Patents

Literature

66results about How to "Provide work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

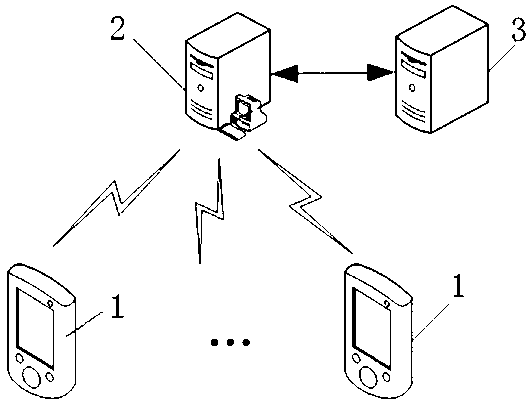

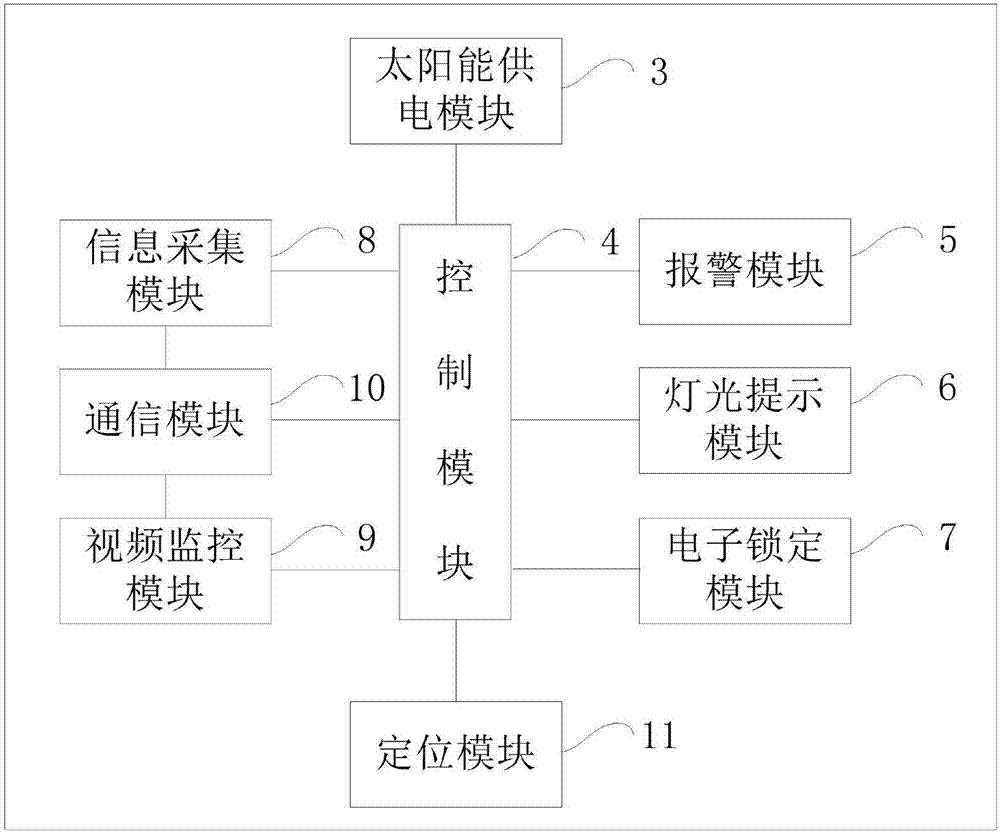

System and application method for base station maintenance information management

ActiveCN101720098AProvide work efficiencyMaintenance doesWireless communicationLocation technologyBase station

The invention relates to a system and an application method for base station maintenance information management by utilizing wireless network resources and GPS location technology. The system is characterized in that the system comprises a front end base station maintenance system and a rear end monitoring center management platform system; the front end base station maintenance system comprises equipment and a function module, wherein the equipment is special for a routing inspection and is carried by base station maintainers, and the function module is used for realizing base station maintenance; a management platform of the rear end monitoring center comprises a background server and a function module used for realizing the information management of the base station maintenance; and the function module can monitor implementation of base station maintaining operations, manage data transmitted by the front end base station maintenance system, and process base station information and feedback problems which are transmitted by the front end base station maintenance system. The invention solves the problem of monitoring the field work of the base station maintainers, ensures the base station to receive reliable maintenance periodically, and effectively improves work efficiency.

Owner:中国移动通信集团云南有限公司

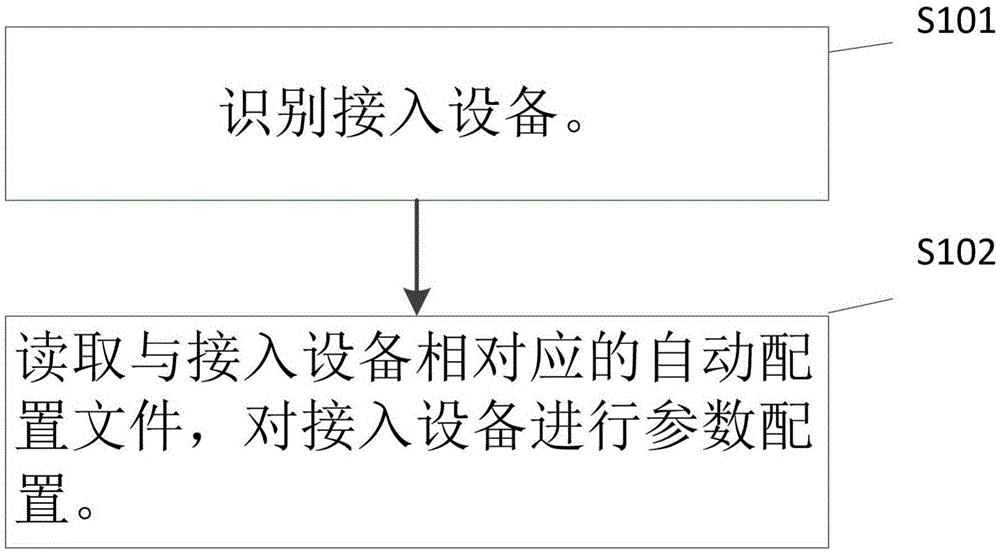

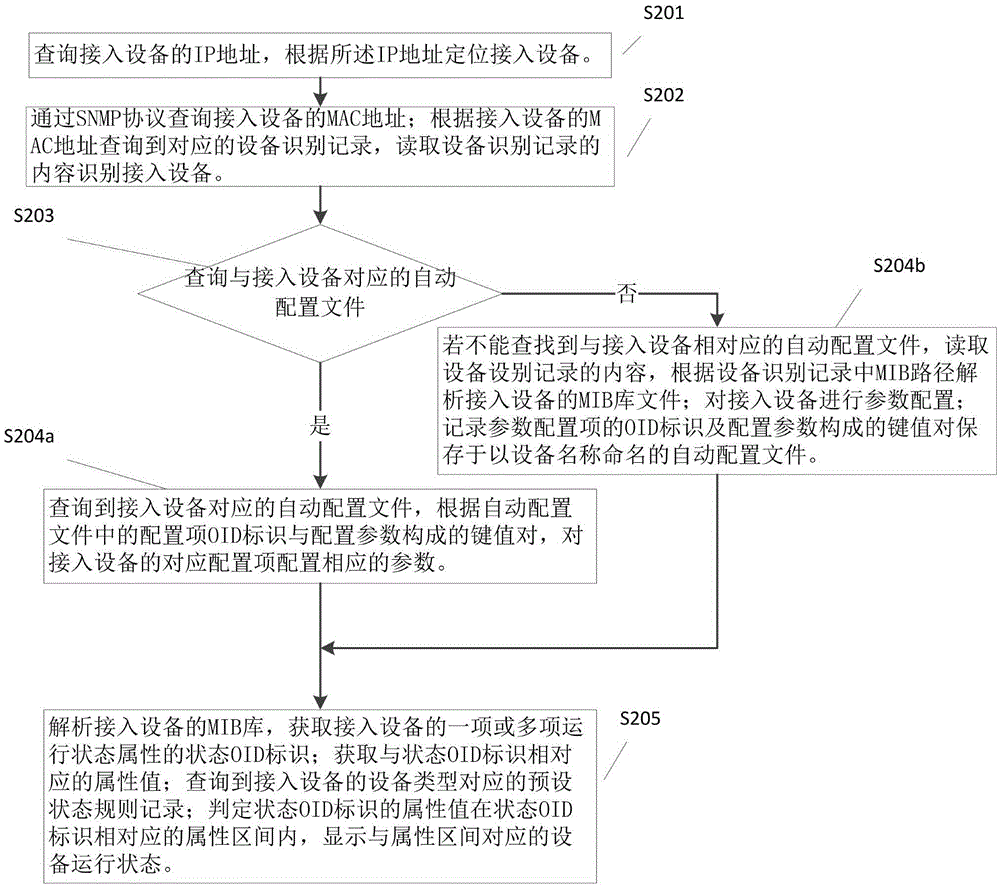

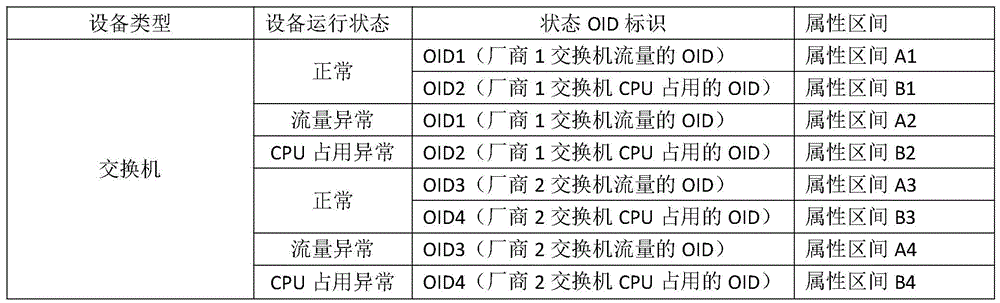

Network device management method

ActiveCN105634829ASimplify configuration workProvide work efficiencyData switching networksTroubleshootingAuto-configuration

The present invention provides a network device management method. The network device management method comprises: identifying a connected device; and reading an automatic configuration file corresponding to the connected device, to perform parameter configuration on the connected device. The connected device is identified, and the automatic configuration file corresponding to the connected device is read, so that the connected device is automatically configured. Therefore, work of configuring the network device is greatly simplified, and in addition to the working efficiency is improved, the risk of errors caused by manual network device configuration is avoided, and maintenance and troubleshooting are facilitated.

Owner:ZHEJIANG ANGEL SCI & TECH CO LTD

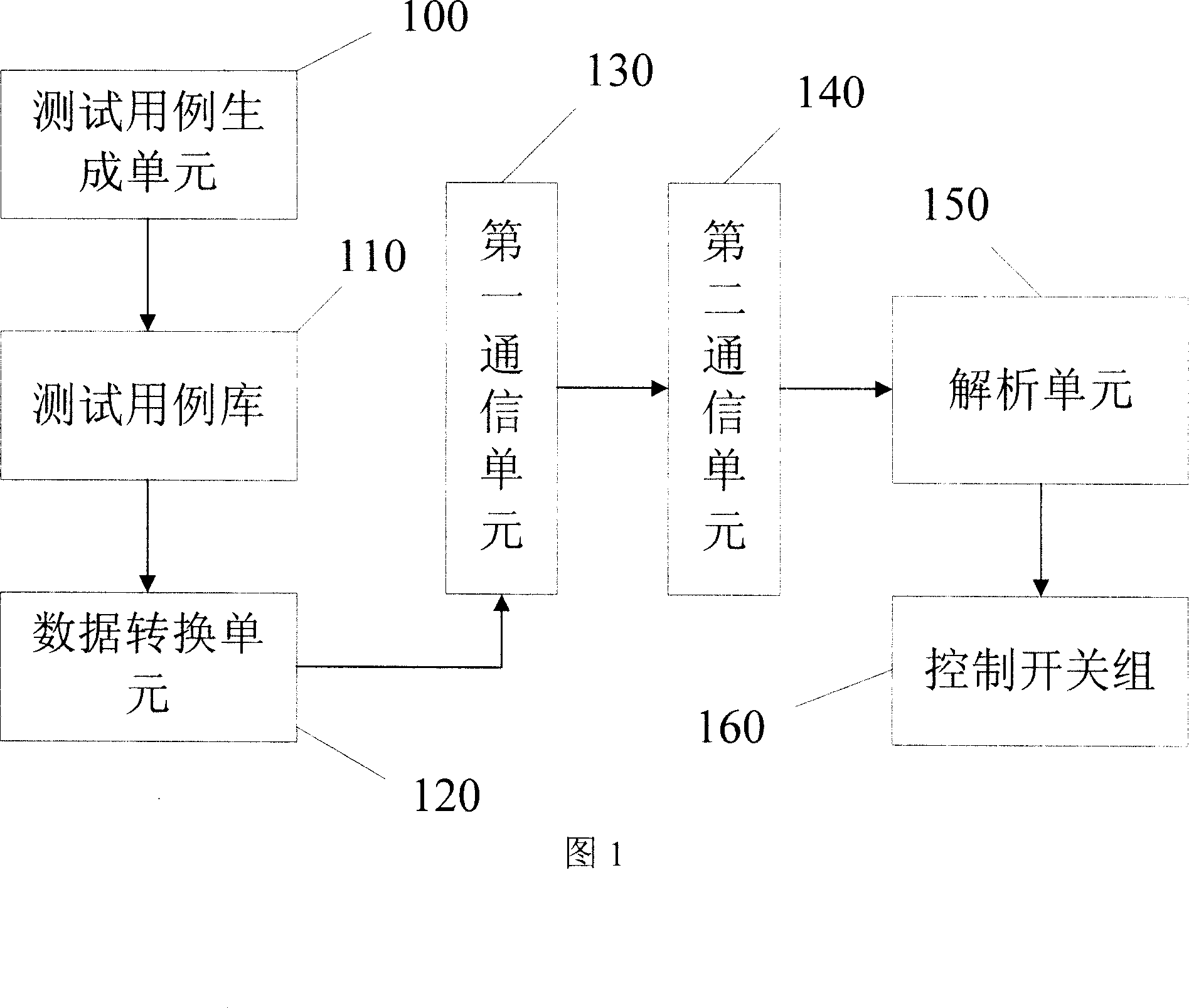

Mobile telephone testing system

InactiveCN1976485AProvide work efficiencyProvide work ethicSubstation equipmentRadio/inductive link selection arrangementsData conversionControl switch

A mobile phone test system comprises test databank for storing test data used to carry out mobile phone test, data conversion unit for generating control data according to test data and preset format, analysis unit for converting control data to be electric signal of control switch, control switch set being set with multiple control switch and being switched on or off according to analyzed electric signal.

