Star wheel bobbin rotary disc

A rotary disk and star wheel type technology, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient replacement of the coil paper, and achieves a product that is not easy to accumulate dust, has good splicing stability and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

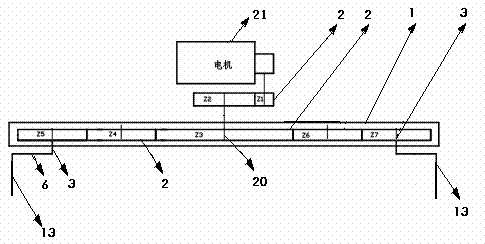

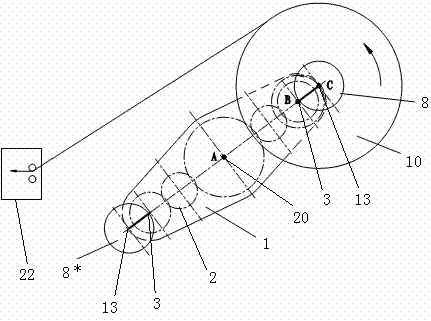

[0039] as attached figure 1 , 2 The star-wheel type paper turntable shown in has the components of a turntable 1, a gear transmission system and two paper tray holders 19.

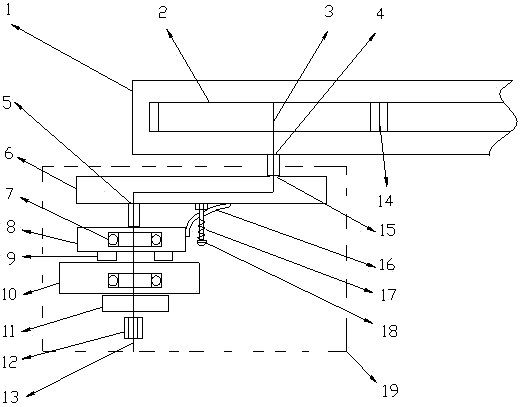

[0040] The turntable 1 is composed of a detachable and sealed metal shell. There is a center shaft hole at the center point, and a transmission shaft hole at each end; the gear transmission system consists of a motor 21, a center shaft 20, and multiple meshing or linkage gears. 2 gear sets, 2 transmission shafts 3; 2 tray holders 19 respectively have eccentric support plate 6, tray shaft 13, bearing 7, tray seat 8, brake assembly, block cap 11, adjustment nut 12, etc. parts.

[0041] The turntable 1 can rotate around the central shaft 20; the motor 21 can drive the central shaft 20 to rotate, and drive the gear set and the two transmission shafts 3 to rotate; the inner shaft hole 15 of the eccentric support plate 6 is set on the transmission shaft 3, and can rotate around the transmission shaft The shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com