Patents

Literature

358results about How to "Not easy to pass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kind of laminated granule for oil extraction, proppant and oil extraction method using the proppant

InactiveCN101586024AIncrease surface tensionIncrease productionFluid removalDrilling compositionEpoxyShale oil extraction

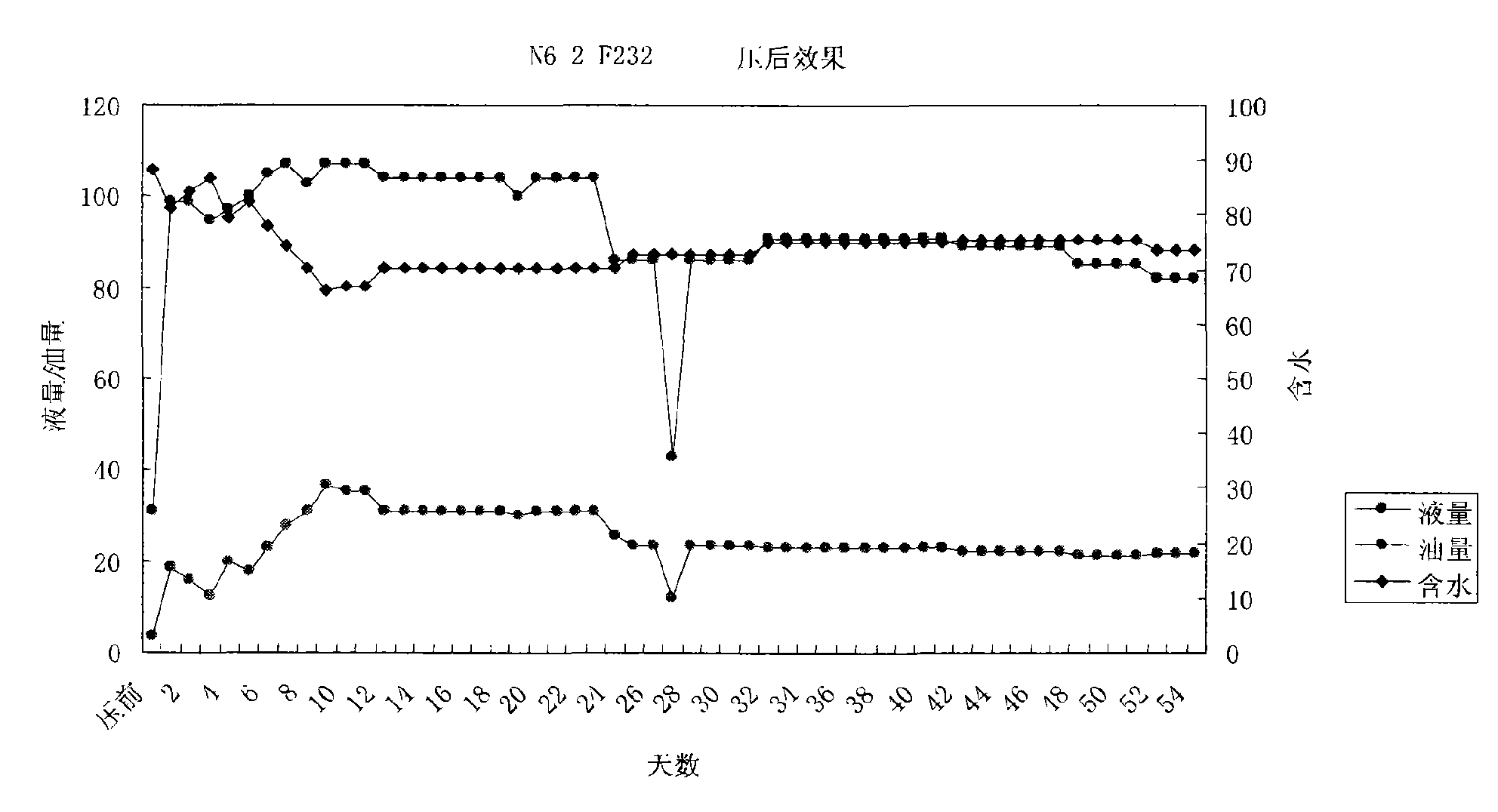

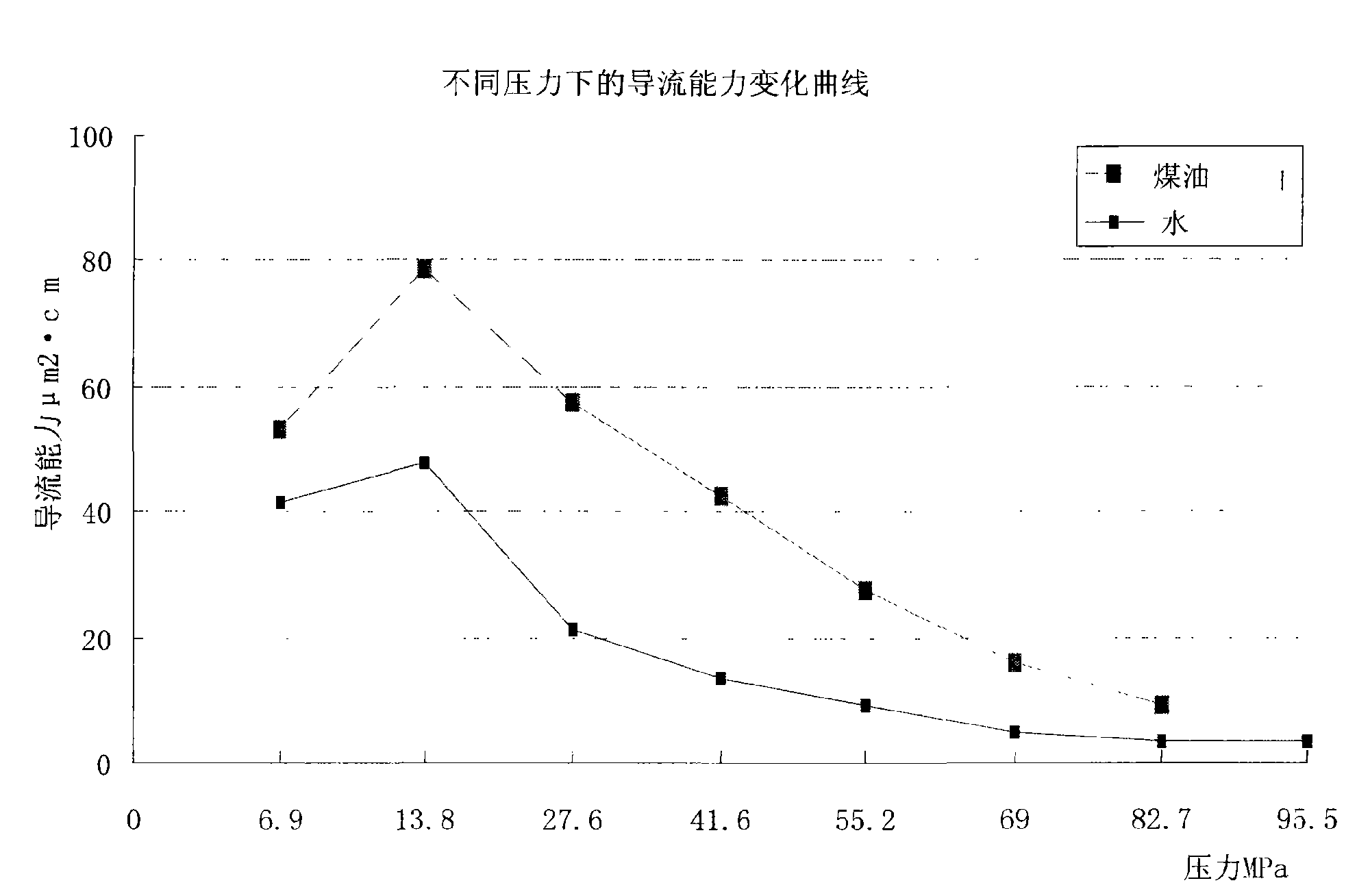

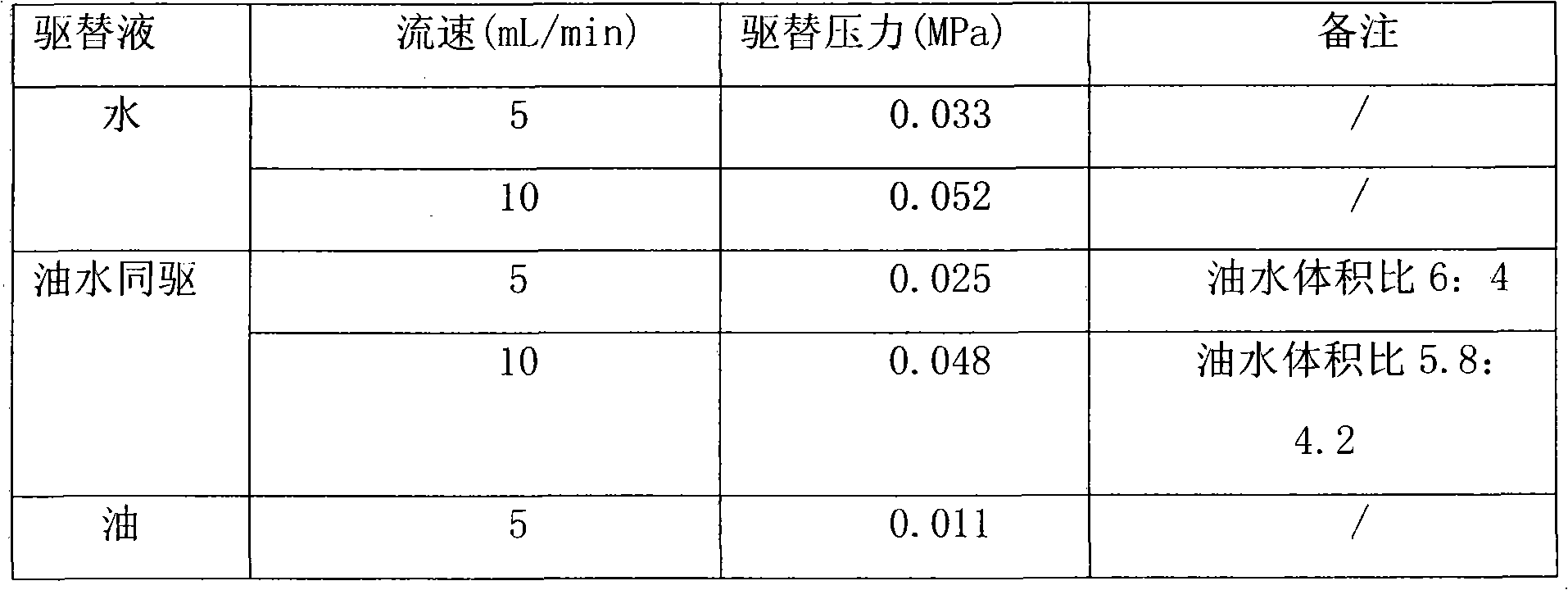

The invention discloses a kind of laminated granule for oil extraction, proppant having the laminated granule and oil extraction method using the proppant. The laminated granule comprises aggregate granules and oil permeating waterproof thin film coated on surface of the aggregate granules. The oil permeating waterproof thin film comprises resin. Weight ratio of the resin to quartz sand is 0.2-15:100. The laminated granule is oil permeating waterproof granule. The oil permeating waterproof thin film is one formed by one or more of oleophylic hydrophobic ethoxyline resin, phenolic resin, polyurethane resin and silicon resin. The laminated quartz sand and proppant thereof are oil permeating and water proof at regular atmospheric pressure. Oil permeation resistance in pressurized condition is less than water permeation resistance. Therefore, in oil extraction industry, water yield is reduced effectively and oil yield is improved.

Owner:BEIJING RECHSAND SCI & TECH GRP

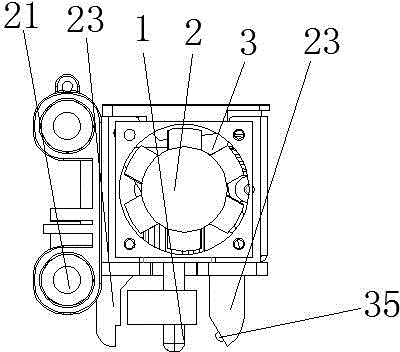

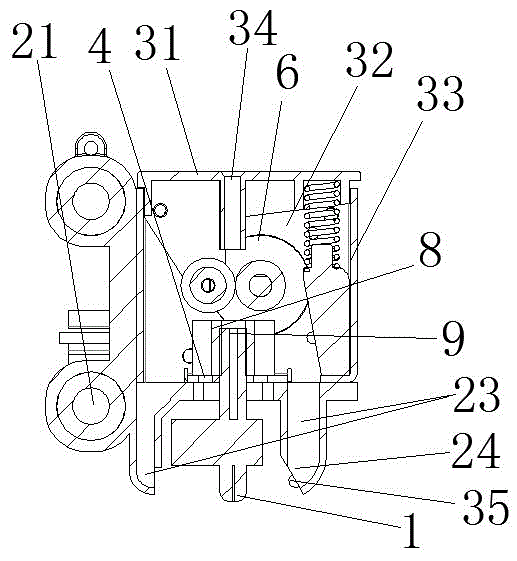

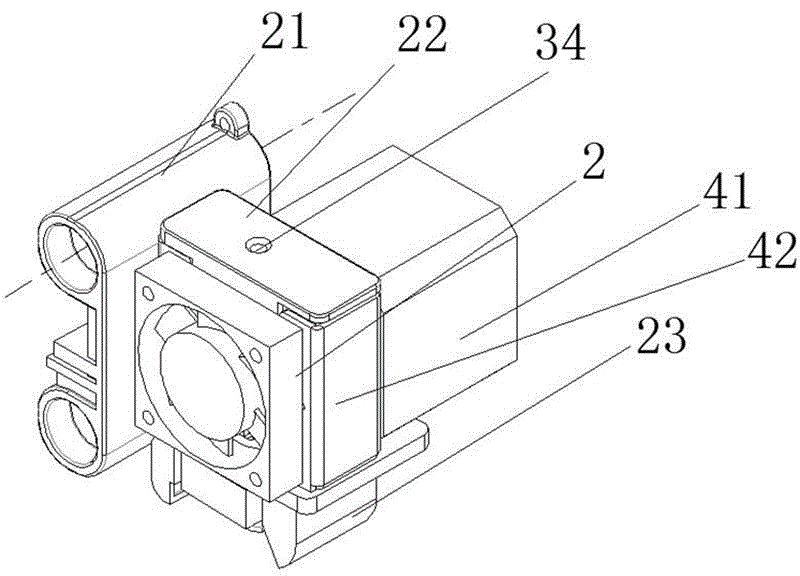

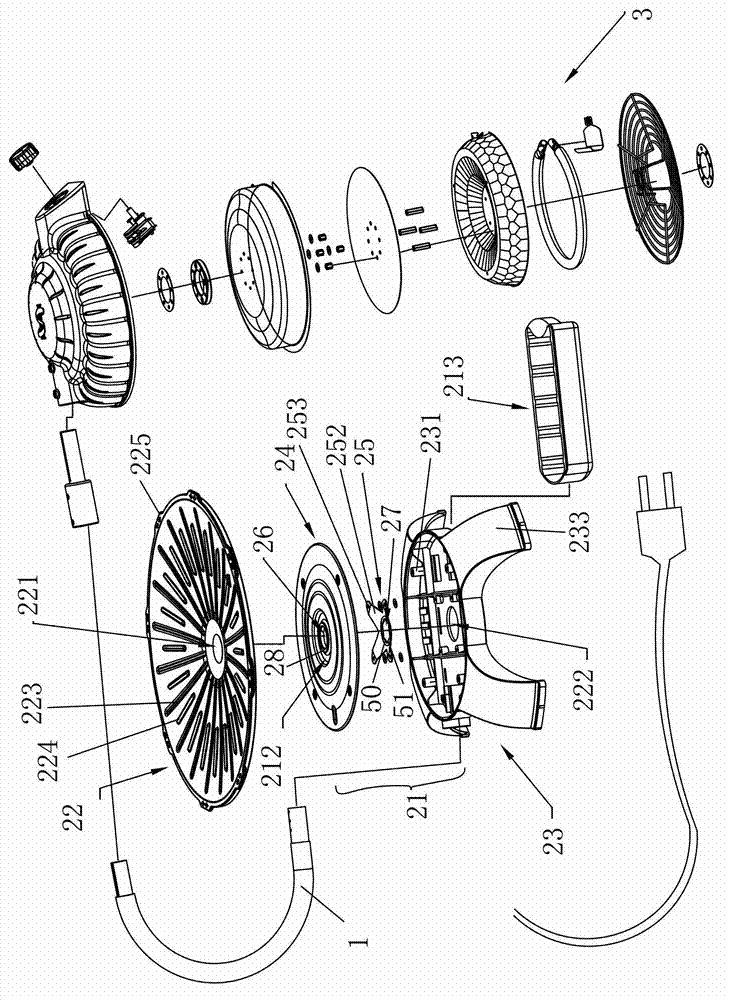

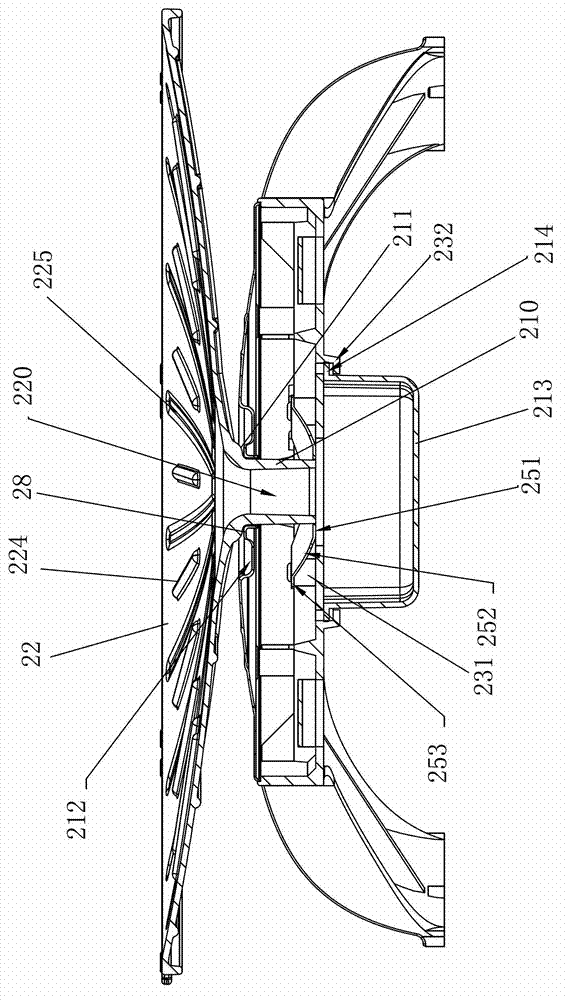

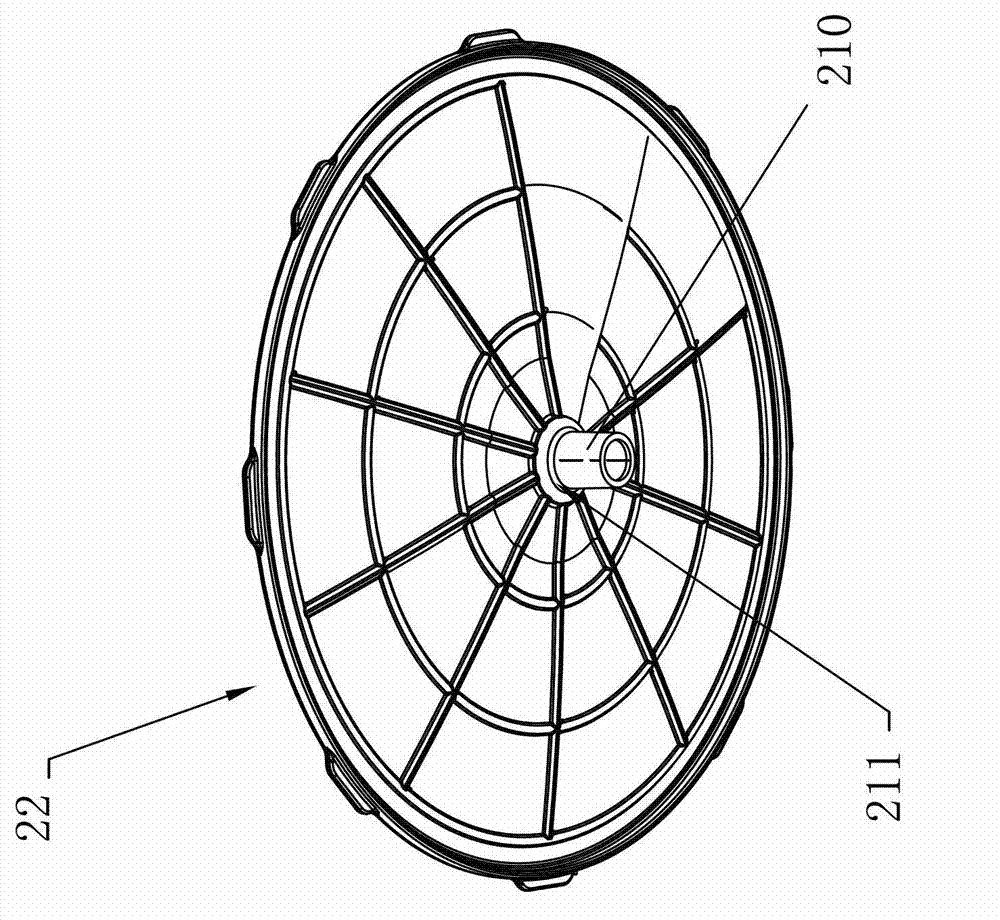

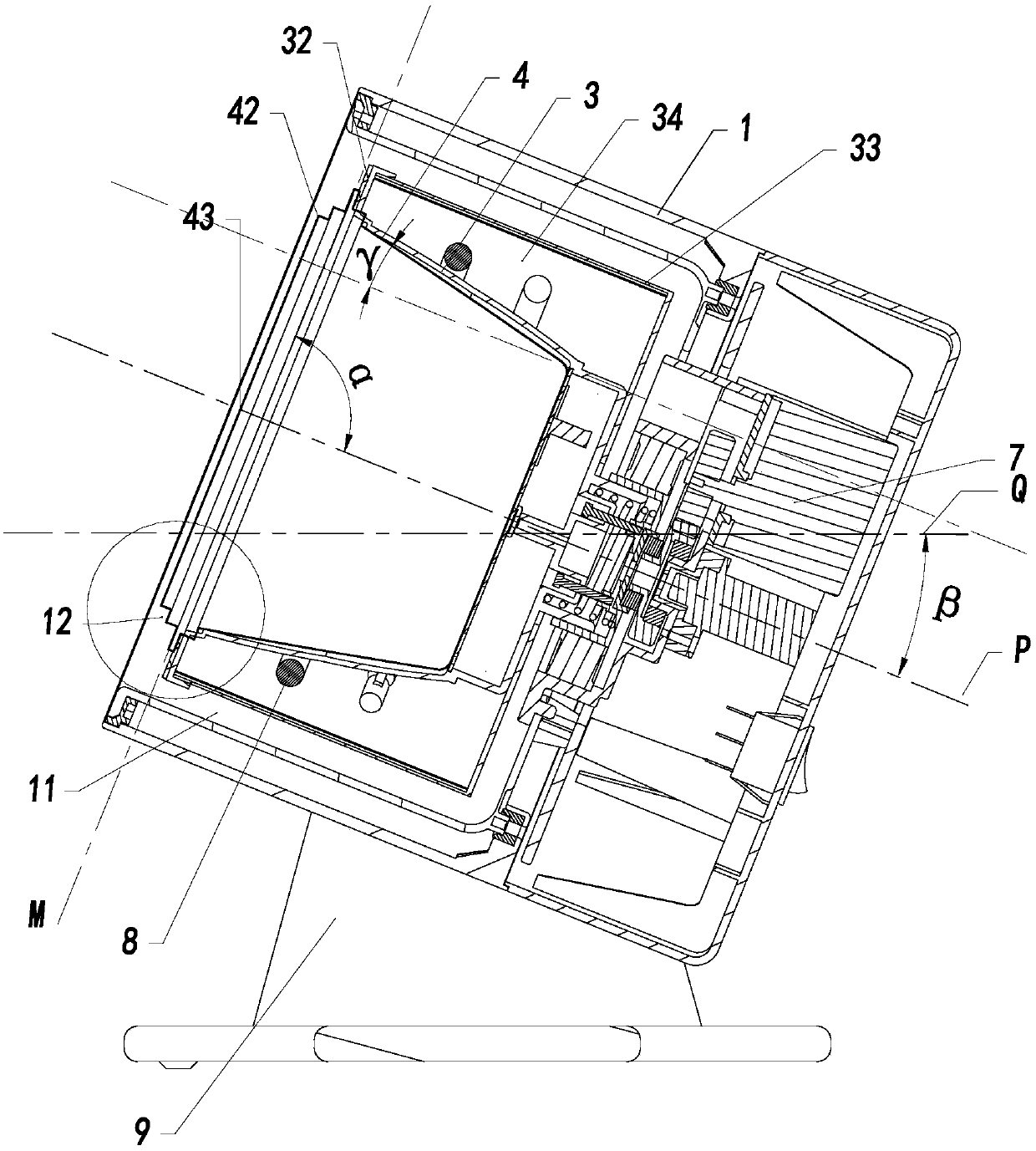

Air-cooling device for printing head of 3D (three-dimensional) printing machine

InactiveCN104786510AHigh efficiency of active coolingSmall footprintManufacturing platforms/substratesAdditive manufacturing with liquids3d printerWorking space

The invention discloses an air-cooling device for a printing head of a 3D (three-dimensional) printing machine. The printing head is arranged at a slide rod of the printing machine in a sleeving manner by lug rings and axially slides; the air-cooling device is integrated on the printing head; a wire conveying mechanism is arranged in a seat housing cavity body of the printing head; a cooling fan aligned to the wire conveying mechanism is arranged on one axial side of the seat housing cavity body; a printing head nozzle is formed in the lower part of the seat housing cavity body; the seat housing cavity body is provided with air guide pipelines leading to the printing head nozzle. The air-cooling device improves heat dissipation of the printing head of the printing machine and enables occupied working space of the printing head to be further reduced, thereby being favorable for improving the portability of the folding-type 3D printing machine.

