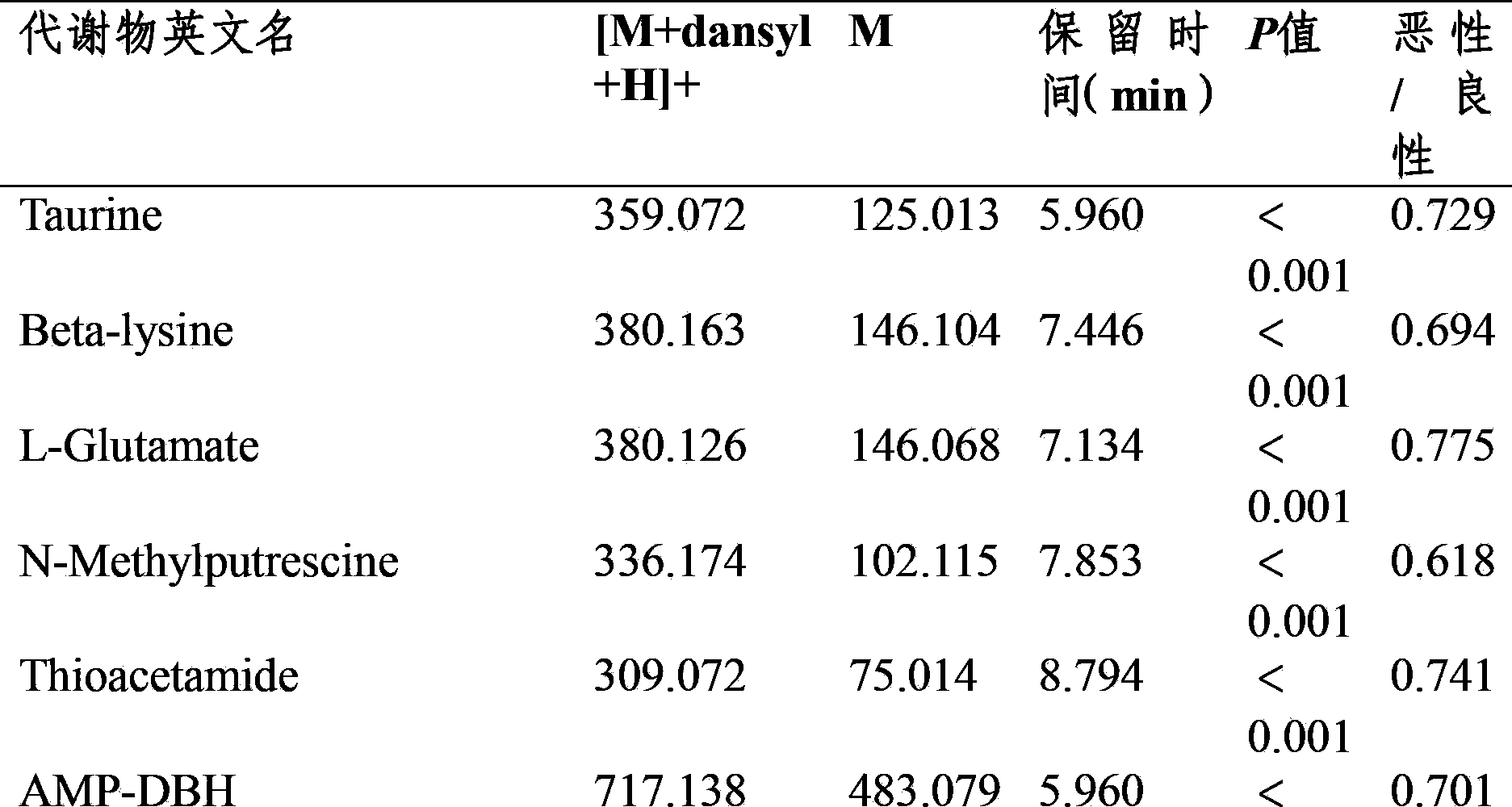

Method for analyzing amine substances in dansyl chloride derived-plasma based on liquid chromatography mass spectrometry

InactiveCN103822998AReduce consumptionStrong specificityComponent separationDipeptideGas chromatography–mass spectrometry

The invention discloses a method for analyzing amine substances in dansyl chloride derived-plasma based on liquid chromatography mass spectrometry. The method is characterized in that dansyl chloride is used as a derivatization reagent to perform derivatization on a metabolite containing primary amine and secondary amine, therefore the retention capability of the amine substances in reversion phase chromatography is increased, the ionization efficiency in mass spectrometric detection is increased, and the purpose of increasing the quantitative accuracy and detection sensitivity of the amine substances is achieved. The method has wide coverage for amine metabolites (comprising amino acid, methylation products, acetylation products, dipeptide and the like), can utilize 100 [mu]L of plasma samples to detect 113 amine substances, supplies the outline information of metabolome of the amine substances, and has the characteristics of good specificity, high accuracy and repeatability, less reagent consumption and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

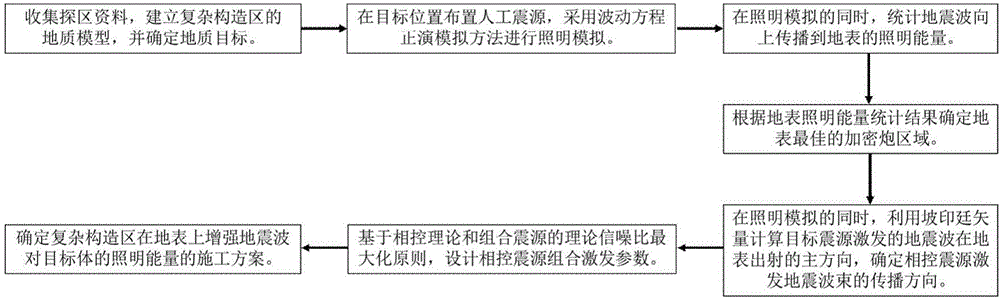

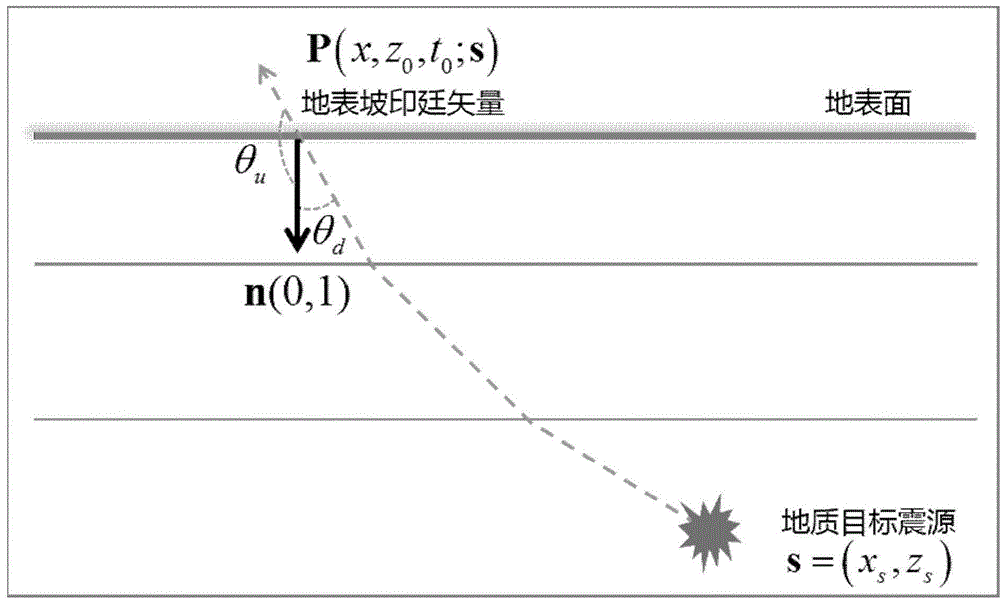

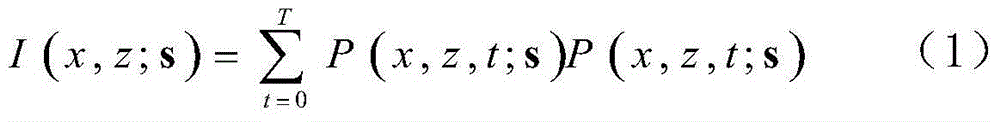

Design method for enhancing seismic waves to stimulate illumination

InactiveCN104614765AAdapt to speed changesGet energy distributionSeismic signal processingSignal-to-noise ratio (imaging)Model method

The invention mainly relates to a design method for enhancing seismic waves to stimulate illumination in a complex structure region. The design method comprises the following steps that (1) exploration area data are collected, a geological model of the complex structure region is established, and a geological target is determined; (2) an artificial seismic source is arranged at the target position, and illumination simulation is conducted through a wave equation forward modeling method; (3) statistics of illumination energy, upwards spread to the ground surface, of the seismic waves is conducted when illumination simulation is conducted; (4) an optimal encryption shot region on the ground surface is determined according to the statistical result of the illumination energy on the ground surface; (5) the main direction of emergence, on the ground surface, of the seismic waves stimulated by a target seismic source is calculated through a poynting vector, and the spread direction of a seismic wave beam stimulated by a phase-controlled seismic source is determined; (6) combined stimulation parameters of the phase-controlled seismic source are designed on the basis of a phase-controlled theory and the theoretical signal-to-noise ratio maximization principle of combined seismic sources; (7) a construction scheme for enhancing the illumination energy provided by the seismic waves for the target on the ground surface in the complex structure region is determined. The design method is good in application effect and can reduce the collection cost.

