Patents

Literature

389results about How to "Not easy to accumulate dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

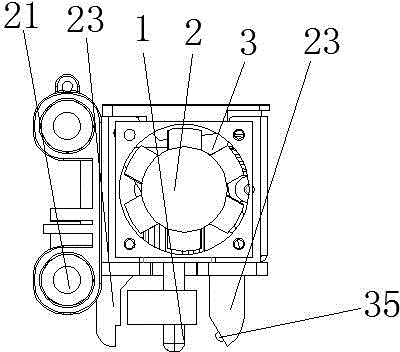

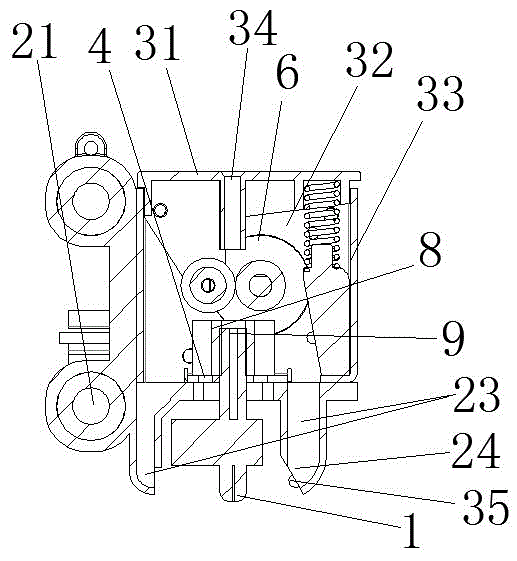

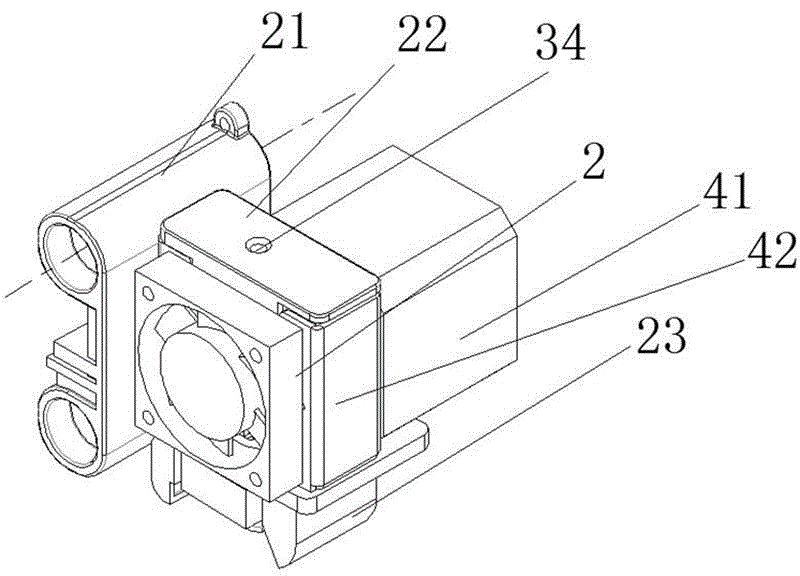

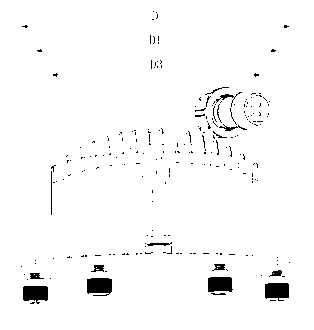

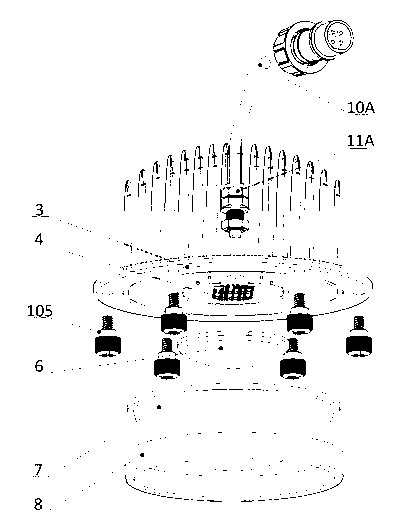

Air-cooling device for printing head of 3D (three-dimensional) printing machine

InactiveCN104786510AHigh efficiency of active coolingSmall footprintManufacturing platforms/substratesAdditive manufacturing with liquids3d printerWorking space

The invention discloses an air-cooling device for a printing head of a 3D (three-dimensional) printing machine. The printing head is arranged at a slide rod of the printing machine in a sleeving manner by lug rings and axially slides; the air-cooling device is integrated on the printing head; a wire conveying mechanism is arranged in a seat housing cavity body of the printing head; a cooling fan aligned to the wire conveying mechanism is arranged on one axial side of the seat housing cavity body; a printing head nozzle is formed in the lower part of the seat housing cavity body; the seat housing cavity body is provided with air guide pipelines leading to the printing head nozzle. The air-cooling device improves heat dissipation of the printing head of the printing machine and enables occupied working space of the printing head to be further reduced, thereby being favorable for improving the portability of the folding-type 3D printing machine.

Owner:FUZHOU ZHANXU ELECTRONICS

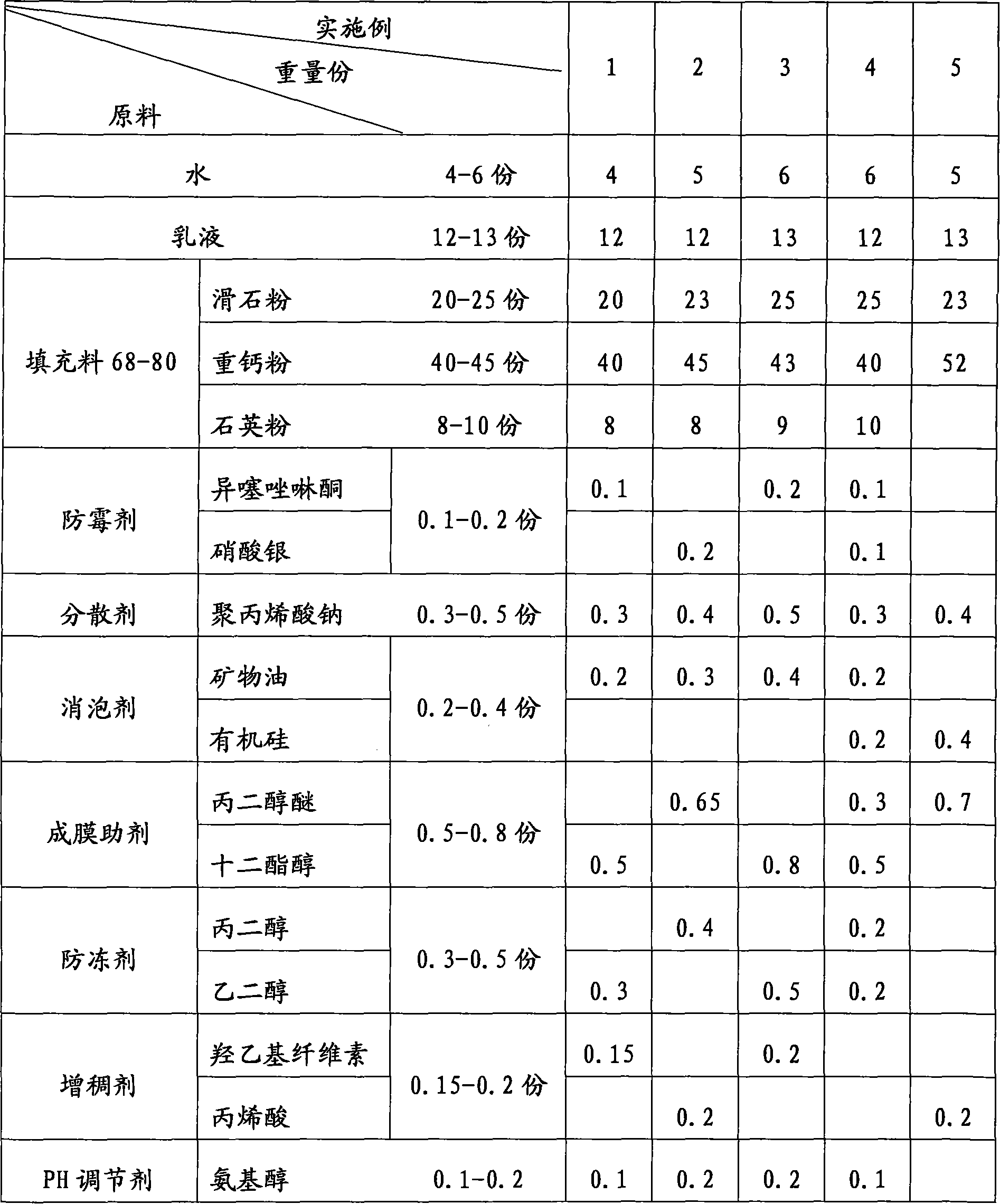

Method of producing and painting stone similar paint for flexible flat surface

InactiveCN101108943ANot easy to accumulate dustLow costLiquid surface applicatorsCoatingsEmulsionLacquer

A production method of a flexible stone-like paint is provided, which consists of the following raw materials and weight portion mixture ratios: 4 to 6 of water, 12 to 13 of waterborne pure acrylic acid emulsion, 68 to 80 of fillers and 0.65 to 2.8 addition agents. The method is that water, emulsion and addition agents are mixed first and are dispersed for 5min to 10min at medium speed, and are dispersed for 20min to 30min at low speed after adding the fillers; each half of antifoamers are added into the above two procedures respectively and are mixed with color and stirred evenly to form the stone-like paint. The wall is neatened first when painting and then sprayed by primer or rendered by roller coat, and tackiness paper tapes are stuck in grids; the stone-like paint is adopted to spray spots which are polished by abrasive paper after drying; the stone-like paint is adopted to level and polish twice until the spots are completely set off, to remove the dust and rip off the tackiness paper tapes and spray finishing varnish finally. The stone-like paint is applied in the decoration of the walls of construction or the table-board of the kitchens and toilets, and is beneficial for environment protection, light in quality and strong in toughness, which can be directly coated on the wall with surface low cost and energy-saving, therefore, the wall surface is not easy to store dust and the shapes and colors of the plane-imitating marble slab and the granite slab are lifelike.

Owner:浙江华特新材料有限公司

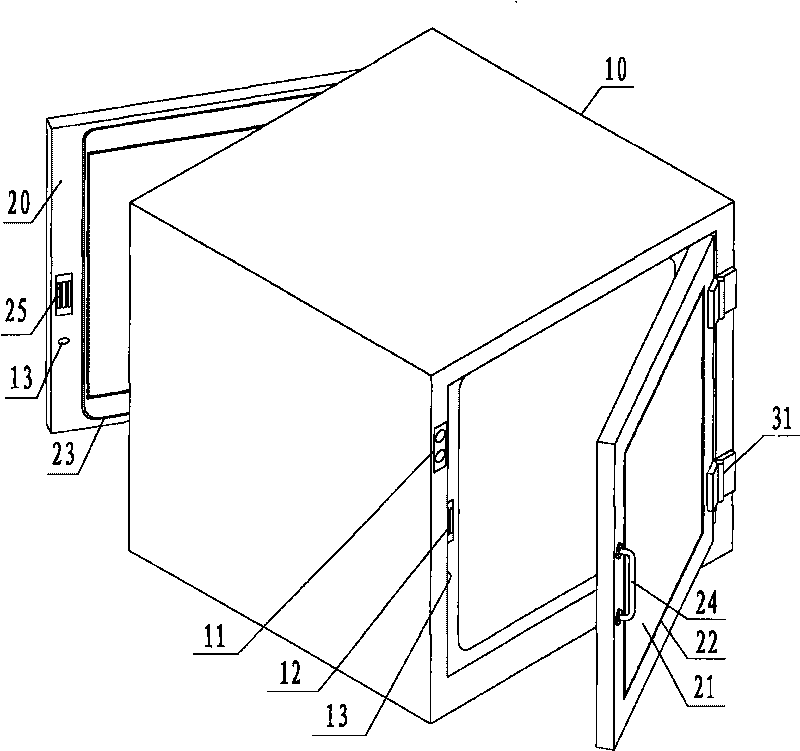

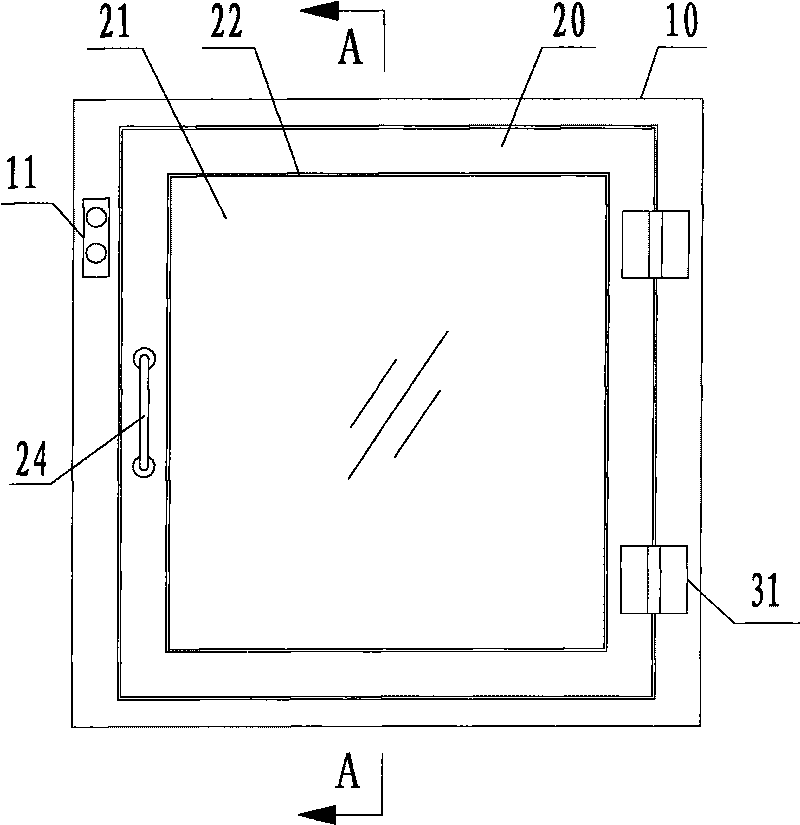

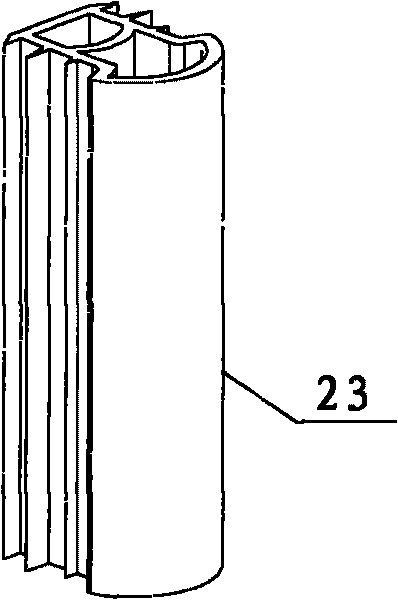

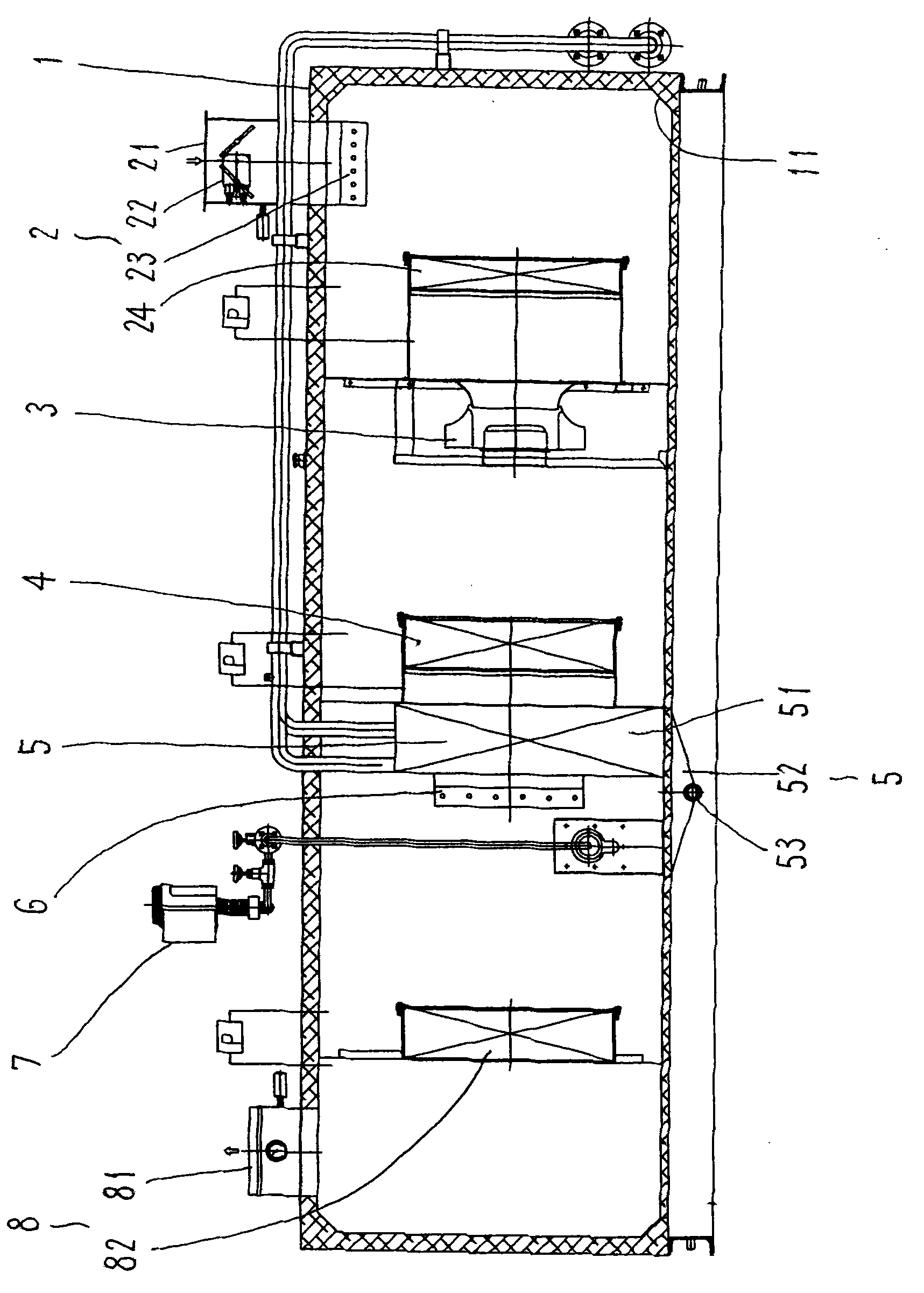

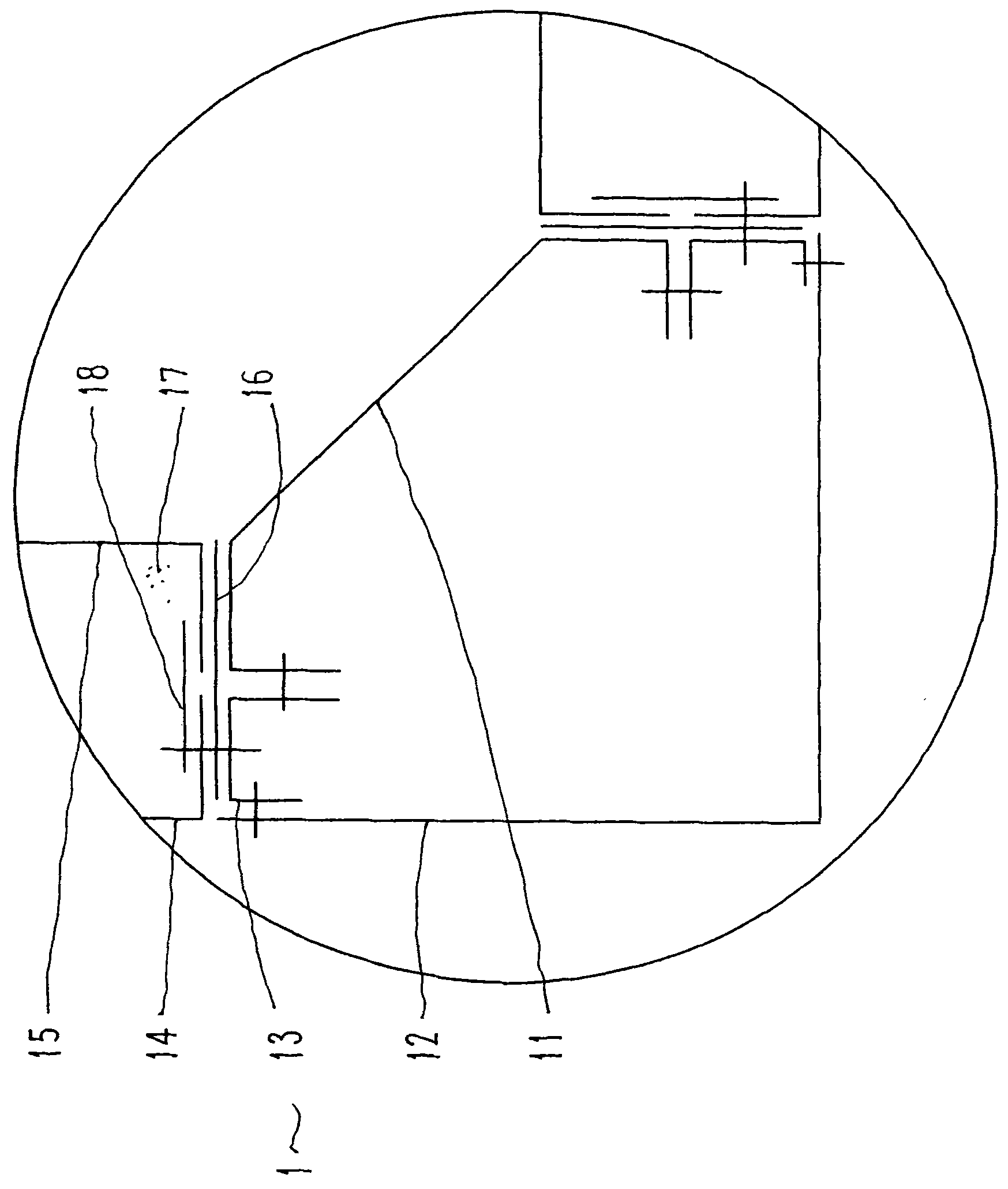

Pass box

InactiveCN101698108AImprove air tightnessNot easy to accumulate dustLavatory sanitoryDisinfectionElectromagnetic lockEngineering

The invention relates to a pass box, in particular relates to an airtight pass box for a medical and biological clean room. The pass box consists of a box body of which two ends are communicated, two door leaves mounted at the parts where the two ends of the box body are communicated, and an interlocking device, wherein the two door leaves mounted at the parts where the two ends of the box body are communicated, an electromagnetic lock and an interlocking sensor constitute the interlocking device; the external part of the box body is square-shaped; each chamfer part in the channel of the box body is arc-shaped; the two door leaves are mounted on the box body in an embedded manner; when the two door leaves are closed, the two door leaves and the box body are located on the same plane; transparent double-layer windows are arranged in the middle of the two door leaves; the double-layer windows are fixedly and hermetically connected with the door leaves by sealant; and the width of the double-layer windows is the same as that of the door leaves, so that a level plane can be formed by the double-layer windows and the door leaves. For the pass box of the invention, the width of the double-layer windows is the same as that of the door leaves, and the double-layer windows and the door leaves are located on the same plane, so as to form a whole having the advantages of levelness and smoothness, high air tightness, dust retention prevention and easiness of clean.

Owner:SUZHOU FLEXCON CLEAN ROOM SYST

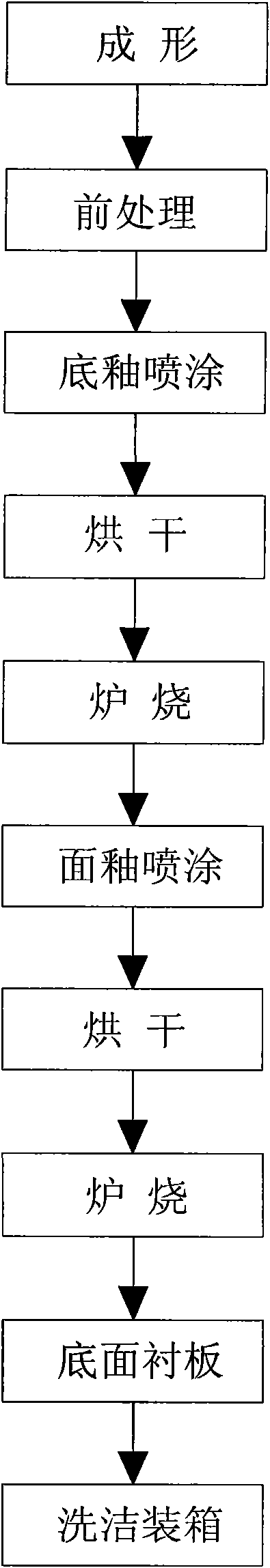

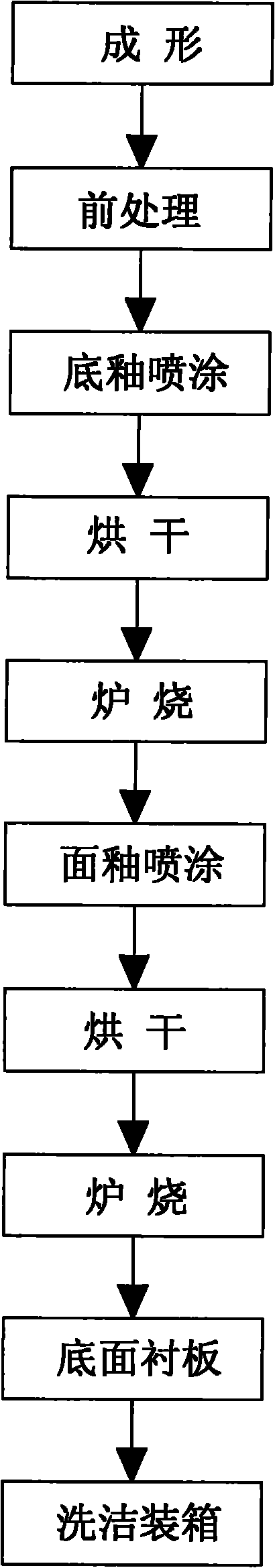

Production process of enamel steel plate

The invention provides a production process of an enamel steel plate, comprising the steps of forming, pretreating, ground coat spraying, drying, furnace burning, over glaze spraying, drying, furnace burning and back surface underboarding. The enamel steel plate has the advantages of bright color, even glaze distribution, seismic resistance, noise reduction and long service life, and is safe and environmental-friendly, and can be applied in the industries such as art murals, household enamel products, industries, buildings and the like. The enamel steel plate in the invention is a compound material which is formed by the steps that a high quality steel plate as a substrate is processed by a static dry method and then is burnt with inorganic nonmetallic material at high temperature so that tight chemical bonds are between the high quality steel plate and the inorganic nonmetallic material generate, and the enamel steel plate is a perfect combination of metals and inorganic materials. The enamel steel plate has flexibility of a steel plate substrate and also has the characteristics of acid-base resistance, endurance, non-combustion, safety, environmental protection and the like of an inorganic enamel layer. The enamel steel plate in the invention is static-free and is easy to clean, the enamel surface is fine and smooth, shakeproof, compression resistant and noise resistant and has small possibility of dust accumulation, the service life is long, and the enamel steel plate does not need to be maintained for 50 years under regular atmospheric environment.

