Rotary cooker

A cooking machine and rotary technology, which is applied to the lids of cooking utensils, the brackets of cooking utensils, the shells/sleeves of cooking utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

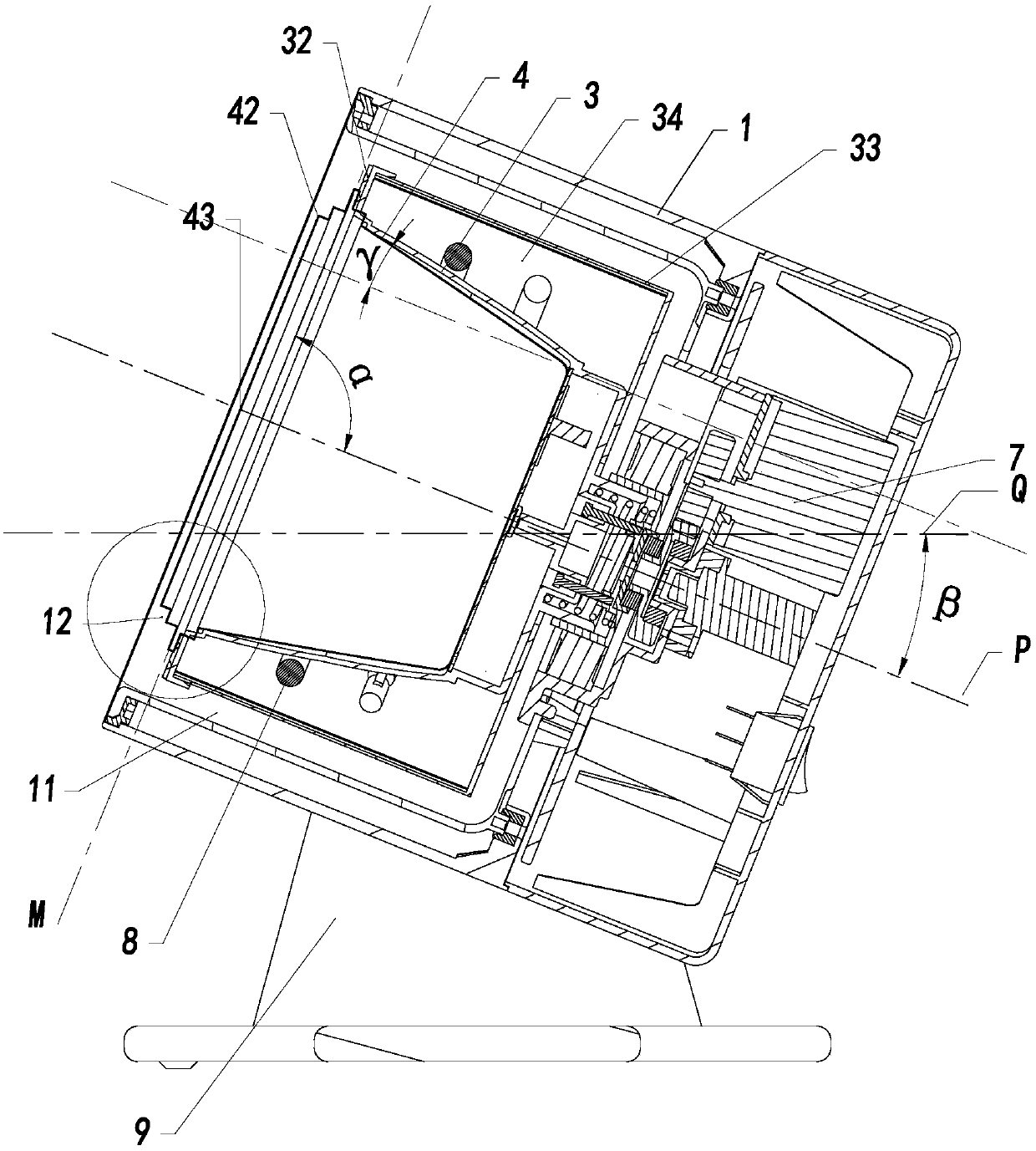

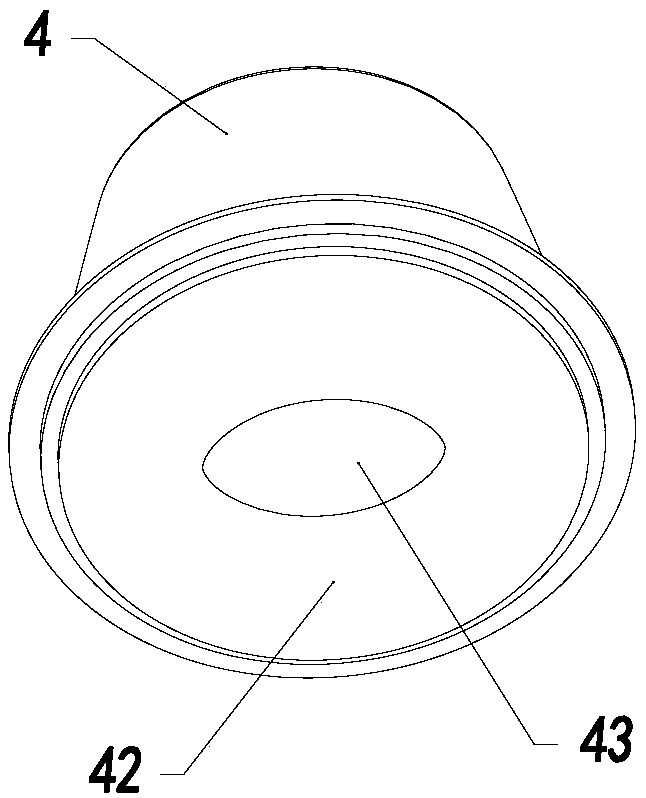

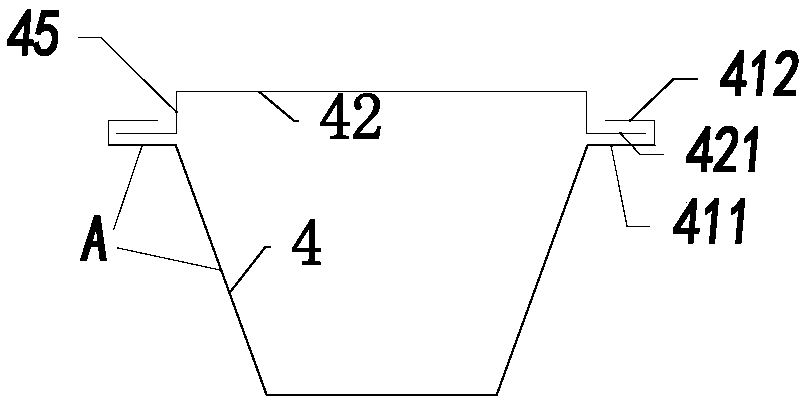

[0044] refer to figure 1 , The rotary cooking machine proposed in this embodiment includes a housing 1 and an accommodating body 3 disposed in the housing 1, a cooking container 4 is placed in the accommodating body 3, and the cooking container 4 is used for cooking ingredients. The housing body 3 is rotatable, refer to figure 1 , the containing body 3 rotates around the rotation axis P, specifically, a driving device is provided in the casing 1, and the driving device drives the containing body 3 to rotate. In this embodiment, the driving device is a driving motor 7, which is arranged at the bottom of the containing body 3, and the driving device drives the containing body 3 to rotate. It can be understood that the bottom of the housing body 3 is provided with a connecting structure connected with the driving motor 7 , and the bottom may be provided with grooves or ribs to match the connection of the driving motor 7 . Specifically, the rotation speed of the cooking containe...

Embodiment 2

[0065] The difference with embodiment 1 is that, refer to Figure 7 with Figure 8 , The rotary cooking machine proposed in this embodiment includes a machine cover 2, and the machine cover 2 is provided with an exhaust steam passage 6.