Owner:SOUTHWEST PETROLEUM UNIV

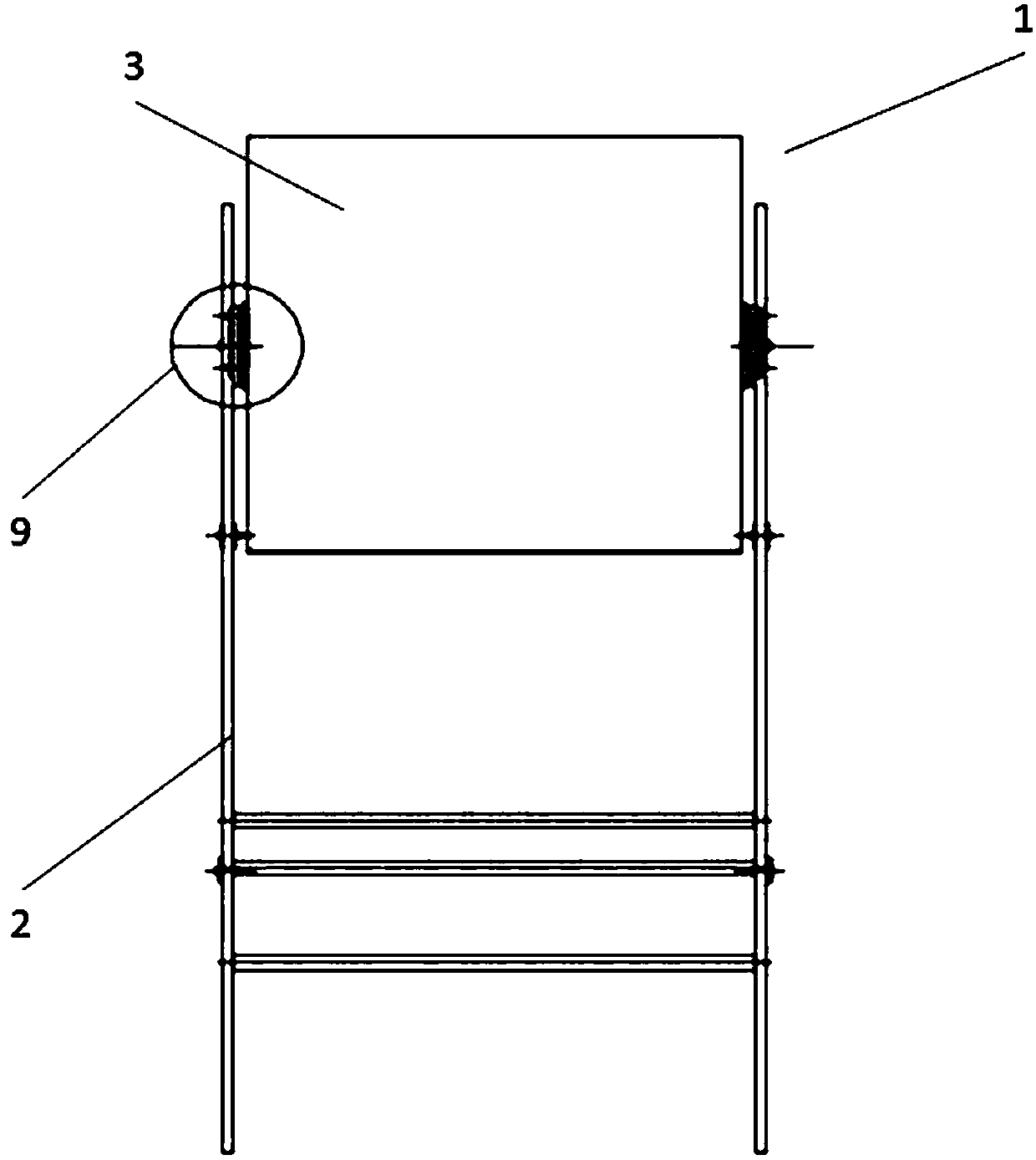

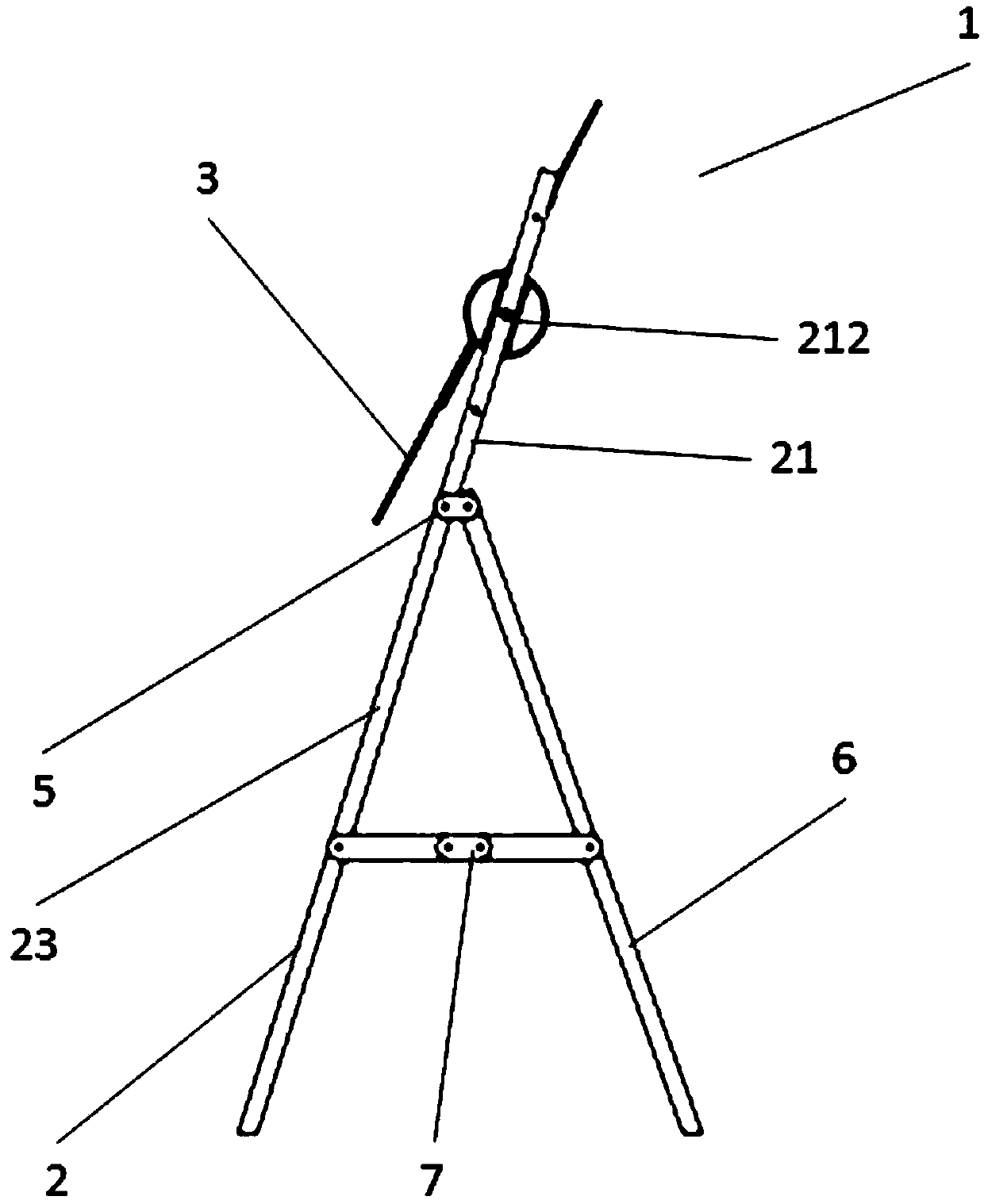

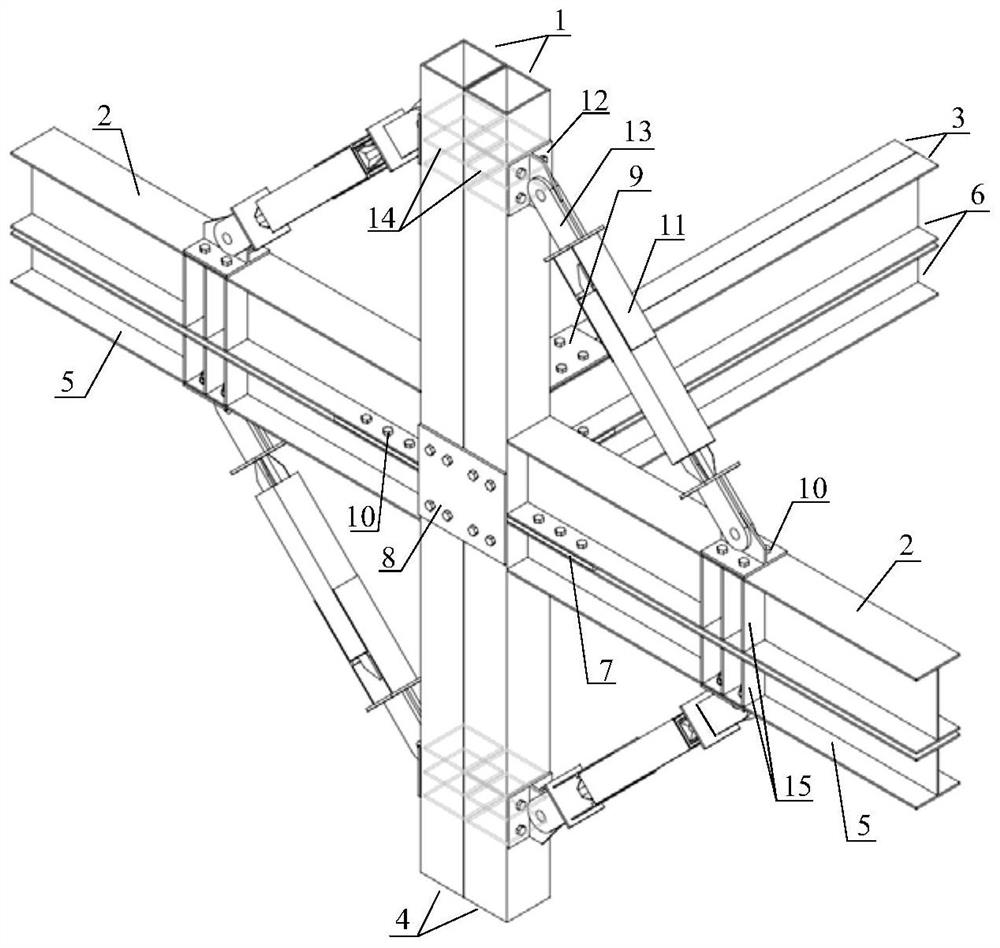

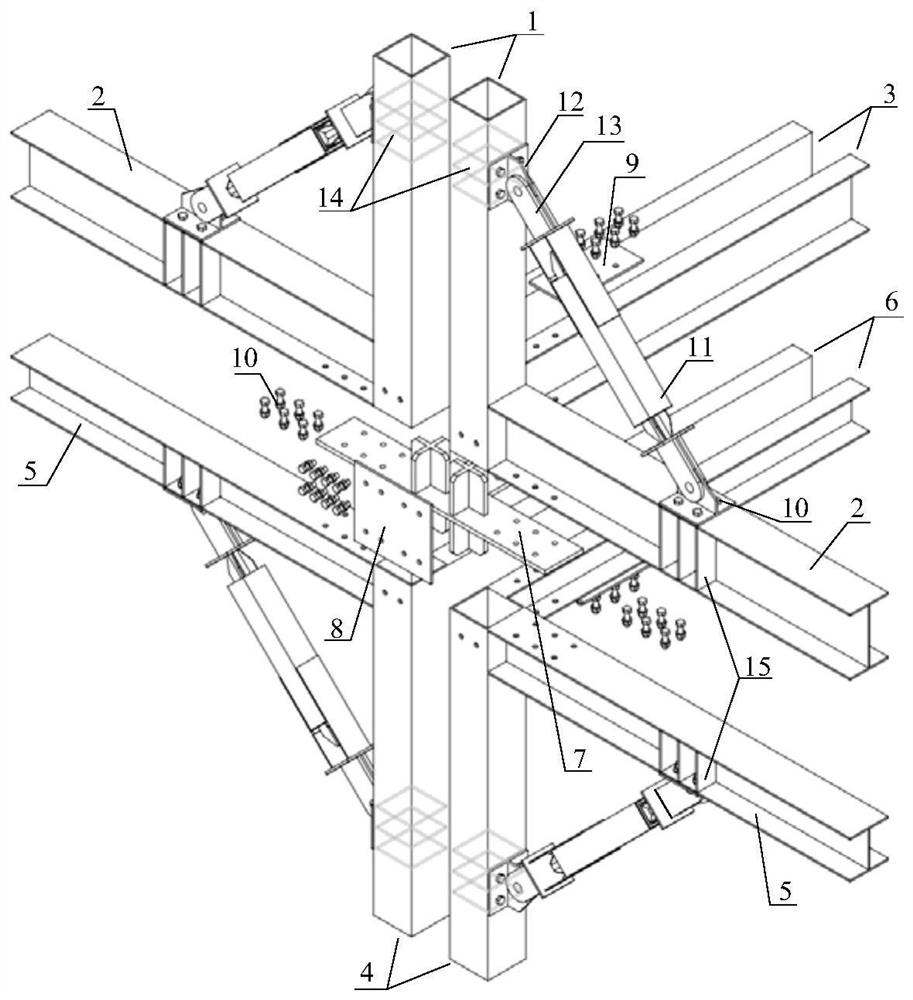

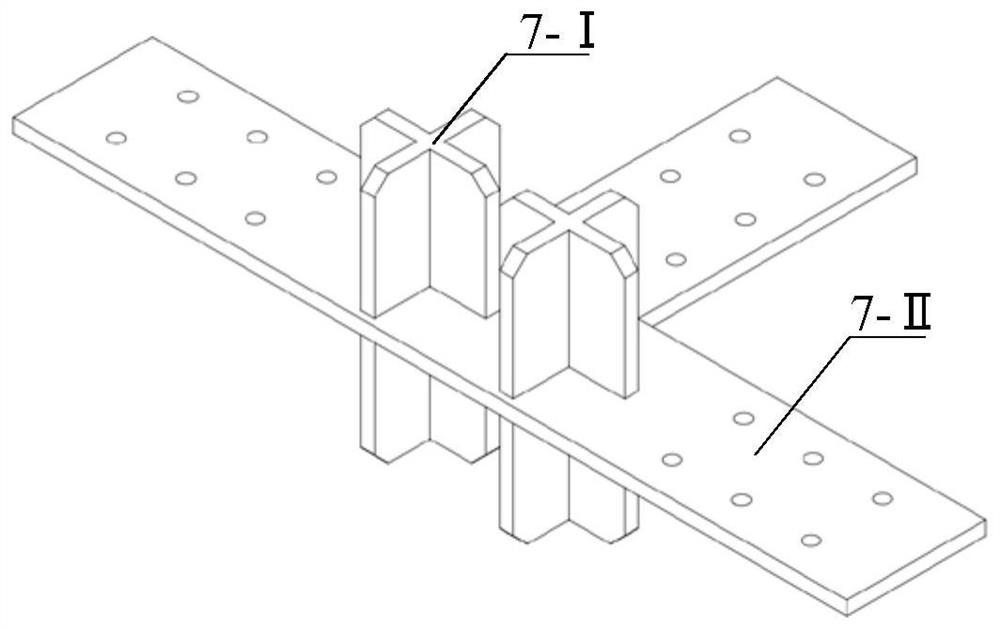

Inserting type modular steel structure connecting joint with reset function

ActiveCN111636561AEasy constructionQuality improvementProtective buildings/sheltersShock proofingFlexural rigidityMechanical engineering

The invention relates to an inserting type modular steel structure connecting joint with a reset function. The inserting type modular steel structure connecting joint comprises a modular steel structure connecting joint body and self-reset haunch supports, wherein the modular steel structure connecting joint body comprises two upper module units, two lower module units, a cross-shaped inserting pin connecting piece, a vertical cover plate, a horizontal cover plate and high-strength bolts, and the four self-reset haunch supports internally provided with disc springs are symmetrically arranged at the corner parts of the joint body and are hinged to module beam columns. According to the inserting type modular steel structure connecting joint, module units are connected through the cross-shaped inserting pin connecting piece, the cover plate and the high-strength bolts, so that it is guaranteed that the joint has enough tensile strength, shear strength and bending strength, a connecting device has no need occupying the use space of a building, the application range is wide, and meanwhile attractiveness is guaranteed; and the arrangement of the self-reset haunch supports can improve thebearing capacity of the joint, delay degradation of the rigidity and strength of the joint, reduce damage to the joint beam-column intersection, avoid premature damage to components, achieve rapid repair and guarantee stability and reliability of the joint performance, and residual deformation after an earthquake is small.