Owner:洪立业

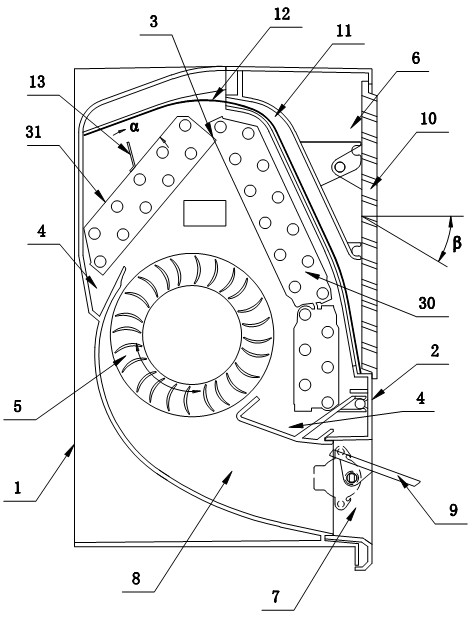

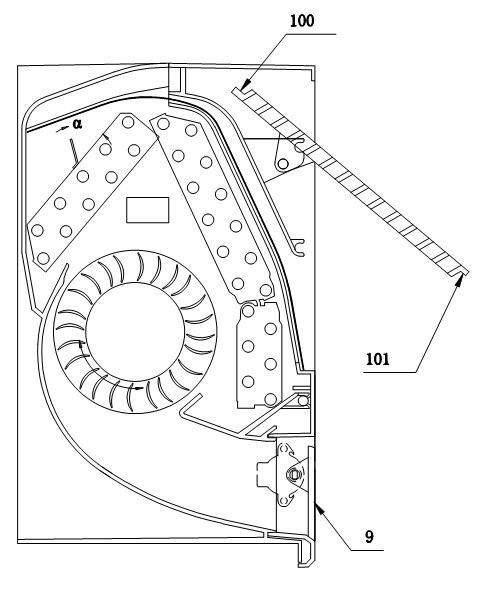

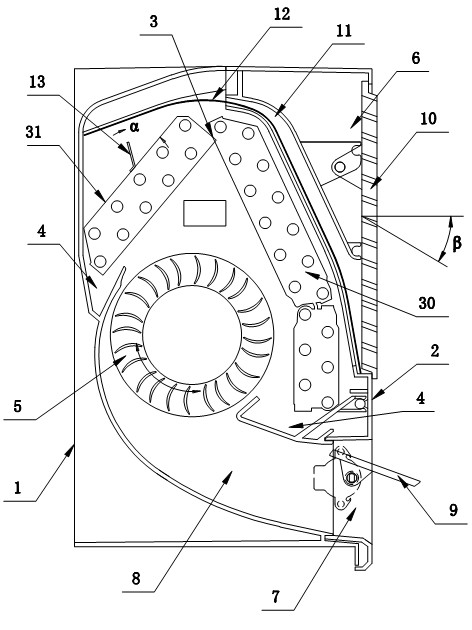

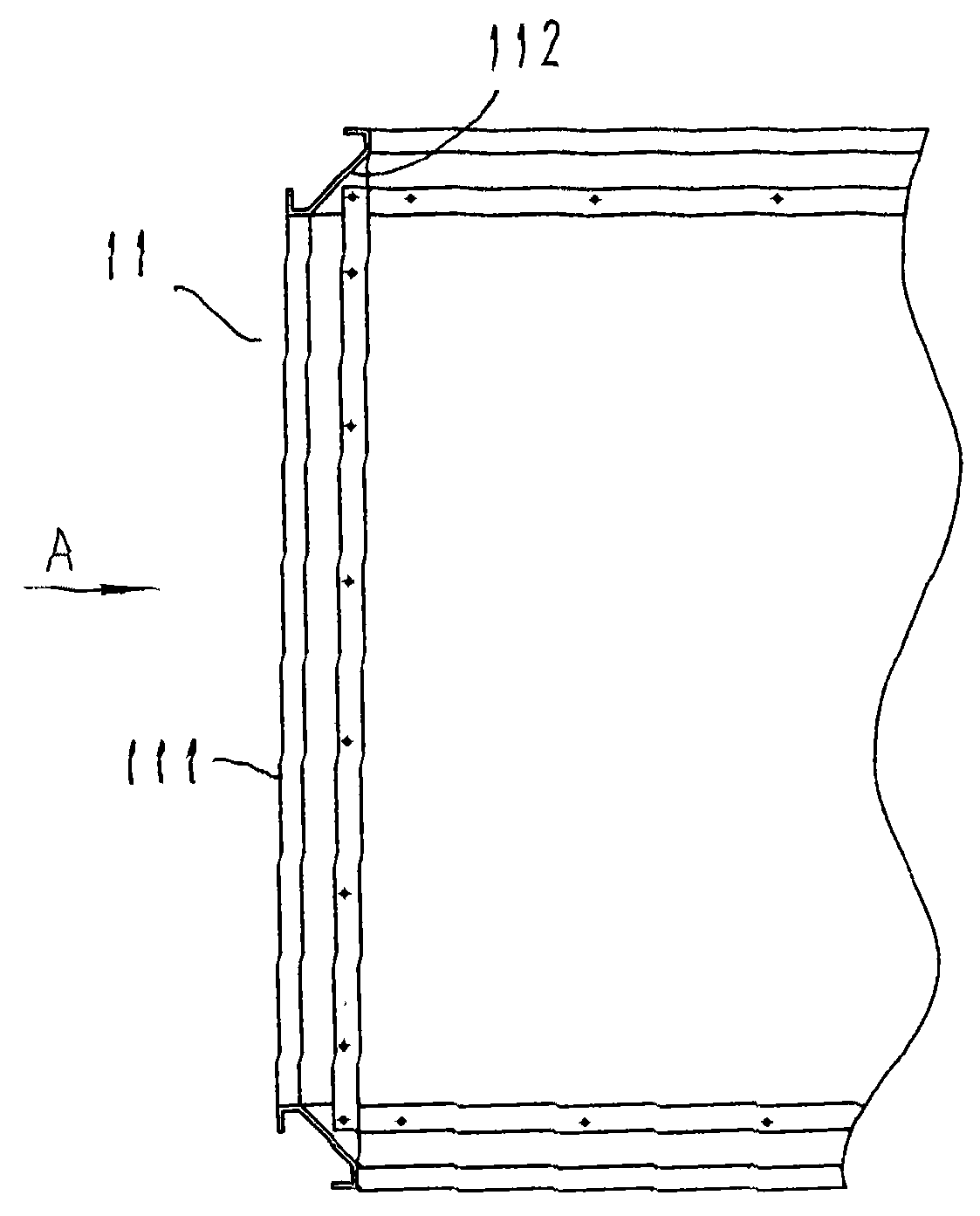

Split wall mounting type air conditioner indoor machine

InactiveCN102062447AWide range of installation methodsWide range of installation positionsLighting and heating apparatusAir conditioning systemsEngineeringLouver

The invention relates to a split wall mounting type air conditioner indoor machine comprising a shell, a front panel, a heat exchanger, a defrosting tray, a draught fan, an air inlet, an air outlet and an air duct, wherein the front panel is arranged on the front part of the shell; the heat exchanger and the draught fan are arranged in the air duct formed between the shell and the front panel; the defrosting tray is positioned below the heat exchanger; the air outlet is arranged on the lower part of the front panel or at the bottom of the shell; and an air supply and guide plate is arranged on the air outlet. The split wall mounting type air conditioner indoor machine is characterized in that the air inlet is arranged on the upper position of the front panel; and a louver grille is arranged at the air inlet. The invention is suitable for more installation spaces and positions without supplying air from the top of the shell, dost not have the problem of dust accumulation and diverts air flows of the air supply and guide plate by adopting the heat exchanger, thereby improving the uniformity of the air flow distribution of the heat exchanger and enhancing the integral heat exchange efficiency of the heat exchanger.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

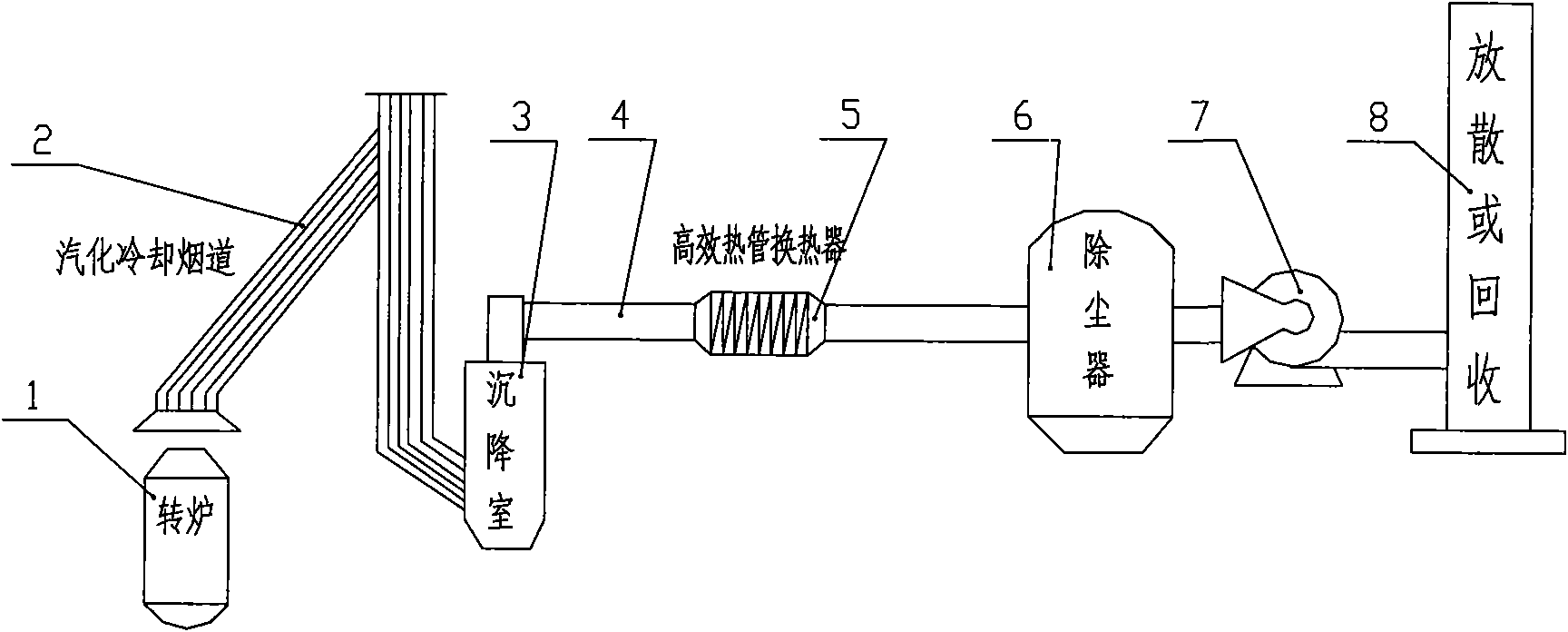

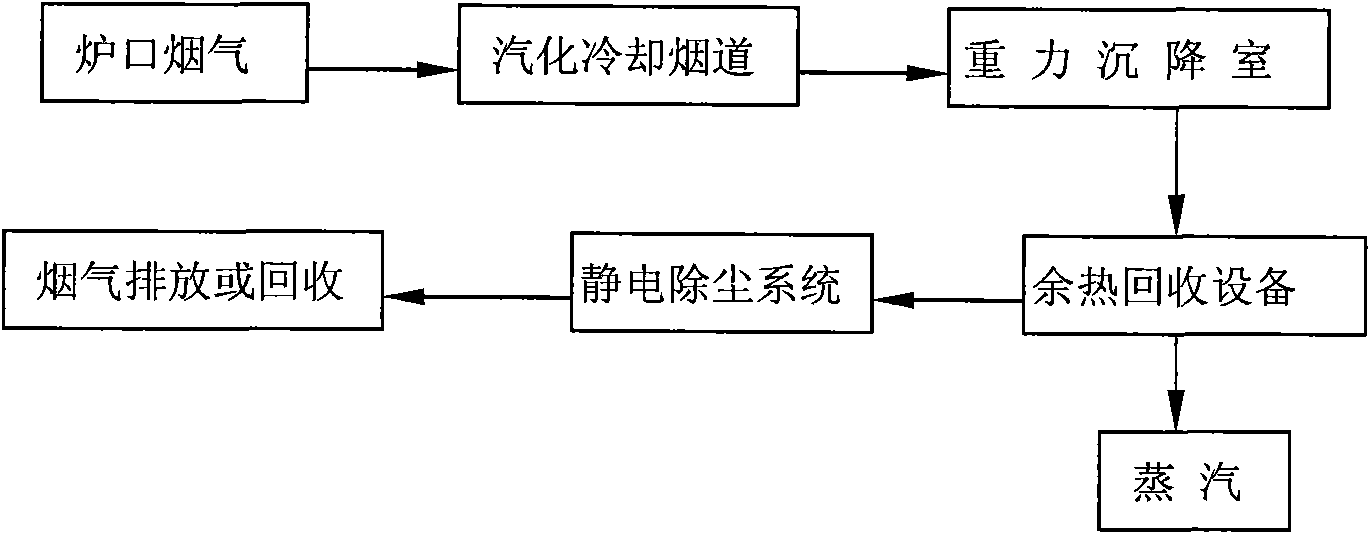

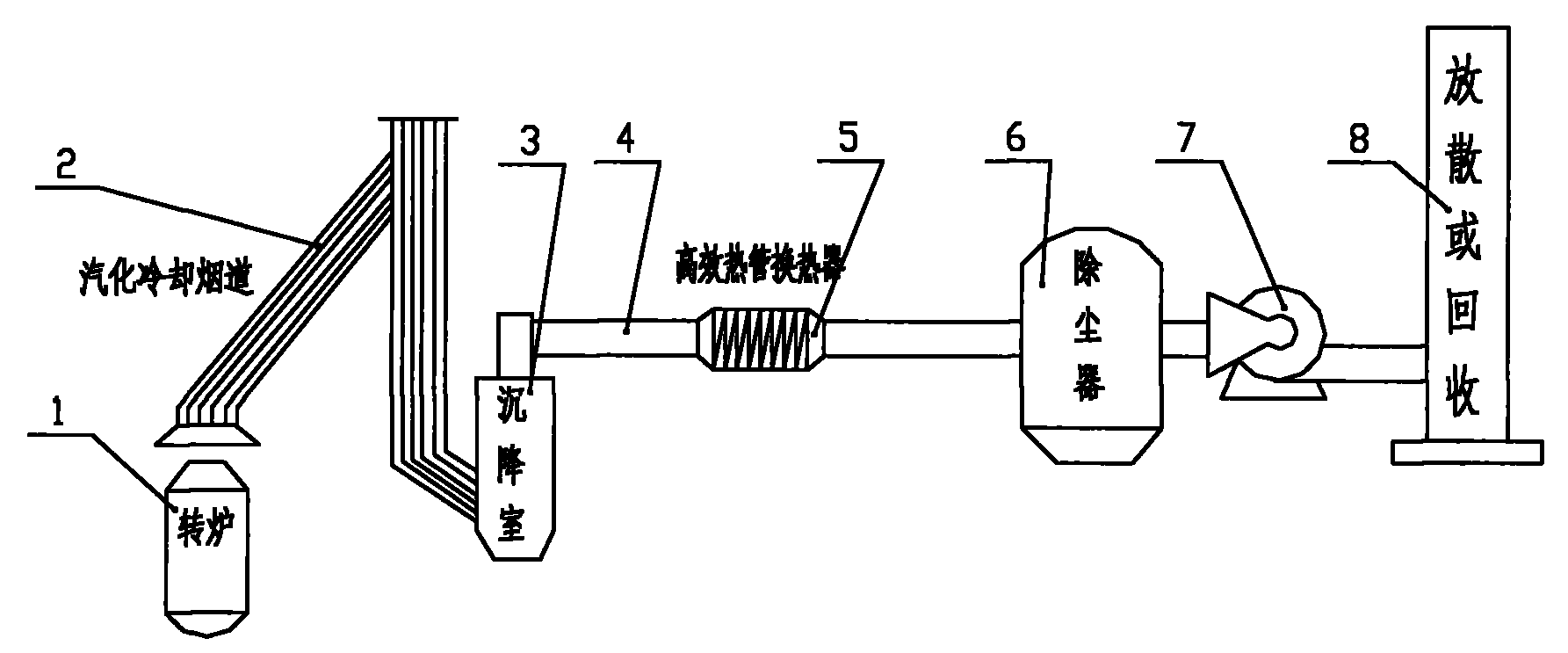

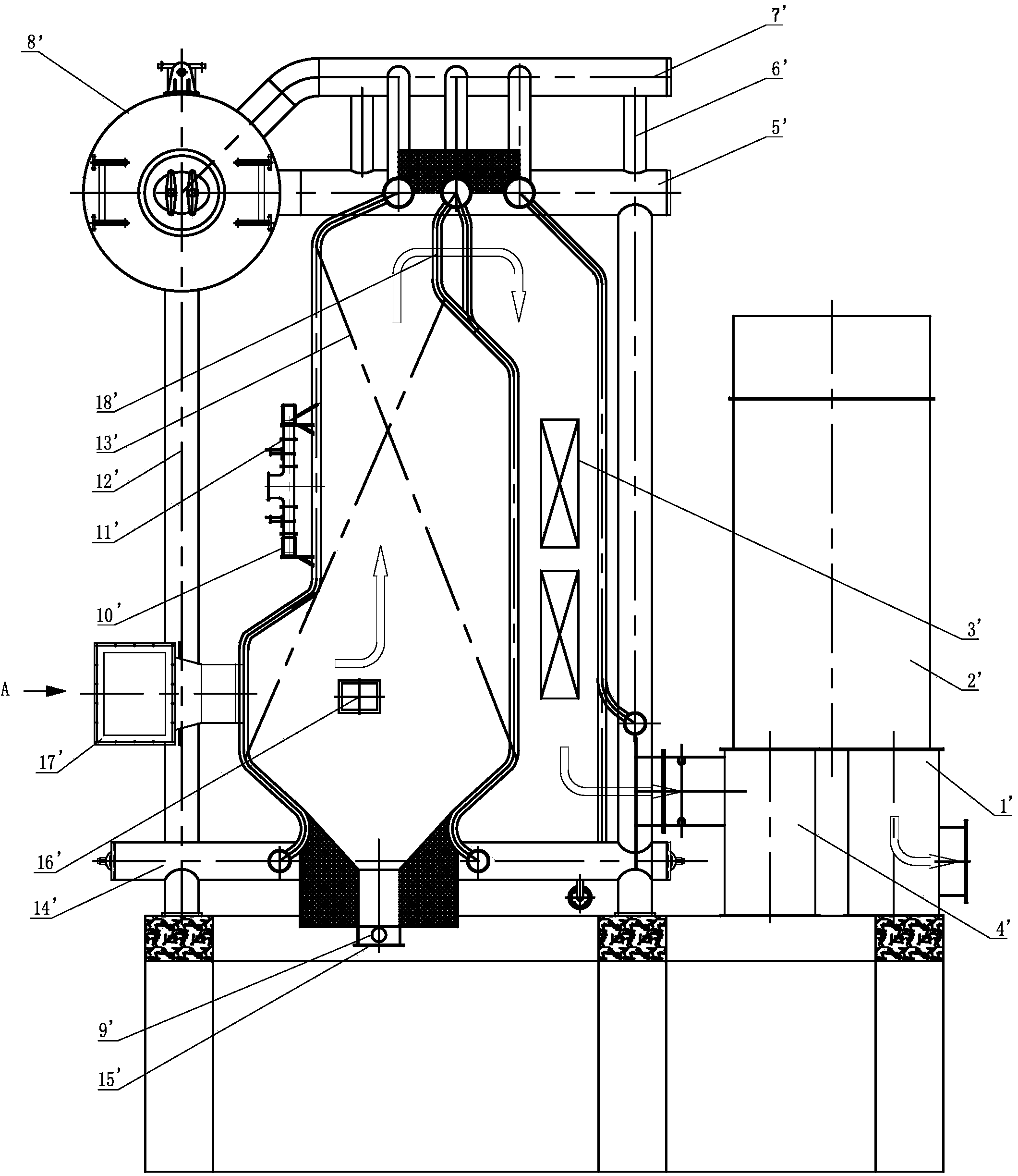

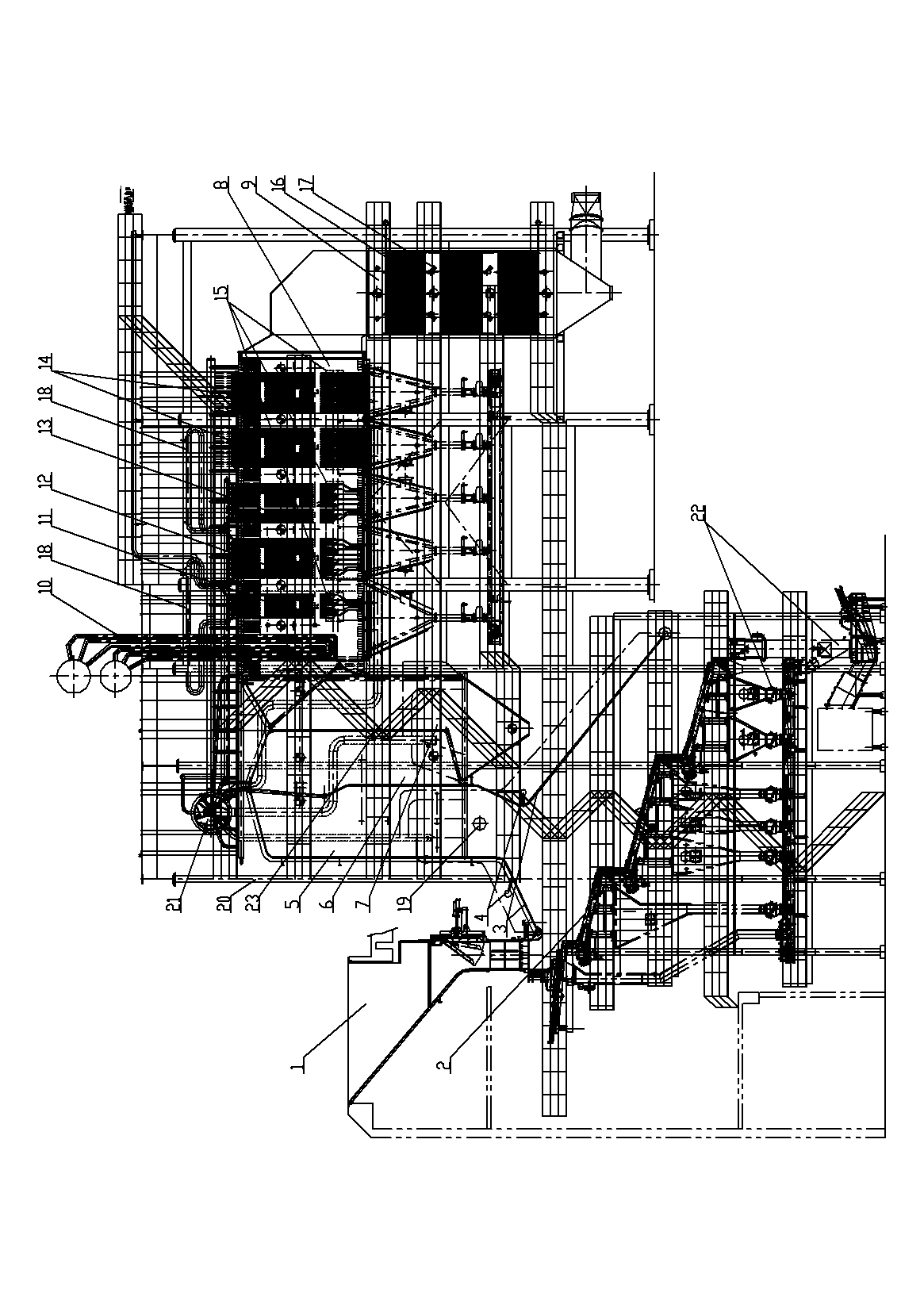

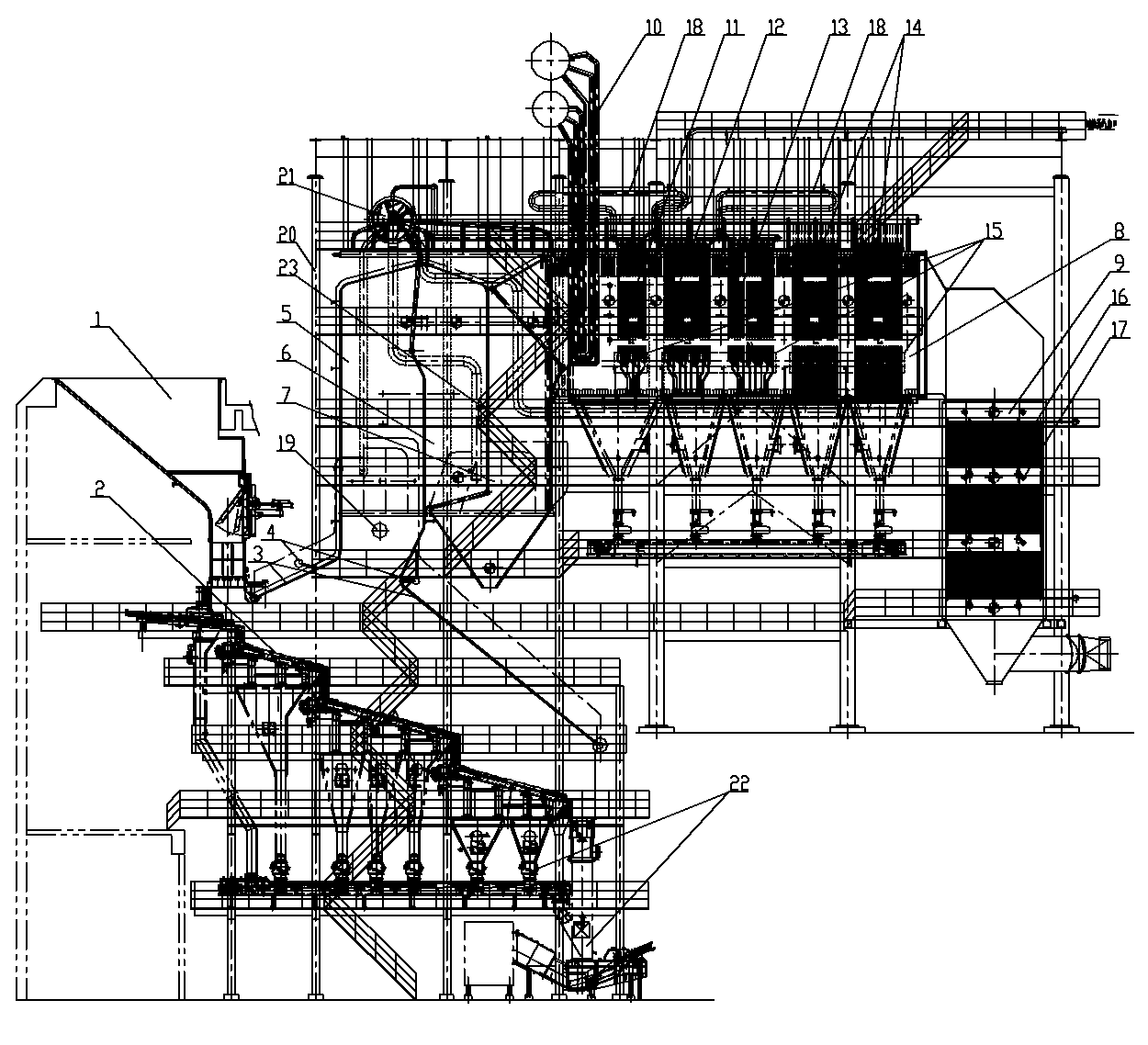

Device and method for removing dust from converter smoke by dry method and recycling waste heat

InactiveCN101875992AImprove heat transfer efficiencyReduce resistanceManufacturing convertersWaste heat treatmentTowerGas chamber

The invention discloses a device and a method for removing dust from converter smoke by a dry method and recycling waste heat and belongs to the technical field of comprehensive utilization of the converter smoke. The device comprises a converter, a vaporizing and cooling flue, a gravity settling chamber, a flue, a heat exchanger, an electrostatic dust remover, an axial flow fan and a smoke diffusing tower or a gas chamber, wherein the gravity settling chamber is connected with the converter through the vaporizing and cooling flue and is connected with an efficient heat pipe exchanger through the flue; the heat exchanger is connected with the electrostatic dust remover through the flue; the electrostatic dust remover is connected with the axial flow fan through the flue; the axial flow fan is connected with the smoke diffusing tower or the gas chamber through the flue; and the lower ends of the gravity settling chamber, the efficient heat pipe exchanger and the static dust remover are all provided with an ash discharge port. The device and the method are suitable for all converters and have the advantages of improving the dust removing effect compared with the OG method, making the emission index of smoke concentration lower than 20 mg / m<3>, greatly saving the cooling water and recycling a large amount of physical heat of the smoke.

