Method for forming thin-walled parts through stamping and drawing

A technology for stamping stretched and thin-walled parts, which is applied in the field of stamping and forming. It can solve the problems that affect the smooth production, take a long time for equipment, and poor surface quality, so as to optimize the mold and process design, reduce mold costs, surface quality and Effect of improved dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

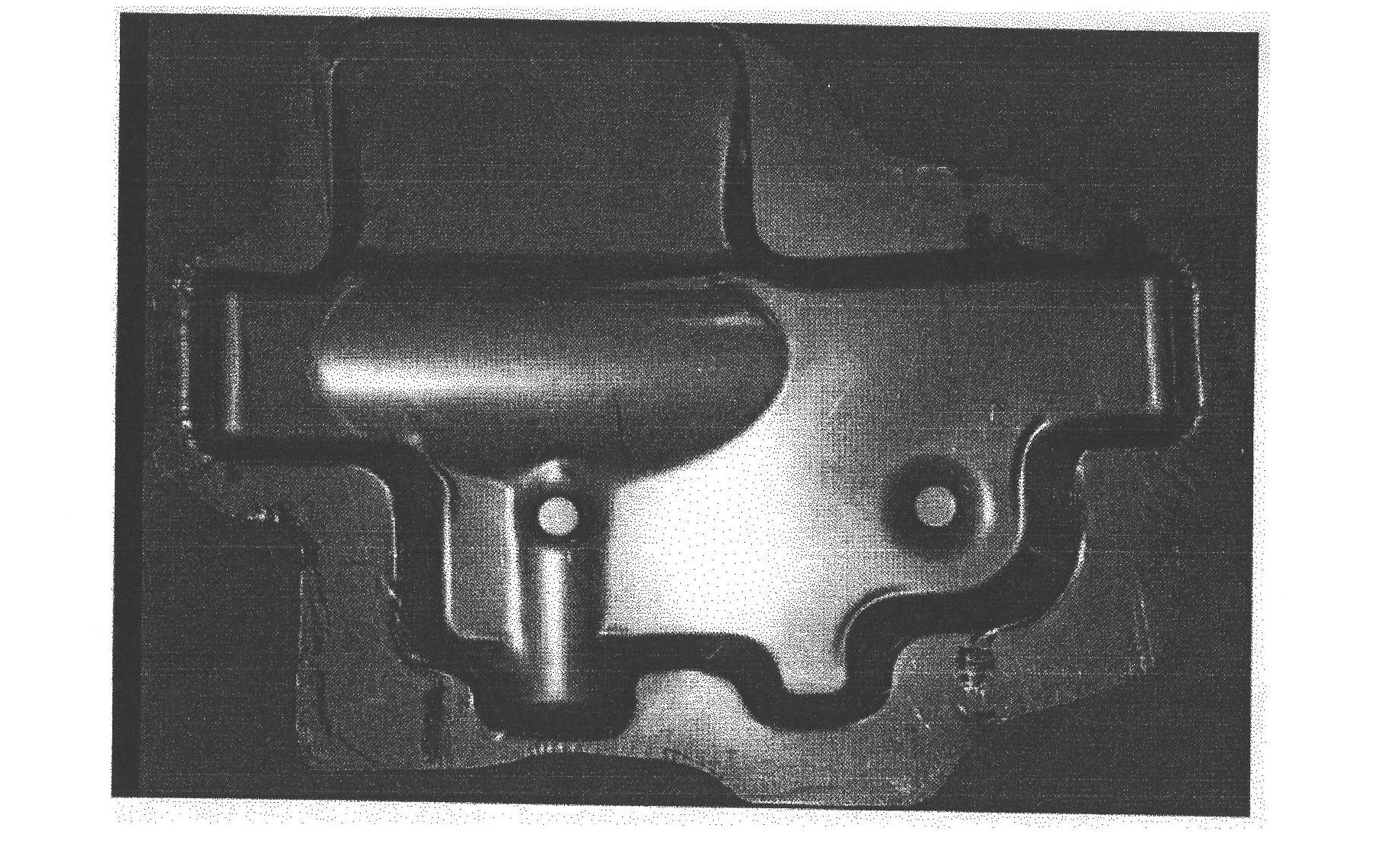

[0130] A stamping and stretching forming method for thin-walled parts. The stamping and stretching forming method for thin-walled parts is specifically aimed at raw materials with a thickness of 0.5mm, and requires that the thickness be reduced to 0.35-0.5mm of the original thickness;

[0131] The stamping and stretching forming method for thin-walled parts specifically uses 1Gr18Ni9Ti plate as raw material, the required anti-expansion pressure of the part is 2-3 MPa, the optimal working pressure of the liquid chamber is 10 MPa, and the most reasonable blank-holding gap is 0.55-0.61 mm.