Owner:SHANGHAI WINGTECH ELECTRONICS TECH

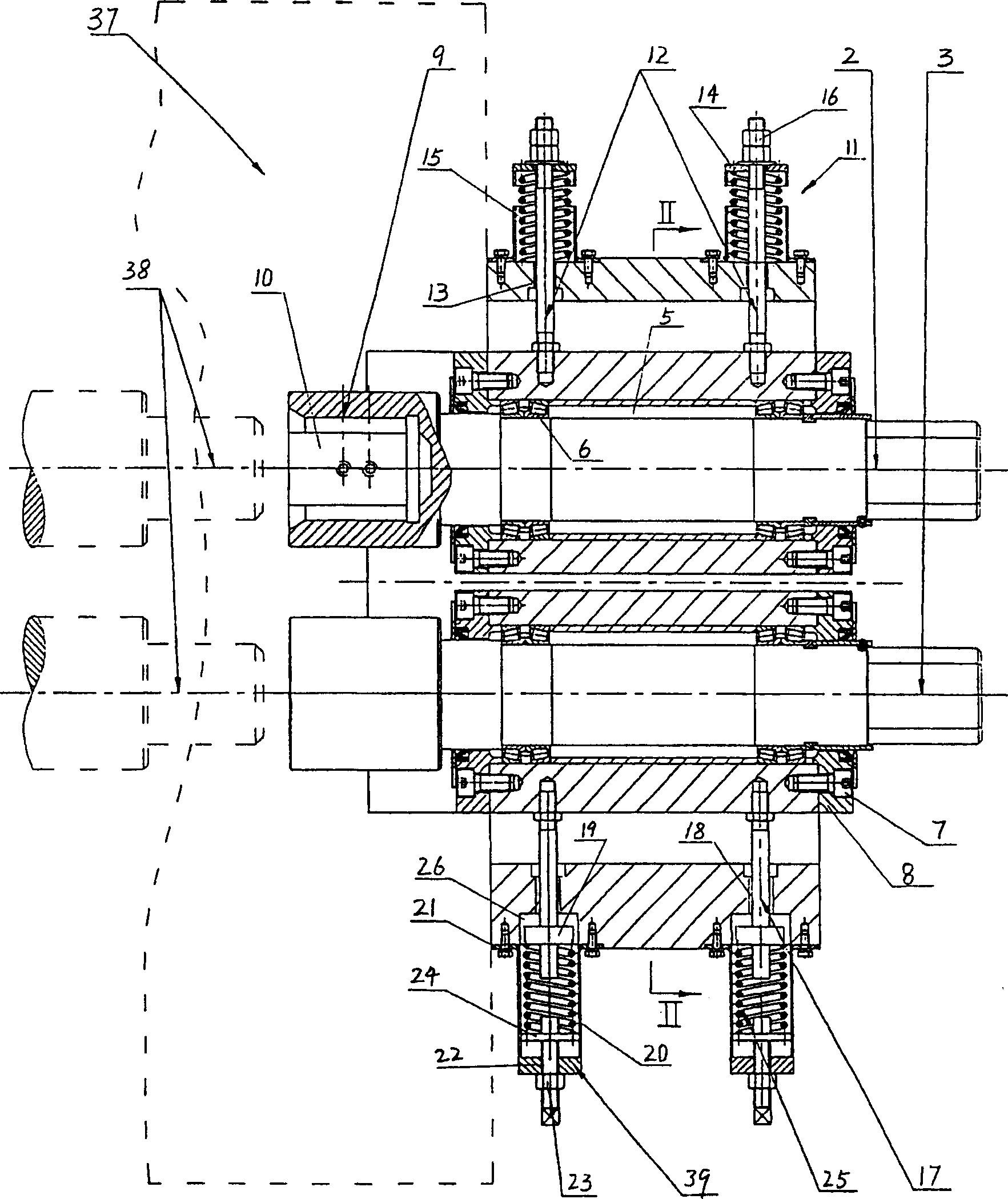

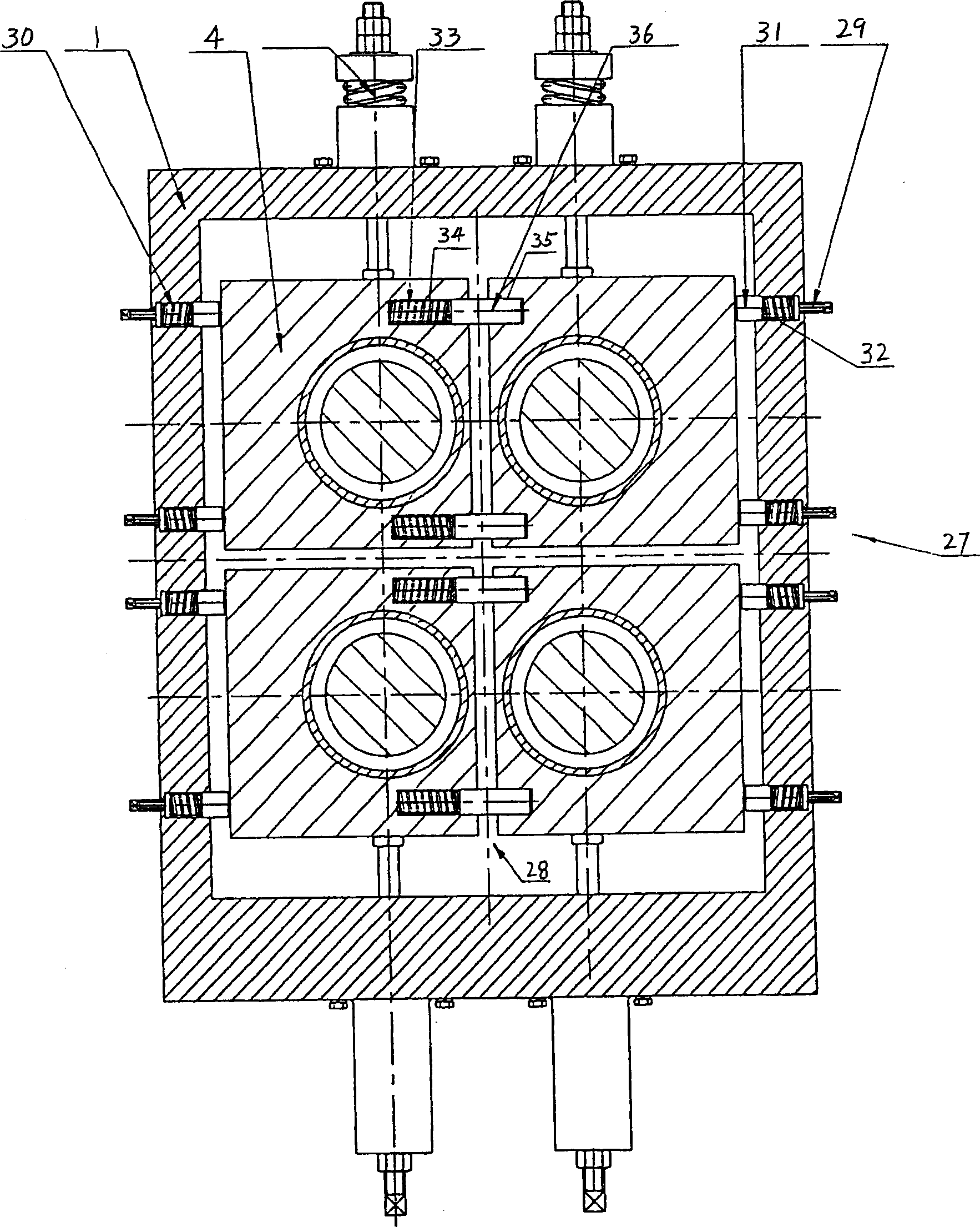

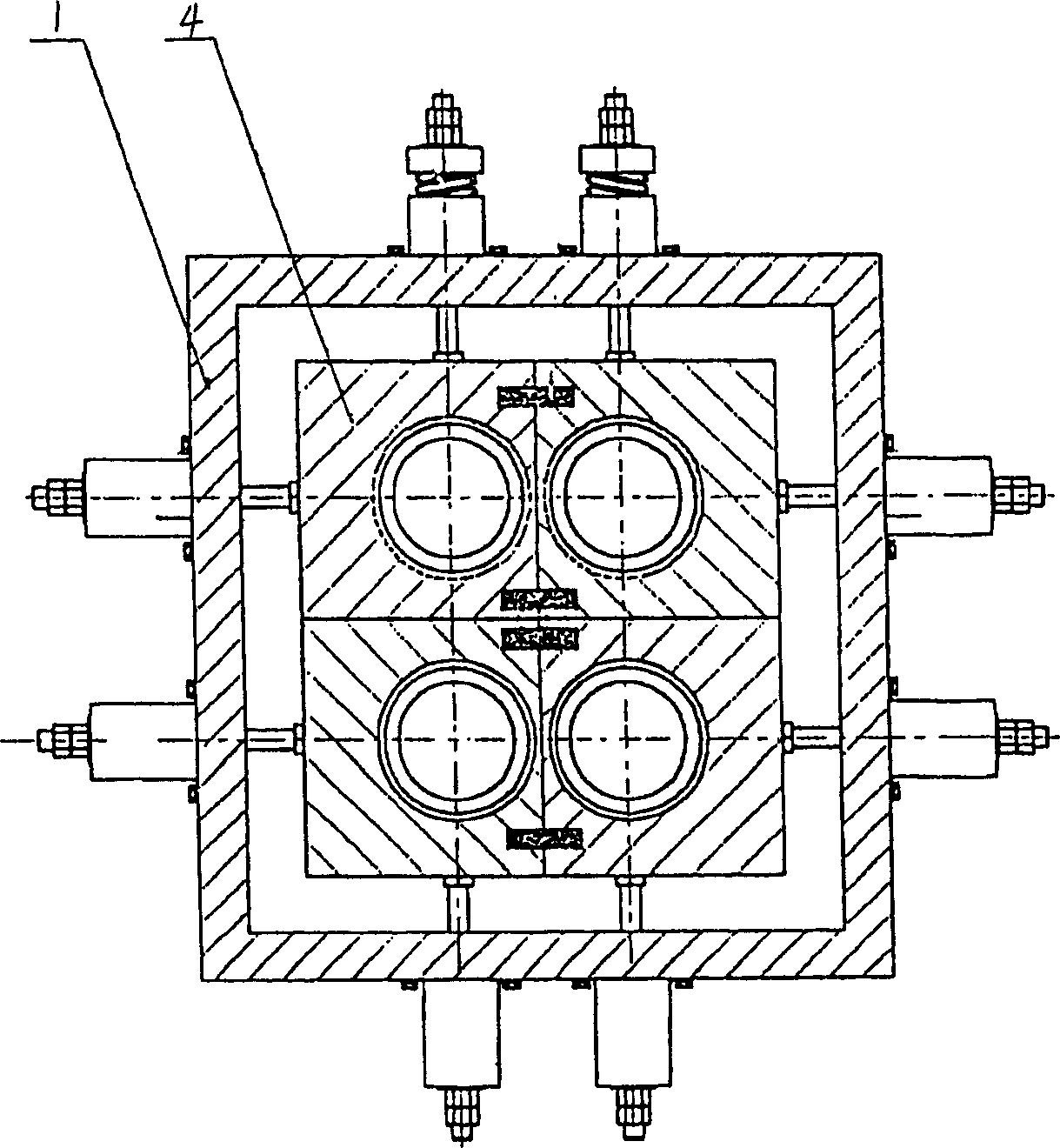

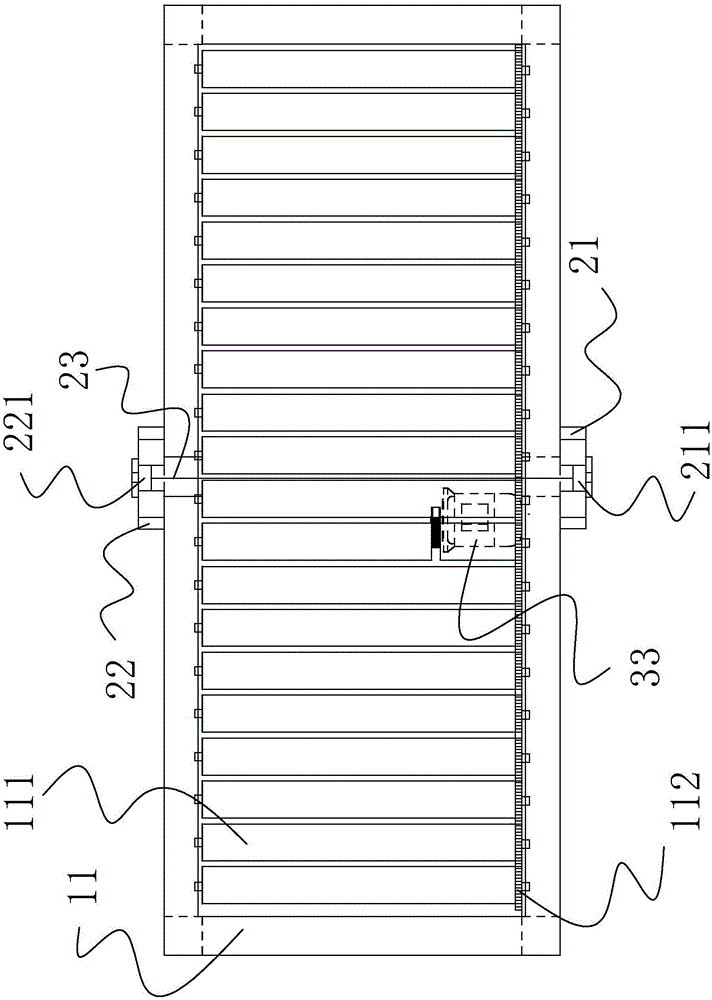

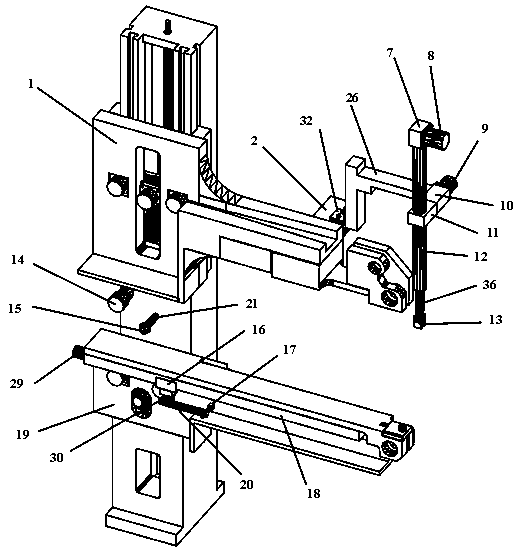

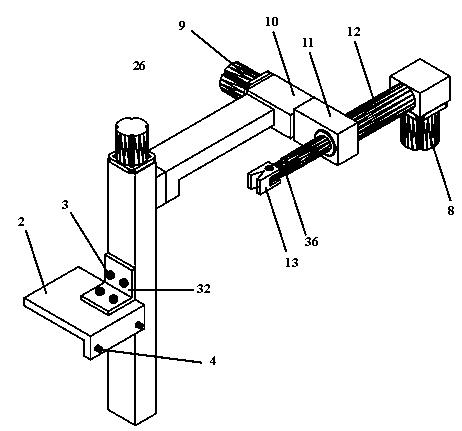

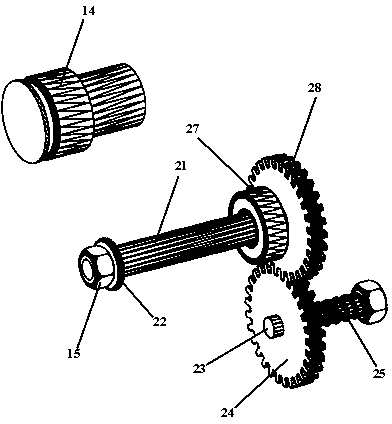

Roller changer for multiple roller rolling mill

InactiveCN1647866AQuick roll changeProvide work efficiencyMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The roller changer for multiple roller rolling mill includes frame, two-layer connecting shaft seats, rotary connecting shafts supported with the connecting shaft seat, and sleeves in one end of the connecting shafts. Under the support of the frame, the connecting shaft seats and thus the connecting shafts may be shifted vertically and / or horizontally, while the sleeves are relatively fixed. The present invention is favorable to the centering of driving rollers and the automatic centering of the sleeves to realize fast roller change in high efficiency.

Owner:郑红专 +1

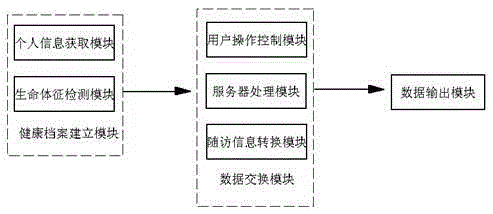

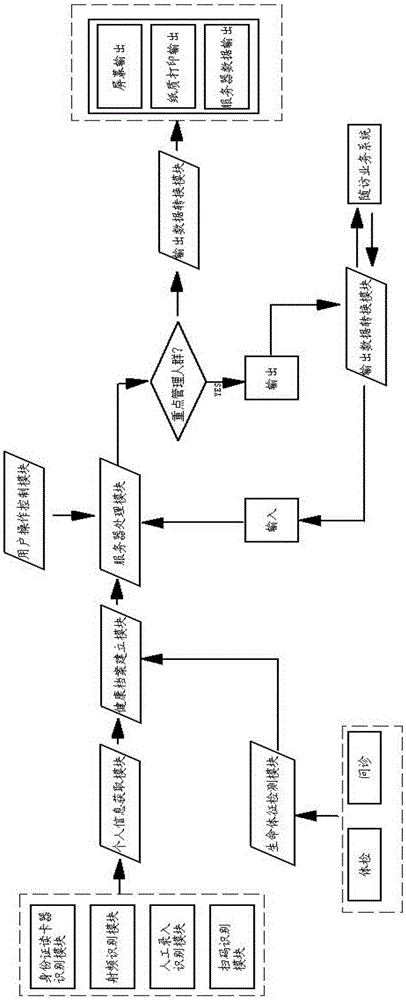

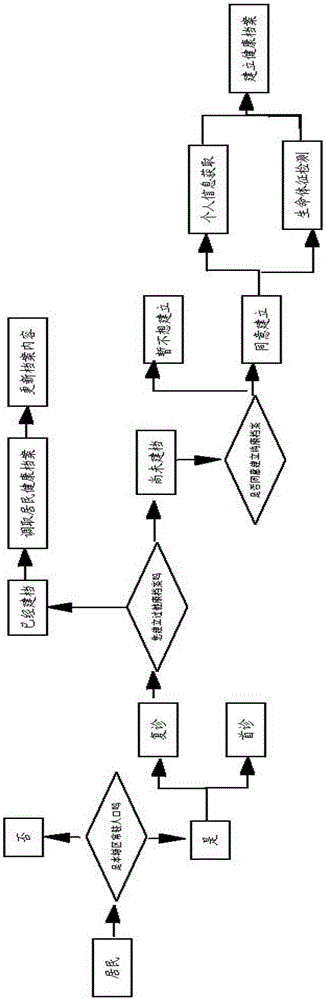

Intelligent medical physical examination system and information processing method thereof

InactiveCN105279389AProvide work efficiencyReduce labor costsSpecial data processing applicationsData conversionPopulation

The invention discloses an intelligent medical physical examination system. The system comprises: a health archive establishing module including a personal information obtaining module and a vital sign obtaining module; a data exchange module including a server processing module and follow-up survey information conversion module; and a data output module. The invention further discloses an information processing method. The method comprises the following steps: 1, obtaining basic information of physical examination personnel; 2, archiving the basic information through the archive establishing module; 3, logging archived information into the server processing module, the follow-up survey information conversion module performing key population information data uploading on the information logged into the server processing module, and the follow-up survey information conversion module performing updating processing on data in a follow-up survey service system of key population; and 4, according to needs, performing data scheduling and data output on an output data conversion module. The system provided by the invention improves the work efficiency, decreases the labor cost, forms systematic information management of the data and reduces the fault rate; and the method realizes intelligent processing of batch information.

Owner:SHANDONG QINCHENG INFORMATION TECH CO LTD

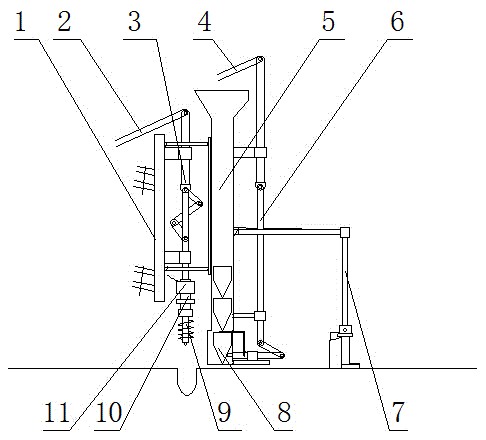

Agriculture digging, planting and burying mechanical apparatus

ActiveCN104823562AReduce manual labor intensityProvide work efficiencyRoot feedersPotato plantersElectric machineryAgriculture

The present invention relates to a mechanized digging, planting and burying apparatus designed for a rod-shaped or cone-shaped material holding device or plant tuber. The apparatus comprises a tractor power transmission device, a lifting arm mechanism, a connection rod device, a drill rod device, a holding cylinder, and a burying device, wherein the tractor power transmission device comprises a diesel engine, a hydraulic motor, and a hydraulic cylinder, the connection rod device comprises a drilling rod lifting control mechanism and the pushing connection rod of the rod-shaped or cone-shaped material holding device, the drilling rod device comprises a motor, a speed reducer and a drilling head, the motor is connected with the storage battery of the tractor, and a connection support frame is connected with the upper drilling rod device, the holding cylinder and the burying device. The apparatus of the present invention provides mechanized assurance for ecological construction, plant survival rate increasing, and greening quality increasing in the drought or desert areas, and further has effects of labor intensity reducing and efficiency improving.

Owner:BEIJING UNIV OF CHEM TECH

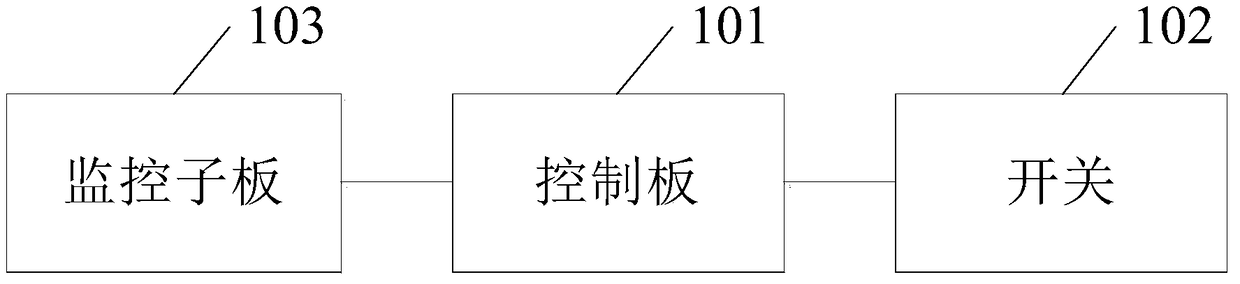

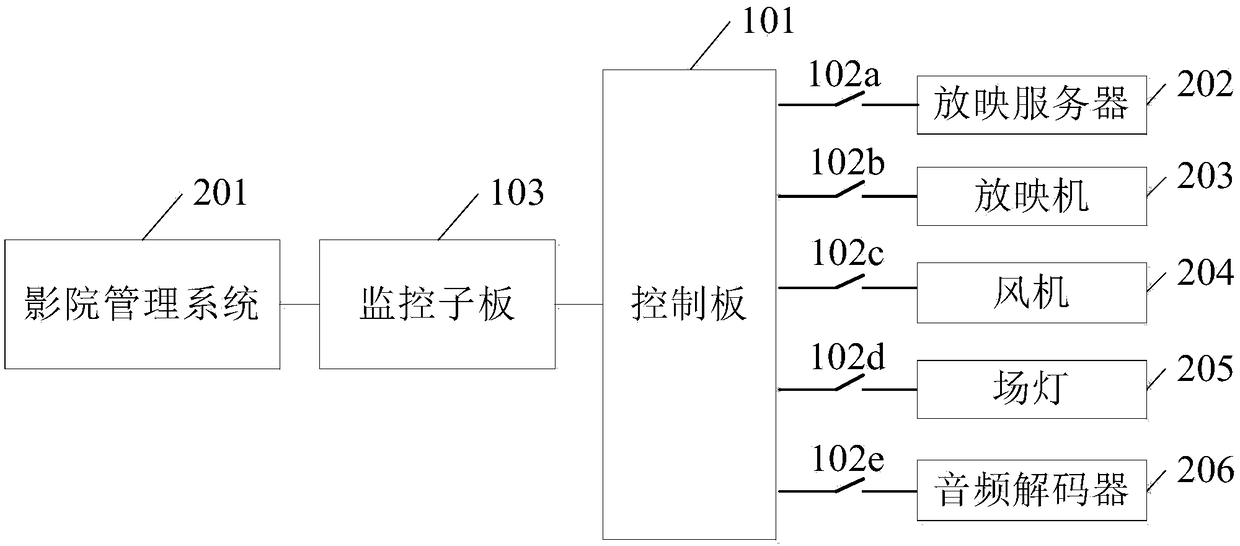

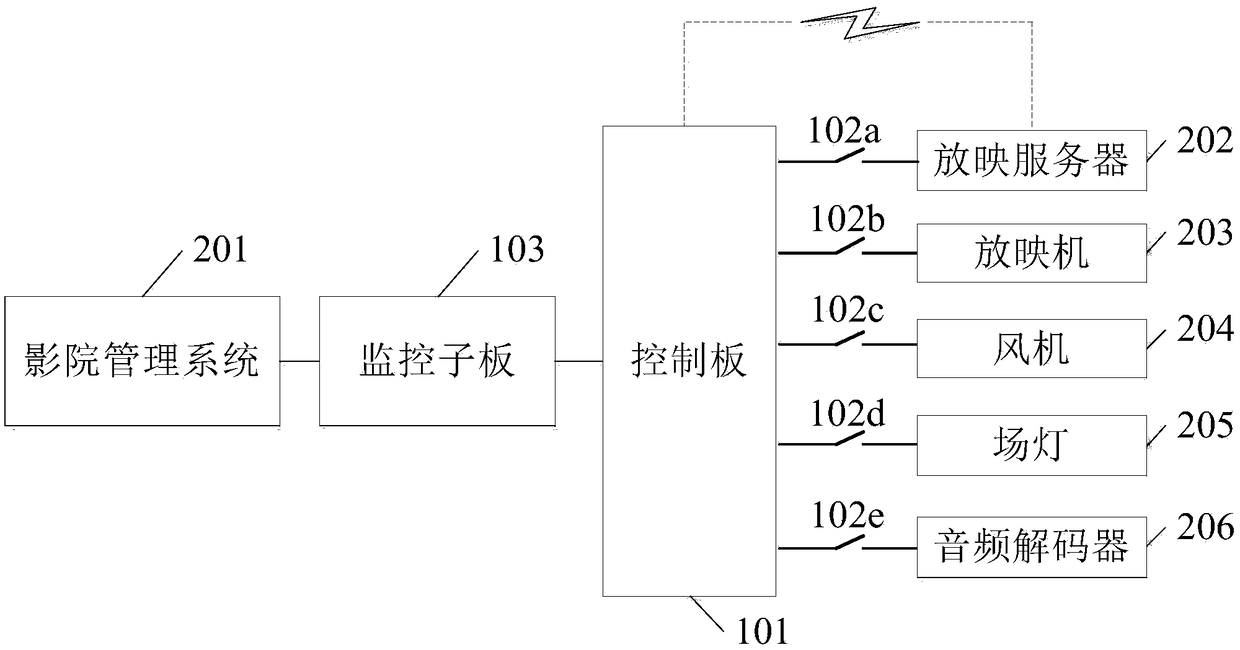

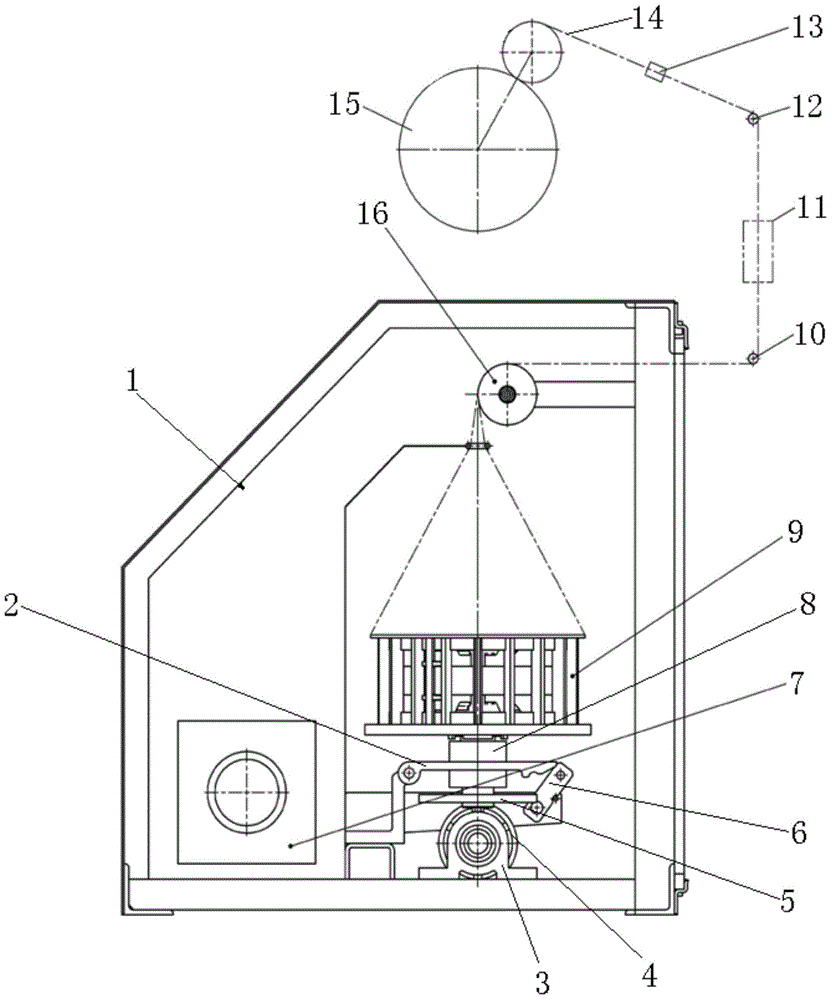

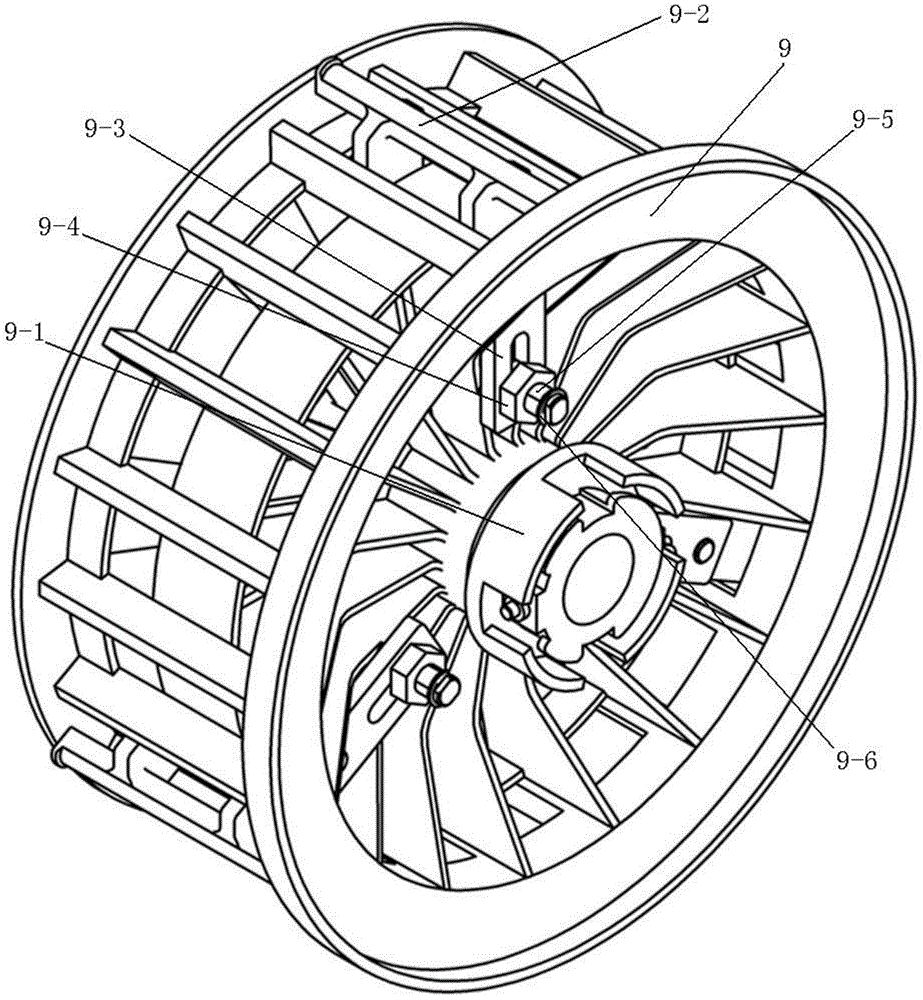

Control system and startup-shutdown management system of projection equipment

ActiveCN108762820AProvide work efficiencyReduce labor costsHardware monitoringBootstrappingManagement systemConnection control

The invention discloses a control system of projection equipment. The control system is applied to the startup and shutdown control of the projection equipment in a theater. The control system comprises a control panel, switches and a monitoring daughter board; a movie hall comprises multiple pieces of projection equipment; each piece of the projection equipment corresponds to one switch; the first end of the switch is connected with a power supply, the second end of the switch is connected with the power supply end of the projection equipment, and the control end of the switch is connected with the control panel; the control panel receives a startup-shutdown command sent by the monitoring daughter board, and the startup-shutdown command is sent to the monitoring daughter board by a theater management system (TMS); the startup-shutdown command comprises a channel number and a startup-shutdown mode of the projection equipment, and the startup-shutdown mode includes a startup mode and ashutdown mode; when the startup-shutdown mode is the startup mode, the control panel controls the corresponding switch to be on according to the channel number of the projection equipment; and when the startup-shutdown mode is the shutdown mode, the control panel controls the corresponding switch to be off according to the channel number of the projection equipment. The system automatically controls the startup and shutdown of the projection equipment, and watching of a projectionist is not needed, so that the labor cost is reduced.