Owner:CENT IRON & STEEL RES INST

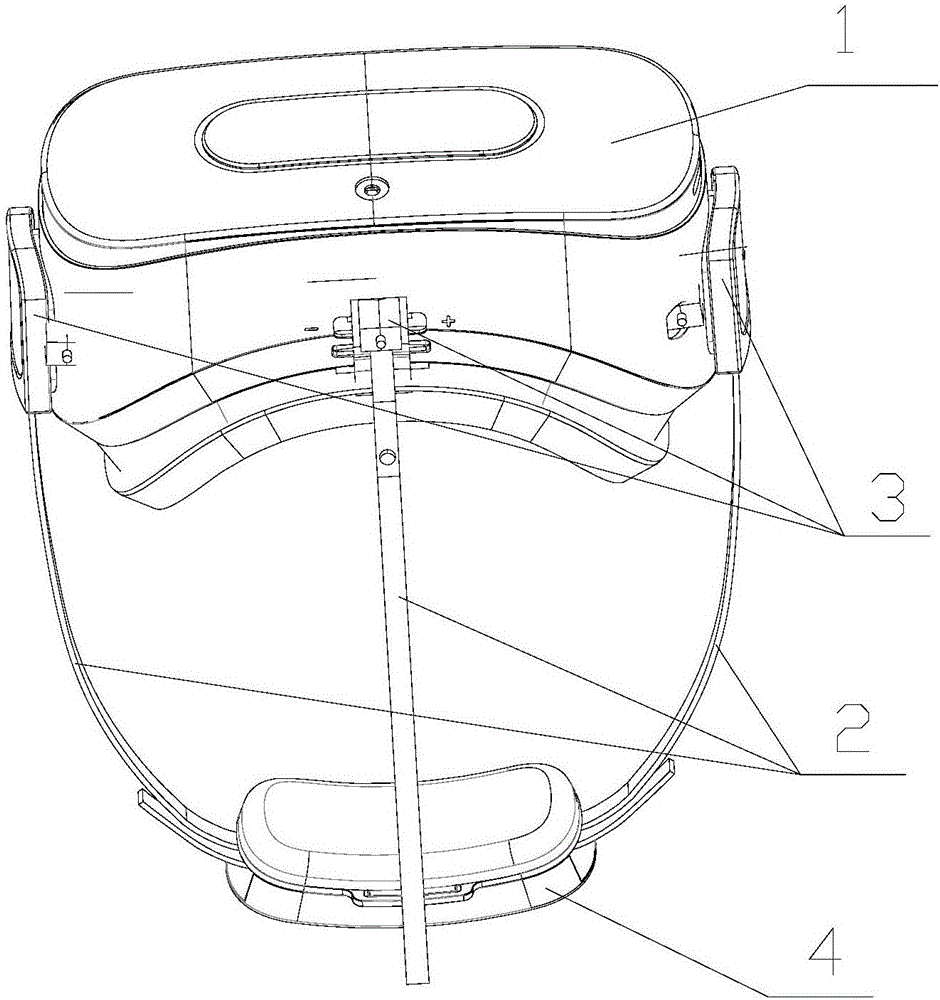

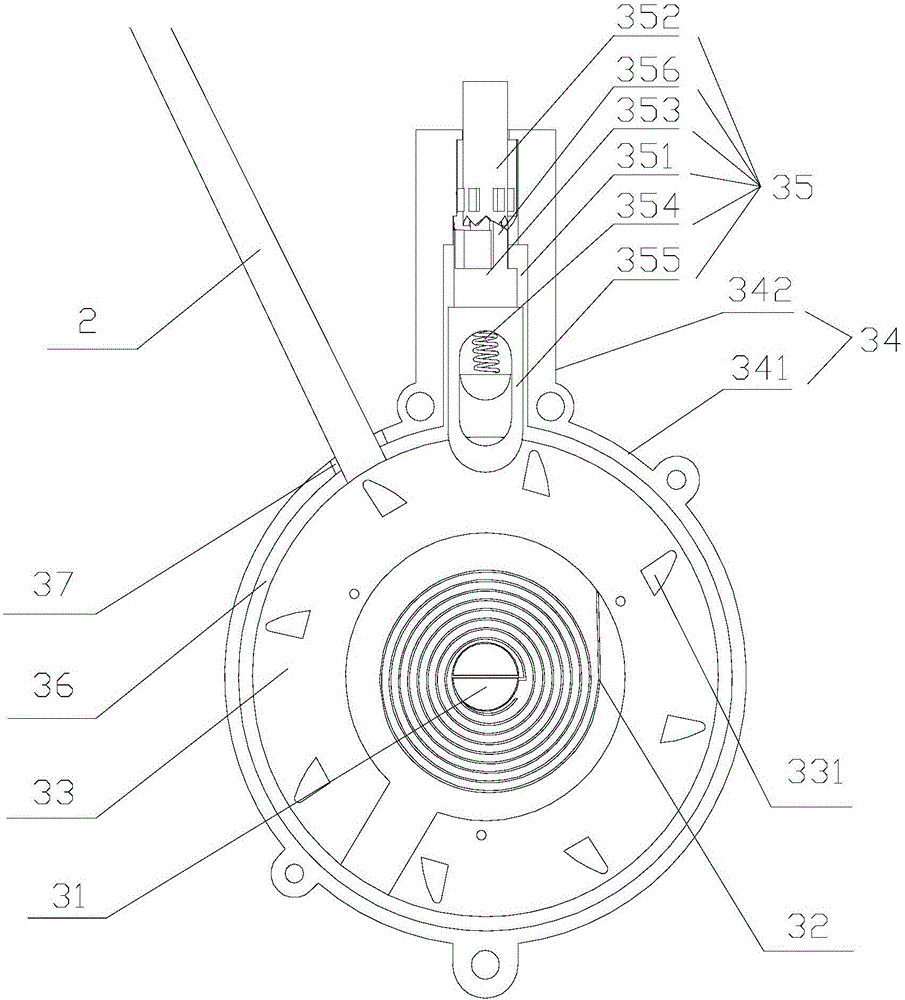

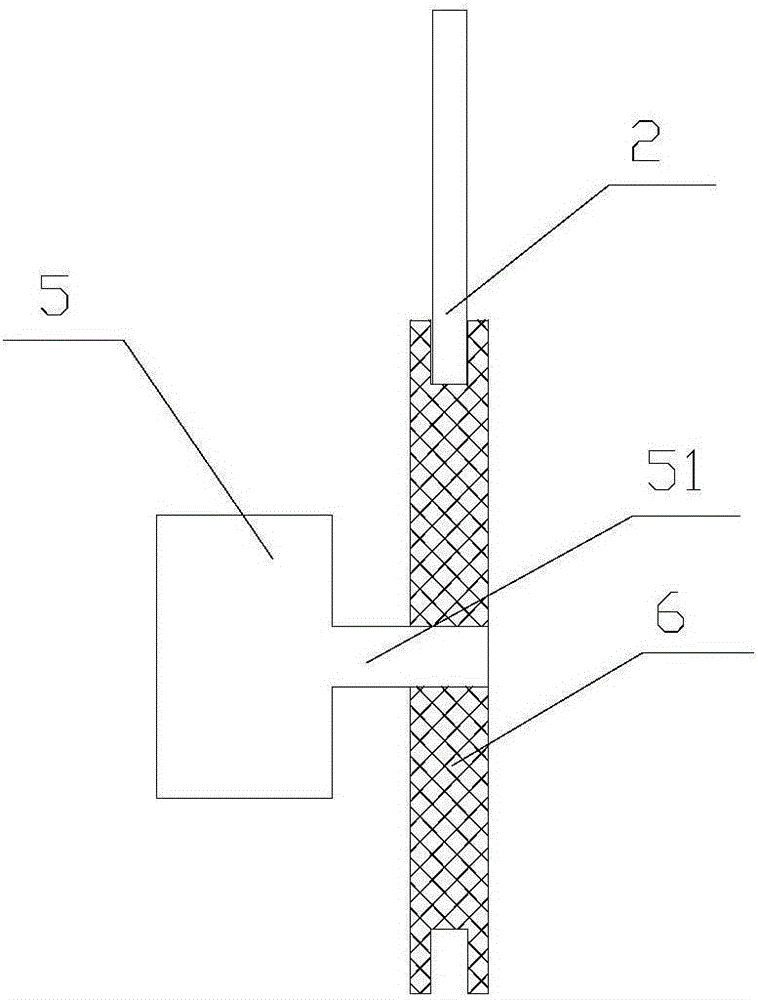

Virtual reality glasses capable of extending and retracting headband

ActiveCN106054391AEasy to useEasily stretch and retract the headbandOptical elementsVirtual realityComputer science

The present invention relates to a virtual reality glasses capable of extending and retracting a headband. The virtual reality glasses comprise a virtual reality glasses shell, the headband and a telescopic mechanism which is removably arranged on the virtual reality glasses shell. The telescopic mechanism is connected to the headband and is used for extending and retracting the headband. By using the above structure, the virtual reality glasses have the advantages that the virtual reality glasses are convenient to use, the headband is connected to the telescopic mechanism, the telescopic mechanism can provide the energy of winding the headband, and thus the extension and retraction of the headband can be conveniently realized.