Owner:FUZHOU ZHANXU ELECTRONICS

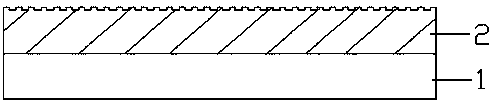

Ecological warm-keeping cotton and manufacturing process thereof

InactiveCN105603634AImprove the bactericidal effectNot easy to passNon-woven fabricsCardingEngineering

The invention provides ecological warm-keeping cotton and a manufacturing process thereof. The ecological warm-keeping cotton has good wind-resistant water-repellent effects, also has a certain sterilization function and is better in warm-keeping effect, lots of raw materials are renewable raw materials, and an environmental protection effect is good. The ecological warm-keeping cotton comprises a warm-keeping layer and a waterproof breathable sterilization layer adhered to one side of the warm-keeping layer, wherein the thickness of the waterproof breathable sterilization layer is 10%-15% of the thickness of the warm-keeping layer, the warm-keeping layer is manufactured from, by weight, 30% of Sorona polymer fiber, 30% of superfine warm-keeping fiber, 30% of three-dimensional hollow warm-keeping fiber and 10% of native cotton fiber through mixing, the waterproof breathable sterilization layer is manufactured from, by weight, 40% of collagen fiber, 20% of bamboo fiber, 20% of seaweed carbon fiber and 20% of nanoscale antibacterial silver ion masterbatch native fiber through mixing, the surfaces of the two sides of the waterproof breathable sterilization layer are coated with treatment layers formed by blending silicon nanoparticles and nano titanium dioxide, and the surfaces of the treatment layers are coated with hydrophobic fluorine quaternary amine silane coupling agent coatings. The manufacturing process of the ecological warm-keeping cotton comprises the steps of automatic material preparation and mixing through a machine, opening, carding, web laying, adhesive spraying, heat setting and rolling.

Owner:FUJIAN JINJIANG HENGFENG SPEWING WEAVING

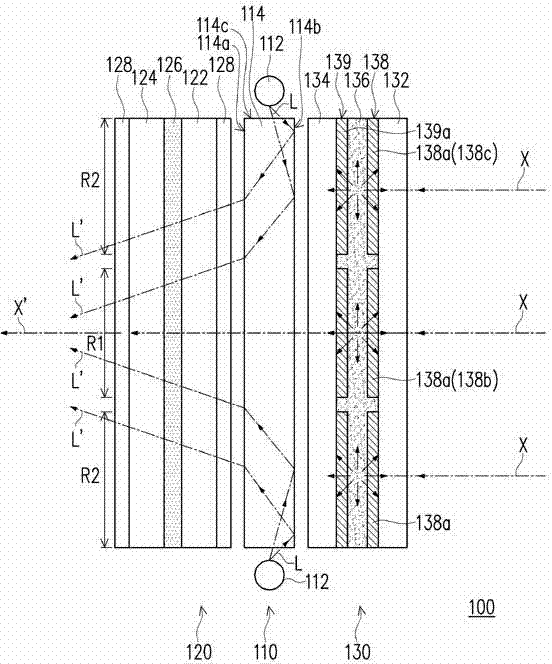

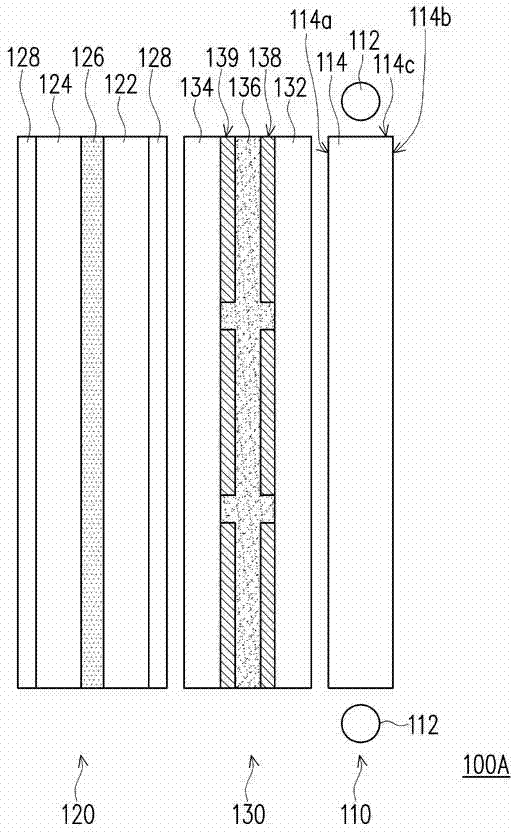

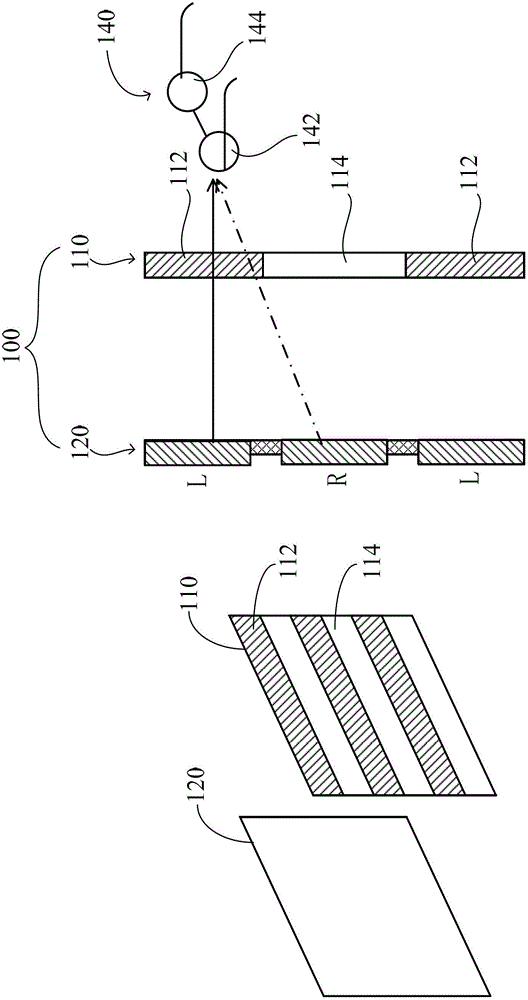

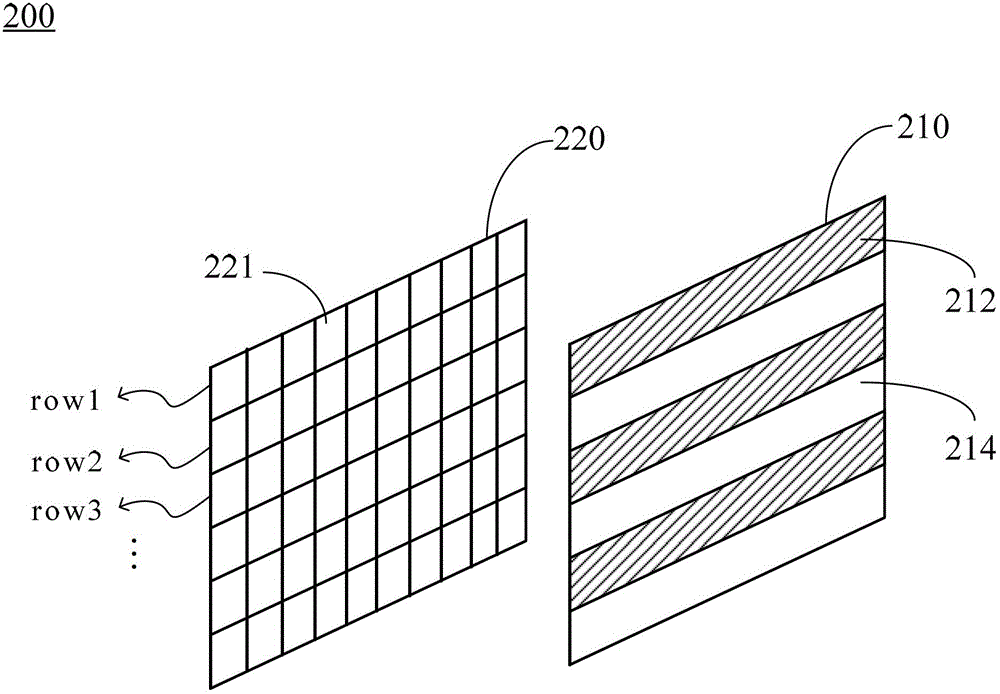

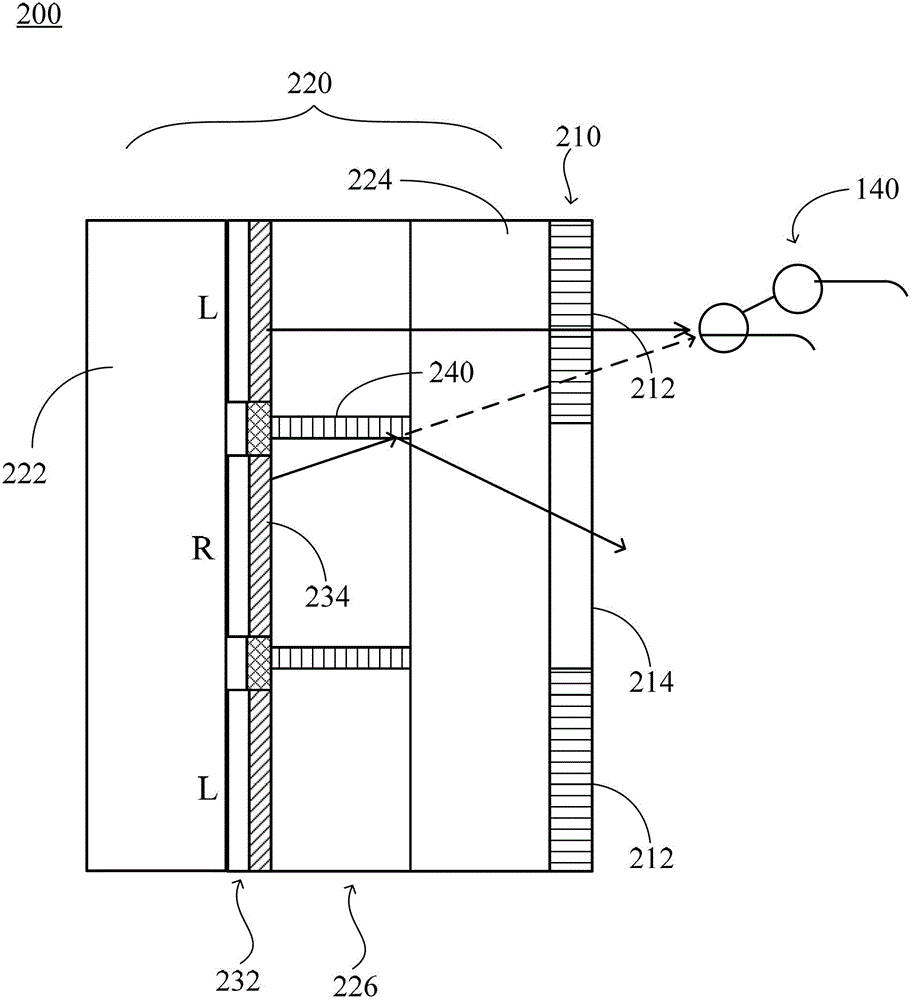

Transparent display device

The invention provides a transparent display device. The transparent display device comprises a backlight module, a display panel and a switching panel. The backlight module comprises a light source and a light guide board. The display panel is arranged on the light emergent surface of the light guide board. The switching panel and the backlight module are arranged on the same side of the display panel. The switching panel comprises a first substrate, a second substrate, a polymer dispersion liquid crystal layer, a first electrode layer and a second electrode layer, wherein the second substrate is opposite to the first substrate, the polymer dispersion liquid crystal layer is arranged between the first substrate and the second substrate, the first electrode layer is arranged between the first substrate and the polymer dispersion liquid crystal layer, and the second electrode layer is arranged between the polymer dispersion liquid crystal layer and the second substrate. The first substrate is divided into a plurality of first electrode patterns which are separated from one another and electrically independent of one another. In addition, the invention further provides another transparent display device.

Owner:华映视讯(吴江)有限公司 +1

Upper heat source type electric oven

The invention relates to an upper heat source type electric oven. The upper heat source type electric oven comprises an electric heater and an oven seat with a barbecue frame, wherein the oven seat comprises an oven seat mechanism and a baking tray supported on the oven seat mechanism. The upper heat source type electric oven is characterized in that a biased supporting component is arranged on the oven seat; the electric heater is fixedly connected and positioned above the oven seat through the supporting component; the oven seat mechanism comprises a pedestal and a supporting tray arranged on the upper part of the pedestal, wherein the supporting tray is a metal component; the pedestal is a plastic component; and the baking tray is supported on the supporting tray. The upper heat source type electric oven has the beneficial effects that the barbecuing effects the same as those of a lower heat source type electric oven are provided along with smoke reducing; the oven seat mechanism is the plastic component, thus the consumption of metal materials is reduced, and the pedestal is kept at relatively low temperature for avoiding being scalded.

Owner:李琎熙

Polarizer and liquid crystal display device

ActiveCN106772755APrevent shrinkageBlock deliveryPolarising elementsMountingsLiquid-crystal displayPolarizer

The invention discloses a polarizer and a liquid crystal display device. The polarizer comprises a first protection layer, a polarization layer and a second protection layer, wherein the first protection layer is arranged on one surface of the polarization layer, and the second protection layer is arranged on the other surface of the polarization layer; at least one of the first protection layer and the second protection layer has a porous structure. According to the polarizer, the first protection layer and / or the second protection layer has the porous structure, the porous structure better stops external heat from being transferred to the polarization layer, and shrinkage of the polarization layer can be avoided, and bending of a glass substrate can be effectively prevented when the polarizer is made into a display module.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Ecological heat preservation cotton and production technology thereof

ActiveCN105908360AImprove the bactericidal effectEasy to passLiquid surface applicatorsSevering textilesManufacturing technologyCarding

The invention provides ecological heat preservation cotton and a production technology thereof. The ecological heat preservation cotton has the good windproof and water-repellent effect and has the certain sterilization function, and the heat preservation effect is better. The ecological heat preservation cotton comprises a heat preservation cotton core, a waterproof breathable layer and a soft close-fitting layer, the heat preservation cotton core is manufactured by mixing 30% of Sorona polymer fiber, 30% of superfine heat preservation fiber, 30% of three-dimensional hollow heat preservation fiber and 10% of native cotton fiber, the waterproof breathable layer is manufactured by mixing 70% of collagenous fiber and 30% of meldable fiber, the waterproof breathable layer is coated with a nanometer silicon particle treatment layer, the treatment layer is coated with a fluorine quaternary amine silane coupling agent coating, a sterilization layer is arranged between the soft close-fitting layer and the heat preservation cotton core, the soft close-fitting layer is fixed to the inner side of the sterilization layer in a flocking mode, and the soft close-fitting layer is composed of short fiber with the length being 0.05-0.2 cm. The manufacturing technology of the ecological heat preservation cotton comprises the steps of automatic machine blending mixing, opening, carding, lapping, glue spraying, heat setting and lap formation..

Owner:广州泰达纤维制品有限公司

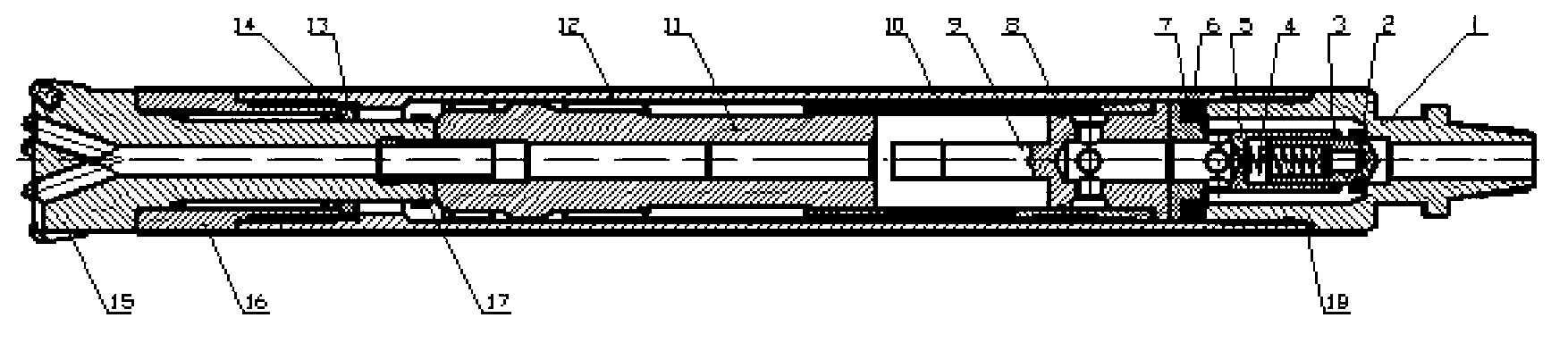

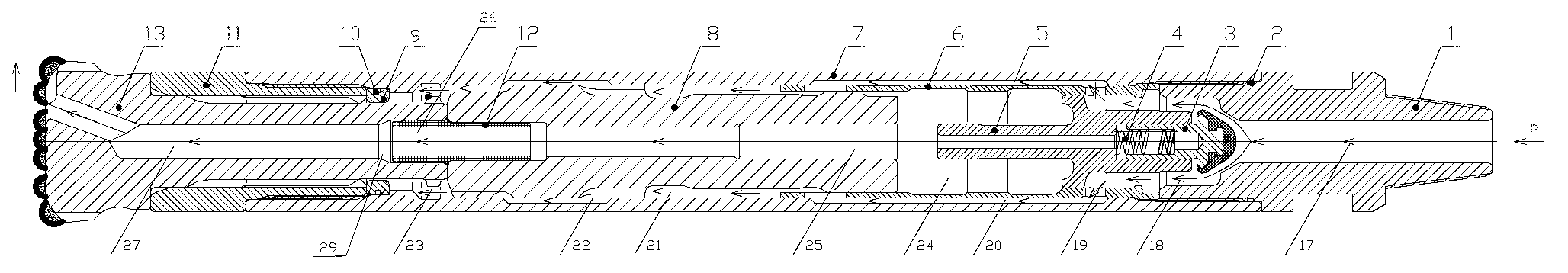

Cyclone high wind pressure down-hole hammer with tail pipe

The invention relates to a cyclone high wind pressure down-hole hammer with a tail pipe. The cyclone high wind pressure down-hole hammer with the tail pipe comprises a rear joint, a check valve, a gas distribution rod, a piston, an inner cylinder, an outer sleeve, a clamp ring, a front joint and a drill. The check valve is a single-direction valve and provided with a valve seat and a spring. The piston is a thin and long piston with a hole channel. The tail end of the piston is arranged in a center air hole of the piston and provided with a drill tail pipe. The gas distribution rod and a gas entering seat at the rear end of the check valve are of an integral structure. The inner cylinder is arranged outside the gas distribution rod and the piston. When the piston moves, matching ends of the piston and the gas distribution rod are always arranged in the inner cylinder. Part of the piston and the outer sleeve form an empty cavity in between. The rest of the piston is matched with the inner cylinder. The gas distribution rod is integrated with the check valve. The cyclone high wind pressure down-hole hammer with the tail pipe is simple in structure, capable of achieving functions of positioning, absorbing shock and gas entering and stable and reliable in working. Contacted area between the piston and the inner cylinder is reduced, the inner cylinder is wear-resistant and a work pressure range of the hammer is wide.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

