Cyclone high wind pressure down-hole hammer with tail pipe

A down-the-hole impactor and tailpipe technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. Problems such as turning points and long distances, to achieve the effect of simple and smooth air distribution channel, wide working pressure range, and reasonable design of system air path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

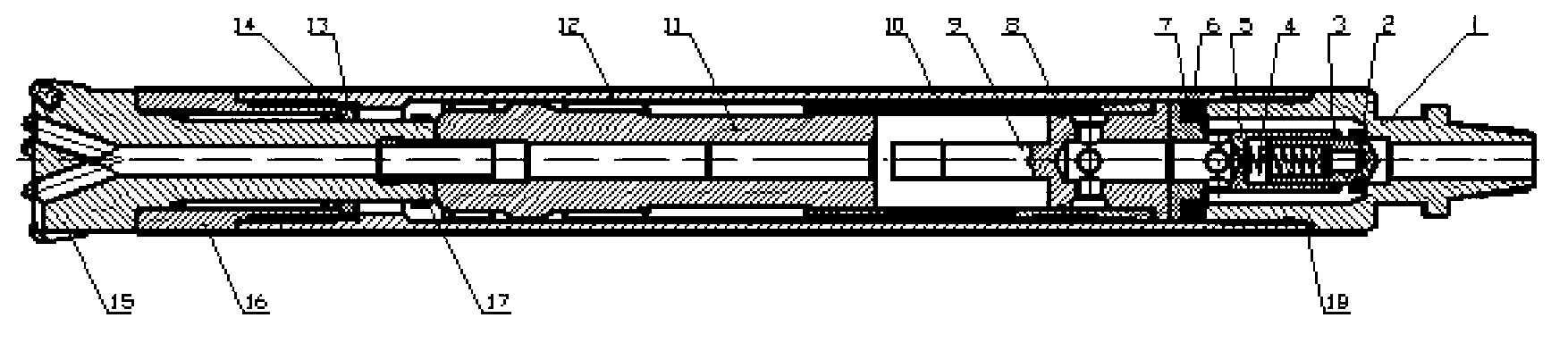

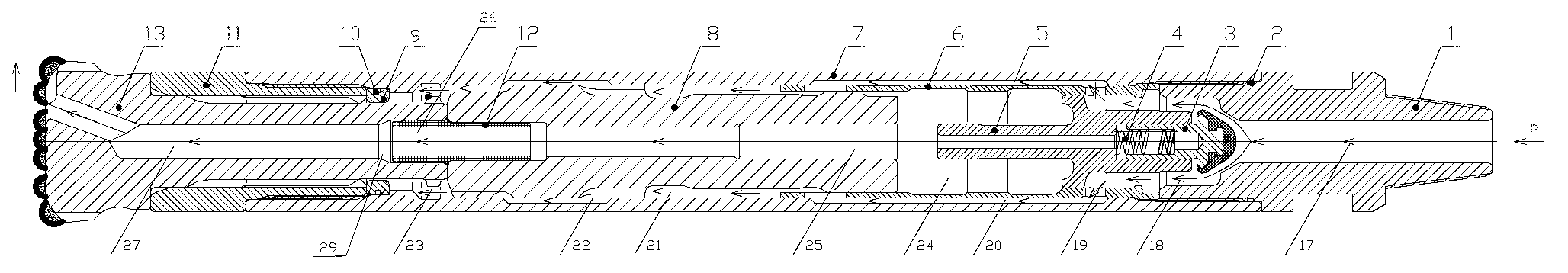

[0014] Such as figure 2 As shown, a cyclone tailpipe high-pressure down-the-hole impactor includes a rear joint 1, a check valve 3, a gas distribution rod 5, a piston 8, an inner cylinder 6, an outer sleeve 7, a snap ring 9, and a front joint 11 and a drill bit 13, the check valve is a one-way valve, which has a valve seat and a spring 4, and the piston is an elongated piston with a hole, and the end of the piston is located in the central air hole 25 of the piston and is provided with a drill bit tail. Pipe 12, drill bit tailpipe stretches in drill bit central air hole 27, and the gas distribution rod and the air intake seat 14 of the check valve rear end are integrally structured, and the inner cylinder is positioned at the outside of the gas distribution rod and the piston. , the mating end of the piston and the gas distribution rod is always inside the inner cylinder, a cavity is formed between the piston part and the outer sleeve, the rest of the piston cooperates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com