Owner:浦录科技(湖北)有限公司

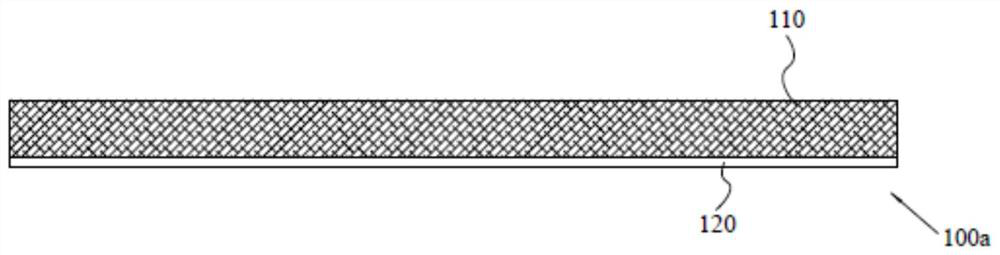

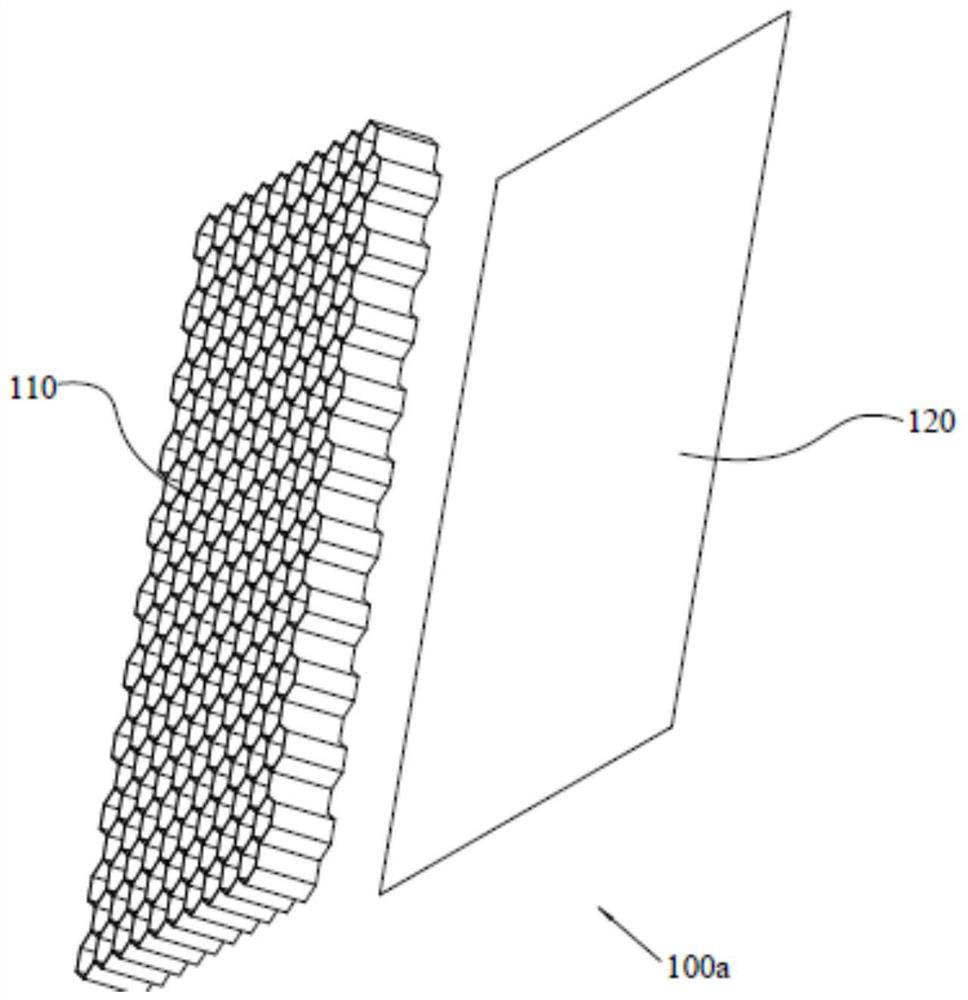

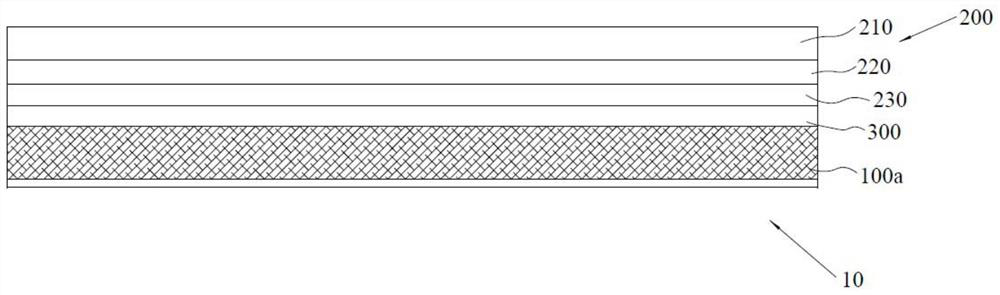

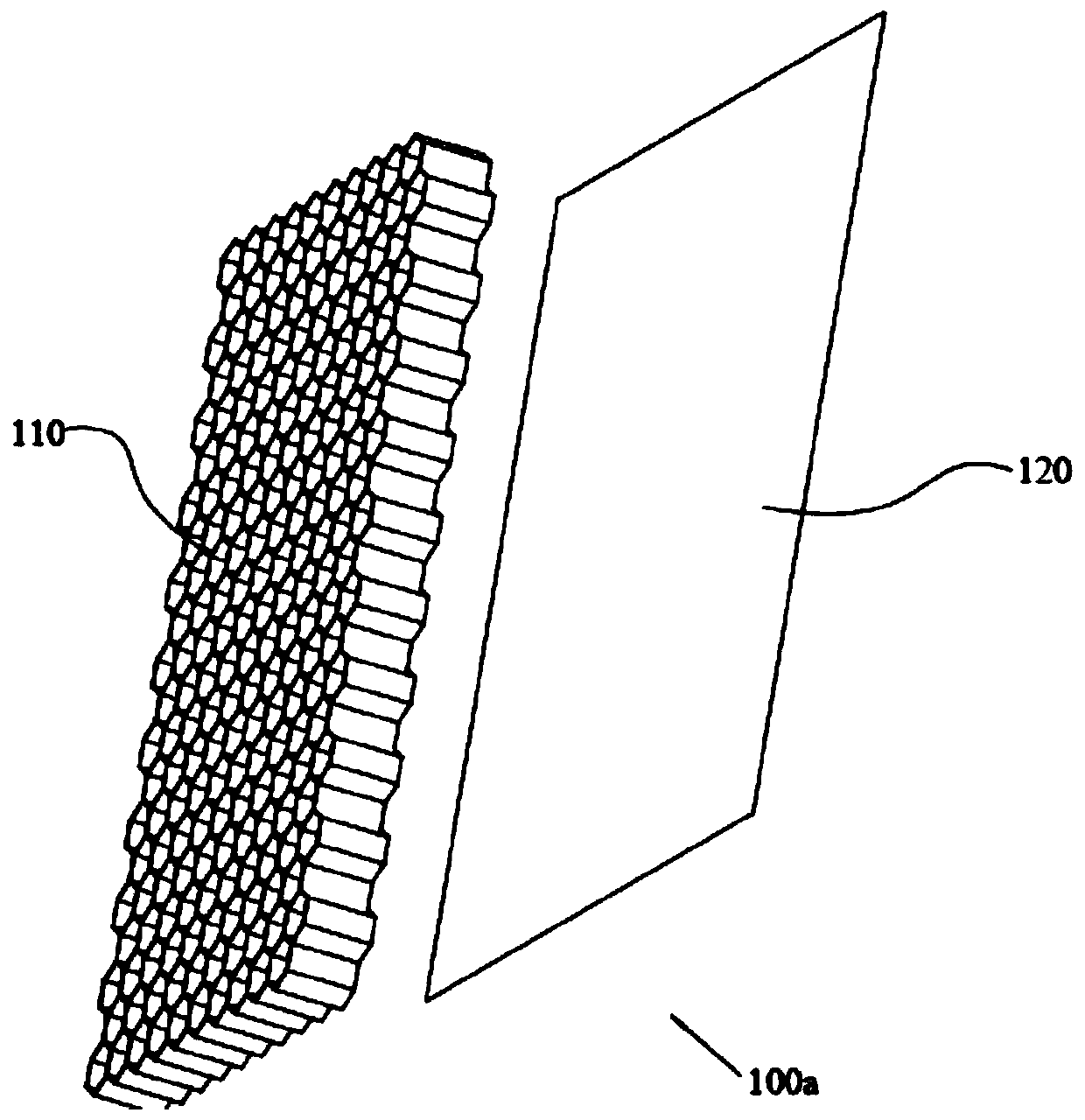

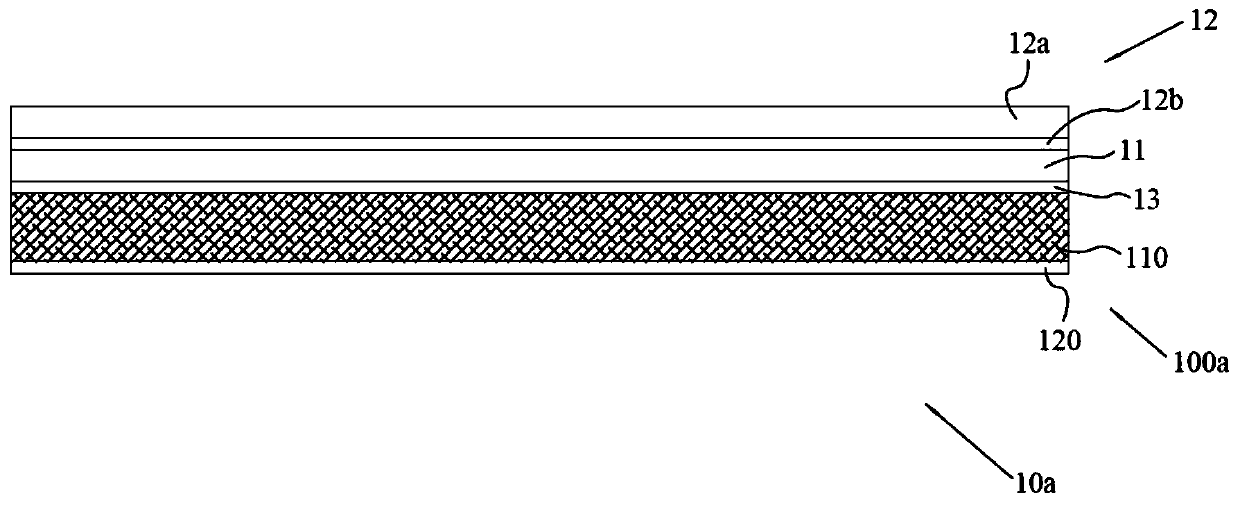

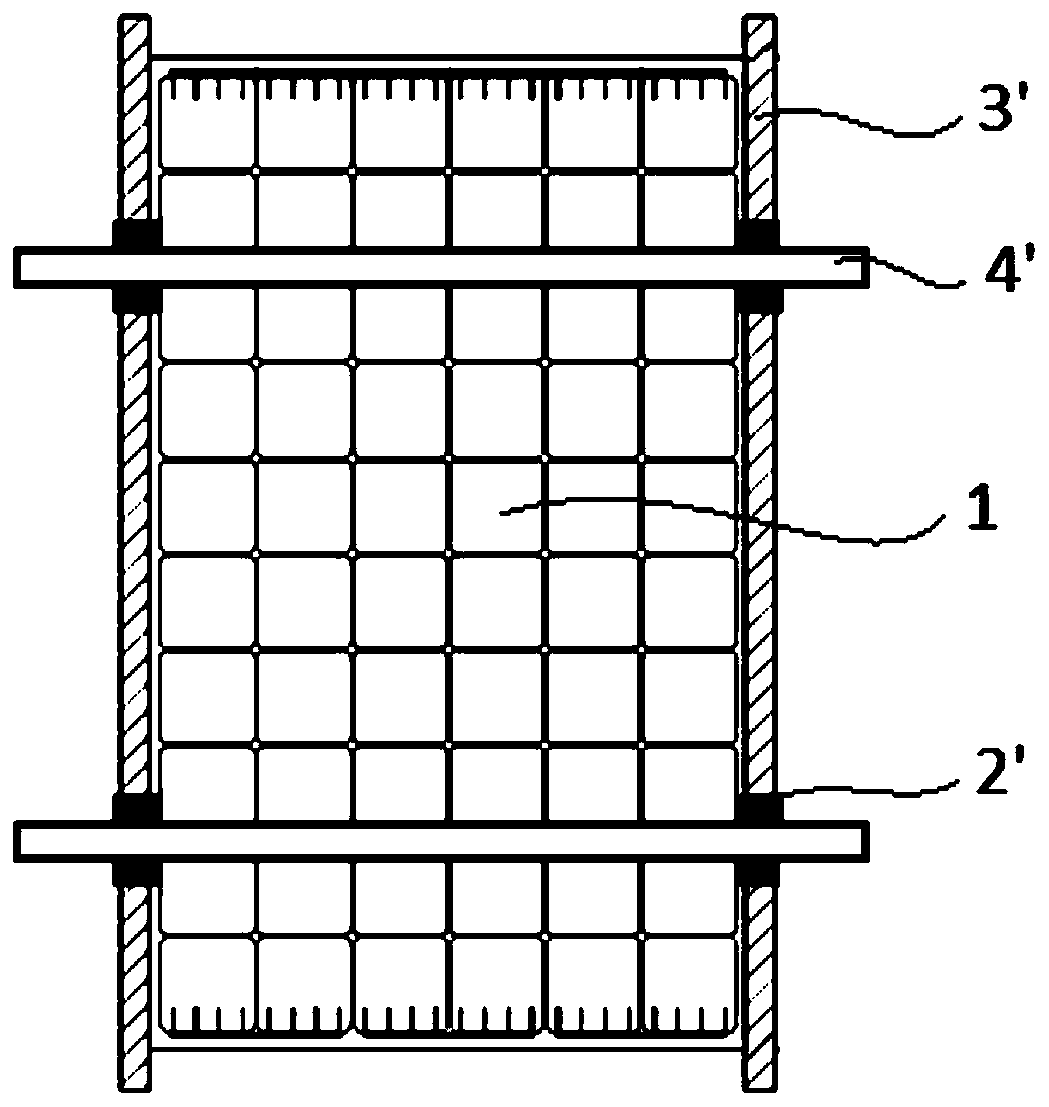

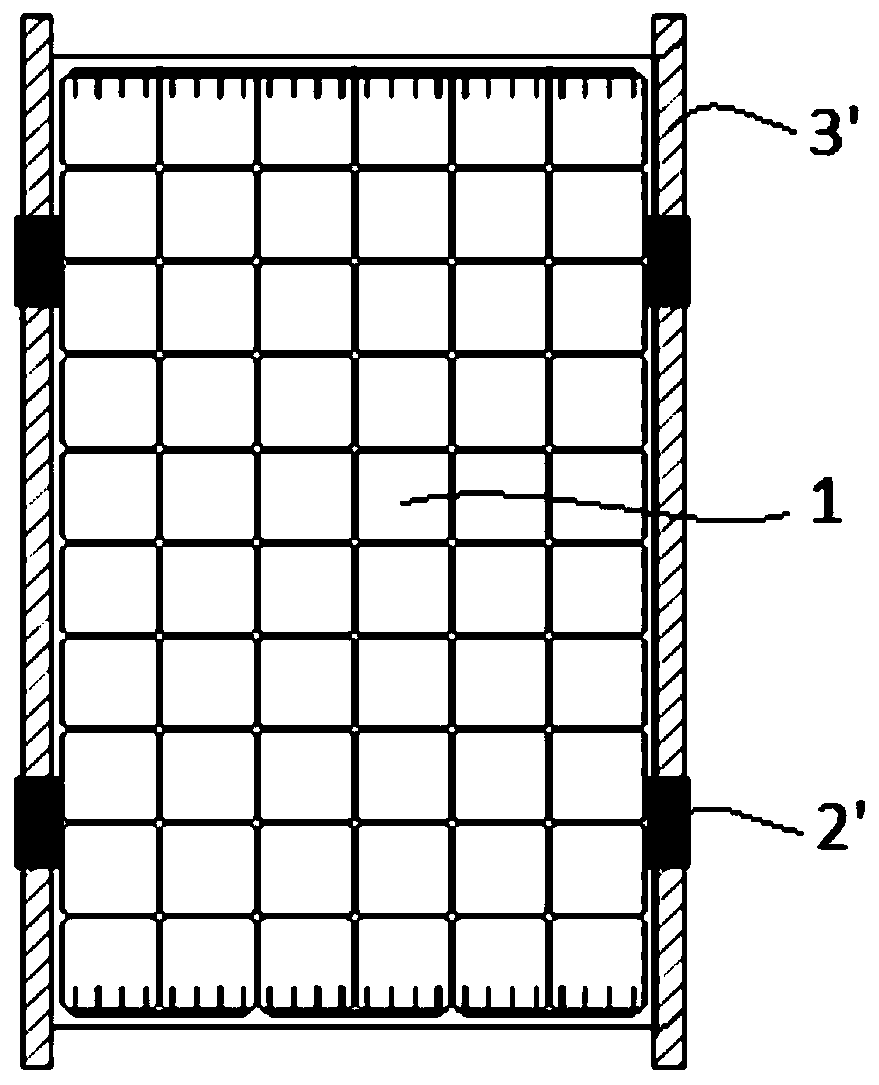

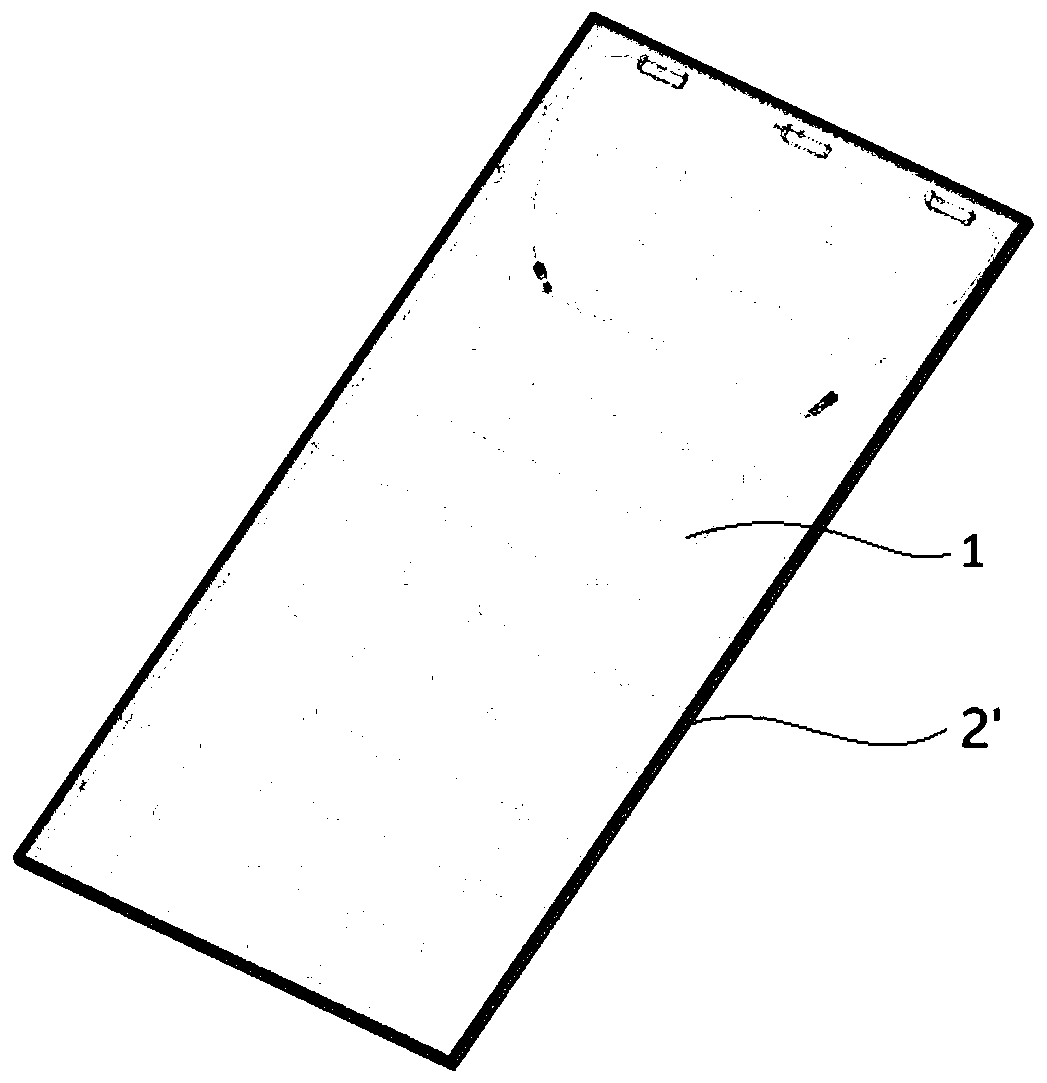

A continuous composite molding lightweight photovoltaic module and its continuous composite molding equipment

ActiveCN110491961BGuarantee the quality of laminationImprove yield rateFinal product manufacturePhotovoltaic energy generationBattery cellMaterials science

The invention discloses a continuous composite molding lightweight photovoltaic module, which includes a photovoltaic laminate and a lightweight photovoltaic backplane. The photovoltaic laminate includes a front flexible packaging layer, a battery sheet layer, and a back flexible packaging that are laminated and packaged as one. layer, the lightweight photovoltaic backplane includes at least a thermoplastic core layer in the shape of a honeycomb or porous foam and a first thermoplastic substrate layer, and the photovoltaic laminate and the lightweight photovoltaic backplane are composited into one body through a continuous composite molding process; The invention also discloses continuous composite molding equipment; the invention also has the advantages of light weight, safety and reliability, frameless design is not easy to accumulate dust and does not need to be grounded, and its layout can be flexible and changeable, avoiding the high burst problem of traditional double glass components, Moreover, the present invention will not cause problems such as bubbling, degumming, deformation and creep under the lightweight photovoltaic backplane scheme using the adhesive film layer structure, and will not be limited by the thickness of the light photovoltaic backplane, which fully meets the requirements of photovoltaic standards. , can realize real-scale promotion and application.

Owner:SUNMAN (ZHENJIANG) CO LTD

Paint brushing construction method

The invention relates to a paint brushing construction method, which sequentially comprises the following steps of brick wall base surface cleaning, base layer brushing, putty priming and surface layer rolling coating. According to a method adopted in the base layer brushing step, firstly, a brick wall base surface is moistened through water spreading, a layer of cement paste is brushed, then, cement mortar is used for brushing, the first layer brushing thickness is 0.08 to 0.1cm, the second layer brushing thickness is 0.05 to 0.08cm, then, the scraping leveling is carried out through a darby, and finally, the floating leveling is carried out through a wood float. According to a method adopted in the putty priming step, the priming is carried out in two layers, the first layer putty priming thickness is 0.3 to 0.5cm, the second layer putty priming is carried out after 22 to 26 hours, the priming thickness is 0.2 to 0.3cm, and two work procedures of grinding leveling machine and sand paper are adopted for grinding leveling after the natural maintenance. According to a method in the surface layer rolling coating step, firstly, a layer of paint is brushed on the putty surfaces primed in the former step, the paint rolling coating is carried out once again after 3 to 5 hours, and then, the maintenance is carried out. The surface layer brushed according to the construction method is smooth, flat and uniform without cracks, in addition, convex-concave corners of wall posts are made into micro arc shapes, the appearance is attractive, simple and compact, and the dust accumulation cannot easily occur.

Owner:无锡市康顺节能材料科技有限公司

Lightweight backsheet for photovoltaic module, and photovoltaic module therefor and preparation method thereof

PendingCN110400853AGuarantee the quality of laminationAvoid high burst problemsSynthetic resin layered productsPhotovoltaic energy generationThermoplastic elastomerHoneycomb

The invention discloses a lightweight backsheet for a photovoltaic module, and a photovoltaic module therefor and a preparation method thereof. The lightweight backsheet at least comprises a thermoplastic core layer and a first thermoplastic substrate layer which are integrated by hot melt pressing, wherein the base material of the thermoplastic core layer is a core layer thermoplastic polymer, the base material of the first thermoplastic substrate layer is a substrate layer thermoplastic polymer, and the core layer thermoplastic polymer is the same as the material of the substrate layer thermoplastic polymer; the thermoplastic core layer has a honeycomb shape or a porous foam shape; the lightweight backsheet can simultaneously replace a metal frame as the lining structure of the photovoltaic module; the lightweight backsheet for the photovoltaic module, and the photovoltaic module therefor and the preparation method thereof have the advantages of the light weight, safety and reliability, no border design, no easy accumulation of dust and no grounding, The version can be flexible and changeable, avoiding the high bursting problem of the traditional double glass component, and the lightweight backsheet for the photovoltaic module, and the photovoltaic module therefor and the preparation method thereof fully meet the requirements of the photovoltaic standard, and can achieve thereal scale promotion application.

Owner:SUNMAN (ZHENJIANG) CO LTD

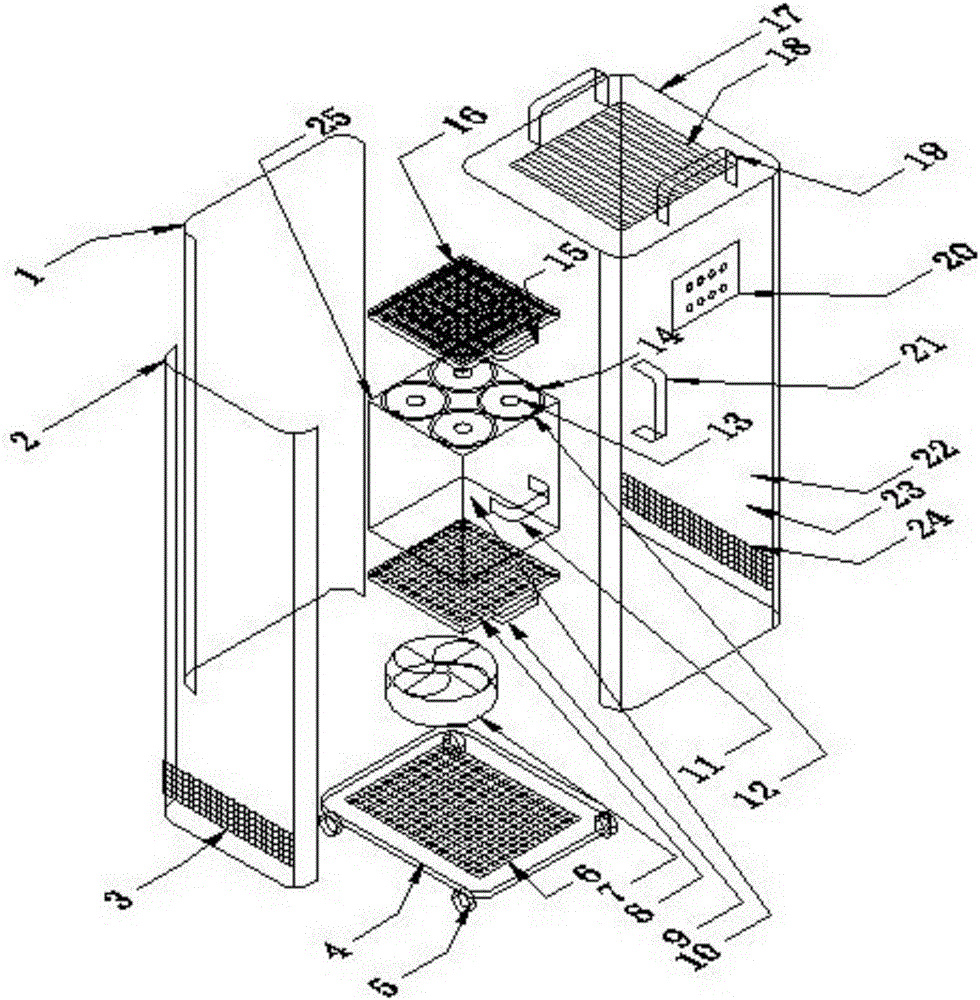

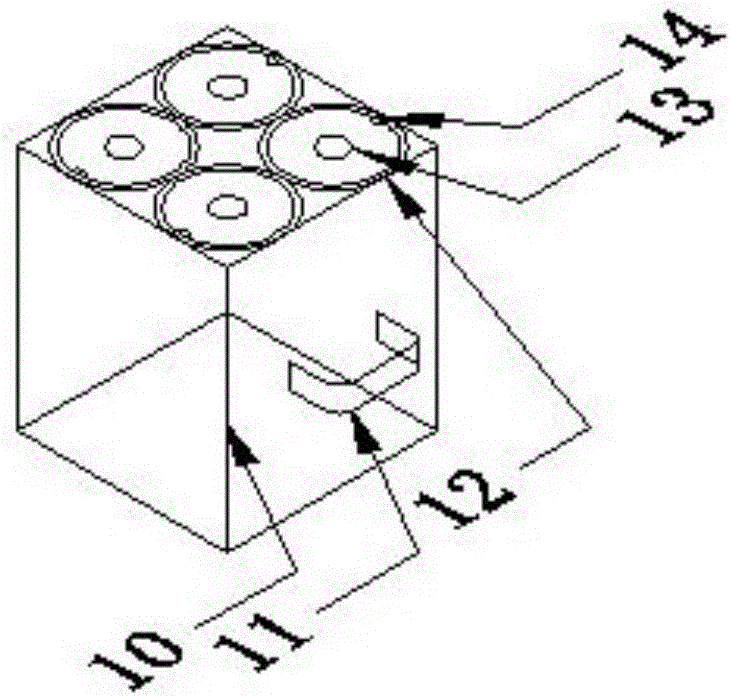

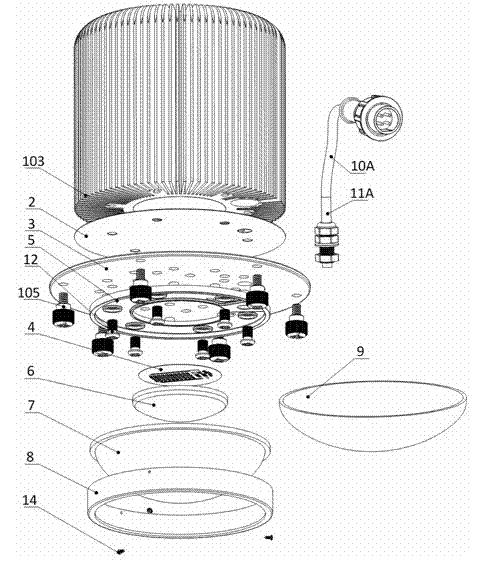

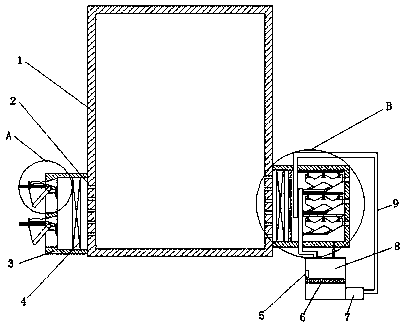

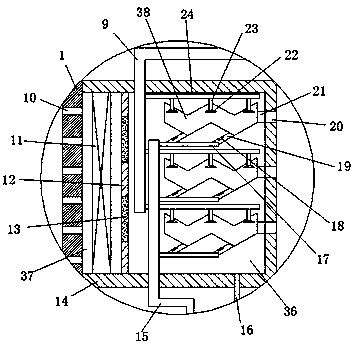

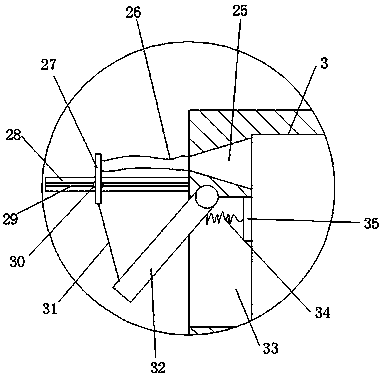

Indoor air purifying device based on low-temperature plasma

InactiveCN105864904AReduce energy consumptionQuick resultsMechanical apparatusLighting and heating apparatusAir cleaningAir treatment

The invention discloses an indoor air purifying device based on low-temperature plasma. The indoor air purifying device comprises a shell; inside the shell, a fan, a primary filter screen, a low-temperature plasma reaction device and an adsorptive catalytic layer are sequentially arranged from a base plate to a top face cover; the low-temperature plasma reaction device comprises an insulating bracket; a plurality of low-temperature plasma discharging units are mounted on the insulating bracket; each low-temperature plasma discharging unit comprises an outer layer metal cylinder, an inner layer insulating cylinder and a plurality of metal corona wires; the outer layer metal cylinders and the inner layer insulating cylinders are arranged in parallel at intervals; the metal corona wires are arranged in parallel on the sidewall of each inner layer insulating cylinder; the metal corona wires are connected with the high-voltage end of a power supply; each outer layer metal cylinder is connected with the ground terminal of the power supply; a reaction chamber is formed between the metal corona wires and the outer layer metal cylinders. The indoor air purifying device disclosed by the invention is simple and compact in structure, low in wind resistance, large in air treatment capacity, capable of purifying indoor particulate matters, gaseous pollutants, bacteria, viruses and the like, also high in purification efficiency and good in practicability.

Owner:XI AN JIAOTONG UNIV

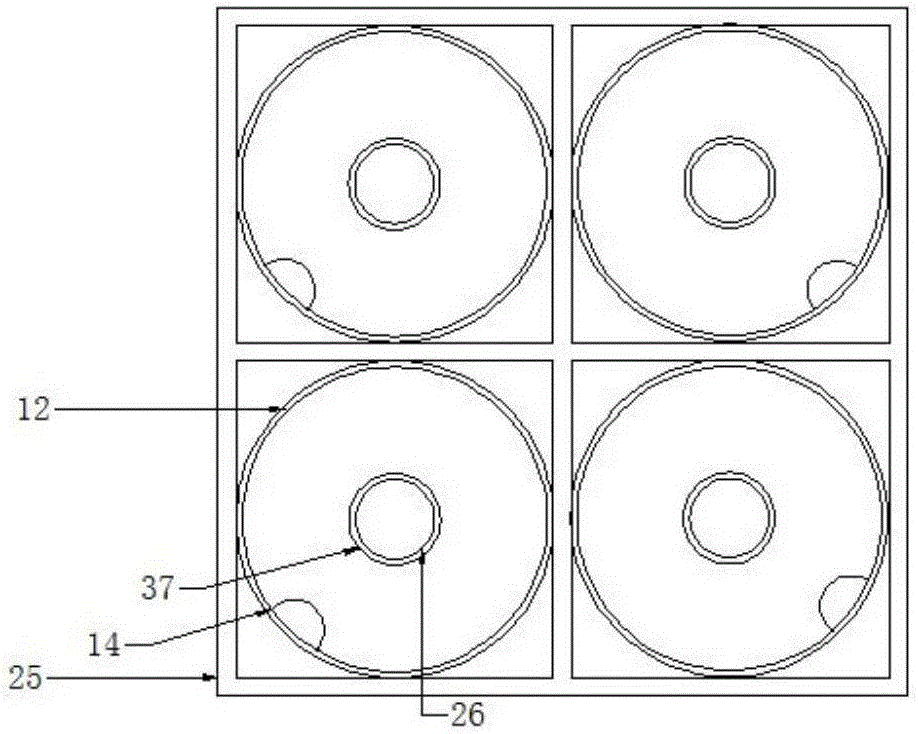

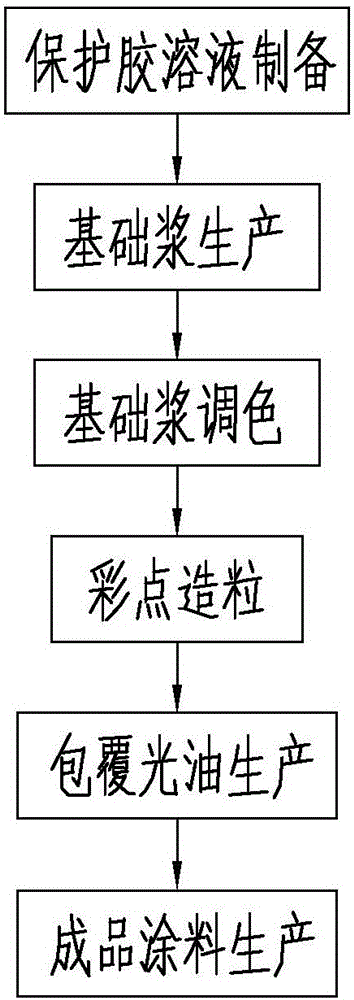

Production method of water-in-water colorful paint containing color sand

ActiveCN105925096ACost-effectiveFast manufacturingAntifouling/underwater paintsPaints with biocidesWeather resistanceSlurry

The invention discloses a production method of water-in-water colorful paint containing color sand. The production method comprises the following steps: (a), preparing a protection glue solution; (b), producing basic slurry; (c), matching the color of the basic slurry; (d), performing color point granulation; (e), producing coating gloss oil; (f), producing finished paint. Granite-shaped particle containing particles are formed on the surface of the paint produced by the method, imitated-marble granite paint can be prepared from the paint, formed patterns are simple, artistic and elegant, and the paint prepared by the method is level in surface and not easy to form ash deposition, can keep the overall appearance longer, and has stain resistance; the special coating gloss oil can keep the color on the surface of the paint to be permanent and fresh, and has weather resistance; the paint is high in water resistance and rot resistance, is neither absorbed by a wall surface nor damaged in rainy days, and can protect the overall shapes of buildings.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

