Processing method of SP700 titanium alloy sheet for superplastic forming

A technology of superplastic forming and processing methods, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increased workload such as shaping, grinding, and cutting, affecting the shape, size and surface quality of plates, and poor thermal conductivity. , to achieve the effect of reducing the requirements of on-site process operation and rolling equipment, easy control of deformation and shape, and improving consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

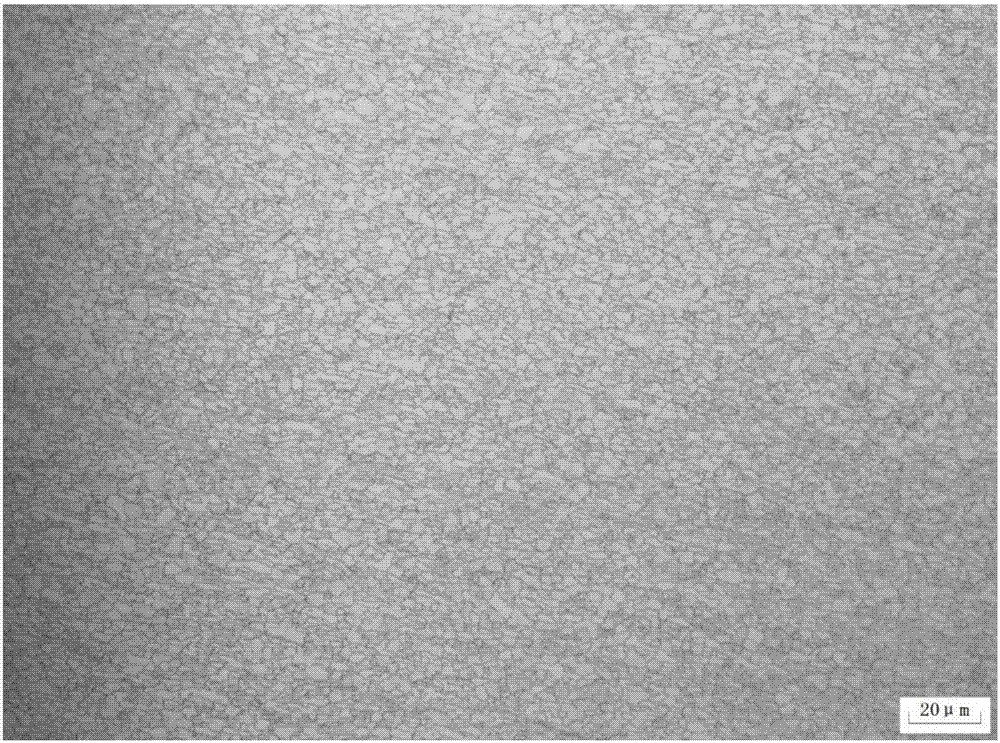

Embodiment 1

[0039] Present embodiment is the processing method of SP700 titanium alloy sheet for superplastic forming of thickness 0.5mm, comprises the following steps:

[0040] Step 1. The qualified SP700 titanium alloy slab is subjected to primary forging near the transformation point under the condition that the initial forging temperature is 10°C above the β transformation point and the final forging temperature is not lower than 15°C below the β transformation point. Forging, then immersing in water to quickly cool to room temperature, and surface grinding to obtain an intermediate slab with a thickness of 20mm.

[0041] Step 2: heat the intermediate slab described in step 1 at 65°C below the β transformation point for 15 minutes, and then carry out 5 passes of first hot rolling, keeping the rolling direction of the first hot rolling as unidirectional rolling, each pass The secondary deformations are respectively: 20%, 30%, 35%, 25%, 20.5%. After air cooling to room temperature, surf...

