Vertical kiln

A shaft kiln and kiln chamber technology, applied in the field of shaft kilns, can solve the problems of excessive dust and harmful gas emissions, inability to burn powdery materials, insufficient fuel combustion, etc., to reduce construction costs, prolong residence time, and increase cleanliness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

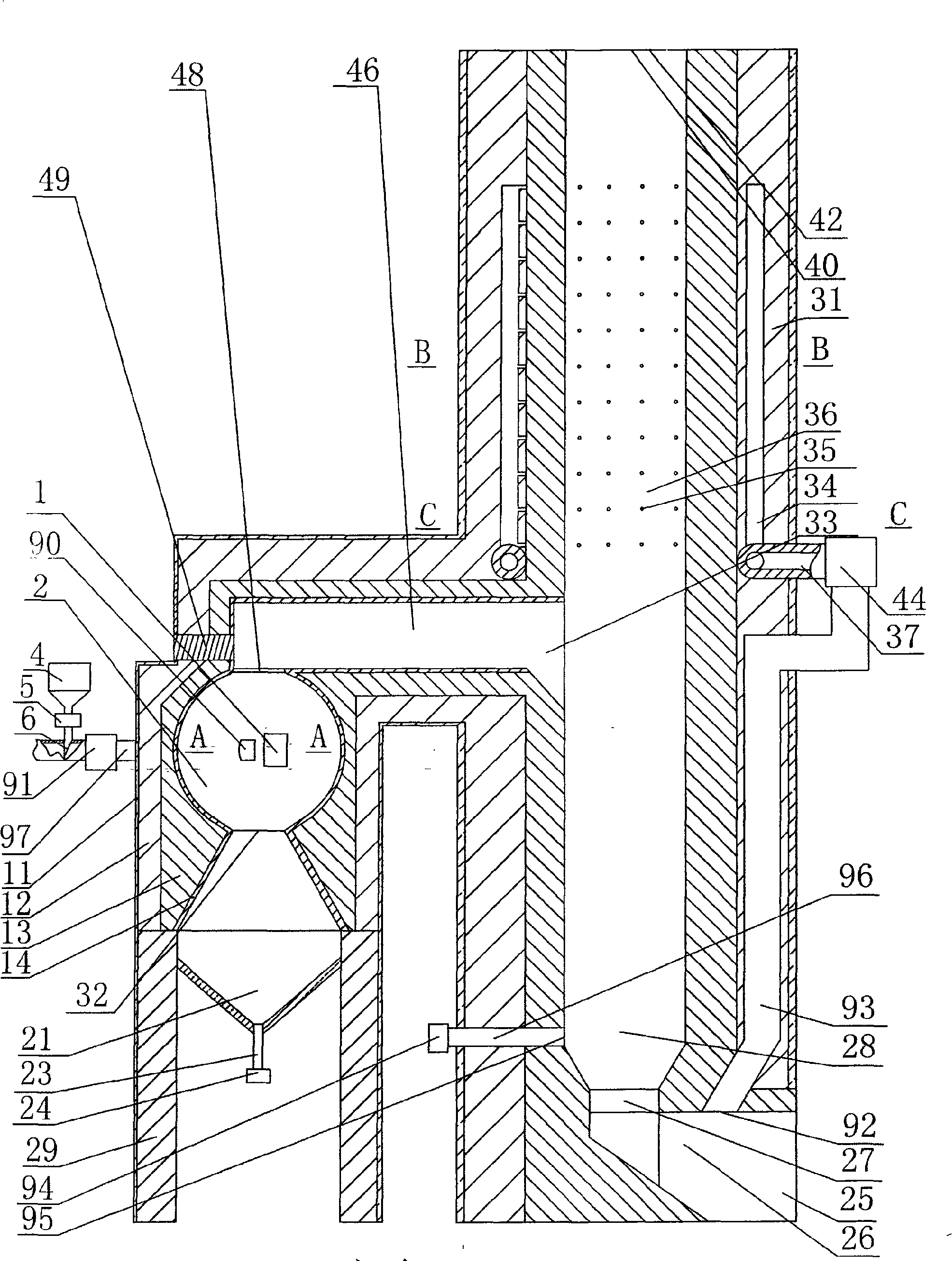

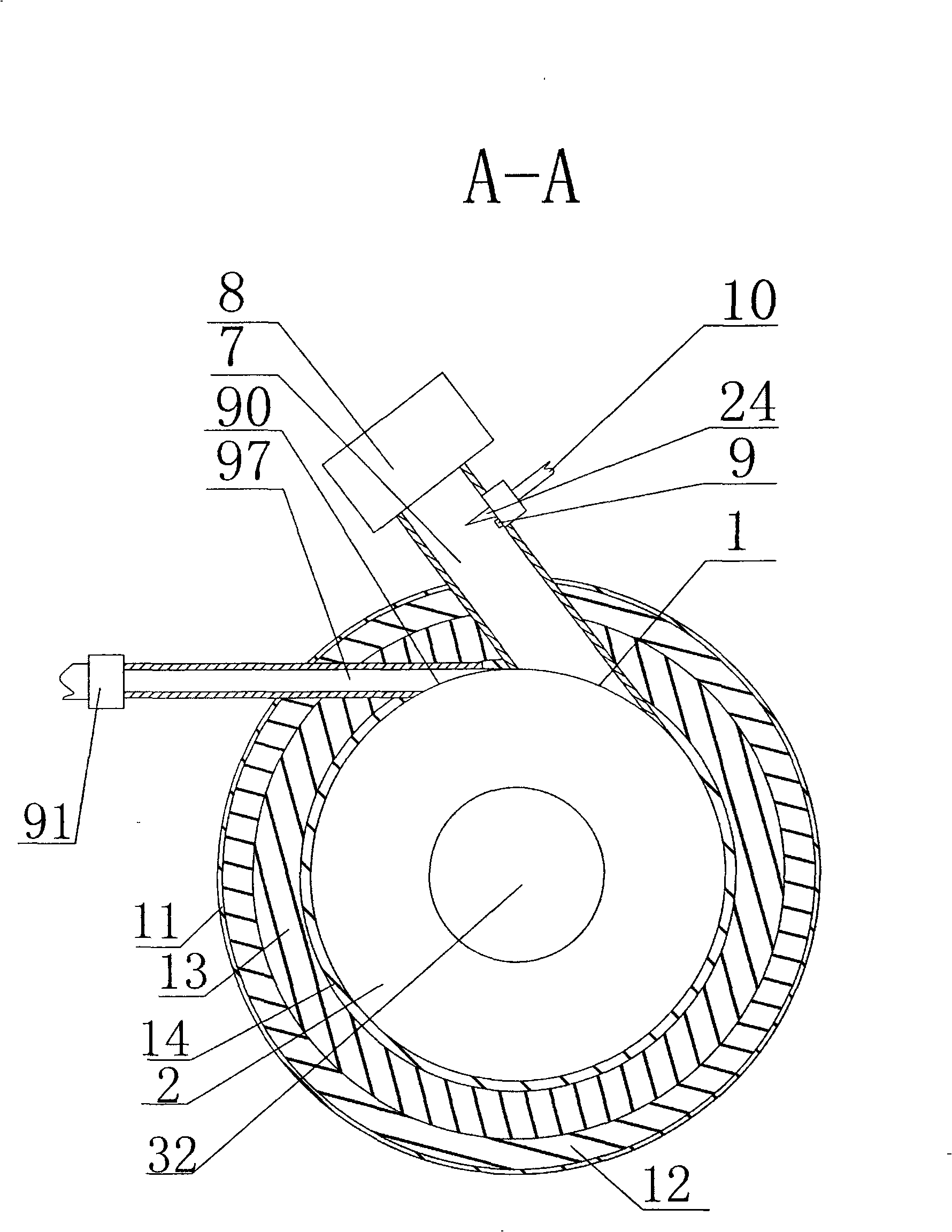

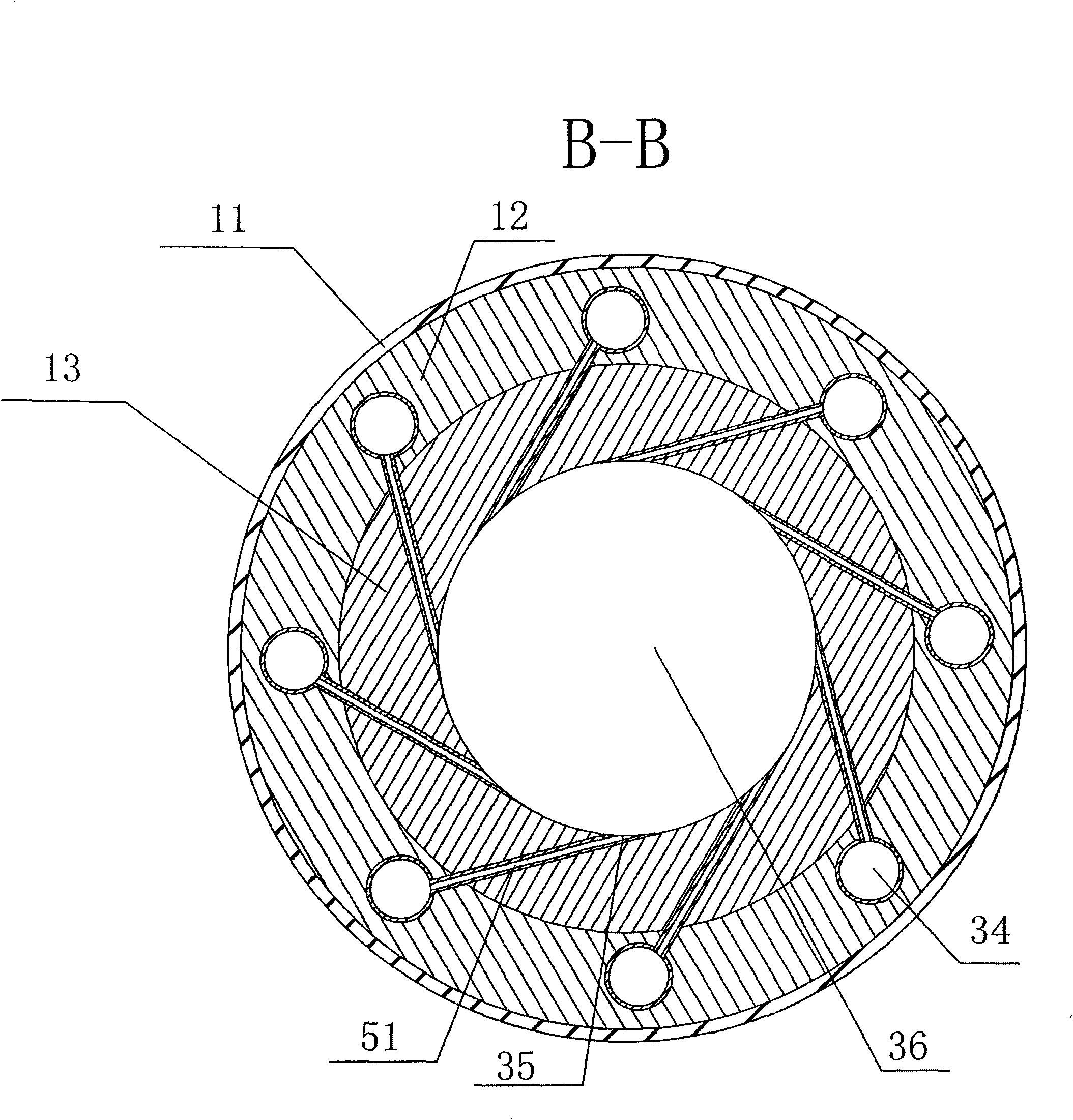

[0007] The main structure of the present invention is: the vertical kiln includes: fuel supply device, combustion chamber, kiln chamber, fan, air pipe, refractory material, heat preservation material, the side wall of the combustion chamber 2 is provided with an air inlet 1, and the air inlet 1 is connected to the air inlet pipe 7 , blower fan 8 is installed on the intake pipe 7, and the combustion chamber is connected to the fuel supply device, and the blower fan 8 can make the airflow rush into the combustion chamber by the blower fan 8 to pressurize the airflow, so that the airflow forms a vortex in which the rotation axis is perpendicular to the ground in the combustion chamber. The fuel supply device can be directly connected to the combustion chamber through the fuel pipe. When liquid or gaseous fuel is used, the fuel supply device can directly deliver the pressurized liquid or gaseous fuel into the combustion chamber through the fuel pipe. When solid fuel is used, the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com