Owner:CFGDC (BEIJING) TECH CO LTD

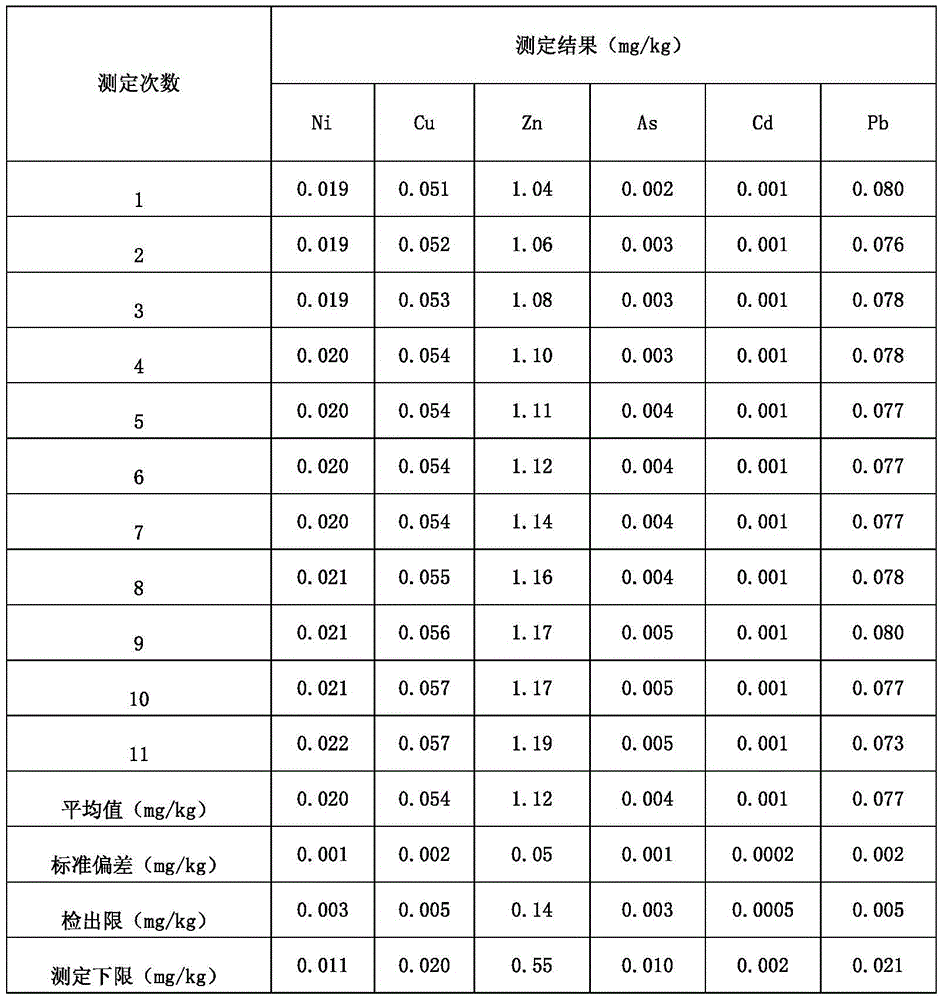

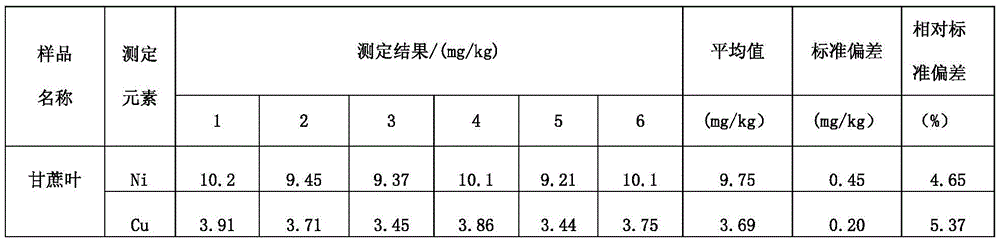

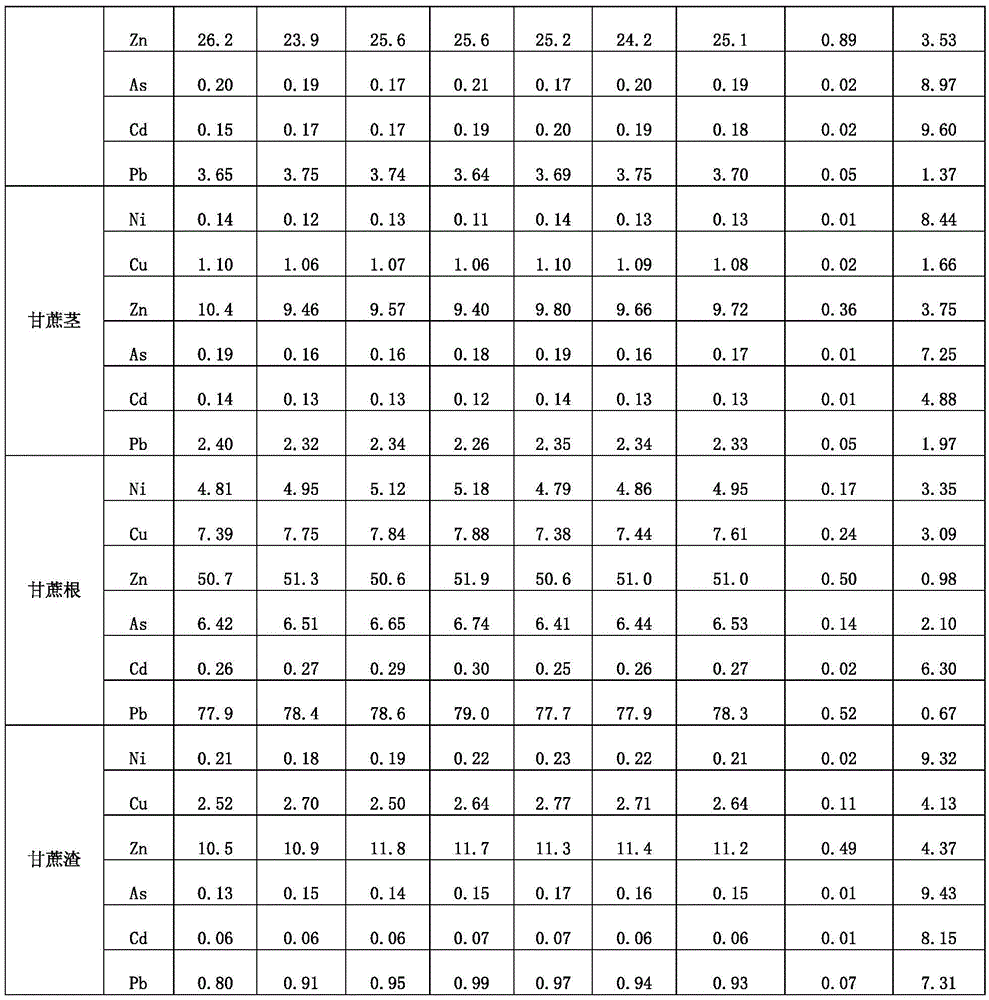

Method for determining heavy metal content of sugarcane with electric heating board digestion/ICP-MS (inductively coupled plasma mass spectrometry) methods

InactiveCN105527333AProvide work efficiencyLow detection limitPreparing sample for investigationMaterial analysis by electric/magnetic meansTandem mass spectrometryInductively coupled plasma mass spectrometry

The invention discloses a method for determining heavy metal content of sugarcane with electric heating board digestion / ICP-MS (inductively coupled plasma mass spectrometry) methods. The method comprises following steps: 1), sample pretreatment is performed: a sugarcane sample is selected and subjected to digestion and heating digestion, after digestion is finished, residues in a glass beaker are dissolved and washed with 2mL of a salpeter solution (prepared from nitric acid and water through isovolumetric mixing) in a 50-mL volumetric flask, a product is subjected to repeated washing with ultrapure water and constant volume processing until the product reaches the volumetric flask scale and is shaken uniformly to serve as a sample solution for online determination; 2), multiple blank solutions are prepared according to the step 1 except that the sugarcane sample is not added; 3), a standard solution is prepared from a mixed standard storage solution containing multiple elements including Cu, Zn, Pb, Cd, As and Ni, and a working curve of the standard solution is determined; 4), ICP-MS determination is performed. With the adoption of the method, the heavy metal content of the sugarcane can be detected simply, rapidly, efficiently and accurately.

Owner:广西壮族自治区环境监测中心站

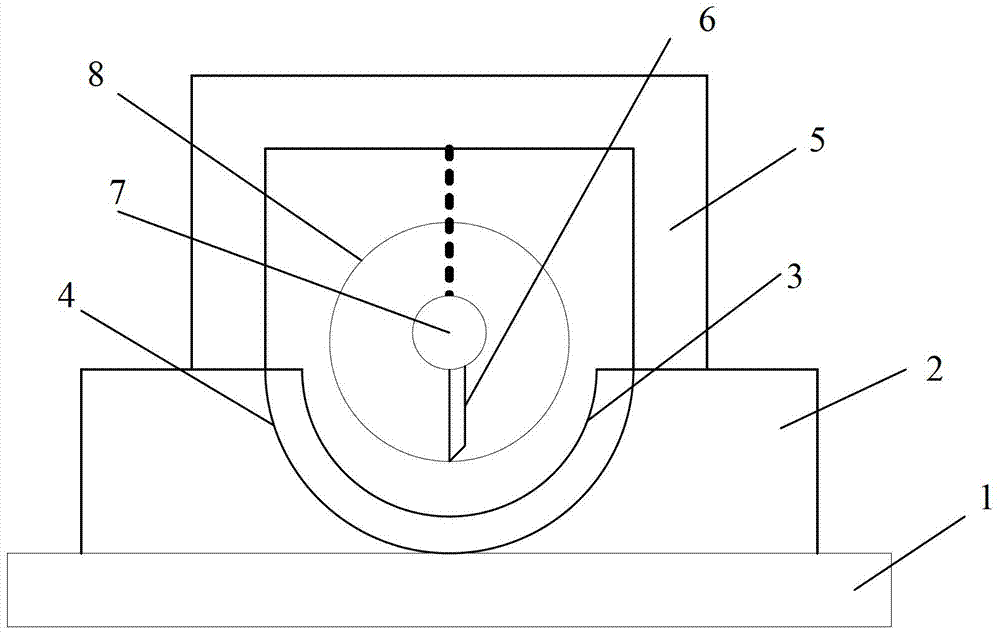

High-accuracy bearing bush inner side machining device

The invention discloses a high-accuracy bearing bush inner side machining device. According to the high-accuracy bearing bush inner side machining device, a grinding wheel is installed at a position, close to a tool, of a rotary shaft, primary rough machining is carried out on the inner side of a bearing bush by means of the tool to enable the inner surface of the bearing bush to be machined into a needed shape when the rotary shaft rotates, and along with the movement of the rotary shaft in the axial direction of the bearing bush, secondary fine machining is carried out on the inner side of the bearing bush by the grinding wheel to enable the inner surface of the bearing bush to be smooth and meet requirements. Therefore, two machining procedures are achieved through one-time machining, working efficiency is improved, and labor cost is reduced.

Owner:安徽科达汽车轴瓦有限公司

Glass breaking device

InactiveCN104646153ASave human effortProvide work efficiencyGlass recyclingGrain treatmentsAutomatic controlElectrical and Electronics engineering

The invention relates to a glass breaking device which comprises a glass bearing unit, a glass breaking unit and a control unit, wherein the glass bearing unit is used for bearing the glass; the glass breaking unit is arranged above the glass and is used for breaking the glass; and the control unit is used for controlling the glass breaking unit to move to the direction close to or far away from the glass. The glass breaking device disclosed by the invention has the beneficial effects that automatic control of glass breaking is realized, the manual labor is saved, and the working efficiency is improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

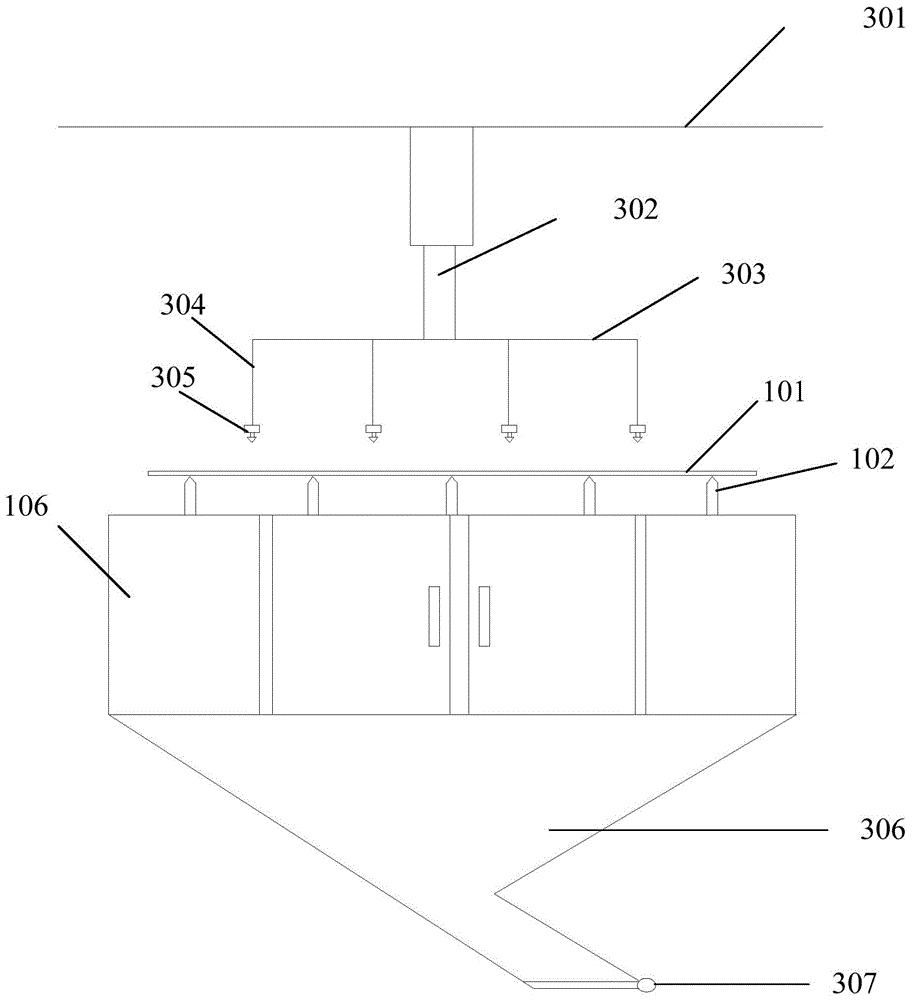

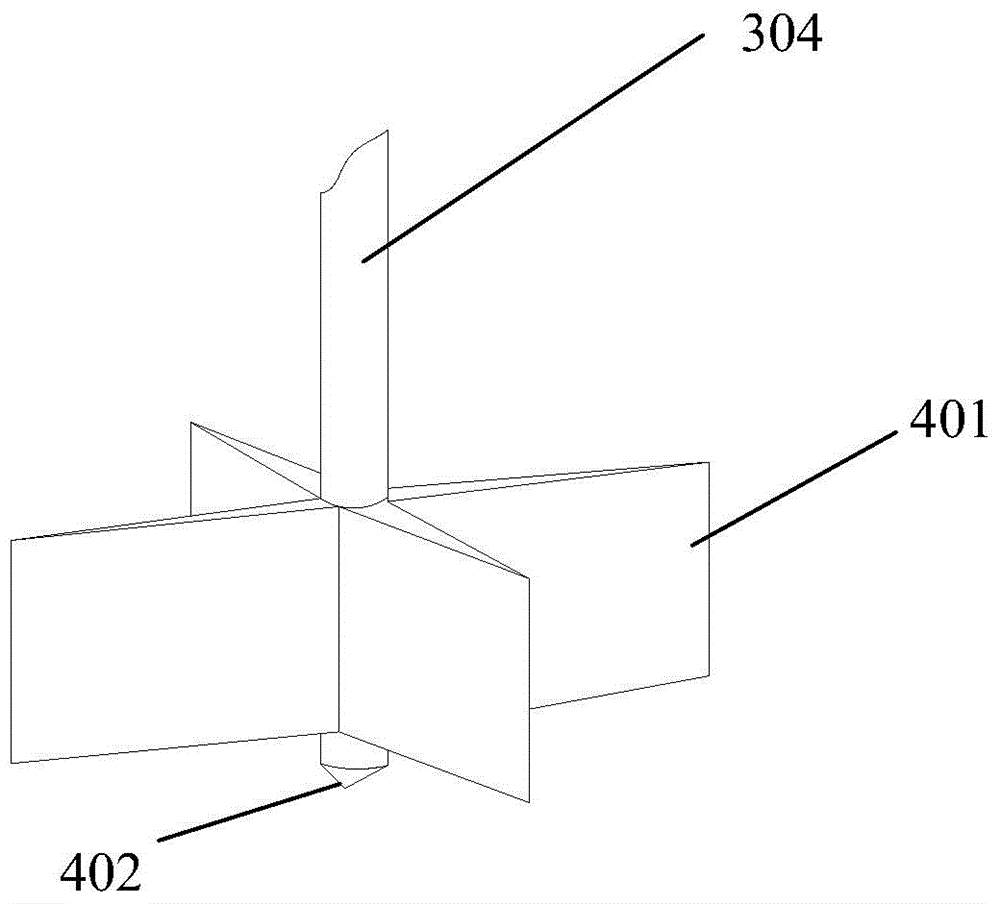

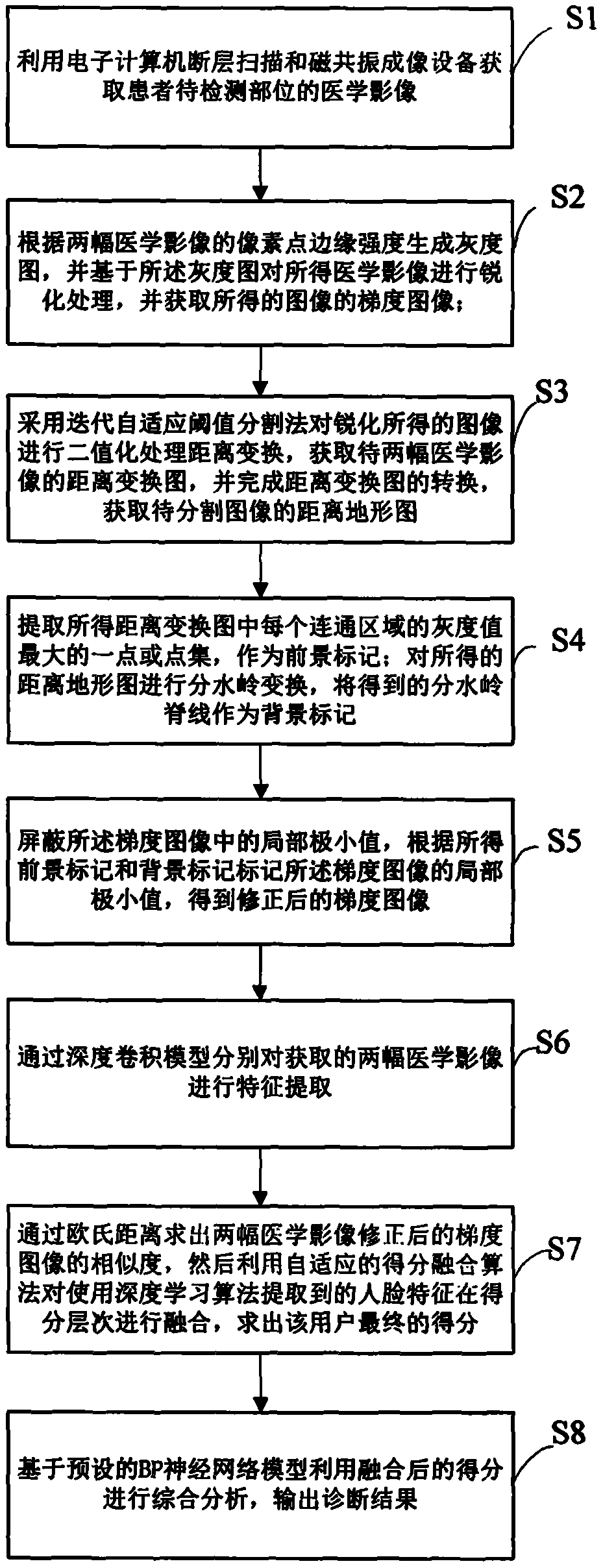

Multi-modal medical image method based on deep learning

The invention discloses a multi-modal medical image method based on deep learning. The method comprises: utilizing a deep learning algorithm to simultaneously carry out tomography on the electronic computer; performing feature extraction on the magnetic resonance image; secondly, the gradient image of the image is corrected through the foreground mark obtained through distance transformation and the background mark obtained through watershed transformation, then the features extracted by the deep learning model are subjected to score level fusion through a fusion algorithm, the accuracy of similarity calculation between the images is improved, and therefore the accuracy of a follow-up diagnosis result is improved; and finally, the fused image score is used for realizing automatic output ofa diagnosis result based on the BP neural network model, so that the working efficiency of medical personnel is greatly improved.

Owner:SHAANXI UNIV OF CHINESE MEDICINE

Drying and winding integrated device for silk processing

ActiveCN104562218AShorten production timeProvide work efficiencyFilament handlingSilk filament obtainingThermal insulationEngineering

The invention relates to the technical field of silk raw material fiber silk, in particular to a drying and winding integrated device for silk processing. The drying and winding integrated device for silk processing comprises a thermal insulation working chamber, and is characterized in that spindle rotating bases are arranged on the two sides of the ground in the thermal insulation working chamber, the spindle rotating bases on the two sides are connected through a spindle, a plurality of rotating wheels sleeve the spindle, the upper portions of the rotating wheels abut against a friction wheel, the center of the friction wheel is connected with a rotating shaft in a coupling mode, a bearing pedestal sleeves the portion, arranged above the friction wheel, of the rotating shaft, the portion, arranged above the bearing pedestal, of the rotating shaft is connected with a small device through a bearing in a coupling mode, and a guide wheel is arranged above the small device. Compared with the prior art, the drying and winding integrated device for silk processing has the advantages that drying and silk winding are integrated, silk winding and drying are conducted at the same time, the conventional drying working procedure and the conventional rewinding working procedure are combined to form one working procedure, the strength, the extension degree and the wear-proof degree of dried silk can be greatly higher than the industrial standards, and the production time is greatly shortened.