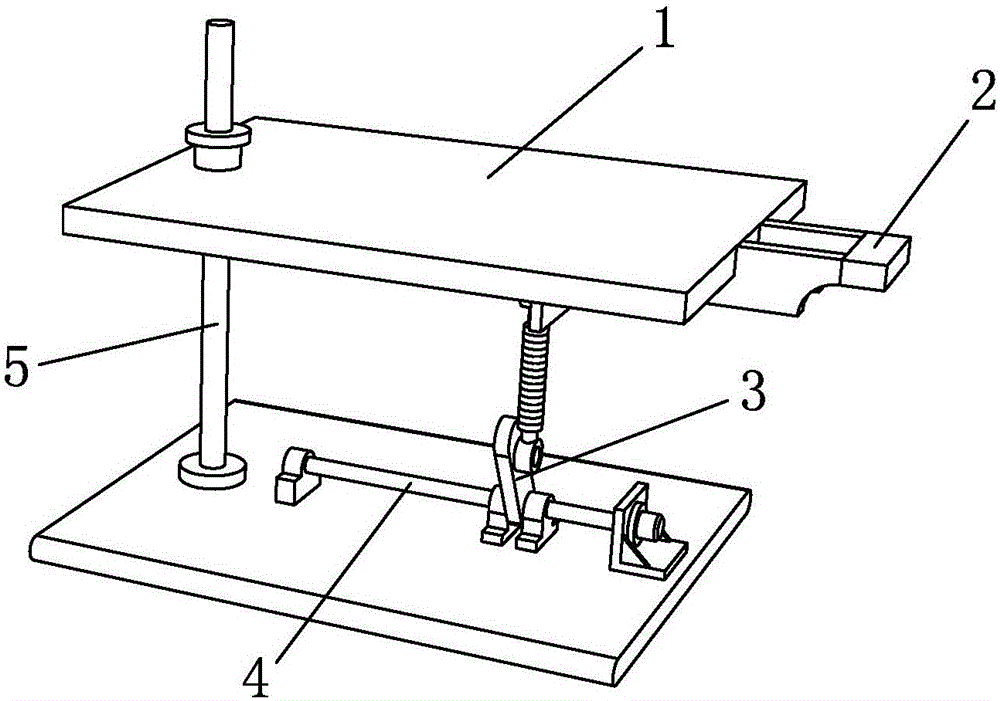

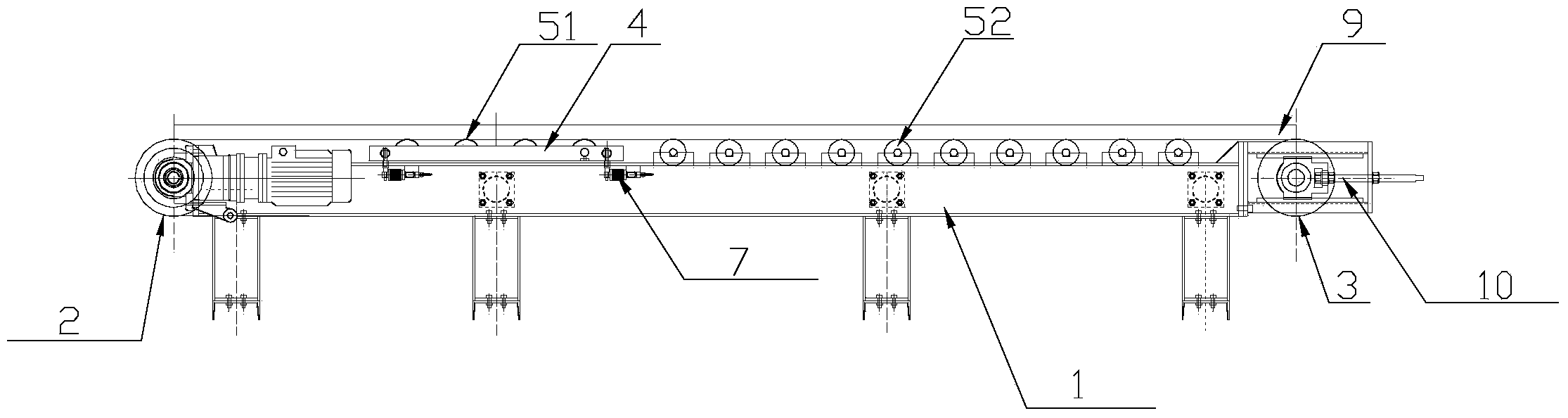

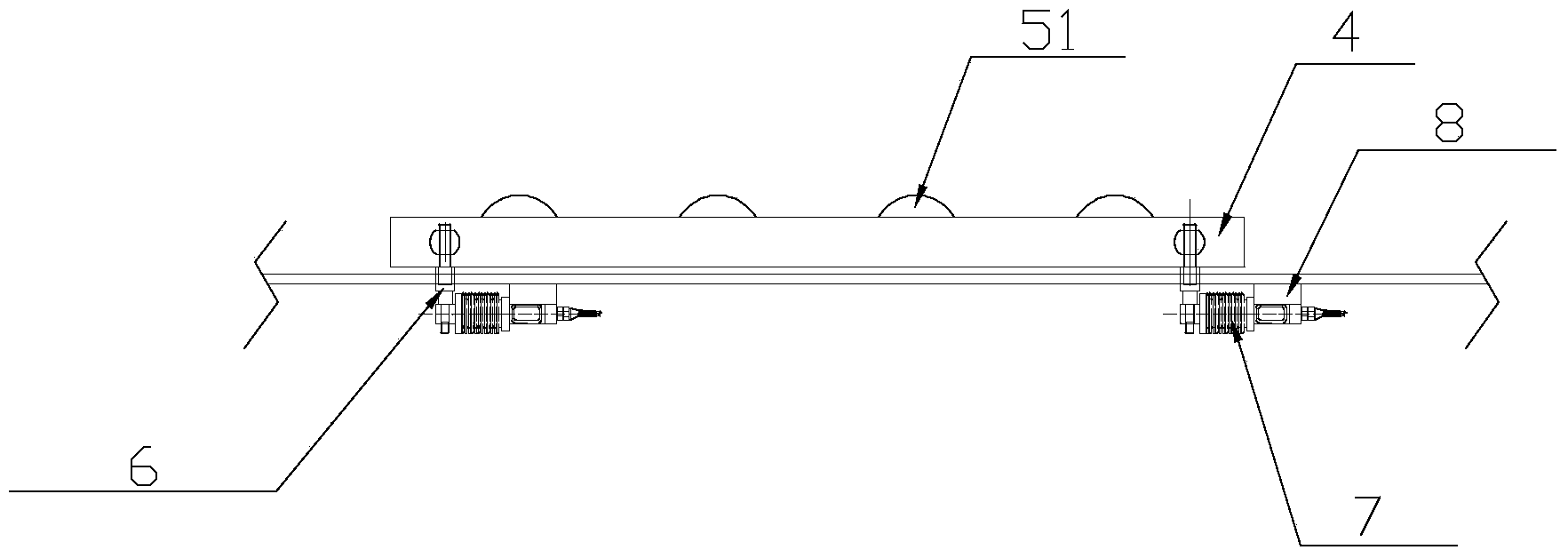

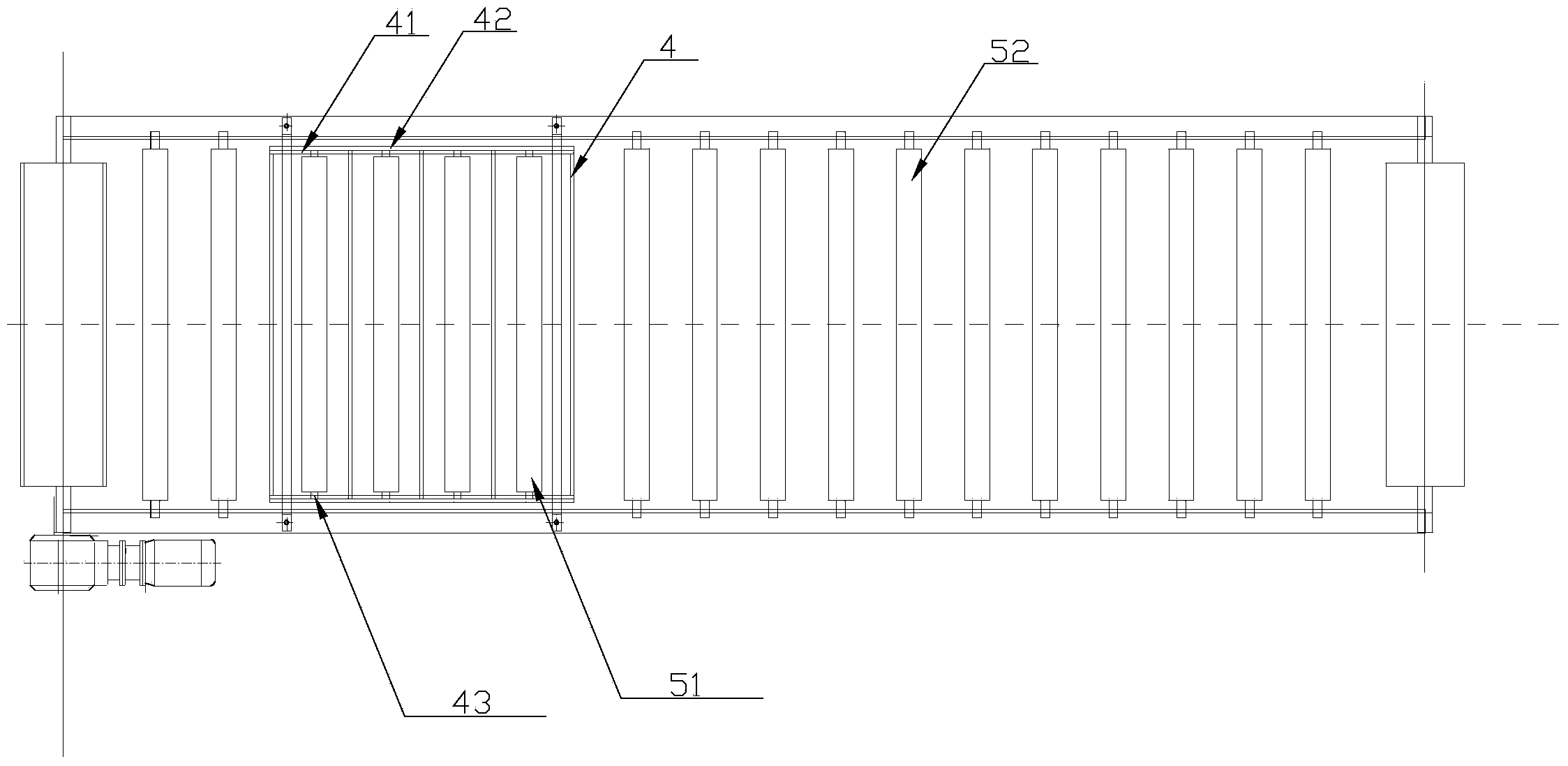

High-precision electronic belt scale

InactiveCN104236686AEasy to installEasy to adjustWeighing apparatus for continuous material flowEngineeringMeasurement precision

The invention relates to a high-precision electronic belt scale, in particular to a constant weight feeder. The high-precision electronic belt scale is characterized in that a rectangular metering scale frame is fixed to a body frame, one end of each weighing sensor is connected with a lead screw arranged on the metering scale frame, the other ends of the weighing sensors and the body frame are fixed through bolts, and mounting cushion blocks with the inclination identical with that of the body frame are arranged between the weighing sensors and the body frame. The metering scale frame is formed by welding six pieces of flat iron, the two sides, perpendicular to the direction of metering carrier rollers, of the metering scale frame are formed by welding outer flat iron and inner flat iron, clamping grooves are formed in the upper edge of the inner flat iron, and the two ends of the metering carrier rollers are clamped with the corresponding clamping grooves respectively and are fixed through bolts. The problem that a common constant weight feeder is not high in measurement precision is solved, the measurement precision can reach the level 0.1, meanwhile, materials of the metering scale frame arranged in order to improve the measurement precision are light, dust accumulation in the structure is not prone to happening, and long-term belt stability is facilitated.

Owner:HANGZHOU ZHONGNAN ELECTRONICS ENG

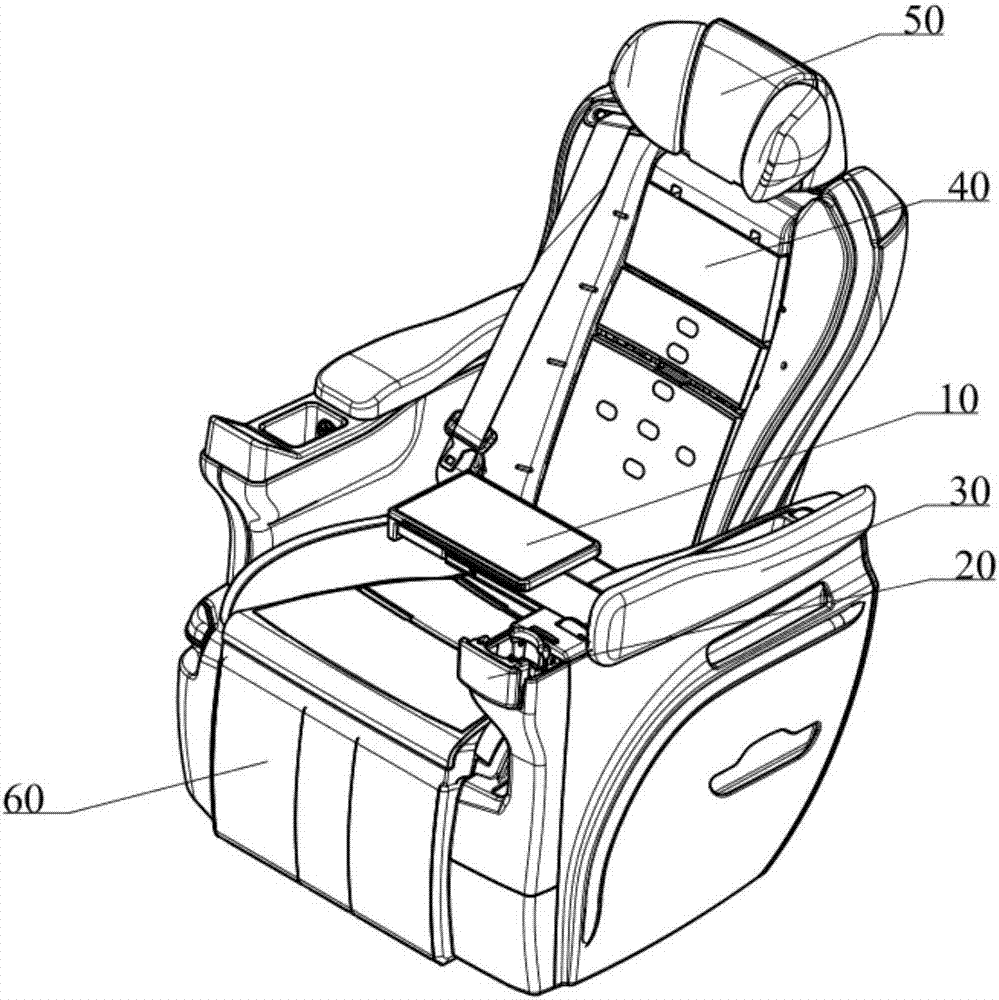

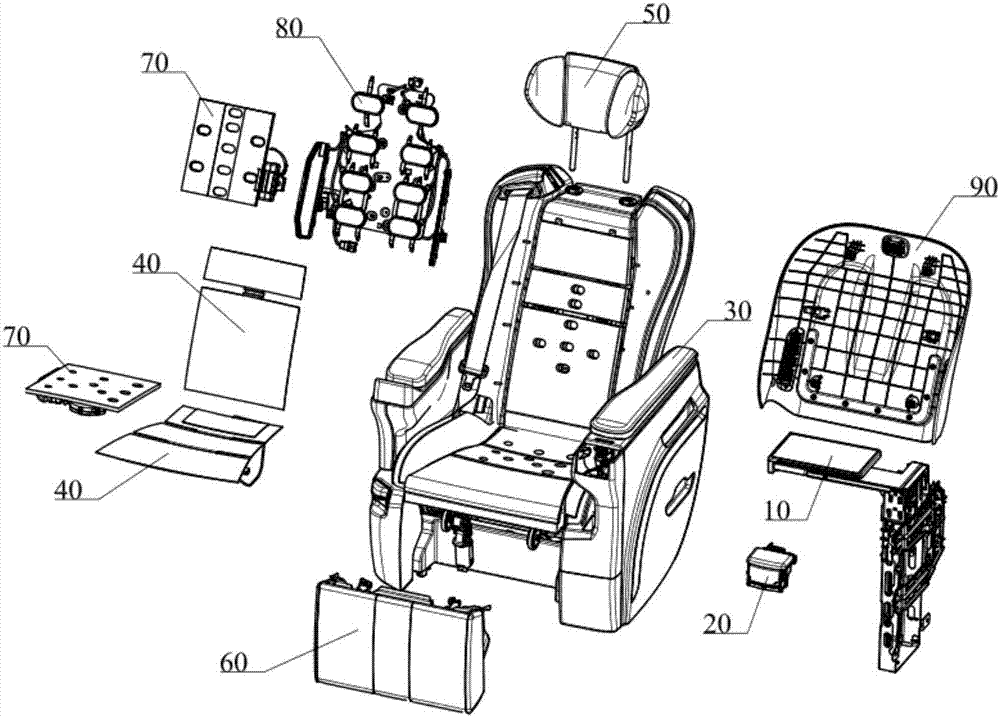

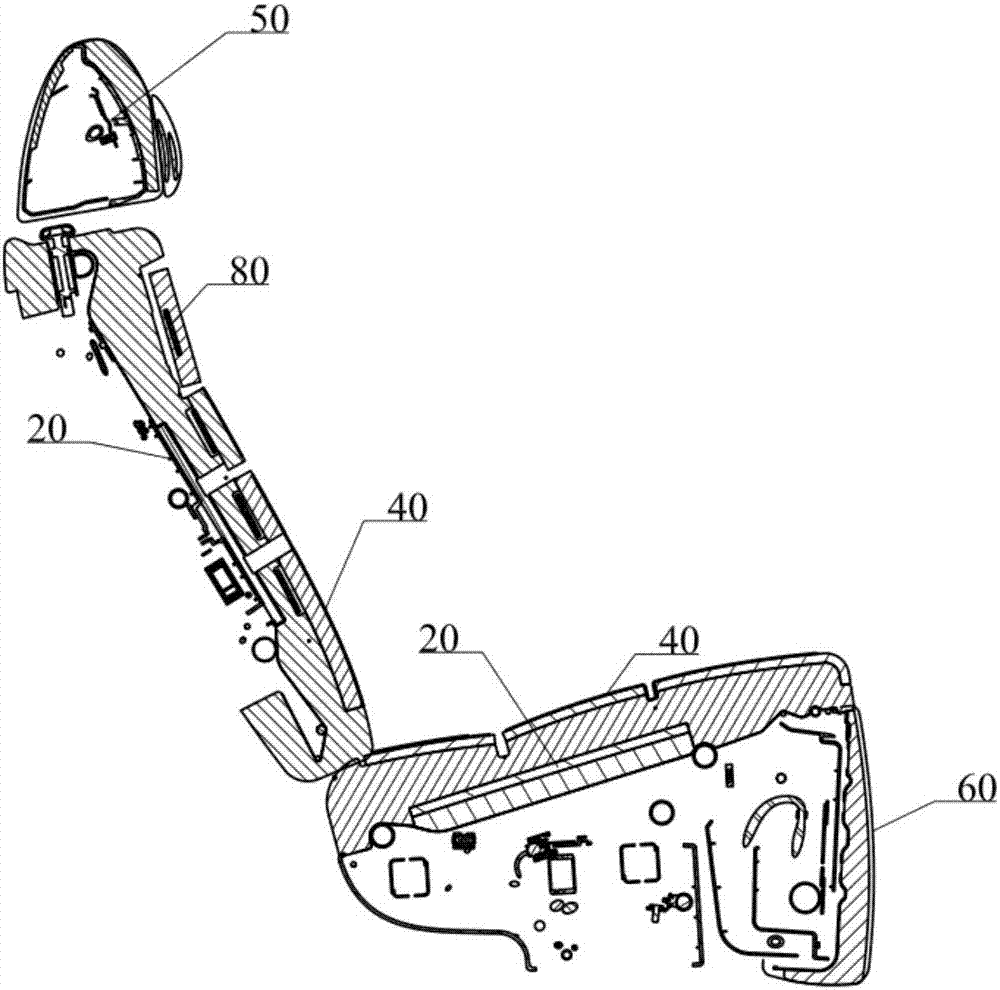

Automobile seat

The invention discloses an automobile seat and belongs to the technical field of automobiles. A seat skeleton of the automobile seat comprises armrest parts, a backrest part and a cushion part. The armrest parts each comprise an armrest face plate and an armrest cover assembly which are slidably or rotatably connected. Cup holder structures or table plate structures are arranged on the armrest face plates. The table plate structures can slide out of the armrest parts and rotate relative to the armrest parts and can also slide into the armrest parts and locked with the armrest parts. The cup holder structures are arranged on the armrest face plates in a foldable mode, and a space for containing a water cup is formed when the cup holder structure is unfolded. The rotatable table plate structures, the foldable cup holder structures, the armrest face plates and the armrest cover assemblies are arranged on the armrest parts, wherein the armrest face plates and the armrest cover assemblies are connected rotatably or slidably, so that the automobile seat has an office function, attractiveness and comfort are easily improved, the space can be reasonably utilized, and the automobile seat is high in integration level, small in occupied space and attractive, and dust is not liable to be accumulated on the automobile seat.