Owner:BEIJING JIAOTONG UNIV

Manufacturing method of fired mold precision cast aluminum alloy case

InactiveCN102921888AReduce manufacturing costConvenient sourceFoundry mouldsFoundry coresSurface layerMullite

The invention discloses a manufacturing method of a fired mold precision cast aluminum alloy case. The method includes the following steps: 1) blending binder; 2) preparing surface layer slurry; 3) sanding on a surface layer; 4) preparing transition surface layer slurry; 5) sanding on a transition layer; 6) preparing reinforcing layer slurry; 7) sanding on a reinforcing layer; 8) preparing sealing layer slurry; 9) drying a sealing layer. According to the method, mullite sand which is cheap is used, purchasing is convenient, proportioning is easy, and the surface quality and the size accuracy of a mold shell and even a final cast piece can be greatly improved.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

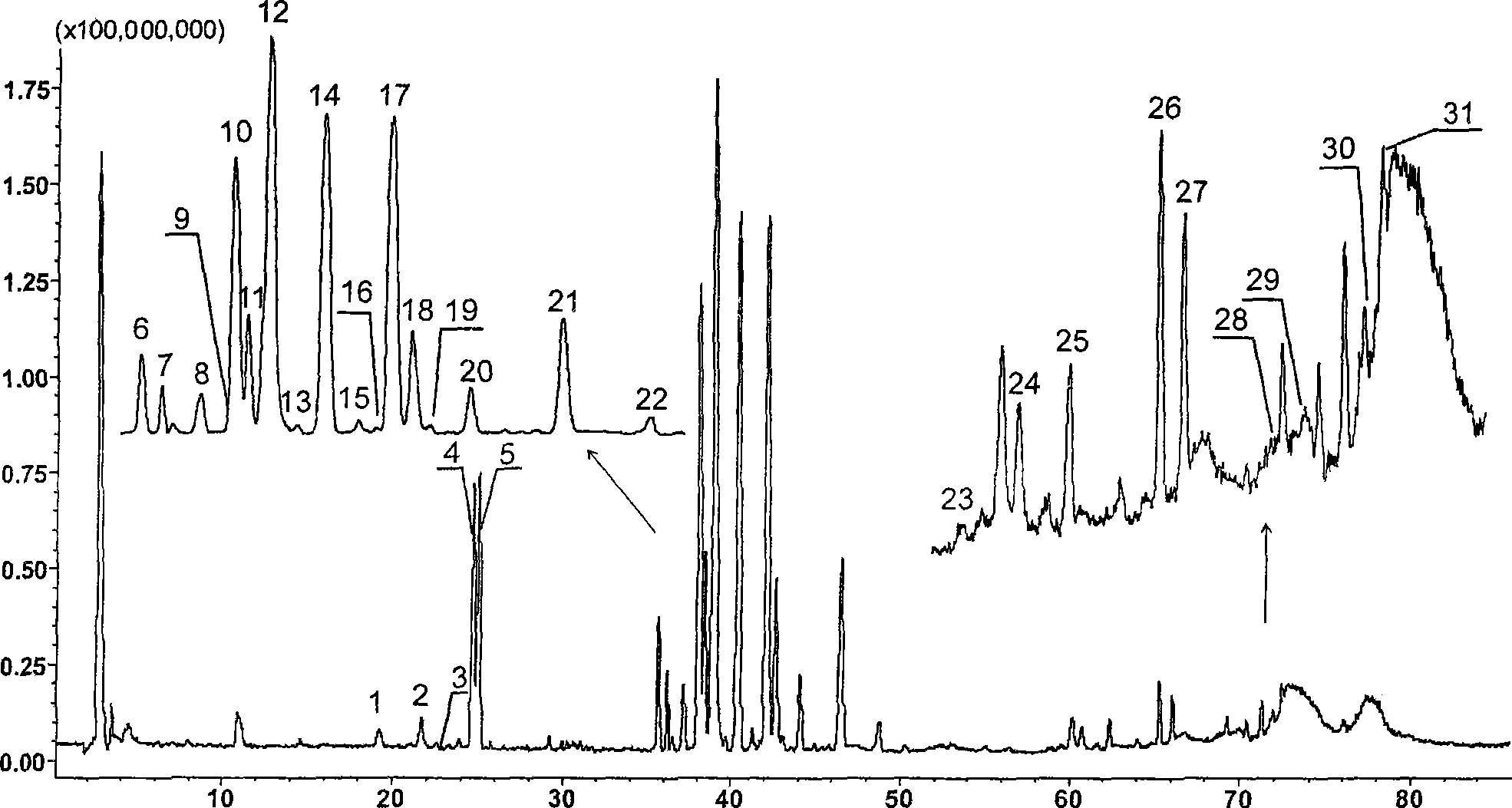

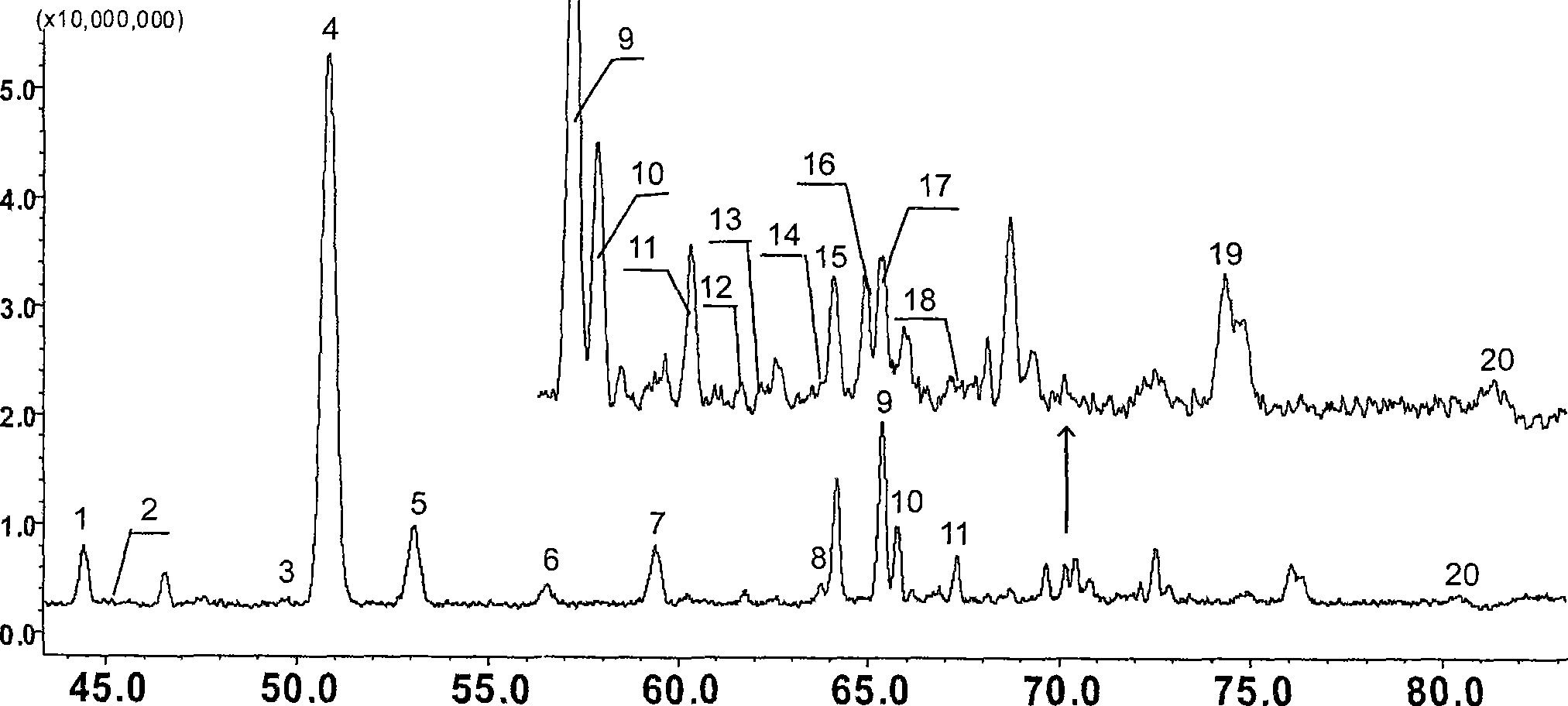

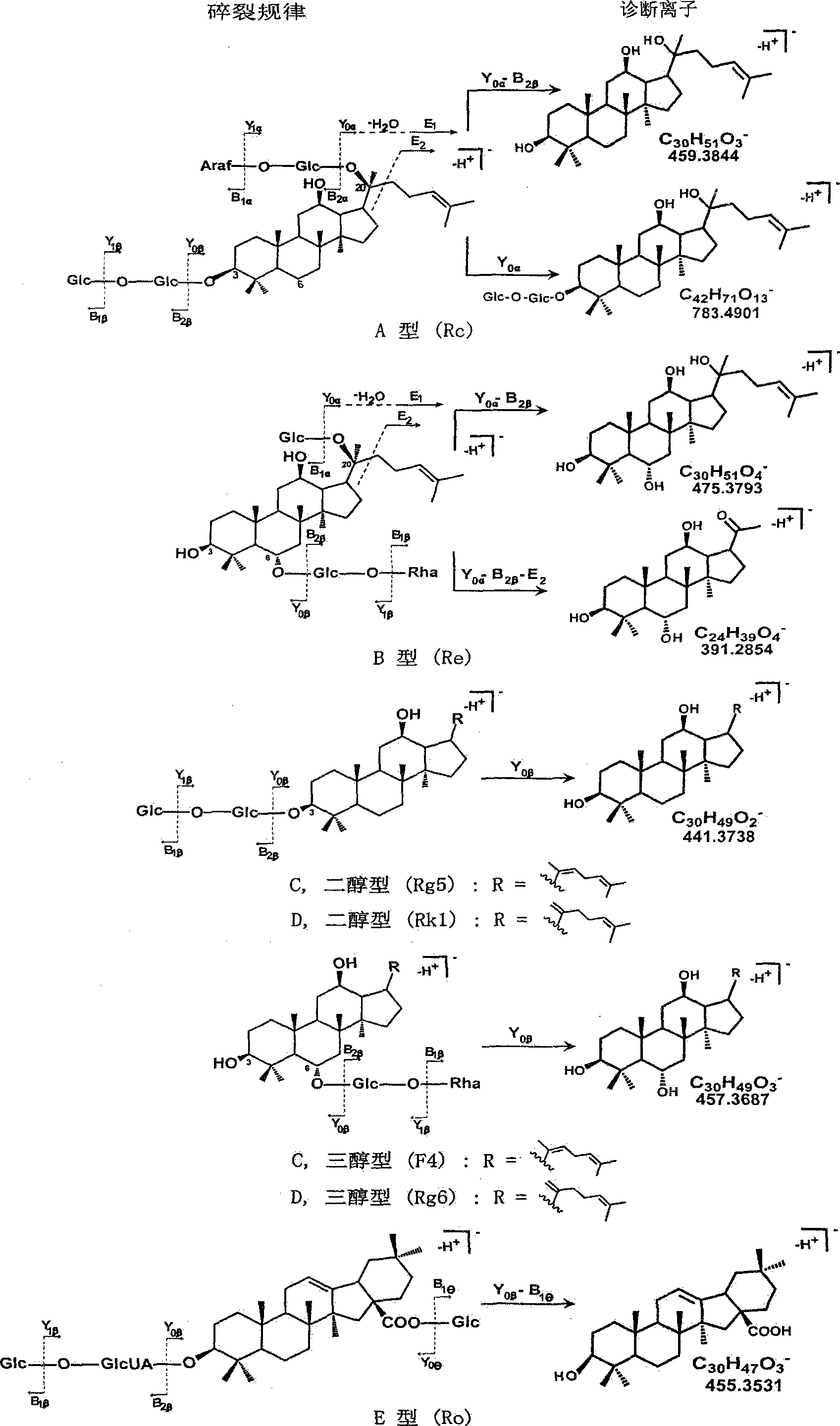

Rapidly screening and identifying method for series components in Chinese traditional medicine complex system

InactiveCN101382525AIn line with the overall roleHigh quality and precisionComponent separationMaterial analysis by electric/magnetic meansTraditional medicineFlight time

The invention relates to the field of traditional Chinese medicine and pharmaceutical analysis, in particular to the component analysis in the traditional Chinese medicine complex system, and provides a universal strategy which can be used for quick screening and identification of series components in the traditional Chinese medicine complex system, the steps are as follows: test solution containing the series components in the traditional Chinese medicine complex system is prepared, the test solution is carried out positive or negative ion full scan by adopting a high-efficiency liquidoid-ion trap-flight time tandom mass spectrometer to obtain a total ion chromatogram and multi-stage fragment information, the quick screening and identification of the series components in the traditional Chinese medicine complex system are carried out by using the diagnosis ion extension strategy. The invention can be applied to the quality control of such traditional Chinese medicine preparations as traditional Chinese medicine injection and the determination of active ingredients in the traditional Chinese medicine complex system.

