Air-cooling device for printing head of 3D (three-dimensional) printing machine

A technology of 3D printers and air-cooling devices, which is applied to coating devices, 3D object support structures, and additive manufacturing. Problems such as heat dissipation and air flow, to achieve the effect of improving folding degree and portability, reducing space occupation, and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

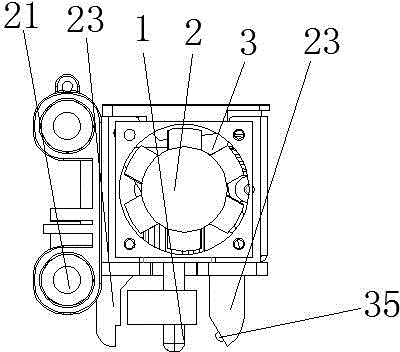

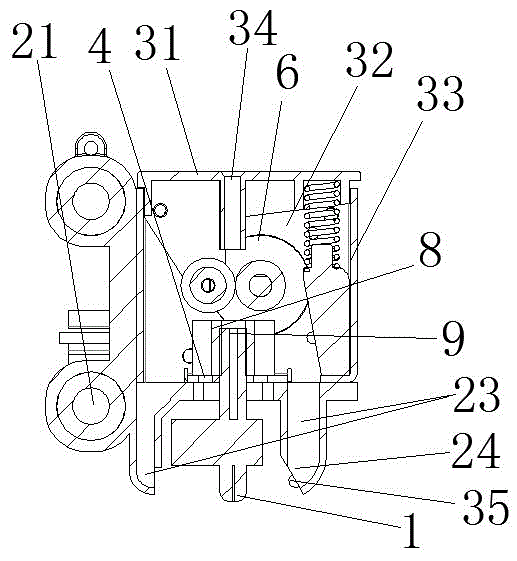

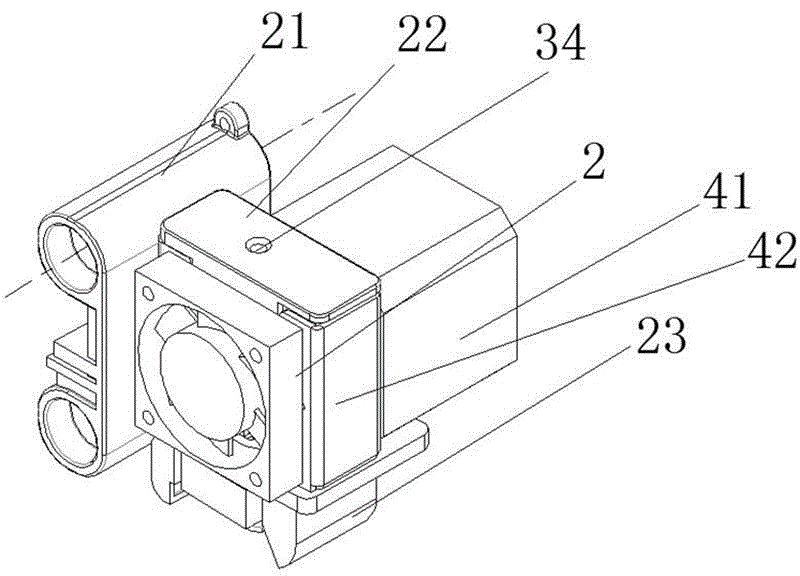

[0047] When the cooling fan 2 is working, the external cold air is blown into the print head housing cavity 22 through the fan through hole 3, and the external cold air flows through the wire material conveying mechanism 6 and the cooling block 8 for heat exchange to dissipate heat for it, and from the guide The air duct 23 flows out of the housing cavity 22, and is sent to the nozzle 1 below the print head by the air guide duct 23, and is sent out from the outlet 24 at the end of the air guide duct 23 to cool the molten material extruded from the nozzle 1 to make it solidify.

[0048] The cooling fan 2, the fan through hole 3, the print head housing cavity 22 and the air guide duct 23 together form an air duct, the fan through hole 3 is the air duct inlet, the end outlet 24 of the air guide duct 23 is the air duct outlet, and the cooling fan 2. The blown cold air flows out from the air guide duct 23 under the restriction of the side wall plates 32, 33 and the top plate 31 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com