Owner:段肇祥

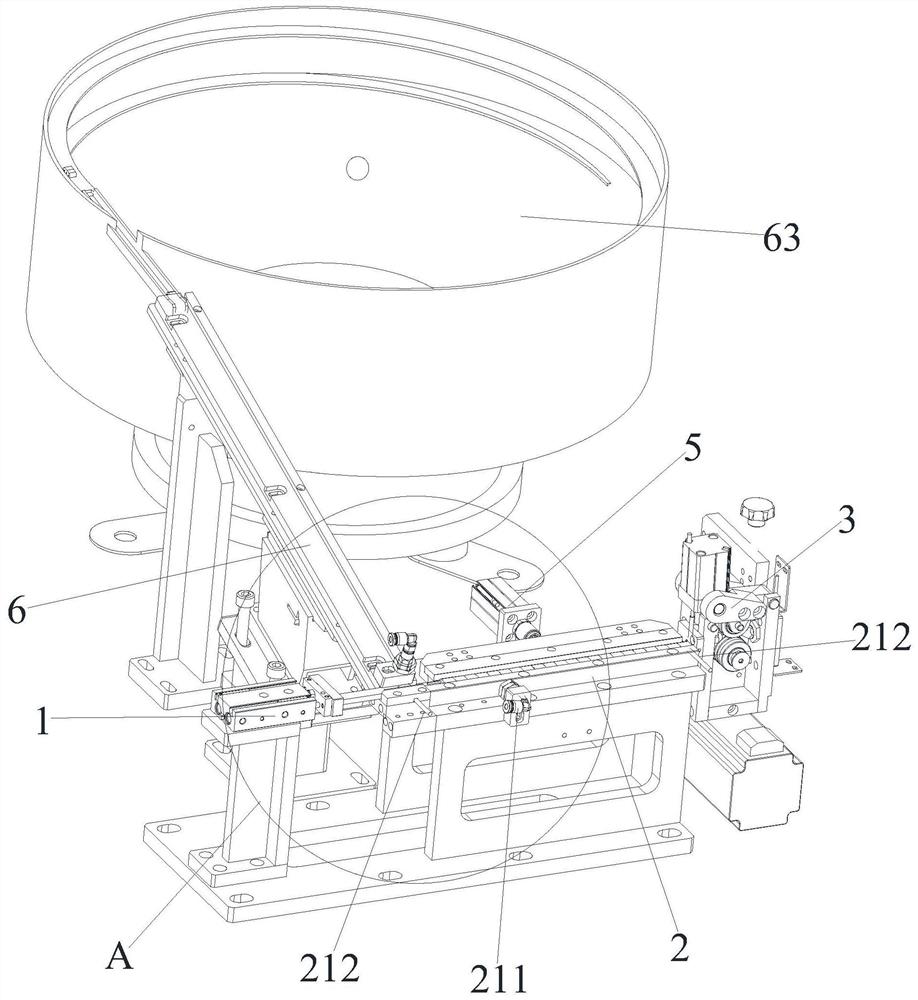

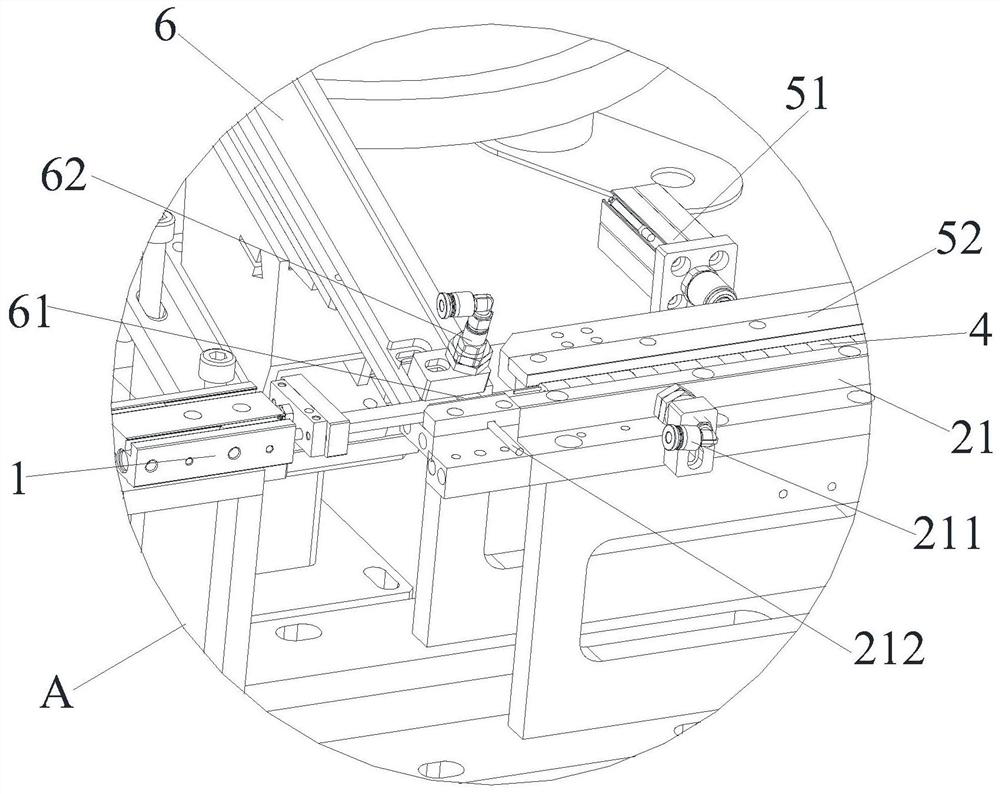

Hardware bead threading device

PendingCN111975320AProvide work efficiencyReduce labor costsAssembly machinesMetal working apparatusPhysicsBiology

Owner:SHENZHEN QIANHAI WELL SELL TECH CO LTD

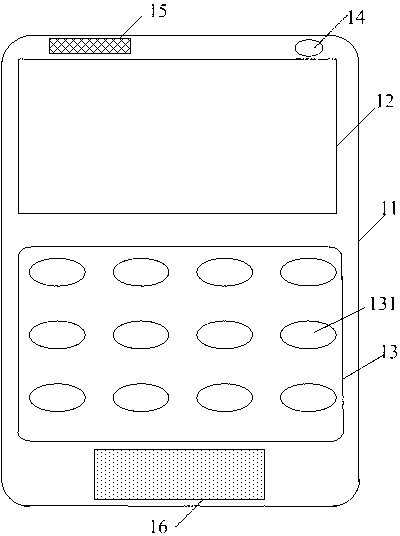

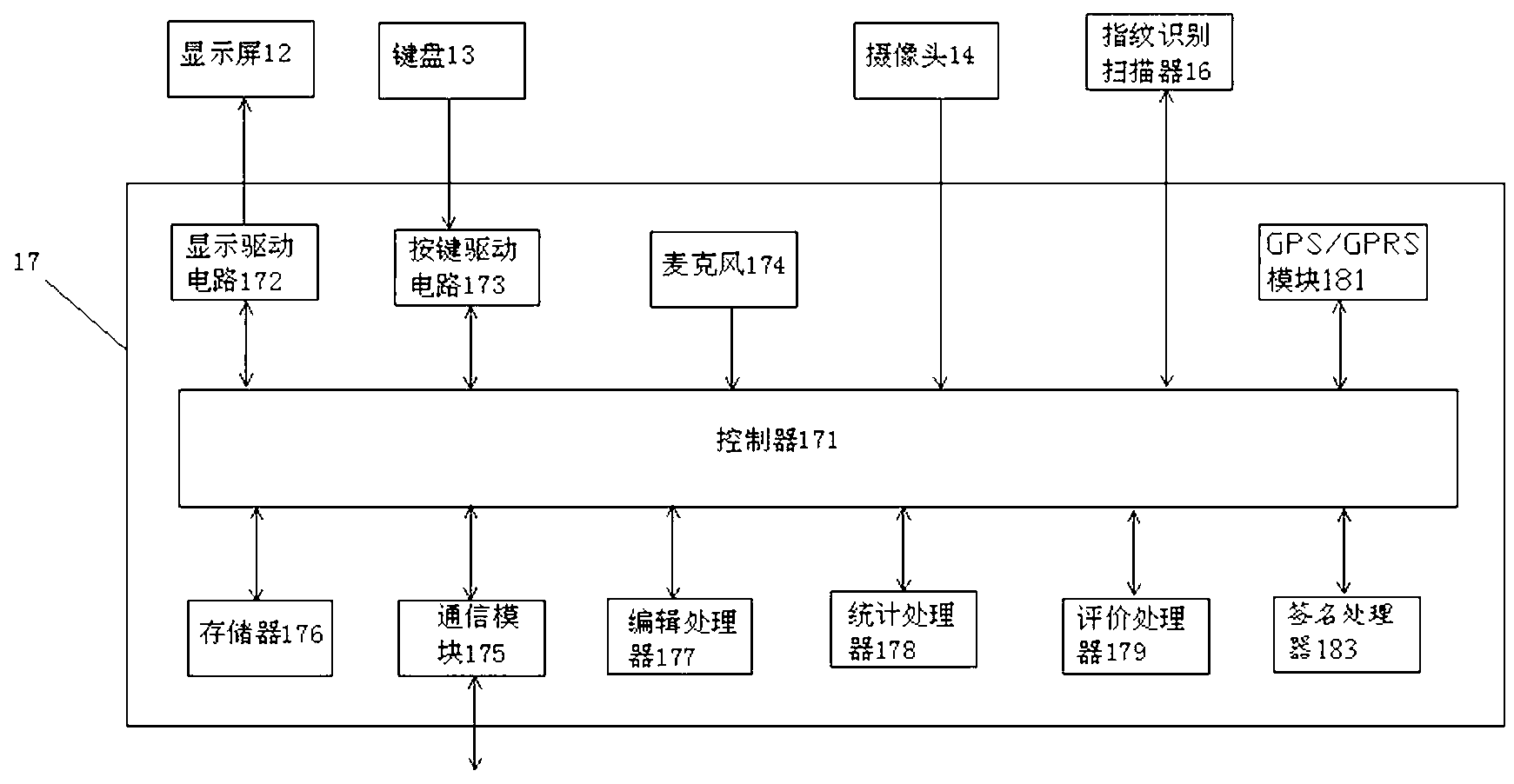

Nutrition assessment system

InactiveCN103295174AAvoid human errorProvide work efficiencyData processing applicationsNetwork topologiesStatistical processingPersonalization

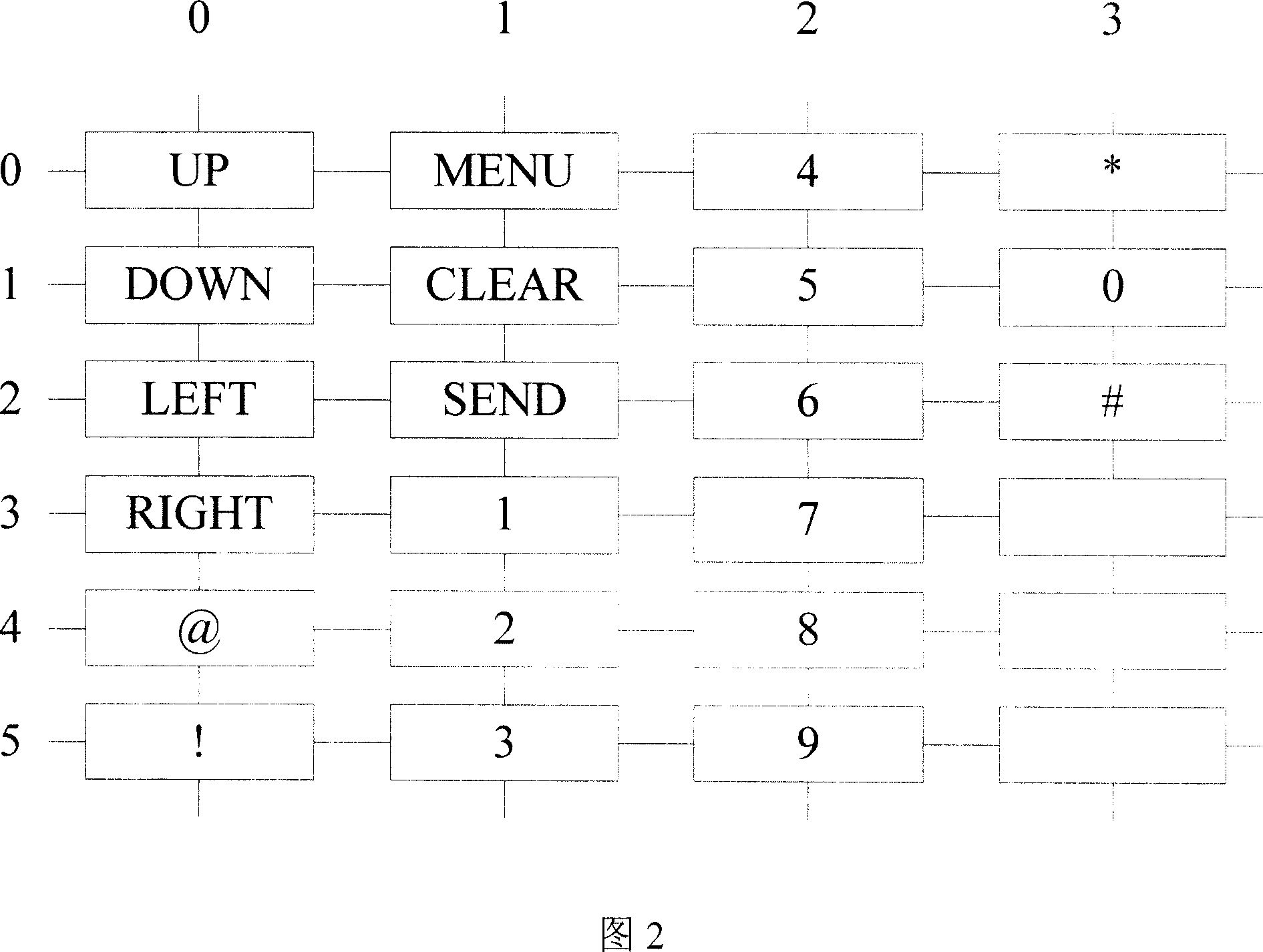

A nutrition assessment system comprises a plurality of handheld survey devices and a server, wherein an information processing circuit board is arranged in each handheld survey device. Each information processing circuit board comprises a controller, a display drive circuit, a key drive circuit, a microphone, a communication module, a memorizer, an editing processor, a statistics processor, an assessment processor, a GPS / GPRS module and a signature processor. The server comprises a controller, a communication module, a first memorizer, a second memorizer, a data processing module and an assessment processing module, wherein the communication module, the first memorizer, the second memorizer, the data processing module and the assessment processing module are connected with the controller. The nutrition assessment system can relieve human work intensity, is beneficial to improvement of work efficiency, can accurately locate the position where an investigator is located, enables an interviewee to conduct handwritten signature, can effectively monitor the investigator, improves the authenticity and accuracy of investigation, and provides personalized expert opinions and suggestions for the interviewee.

Owner:SHENZHEN CENT FOR CHRONIC DISEASE CONTROL

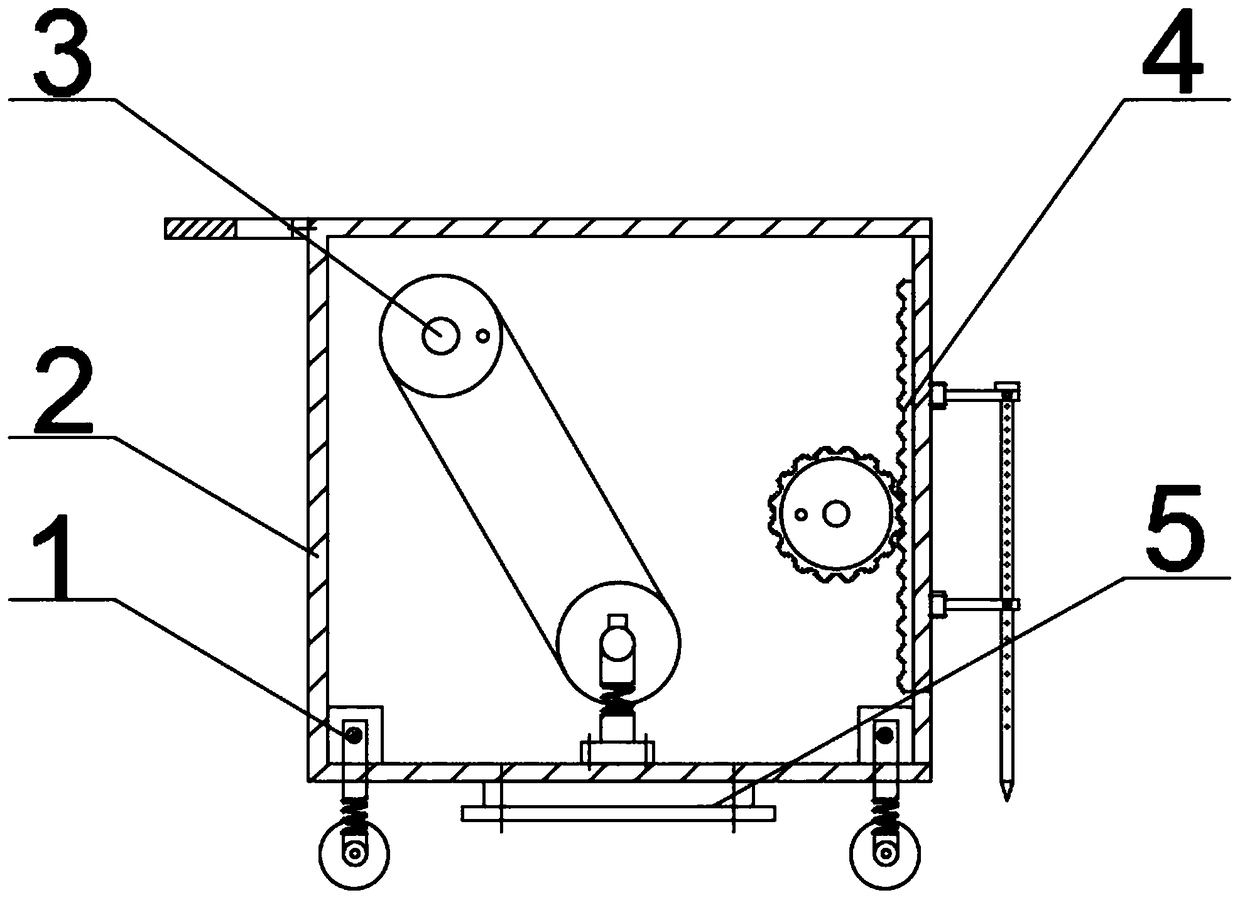

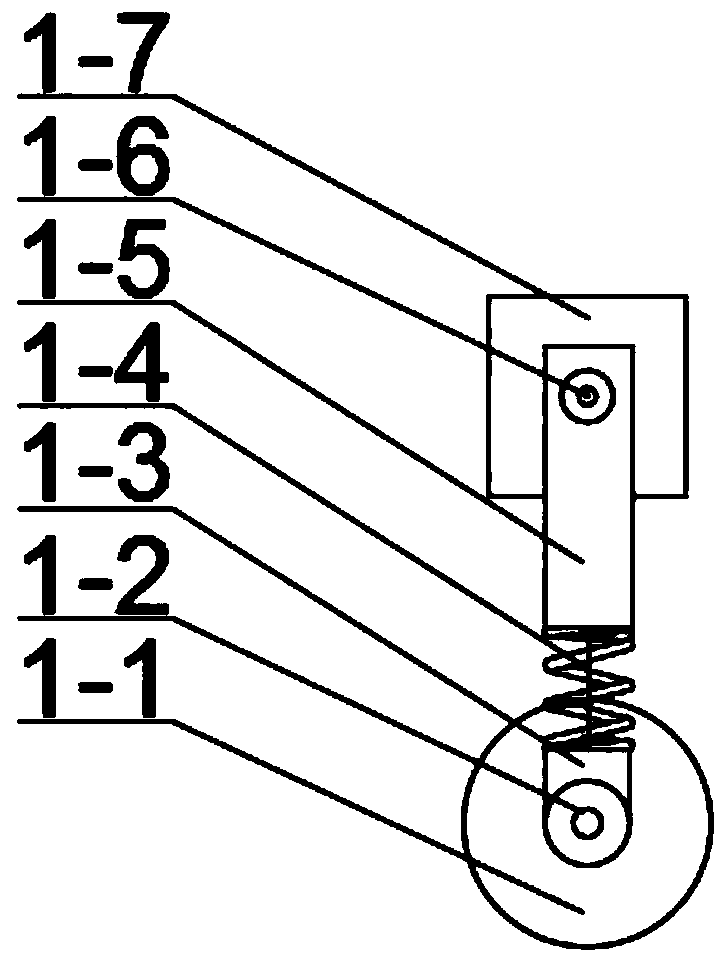

Vibration tamping drilling device for water conservancy and hydropower

InactiveCN108824144AProvide work efficiencyReduce vibrationRoads maintainenceVehicle frameRoad surface

The invention relates to a tamping tool, in particular to a vibration tamping drilling device for water conservancy and hydropower. The vibration tamping drilling device comprises a rotary damping wheel mechanism, a vehicle frame mechanism, an eccentric block exciting mechanism, a drilling mechanism and a tamping hammer. The vibration tamping drilling device has the advantages that the sheared branches are crushed, the vibration tamping drilling device can be moved, the vibration can be reduced in the movement process, and the vibration tamping drilling device can be used for tamping the roadpavement, and also can be used for drilling, so that the operation efficiency of a worker is improved; the tamping hammer is positioned at the lower part of the vehicle frame mechanism and is connected with the vehicle frame mechanism by bolts, the rotary damping wheel mechanism is positioned at the lower part of the vehicle frame mechanism and is connected with the vehicle frame mechanism in a hinge way, the eccentric block exciting mechanism is arranged in the vehicle frame mechanism and is connected with the vehicle frame mechanism by bolts, and the drilling mechanism is positioned at the right side of the vehicle frame mechanism and is in clearance fit with the vehicle frame mechanism.