Owner:CHINA PHARM UNIV

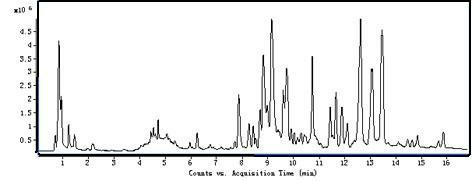

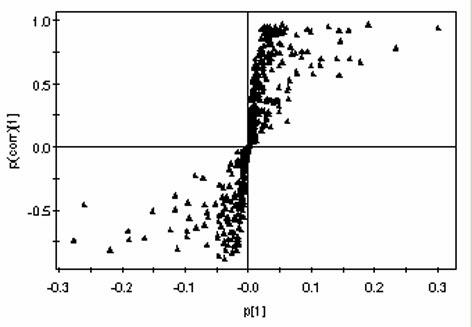

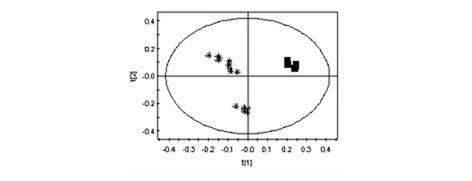

Method for studying metabolic difference of transgenic rice and non-transgenic rice

InactiveCN102478563AThe pre-processing process is simpleImprove reliabilityComponent separationBiotechnologyGenetically modified rice

The invention discloses a method for studying metabolic difference of transgenic rice and non-transgenic rice. The method analyzes rice seed extract with liquid chromatography-mass spectrometry (LC-MS) technology to obtain metabolic profiling of rice, studies integral difference of metabolic profiling data between transgenic rice and non-transgenic rice by multivariate statistics method, and finds out compound with significant contribution to metabolic phenotype difference, to provide a basis for evaluation of unintended effect and safety of transgenic rice. The simple and rapid analysis method with good repeatability is suitable for batch analysis of practical samples.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Production process of large-caliber thin-walled seamless stainless steel pipe

ActiveCN101862763AHigh quality and precisionImprove production accuracyMetal rolling arrangementsSolution treatmentElectric arc furnace

The invention relates to a production process of a large-caliber thin-walled seamless stainless steel pipe, which comprises the following production steps: (a) firstly, preparing 0Cr18Ni10Ti stainless steel pipe bloom made by an arc furnace and electroslag remelting or vacuum induction and electroslag remelting; (b) after pickling and solution treatment, carrying out first cold-rolled processing for the stainless steel pipe bloom to make a coarse steel pipe; (c) after degreasing and solution treatment, carrying out the crude steel pipe by cold-drawing and caliber-enlarging processing for the coarse steel pipe to make a large-caliber steel pipe; (d) after degreasing and solution treatment, carrying out second cold-rolled processing for the stainless steel pipe to make a refined steel pipe;and (e) after degreasing and solution treatment, straightening, pipe cutting, pickling and inspection, the refined steel pipe being made into a large-caliber thin-walled seamless stainless steel pipefinished product. With the process of the invention, the length of the steel pipe can reach or exceed 6000mm, and the steel pipe does not produce twisting and spinning amboss phenomenon and the like.

Owner:常州市联谊特种不锈钢管有限公司

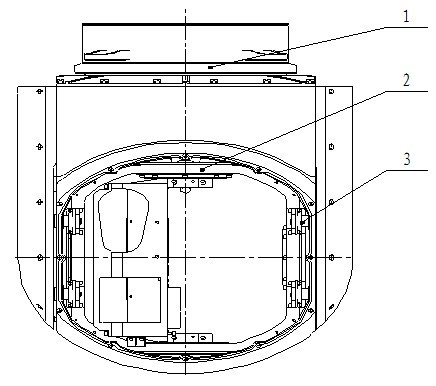

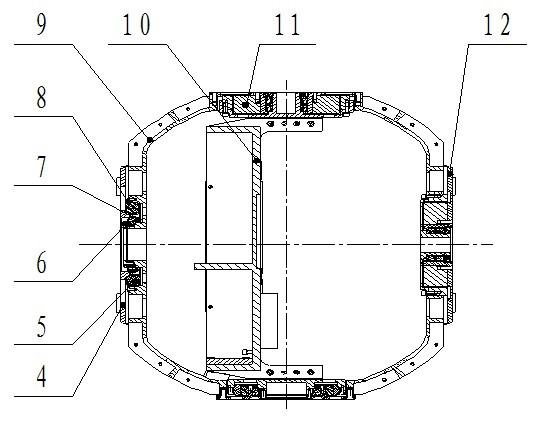

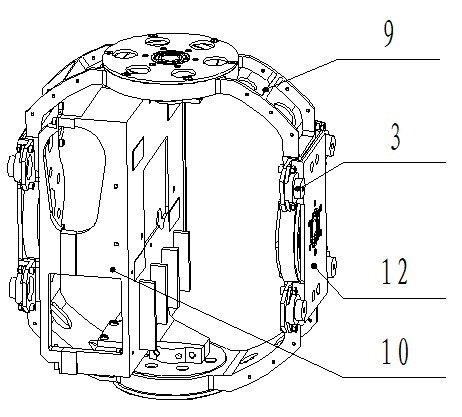

Photoelectric stable platform

InactiveCN102155517AOutstanding FeaturesHighlight significant effectNon-rotating vibration suppressionIsolation effectImaging quality

The invention relates to a photoelectric stable platform, which has a vibration-isolating inner ring and a plurality of frames. The photoelectric stable platform comprises an outer ring frame, an inner ring frame and an even number of vibration isolators of the same specifications, wherein various sensors are placed on the inner ring frame; and the vibration isolators are symmetrically installed relative to the centre of mass of the integration of the inner ring frame in which the various sensors which are installed. The invention has the advantages that: an isolation effect of the photoelectric stable platform on external interference is good; imaging quality and stabilization precision are high; the photoelectric stable platform is small in size, light in weight, large in bearing capacity, and convenient for assembly and disassembly; the weight of the platform can be reduced effectively; the assembly of the photoelectric stable platform can be adjusted quickly and conveniently according to requirements; and the photoelectric stable platform is characterized by simple structure, wide application range and the like.

