Method for preparing bulletproof, cutting-resistant and inflaming-resistant fabric

A flame-retardant fabric and fabric technology, applied in the direction of fabric surface trimming, abrasion-resistant fibers, roughening, etc., can solve the problems of low ignition point, fire and armed police personnel injuries, etc., achieve strong ballistic resistance, improve tear resistance, The effect of strong tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a bulletproof, cutproof and flame retardant fabric, comprising the steps of:

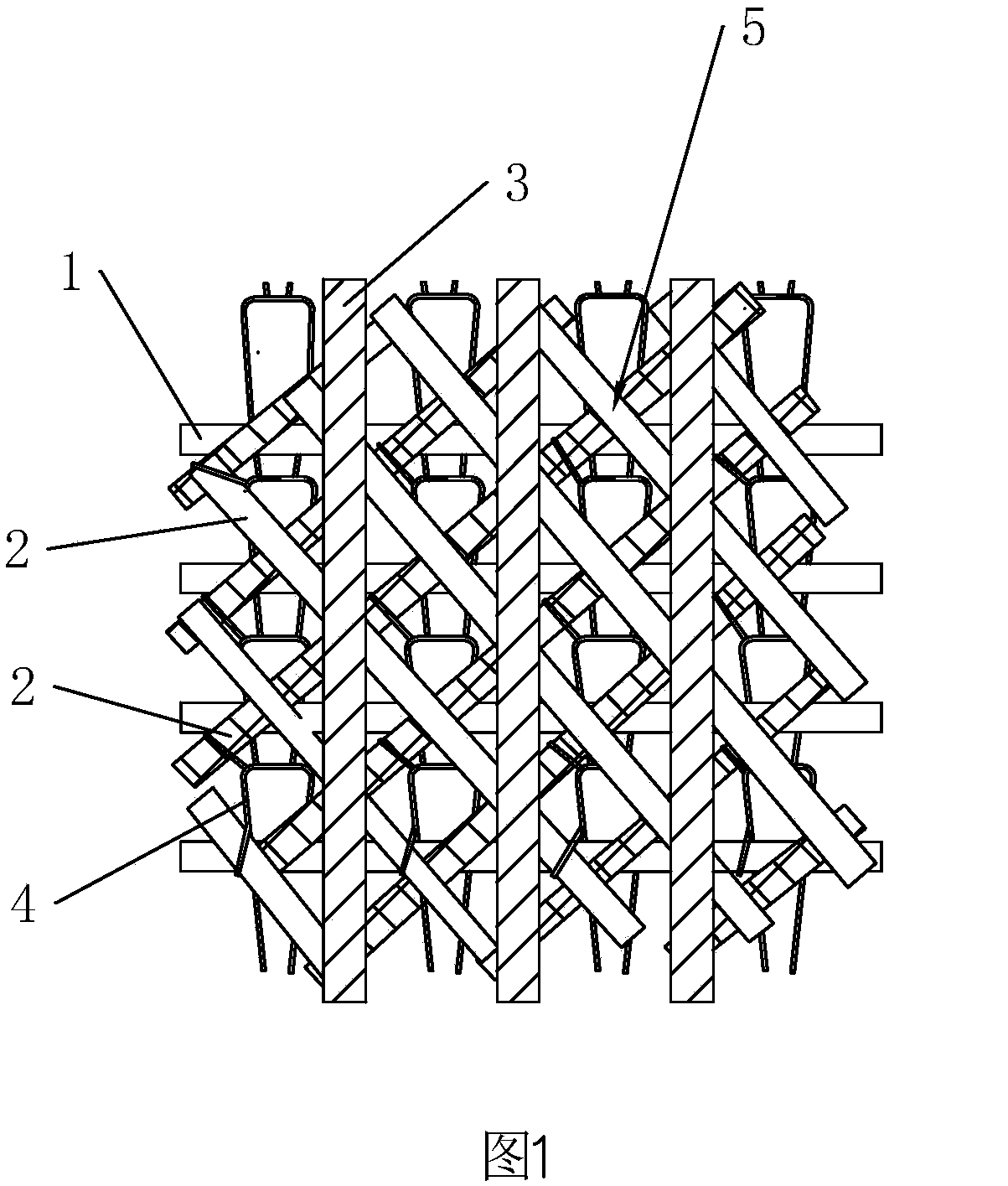

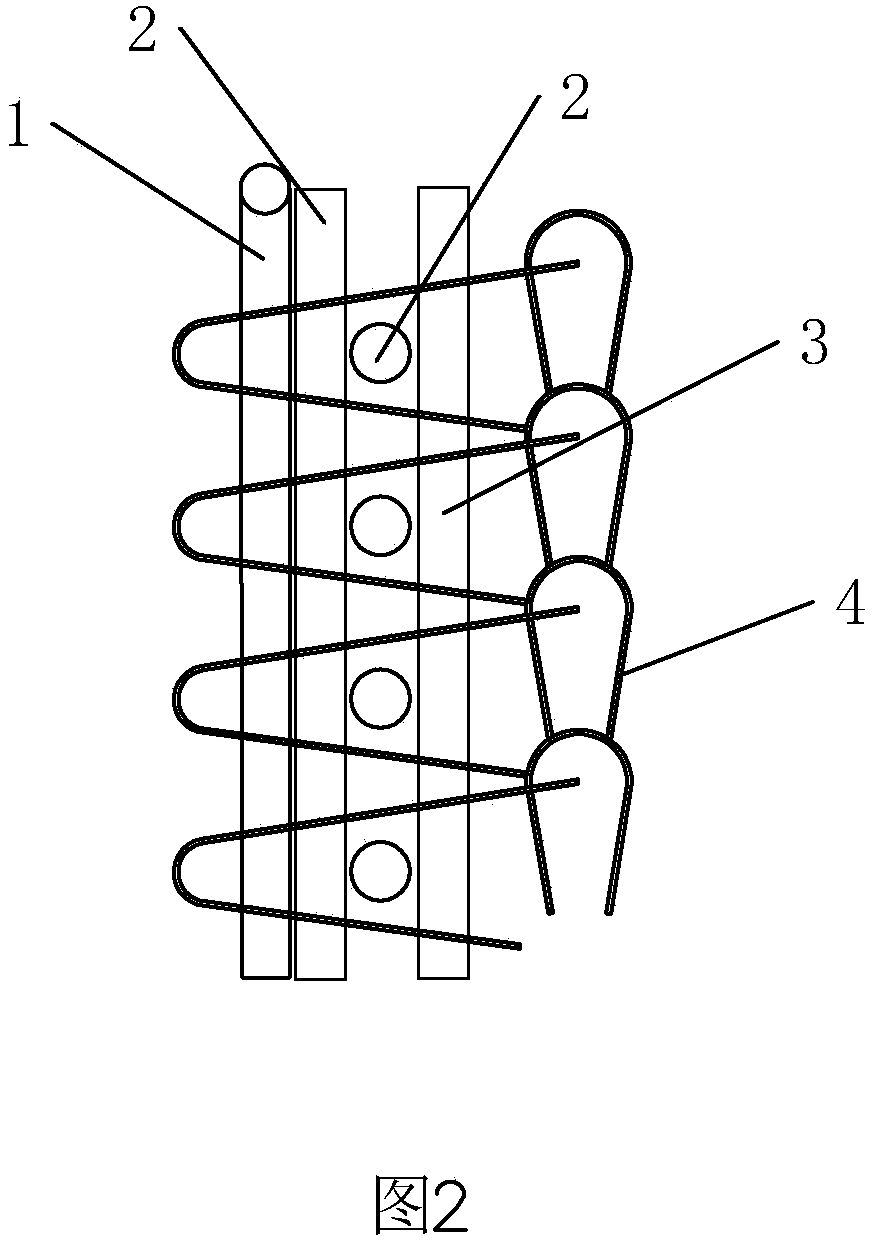

[0039] Step 1: manufacture gray cloth, gray cloth comprises base yarn and veil, as attached figure 1 and figure 2 As shown, the bottom yarn is manufactured by the multi-axis warp knitting method, and the bottom yarn includes aramid fiber yarn 1, carbon fiber yarn 3 and steel-clad wire yarn 2; the aramid fiber yarn 1 in the bottom yarn can choose aramid 1313 In any one of the three filaments, aramid 1414 filaments or mixed fibers of aramid 1313 and aramid 1414, a plurality of aramid fiber yarns 1 are arranged and distributed in parallel to form the first tensile stress layer.

[0040] Steel-clad yarn 2 is made of stainless steel wire as the base, and then covered with aramid 1414 yarn. There are two groups of steel-clad yarn 2, which are laid on the first tensile layer in two layers. A plurality of steel-clad yarns 2 are arranged in parallel to form a tear-resistant f...

Embodiment 1

[0069] Embodiment 1: Aramid fiber yarn 1 in the bottom yarn is made by blending aramid 1313 staple fiber and aramid 1414 staple fiber, wherein the weight ratio of aramid 1313 staple fiber is 30%, and aramid 1414 staple fiber The weight ratio is 70%.

Embodiment 2

[0070] Embodiment 2: Aramid fiber yarn 1 in the bottom yarn is made by blending aramid 1313 staple fiber and aramid 1414 staple fiber; wherein, the weight ratio of aramid 1313 staple fiber is 40%, and aramid 1414 staple fiber The weight ratio is 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com