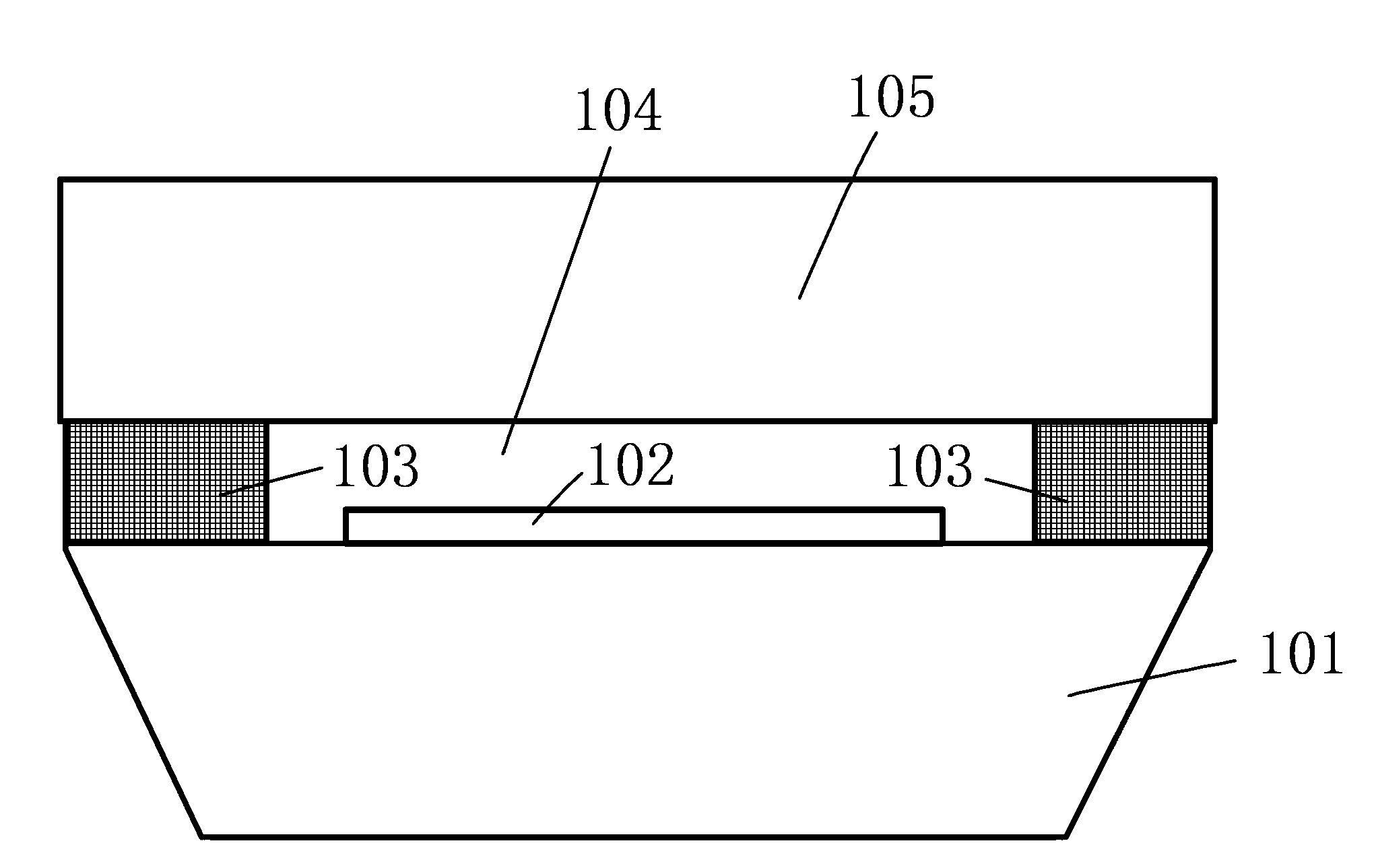

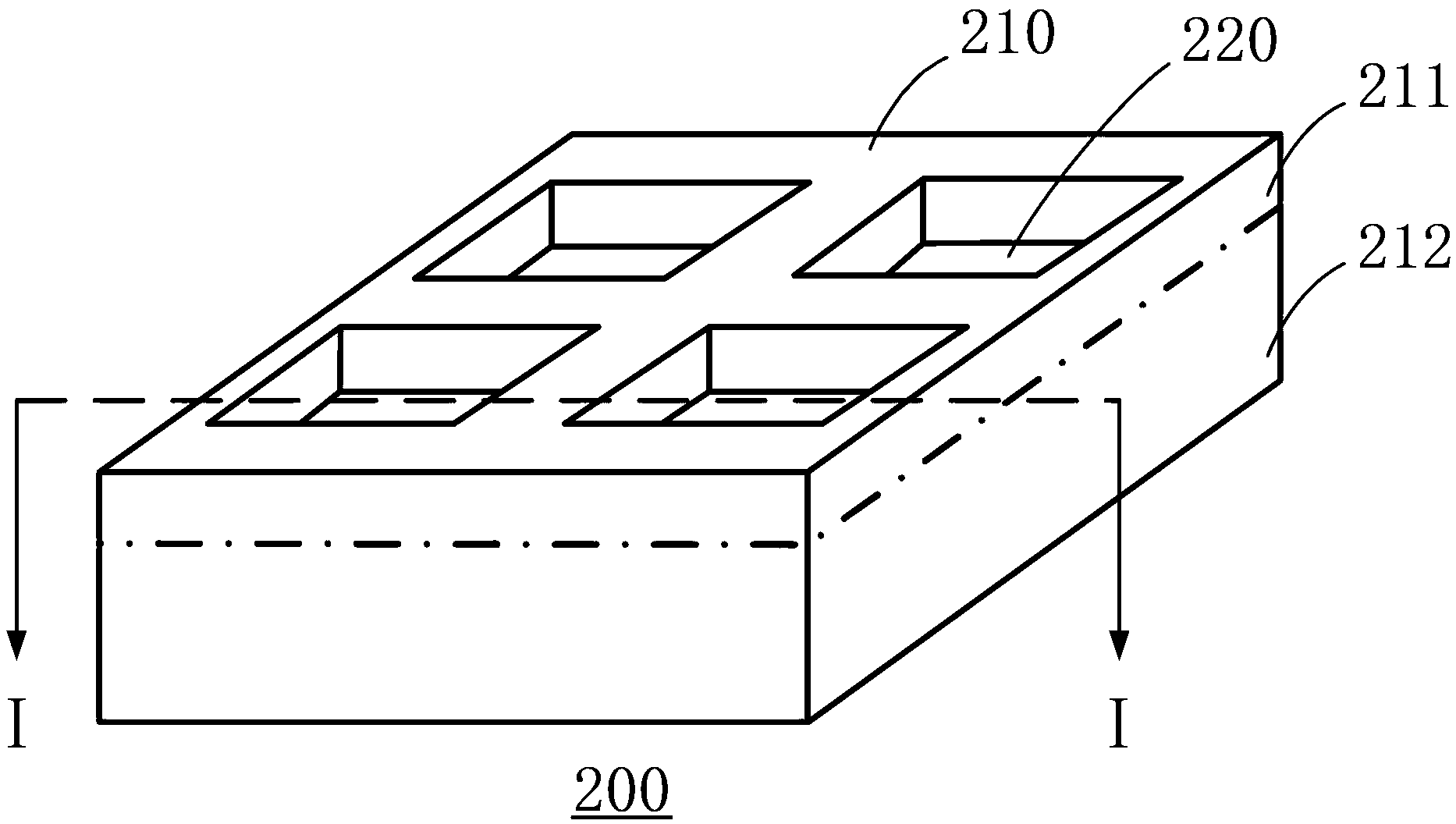

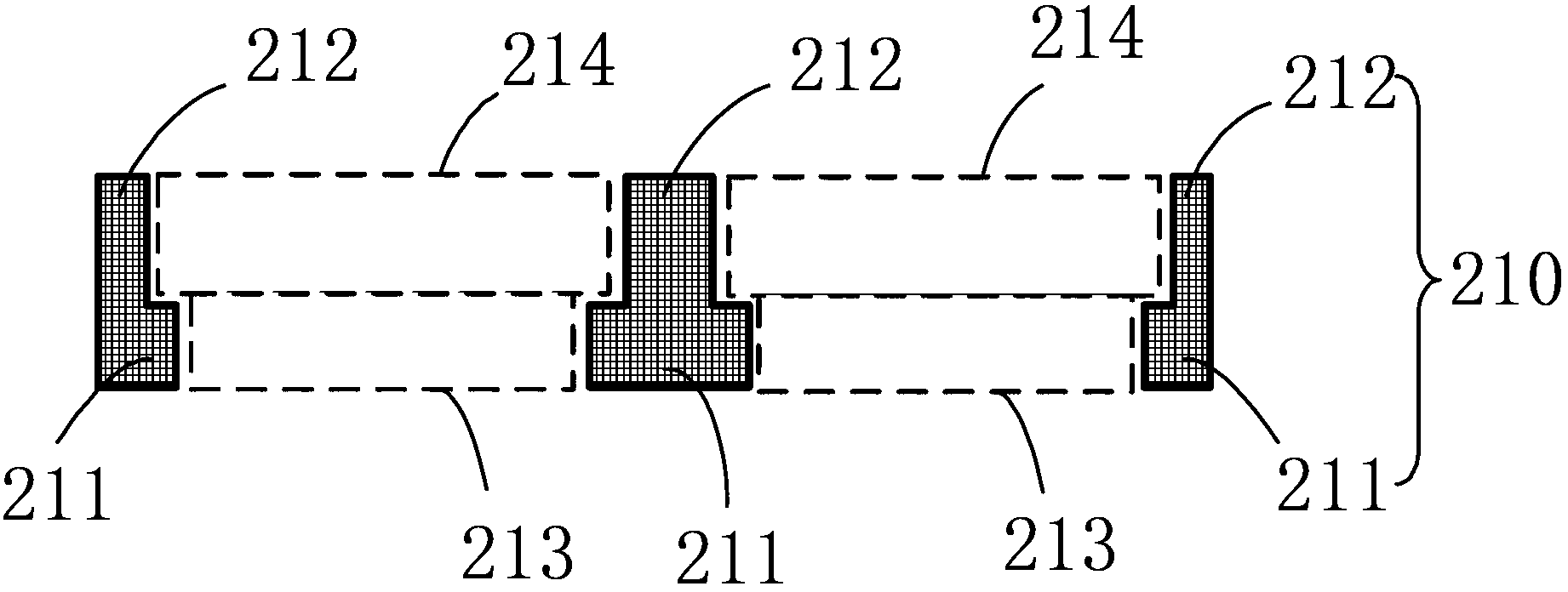

Mixed substrate encapsulation method and mixed substrate encapsulation structure for semiconductor device

ActiveCN103178023AReduce usageHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesOptical glassUltimate tensile strength

The invention provides a mixed substrate encapsulation method and a mixed substrate encapsulation structure for a semiconductor device. A mixed substrate is used for encapsulating the semiconductor device and comprises a support frame and a transparent substrate. The support frame comprises a frame bottom and a frame wall which are connected with each other, wherein the frame bottom is provided with a first through hole, the frame wall is provided with a second through hole, the area of the first through hole is smaller than that of the second through hole, and the first through hole is communicated with the second through hole. The transparent substrate is located in the second through hole and fixed on the upper surface of the frame bottom or the side of the frame wall. A first micropore is arranged between the transparent substrate and the frame bottom. A second micropore is arranged between the transparent substrate and the frame wall. The first micropore is communicated with the second micropore. The strength of the mixed substrate is much higher than that of a large optical glass, so that yield and efficiency of the mixed substrate encapsulation structure and the mixed substrate encapsulation method are increased while cost is reduced.

Owner:GALAXYCORE SHANGHAI

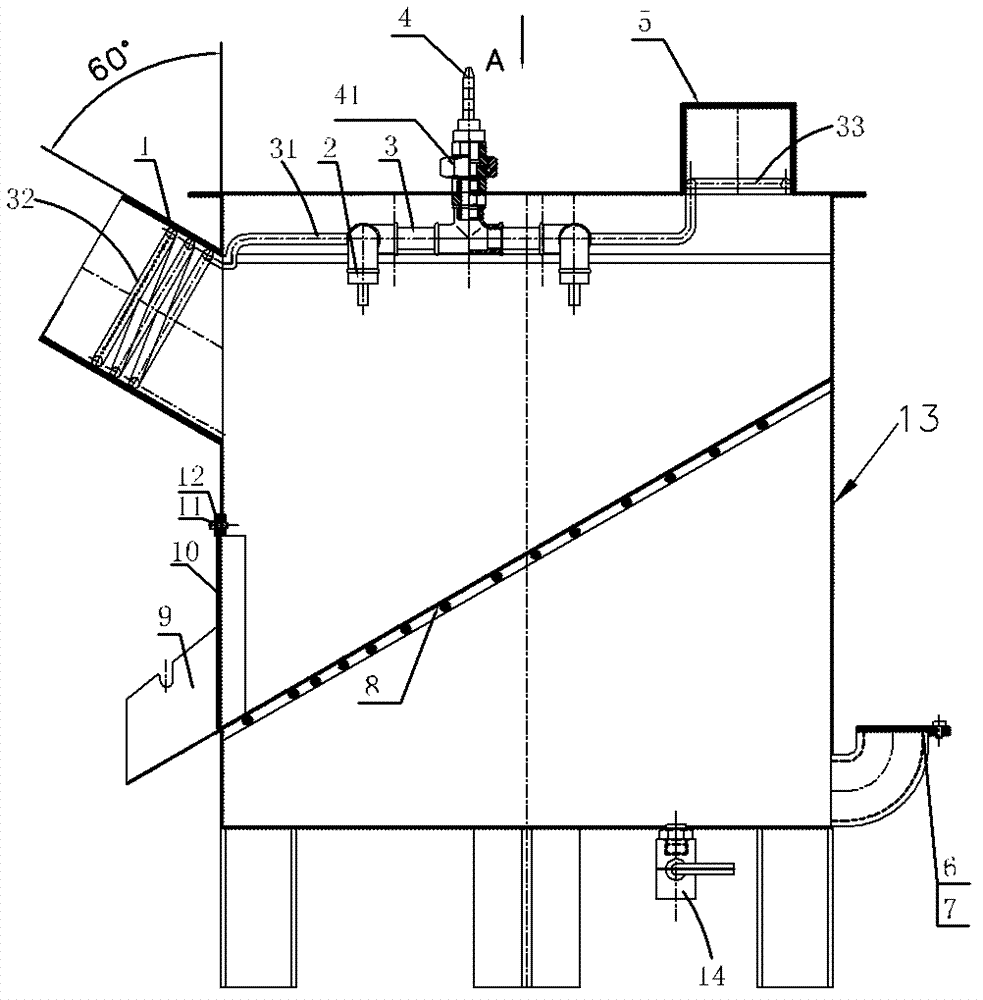

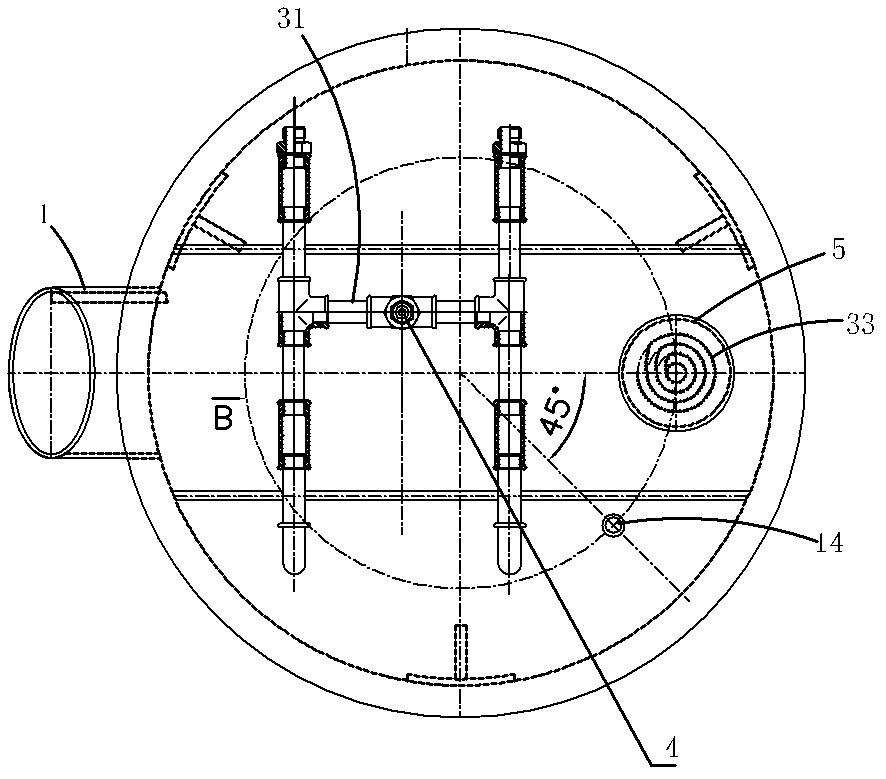

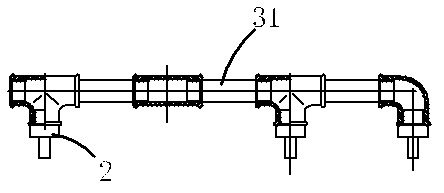

Gas dust and slag water collector

The invention relates to a gas dust and slag water collector which comprises a box body, a gas and water slag inlet pipe arranged on the upper part of the side wall of the box body and aslant downwards inserted into the side wall of the box body, a slag discharging hopper arranged on the lower part of the side wall of the box body and aslant downwards inserted into the side wall of the box body, a water outlet arranged on the lower part of the side wall of the box body, a filter net arranged inside the box body and aslant arranged, and an air outlet arranged on the upper end face of the box body, vertically inserted into the box body and used for exhausting, wherein the lower end of the filter net is connected with the slag discharging hopper; water pipes for spraying water are arranged inside the upper end face of the box body, the pipeline of the gas and water slag inlet pipe and the pipeline of the air outlet; a water inlet of a water pipe inside the upper end face of the box body penetrates through the end part of the box body and is connected with an external water source through a movable joint and a quick plug; and at least one nozzle is arranged at the lower end of the water pipe inside the upper end face of the box body. The gas dust and slag water collector has the beneficial effect that potential safety hazard that harmful materials, such as gas, water and boring mud are collected in an underground tunnel so that gas exceeds limit, a large quantity of mixtures of boring mud and water are accumulated is prevented.