Owner:钟秀国

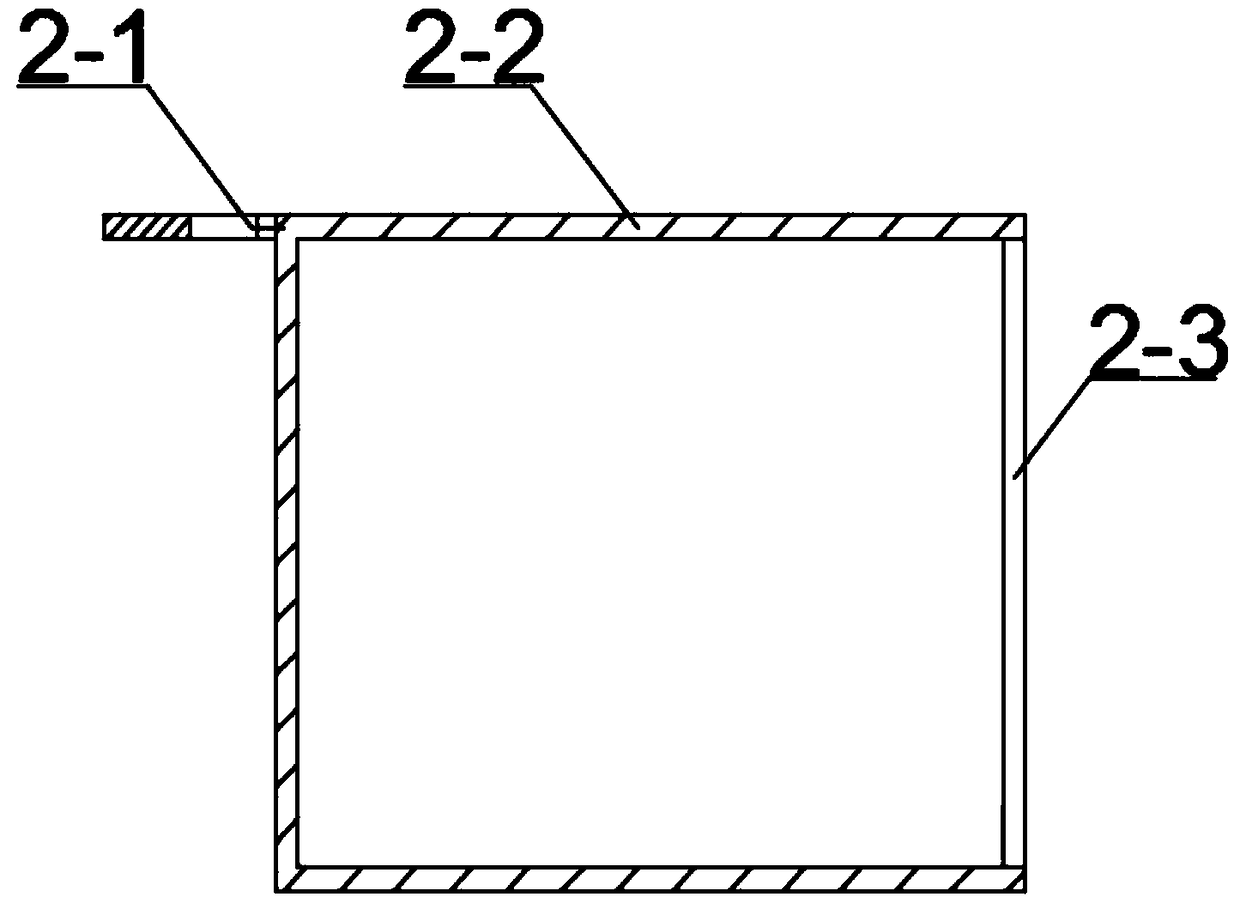

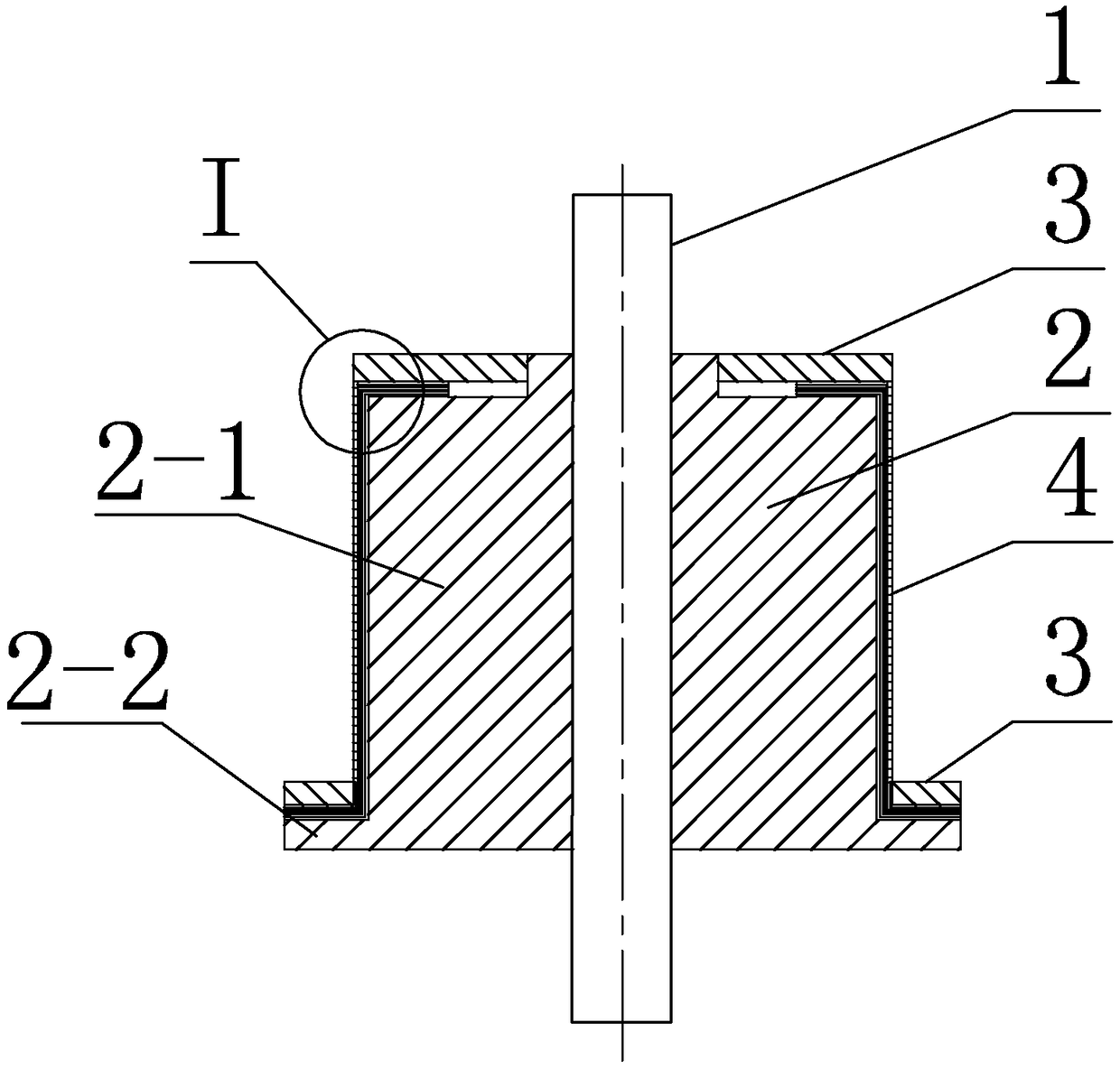

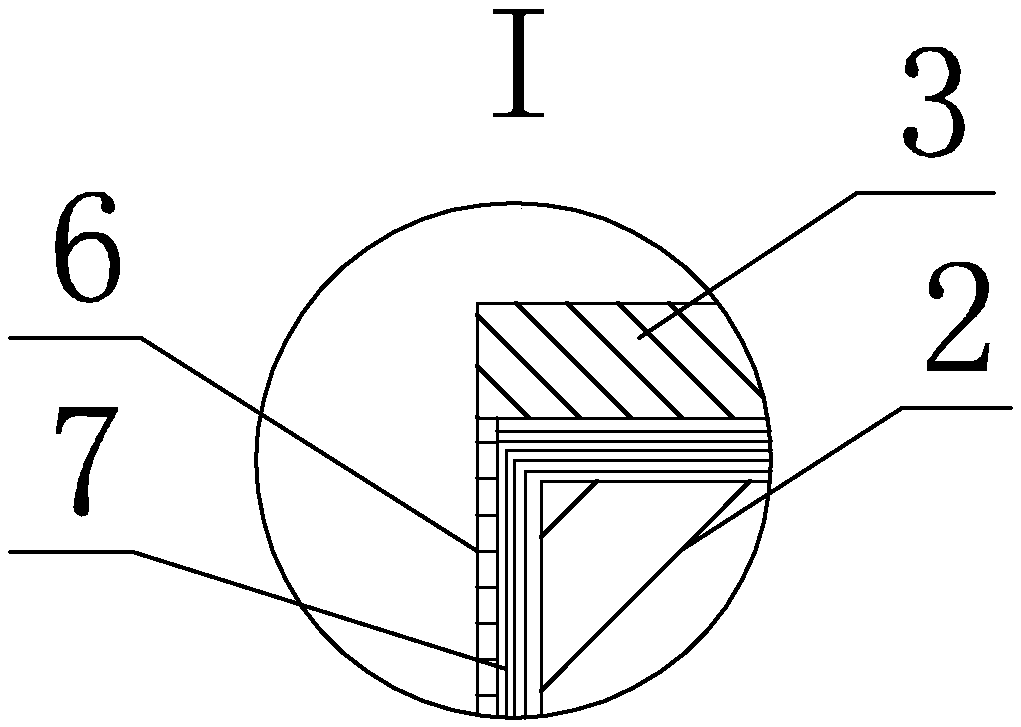

Vertical type winding device for composite-material thin-wall high flange cylinder and manufacturing method

The invention relates to a vertical type winding device for a composite-material thin-wall high flange cylinder and a manufacturing method, and relates to the technical field of flange manufacturing.The problem that the texture of a flanging flange is loosened in texture since an existing horizontal type winding machine cannot turn over a cylinder section longitudinal fiber to the preset positionwhen the flange is flanged and cannot apply pressure is solved. The vertical type winding device for the composite-material thin-wall high flange cylinder comprises a rotary shaft, a winding mold andtwo pressing plates, wherein the rotary shaft is vertically arranged on a rack and can rotate; the winding mold is fixed onto the rotary shaft; a first cylinder and a second cylinder are processed onthe winding mold; the diameter of the first cylinder is larger than the diameter of the second cylinder; the first cylinder and the second cylinder are concentric to the rotary shaft; the side surface of the first cylinder is connected with one pressing plate through a screw; and the side surface of the second cylinder is connected with the other pressing plate. The vertical type winding device for the composite-material thin-wall high flange cylinder provided by the invention is suitable for a flange cylinder with the ratio of the height to the wall thickness is more than 10 times.

Owner:HARBIN FRP INST

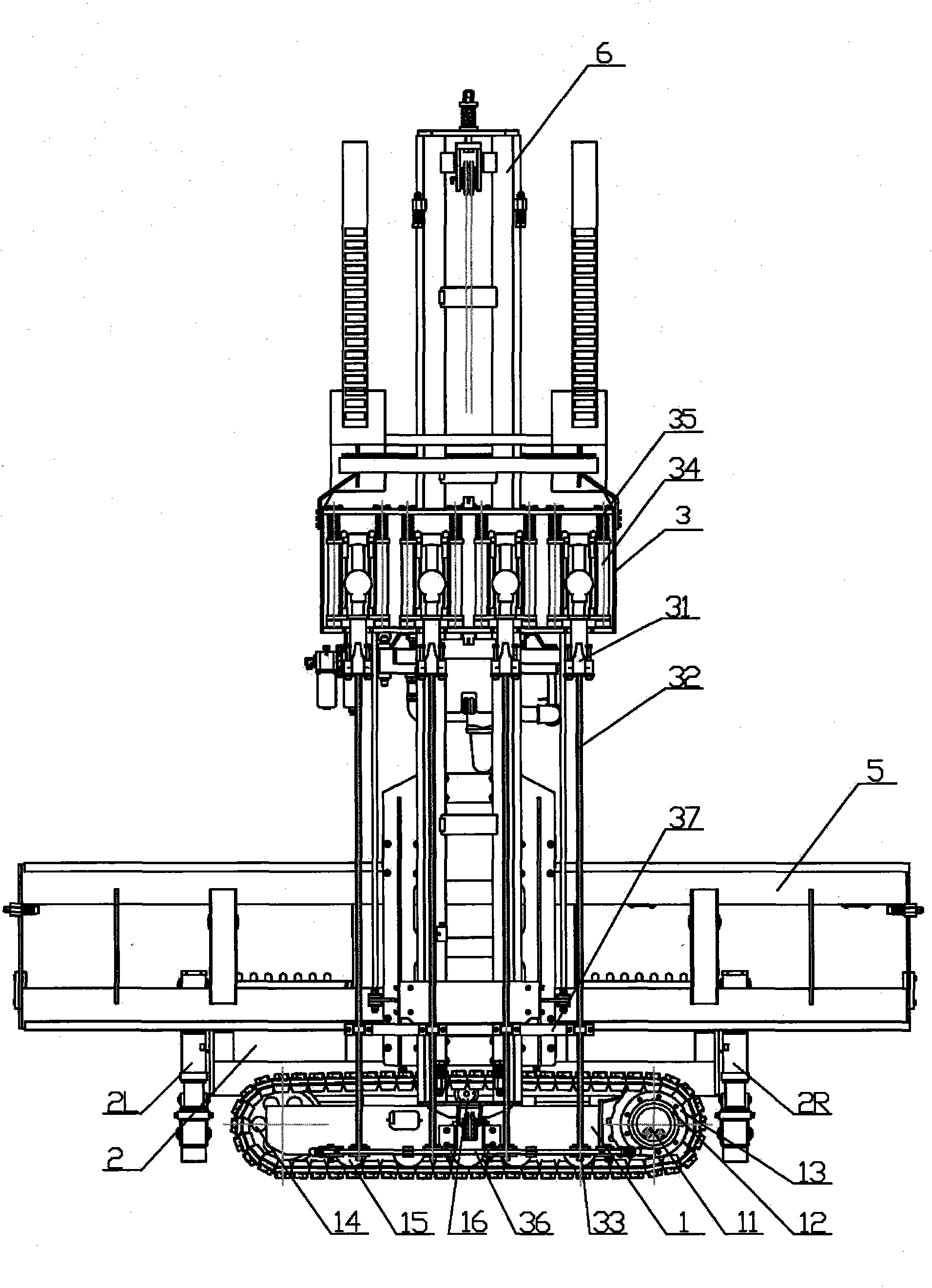

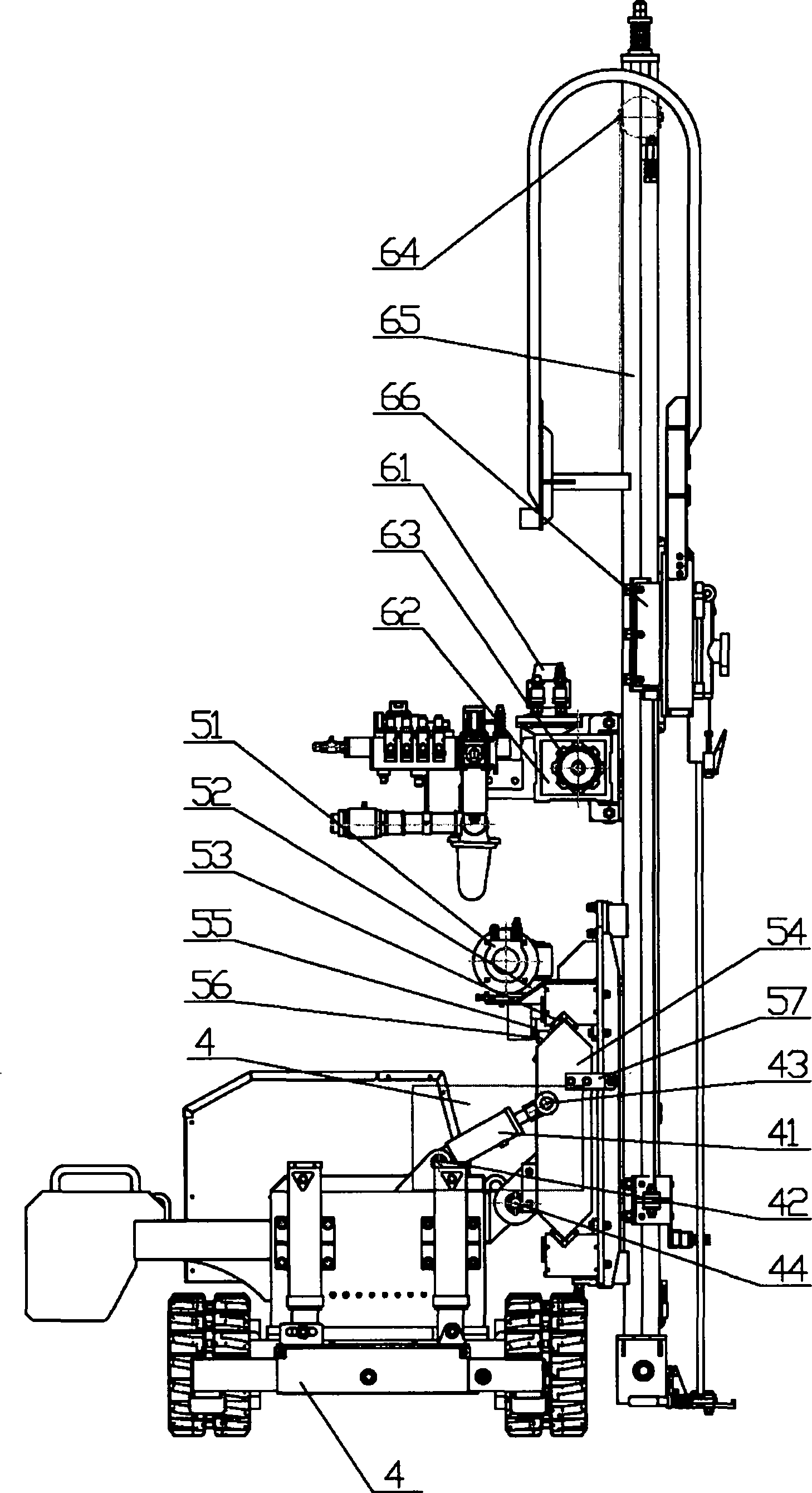

Track-type multi-head rock drilling machine for mine

ActiveCN103967409AReduce labor intensityProvide work efficiencyDrilling machines and methodsVehicle frameDrill hole

The invention discloses a track-type multi-head rock drilling machine for a mine. The machine is formed in the mode that a rock drilling device, a transverse moving device and a drilling feeding device are assembled and are connected with a vehicle frame and drilled hole trimming device through an upright column adjusting device, and then arranged on a track walking device through the vehicle frame and drilled hole trimming device. The drilling machine is characterized in that needed moving forward, moving backward, steering and other functions can be easily achieved by means of track walking. A remote electric control device can achieve remote control of the drilling machine, and enables the drilling machine to move away from equipment and avoid dust and other damage during operation. Meanwhile, operation situations of parts in all directions during drilling can be taken into consideration. Compressed air serves as a power system. By means of the system, gas-liquid conversion and gas-electric conversion functions are achieved, and centralized control and analysis are carried out by means of an electric control console.

Owner:泉州华大超硬工具科技有限公司

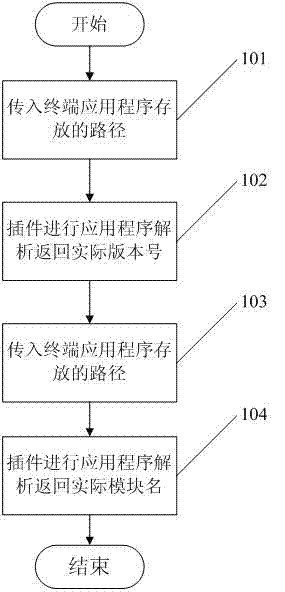

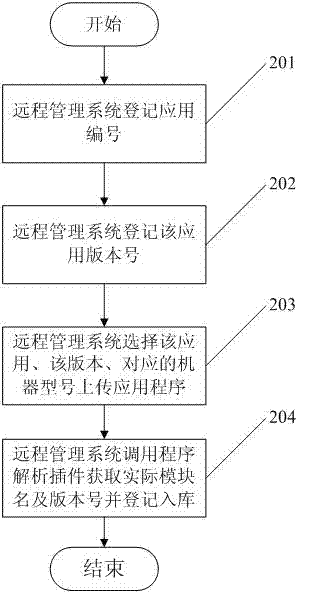

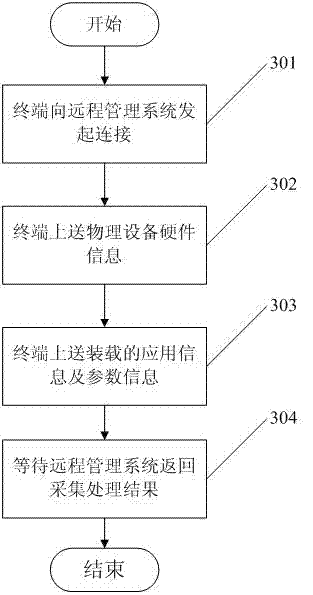

Terminal information collection method and system

ActiveCN103116521AReduce labor costsProvide work efficiencyMultiprogramming arrangementsApplication softwareRemote management

The invention relates to the technical field of terminal management, in particular to a terminal information collection method and a system, and solves the problems that existing manual terminal information registration is wasted in labor cost, low in working efficiency, and biased in information. The method includes a first step of using a terminal to upload a terminal application program analysis plug-in unit to a remote management system, a second step of using the terminal to register terminal application and version information on the remote management system, and uploading corresponding terminal application programs to the remote management system, a third step of enabling the terminal and the remote management system to be on-line, and uploading terminal hardware information and terminal software information, and a fourth step of using the remote management system to carry out hardware information automatic collection registration and software information automatic collection registration according to terminal hardware information and terminal software information which are uploaded by the terminal.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