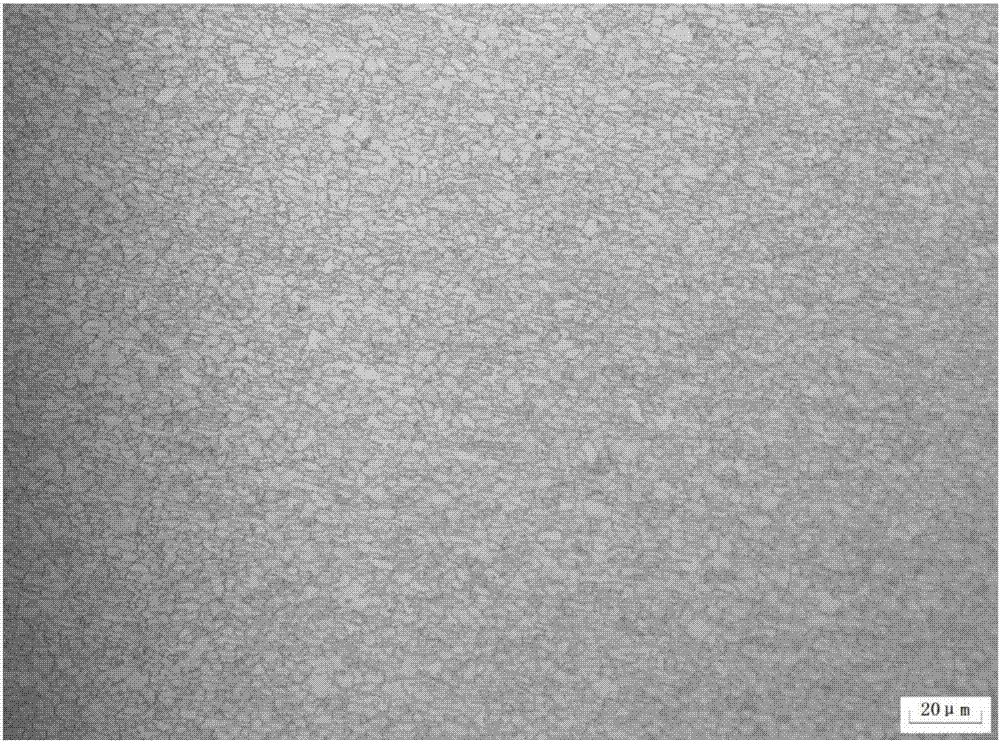

Embodiment 2

[0048] Present embodiment is the processing method of SP700 titanium alloy sheet for superplastic forming of thickness 0.8mm, comprises the following steps:

[0049] Step 1. The qualified SP700 titanium alloy slab is subjected to primary forging near the transformation point under the condition that the initial forging temperature is 20°C above the β transformation point and the final forging temperature is not lower than 15°C below the β transformation point. Forging, then immersing in water to quickly cool to room temperature, and surface grinding to obtain an intermediate slab with a thickness of 30 mm.

[0050] Step 2: heat the intermediate slab described in step 1 at 90°C below the β transformation point for 35 minutes, and then perform 7 passes of the first hot rolling, keeping the rolling direction of the first hot rolling as unidirectional rolling, each pass The secondary deformations are respectively: 22%, 35%, 28.5%, 24%, 21%, 20.5%, 16%. After air cooling to room te...

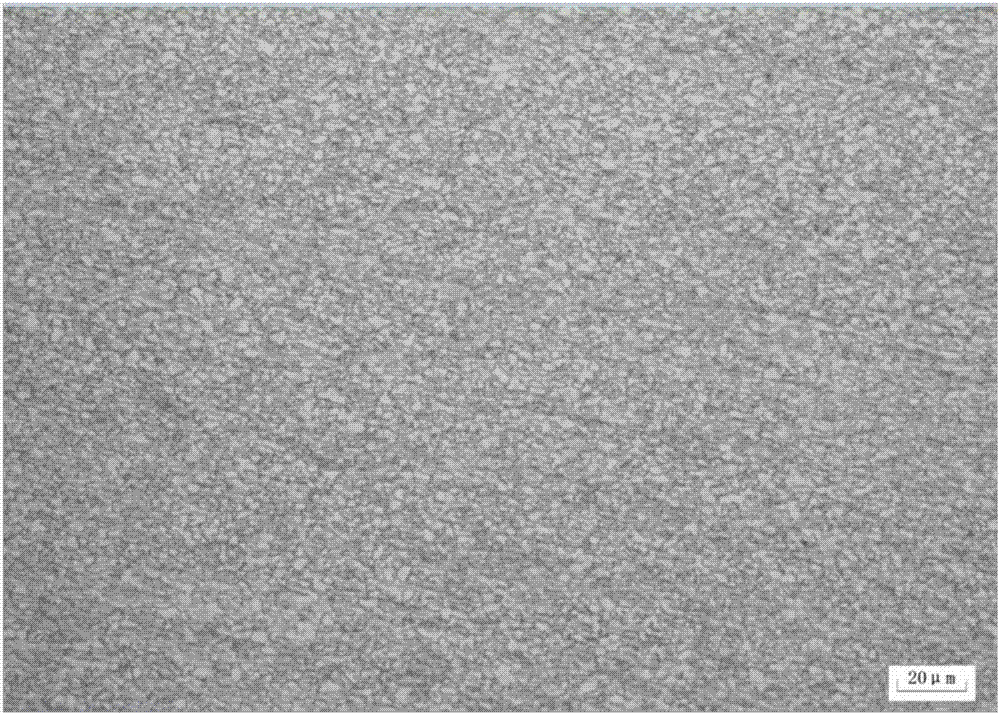

Embodiment 3

[0057] Present embodiment is the processing method of SP700 titanium alloy sheet for superplastic forming of thickness 1.0mm, comprises the following steps:

[0058] Step 1. The qualified SP700 titanium alloy slab is subjected to primary forging near the transformation point under the condition that the initial forging temperature is 15°C above the β transformation point and the final forging temperature is not lower than 15°C below the β transformation point. Forging, then immersing in water to quickly cool to room temperature, and surface grinding to obtain an intermediate slab with a thickness of 40 mm.

[0059] Step 2, heat the intermediate slab described in step 1 at 80°C below the β transformation point for 45 minutes, and then perform 6 passes of first hot rolling, keeping the rolling direction of the first hot rolling as unidirectional rolling, each pass The secondary deformations are respectively: 27%, 35%, 32%, 26.5%, 21.5%, 16%. After air cooling to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com