Owner:成都晟鑫机电设备有限公司

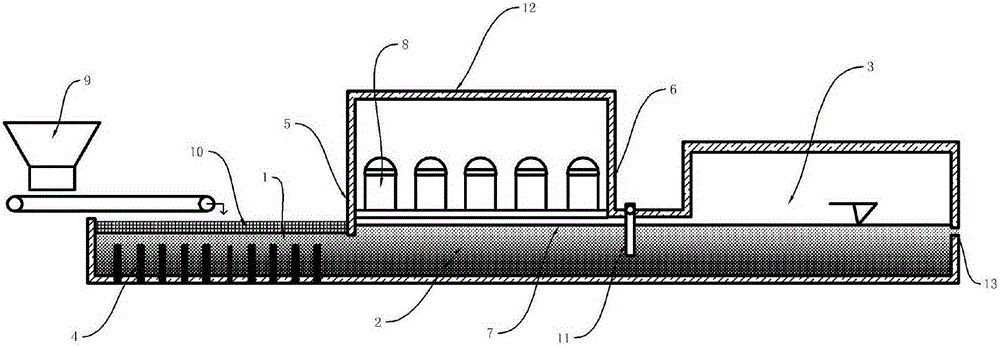

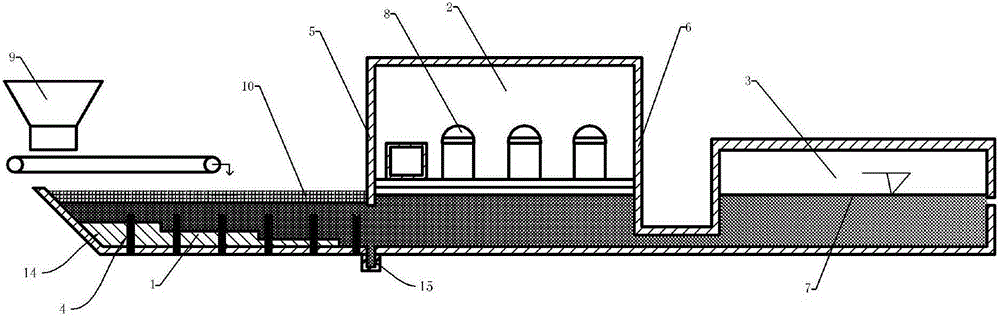

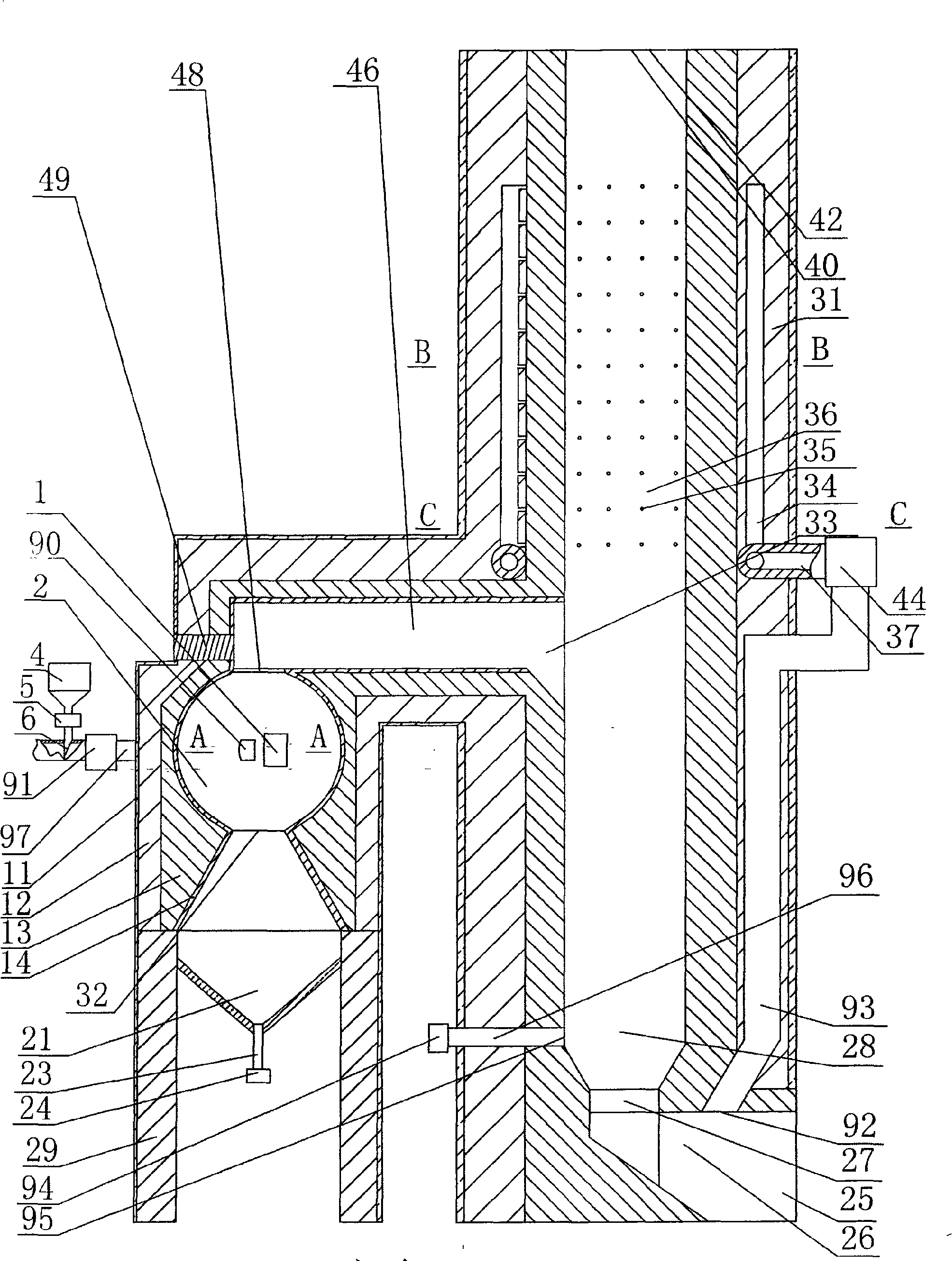

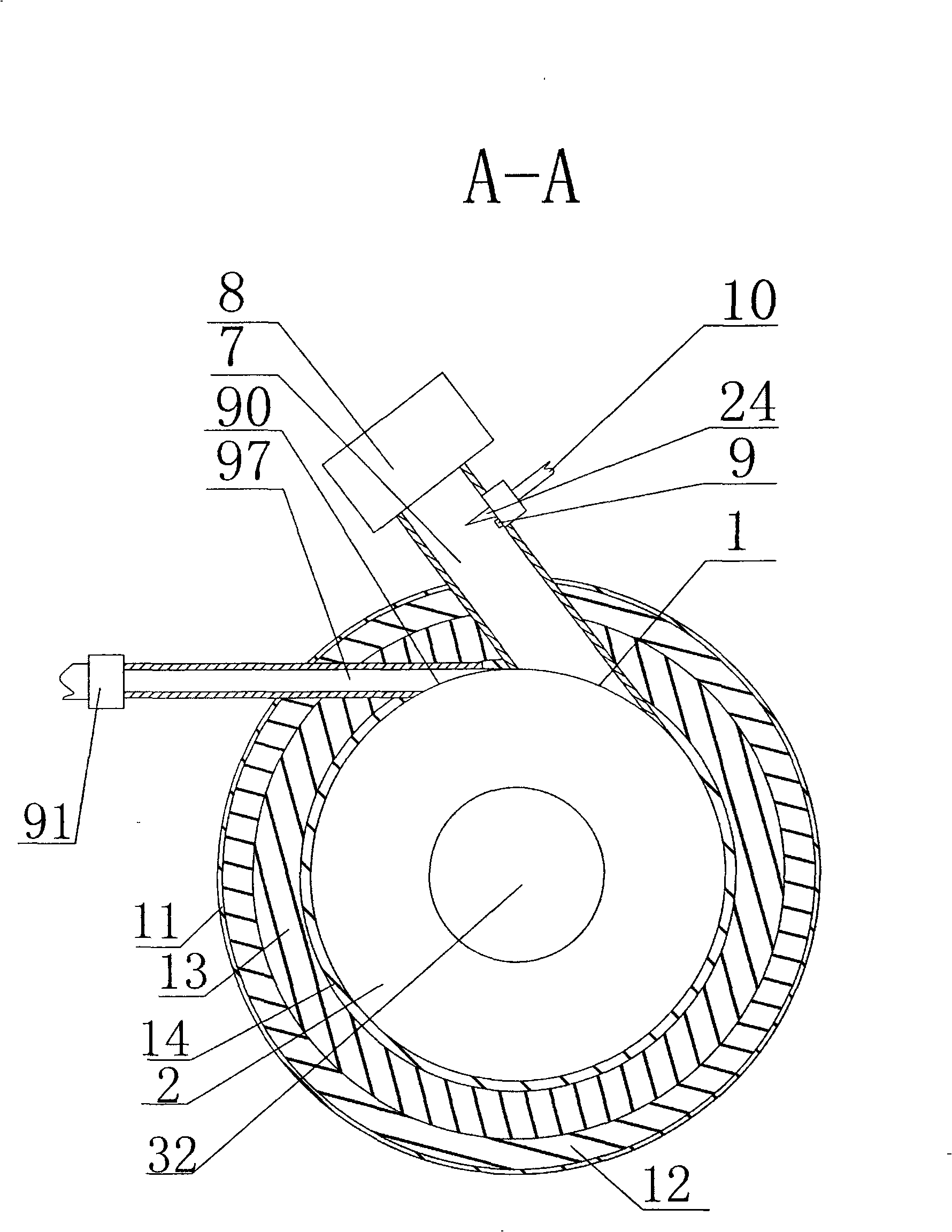

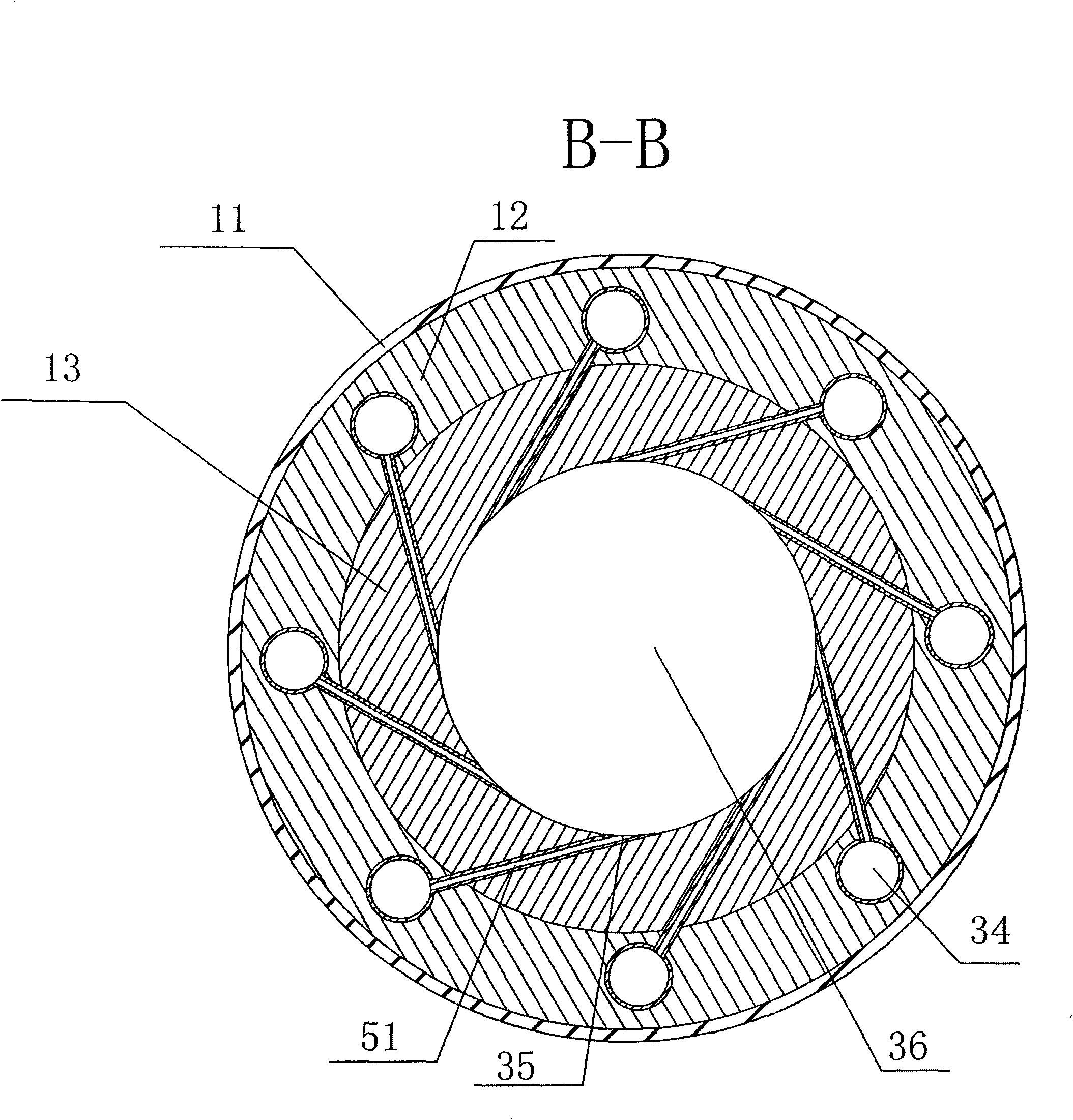

Melting furnace for founding high-volatility-component glass

ActiveCN106517736AAvoid Dissipation and Energy LossImprove energy efficiencyElectric furnaceGlass productionCombustionMaterials science

The invention discloses a melting furnace for founding high-volatility-component glass. The melting furnace comprises an electric melting tank, a flame clarifying tank and a working part, wherein the electric melting tank, the flame clarifying tank and the working part are distributed in sequence from left to right; the bottom of the electric melting furnace is provided with heating electrodes; at least one group of oppositely arrayed combustion spray guns are arranged on two side surfaces, where a first partitioning suspended wall and a second partitioning suspended wall are not located, above the liquid level of the flame clarifying tank; the combustion guns generate flame gas flows through combustion to sweep a glass liquid level; the first partitioning suspended wall separates the electric melting tank from the flame clarifying tank; the second partitioning suspended wall separates the flame clarifying tank from the working part; the first partitioning suspended wall at least stretches to a position which is not less than 50mm below the liquid surface; a partitioning structure is arranged at a joint between the second partitioning suspended wall and the working part; the partitioning structure stretches into the glass liquid level for not les than 250mm; the working part is provided with a material discharging port; the melting furnace also comprises a material distributing device loaded with a compound material; the material distributing device vertically adds the compound material to be above the liquid level of the electric melting furnace; a cold roof covered material pile is formed.

Owner:江苏华东耀皮玻璃有限公司

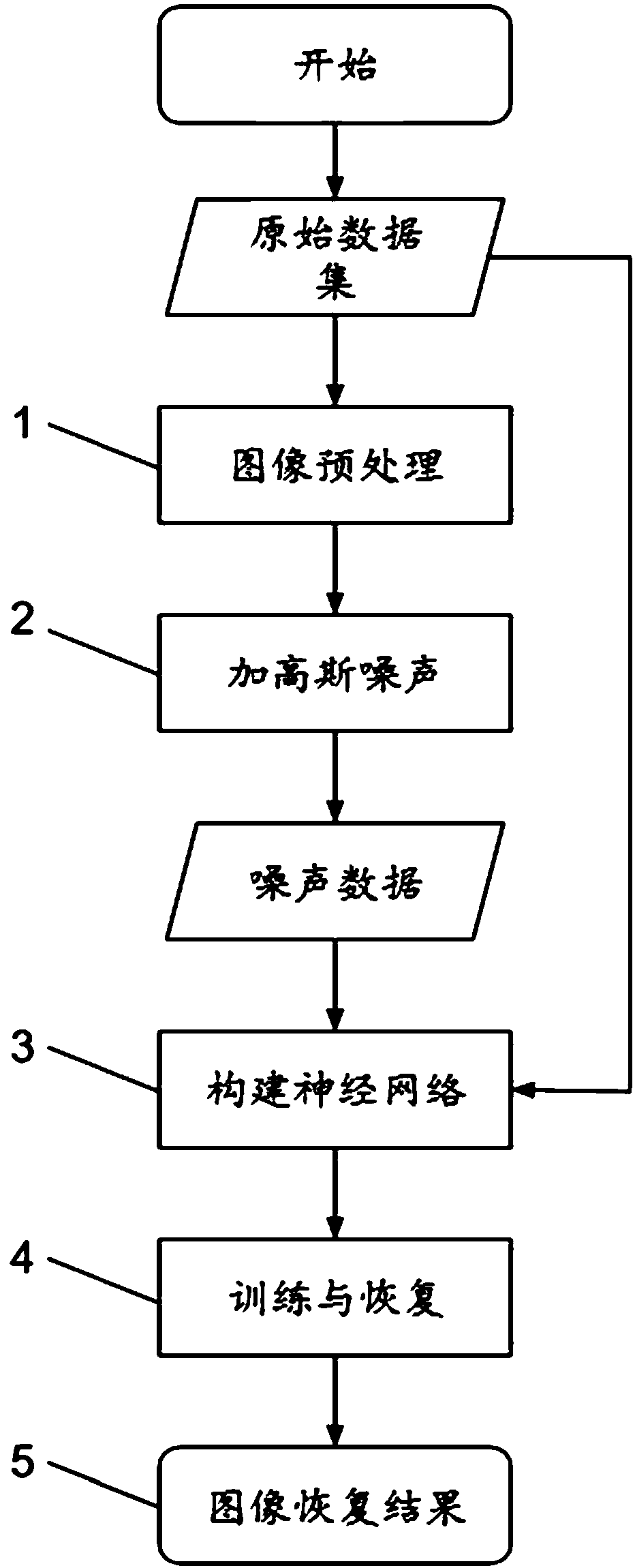

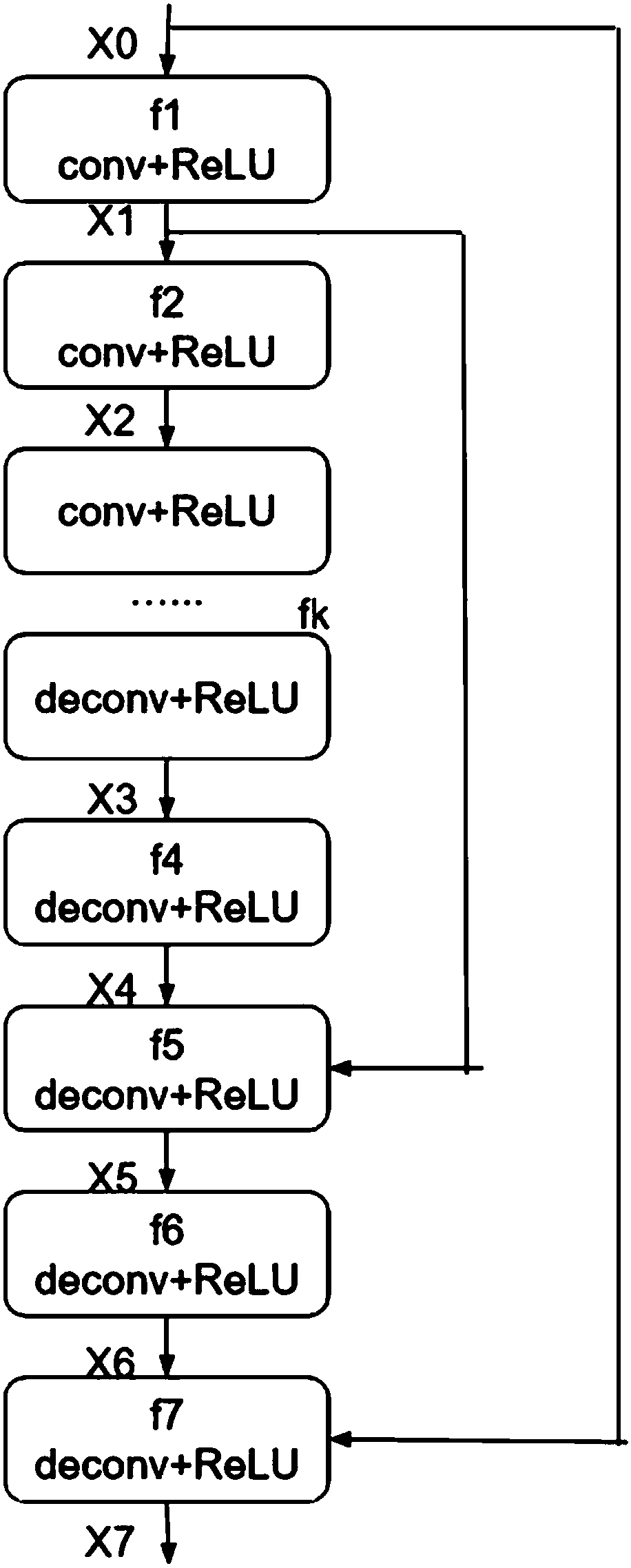

Image restoration method based on convolutional neural network with symmetric cross layer connection

InactiveCN108537747APromote recoveryFast convergenceImage enhancementNeural architecturesImage resolutionDeep level

The invention discloses an image restoration method based on a convolutional neural network with symmetric cross layer connection. The method comprises the following steps: training data are preprocessed; a fuzzy training image is generated automatically; a neural network is built; the neural network is trained; and restoration effects are verified and parameter adjustment is carried out. On the basis of a damaged image, a clearer original image can be restored, and the effectiveness of methods such as traditional image denoising, image super resolution and image completion is enhanced. Besides, through adding symmetric cross layer connection to the convolutional neural network, a deeper neural network can be optimized more easily, the model generalization ability is improved, the detailsof an underlying image are kept at the same time, and a better restored image can be obtained. High-efficiency and distinct image restoration is realized, and the practical value is high.