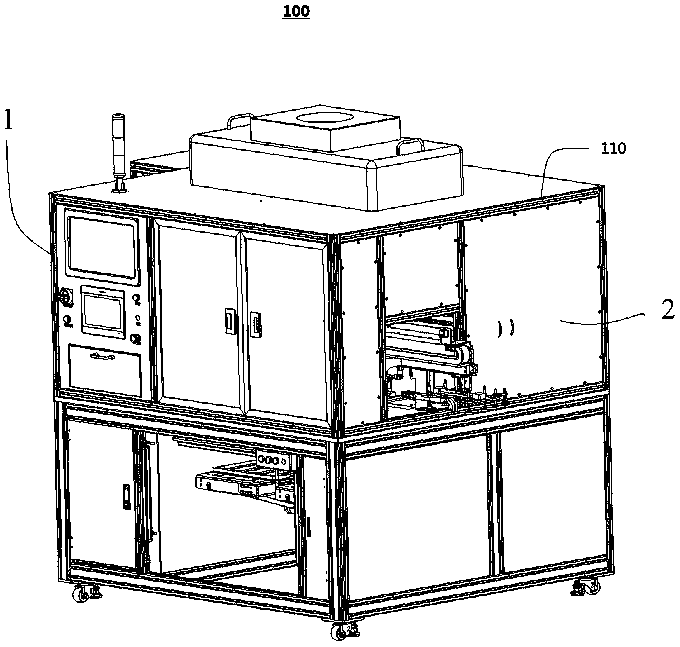

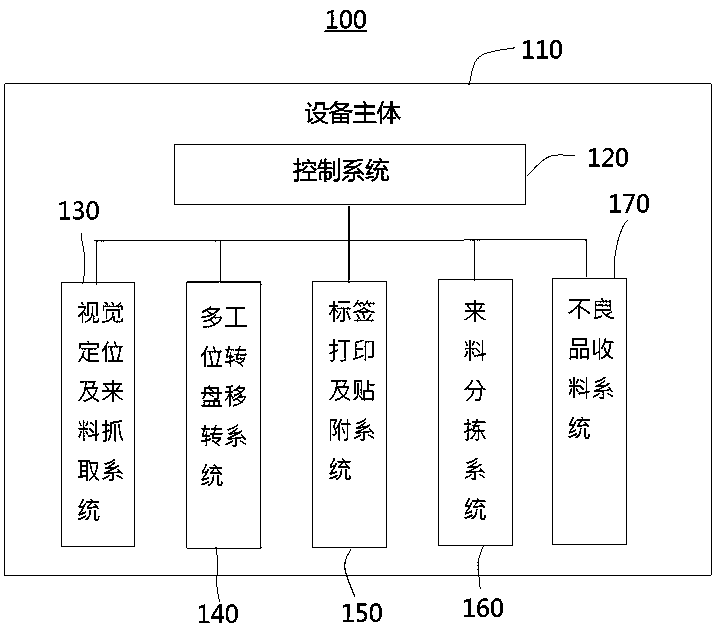

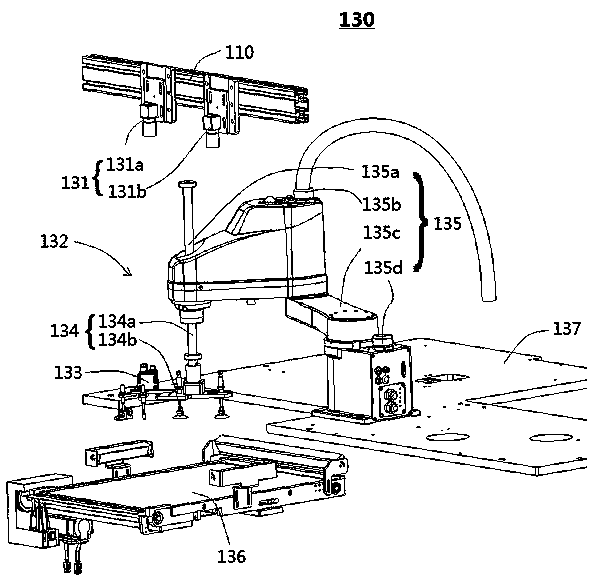

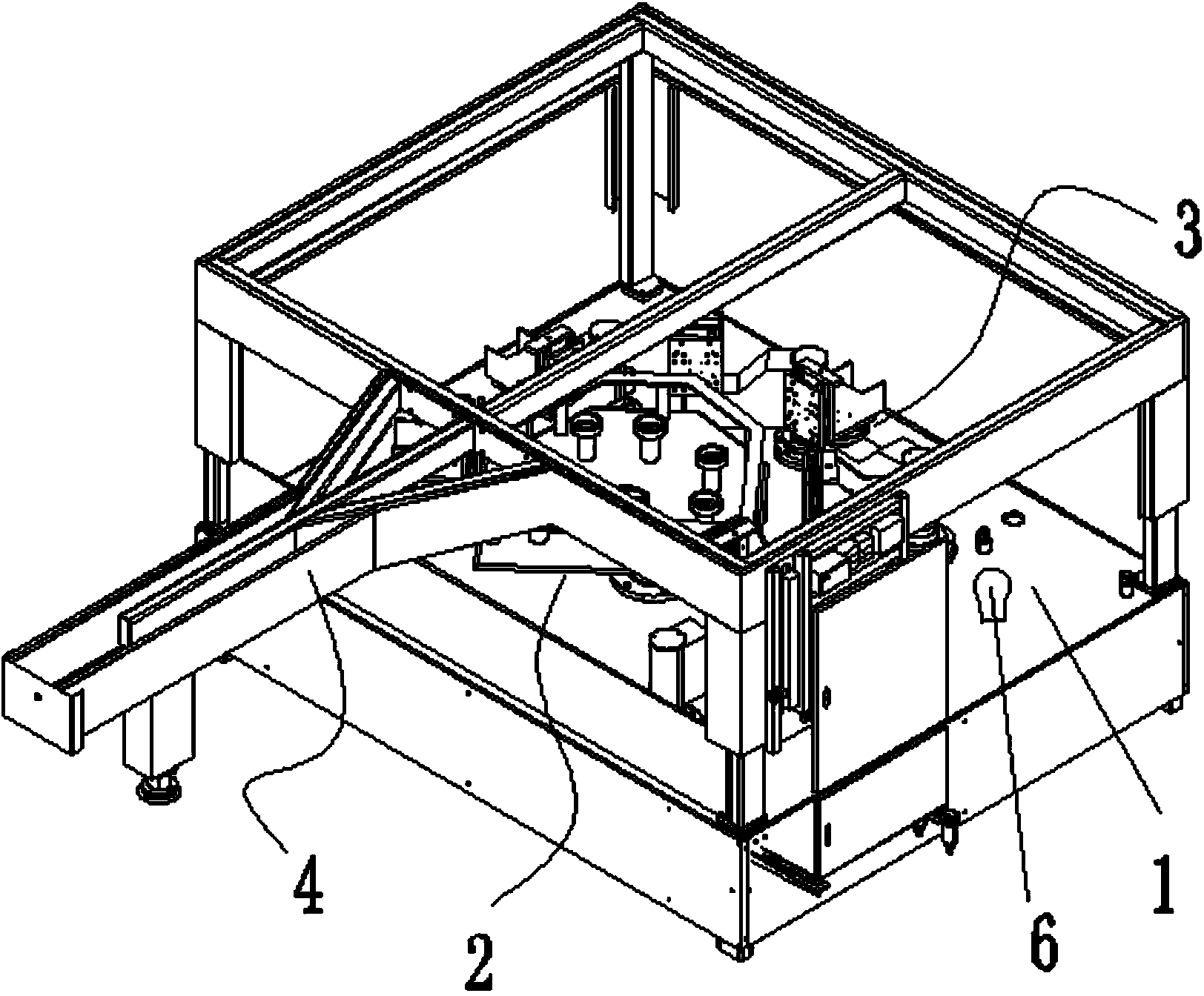

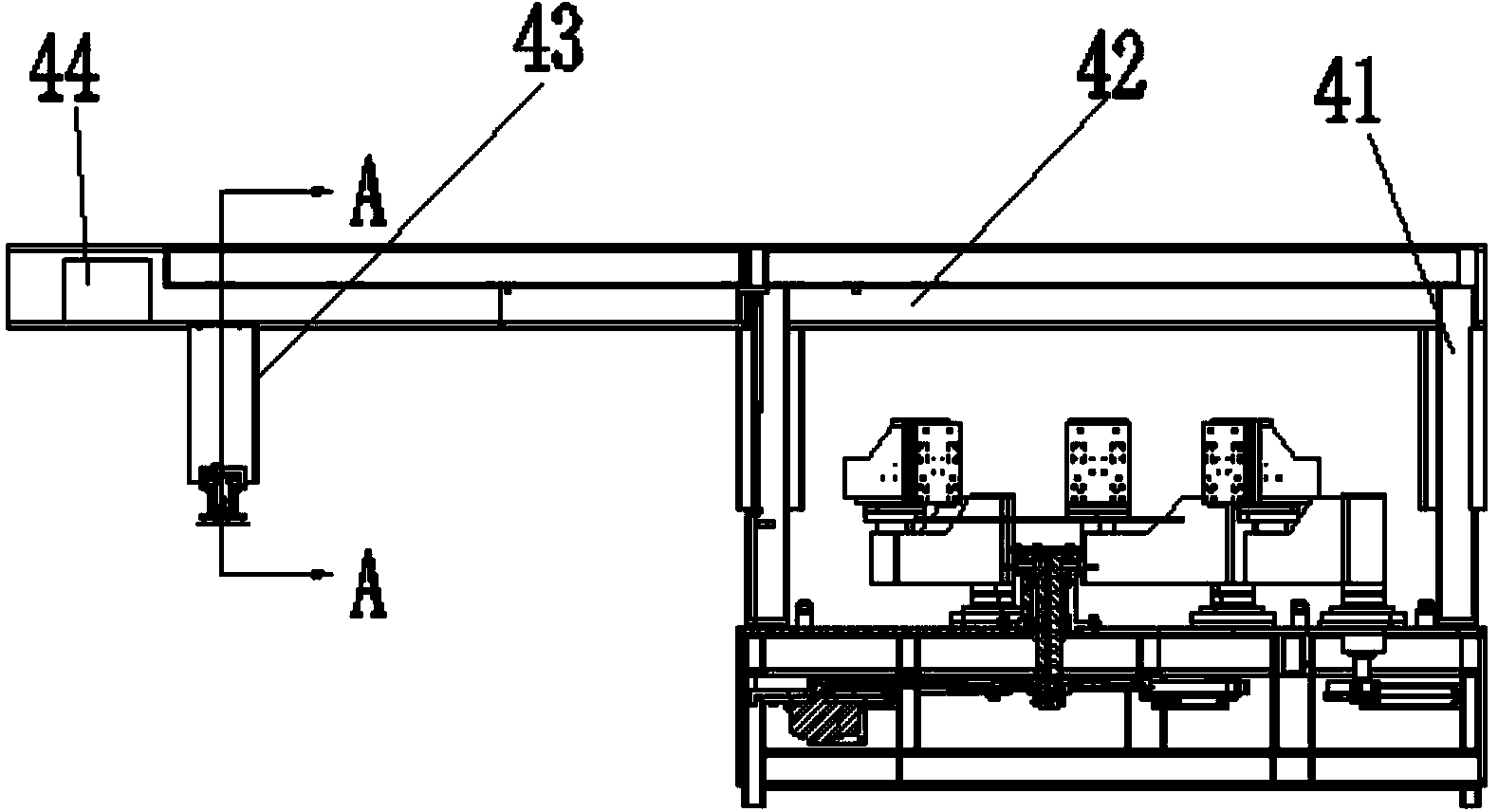

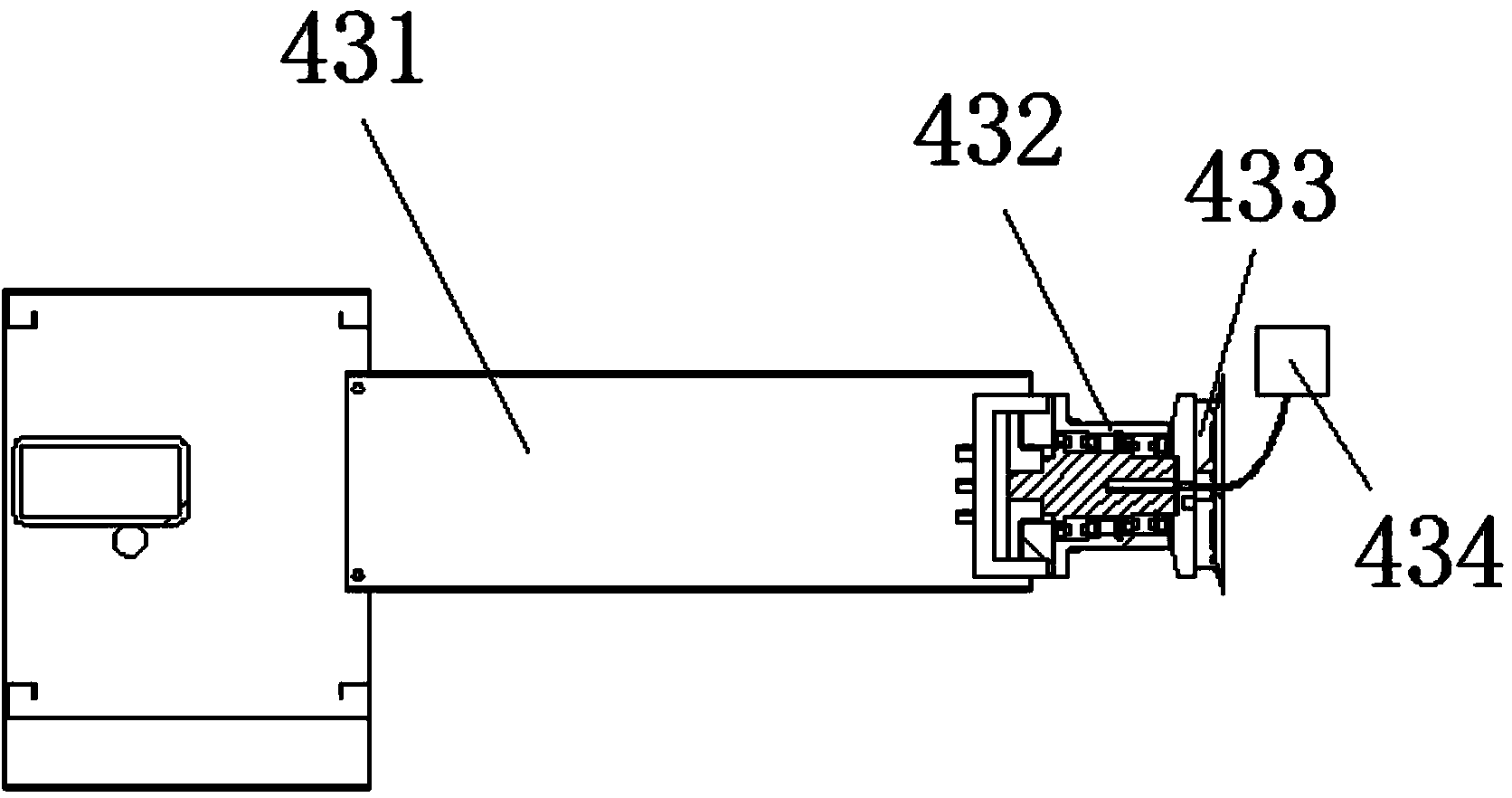

Automatic product code binding equipment

PendingCN108945688AStrong applicabilityProvide work efficiencyLabelling machinesEngineeringMechanical engineering

The invention relates to automatic product code binding equipment which comprises a control system, a visual positioning and coming material grabbing system, a multi-station rotary disc transferring system and a label printing and attaching system. The visual positioning and coming material grabbing system is used for conducting visual positioning on products, reading code information on the products, and grabbing the products to the multi-station rotary disc transferring system; the multi-station rotary disc transferring system comprises multi-station rotary discs used for bearing the multiple products and a transferring driving structure, and the transferring driving structure is used for driving the multi-station rotary discs to rotate so as to move the products on the multi-station rotary discs; and the label printing and attaching system is used for printing corresponding code labels according to the product code information read by the visual positioning and coming material grabbing system and attaching the coding labels to the products on the multi-station rotary discs.

Owner:深圳市博视科技有限公司

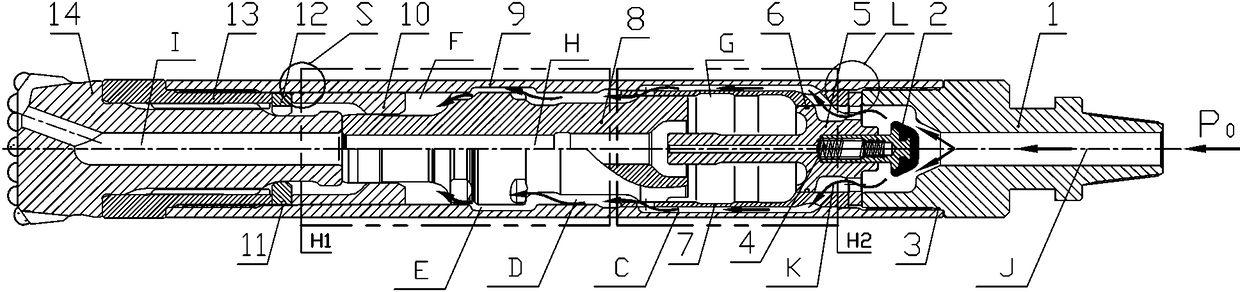

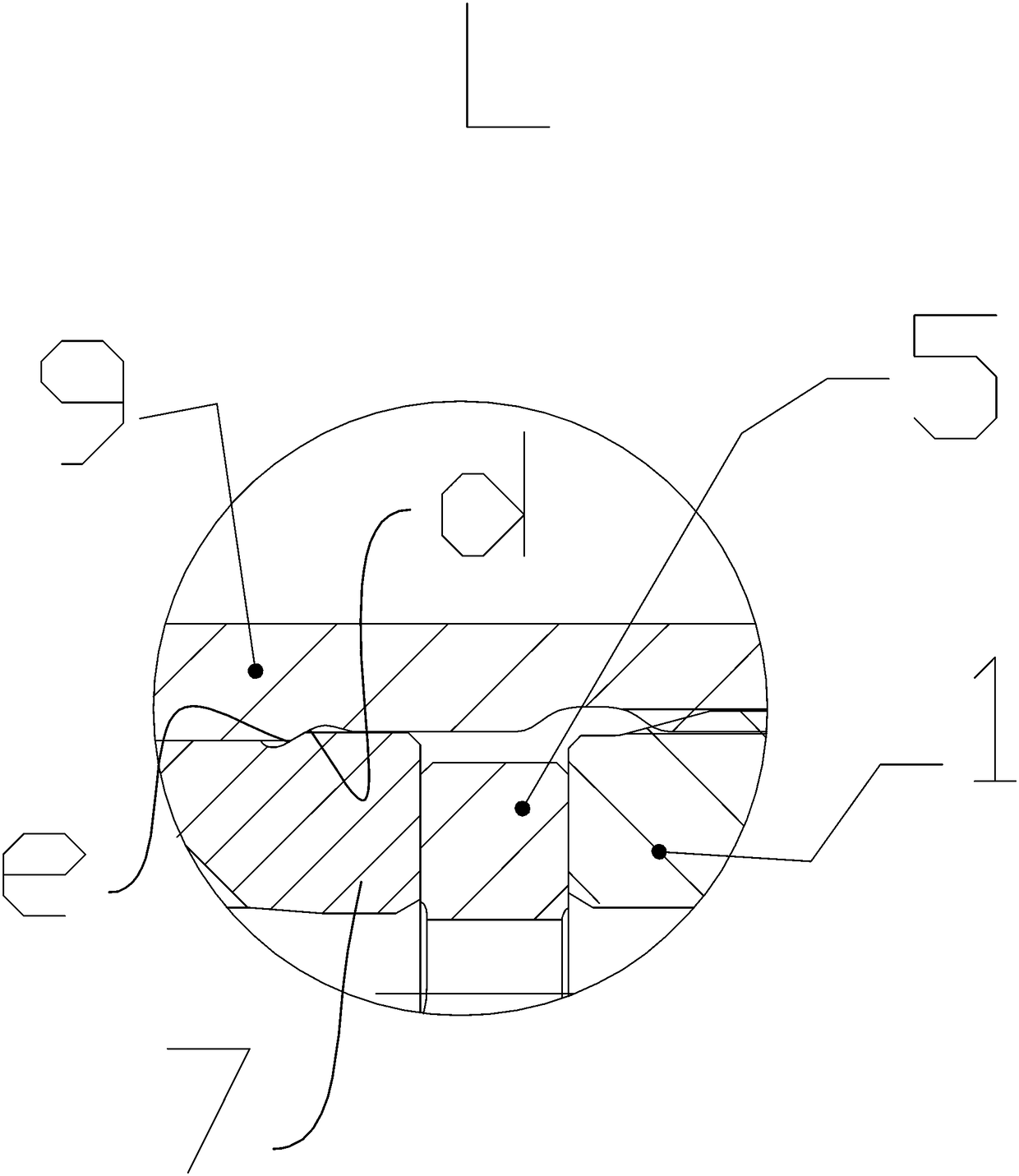

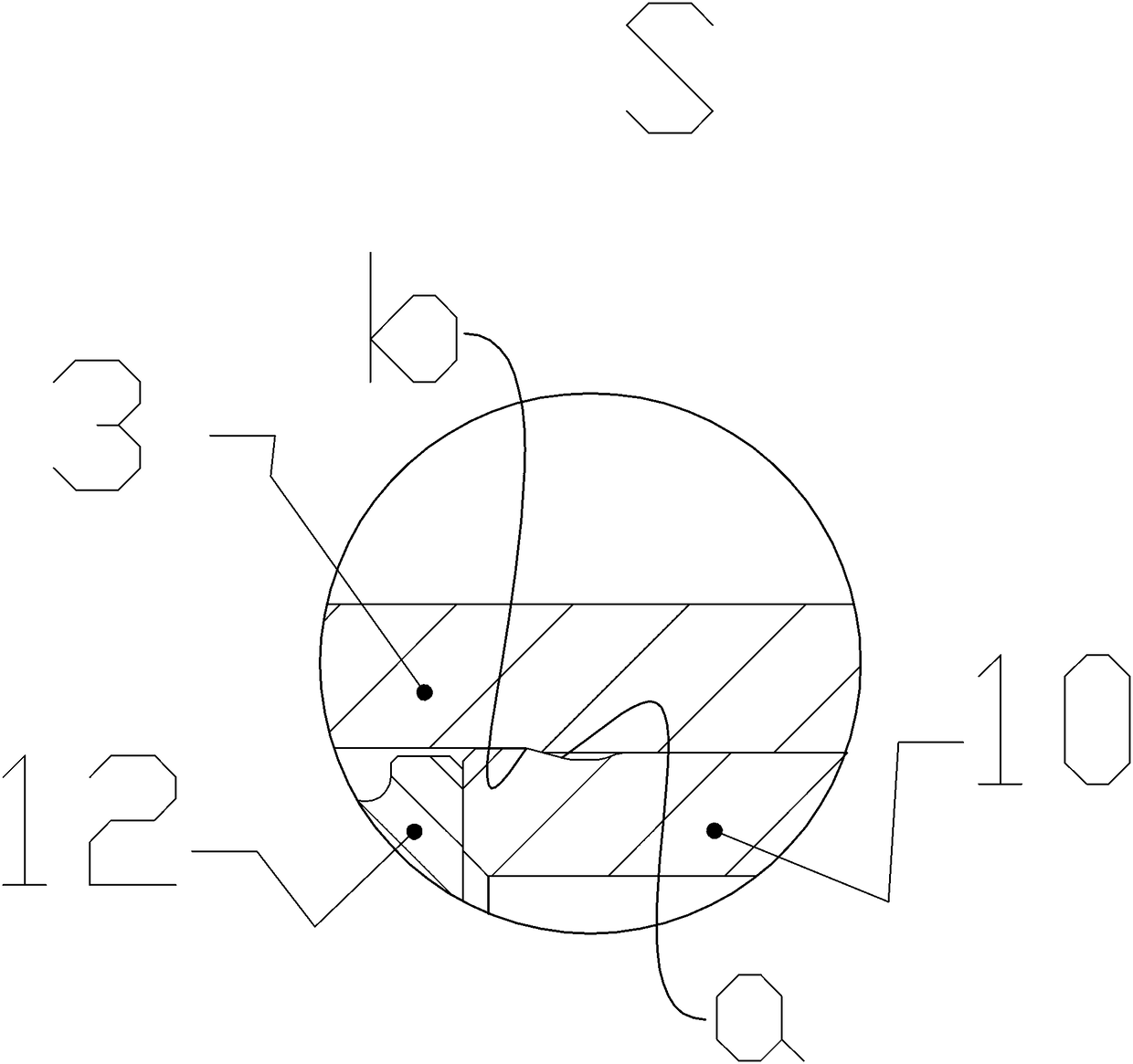

Double-cavity type impacter with external casing pipe structure

PendingCN108222817APrevent jumpingProvide work efficiencyDrilling rodsBorehole drivesPistonDrill bit

The invention relates to a double-cavity type impacter with an external casing pipe structure. The double-cavity type impacter comprises a rear joint, and an external casing pipe is connected to the rear joint; an inner cylinder is mounted in the external casing pipe in a sleeved mode, a gas distributing rod is mounted in the inner cylinder through the rear joint in a positioned mode, a check valve is mounted in a cavity of the gas distributing rod, and a spring is mounted in a cavity of the check valve; a piston is mounted in the external casing pipe, one end of the piston is matched with theinner wall of the inner cylinder, and the other end of the piston is matched with a guiding sleeve mounted in the external casing pipe; a front joint is mounted at the tail end of the external casingpipe, and a clamping ring is mounted on the end face, matched with the guiding sleeve, of the front joint in a positioned mode; and a drilling bit is mounted in the front joint through the clamping ring in a limiting sliding fit mode, the impacting end face of the drilling bit is matched with the end face of the piston in a contact mode, and impact energy is transmitted. The working area of the impacting piston is effectively increased, so that the utilization ratio of compressed gas is greatly increased.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

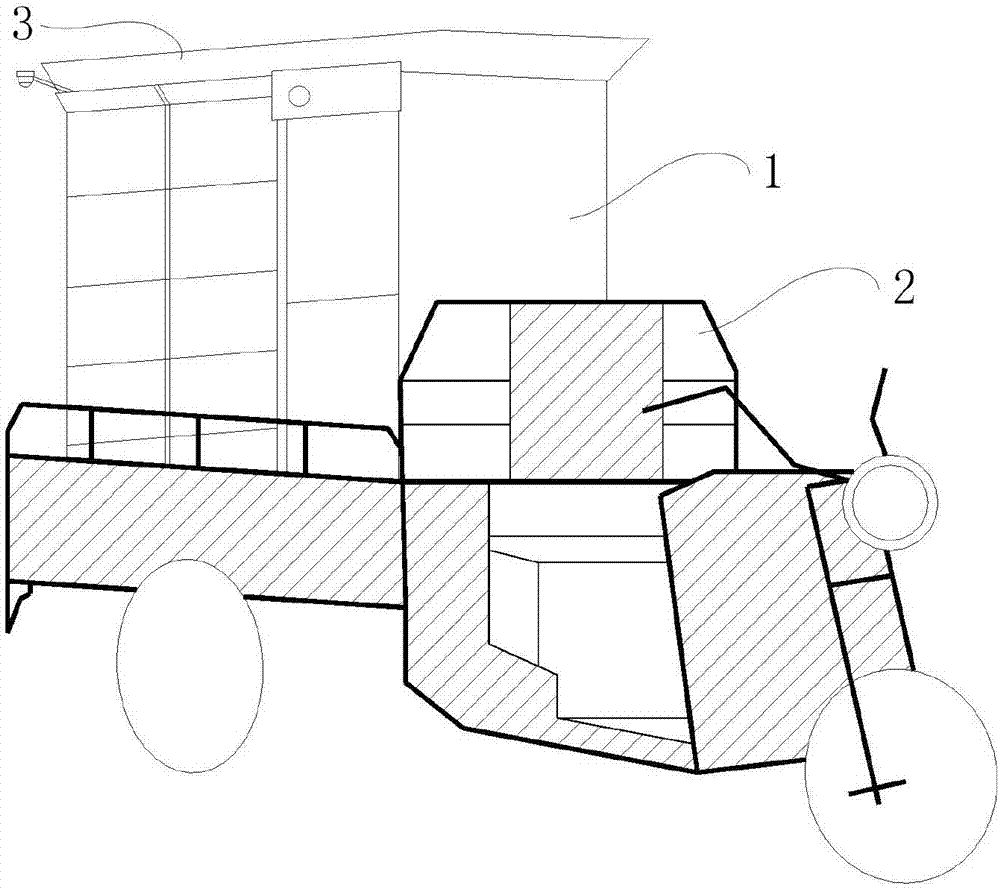

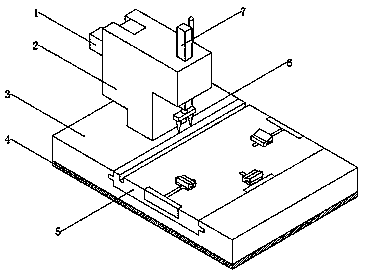

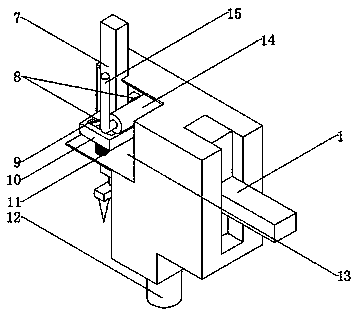

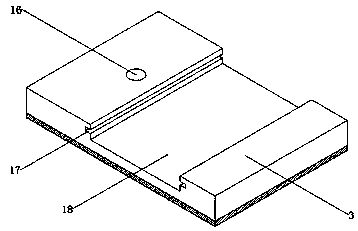

Mobile smart express cabinet

PendingCN107149313AReduce walking pathProvide work efficiencyCabinetsFittingEmbedded systemPublic place

The invention relates to the technical field of express cabinets, and aims to solve the problems that the conventional express cabinet cannot move and is inconvenient to use in a public place. In order to solve the problems, the invention provides a mobile smart express cabinet. The mobile smart express cabinet comprises a cabinet body, a moving mechanism and a solar power supply module, wherein the cabinet body is used for storing items; the moving mechanism is arranged at the bottom of the cabinet body and used for driving the cabinet body to move; the solar power supply module is used for supplying power to the cabinet body and the moving mechanism. Through movement of cabinet body under the driving of the moving mechanism, the cabinet body can be moved to a specified position in accordance with needs of a courier or a user, and the courier or the user can store or take out the items without needing to go to a mounting position of the express cabinet, so that the courier or the user is avoided from walking back and forth between the own position and the mounting position of the express cabinet, the walking path is shortened when the courier or the user stores and takes out the items, the working efficiency of the courier is improved, and a use experience of the user is improved.