Owner:武汉华中天经通视科技有限公司

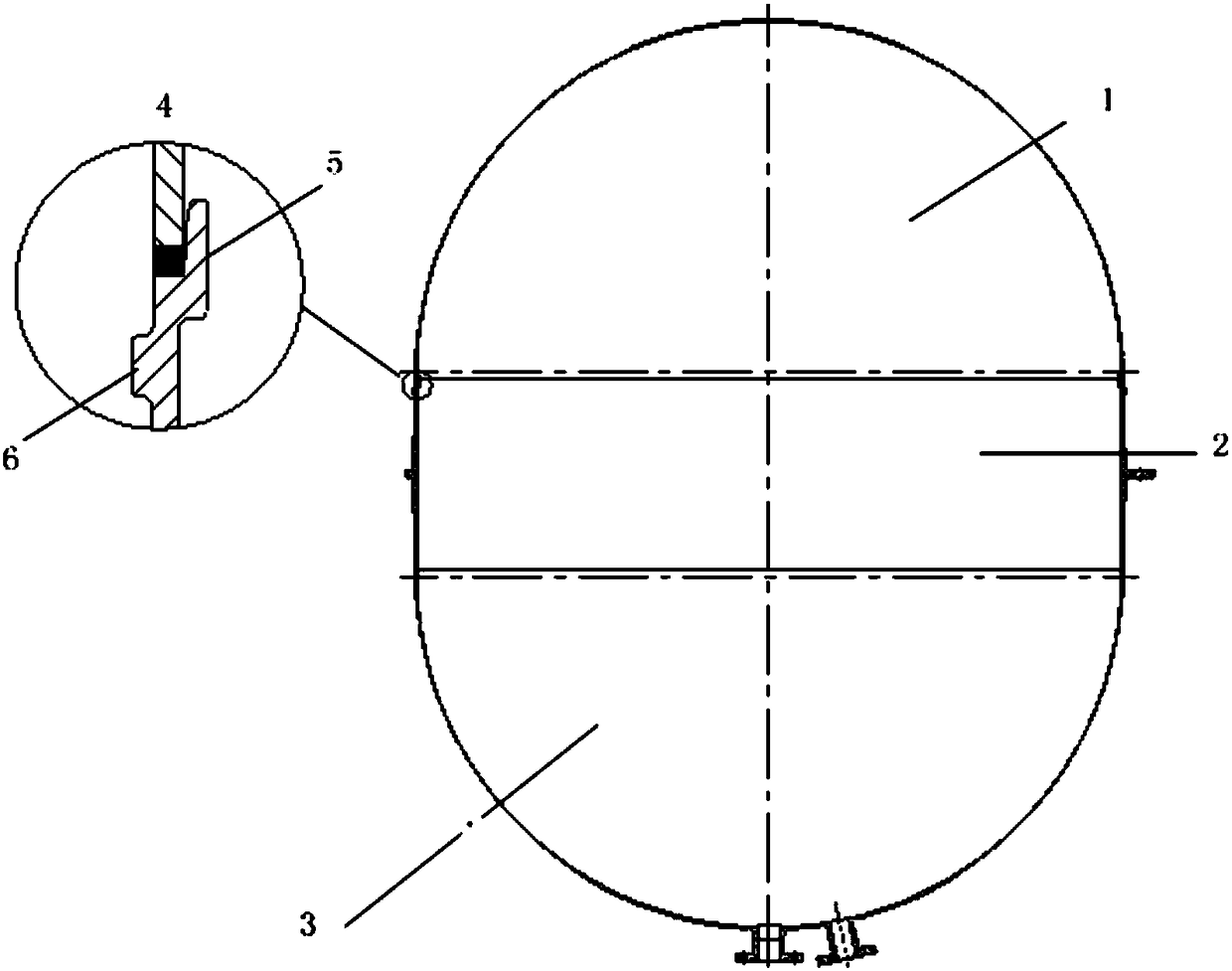

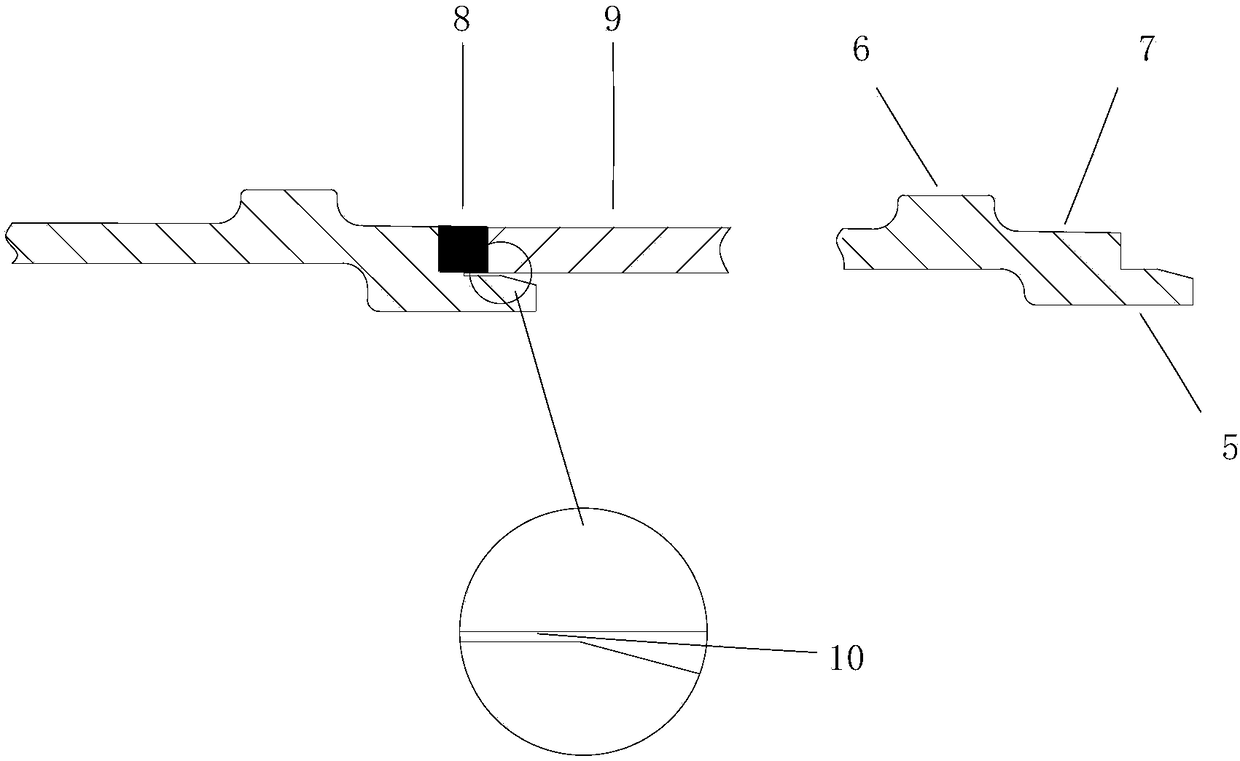

All-welded ultra thin-walled storage tank and welding structure suitable for all welding

InactiveCN108488006AIncrease stiffnessImprove welding qualityCosmonautic vehiclesCosmonautic propulsion system apparatusMechanical engineeringElectron bunches

The invention discloses an all-welded ultra thin-walled storage tank and a welding structure suitable for all welding. The all-welded ultra thin-walled storage tank comprises a front bottom (1), a cylinder segment (2) and a rear bottom (3). The welding structure comprises a lock bottom (5), a reinforcing boss (6) and a middle connection structure (7). The welding structure is connected with the cylinder segment (2) through the middle connection structure (7). The front bottom (1) comprises a front bottom welding edge (9) or the rear bottom (3) comprises a rear bottom welding edge (9). The welding edge (9) and the middle connection structure (7) are connected through electron beam welding. According to the all-welded ultra thin-walled storage tank and the welding structure suitable for allwelding, the technical effects that the welding process is simplified, the welding quality is improved, the sealing level reaches the limit and the storage box wall is ultra thin are achieved, and thetechnical purpose of designing the storage box with the leak rate reaches the limit is achieved.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

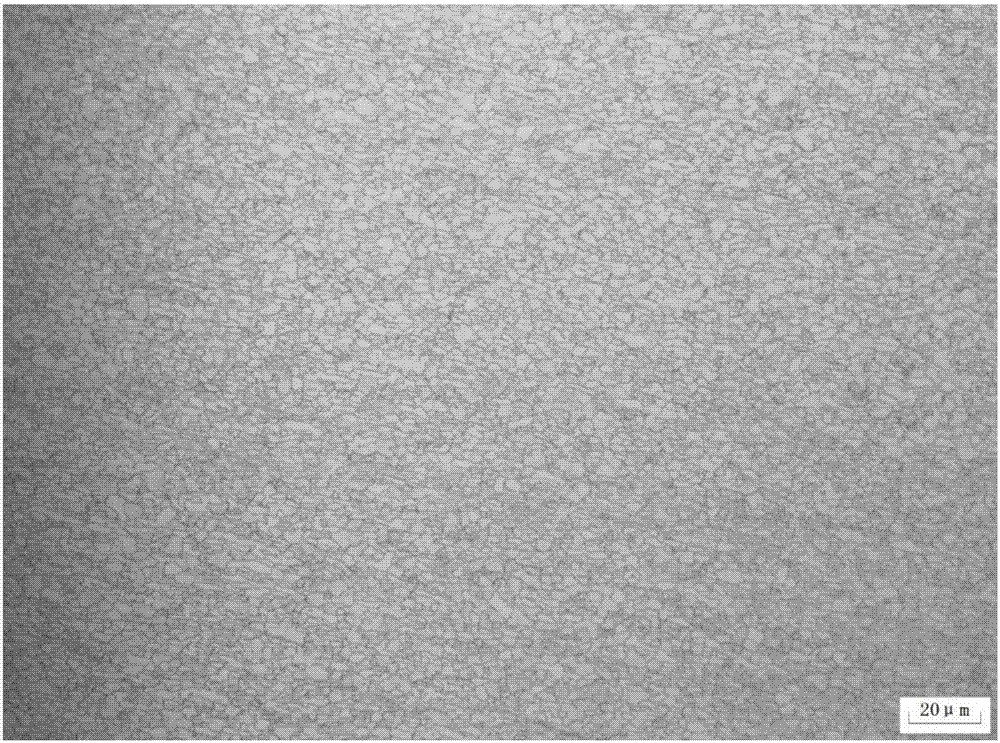

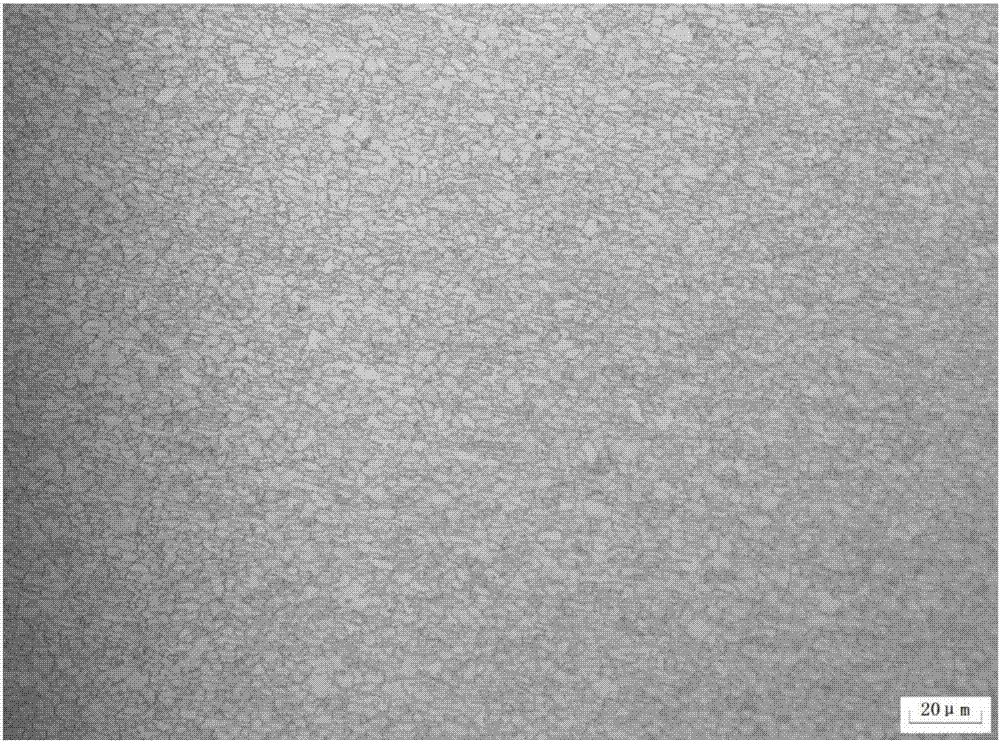

Processing method of SP700 titanium alloy sheet for superplastic forming

ActiveCN106955893AImprove consistencyImprove stabilityForging/pressing devicesMetal rolling arrangementsBeta phaseWater cooling

The invention belongs to the technical field of processing of titanium alloy materials, and relates to a processing method of an SP700 titanium alloy sheet for superplastic forming. The processing method comprises step I, carrying out heating number casting around a beta phase transformation point, and carrying out water cooling to obtain an intermediate billet; step II, carrying out first hot rolling, so as to obtain a first hot rolled plate blank; step III, carrying out second hot rolling, so as to obtain a second hot rolled plate blank; step IV, carrying out intermediate annealing treatment; step V, carrying out cold rolling, so as to obtain a hot rolled plate blank; and step VI, carrying out annealing treatment on a finished product, so as to obtain the SP700 titanium alloy sheet of which the thickness is 0.5 mm to 1.2 mm. According to the processing method, operation is simple, the technology is stable and controllable, and the prepared SP700 titanium alloy sheet is uniform in structure, fine in grains and good in performance consistency, and meets the relative technological requirement of superplastic forming.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Stainless steel water meter shell and machining method thereof

InactiveCN103170579AHigh strengthHigh temperature strengthFoundry mouldsVolume meteringPalygorskiteN-Butyl Alcohol

The invention relates to a stainless steel water meter shell which is cast by using a lost foam process. The fireproof paint of the lost foam comprises 15 parts of zirconite powder, 15 parts of ferrochromium powder, 12 parts of pyrophillite powder, 10 parts of bauxite, 5 parts of magnesium powder, 5 parts of limestone powder, 4 parts of brown emery powder, 1 part of white emery powder, 2.5 parts of lithium-base bentonite, 2 parts of carboxymethyl cellulose, 1 part of palygorskite, 2 parts of sodium silicate, 2 parts of aluminum sulfate, 1.5 parts of VAE (Vinyl Acetateethylene Emulsion), 0.6 part of n-butyl alcohol, 0.2 part of n-caprylic alcohol and 25 parts of water; an energy converter intubation tube with internal and external threads is arranged inside an inclined tube of the water meter shell; and after being inserted, an energy converter is not directly contacted with a water fluid, so that the service life of the energy converter is prolonged and the stainless steel water meter shell has a wide application prospect.

