Track-type multi-head rock drilling machine for mine

A technology of rock drilling rigs and crawlers, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., which can solve problems such as large noise and dust, equipment damage, time-consuming and labor-intensive, etc., to improve work efficiency and reduce labor intensity , to ensure the effect of rock drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is attached Figure 1 to Figure 4 The present invention is described in detail, and this embodiment can make it easier for those skilled in the art to understand the present invention, but this embodiment does not limit the present invention.

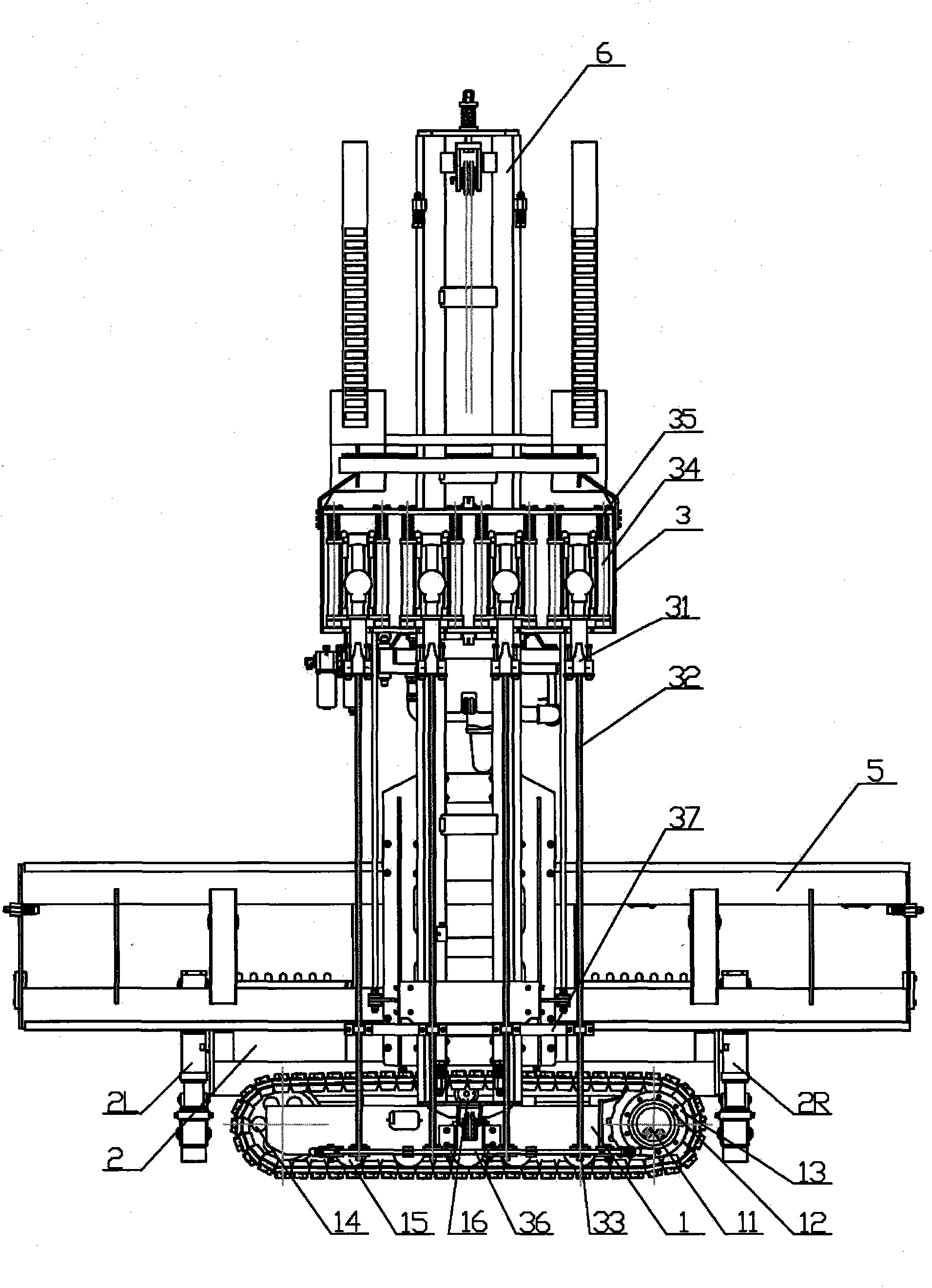

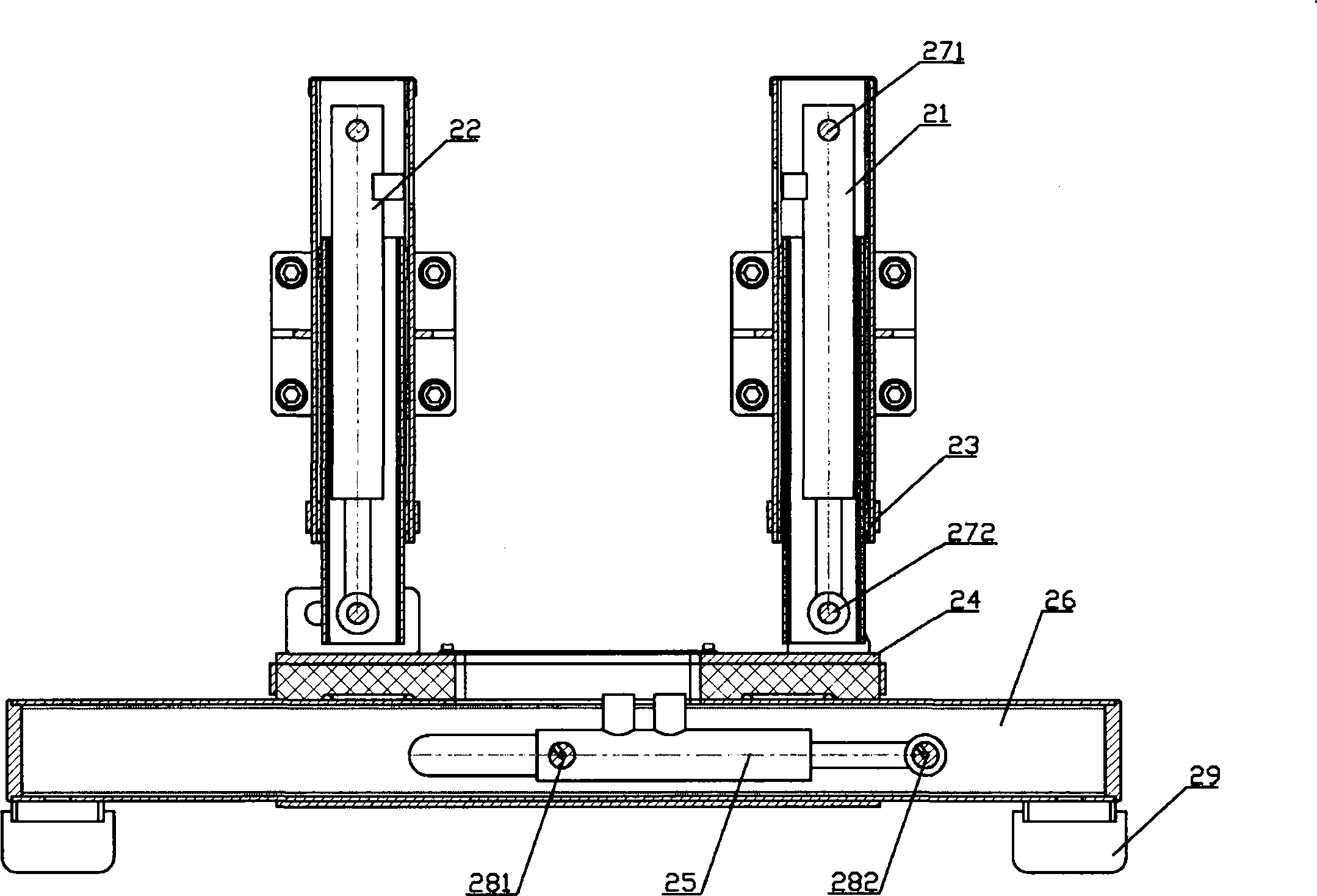

[0021] figure 1 Shows the front view of the drilling rig of the present invention, including crawler belt traveling device 1, vehicle frame & drilling fine-tuning device 2, rock drilling device 3, traverse device 5, and drilling feed device 6.