Owner:天津陆耐酷车科技有限公司

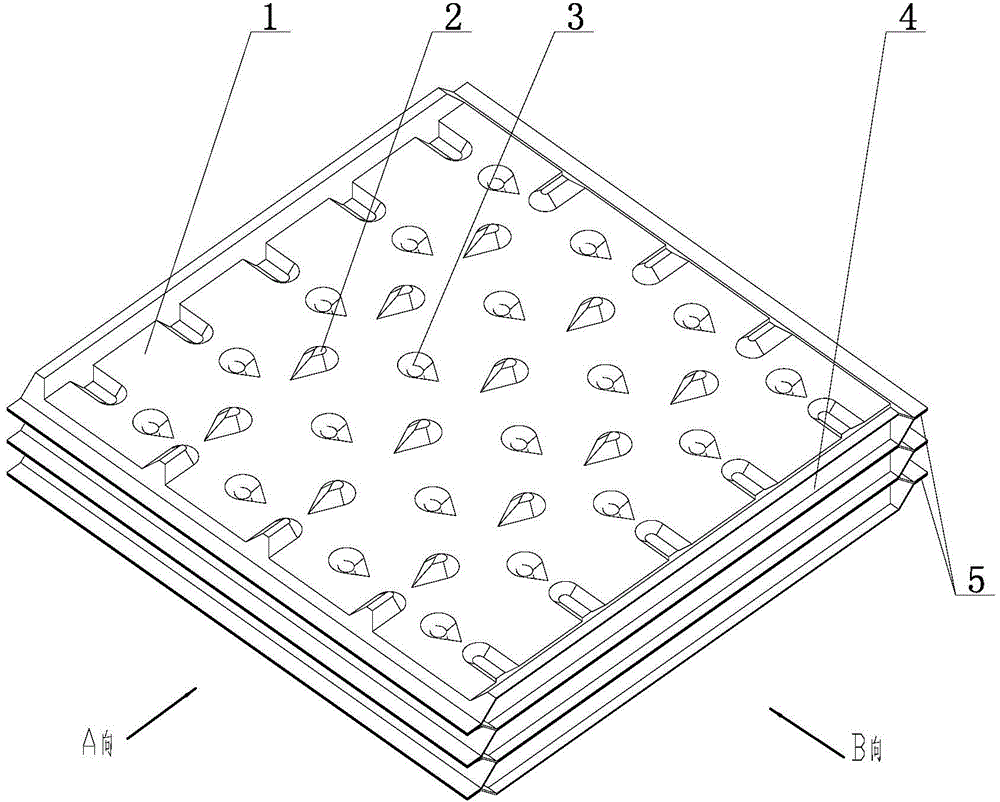

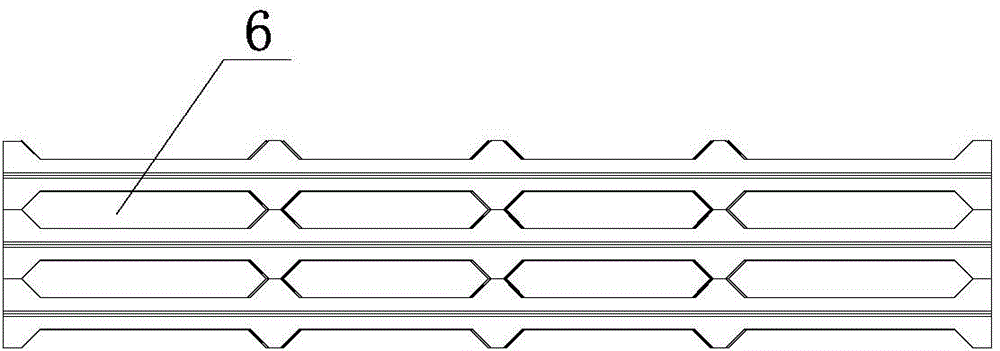

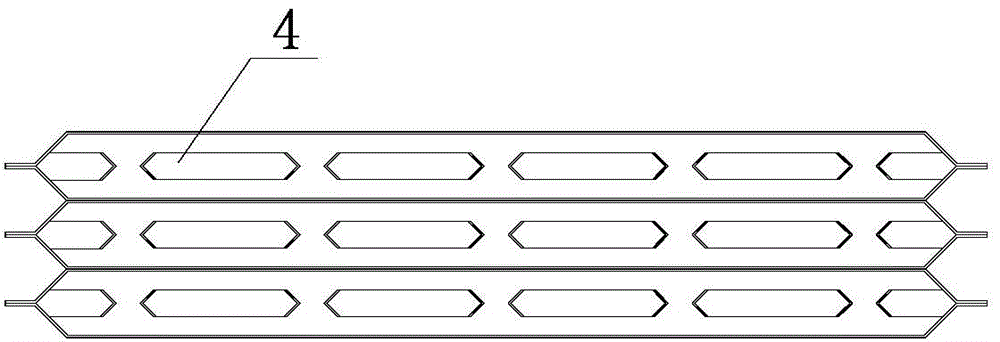

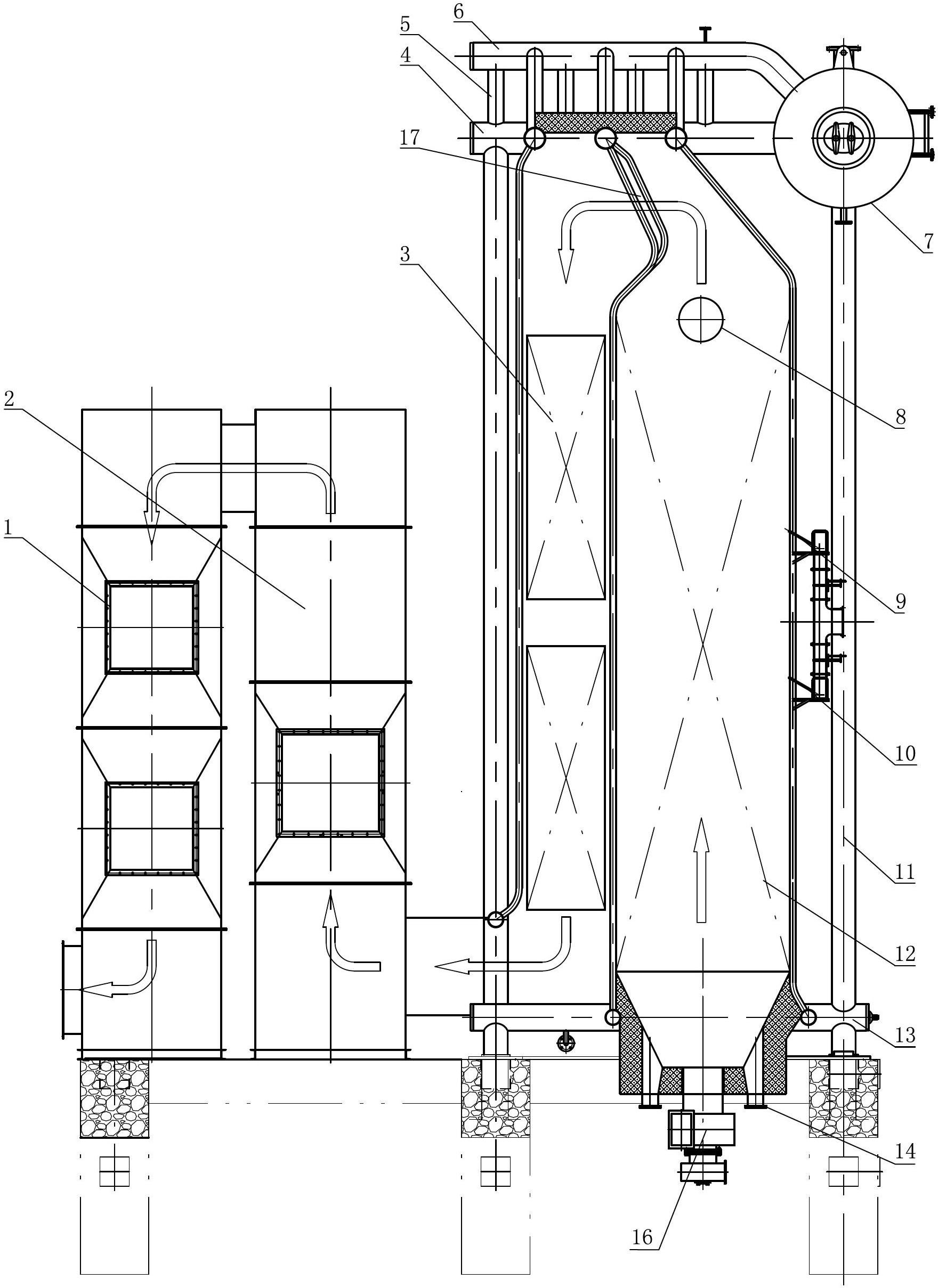

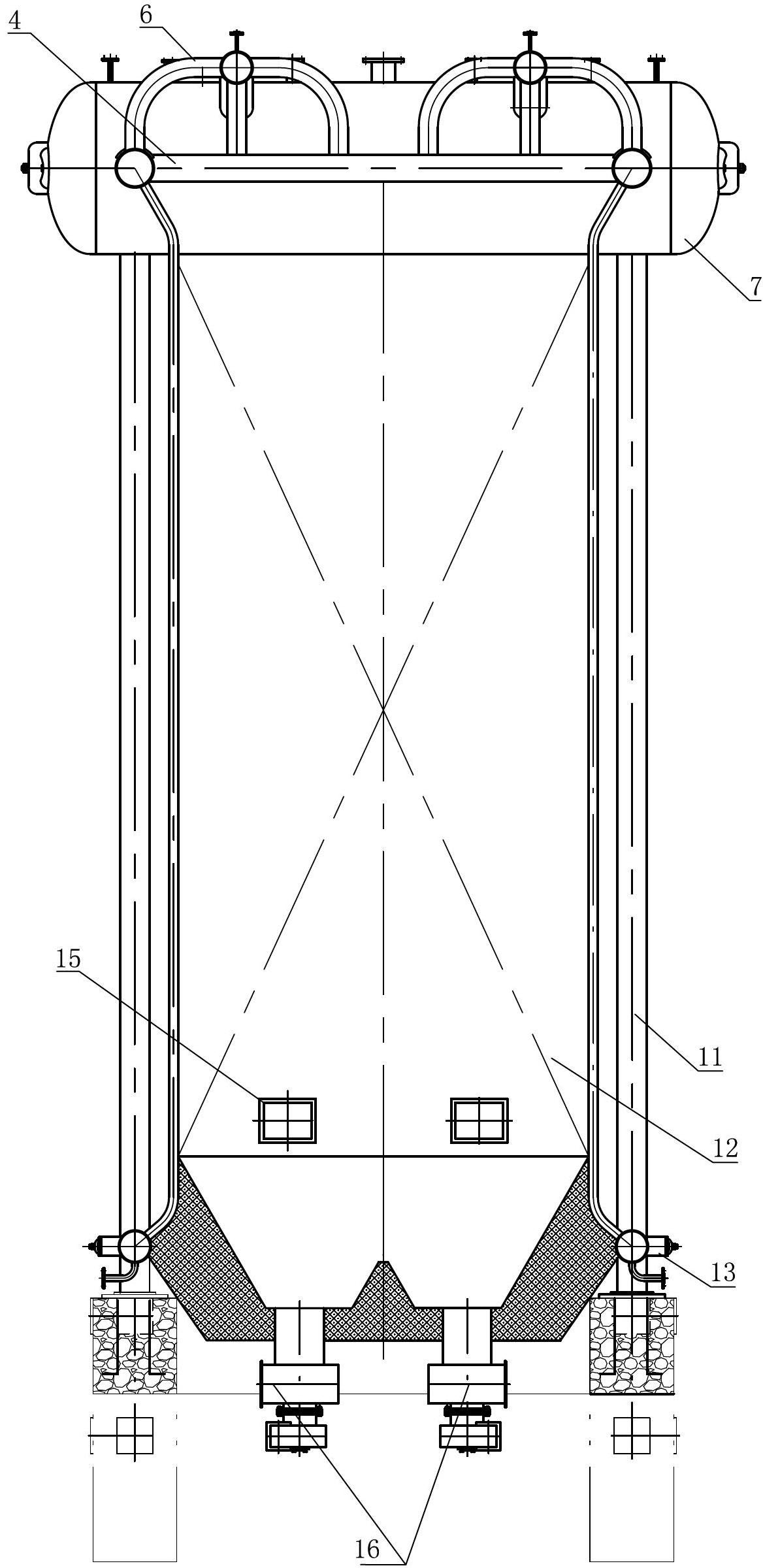

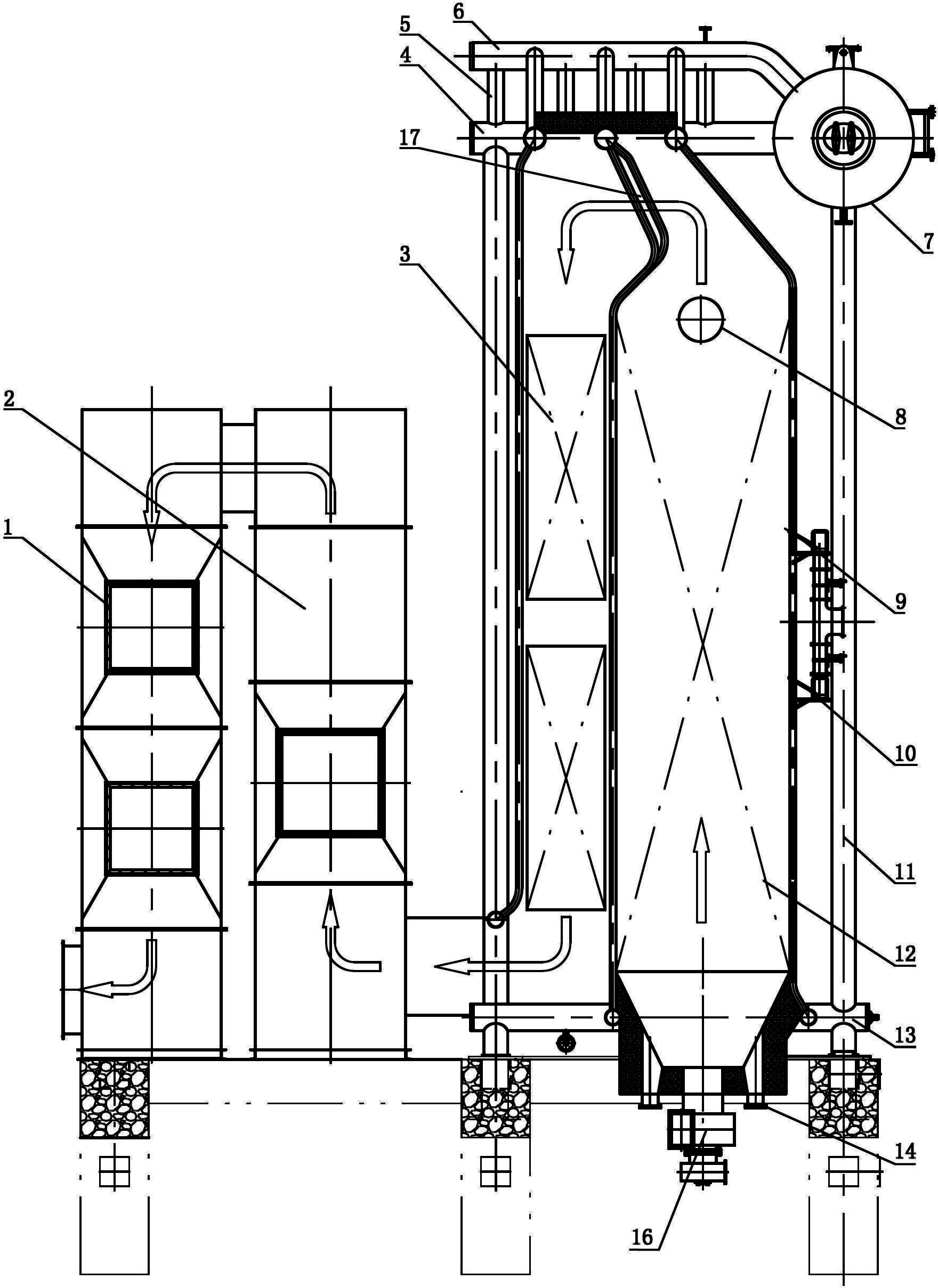

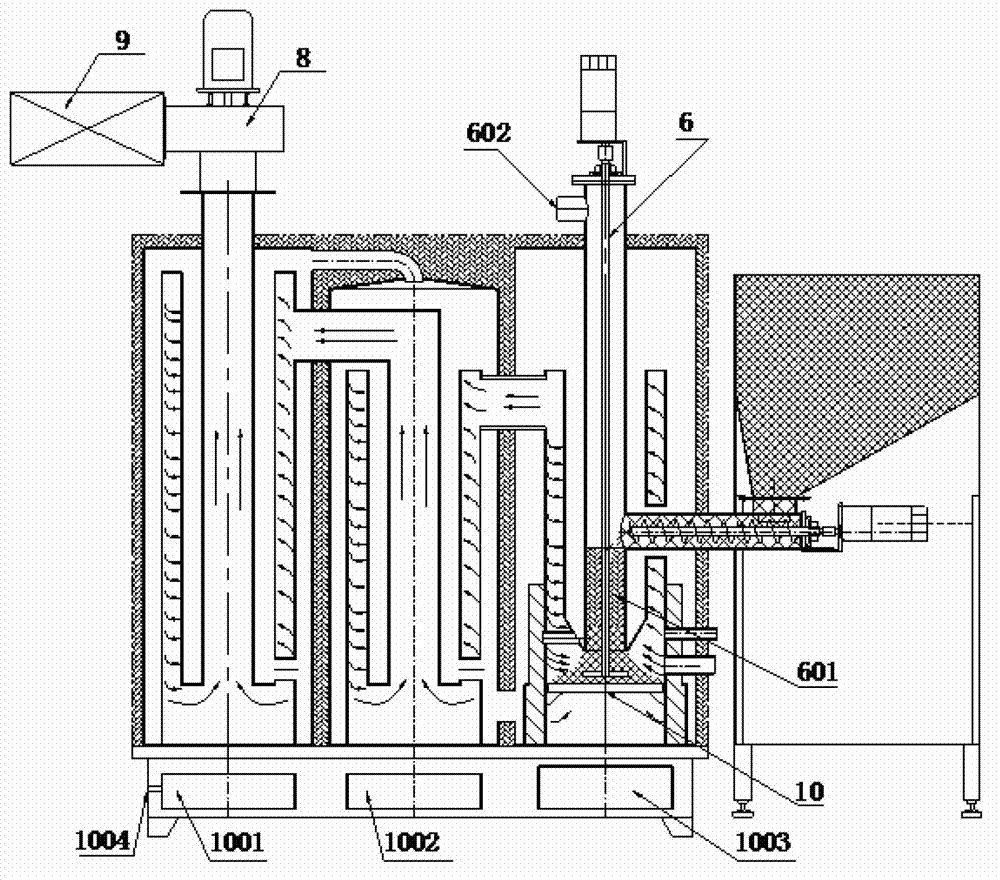

Self-supporting wide gap heat exchanging element

ActiveCN104696983ASelf-supportingReduce manufacturing costCombustion processIndirect carbon-dioxide mitigationFlue gasWide gap

The invention is applicable to the field of air cold medium pre-heating and particularly relates to a self-supporting wide gap heat exchanging element. The self-supporting wide gap heat exchanging element comprises a plurality of plate pairs which are overlapped layer by layer; each plat pair comprises upper and lower plate sheets which are arranged oppositely; a plurality of rows of convex ripples and concave ripples are distributed on the upper surfaces of the plate sheets along the same axis direction; the convex ripples and concave ripples are obtained by upwards and downwards pressing and molding the plate sheets; the convex ripples and concave ripples are distributed at intervals; the positions of the convex ripples and concave ripples on the upper plate sheets in the plate pairs correspond to the positions of the convex ripples and concave ripples on the lower plate sheets in the plate pairs; one group of opposite edges of the plate sheets are upwards folded and are transited into planes; the other group of opposite edges of the plate sheets are downwards folded and are transited into planes; the two adjacent folding edges in each plate pair are welded to form an air channel; the two adjacent plate pairs are symmetrical up and down, and the adjacent folding edges between the two adjacent plate pairs are welded to form a flue gas channel. The self-supporting wide gap heat exchanging element has the advantages that a wide gap channel can be combined, dirt and dust are not easy to deposit, the resistance fall also can be reduced and the heat exchanging efficiency is sufficiently improved.

Owner:SHANDONG WINTECH TECH CO LTD

Vertical coal dust corner tube boiler

InactiveCN102644911ACompact structureStructure, compact arrangement of four cornersSteam boilersAir preheaterCoal dust

The invention discloses a vertical coal dust corner tube boiler, which comprises a burner, a boiler body, an air preheating device, a waste heat water tank, a convection bank, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of the boiler body, and the upper collecting box and the top collecting box are arranged on top of the boiler body and communicated through a steam communicating pipe. The vertical coal dust corner tube boiler is characterized in that the burner is arranged at the bottom of the boiler body which adopts a vertical film type water cooling wall structure, four lowering pipes are arranged at four corners, and two ends of the lowering pipe and the film type water cooling wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged outside the film type water cooling wall, the top of the convection tube bundle is communicated with a boiler chamber smoke outlet, and the bottom of the convection tube bundle is communicated with the waste heat water tank. The vertical coal dust corner tube boiler has the advantages of being compact in integral structure, simple in appearance display, small in covered area, low in steel consumption, big in boiler water circulation pressure difference and safe and reliable in water circulation and the like.

Owner:HANGZHOU JUNENG BOILER

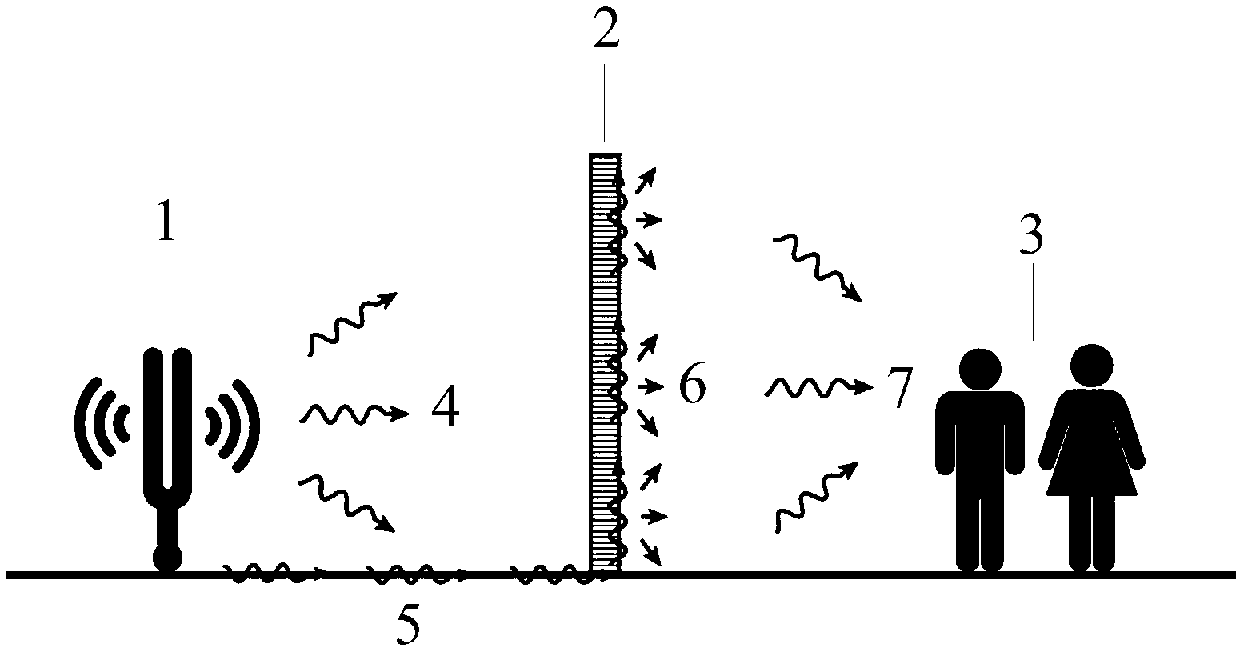

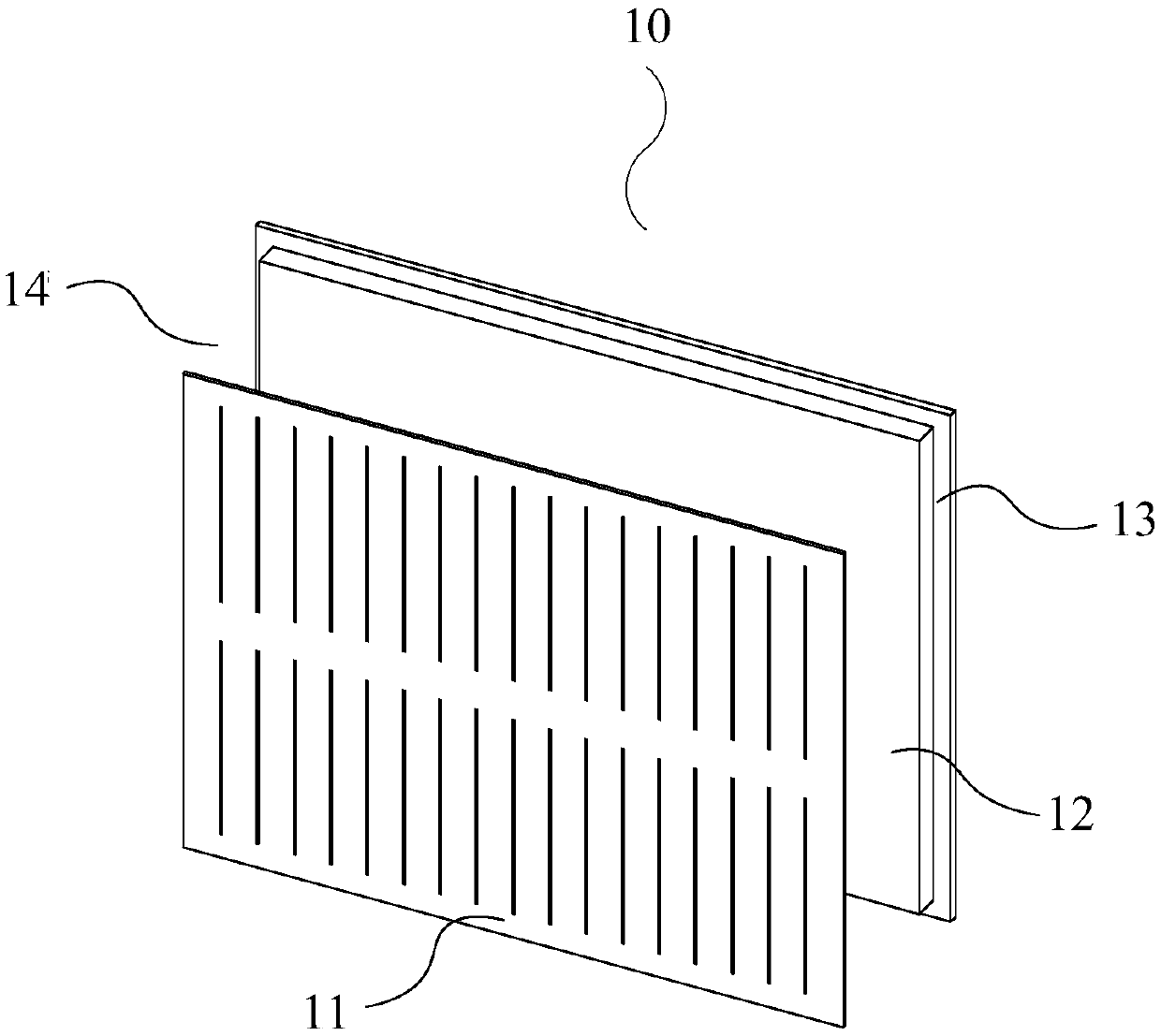

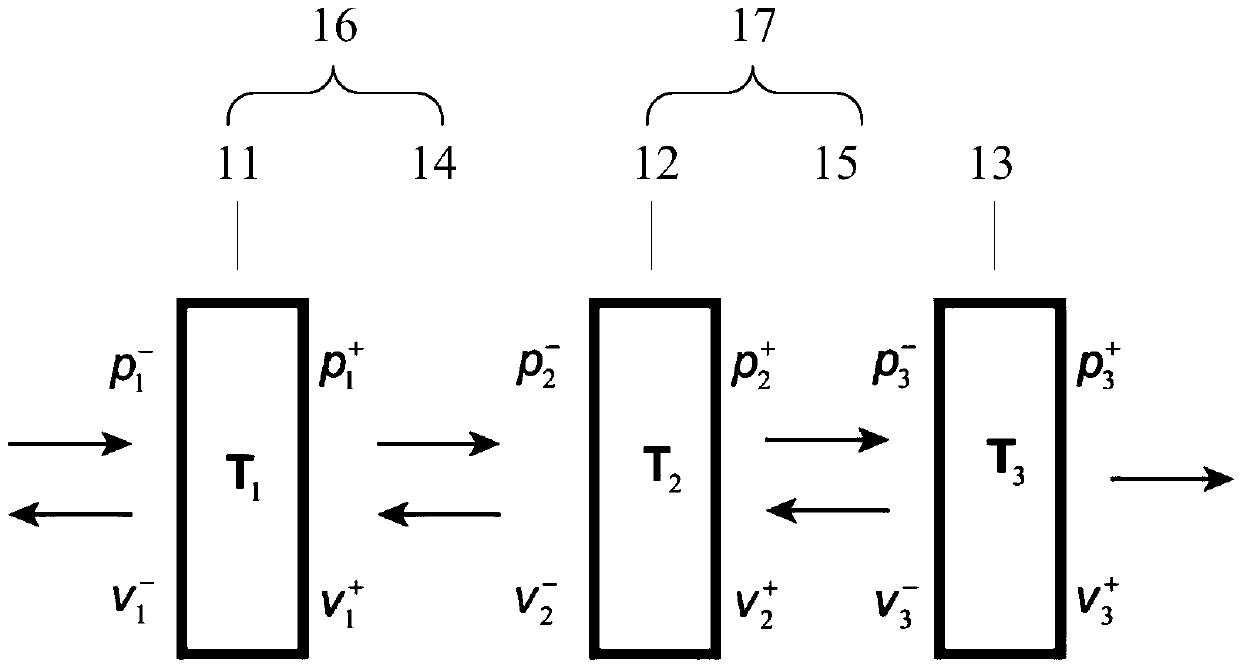

Acoustic structure and design method thereof

ActiveCN108847211ASimple and thin structureImprove sound insulation performanceSound producing devicesResonanceSound Absorber

The invention relates to an acoustic structure and a design method thereof. The acoustic structure includes a perforated plate layer, a resonance type metamaterial layer and a back plate layer which are sequentially disposed, wherein a first cavity is formed between the perforated plate layer and the resonant type metamaterial layer, a second cavity is formed between the resonant type metamateriallayer and the back plate layer, a first resonant sound absorber is formed between the perforated plate layer and the first cavity, a second resonance sound absorber is formed between the resonance type metamaterial layer and the second cavity, if the second resonant sound absorber is in a resonant state, the vibration response amplitude of the back plate layer is close to zero. The acoustic structure is advantaged in that the acoustic structure is simple and thin in structure and is easy for assembling and maintenance.

Owner:上海超颖声学科技有限公司

Preparing method of dustproof surface

ActiveCN107058980ALoose structureImprove dust resistanceChemical vapor deposition coatingSuperimposed coating processMicro nanoNitrogen gas

The invention discloses a preparing method of a dustproof surface, and belongs to the technical field of plasma chemical vapor phase deposition. According to the method, a base material is placed in a reaction cavity, continuous vacuum pumping is carried out, and inert gases or nitrogen is led in; monomer steam is led to start chemical vapor phase deposition, and a compact coating is prepared; after the compact coating is deposited, power of plasma discharge is adjusted so as to achieve chemical vapor phase deposition, and a rough coating is prepared; a dustproof surface with the inner layer as the compact coating and the outer layer as the rough coating is prepared on the surface of the base material; the lead monomer steam is a mixture of at least one kind of single-functional unsaturated fluorocarbon resin and at least one kind of polyfunctionality unsaturated hydrocarbon derivatives, wherein the mass percent of the polyfunctionality unsaturated hydrocarbon derivatives in the monomer steam ranges from 10% to 80%. low-surface-energy fluorocarbon resin of a micro-nano structure is deposited on the surface of the base body, the surface energy and the contact area of the material are reduced, and the effect of restraining dust absorbing and stacking is achieved.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

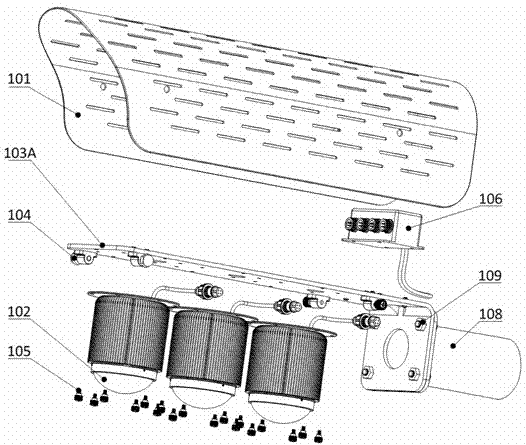

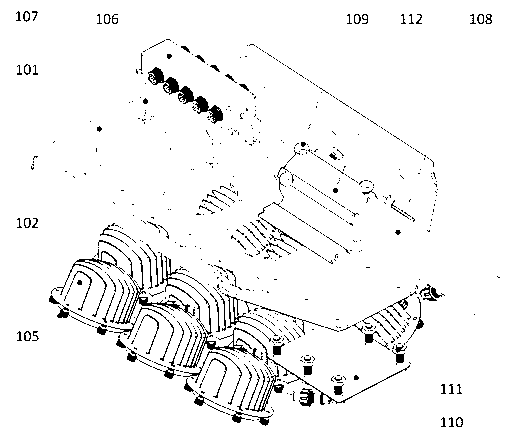

Road lamp adopting installing interface bracket structure

ActiveCN102818177ASimple structureLow costPoint-like light sourceLighting heating/cooling arrangementsEnergy efficient lightingEngineering

The invention discloses a road lamp adopting an installing interface bracket structure. The road lamp comprises an installing interface bracket (103A) formed by a metal plate in an extruding manner; the installing interface bracket (103A) is provided with an installing interface; the installing interface is provided with an LED bulb (102) with a radiator; the installing interface bracket (103A) is installed on a lamp post (108); a lamp shell (101) formed by metal in a punching manner or formed by casting plastic is arranged outside the installing interface bracket (103A); the road lamp adopting the installing interface bracket structure further comprises a harness connector (106); and the harness connector (106) is used for connecting the LED bulb (102) into the mains supply. According to the road lamp adopting the installing interface bracket structure, the lamp shell, the lamp bulb and other auxiliary parts are installed on the installing interface bracket by taking the installing interface bracket as the center, and the road lamp is simple in structure, low in construction cost, rapid and convenient to install, use and maintain without worsening breakdown, so that the links in the production chain are greatly reduced, the mass production is realized, and the application and large-scale industrialization of LED energy-saving lighting products are facilitated.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