Owner:NANJING UNIV

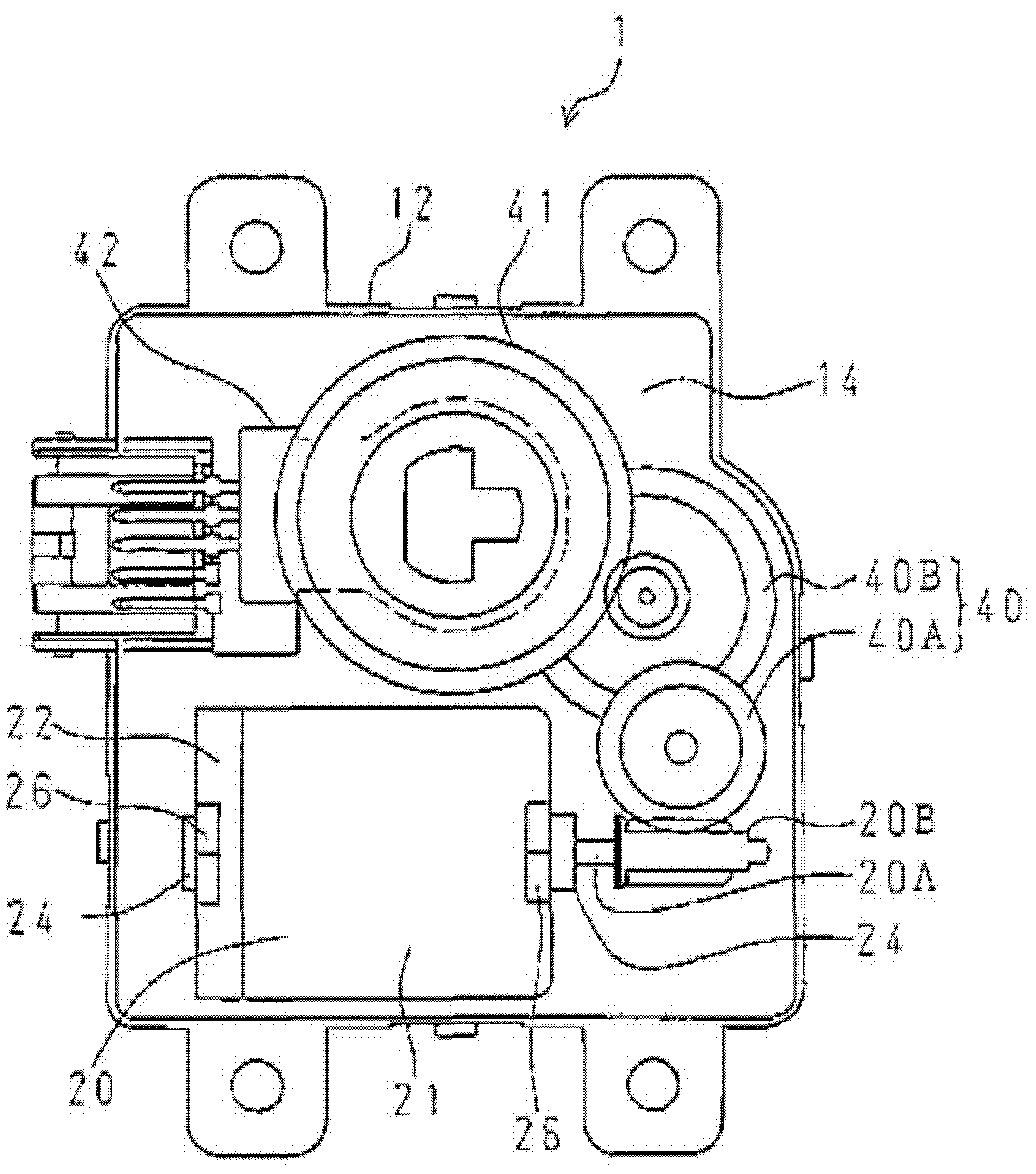

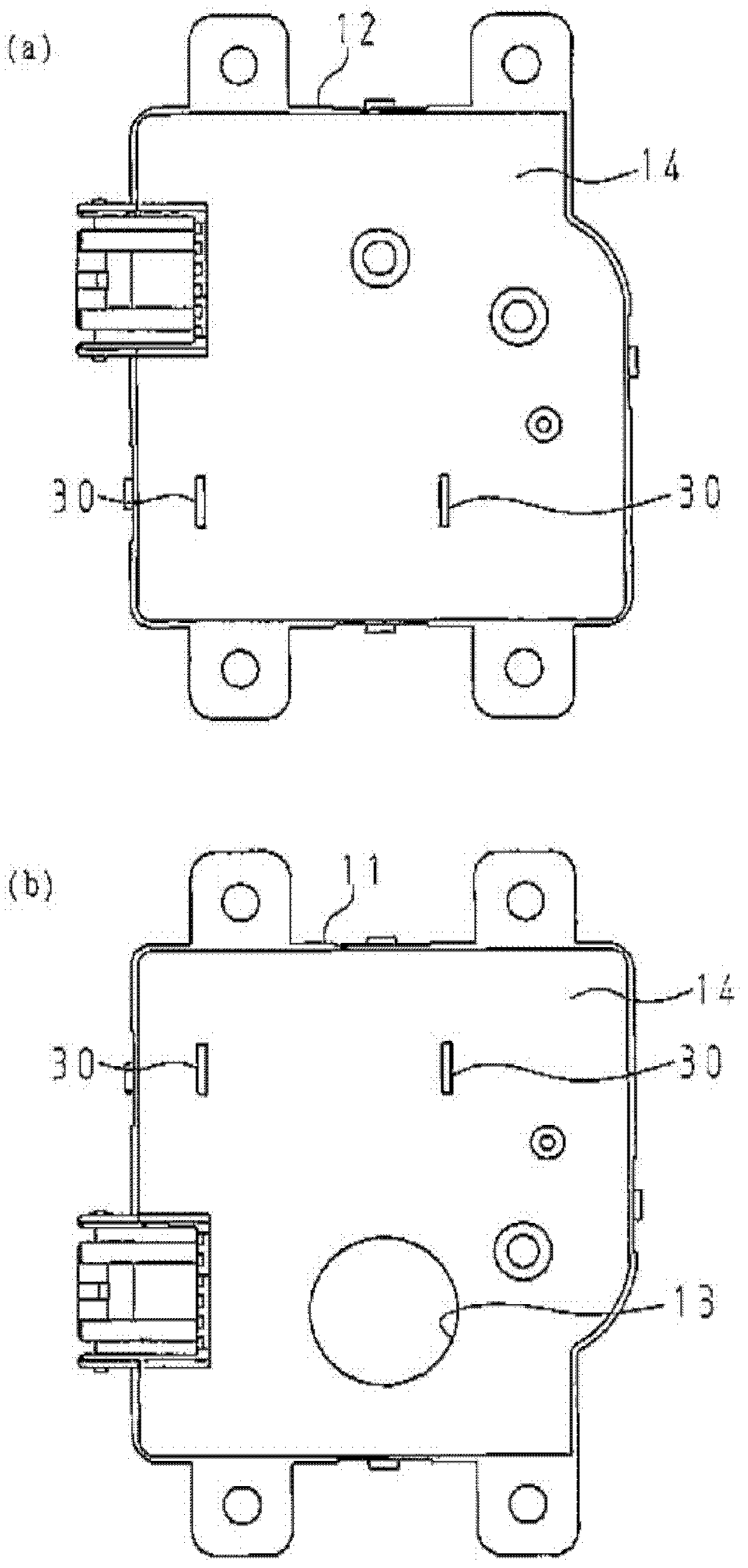

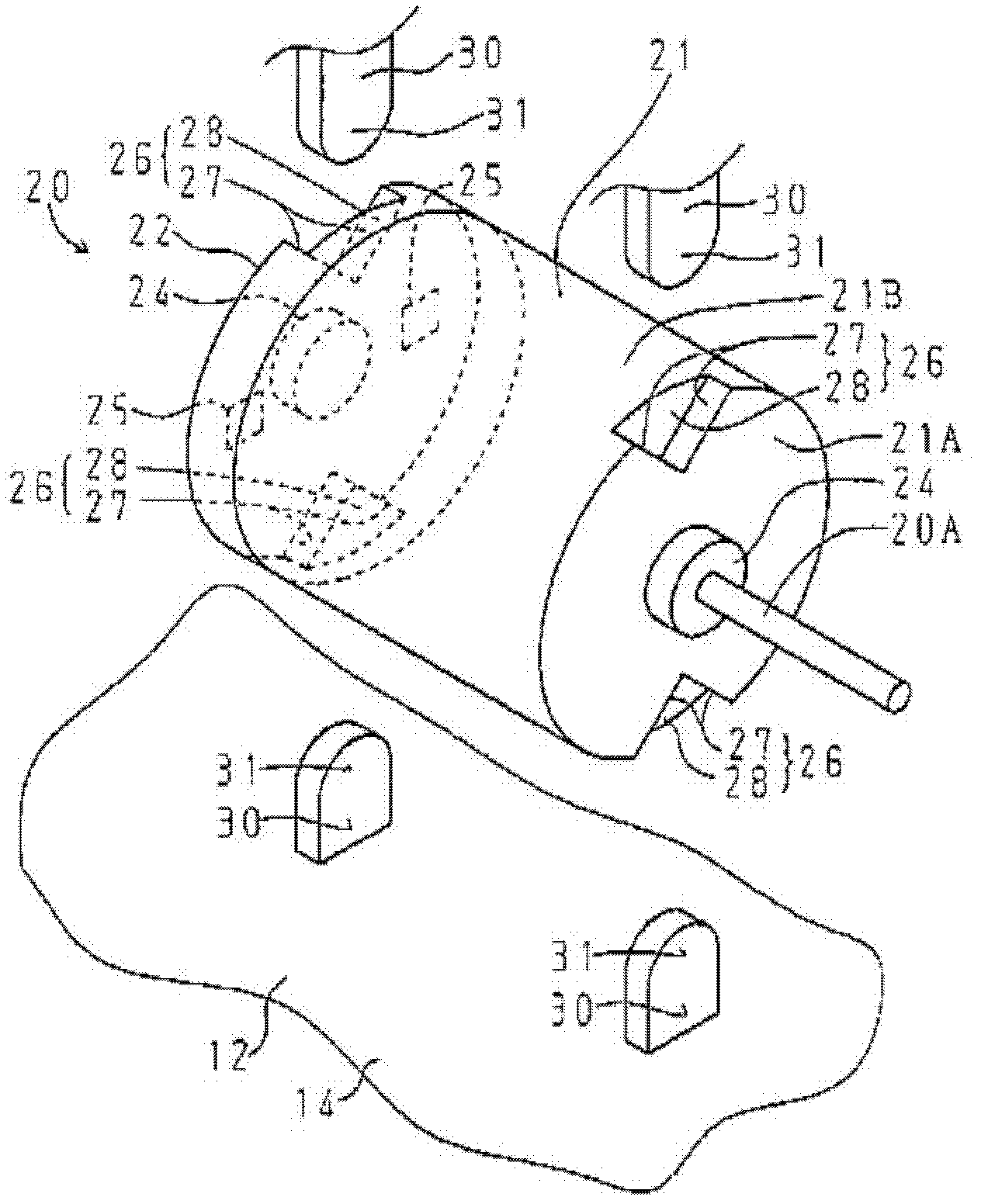

motor actuator

InactiveCN102290913APrevent rotationEasy transferMechanical energy handlingSupports/enclosures/casingsEngineeringActuator

Provided is a motor actuator which prevents the rotation of a motor by using a simple structure, and the vibration of the motor is not easy to transfer to a casing. A motor (20) disposed in the upper and lower casings (11,12) of the motor actuator is provided with a motor casing (21) and a motor casing cover (22), and the bottom (21A) of the motor casing and the motor casing cover (22) are respectively provided with two recessed portions (26). The recessed portions (26) clamp the rotating shaft of the motor (2) and are disposed above and below the assembling direction of the upper and lower casings (11,12), the inner sides of the upper and lower casings (11,12) are respectively provided with two motor support portions (3) composed of vertical rib plates. The two motor support portions (30) of the lower casing (12) are fastened with the recessed portions (26) below, the two motor support portions (30) of the upper casing (11) are fastened with the recessed portions (26) above, and the motor in non-contact with the bottom surfaces of the upper and lower casing is supported.

Owner:TOKYO PARTS IND CO LTD

Resource treatment process for inorganic salt hazardous wastes

ActiveCN110756172AImprove the adsorption effectSolve environmental problemsOther chemical processesTransportation and packagingSlagProcess engineering

The invention relates to the field of environmental protection treatment, in particular to a resource treatment process for inorganic salt hazardous wastes; and the main steps comprise feed treatment,high-temperature oxidation, waste salt refining treatment and evaporative crystallization. According to the process, the inorganic salt hazardous wastes are subjected to resource treatment through aprocess of negative pressure drying, a multilayer suspended oxidation furnace and a high-temperature rotary oxidation furnace, and compared with a traditional industrial slag salt high-temperature heat treatment process, the process can efficiently remove organic matters and effectively solve the problems of inorganic salt melting agglomeration, high-temperature refractory material corrosion and pipeline blockage caused by cooling in a pipeline during inorganic salt refining which may exist at high temperature; by using a carbamido modified bagasse adsorbent, trace organic matters remaining ina salt solution can be effectively removed, and the process of negative pressure drying and high-temperature liquefaction oxidation furnace is adopted, so that the high-temperature decomposition rateof the organic matters in the slag salt can be guaranteed and the problem of melting agglomeration can be solved.

Owner:内蒙古中泰汇金环保科技有限公司

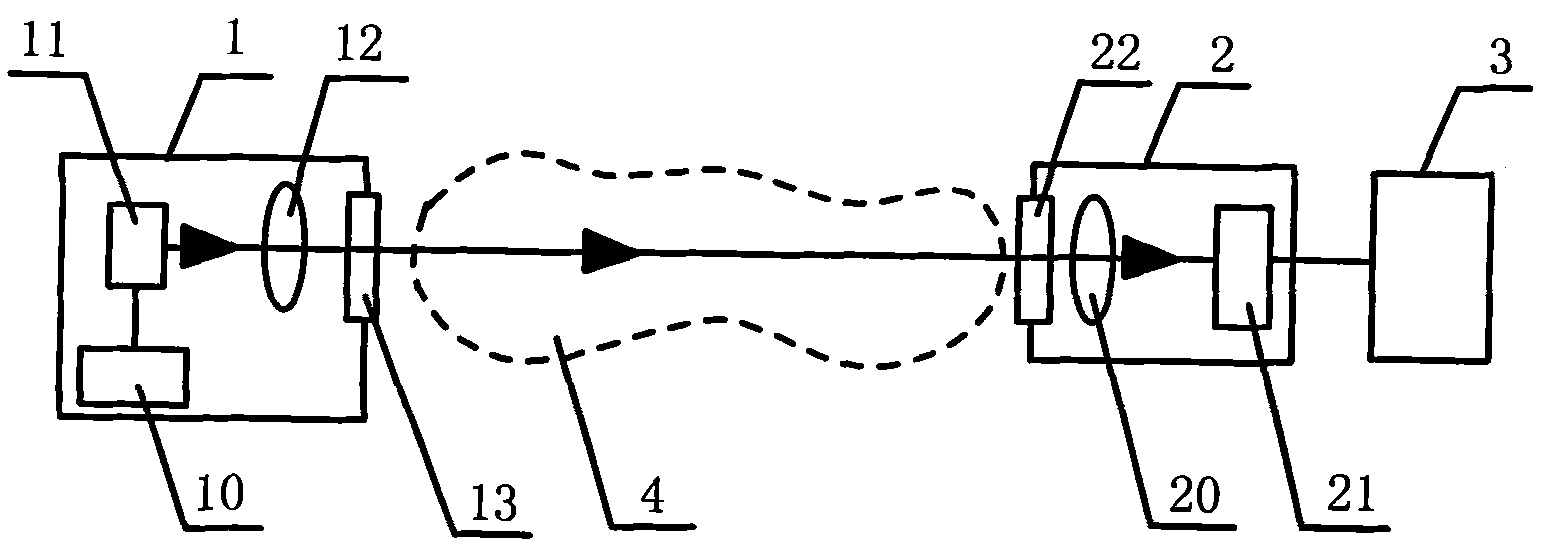

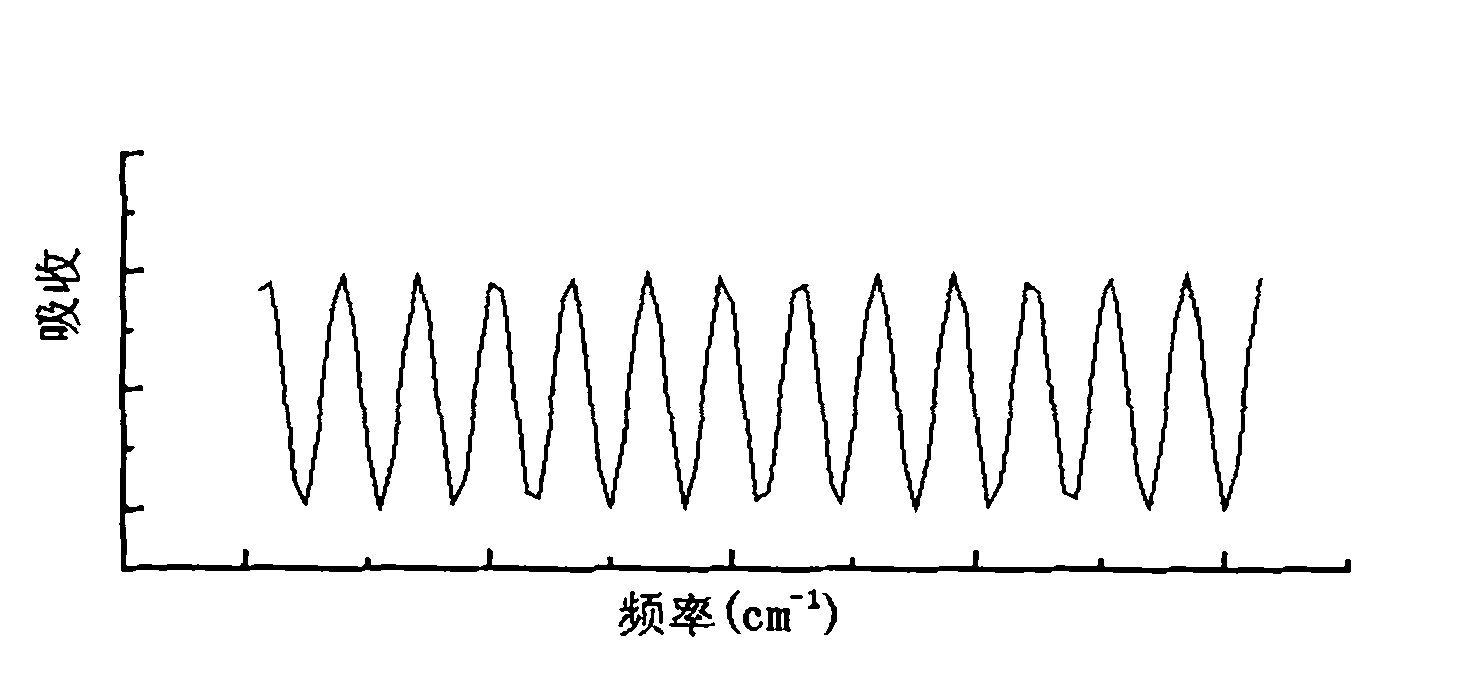

On-site absorption spectrum gas analysis system

InactiveCN102103071ARealize online calibrationReal-time online calibrationColor/spectral properties measurementsGas analysisOptoelectronics

The invention discloses an on-site absorption spectrum gas analysis system. The system comprises a light transmitting unit, a light receiving unit and a signal analysis unit, wherein the light transmitting unit comprises a light source and a converging lens. The system is characterized in that: one end of the converging lens back to the light source is provided with an arc surface; the arc surface end of the converging lens is provided with a calibration chamber of which one end is provided with an opening and the other end is closed; the opening end is hermetically connected with the converging lens; an A-A section on the middle part of the converging lens is in any geometrical shape; and light emitted by the light source passes through the converging lens and the calibration chamber and enters a medium to be measured. The system has the advantages of real-time on-line calibration, high measuring accuracy and measuring sensitivity, simple and reliable structure, easily realized explosion isolation function, no need of blowing, low sealing requirement and the like, and is convenient to manufacture.

Owner:FOCUSED PHOTONICS

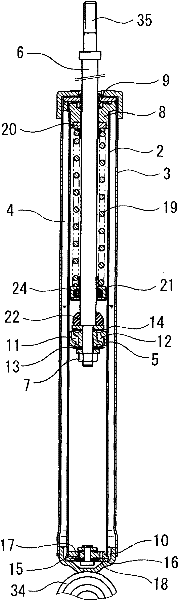

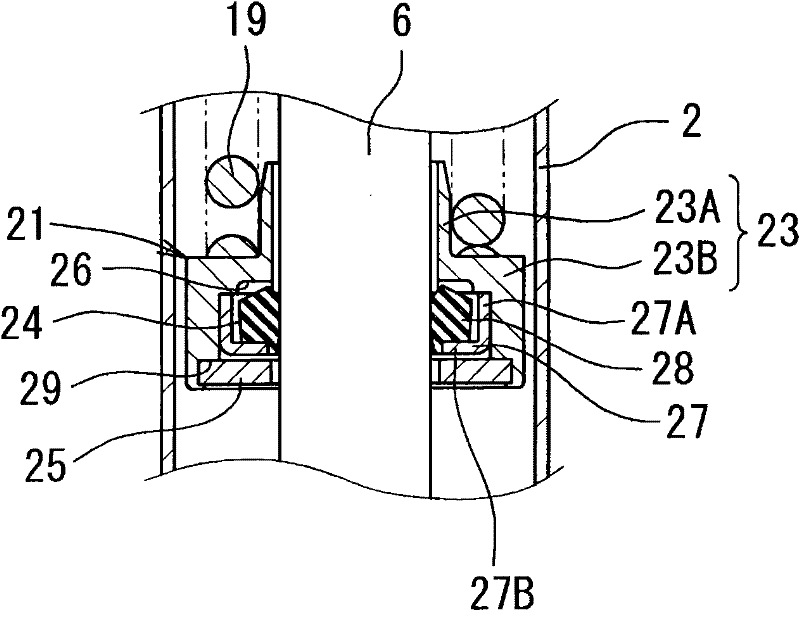

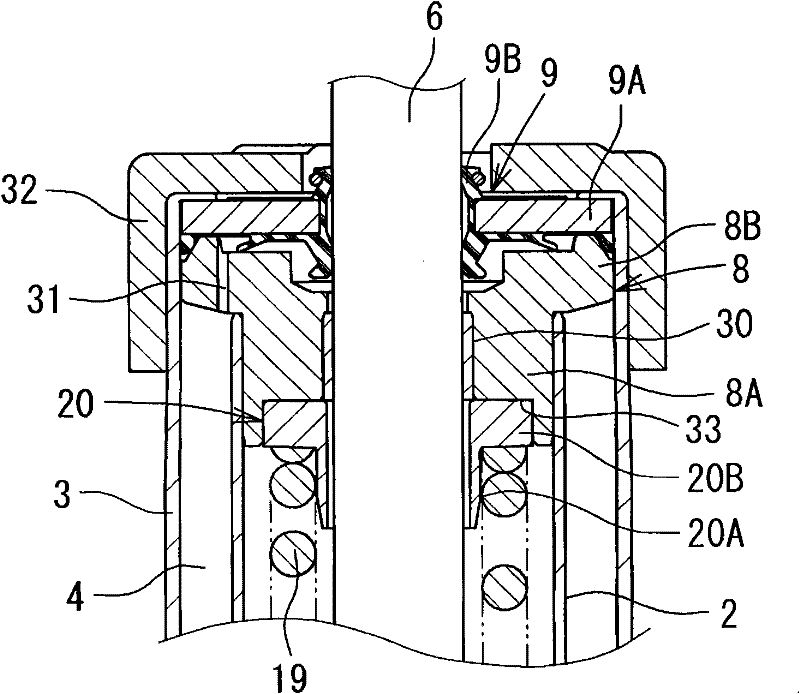

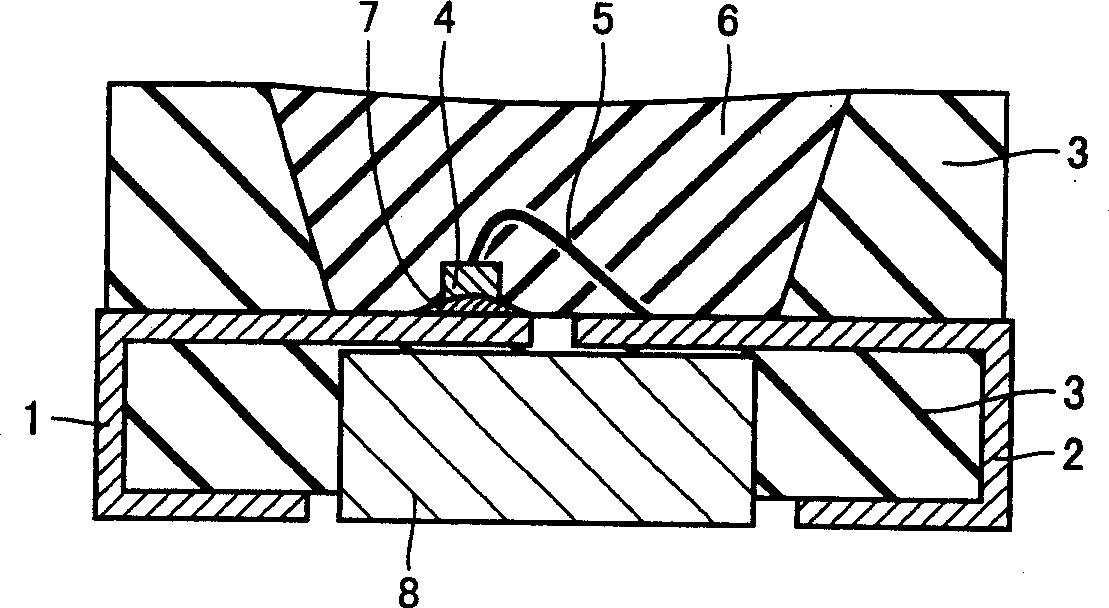

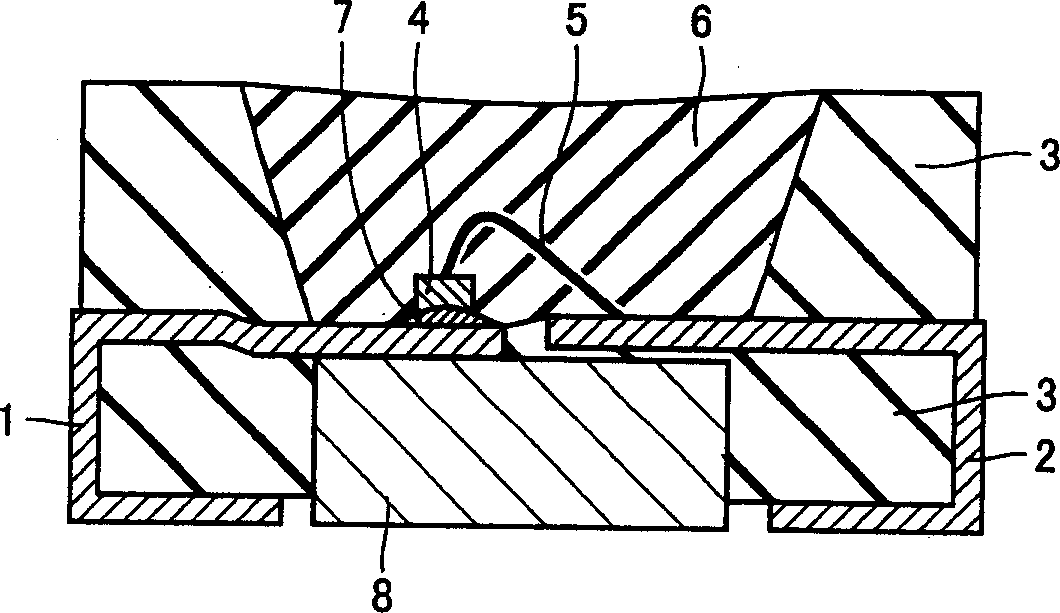

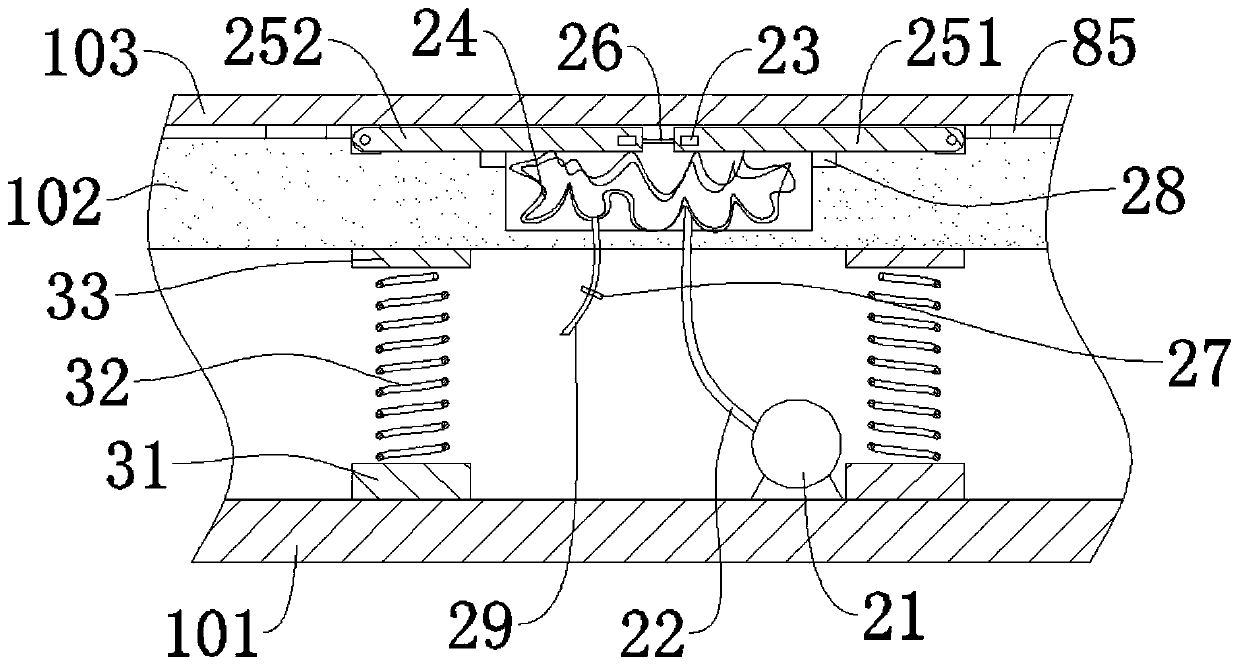

Shock absorber

InactiveCN102052424AAchieve vibrationNot easy to passSpringsGas and liquid based dampersUltrasound attenuationForce generation

The invention relates to a hydraulic shock absorber which can rebound spring vibration to prevent the noise from being transmitted to the vehicle body side. a piston (5) connected with a piston rod (6) is inserted into the a cylinder filled with oil in a slidable waby; the stroke of the piston rod (6) is applied with a attenuation force generated by a elongating side, a shortening side attenuation force generation mechanism (13, 14) and a attenuation force generation mechanism (18). A rebounding spring (19) is disposed around the piston rod (6) inside the cylinder (2); one end of the spring is fixedly mounted on a rod guiding element (8) of the cylinder (2), the other end is free. A spring guiding element (21) having a flexible assembly (24) is mounted on the free end of the rebounding spring (19) while the flexible assembly (24) is arranged in sliding contact with the piston rod (6). The flexible assembly (24) absorbs the vibrations and noises of the rebounding spring (19) to inhibit the vibrations and noises from being transmitted to the vehicle body side by the piston rod (6) easily.

