Mixed substrate encapsulation method and mixed substrate encapsulation structure for semiconductor device

A technology of hybrid substrate and packaging method, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of low mechanical strength of packaging structure, dust pollution, easy breakage, etc., and achieve a firm packaging structure Reliable, simplified packaging process, improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

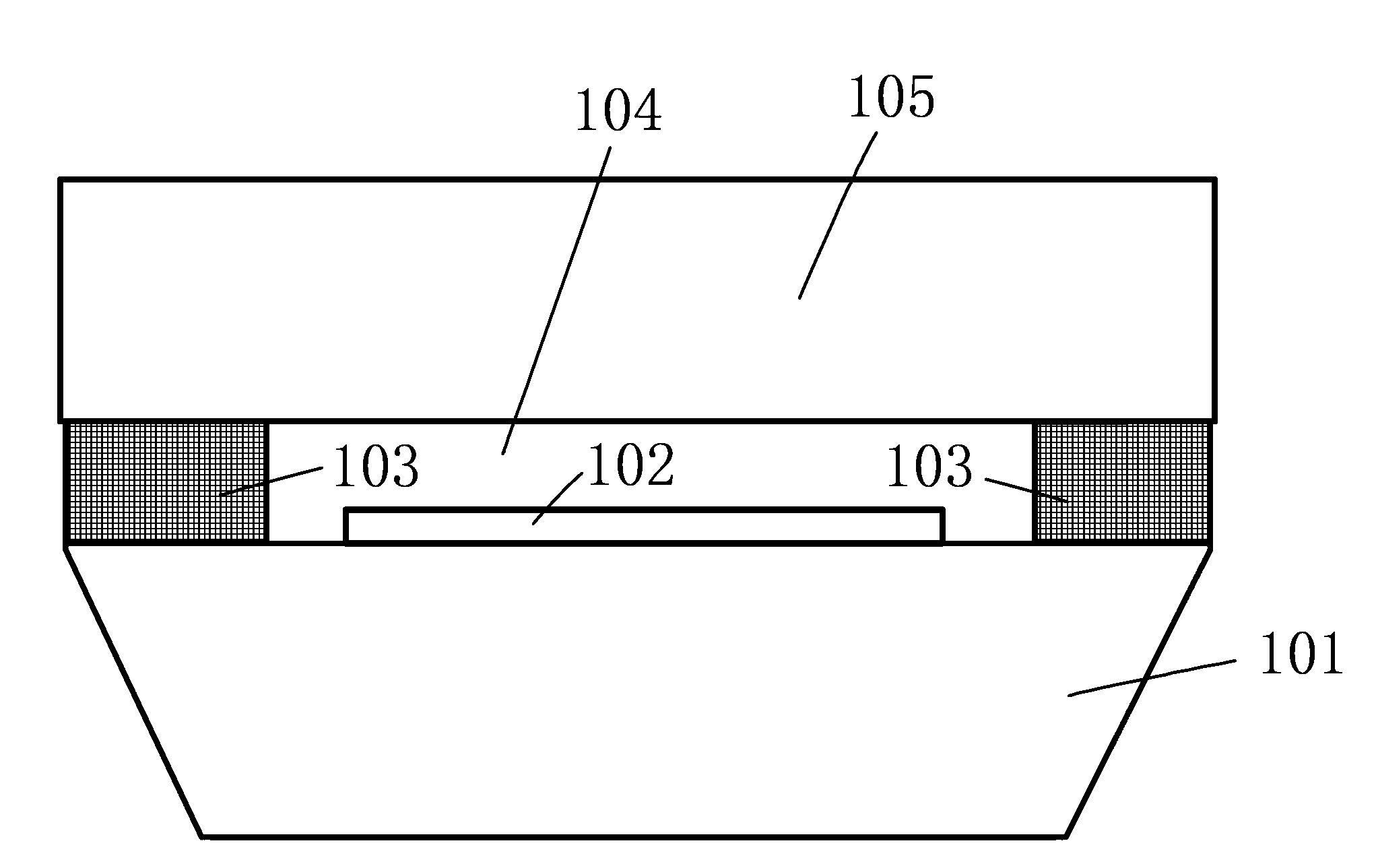

Embodiment 1

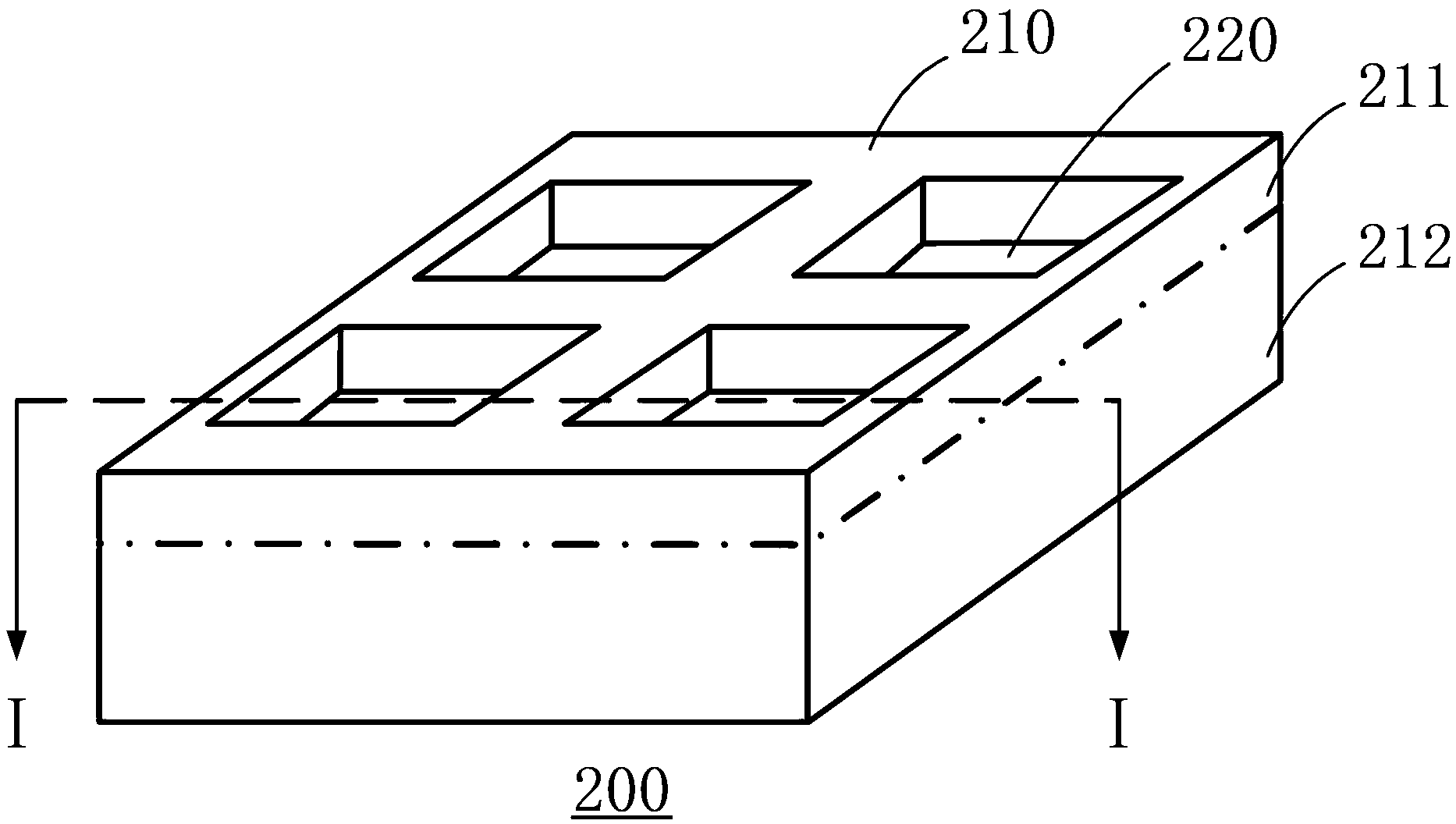

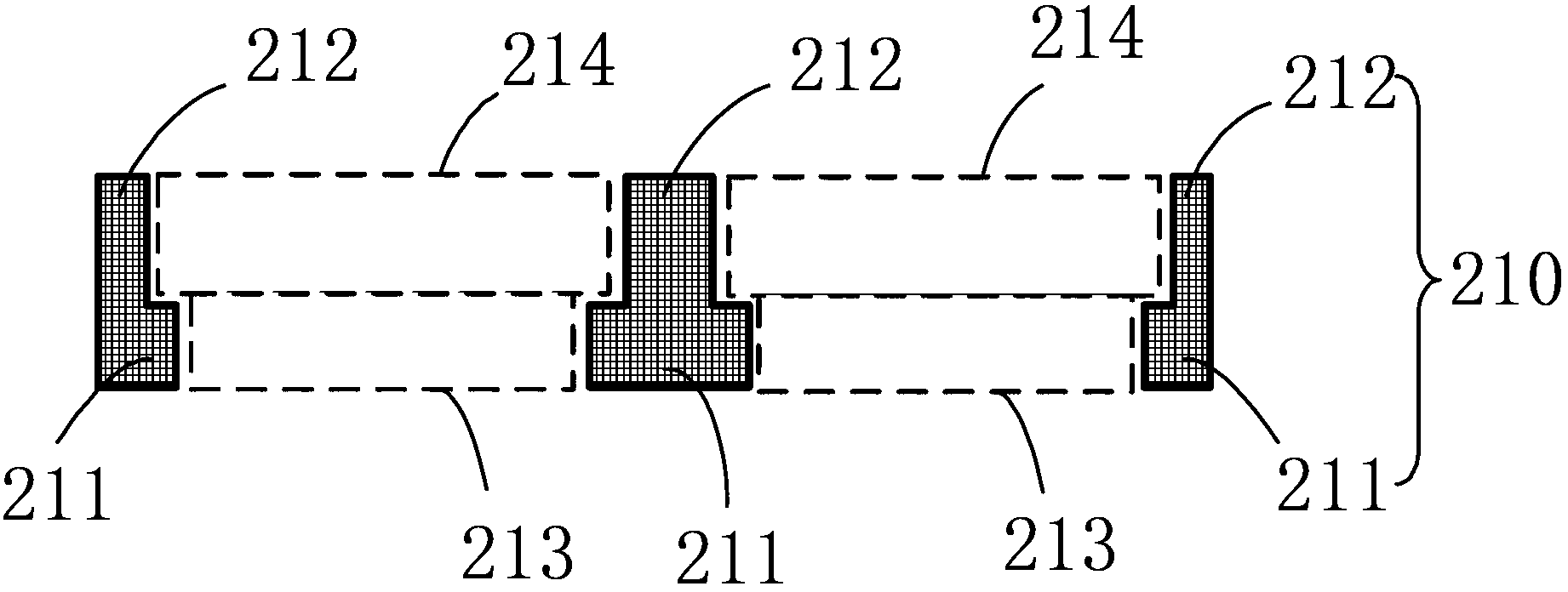

[0058] Please refer to figure 2 , the present embodiment provides a hybrid substrate 200 including a support frame 210 and a transparent substrate 220 . The supporting frame 210 includes a frame bottom 211 and a frame wall 212 . exist figure 2 In , the hybrid substrate 200 is placed upside down, so the part above the dot-dash line in the support frame 210 is the frame bottom 211 , and the part below the dot-dash line is the frame wall 212 . The frame bottom 211 includes a first through hole for exposing the pixel unit of the image sensor ( figure 2 Not marked in, please refer to Figure 3a dashed box in 213).

