A down-the-hole impactor

A technology for a down-the-hole impactor and impactor is applied in the field of impactor manufacturing, which can solve the problems of shortening the working life of the impactor, high production cost, affecting the matching accuracy, etc., so as to reduce the overall length and quality, reduce product costs, and ensure work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

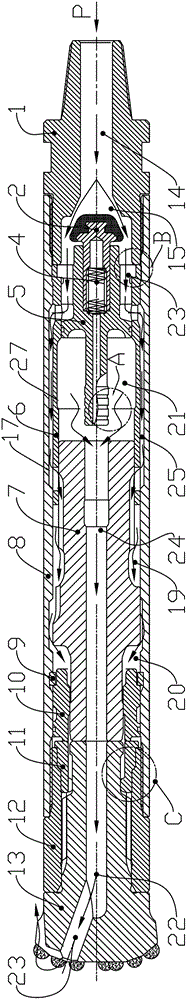

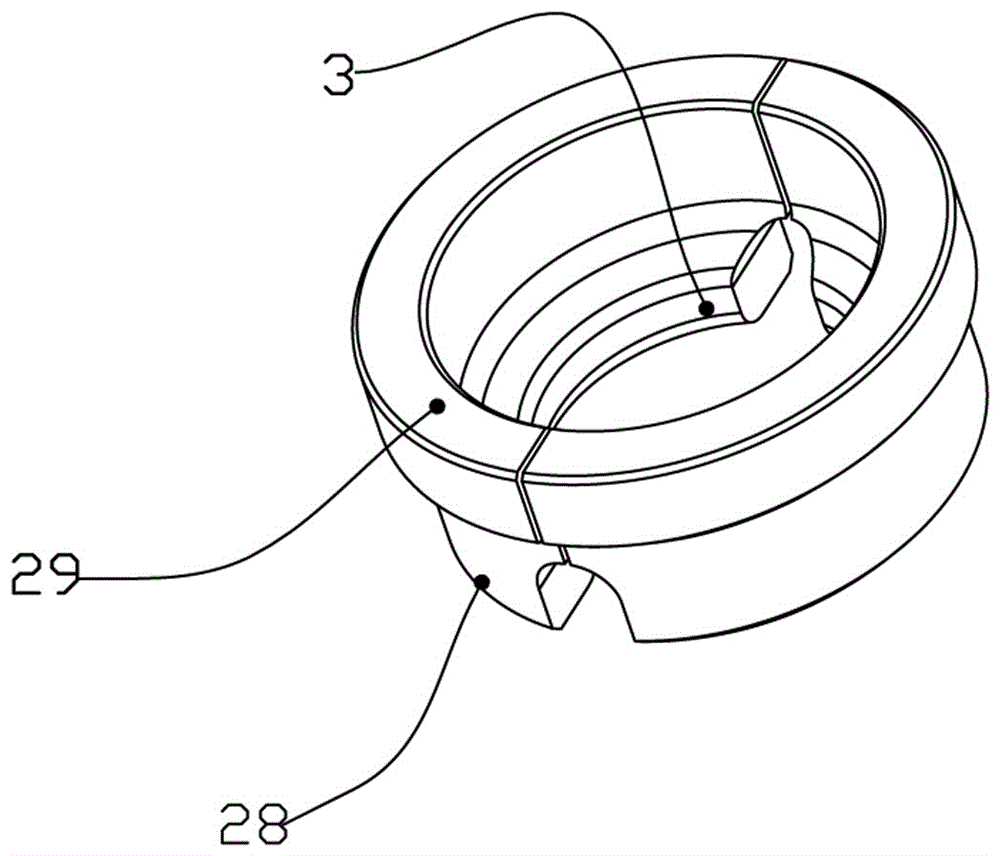

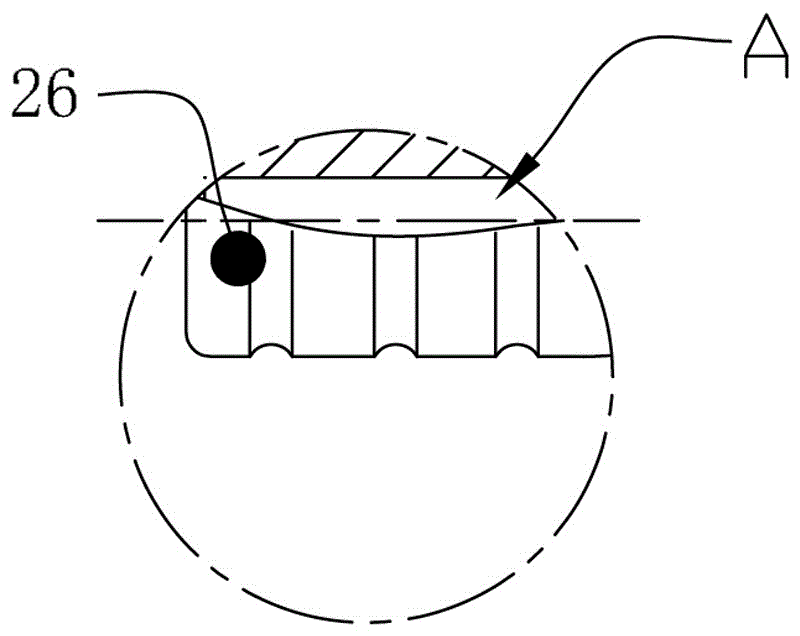

[0034] The structure of the present invention is shown in the figure: A down-the-hole impactor, comprising a main body of the impactor, a rear joint 1 is provided at the rear of the main body of the impactor, a front joint 12 is provided at the front, and a hollow channel 14 is opened in the rear joint 1 , the drill bit 13 is connected with the front joint 12, the drill bit 13 is provided with a drill bit center hole 22, the drill bit center hole 22 communicates with the end face inclined hole 23 of the drill bit, and a check valve 2 is provided at the exit of the hollow channel 14 in the main body of the impactor, The air distribution rod 5 in the main body of the impactor and the valve seat of the check valve are of an integrated structure. In addition to introducing compressed air into the cylinder, it also realizes the air distribution action of the piston movement together with the cylinder and the piston; the piston 7 is installed inside In the cylinder 6, the inner cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com