[0066] It can be understood that, since the machine cover 2 is provided, the container cover 42 in the first embodiment can be omitted. When the container cover 42 is omitted, the cover body can be understood as the set cover 2, because the set cover 2 forms a cooking cavity with it when it is closed to the cooking container.

[0067] Certainly, when the container cover 42 is not omitted, it can be installed on the machine cover 2 . In this embodiment, one side of the casing 1 is open, the cover 2 is closed on the opening of the casing 1 , and the container cover 42 is closed on the cooking container 4 . When the accommodating body 3 rotates during the cooking process, the container cover 42 keeps rotating synchronously with the cooking co...

Embodiment 3

[0079] The difference from Example 1 and Example 2 is that the cooking vessel in this example is a metal inner container, which is also placed in the container for heating, and the metal inner container can still be used for fast cooking and tableware cooking Cooking mode, so it is equipped with a container cover when cooking, the metal liner has higher strength, and the structure is easy to form, so the container cover can be snapped and fixed on the upper side to complete the cover. The metal liner is also suitable for cooking without a cover in Example 1 or with a cover in Example 2, and has equivalent beneficial effects.

[0080]In the case of an organic cover, the container cover can be arranged on the machine cover. At this time, a sealing device can also be provided between the container cover and the cooking container provided by the rotary cooking machine in this embodiment. A second sealing ring (not shown) is arranged between the outer edge of the cover and the fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com