Vibration tamping drilling device for water conservancy and hydropower

A technology of water conservancy, hydropower, and drilling equipment, which is applied to roads, road repairs, roads, etc., can solve problems such as difficult leveling, low manual operation efficiency, time-consuming and laborious, etc., and achieve the effect of reducing vibration and improving worker operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

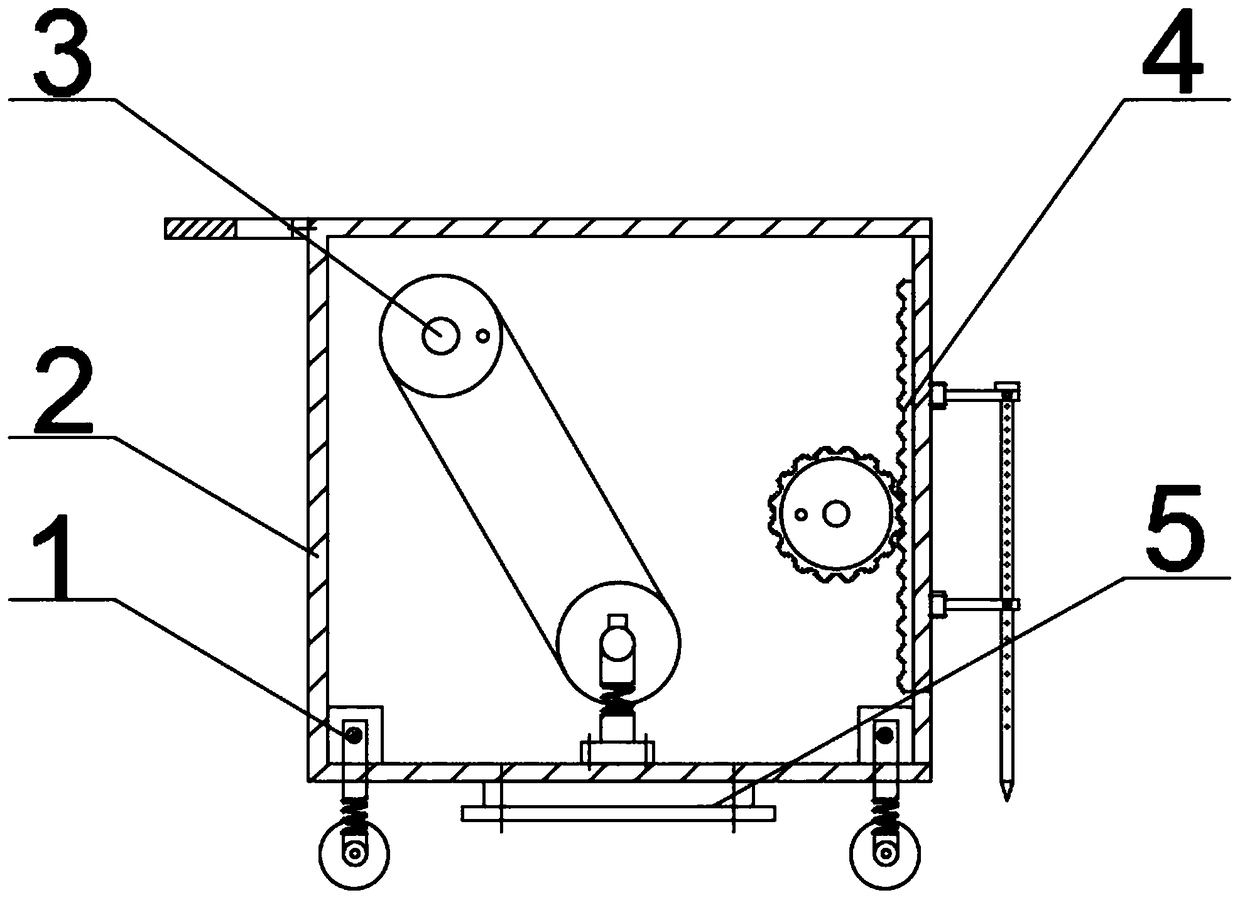

[0051] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 This embodiment is described. The present invention relates to a compacting tool, more specifically, a vibration compacting drilling device for water conservancy and hydropower, including a rotatable damping wheel mechanism 1, a frame mechanism 2, an eccentric block vibration mechanism 3, Drilling mechanism 4, tamping hammer 5, device can cut off the branch that prunes, and device can move, and reduces vibration in the process of moving, and device can tamp road surface, and device can drill, and provides workman's working efficiency.