Owner:HITACHI AUTOMOTIVE SYST LTD

Three-dimensional display

InactiveCN102722045AEasy transferReduce crosstalkSteroscopic systemsNon-linear opticsComputer scienceCrosstalk

The invention discloses a three-dimensional display, which comprises a phase delay sheet, a display panel and a plurality of plate-like structures, wherein the phase delay sheet is provided with a plurality of first strip-shaped regions and a plurality of second strip-shape regions; the first strip-shaped regions and the second strip-shape regions are alternately arranged. The three-dimensional display has a plurality of pixels which are arranged into a plurality of pixel lines corresponding to the first strip-shaped regions and the second strip-shape regions. The plate-like structures are arranged in a liquid crystal layer in the display panel, wherein the pixel lines are separated from one another by the plate-like structures to reduce crosstalk.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

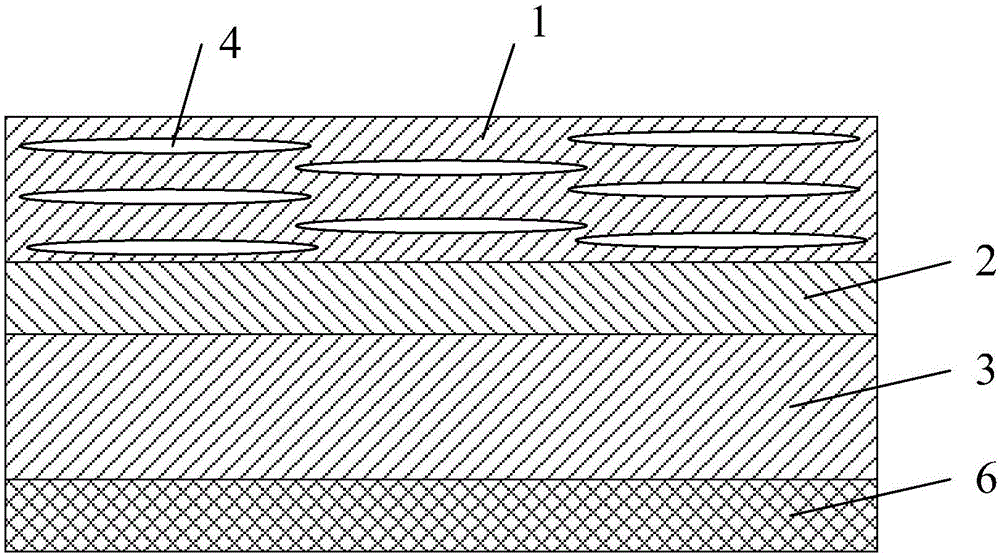

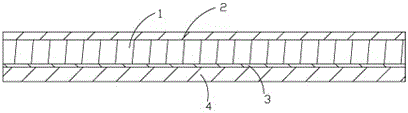

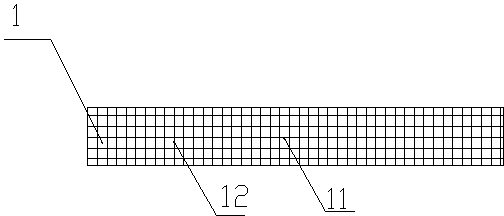

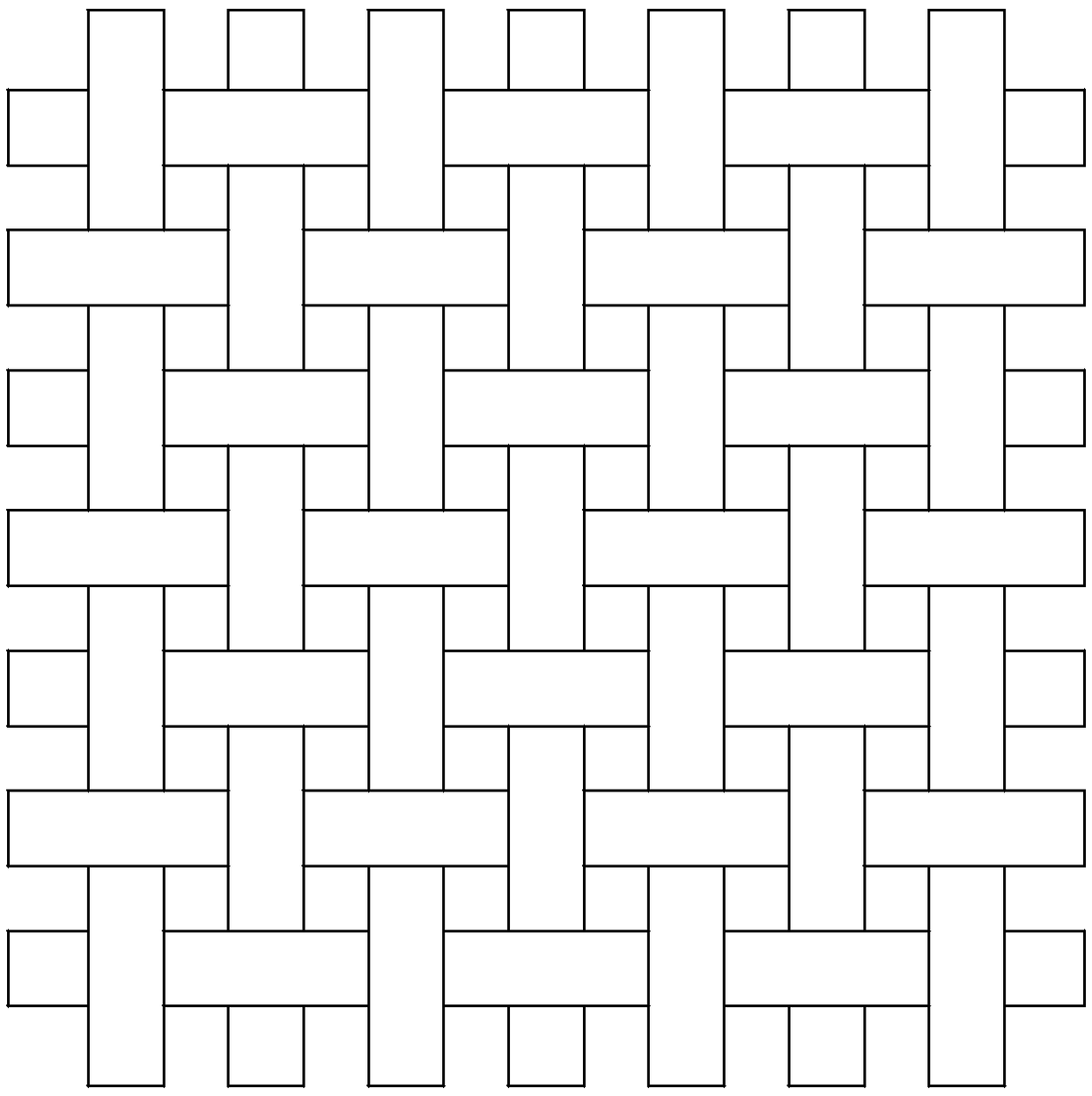

Antibacterial fabric with cotton fabric and super-hydrophobic coatings

InactiveCN104260538AEnhanced inhibitory effectGood killing effectClothingsWoven fabricsFiberNano silicon

The invention relates to an antibacterial fabric with a cotton fabric and super-hydrophobic coatings. The fabric comprises a base layer (2) and an antibacterial layer (1), wherein the antibacterial layer (1) is formed by connecting warps (11) with wefts (12); the warps (11) and the wefts (12) are formed by spinning nano silver fibers; the base layer is made from a fabric; the fabric comprises a cotton fabric; the double layers of surfaces of the cotton fabric are coated with nano silicon particle layers; the surfaces of the nano silicon particle layers are also coated with hydrophobic fluorine quaternary amine silane coupling coatings. The antibacterial fabric with the cotton fabric and the super-hydrophobic coatings has better antibacterial effects, reduces harms of bacteria to human bodies and makes people feel comfortable in the wearing process.

Owner:JIANGYIN XINJIAMEI GARMENTS

Vertical kiln

InactiveCN101349500AExtended stayExtended burn timeVertical furnacesCombustion chambersFuel supplyCombustion chamber

A shaft kiln is more energy-saving and environment-friendly through utilizing hot convection and vortex burning in the novel burning method and heating method. The shaft kiln can form eddying turbulence in a kiln chamber through utilizing pressurized air flow, and makes the material have even heating. As the movement is mutual, the heating method of rolling material is replaced by the movement of hot air flow around the material, and the material naturally moves to a preheating zone, a heating zone and a cooling zone through utilizing the natural settling, and the shaft kiln is provided with a fuel supply device, a burning chamber, a kiln chamber, a fan, an air pipe, refractory material and heat-insulating material. The shaft kiln is characterized in that an air inlet is arranged on the side walls of the burning chamber, and is connected with an air inlet pipe, and the fan is installed on the air inlet pipe, the burning chamber is connected with the fuel supply device, the kiln chamber is provided with a heating chamber and a cooling chamber, the lower portion of the heating chamber is communicated with the cooling chamber, a feeding inlet is arranged on the upper portion of the heating chamber, and an air outlet is arranged on the upper portion of the heating chamber, a discharge port is arranged on the lower portion of the cooling chamber, a kiln chamber air inlet is arranged between the heating chamber and the cooling chamber, and the burning chamber is provided with an air outlet which is communicated with a kiln air inlet.

Owner:陈久斌

Method for preparing bulletproof, cutting-resistant and inflaming-resistant fabric

ActiveCN108708066AImprove tensile propertiesImprove tear resistanceWarp knittingAbrasion resistant fibresYarnEngineering

The invention relates to the field of fabric preparation, and discloses a method for preparing a bulletproof, cutting-resistant and inflaming-resistant fabric. The method comprises the following stepsthat Step 1, gray fabric is prepared, wherein the gray fabric comprises ground yarn and shell yarn, the ground yarn comprises aramid fiber yarn, the shell yarn comprises inflaming-resistant fiber yarn, and the ground yarn and the shell yarn are sewn to be combined to form the gray fabric; Step 2, gray fabric raising is carried out, wherein the surface of the shell fabric fluffs through a raisingmachine, and fluff on the surface of the shell yarn is combed, so that the gray fabric becomes raised cloth; Step 3, the gray fabric is shaped, wherein the raised cloth forms a finished fabric througha shaping machine. The tensile performance and tear resisting performance of the gray fabric can be enhanced through the characteristic of the aramid fiber yarn, the inflaming resistance of the grayfabric can be improved through the inflaming-resistant fiber yarn, and therefore the fabric cannot be ignited by open fire easily. The air chamber effect on the surface of the gray fabric can be enhanced through the fluff, the human body and external air are separated, the temperature of a fire scene cannot be transferred to a wearer easily, and therefore the aim of protecting the human body to acertain degree is achieved.

Owner:绍兴必安防护科技有限公司

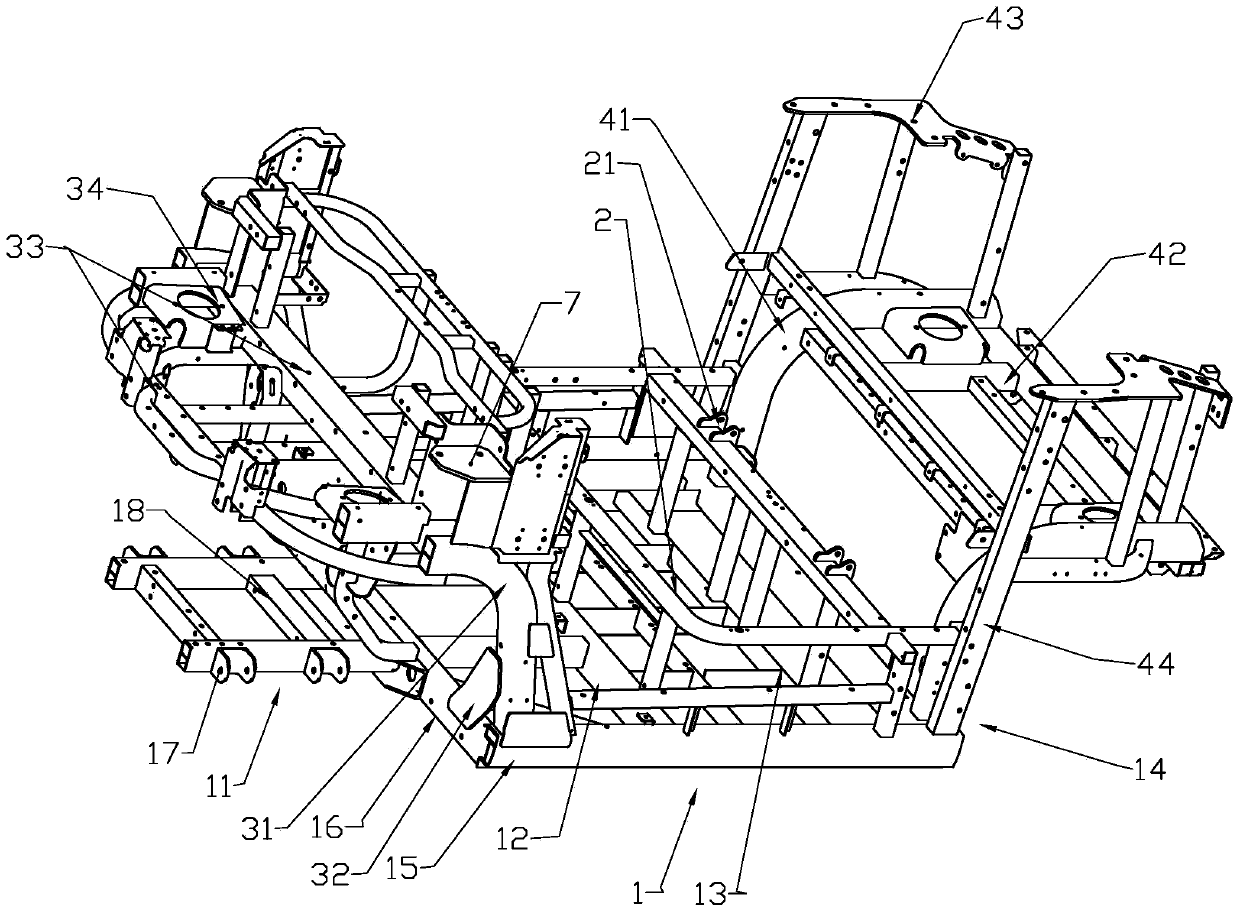

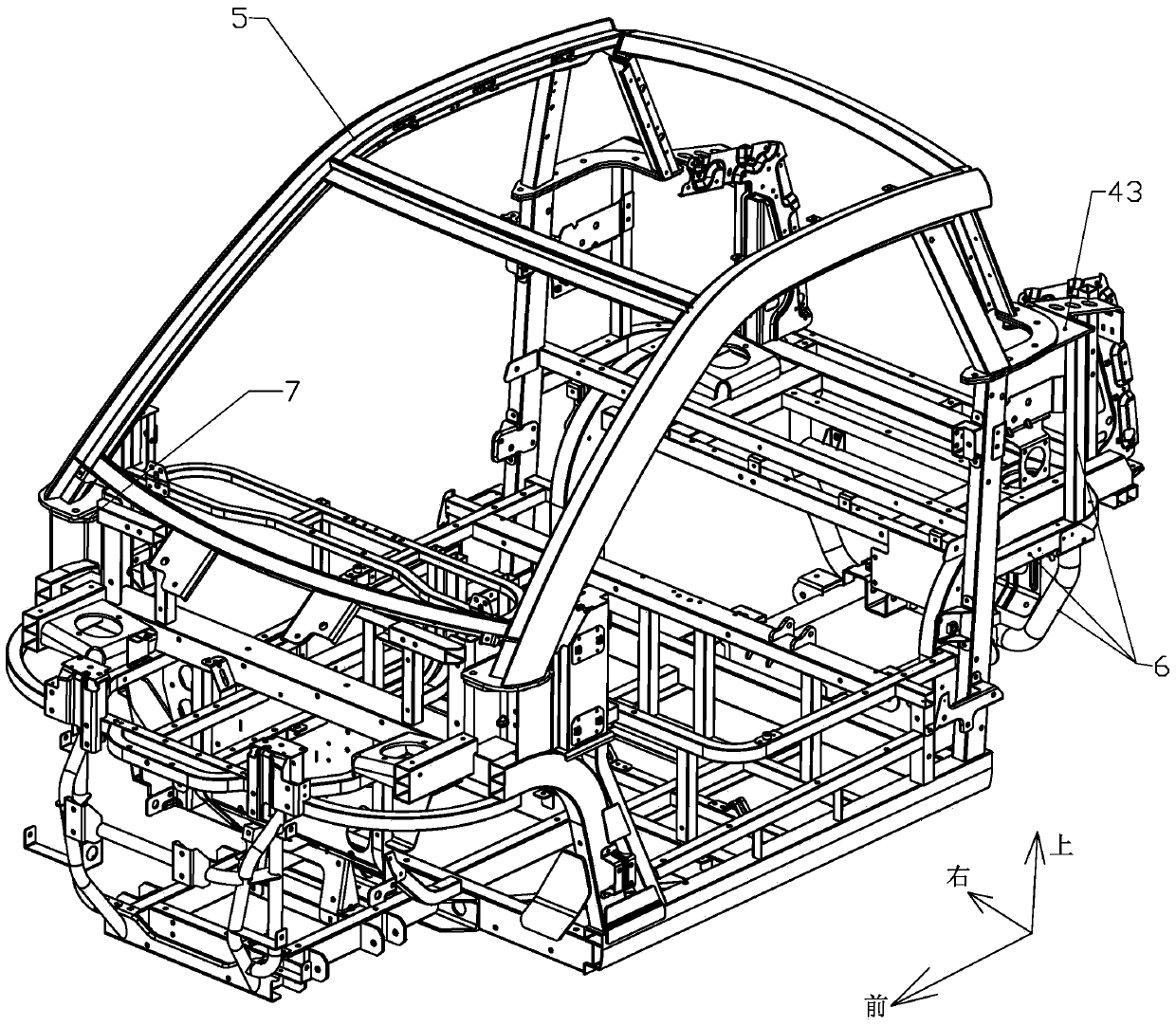

Light electric automobile body structure

InactiveCN104192215AExtend your lifeSmall load factorUnderstructuresSuperstructuresVehicle frameRoad surface

A light electric automobile body structure comprises a frame, an automobile body, an electric motor, suspensions, front wheels and rear wheels. The frame is of an integrated frame structure welded by aluminum alloy profiles and plates, the electric motor, the suspensions and the automobile body are arranged on the frame, the frame is connected with the wheels through a front suspension and a rear suspension, screw holes for fixing the automobile body are formed in the frame, and a base for fixing springs is arranged on the frame. The automobile body is good in comfort, and therefore, riding comfort is improved. The electric motor is not fixed on the automobile body directly, so that noise is unlikely to be transmitted into an automobile. The finished automobile is large in longitudinal rigidness, various impacts transmitted to the automobile body from the road surface can be relieved, and the service life of the automobile body is prolonged. When automobile collision happens, the frame can absorb part of impact energy, and therefore, safety performance is improved. The bearing factor of the automobile body is small, so that development of variants is facilitated. A chassis and the automobile body which serve as assemblies are assembled in advance respectively, so that the assembly process of the finished automobile is simplified.