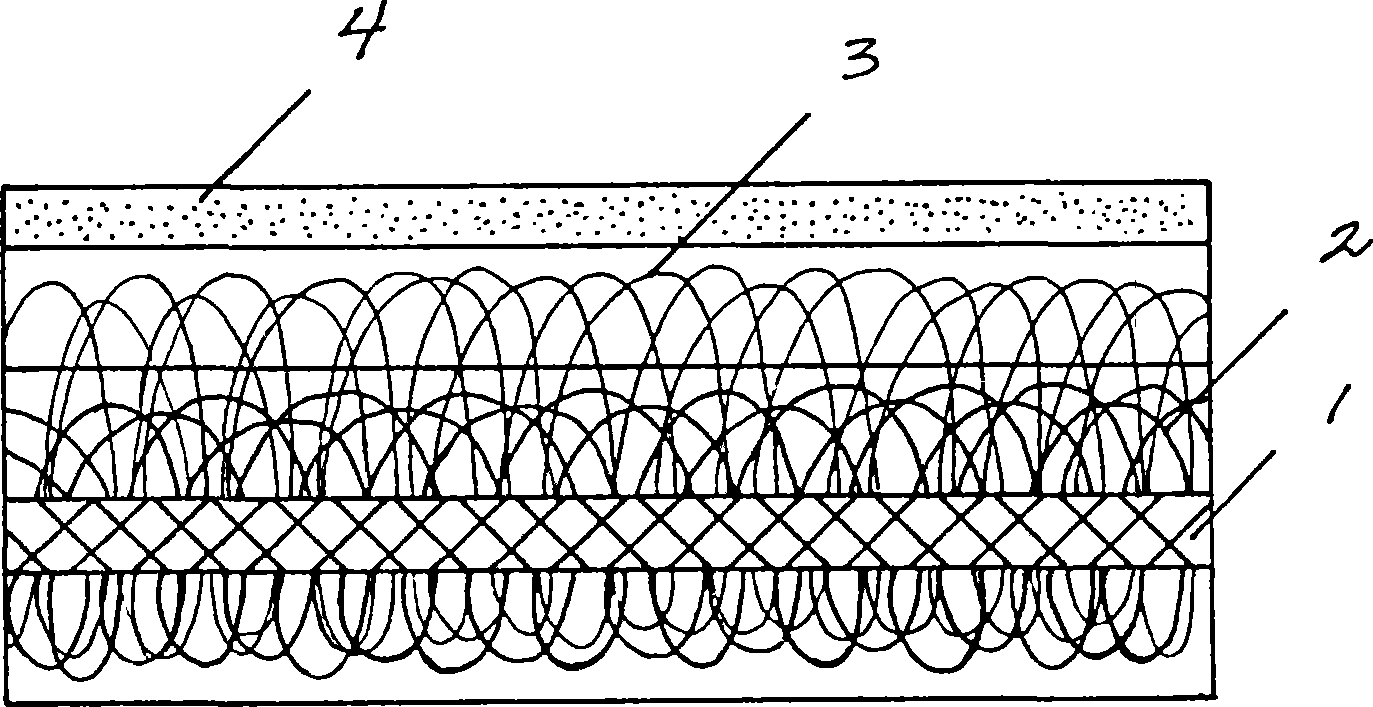

Pure polyfluortetraethylene gradient overlay film filter material with high intensity

The invention relates to a high-strength pure polytetrafluoroethylene gradient coating filter material, which comprises base cloth, and is characterized in that the base cloth is a polytetrafluoroethylene base cloth; a polytetrafluoroethylene coarse fiber layer and a polytetrafluoroethylene superfine fiber layer are pricked on the polytetrafluoroethylene base cloth; and a polytetrafluoroethylene film is coated on the polytetrafluoroethylene superfine fiber layer. The high-strength pure polytetrafluoroethylene gradient coating filter material has the characteristics of high and low temperature resistance, high acid and alkaline resistance, high humidity resistance, good chemical stability, high filtration efficiency, quick filtration speed, long service life and the like, can be used in various bag-type dusters for flue gas purification, dust removal, dust treatment and material recovery, and has wide application scope.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

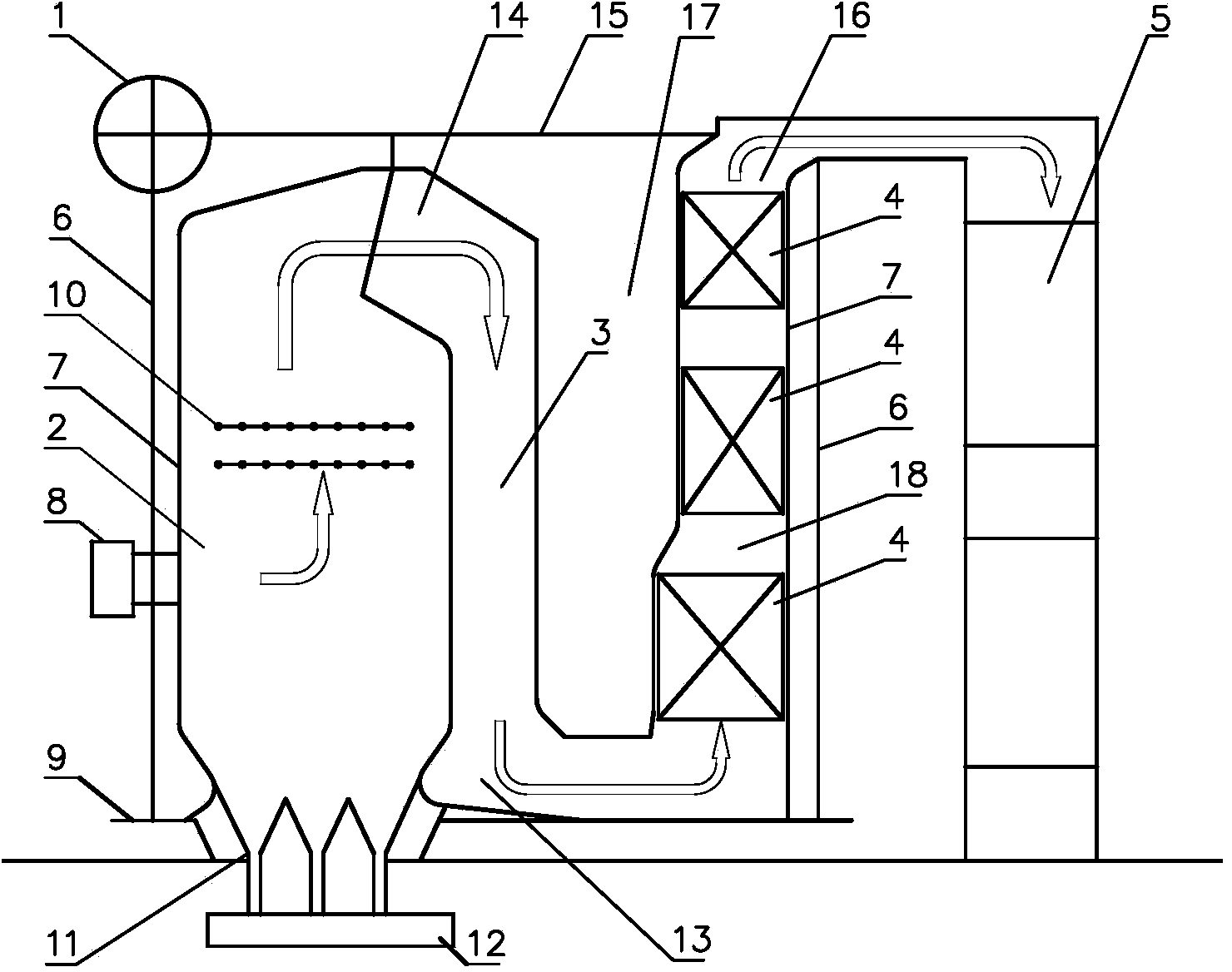

Three-return-stroke powder steam boiler

InactiveCN104359099AReduce generationStop cokingFluidized bed combustionSteam boilersCombustorFlue gas

The invention discloses a three-return-stroke powder steam boiler. The three-return-stroke powder steam boiler comprises a boiler barrel, a hearth, a burnout chamber, a convection tube bundle, tail heat exchange equipment, a combustor, a slag falling device, a lower header and an upper header, wherein the lower header is arranged at the bottom of a boiler body; the upper header is arranged at the top of the boiler body; the combustor is arranged at the front part, the top, the bottom or the side part of the hearth of the boiler; the boiler body has a full-film type water-cooled wall structure, and four main downcomers are arranged at four corners; the convection tube bundle is arranged in a convection tube bundle flue, the convection tube bundle flue is longitudinally arranged, and the height of the convection tube bundle flue is equal to that of the hearth; the upper and lower ends of the convection tube bundle, the main downcomers and a film type water-cooled wall are communicated with the upper header and the lower header respectively; the burnout chamber and the hearth are longitudinally arranged abreast in a back-to-back way, and the height of the burnout chamber is equal to that of the hearth; the hearth, the burnout chamber, the convection tube bundle flue and the tail heat exchange equipment are sequentially conducted in series; two-stage combustion-supporting and denitration secondary air is distributed in the hearth. The three-return-stroke powder steam boiler has the characteristics of long flue gas flow, complete fuel combustion and high heat exchange efficiency.

Owner:HANGZHOU JUNENG BOILER

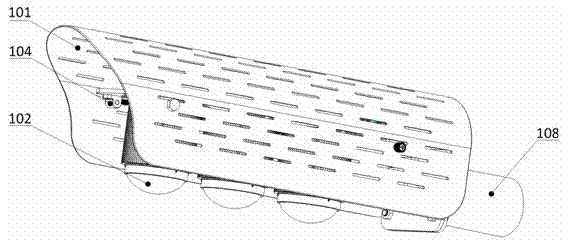

LED (light-emitting diode) street lamp using lamp shell as mounting interface support structure

ActiveCN102818173ASimple structureLow costPoint-like light sourceLighting heating/cooling arrangementsEnergy efficient lightingEngineering

The invention discloses an LED (light-emitting diode) street lamp using a lamp shell as a mounting interface support structure. The LED street lamp comprises a lamp shell (101) which is molded by stamping a metal plate, wherein the lamp shell (101) comprises a support panel which is folded to a plurality of blocks; a mounting interface is arranged on the support panel; an LED bulb (102) is arrangd on the mounting interface; and the lamp shell (101) is fixed on a lamp pole (108) through a lamp pole fixing member. The LED street lamp disclosed by the invention has the advantages of being simple in structure, low in cost and rapid, inexpensive and convenient to mount, use and maintain and hard in fault magnification. According to the LED street lamp using the lamp shell as the mounting interface support structure, the bulb of the LED street lamp, the lamp and a lighting control product are independent in production and use, therefore, production links of the LED street lamp can be greatly reduced and mass production is realized, and the LED street lamp using the lamp shell as the mounting interface support structure is beneficial for application and large-scale industrialization of LED energy-saving lighting products.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

Computer case

InactiveCN107589814ANot easy to accumulate dustAvoid failureDigital processing power distributionCold airWater spray

The invention discloses a computer case and belongs to the field of computer cases. The computer case includes a case body, the bottom end of the right side of the case body is provided with a plurality of first air inlet holes, the left side of the bottom end of the case body is fixedly connected with a cold air box, the cold air box covers the first air inlet holes, and a separating ventilatingplate is fixedly connected inside the cold air box. Water spraying heads in three protruding parts on the upper side of a W-shaped dedusting cooling pipe can spray water for cooling, and dust in the air is adsorbed. The water sprayed out of the W-shaped dedusting cooling pipe and the air are gathered on two protruding parts on the lower side of the W-shaped dedusting cooling pipe, are mixed through a mixing pipe and flow out; under mixing action of the mixing pipe, cooling and dedusting are further performed, the processed air is diffused from a cold air outlet at the position of the mixing pipe and enters a cooling and dedusting chamber, so that the dedusted and cooled air is conveyed into the case body to be cooled, and a heat dissipation effect is good. Dust is not accumulated in the computer case easily, and faults of an electronic device are effectively prevented.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

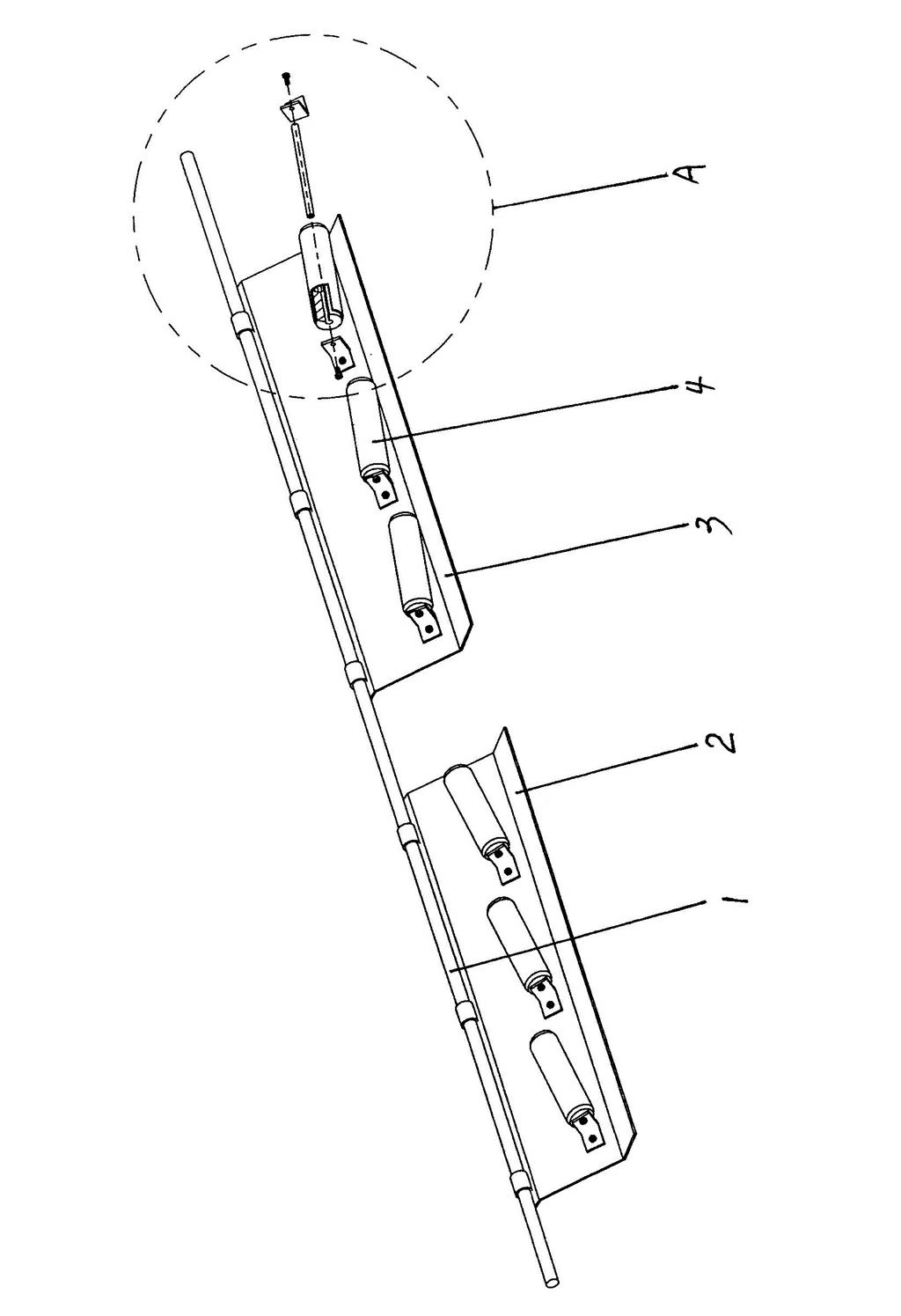

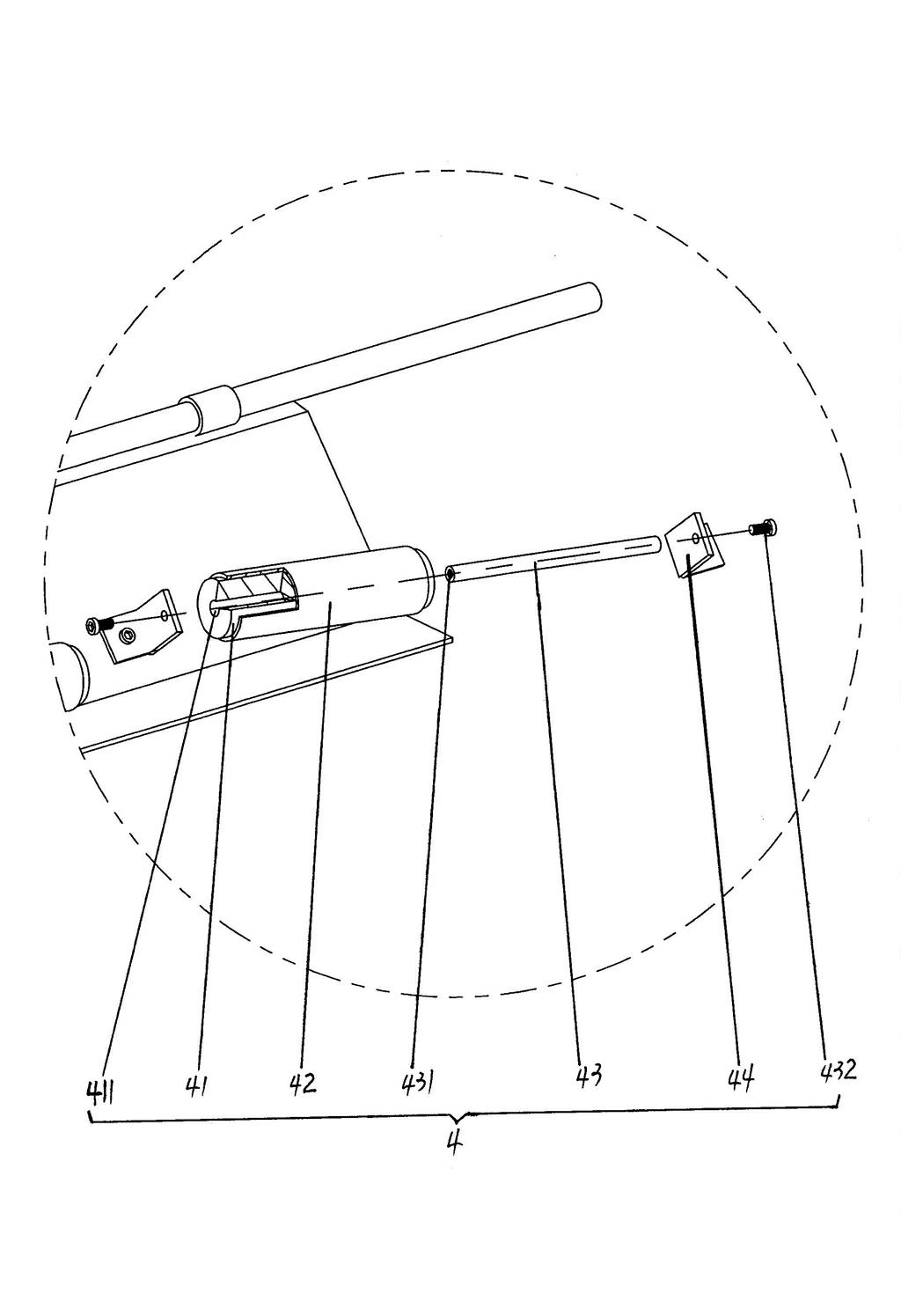

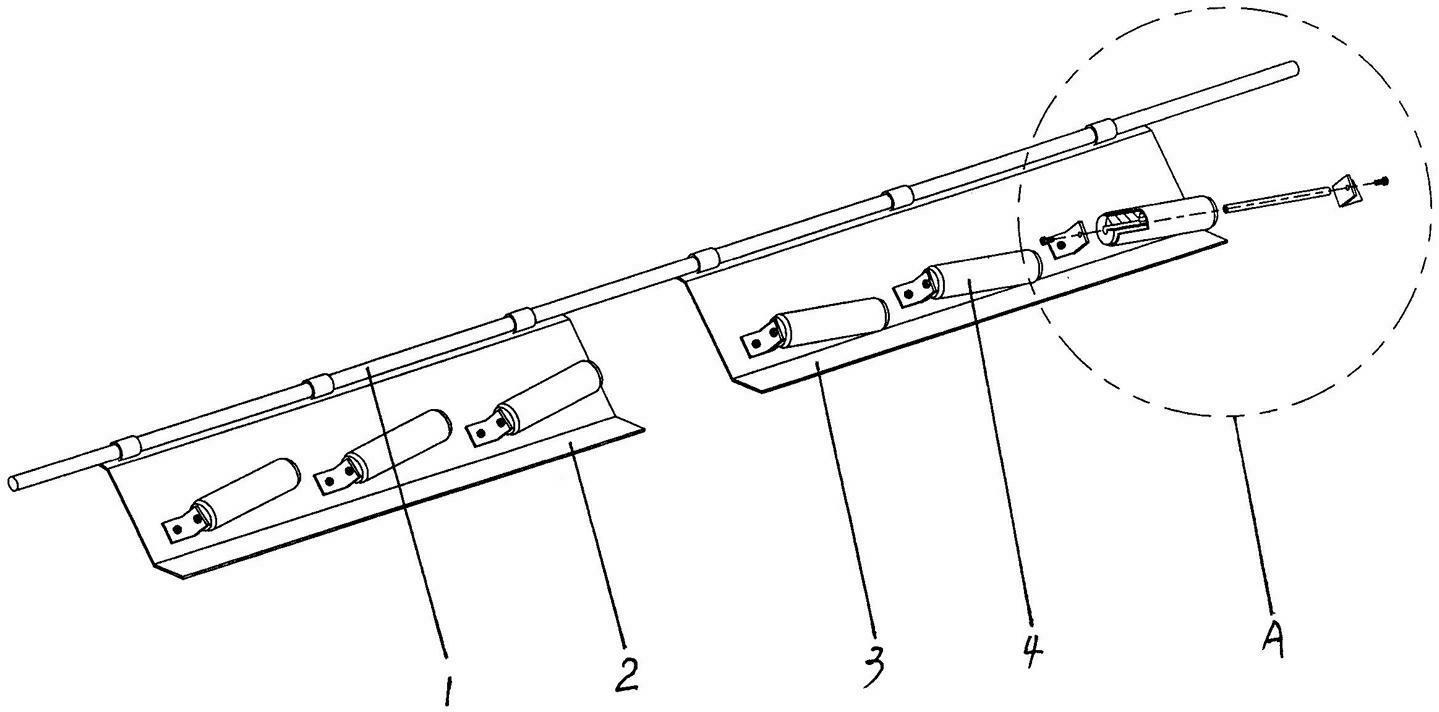

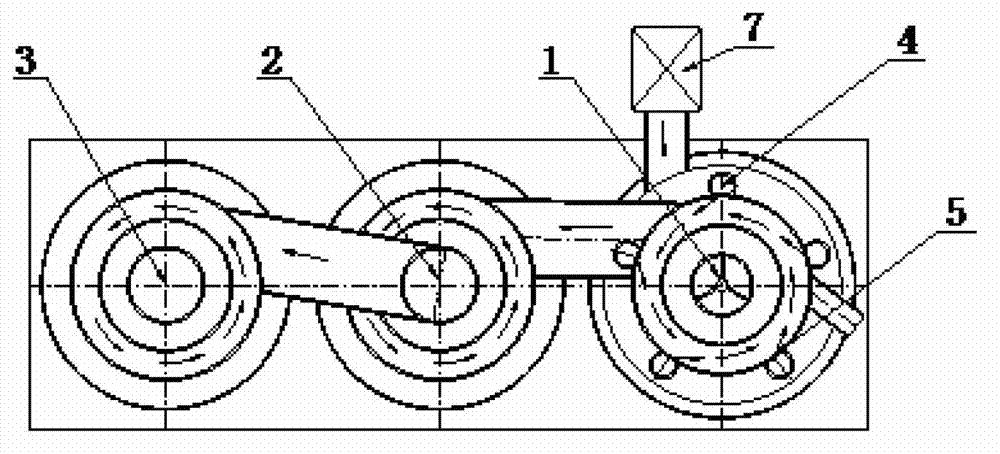

Cloth-unfolding wheel structure of cloth unfolding mechanism for cloth paving machine

The invention relates to a cloth-unfolding wheel structure of a cloth unfolding mechanism for a cloth paving machine and belongs to the technical field of clothes machinery. The cloth unfolding mechanism for the cloth paving machine comprises a fixing rod, a left supporting plate, a right supporting plate and a plurality of cloth-unfolding wheels, wherein the fixing rod is arranged on the cloth paving machine; the left supporting plate and the right supporting plate are arranged on the fixing rod; the cloth-unfolding wheels are the same in structures and are respectively arranged on the left supporting plate and the right supporting plate; the cloth-unfolding wheels on the left supporting plate and the cloth-unfolding wheels on the right supporting plate are distributed in a splayed form. The cloth-unfolding wheel structure is characterized in that each of the cloth-unfolding wheels comprises a nylon rod, a wear-resisting foam gasket, a rotating shaft and a shaft base, wherein the wear-resisting foam gasket coats the outer layer of the nylon rod; a shaft hole is formed in the middle of the nylon rod along the axial direction; the middle part of the rotating shaft penetrates through the shaft hole; the two ends of the rotating shaft extend out of the shaft hole and are respectively mounted on a pair of shaft bases through fastening parts; and the shaft bases are fixed on the supporting plates. The cloth-unfolding wheel structure has the advantages of simple structure, long service life and excellent cloth-unfolding effect, dust is difficult to accumulate, and cleaning and maintenance are convenient.