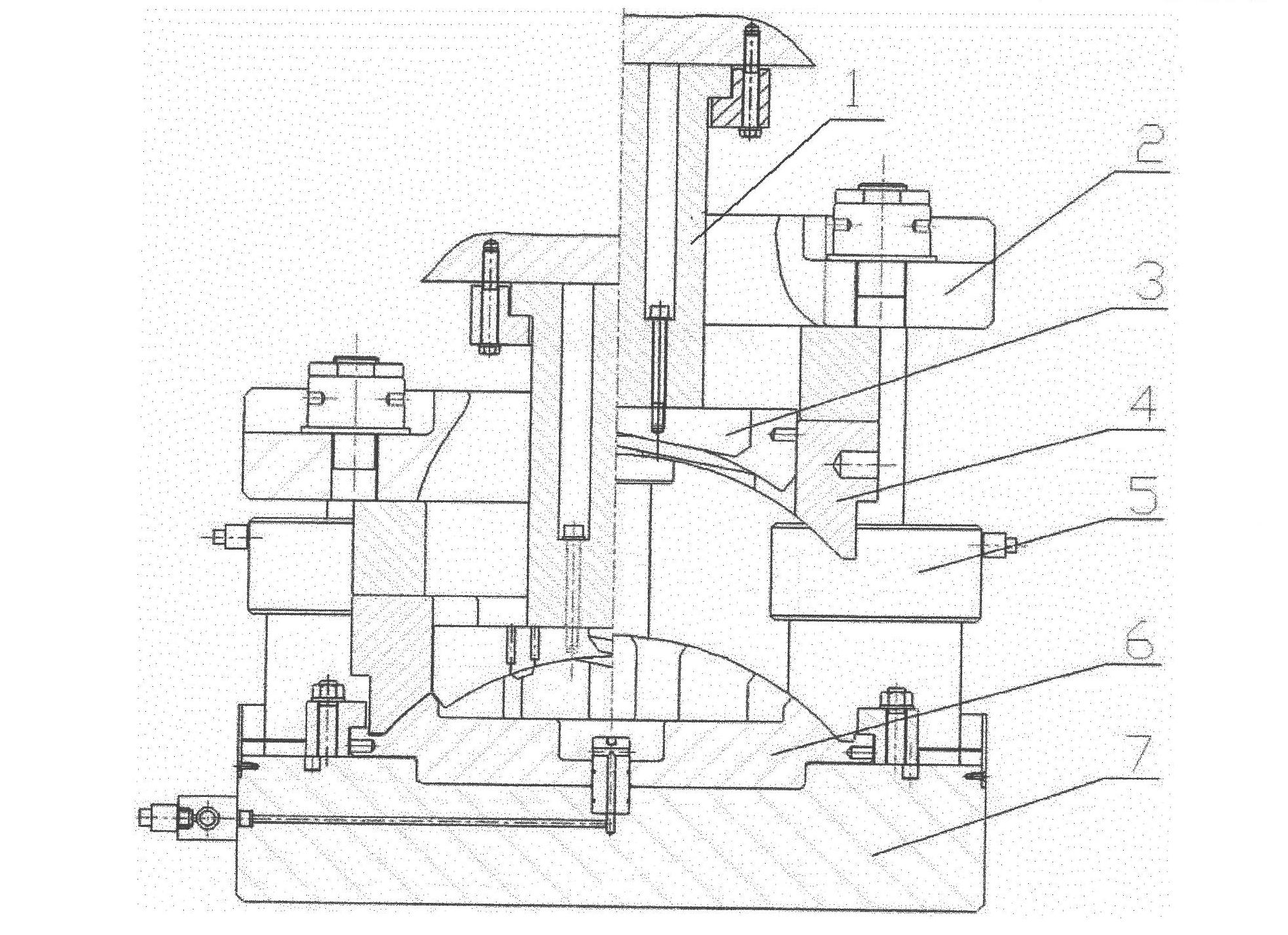

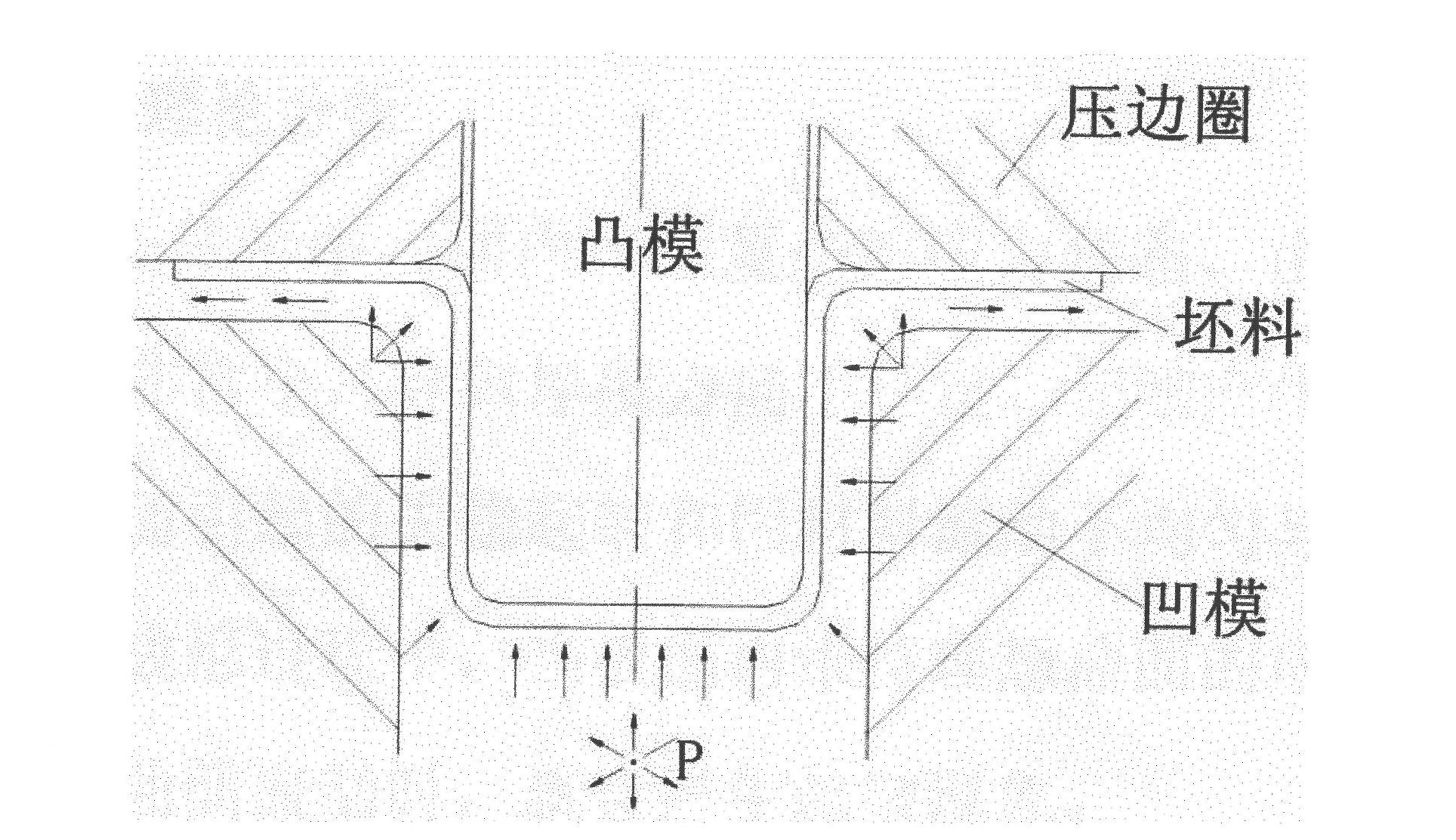

[0132] The stamping and stretching forming method of thin-walled parts is as follows: using flexible forming technology, with the aid of concave-convex molds and hydraulic presses; requiring separate application of hydraulic pressure control on the upper and lower blank holders and concave / convex dies; The nominal pressure requirement of the main hydraulic cylinder on the punch is 3500KN, the ...

Embodiment 2

[0146] The invention provides a stamping and stretching forming method for thin-walled parts. The stamping and stretching forming method for thin-walled parts is specifically aimed at raw materials with a thickness of 0.4 to 2 mm, and it is required to reduce the thickness to 50 to 100% of the original thickness; raw material requirements It is one of the following types: magnesium alloy, aluminum alloy, titanium alloy, superalloy, and other complex structure tailor-welded blanks;

[0147]The stamping and stretching forming method of thin-walled parts is as follows: using flexible forming technology, with the aid of concave-convex molds and hydraulic presses; requiring separate application of hydraulic pressure control on the upper and lower blank holders and concave / convex dies; The nominal pressure of the main hydraulic cylinder on the punch is required to be 25000-4500KN, and the nominal pressure of the edge hydraulic cylinder is required to be 50-67% of the nominal pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com