Owner:山东宝雅新能源汽车有限公司

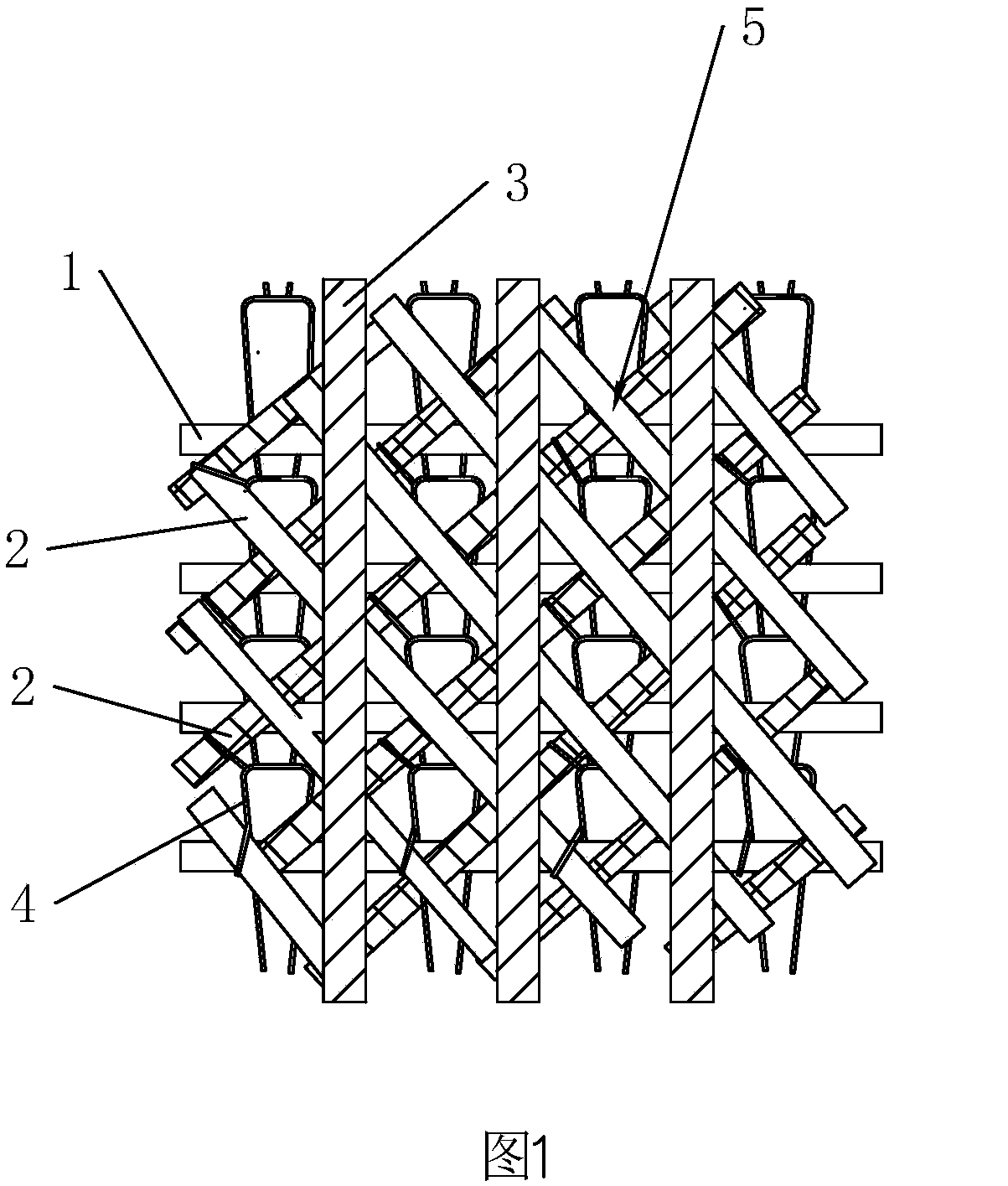

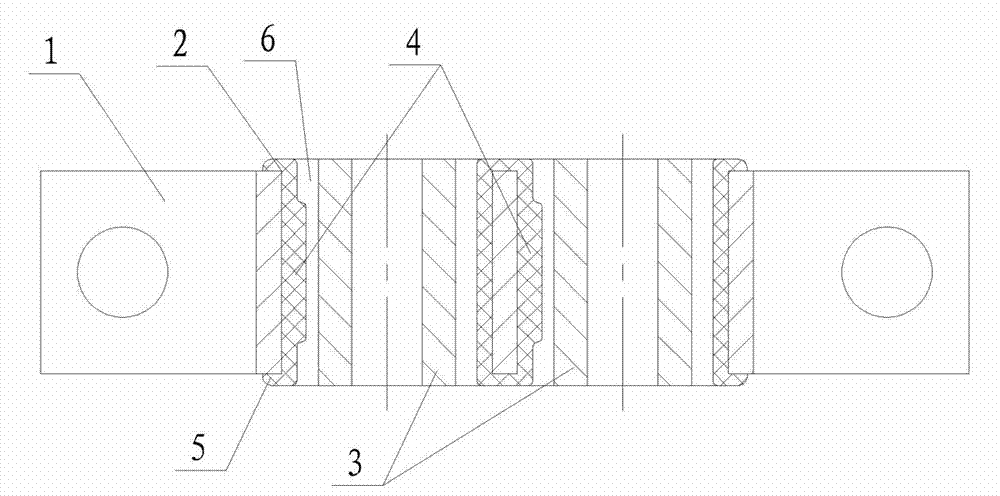

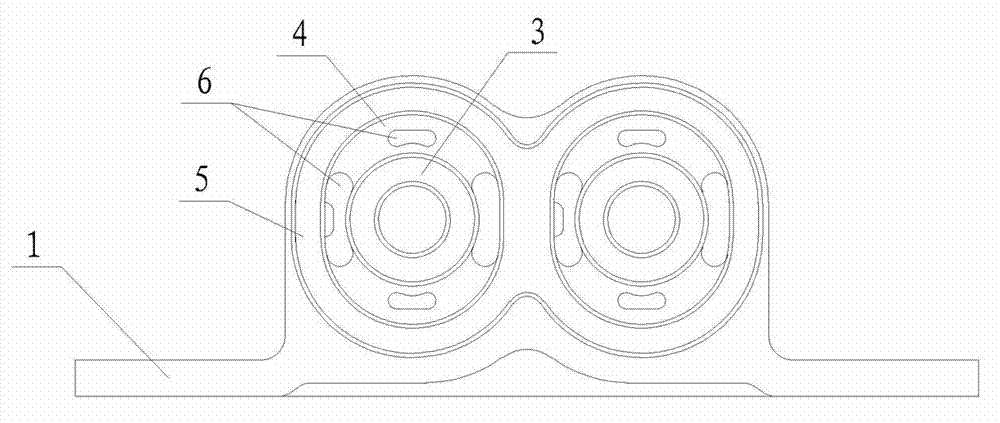

Exhaust pipe support

ActiveCN102777242AReduce noiseImprove elastic deformation abilityExhaust apparatusSilencing apparatusCar drivingEngineering

An exhaust pipe support comprises a support body (1). Two installation holes (2) are arranged on the support body (1), axes of the two installation holes (2) are parallel to each other, connecting sleeves (3) are arranged inside the installation holes (2), the external diameters of the connecting sleeves (3) are smaller than diameters of the installation holes (2), and the installation holes (2) and the connecting sleeves (3) are connected through rubber layers (4). Compared with the prior art, the external diameters of the connecting sleeves are smaller than diameters of the installation holes, the installation holes and the connecting sleeves are connected through the rubber layers, the rubber layers have a good elastic deformation function and have a good shock-absorbing effect, the shock does not transmit between an exhaust pipe and a car frame easily under the condition that the shock of the exhaust pipe and the car frame is filtered by the rubber layers, the shock of the car frame cannot affect the exhaust pipe, the shock of the exhaust pipe is small, and the failure condition of the exhaust pipe, such as rupture, cannot occur easily. Simultaneously, after the rubber layers absorb the shock of the exhaust pipe and the car frame, and the noise due to the car frame and exhaust pipe shock is low during car driving.

Owner:NINGBO QIANHUI AUTOMOBILE MOLDING

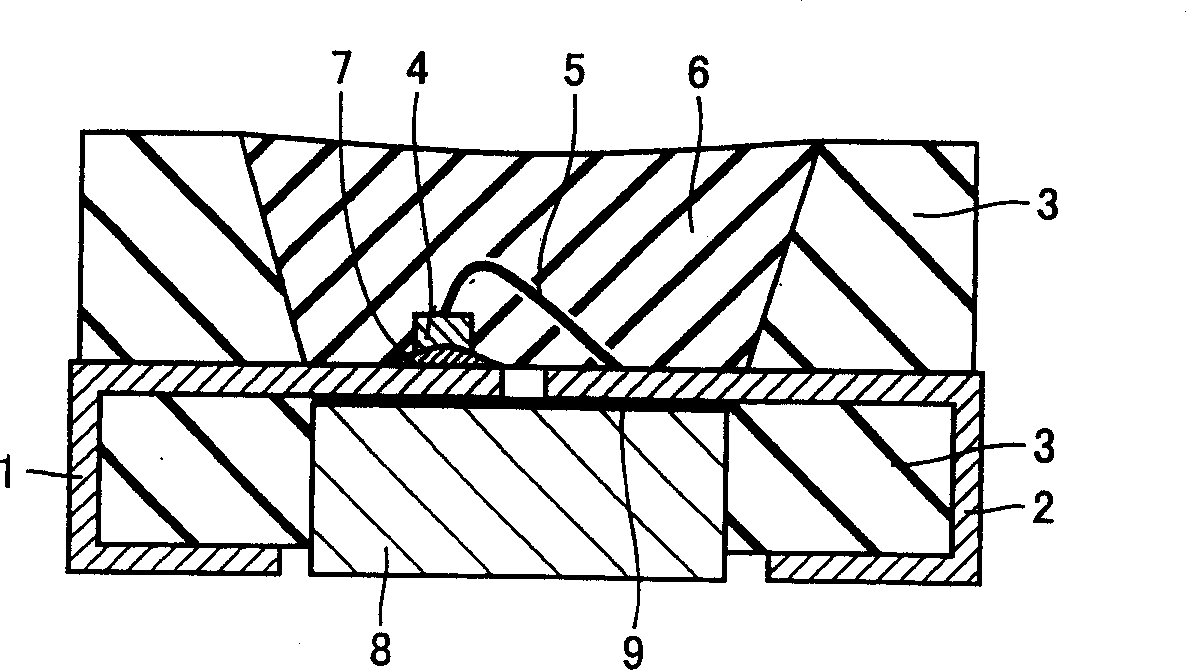

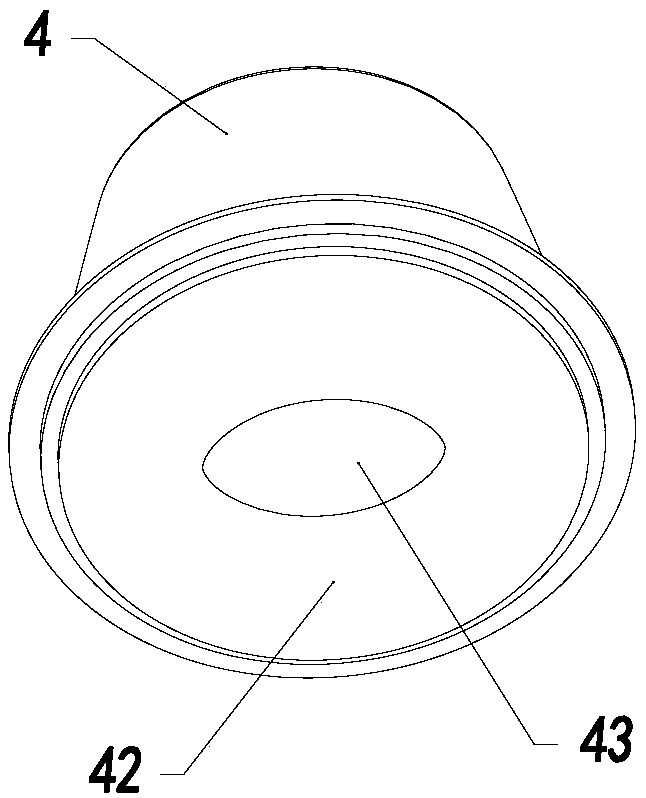

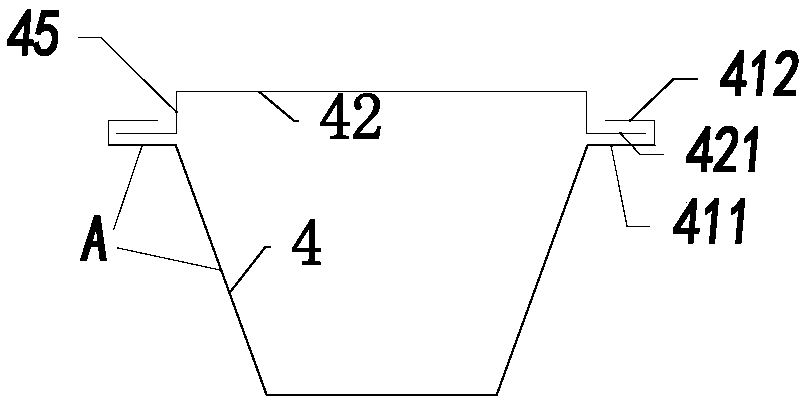

Semiconductor luminescent device and its manufacturing method

InactiveCN1518135AHigh luminous intensityEasy to fixSolid-state devicesSemiconductor devicesEngineeringLead frame

A semiconductor light emitting device includes an LED chip (4), a first lead frame (1) on which the LED chip (4) is mounted, a second lead frame (2) electrically connected to the LED chip (4) via a bonding wire (5), and a resin portion (3) surrounding the circumference of the LED chip (4), and fastening the first and second lead frames (1, 2). A metal body (8) is located under the region of the first lead frame (1) where the LED chip (4) is mounted.