Owner:南通北外滩建设工程有限公司

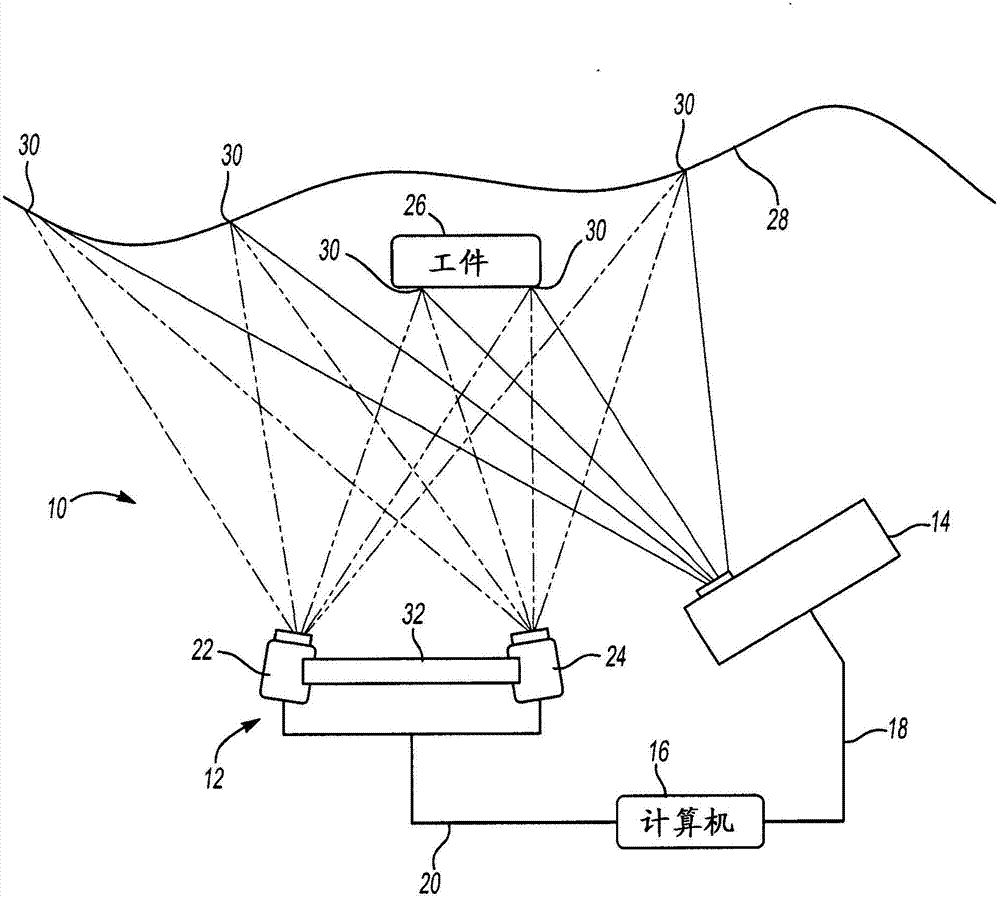

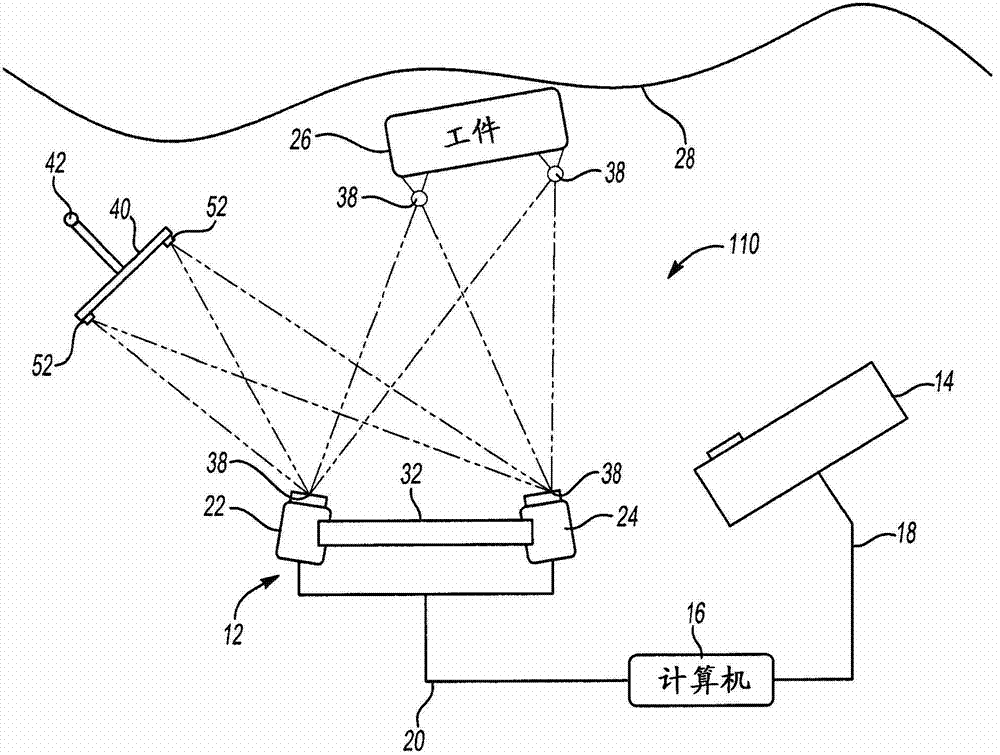

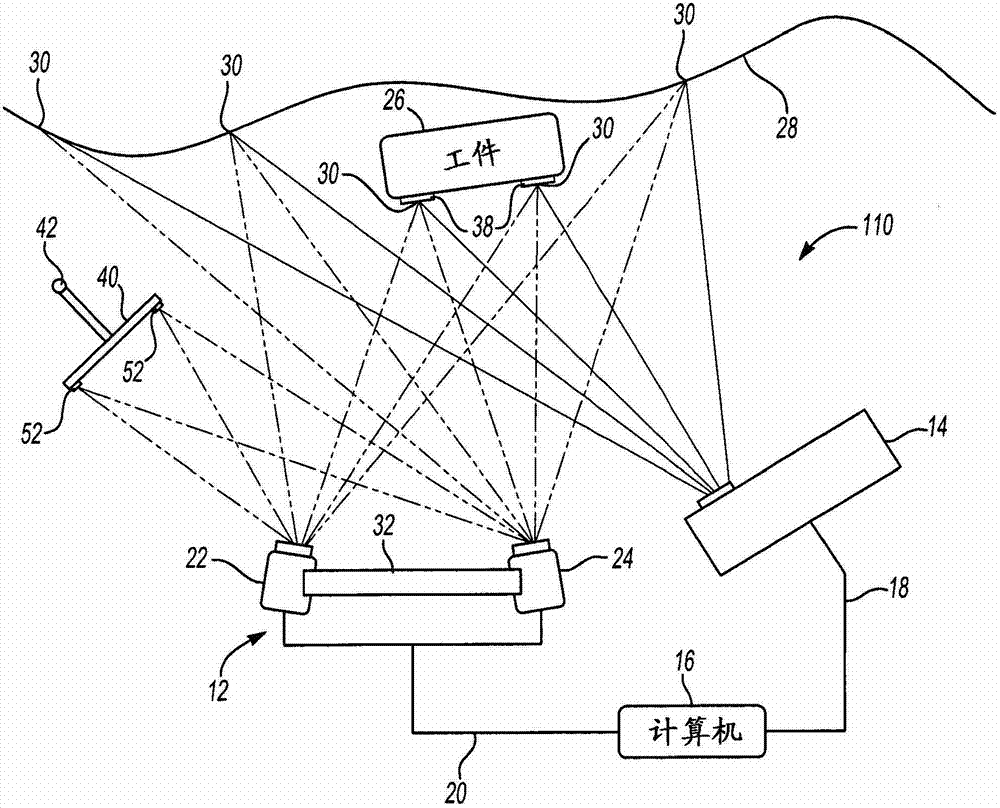

Laser projection system and method

ActiveCN103322943ALow costHigh quality and precisionImage enhancementImage analysisLaser projectorLaser projection

A laser projection system for projecting an image on a workpiece includes a photogrammetry assembly and a laser projector, each communicating with a computer. The photogrammetry assembly includes a first camera for scanning the workpiece, and the laser projector projects a laser image to arbitrary locations. Light is conveyed from the direction of the workpiece to the photogrammetry assembly. The photogrammetry assembly signals the coordinates light conveyed toward the photogrammetry assembly to the computer with the computer being programmable for determining a geometric location of the laser image. The computer establishes a geometric correlation between the photogrammetry assembly, the laser projector, and the workpiece for realigning the laser image to a corrected geometric location relative to the workpiece.