Owner:ZHONGKE FUCHUANG BEIJING TECH

Bookbinding punching device

InactiveCN109677155AReduce lossEasy to punch holesMetal working apparatusSheet bindingPunchingEngineering

The invention relates to a bookbinding punching device. The bookbinding punching device comprises a stapler, a box body, a base, a rubber cushion, a sliding plate, a staple, a vertical column, linkagerods, sliding grooves, an extrusion plate, a spring, a rotary column, a transmission cabin, a rotary shaft, a control rod, a rotary groove, a sliding plate groove, a sliding plate slot, fixing pins,a staple groove, a sliding plate convex contact, fixing clamp convex contacts, fixing clamp sliding ways, fixing pin grooves and fixing clamps. The stapler is arranged at one end of the top of the boxbody, the transmission cabin is arranged in the other end of the top of the box body, the vertical column penetrates through the transmission cabin, the staple is mounted at the bottom of the vertical column, the extrusion plate is arranged at the bottom, in the transmission cabin, of the vertical column and integrally connected with the vertical column, the spring is mounted at the bottom of theextrusion plate, and the sliding grooves are formed in the top, on the two sides of the vertical column, of the extrusion plate. The bookbinding punching device is convenient to operate, manpower andmaterial resources are saved, and the device is safe and reliable.

Owner:临沂九一电子科技有限公司

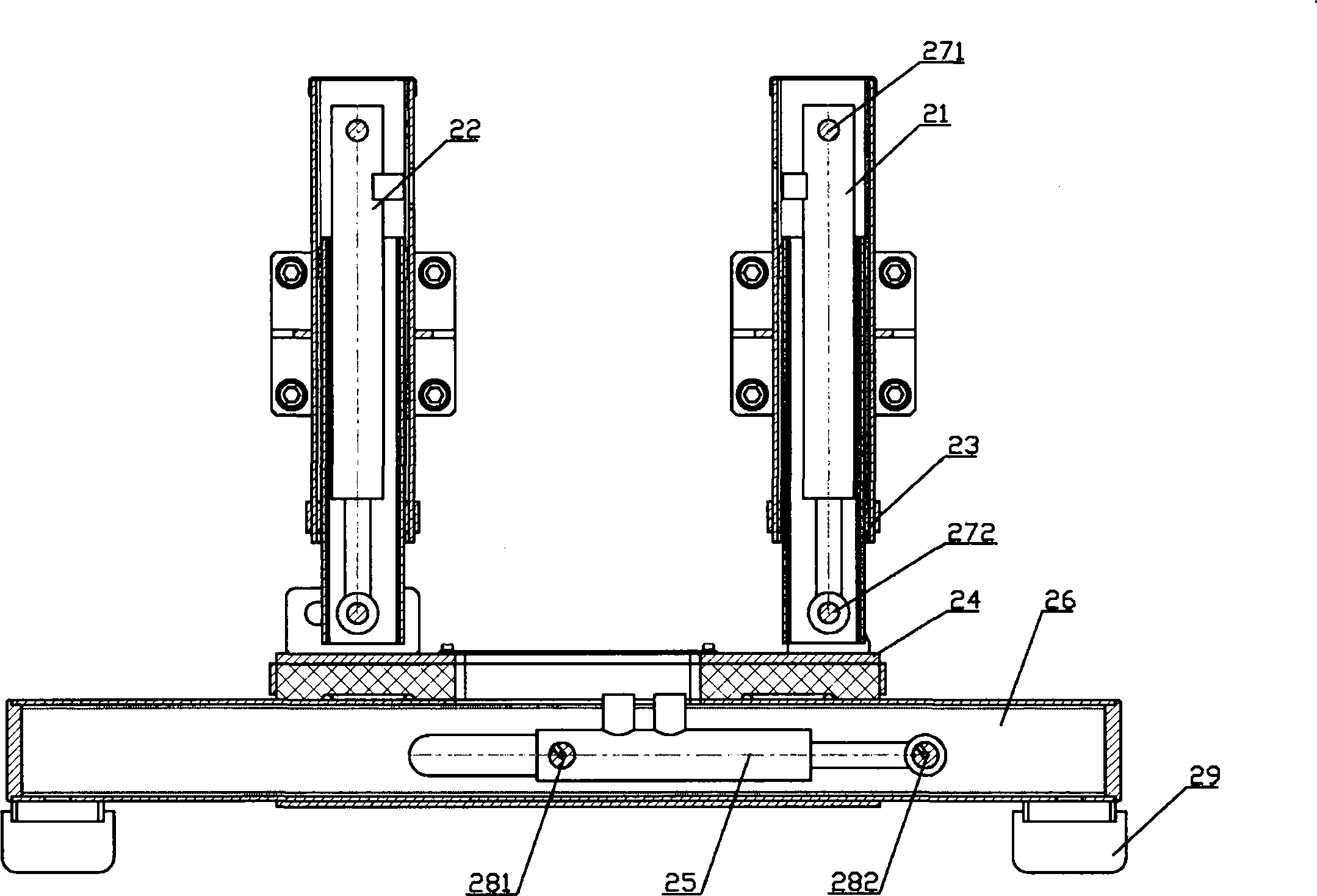

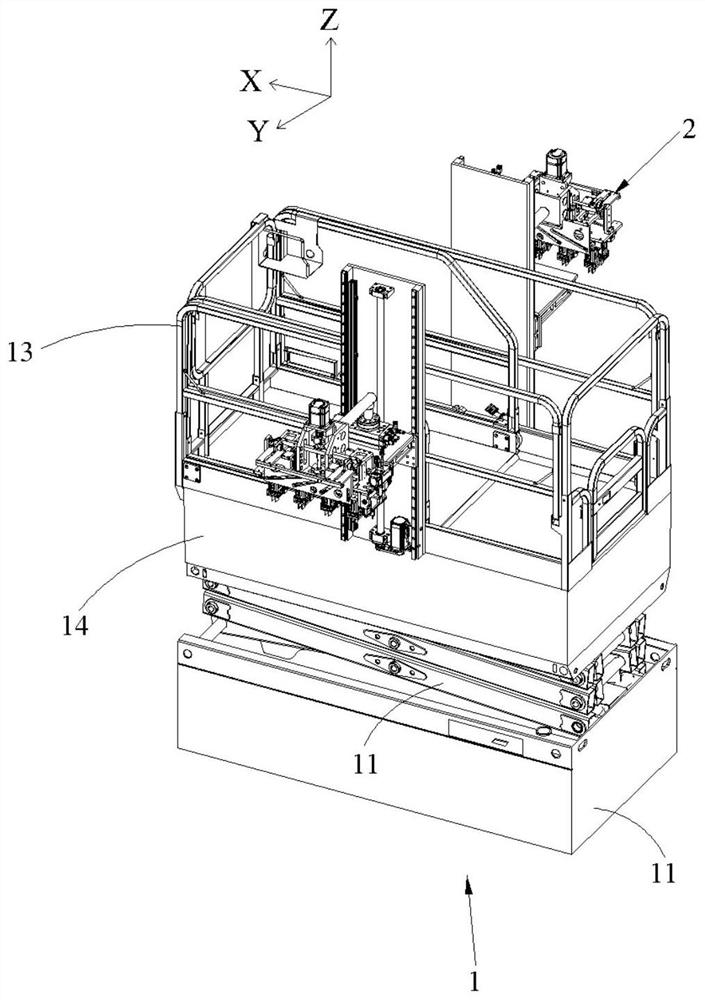

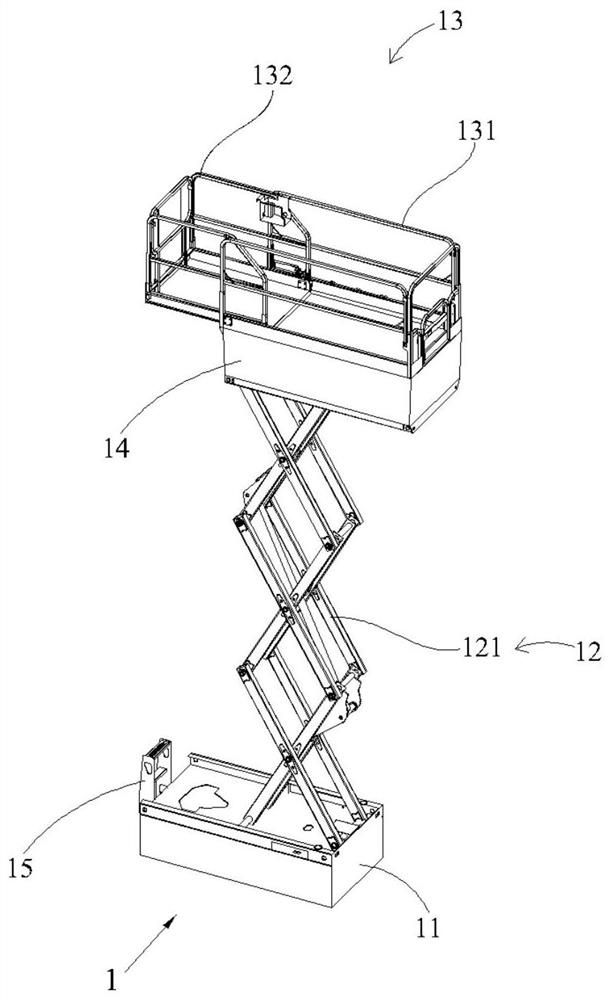

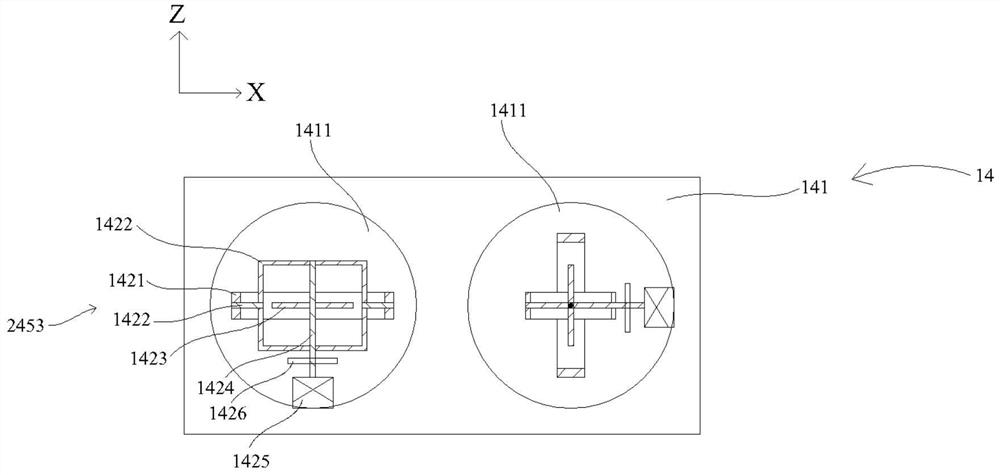

Electric power overhaul lifting device

ActiveCN111943093AImprove work efficiencyProvide work efficiencyLifting devicesStructural engineeringMechanical engineering

The invention discloses an electric power overhaul lifting device. The device comprises a base, a lifting cross assembly, a lifting platform assembly, at least two clamping mechanisms and a controller; the lifting cross assembly is movably arranged above the base; the lifting platform assembly is arranged above the lifting cross assembly and is in transmission connection with the lifting cross assembly; the two clamping mechanisms are fixedly connected to the two sides of the lifting platform assembly in the Y-axis direction correspondingly; and a balance sensor is arranged above the lifting platform assembly, and a balance assembly is fixedly connected below the lifting platform assembly. The balance assembly comprises a protective shell, at least one spherical cavity and at least one group of gyroscope balance modules, wherein the at least one spherical cavity is formed in the protective shell; and each gyroscope balance module is rotatably arranged in the corresponding cavity. According to the device, the lifting platform assembly is kept balanced when a maintainer works so that the maintainer can stably carry out electric power overhaul work, and the working efficiency of the maintainer is greatly improved.

Owner:国网江苏省电力有限公司滨海县供电分公司 +3

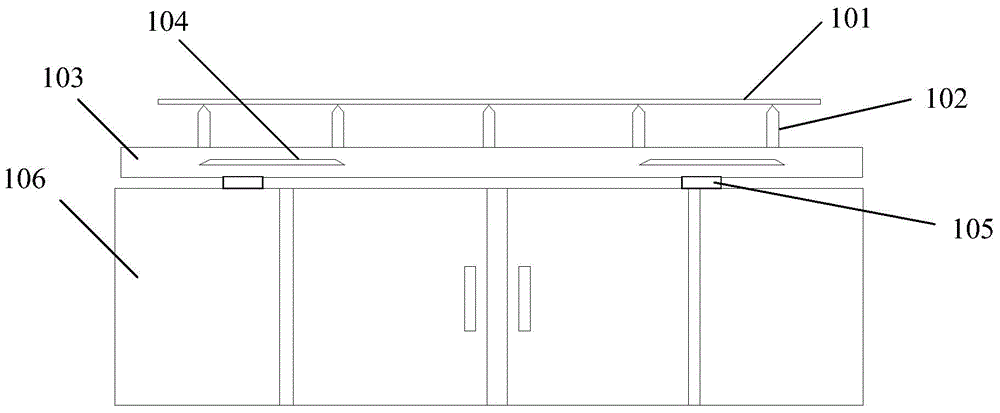

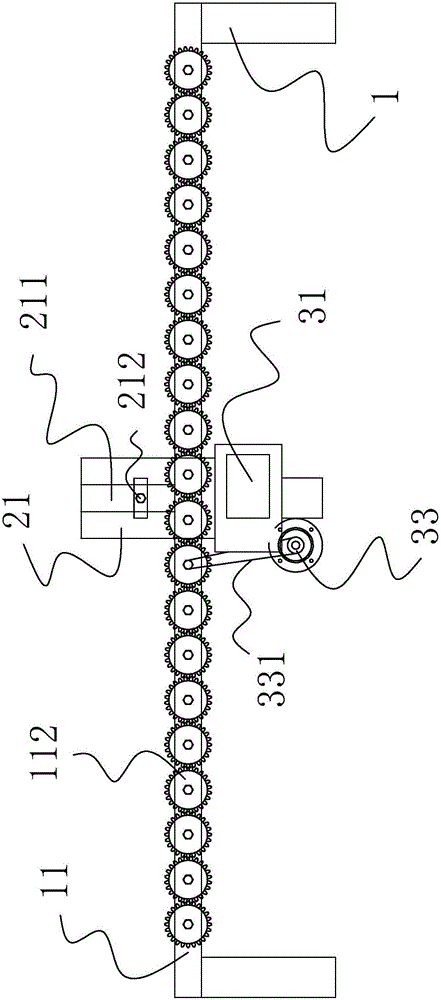

Cutting device for 3D printing end products

InactiveCN105856574ASave manpower and timeProvide work efficiencyAdditive manufacturing apparatusMetal working apparatusEngineering3D printing

The invention discloses a cutting device for 3D printing end products. The cutting device comprises a conveying platform, a cutting device and a control mechanism, wherein the conveying platform comprises a conveying part; the conveying part comprises a plurality of rolling shafts extending along front and back; the rolling shafts are arranged in parallel from left to right; the cutting device comprises a first adjusting frame, a second adjusting frame and a metal heating wire; the metal heating wire is overhead arranged above the conveying part through the first adjusting frame and the second adjusting frame; the control mechanism comprises a control panel, a heating part and a driving device. The cutting device for 3D printing end products is used for automatically separating and cutting the 3D printing end products and the metal plates adhered to the 3D printing end products and has the advantages of convenience, labor-saving and time-saving effects and capability of increasing working efficiency. Meanwhile, the 3D printing end products cut by the cutting device can be prevented from being damaged and deformed; the construction for an ultra-thick supporting bottom is not required in the 3D printing process; the 3D printing supplies are greatly saved; the cutting device provided by the invention is used for cutting the 3D printing end products.

Owner:佛山市晗宇科技有限公司

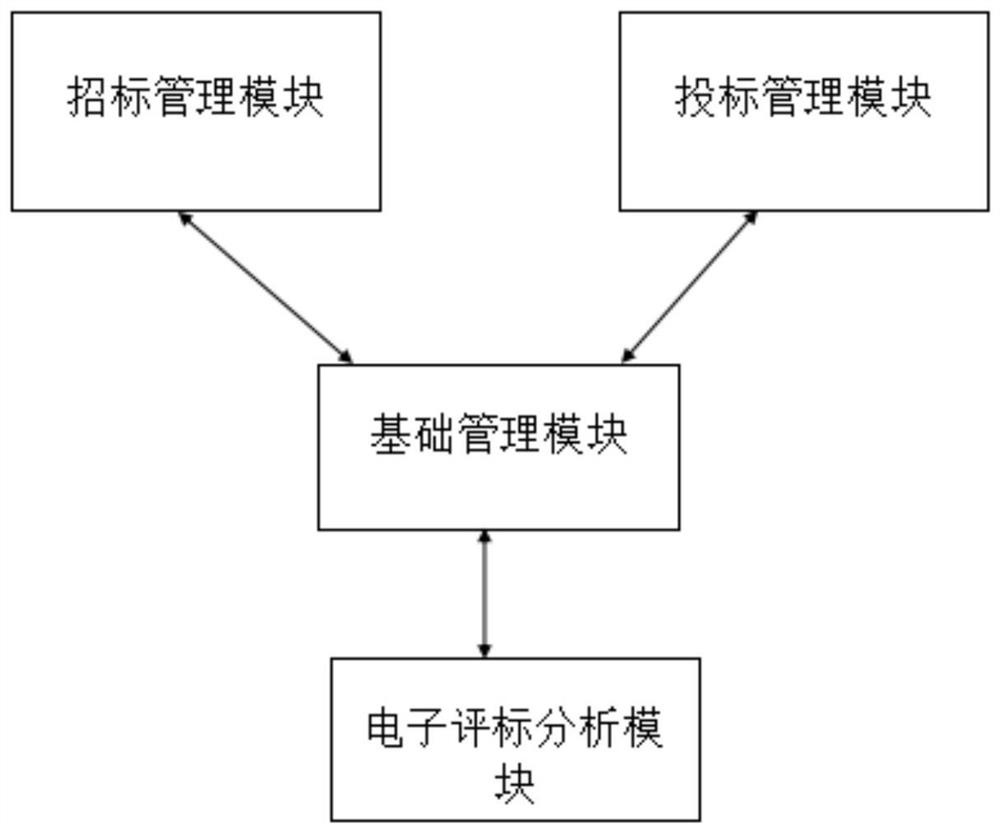

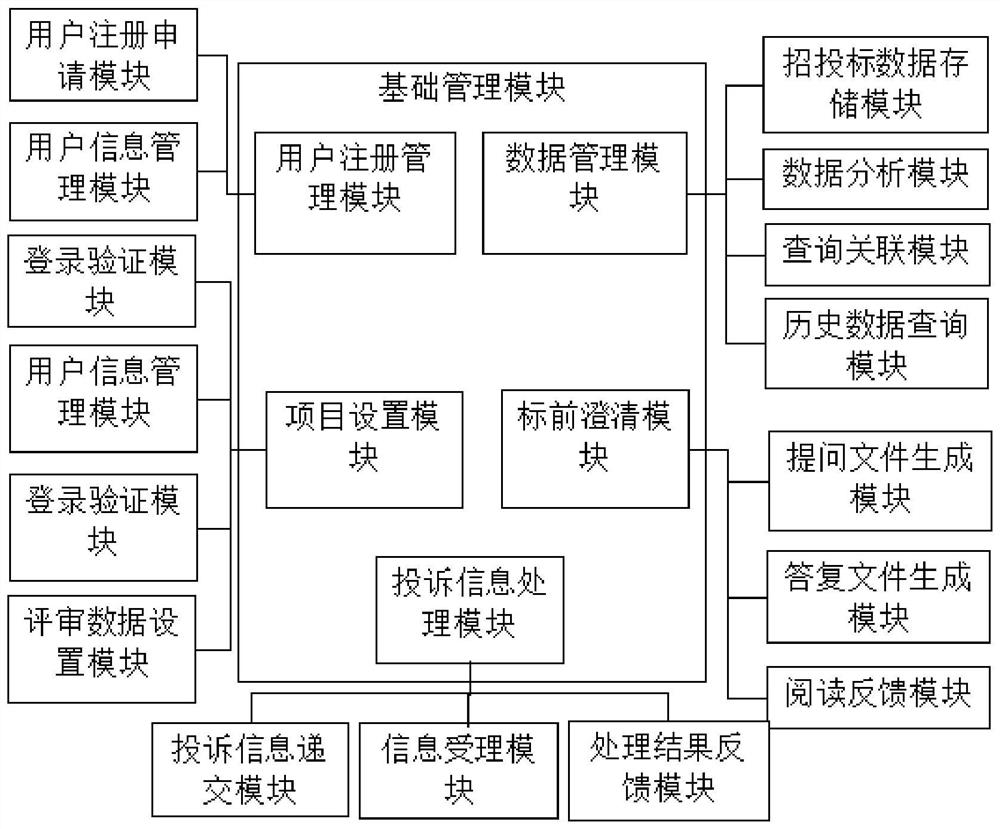

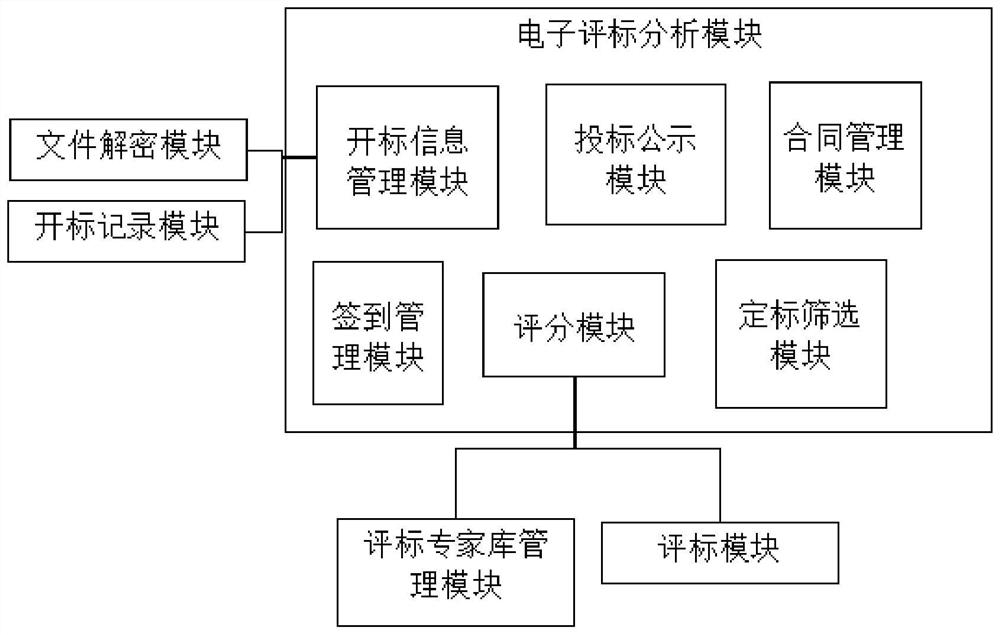

Electronic bidding and tendering management system based on big data

PendingCN114708072ALow costProvide work efficiencyDigital data information retrievalDigital data protectionManagement efficiencyManagement system

The invention provides an electronic bidding and tendering management system based on big data. The electronic bidding and tendering management system comprises a basic management module, a bidding management module, a tendering management module and an electronic bid evaluation analysis module, according to the invention, different types of user information are managed and verified through the basic management module, bid invitation data are analyzed and managed to generate various reports, and suppliers and bid invitation institutions can perform question asking, clear reply and complaint information tracking through the basic management module; the bid invitation institution can upload bid invitation files and supplementary file data through the bid invitation management module, and the bid invitation management module carries out pre-auditing on bid invitation qualification and announces bid invitation process information; the bidding management module is used for a supplier to apply, encrypt and upload bidding data, maintain and manage product information and manage and check bidding guarantee cost; and the electronic bid evaluation analysis module is used for carrying out record management, bid evaluation and contract signing on bid opening information. The bid inviting and tendering management time is saved, and the bid inviting and tendering management efficiency is improved.