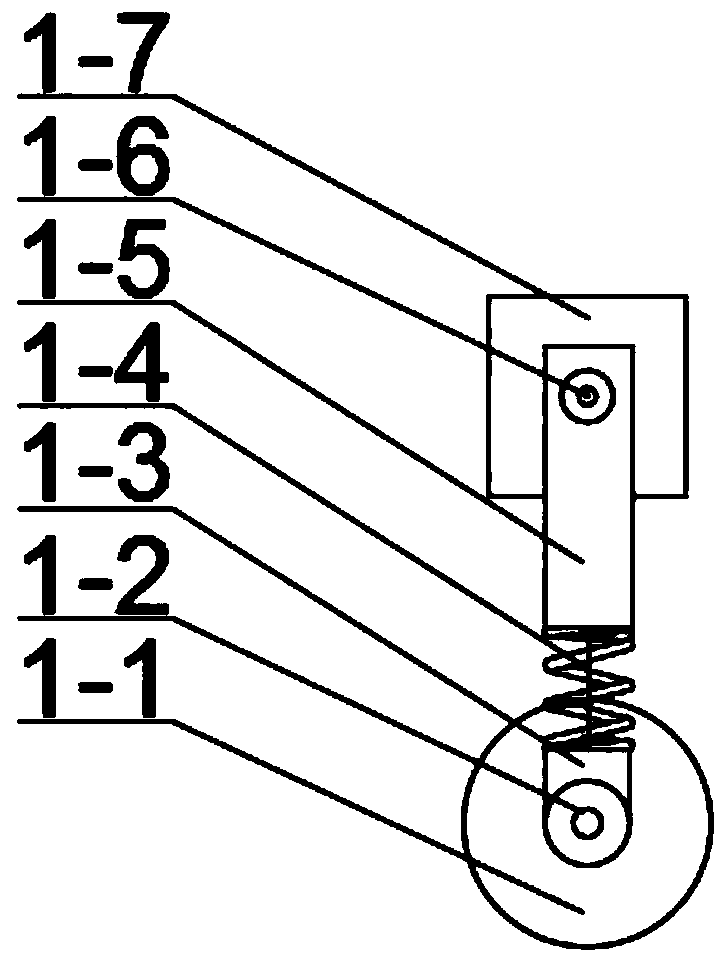

[0052] The rotatable damping wheel mechanism 1 includes a rubber wheel 1-1, a lower locking buckle I1-2, a lower leg 1-3, a spring I1-4, an upper leg 1-5, an upper locking buck...

specific Embodiment approach 2

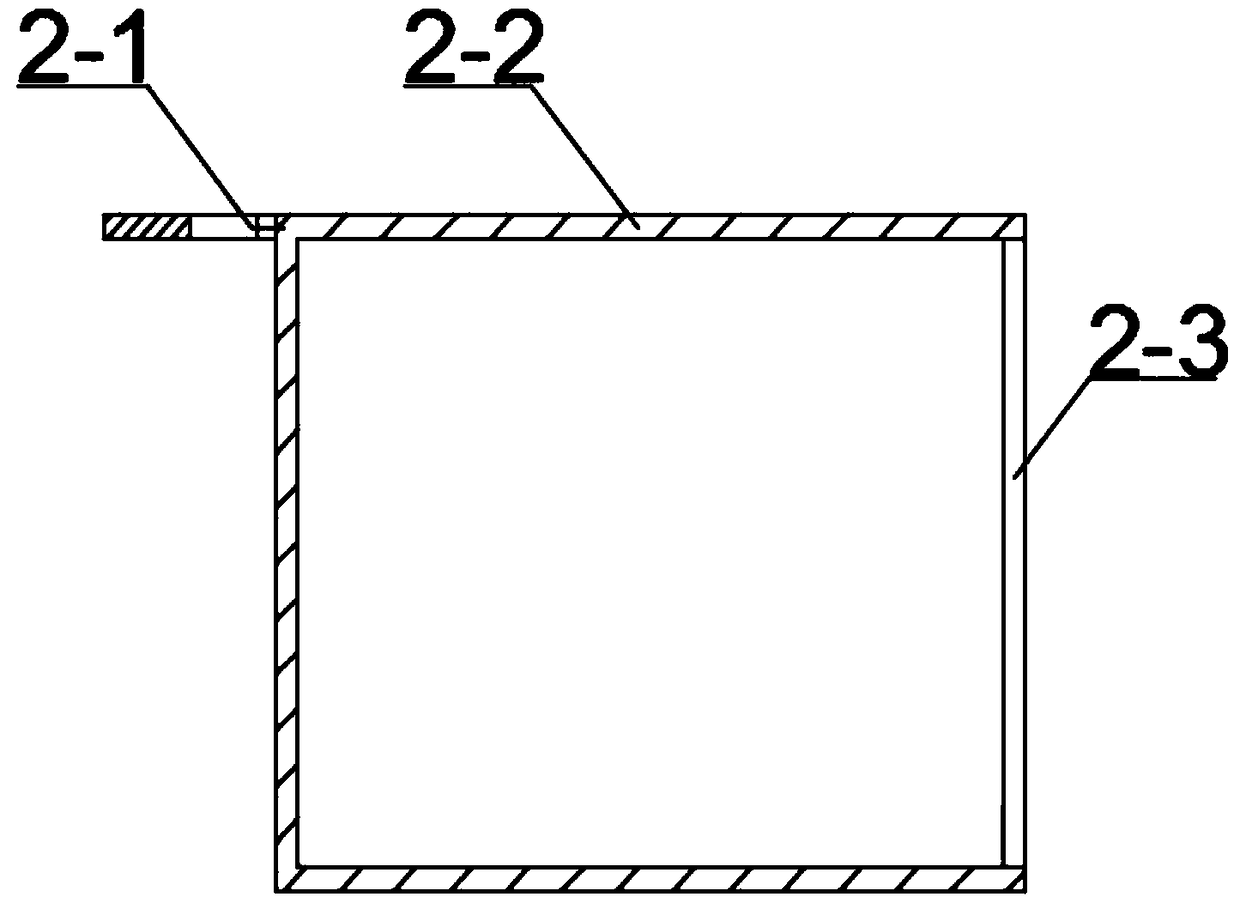

[0070] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the frame mechanism 2 is stainless steel.

specific Embodiment approach 3

[0071] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 This embodiment will be described, and this embodiment will further describe Embodiment 1. The handle 2-1-1 is provided with an anti-slip sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com