Owner:VIRTEK VISION INT ULC

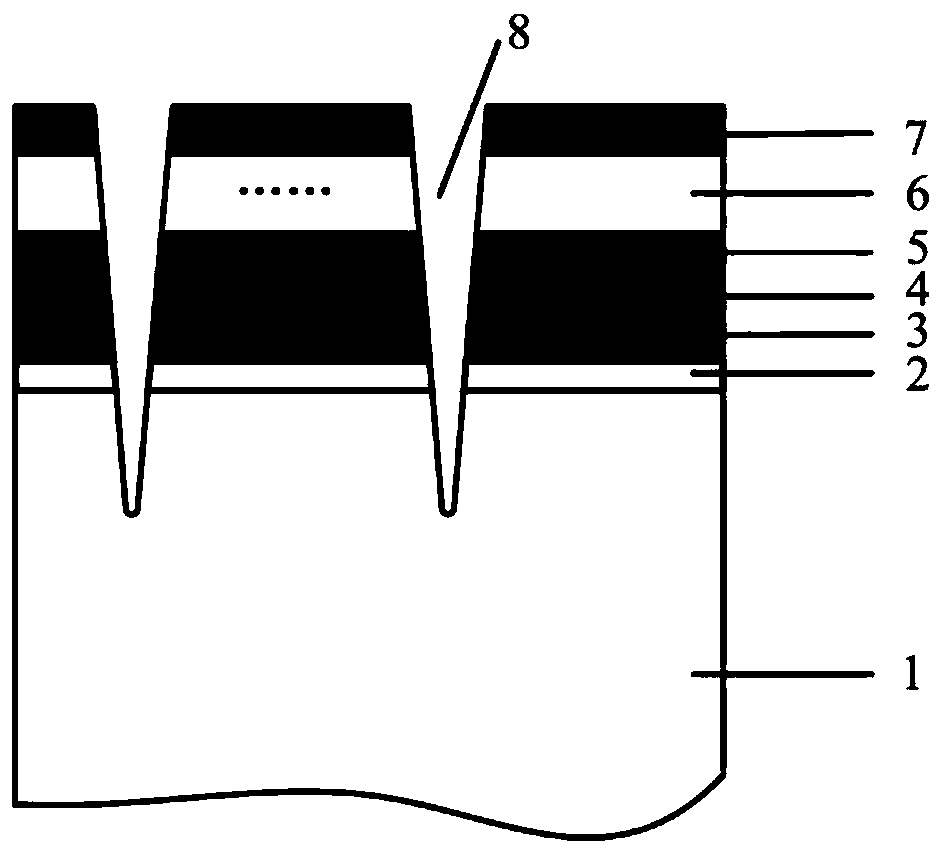

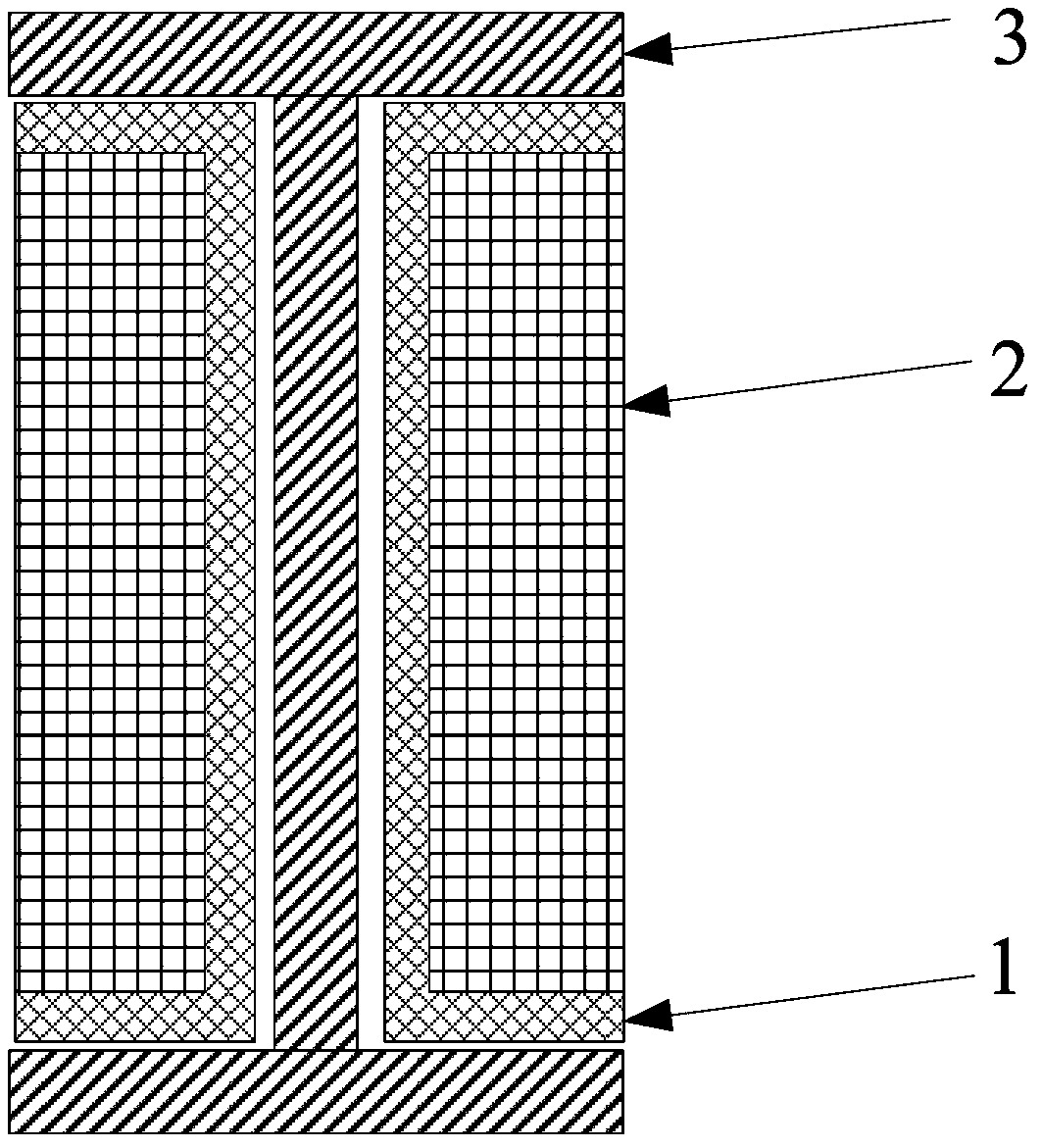

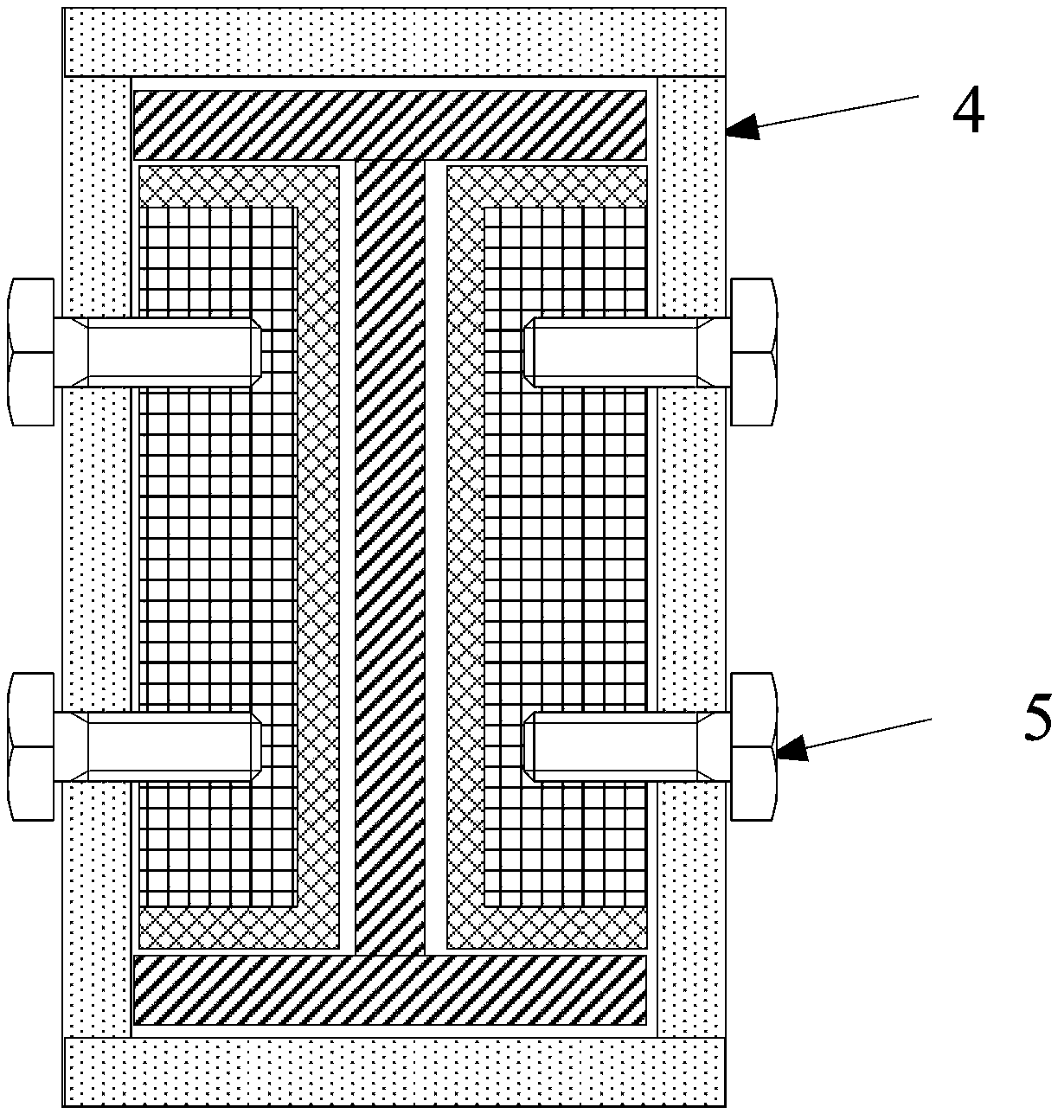

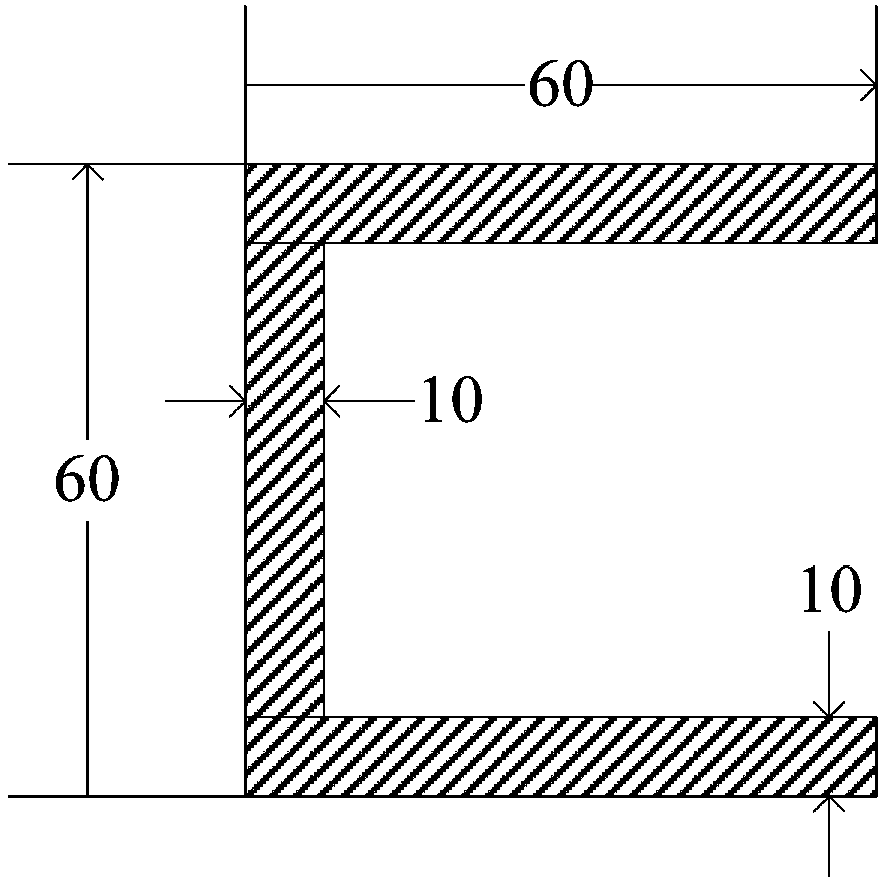

Combined die and its application in molding composite material structure member

The invention relates to a combined die and its application in molding a composite material structure member, and belongs to the technical field of composite material molding. The combined die comprises silicon rubber (1), a metal core (2), a closed metal female die (4) and a connecting piece (5); the closed metal female die (4) is positioned outside a product for molding (3); and the closed metal female die (4) is fixedly connected with the metal core (2) through the connecting piece (5). The product molded through using the silicon rubber / metal core combined flexible die has an obvious better appearance than products molded through complete silicon rubber flexible dies; and the product having an appearance quality and an internal quality which satisfy requirements is obtained through adjusting the volume ratio of the silicon rubber flexible die to the metal core. The adjustment of the ratio of the volume of the silicon rubber flexible die to the volume of the metal core is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

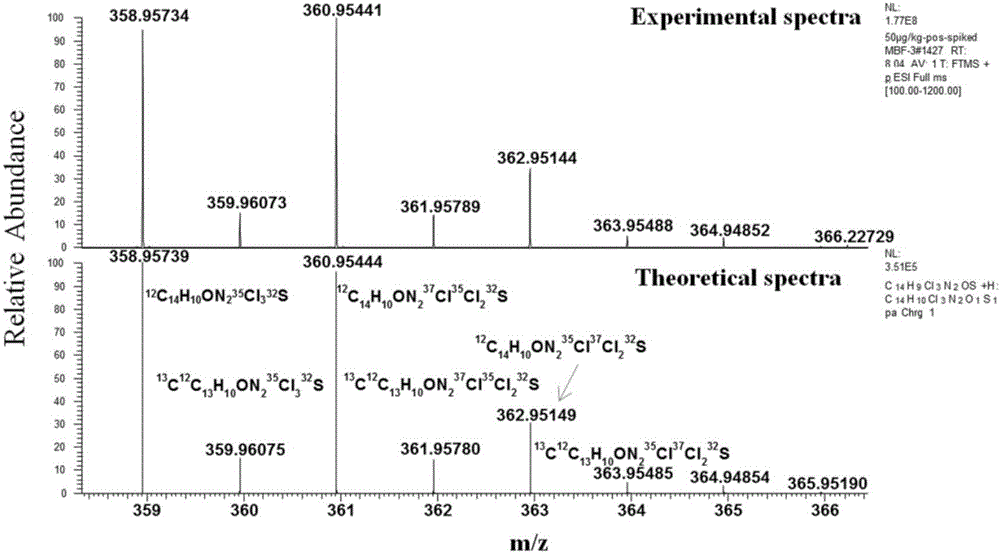

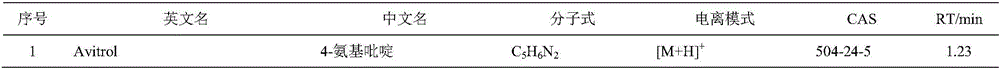

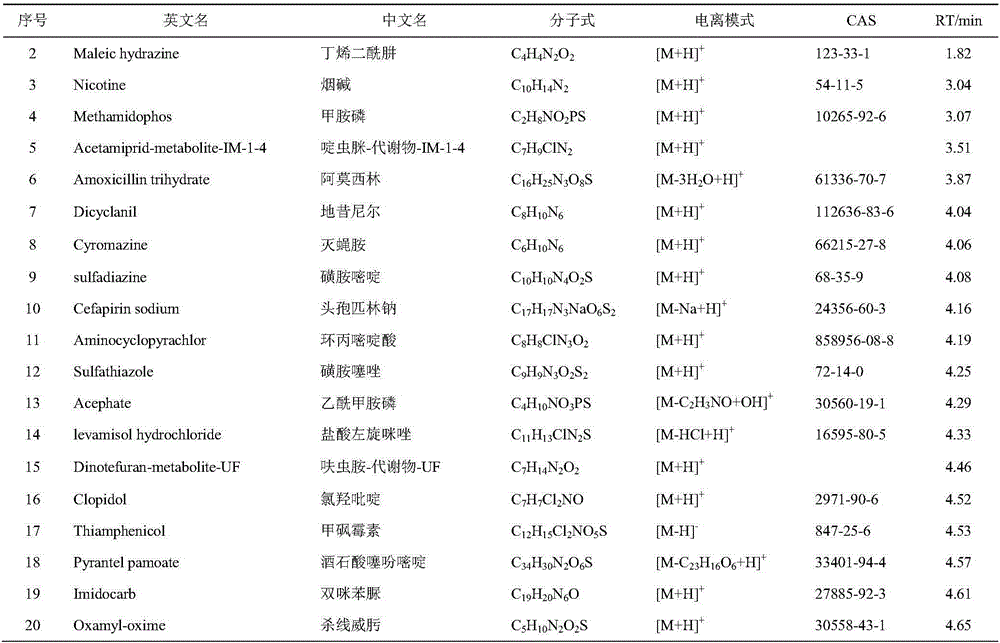

Method for screening pesticide and veterinary drugs in infant formula food by ultra-high performance liquid chromatography-quadrupole static electric field track ion trap mass spectrum

The invention discloses a method for screening pesticide and veterinary drugs in infant formula food by ultra-high performance liquid chromatography-quadrupole static electric field track ion trap mass spectrum, and belongs to the technical field of food safety inspection. The method comprises the following steps: preprocessing a sample by an optimized QuEChERS method; screening by applying ultra-high performance liquid chromatography-quadrupole static electric field track ion trap mass spectrum; selecting a positive ion or negative ion mode for scanning by adopting full-scan / data dependence acquisition, full-scan / variable data independence acquisition and full-scanning / full-ionic acquisition fragmentation acquisition scan modes to obtain complete primary and secondary maps; and processing the primary and secondary maps by applying Exact Finder 2.5 software to extract compound information. According to the method, information in the established spectrum library is compared with the screening result of a to-be inspected object so as to ensure the composition of pesticide and veterinary drugs in an infant formula food. The mass spectrum instrument used in the method has the main advantages of high resolution ratio, accurate qualitative and quantitative results, high sensitivity, high quality precision and the like. The method can be applied to analysis of complex substrates.