Owner:西安翻译学院

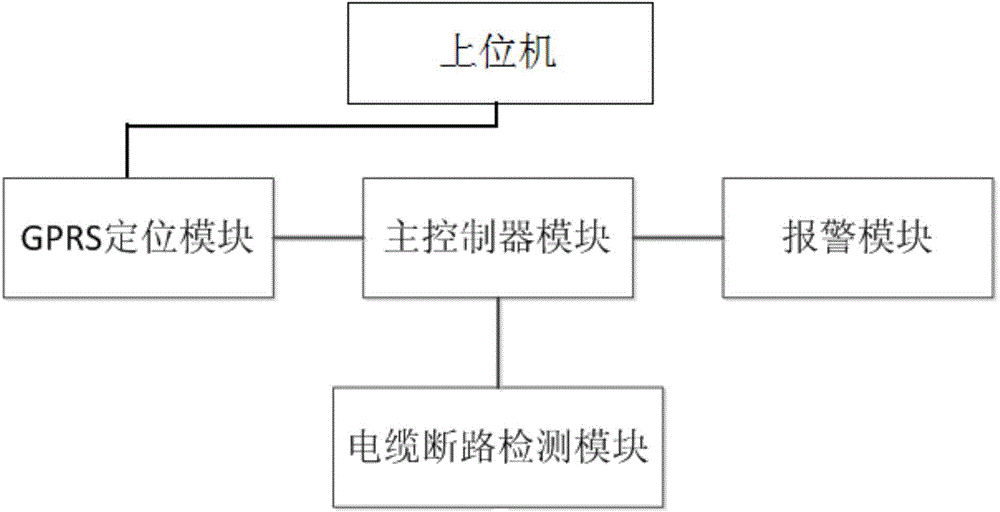

Cable open-circuit fault locating device

The invention discloses a cable open-circuit fault locating device. The device comprises a host computer and a cable open-circuit detector. The cable open-circuit detector includes a main controller module, a cable open-circuit detection module, a GPRS location module, an alarm module and a power supply module, wherein the main controller module is connected with the cable open-circuit detection module, the GPRS location module and the alarm module respectively; the power supply module is connected with the main controller module, the cable open-circuit detection module, the GPRS location module and the alarm module respectively; and the cable open-circuit detector is connected with the host computer through the GPRS location module. By using the cable open-circuit fault locating device provided by the invention, the specific location of a cable open-circuit fault can be determined at the first time to inform the first-aid repair personnel to get to the position of the fault to perform first-aid repair, so that the work load of the working personnel is reduced, and the working efficiency of the working personnel is increased, thereby improving the service quality of power supply.

Owner:STATE GRID CORP OF CHINA +2

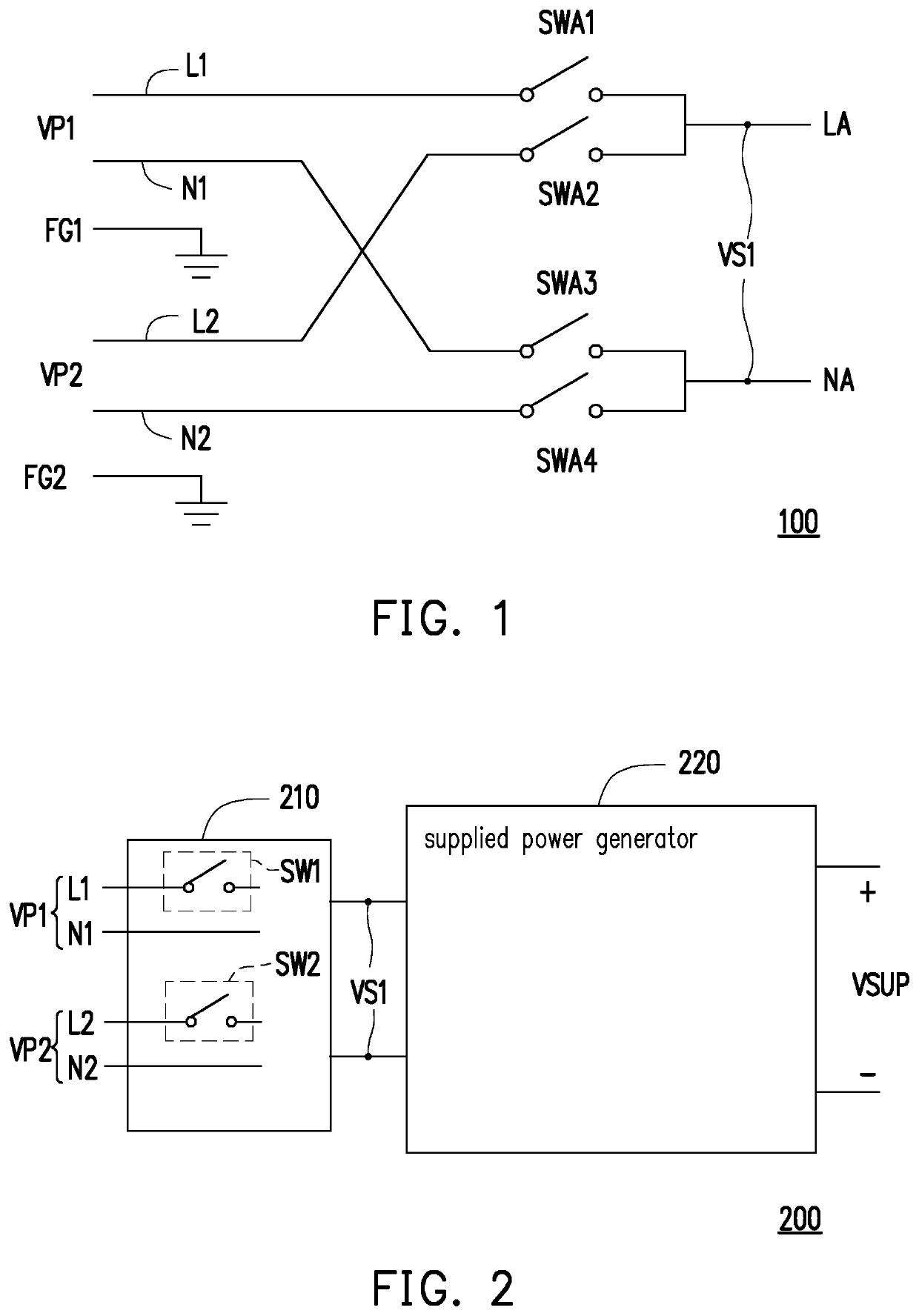

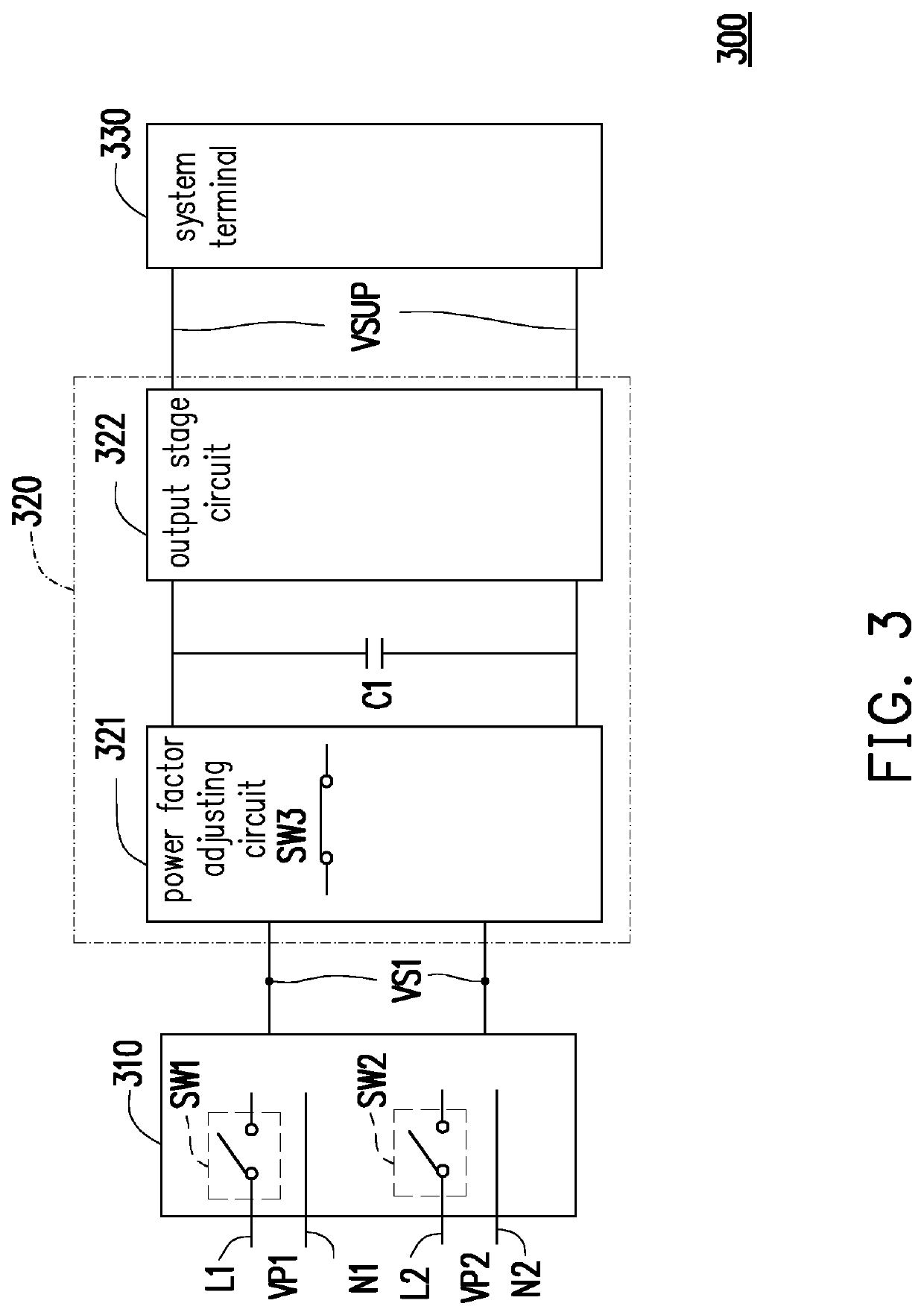

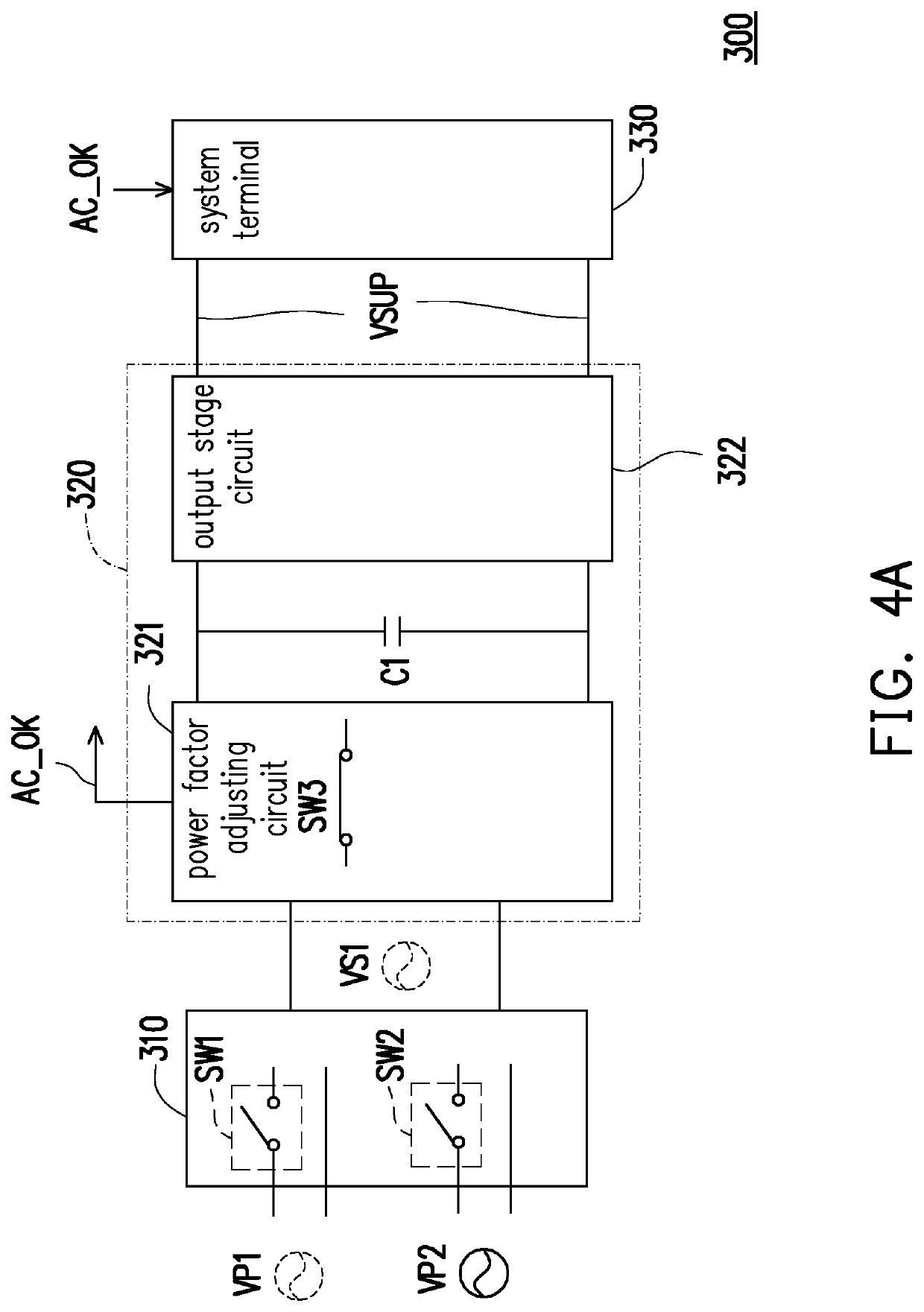

Power supply apparatus and power supplying method thereof

ActiveUS20200144854A1Avoid influenceEffectively decrease the electric arc phenomenonEfficient power electronics conversionEmergency protective circuit arrangementsElectric generatorCut-off

A power supply apparatus and a power supplying method thereof are provided. The power supply apparatus includes a power switch and a supplied power generator. The power switch respectively receives a first power and a second power through a first switch and a second switch. The supplied power generator converts the first power or the second power to generate a supplied power. When the supplied power generator judges the first power being cut off, during a first time period, the first switch is cut off and a voltage converting operation of the supplied power generator is stopped. During a second time period, the second switch is turned on, and the voltage converting operation of the supplied power generator is restarted after the second switch being turned on.

Owner:WIWYNN CORP

Automatic wire electrode penetrating mechanical arm for linear cutting machine tool

An automatic wire electrode penetrating mechanical arm for a linear cutting machine tool comprises an upright. An upper wire stand and a lower wire stand are arranged on the upright. An upper mechanical arm is arranged on the upper wire stand and provided with a fixing frame. The fixing frame is provided with a fixing base. A rotary base capable of rotating is arranged on the fixing base and a rotary line of the rotary base is controlled by a first motor. The rotary base is provided with a first telescopic rod and the telescopic motion of the first telescopic rod is controlled by a telescopic driving piece. A first wire electrode clamp is arranged at one end of the first telescopic rod and the clamping motion of the first wire electrode clamp is controlled by a first clamping motor. A lower mechanical arm is arranged on the lower wire stand and provided with a sliding rail. The sliding rail is provided with a movable sliding table and the movement motion of the sliding table is controlled by a sliding table driving piece. The sliding table is provided with a second telescopic rod. The second telescopic rod is connected with a second wire electrode clamp through a connecting rod. A wire feeding structure is further installed on the upright and comprises a fixing shaft and a wire arrangement guide wheel. According to the automatic wire electrode penetrating mechanical arm, penetration of wire electrodes is automatic and work efficiency is improved.

Owner:NINGBO HUIJIN METAL PRODS

Automated grinding and polishing equipment for processing plate type curved glass structural members

ActiveCN104354085AOvercoming the single function of the equipmentProvide work efficiencyEdge grinding machinesGrinding drivesMechanical engineeringGrinding wheel

The invention discloses automated grinding and polishing equipment for processing plate type curved glass structural members. The equipment comprises a work table, a bearing device which is used for bearing the structural members and arranged on the work table, and at least one grinding and polishing device which is arranged around the bearing device on the work table, wherein the grinding and polishing device comprises a rotating shaft I, at least one grinding wheel or polishing wheel which is mounted on the rotating shaft I, a first driving device which is used for driving the grinding wheel or the polishing wheel to rotate in a horizontal direction, and a regulating device which is used for regulating the position of the grinding wheel or the polishing wheel in horizontal and vertical directions. The invention provides the automated grinding and polishing equipment for processing the plate type curved glass structural members. The structure of the equipment is simple, and the equipment is convenient to operate; the grinding processing and the polishing processing can be performed on the structural members on the same equipment at the same time; and through automated processing of the structural members, the work efficiency is greatly improved, and the processing precision of the structural members is improved.

Owner:张宋林

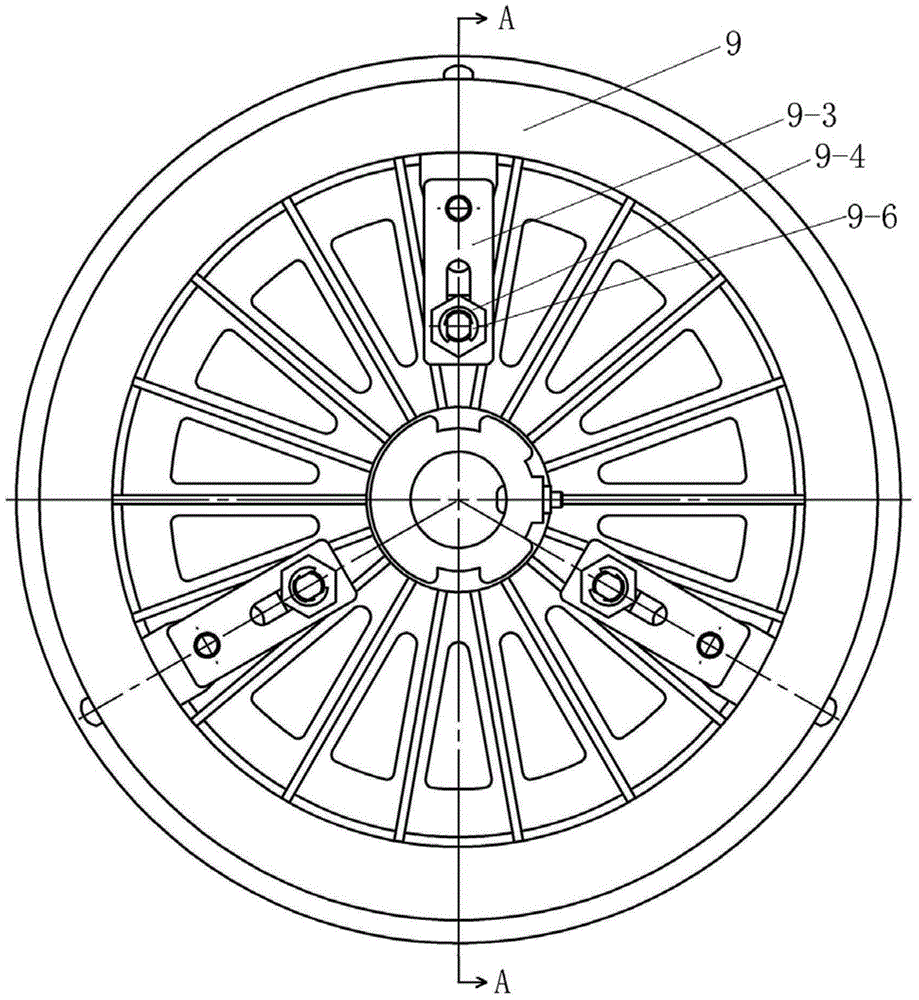

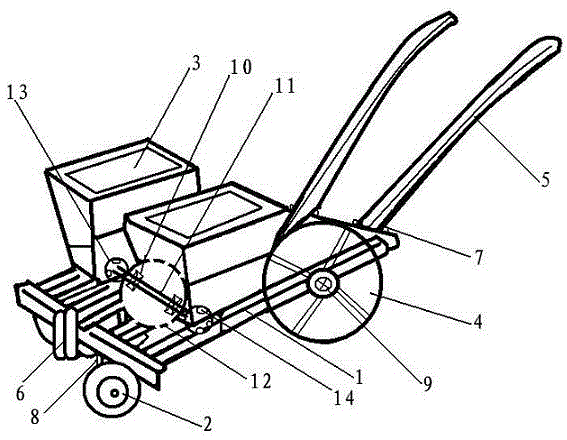

Two-row sower with rolling wheel device arranged inside

InactiveCN104982126AReduce labor intensityProvide work efficiencyRegular seed deposition machinesEngineeringDrive wheel

The invention relates to a two-row sower with a rolling wheel device arranged inside. The two-row sower is composed of a rack, a guide wheel, hoppers, a bearing wheel, handles and a traction hook. The traction hook at the front end of the rack is fixed in a welded mode, the rear end of the rack and the handles are fixed through a screw rod, the lower portion of the front end of the rack is connected with the guide wheel through a universal through-connection sleeve, the rear end of the rack is connected with the bearing wheel through a bearing pedestal, and a set of hoppers is inserted in the upper portion of the rack side by side. The two-row sower is characterized in that the lower portion of the rack is connected with the left-right bearing pedestal through the screw rod, a supporting shaft is inserted in the left-right bearing pedestal, the middle of the supporting shaft is sleeved with a drive wheel, the two ends of the supporting shaft are sleeved with rolling wheels respectively, and a containing vessel is arranged on the rolling wheels. The two-row sower with the rolling wheel device is simple in structure and convenient to operate, sowing operation is completed, the labor intensity of farmers is reduced, and operation efficiency is improved.

Owner:苏细调

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com