Owner:SHARP KK

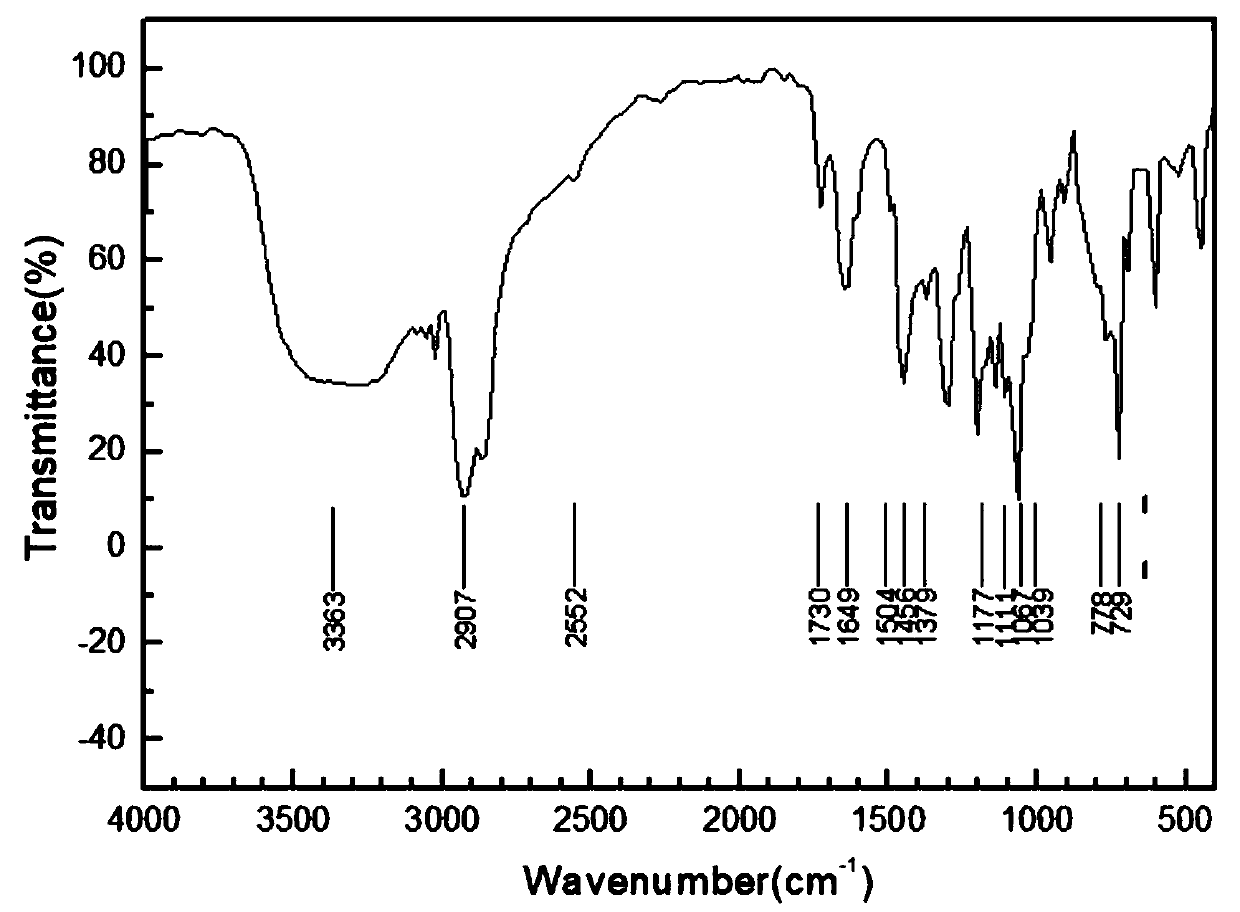

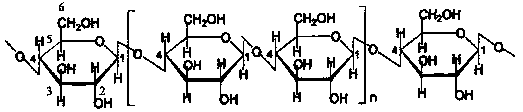

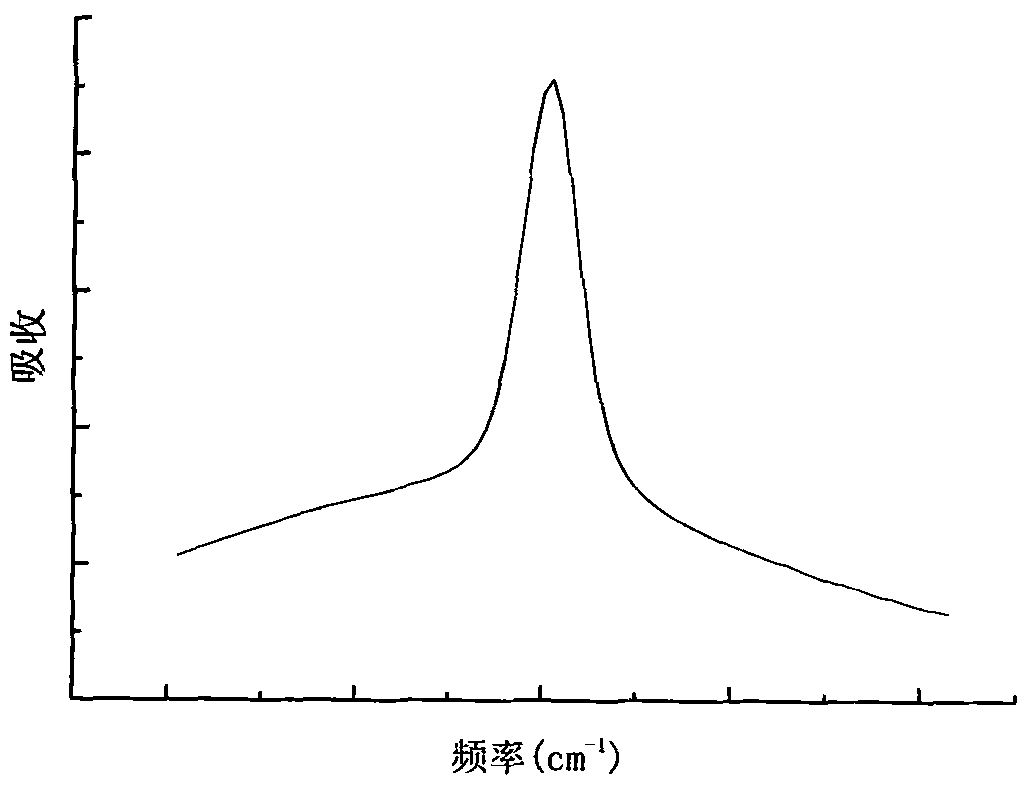

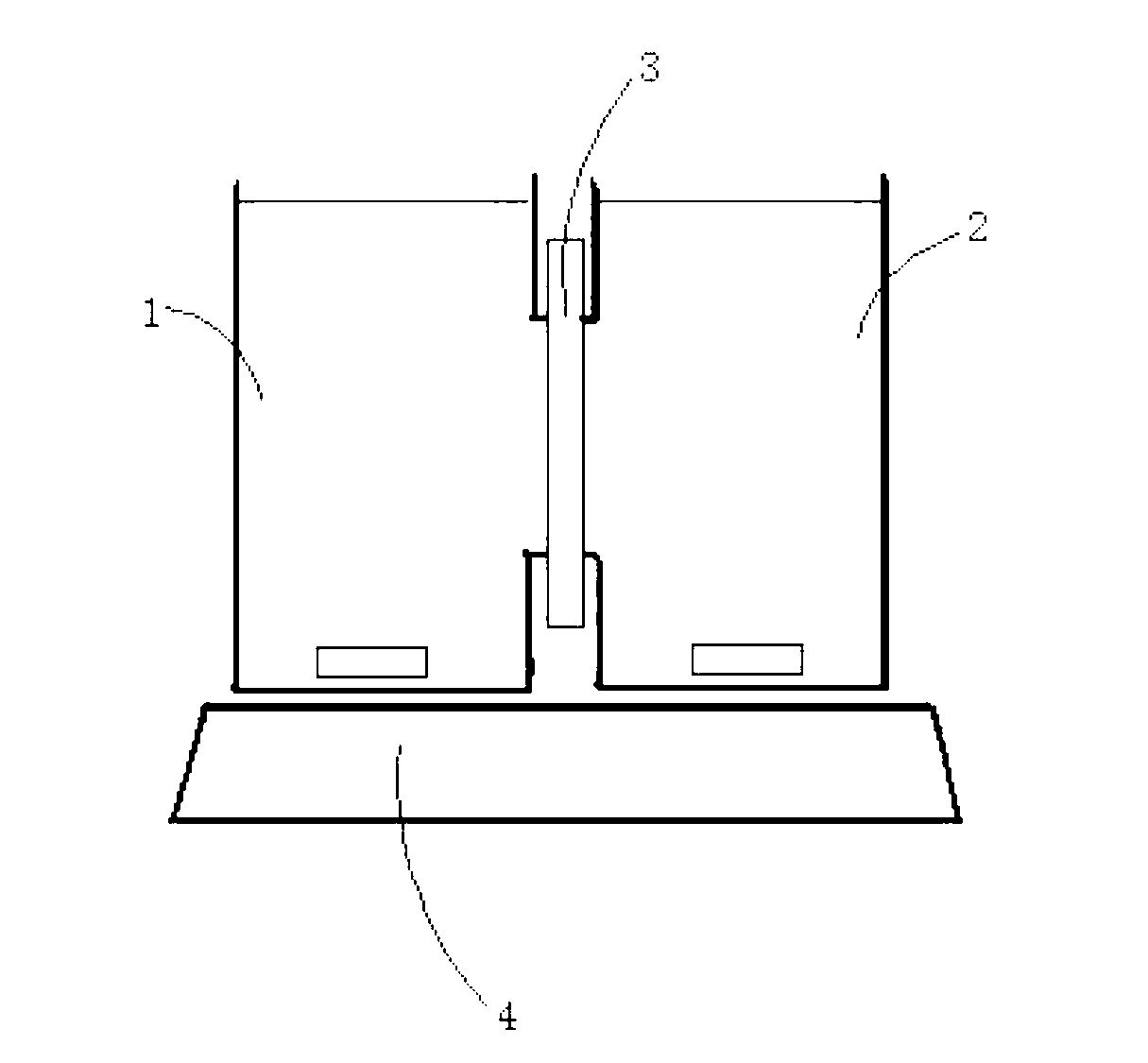

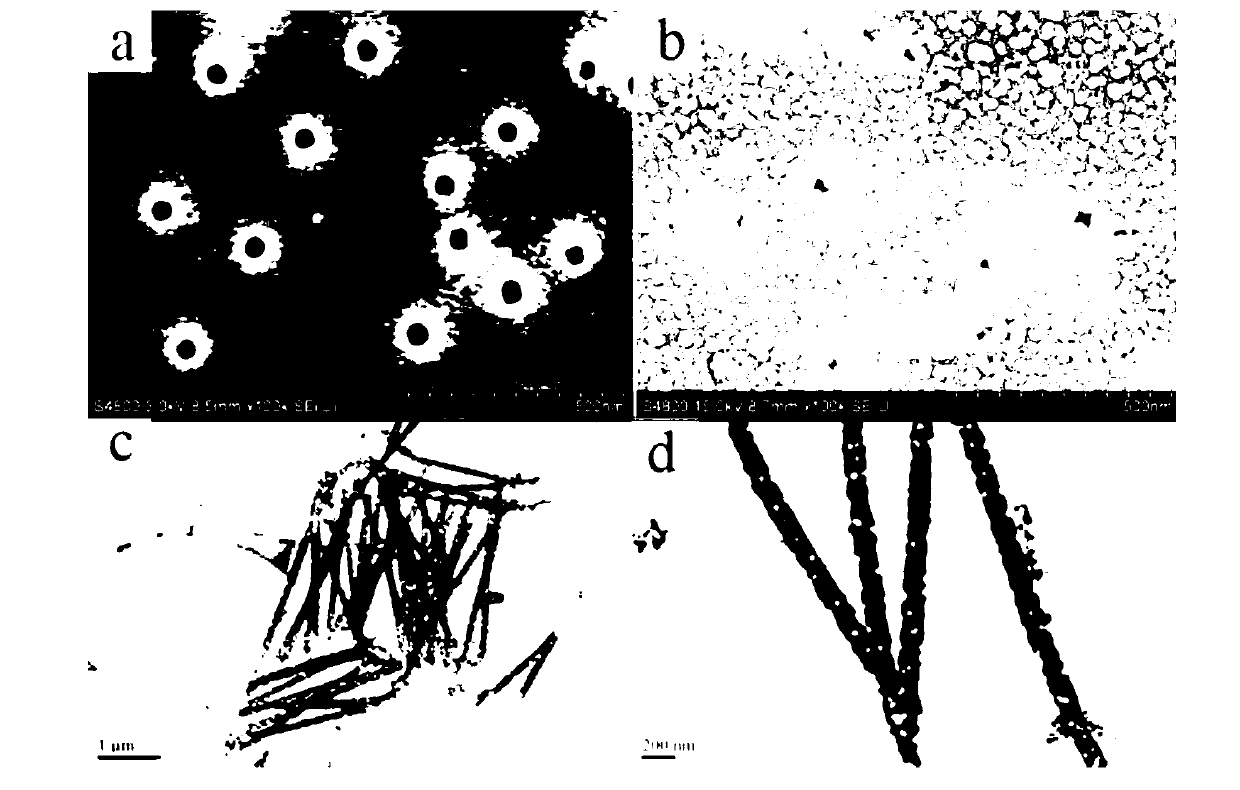

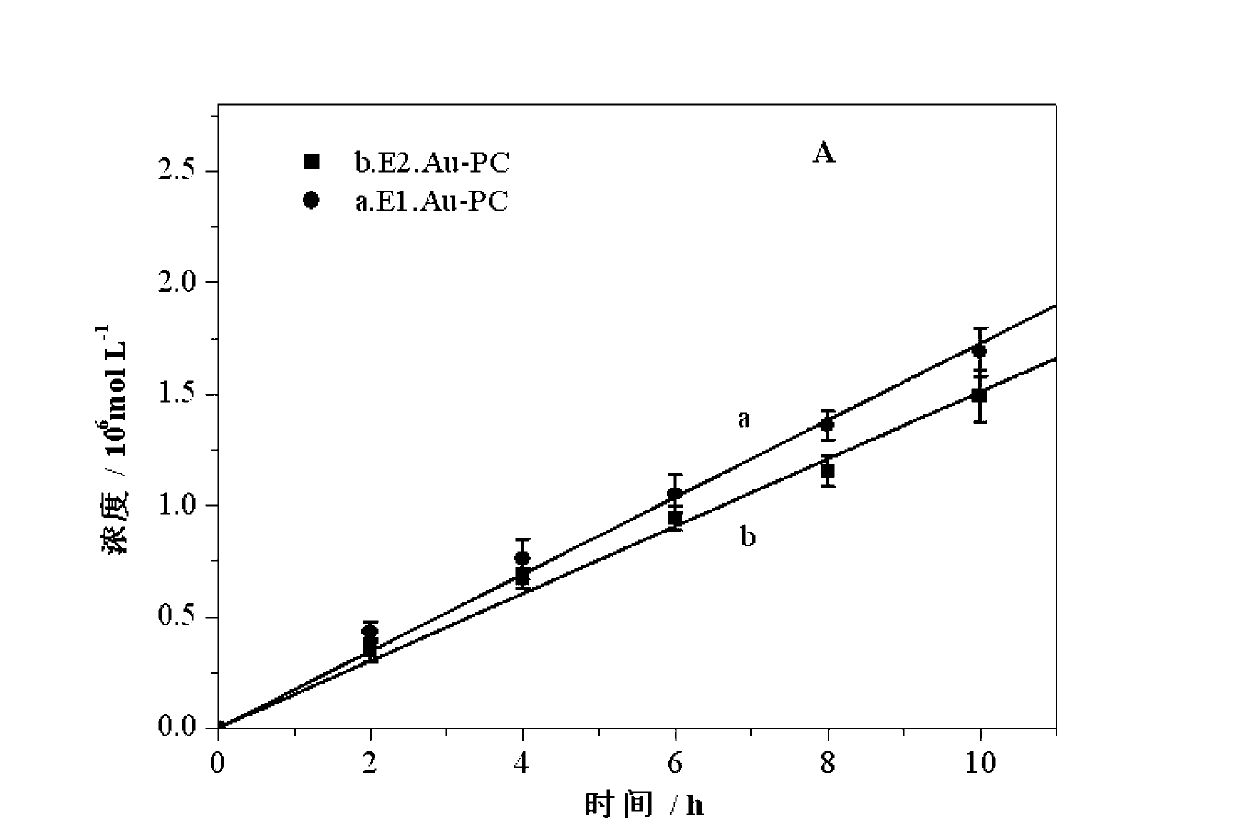

Method for separating beta-estradiol and oestrone based on nanometer channel modified by aptamer

The invention discloses a method for separating beta-estradiol and oestrone method based on a nanometer channel modified by an aptamer. A prepared array gold nanoparticle channel is used as a carrier and aptamer modifies beta-estradiol inside the gold nanoparticle channel so as to obtain a gold nanoparticle channel membrane which has special selectivity to the beta-estradiol. A difference of the beta-estradiol and the oestrone is utilized, transfer speed of the beta-estradiol and the oestrone in the nanometer channel which modifies the aptamer, the aptamer has the selectivity to the beta-estradiol, and comparatively passes through the modified nanometer channel, but the oestrone is not easy to pass through, and the separation of the beta-estradiol and the oestrone is achieved. The method can provide a novel idea for conducting compartment analysis to estrogens with different affinity of other aptamers.

Owner:SHANGHAI NORMAL UNIVERSITY

Cotton-fabric superhydrophobic coating variable-color fabric

InactiveCN104249534AMeet needsAchieve color changing effectLayered productsSurface layerColor changes

The invention relates to cotton-fabric superhydrophobic coating variable-color fabric. The fabric comprises a fabric body (1) and is characterized in that the surface of the fabric body (1) is coated with a variable-color coating (2) which is a temperature-sensitive compound, the fabric body comprises cotton fabric, two surface layers of the cotton fabric are coated with nanometer silicon particle layers, and the surface of each nanometer silicon particle layer is coated with a hydrophobic fluorine quaternary-ammonium silane coupling agent coating. The fabric shows different colors at different temperature, thereby realizing color changing effect and satisfying demands of the young pursuing difference and doing something unconventional. The fabric possesses waterproof air-permeable effects.

Owner:JIANGYIN SHANGFENG TEXTILE

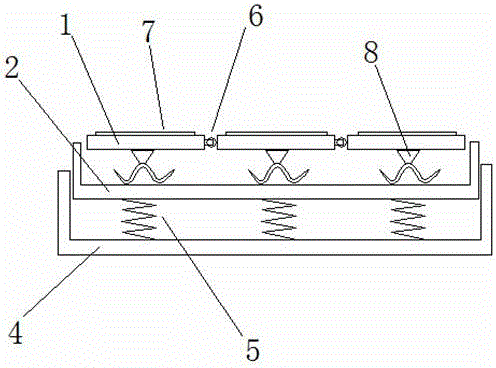

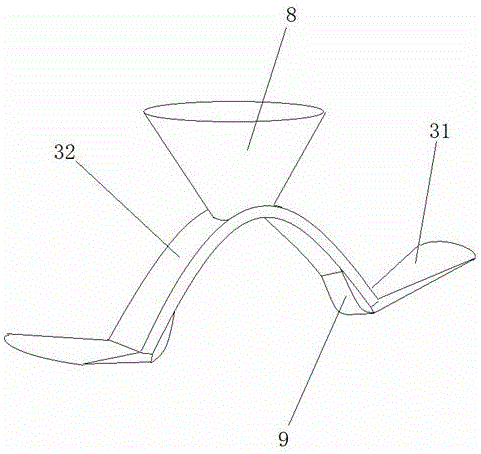

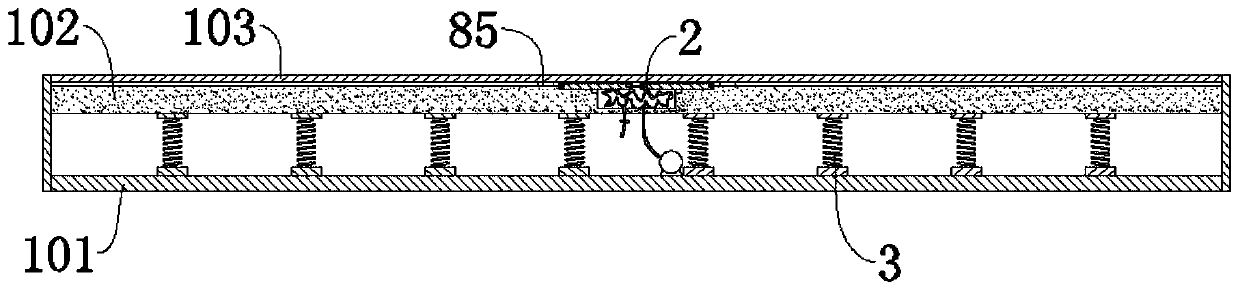

Damping buffer base of machine tool

ActiveCN105729134AHigh precisionReduce the impactLarge fixed membersMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a damping buffer base of a machine tool. The damping buffer base comprises a sectional layer, a damping layer and a compression resistant layer which are arranged from top to bottom, wherein the sectional layer consists of a plurality of sheet boards which are spliced with one another; the damping layer comprises an upper framework tank; the sectional layer is positioned in the upper framework tank; raised sheets are arranged between the sectional layer and the inner bottom surface of the upper framework tank; each sheet board corresponds to one raised sheet; the compression resistant layer comprises a lower framework tank; the upper framework tank is positioned in the lower framework tank; and a spring is arranged between the upper framework tank and the lower framework tank. Compared with the prior art, the damping buffer base of the machine tool can fix and bear the whole machine tool to absorb and damp vibrations generated during working operation of the machine tool, so that precision during workpiece processing can be improved to avoid deviation caused by vibrations, and influences of frequent vibrations on precision parts in machine tool equipment can be reduced, and therefore, the service life of equipment is prolonged.

Owner:台州市智诚工业设计有限公司

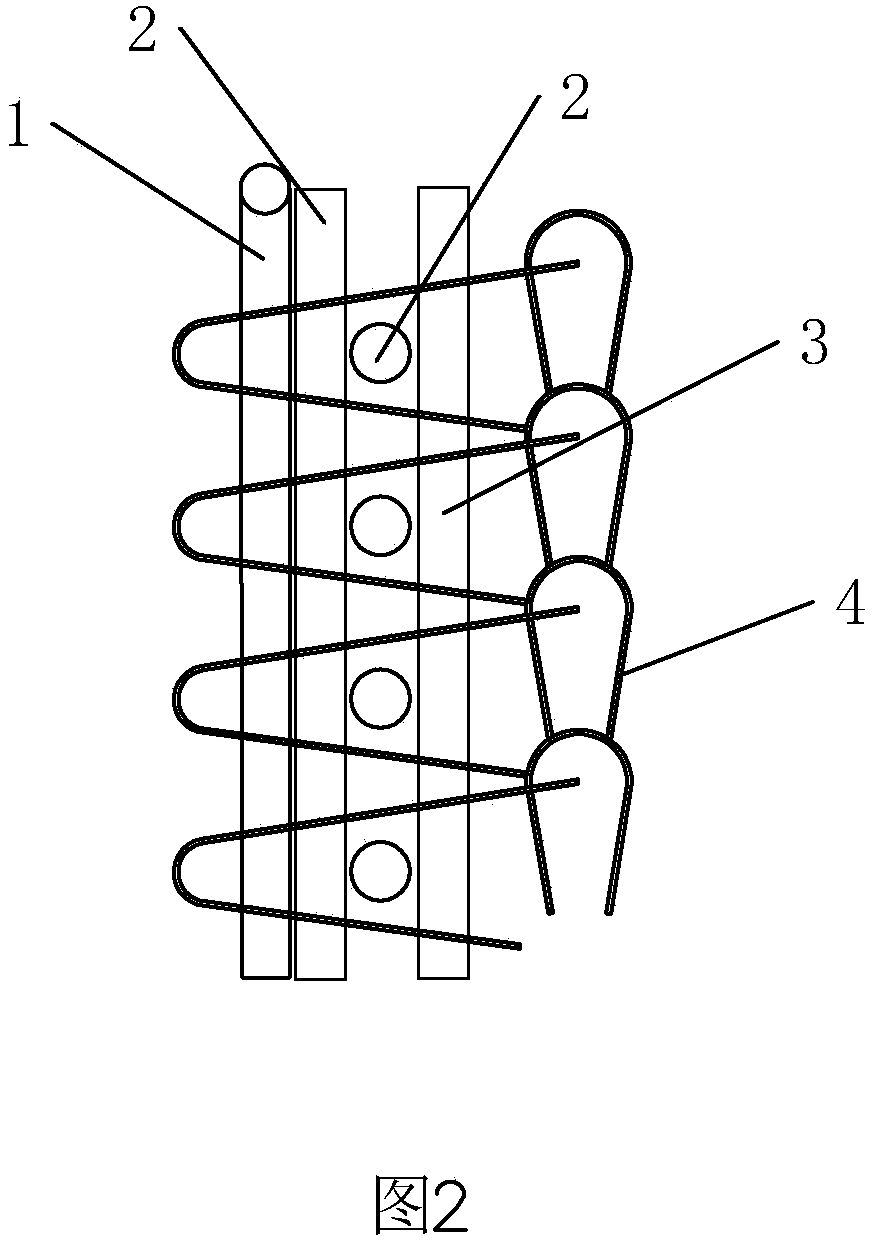

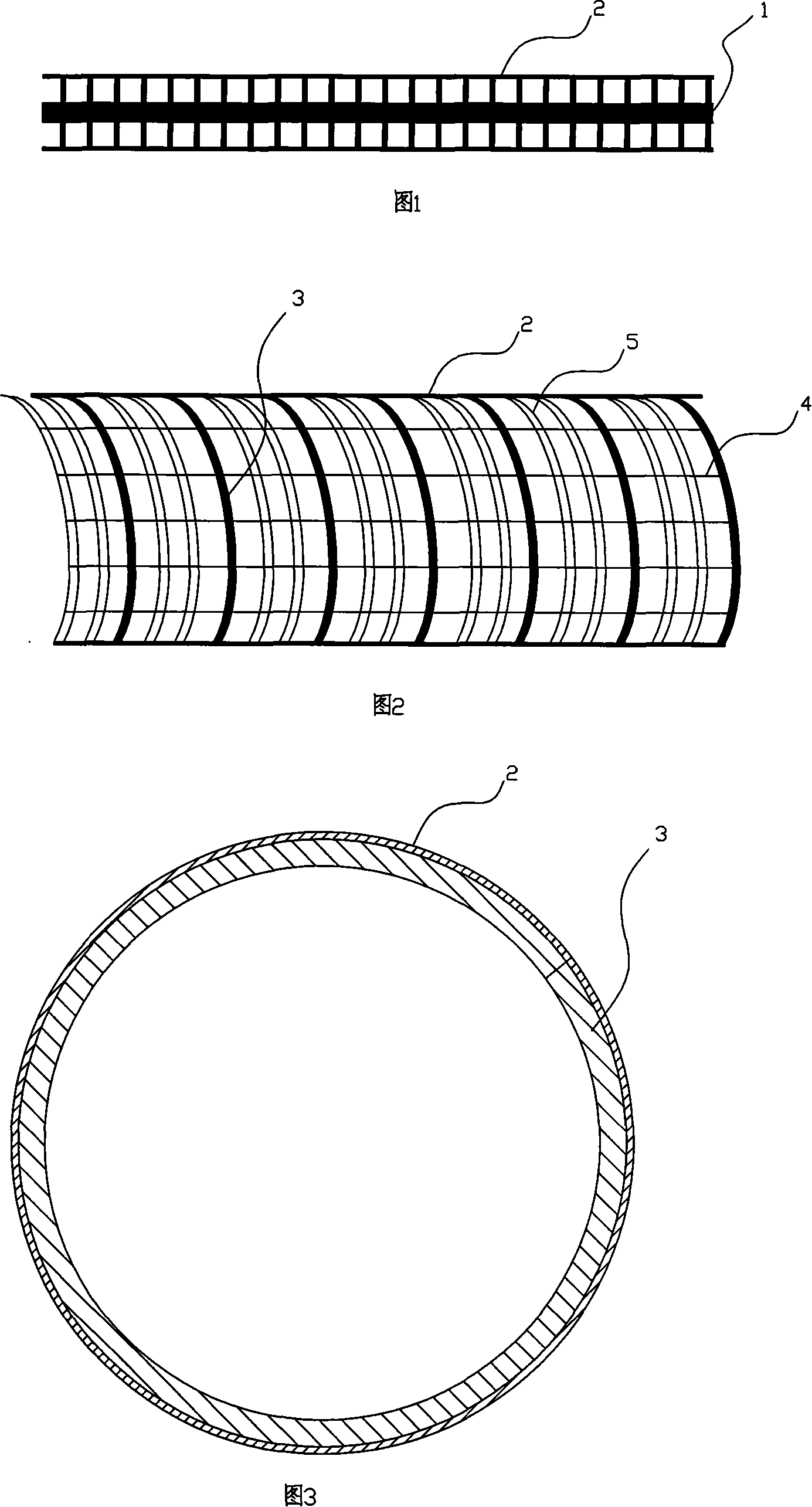

Vertical drainage channel pipe used for soft soil ground treatment

The present invention discloses a vertical drainage channel tube used for the soft soil foundation management, and the vertical drainage channel tube consists of a spiral flexible steel wire skeleton and filter cloth. The present invention is characterized in that the filter cloth is covered on the outer side of the spiral flexible steel wire skeleton. The present invention has the strong drainage effect and the permeable effect, and integrates the water absorbing, the water penetration and the water drainage into a whole by utilizing the capillary phenomenon and the siphon principle, and the present invention has the pressure capability, the water permeability and the counter filter function which meet the requirements of engineering design. The present invention cannot be cracked because of the geological and the geographical changes, and the effect of clean water drainage can be realized without causing secondary pollution to the environment. The construction is simple, the connector is not required, no special requirements to the geology and the topography exist, and the adaptability is strong.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

Method for improving high-temperature endurance performance of large GH4698 turbine disc forged piece

InactiveCN110983107AImprove tissue uniformityImprove high temperature durabilityHot workingSuperalloy

The invention belongs to the technical field of the hot working of high-temperature alloys and relates to a method for improving the high-temperature endurance performance of a large GH4698 turbine disc forged piece. According to the method of the invention, the selection of the components of a GH4698 rod, the deformation heating number of the GH4698 rod and the post-forging-and-hot treatment cooling speed of the GH4698 rod are controlled, and therefore, the structure uniformity of the large GH4698 turbine disc forged piece and the high-temperature endurance performance of the forged piece under a high-stress condition are greatly improved, and the comprehensive performance and market competitiveness of a product are powerfully improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

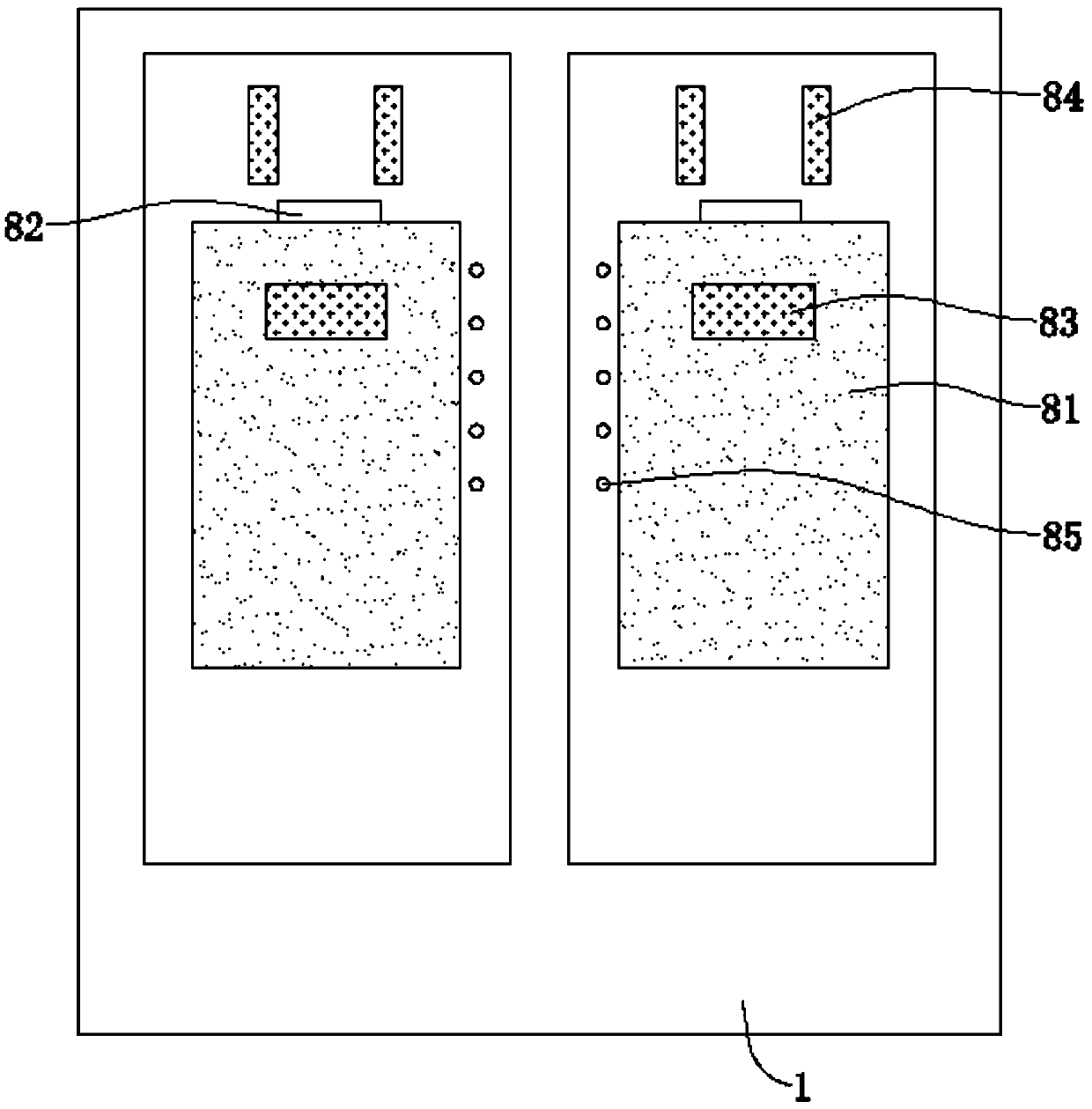

Intelligent double mattress

ActiveCN111568113AEasy to passDoes not cause discomfortStuffed mattressesSpring mattressesPhysical medicine and rehabilitationVital sign detection

The invention discloses an intelligent double mattress, and belongs to the technical field of mattresses. The double mattress comprises a mattress body and a sleep monitoring device, the sleep monitoring device is used for independently and remotely monitoring vital signs of two human bodies on the mattress body, and a blocking device is arranged in the middle of the mattress body; the blocking device comprises a fan, an air inlet pipe, an air outlet pipe, an air bag and movable plates, and the movable plates comprise the first movable plate and the second movable plate which are located on the two sides of the center line of the mattress body respectively; the air bag is located in the center of the mattress body and located below the first movable plate and the second movable plate, oneside of the first movable plate is rotationally connected into the mattress body, the other side of the first movable plate is close to the center of the mattress body, one side of the second movableplate is rotationally connected into the mattress body, and the other side is close to the center of the mattress body. The draught fan is located in the mattress body and used for inflating the air bag, the vital sign detection accuracy is improved, and the situations of breathing, the heart rate and the like of the human body can be monitored in a multi-dimensional and all-around mode.

Owner:湖南慕尔普斯智能科技有限公司

Rotary cooker

ActiveCN111358275AEasy to take outReduced sealing requirementsCooking-vessel lids/coversCooking utensils shields/jacketsRotational axisEngineering

The invention discloses a rotary cooker including a housing, wherein a rotatable accommodating body is arranged in the shell, a cooking container is placed in the accommodating body, the cooking container rotates along with the accommodating body, a container cover is arranged on the cooking container, the cooking container and a cover body are combined to form a combined surface, and a preset included angle formed by the rotating axis of the accommodating body and the combined surface is 60-90 degrees. The problem that in the rotating process of the cooking container, internal food materialsare prone to spilling out of the joint of the cooking container and the cover body is solved.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com