Owner:SHAANXI UNIV OF SCI & TECH

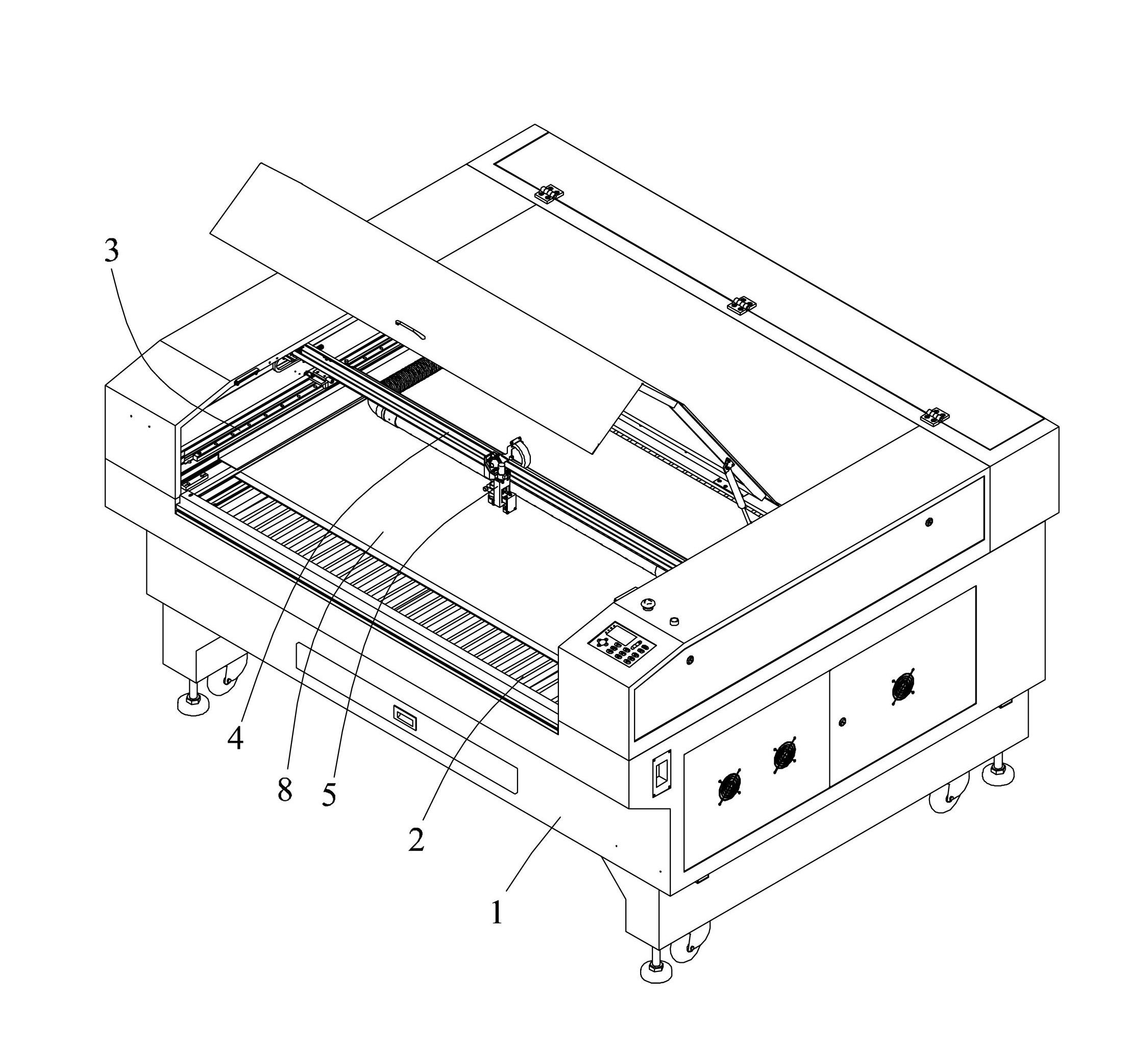

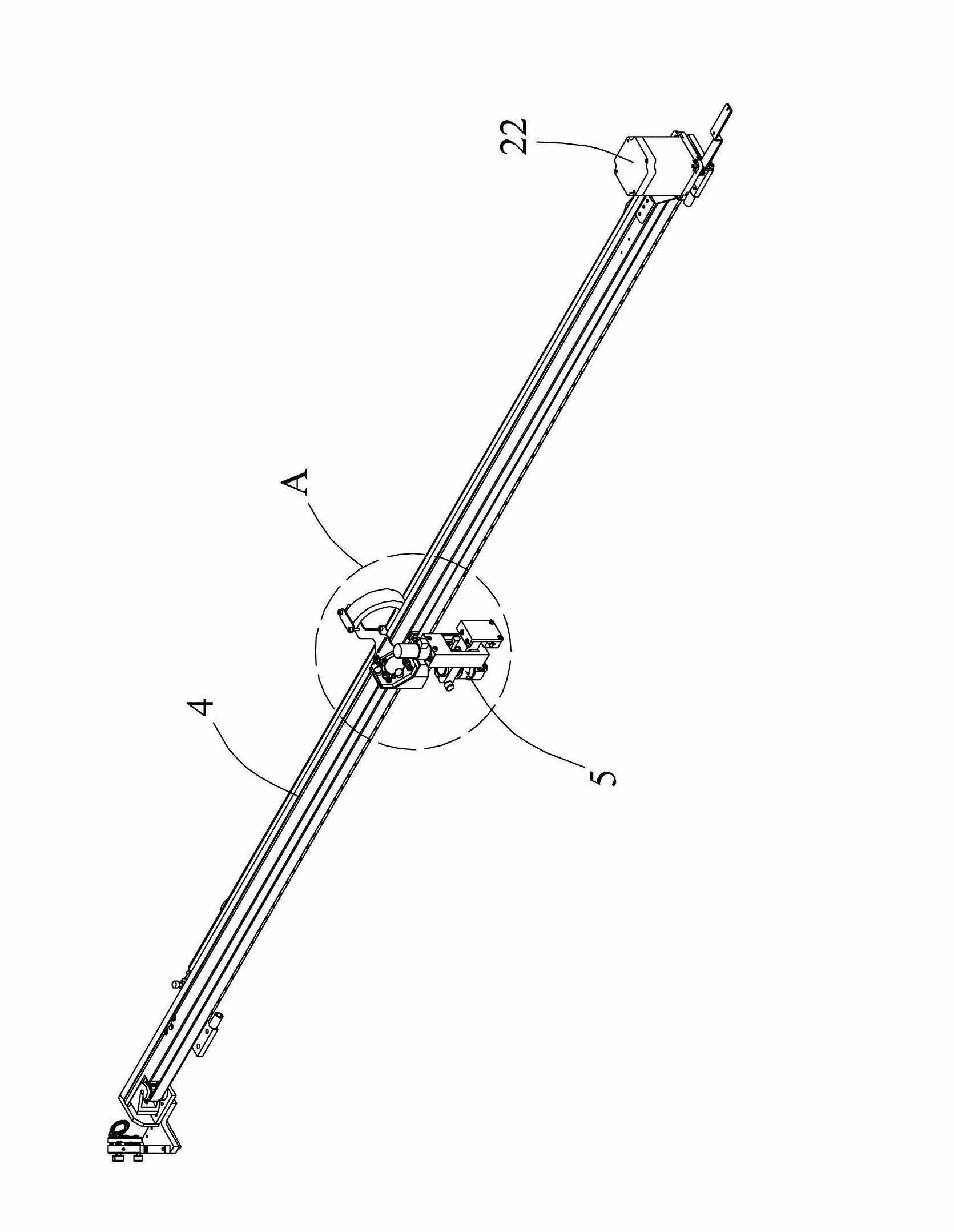

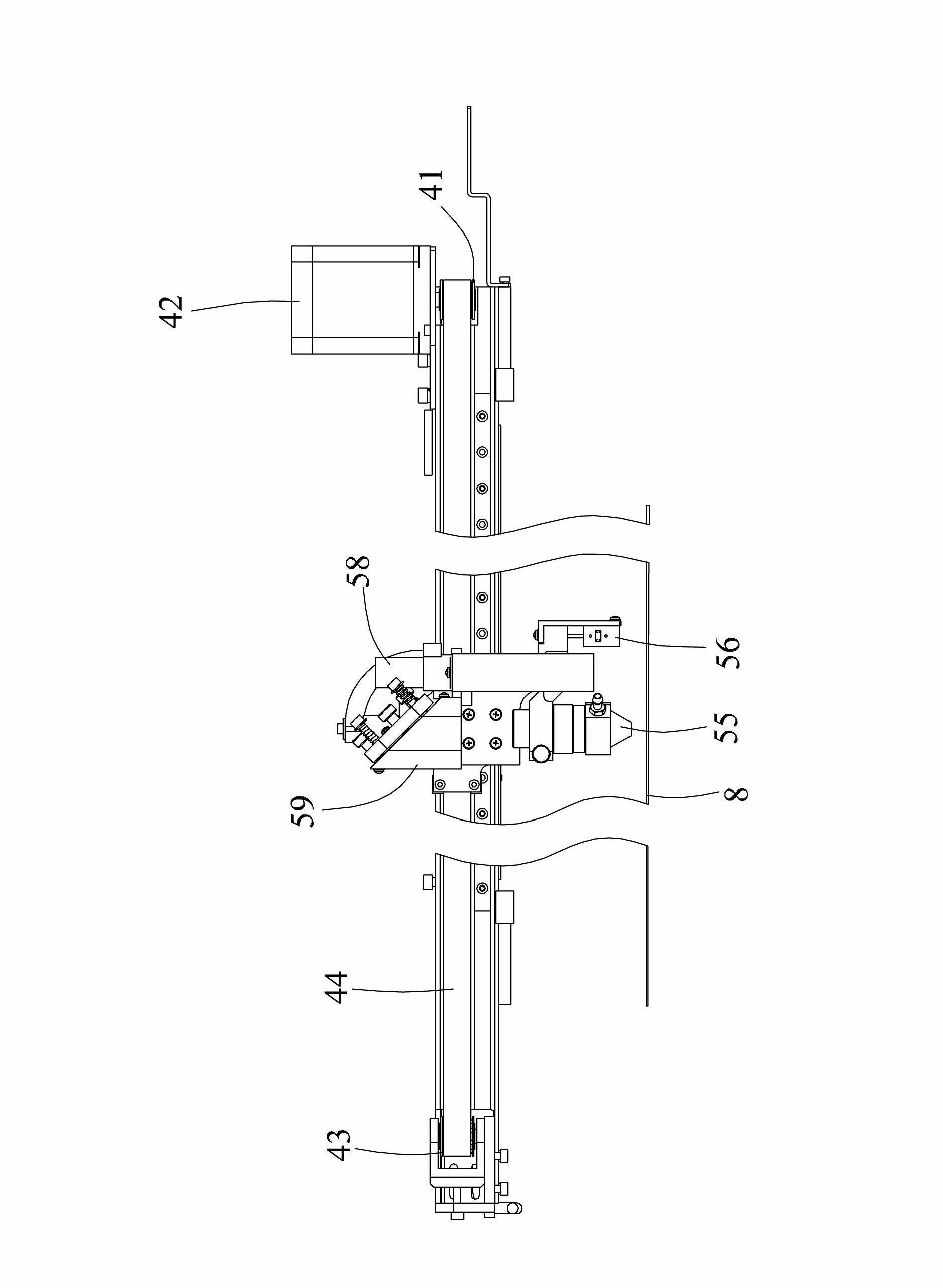

Laser machining equipment

ActiveCN102649198AFast processingEasy to operateLaser beam welding apparatusEngineeringLaser cutting

The invention relates to laser machining equipment which comprises a frame, an operating platform, a pair of guide rail beams, a beam and a laser cutting head. The operating platform is arranged on the frame; the pair of the guide rail beams are respectively arranged on left and right sides of the operating platform; two ends of the beam are respectively installed on the pair of the guide rail beams and can move forward and rearward along the pair of the guide rail beams; the laser cutting head is installed on the beam and can move leftward and rightward along the beam; the laser cutting head is provided with a linear motor, so as to drive a focusing tube to move longitudinally along the vertical direction; and a focal length sensor is also provided, so as to realize the automatic switching of automatic focusing, dynamic defocusing carving and sharp focus cutting during machining. The laser machining equipment can realize automatic focusing and defocusing, is suitable for performing rapid machining on light guide plates, and is convenient to operate.

Owner:GUANGDONG HANS YUEMING LASER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com