[0059] In this embodiment, the frame bottom 211 and the frame wall 212 of the supporting frame 210 are made of the same material, and the material for making it may preferably be ceramic material, flame-resistant resin material, glass material or silicon material. Further preferably, the frame bottom 211 and the frame wall 212 of the support frame 210 may be int...

Embodiment 2

[0069] Please refer to Figure 5 , Figure 5 It is a schematic cross-sectional view of a hybrid substrate 500 according to Embodiment 2 of the present invention. Most of the structure of the hybrid substrate 500 provided in the present embodiment is the same as that of the hybrid substrate 200 provided in the first embodiment. For the same part, refer to the content in Embodiment 1. The hybrid substrate 500 of this embodiment is different from the hybrid substrate 200 in the first embodiment in that, in the transparent substrate 520 of the hybrid substrate 500 , both the upper surface and the lower surface include an optical coating 510 . The optical coating 510 may be an IR (infrared) film or an AR (anti-reflect) film (anti-reflection film, also called anti-reflection film or anti-reflection film), or a laminate of the two. The IR film can allow visible light to pass through the lens and cut off or reflect infrared light, so that the packaged semiconductor device will not ...

Embodiment 3

[0073] Please continue to refer Figure 6 , Figure 6 It is a schematic cross-sectional view of a hybrid substrate 600 according to Embodiment 3 of the present invention. The hybrid substrate 600 provided in this embodiment has the same partial structure as the hybrid substrate 200 provided in the first embodiment. For the same part, refer to the content in Embodiment 1. The difference between the hybrid substrate 600 in this embodiment and the hybrid substrate 200 in Embodiment 1 is that the frame bottom 611 and the frame wall 612 are made of the same material, and then bonded together to form a support frame 610 .

[0074] Similar to the first embodiment, the frame bottom 611 and the frame wall 612 are preferably made of ceramic material, flame-resistant resin material, glass material or silicon material. Further preferably, the frame bottom 611 and the frame wall 612 can be integrally formed of ceramic material, flame-resistant resin material or silicon material, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com