Owner:苏州比阳特服装设备有限公司

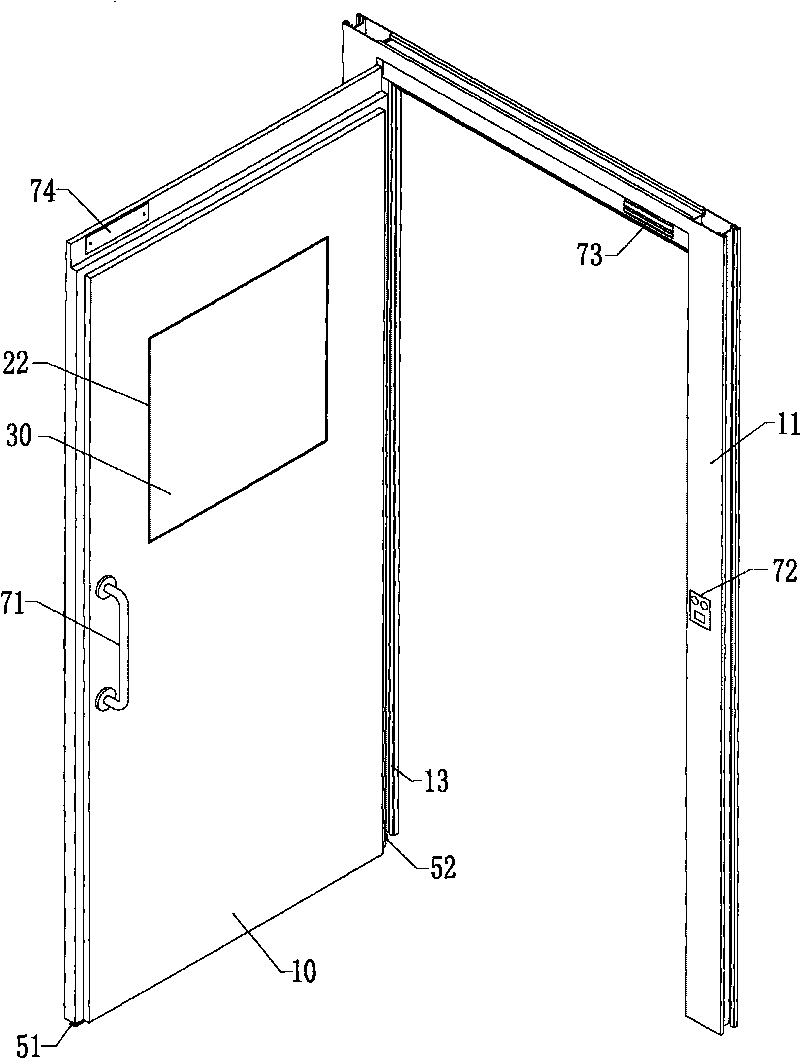

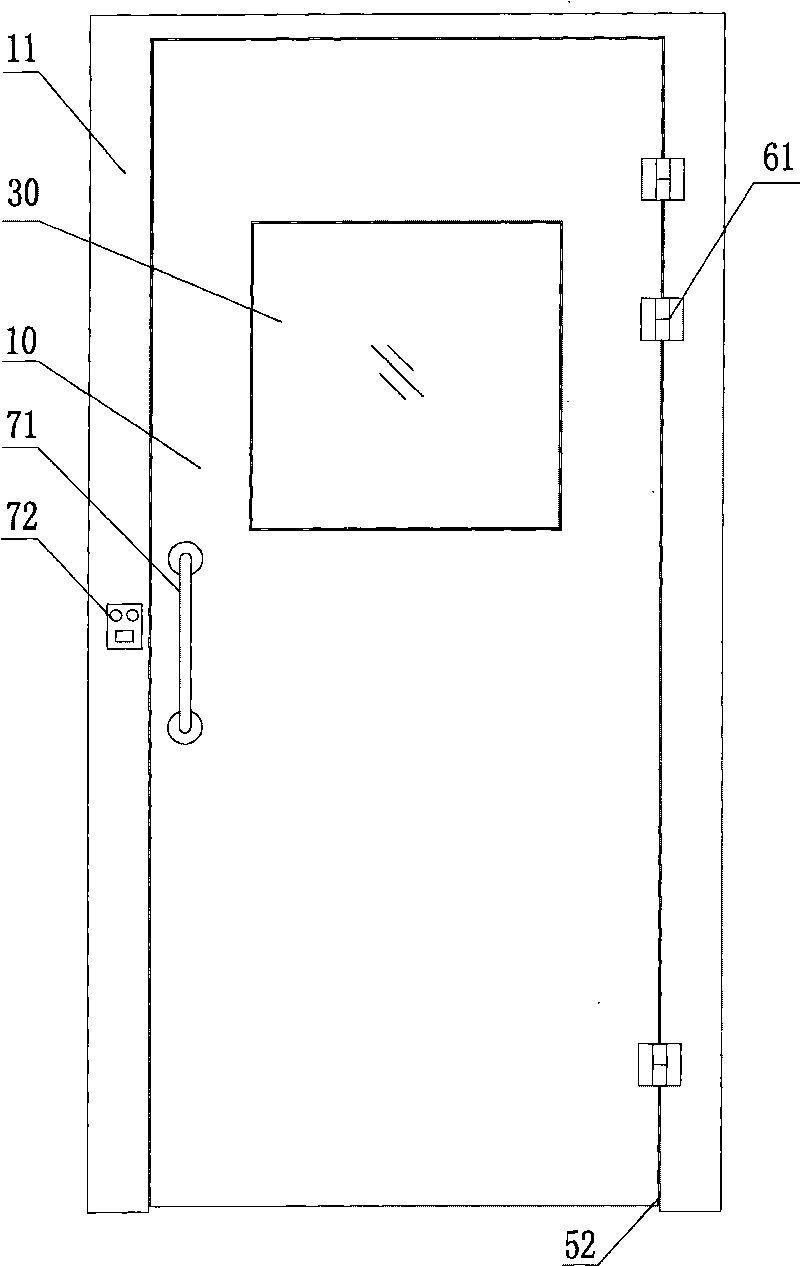

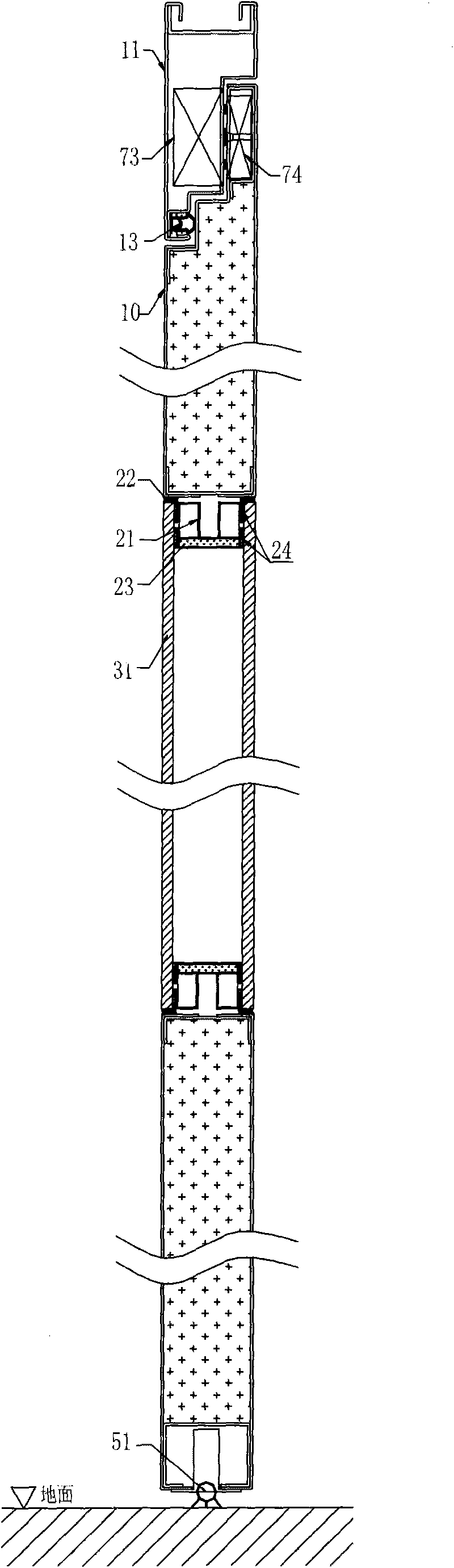

Air tight door of magnetic force lock

InactiveCN101699014AImprove air tightnessNot easy to accumulate dustNon-mechanical controlsSealing arrangementsDevice formEngineering

The invention relates to an air tight door, in particular to an air tight door of a magnetic force lock of a medical biological clean room; the air tight door is composed of a door frame and a door leaf which are connected together by a gemel; a handle is arranged on the door leaf, a double-layer visible window is arranged at the upper part of the door leaf, and the thickness of the door leaf is the same as the thickness of the double-layer visible window and the door frame and the door leaf, the double-layer visible window and the door frame are arranged at the same plane, an automatic lifting air tight strip is arranged below the door leaf, and an electromagnetic force lock is installed between the door leaf and the door frame in a concealing way; in the invention, by adopting the design of the concealed electromagnetic force lock, the whole air tight door and a door lock control device form a whole, so as to be convenient for intelligent control; in addition, the air tight door is hard to accumulate dust and is easy to clean.

Owner:SUZHOU FLEXCON CLEAN ROOM SYST

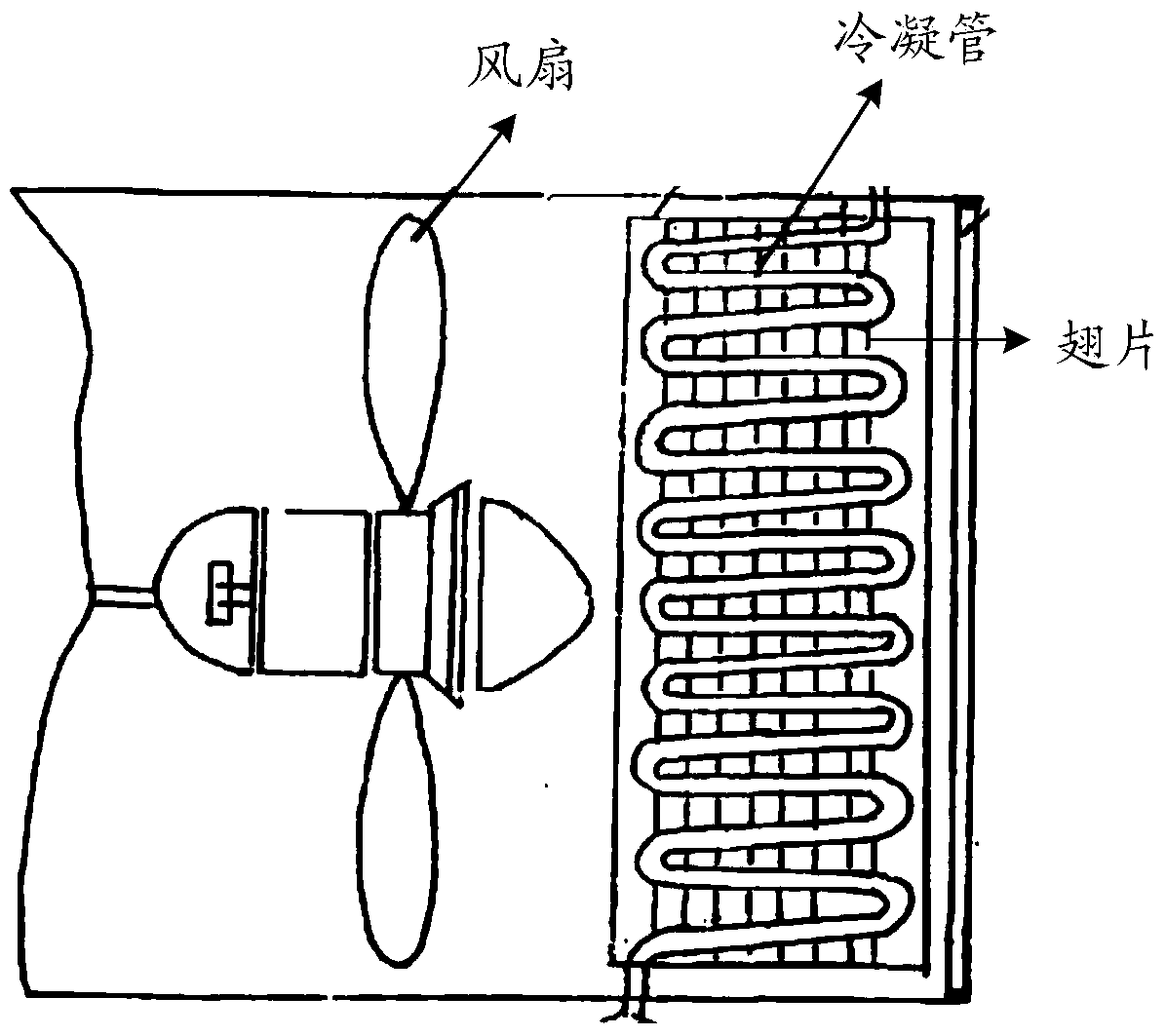

Marine clean air conditioner

InactiveCN102052711AEasy dischargeNo hygienic cornerCondensate preventionHeating and ventilation casings/coversEngineeringCorrosion

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

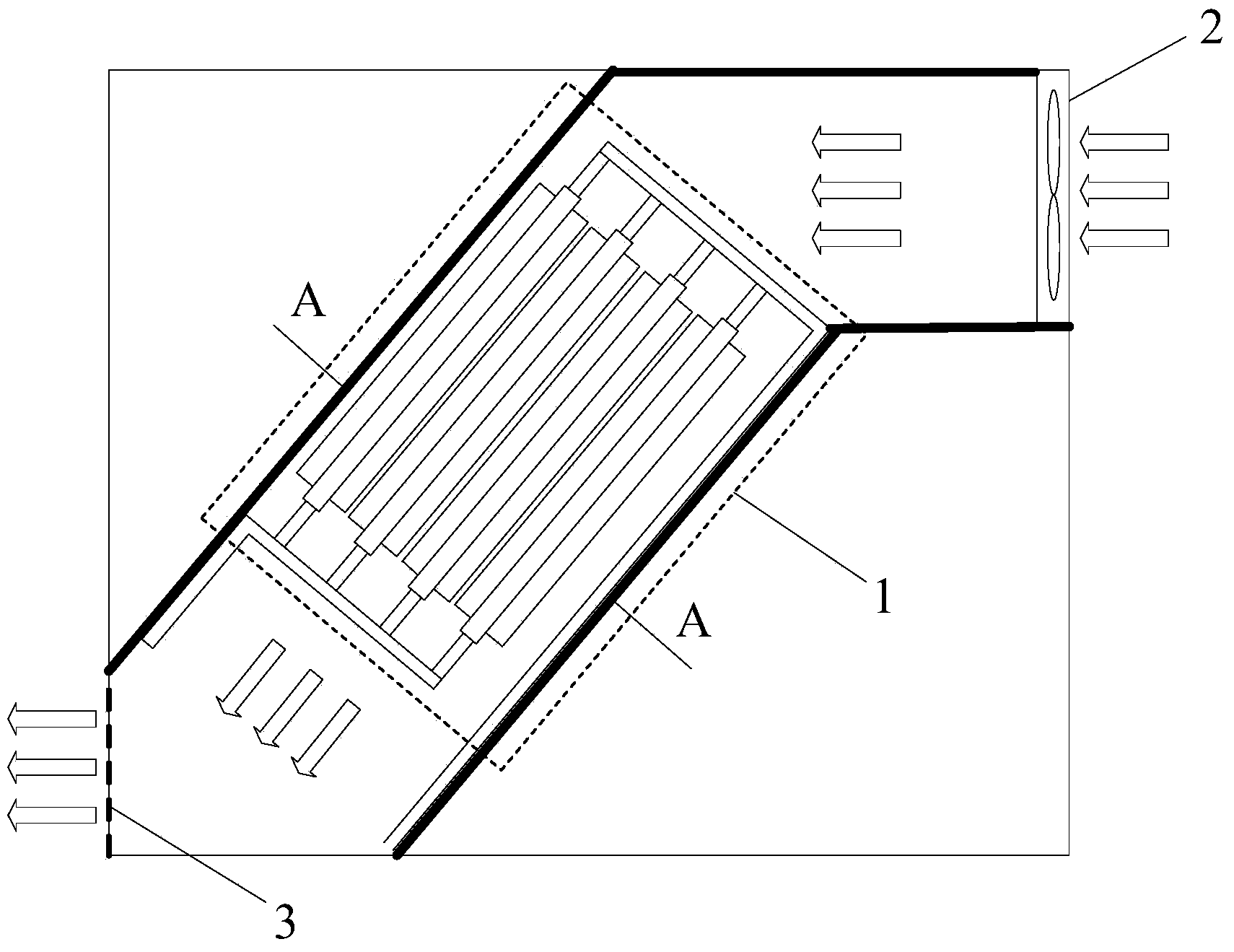

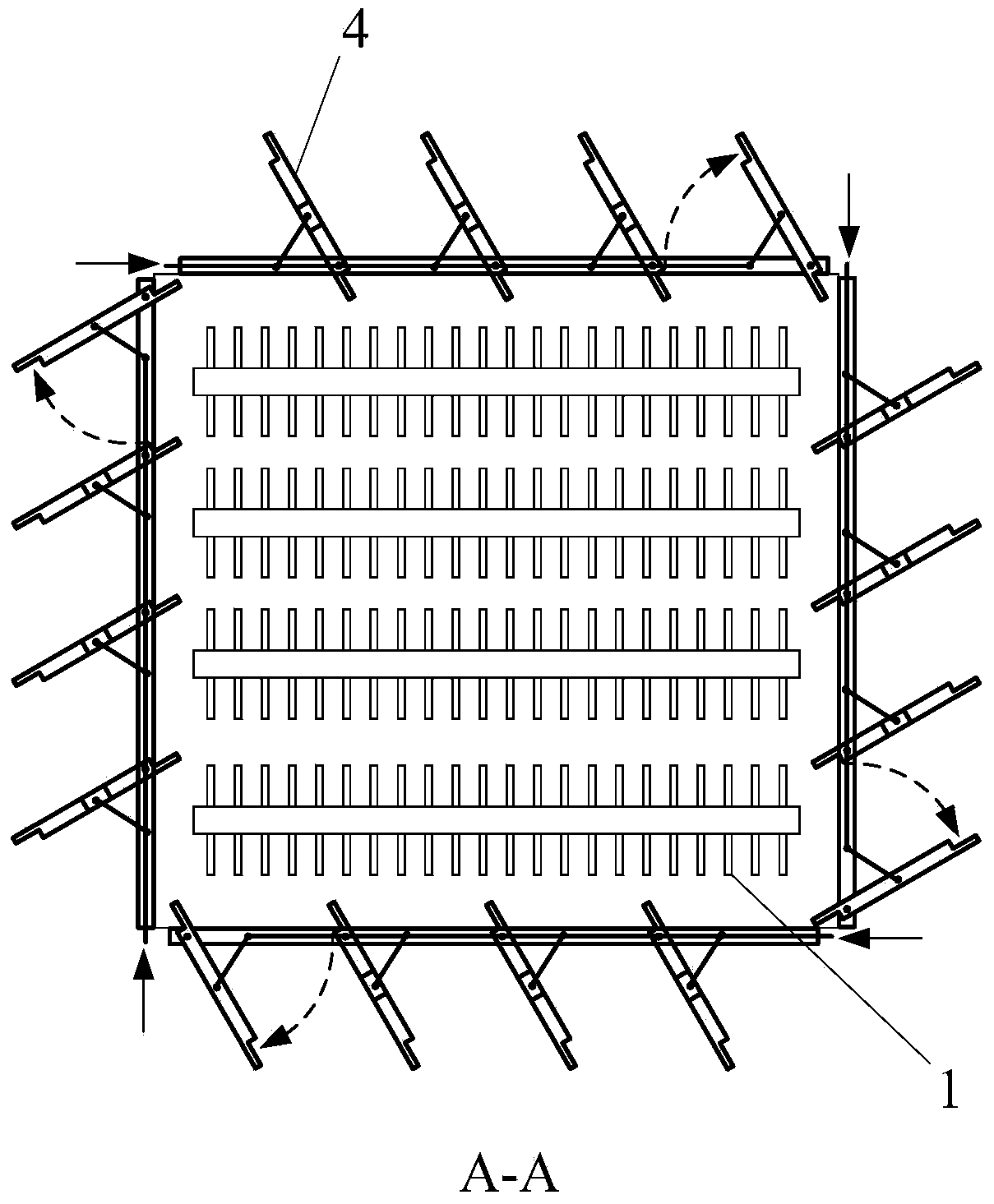

Two-phase cooling device

ActiveCN103512381AImprove wind and sand performanceReduce system noiseSteam/vapor condensersHeat exchanger casingsEngineeringForced-air

The embodiment of the invention discloses a two-phase cooling device used for achieving natural heat dissipation and air cooling, and effectively improving efficiency of the natural heat dissipation and performance of wind and sand prevention. The two-phase cooling device comprises a condenser and a fan. The fan is arranged at the top or the bottom of the two-phase cooling device, and the condenser is arranged in the two-phase cooling device in an inclined or perpendicular mode. The two-phase cooling device further comprises a first air opening formed corresponding to the fan in position, and the condenser is arranged between the fan and the first air opening. Shutters are arranged around the condenser and connected through link mechanisms. An air cylinder is further arranged on the shutters and used for controlling the shutters to open or close. The two-phase cooling device further comprises a second air opening formed in the position the same as that of the fan. A gravity shutter is installed on the air outlet of the fan. Through control over the two-phase cooling device, the two-phase cooling device can be made to form a natural heat dissipation state or form a forced air cooling air channel.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

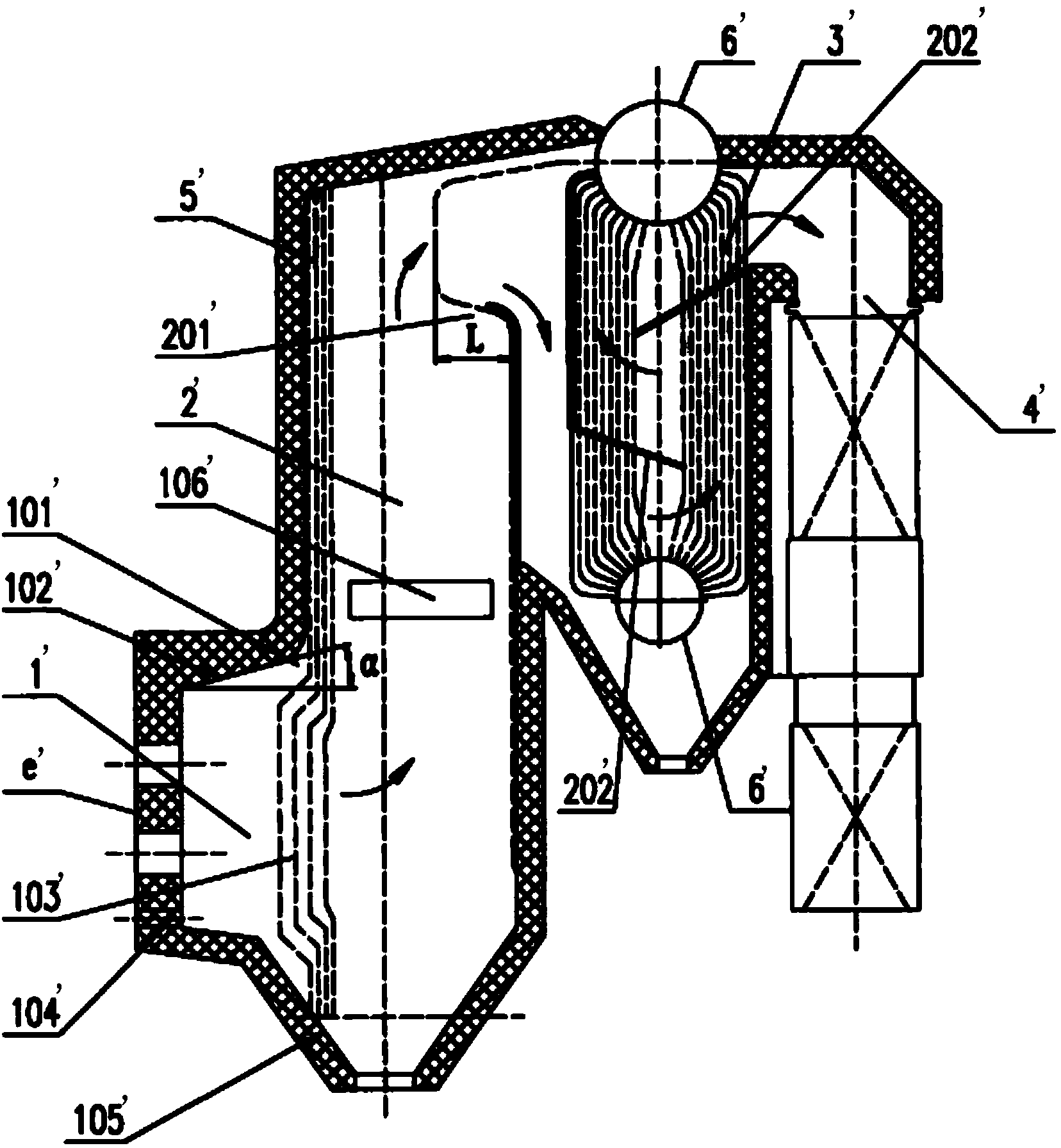

Waste incineration boiler

ActiveCN102322640ANot easy to accumulate dustImprove cleanlinessIncinerator apparatusAir preheaterEngineering

The invention provides a waste incineration boiler, which ensures that a conventional waste incineration boiler is less in dust stratification, convenient in soot cleaning and difficult in leakage, and the operation and maintenance costs of the boiler are reduced. The waste incineration boiler comprises a furnace chamber, a furnace grate and a horizontal flue, wherein the furnace chamber is positioned above the furnace grate; a boiler barrel is arranged above the furnace chamber; a front-back arch is arranged on the lower part of the furnace chamber; secondary air is arranged on the front-back arch, and faces the furnace grate; and an air preheater, an overheater and an evaporator are arranged in the horizontal flue. The waste incineration boiler is characterized in that: the furnace chamber is connected with a vertical burn-out chamber, three vertical flues, the horizontal flue and a tail part vertical flue in turn; a coal economizer is arranged in the tail part vertical flue; a rapping apparatus is arranged on a pipeline of the air preheater, the overheater and the evaporator which are arranged in the horizontal flue; and a shockwave or steam sootblower is arranged in the tail part vertical flue.

Owner:WUXI HUAGUANG BOILER

Biomass smokeless boiler

InactiveCN103206703ANot easy to cokeExtended service lifeSolid fuel combustionAir/fuel supply for combustionDynamic fieldCyclone

The invention relates to a biomass smokeless boiler comprising an automatic-control unit, a feeding mechanism, a combustion mechanism, an air-supply mechanism, an air-inducing mechanism and a boiler body. The boiler body at least includes a main boiler body, a first heat-absorption boiler body and a second heat-absorption boiler body, and the main boiler body, the first heat-absorption boiler body and the second heat-absorption boiler body are eccentrically connected with one another. A plurality of cyclone tubes are arranged on the periphery of the main boiler body, and one tangential hole is formed between each of the cyclone tubes and the main boiler body. The biomass smokeless boiler has the advantages that the biomass smokeless boiler, as compared with a conventional boiler, has larger heat-absorption area and is not prone to dust formation after a plurality of boiler bodies are adopted, and temperature of the smoke is reduced to less than 100 DEG C due to lengthening of a smoke duct; the cyclone tubes facilitate intensive mixing of the biomass fuel and the air prior to high-intensity combusting of biomass fuel, and good air dynamic field inside the boiler is guaranteed by the aid of an air-inducing device and an air blower; since the biomass fuel is pushed when the center rotates, coking inside the boiler is avoided, and ash-removing can be performed automatically; and boiler surface is evenly galvanized, and therefore, service life of the boiler is greatly prolonged.

Owner:陈海洋

Double-glass photovoltaic module

PendingCN109787549ADoes not affect power generationReduce weightPhotovoltaicsPhotovoltaic energy generationGenerating capacityJunction box

The invention discloses a double-glass photovoltaic module, and belongs to the technical field of the photovoltaic. The double-glass photovoltaic module comprises a laminating piece, a junction box and a first frame and a second frame arranged at two long sides of the laminating piece; the laminating piece comprises cover plate glass, a first package adhesive film, a battery string, a second package adhesive film and a backboard glass and a bus bar; a through hole is formed on the backboard glass, one end of the bus bar is connected with the battery string, the other end of the bus bar penetrates the through hole and is bent to form a bending side, thereby connecting with the junction box; the bending side of the bus bar does not contact with the edge of the through hole. The double-glassphotovoltaic module adopts the double-frame design, a loading capacity requirement can be satisfied, and the back generating capacity of the double-glass photovoltaic module cannot be affected since the a frame is inexistent at a module lower side to shield the light on the ground to irradiate to the module back after the double-glass photovoltaic module is arranged on the photovoltaic generationsystem, the double-glass photovoltaic module is hard to accumulate ash and snow, the weight of the double-glass photovoltaic module can be relieved, and the cost of the double-glass photovoltaic module is lowered.

Owner:SHANGHAI & SOLAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com