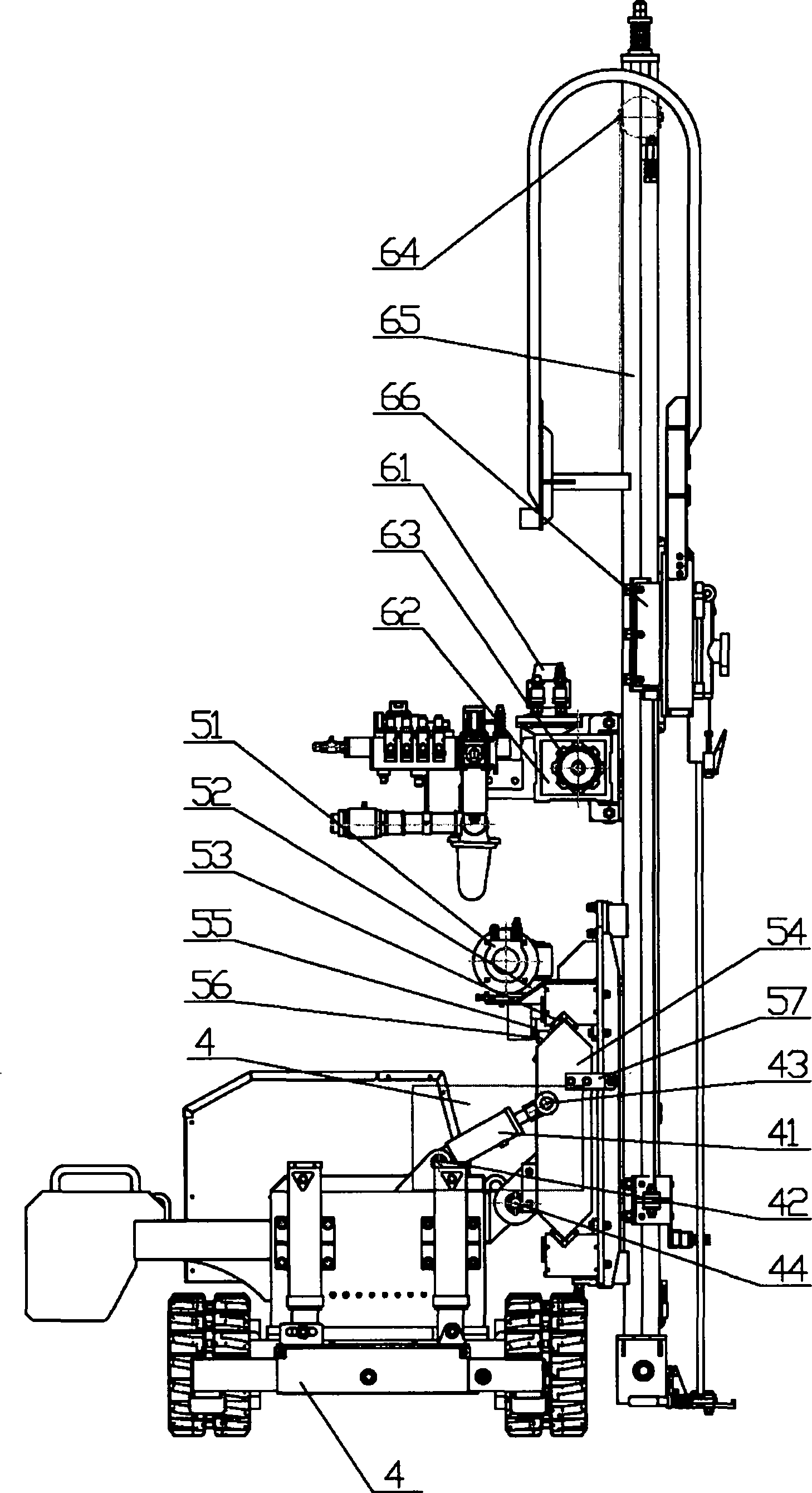

[0022] Wherein, three components of rock drilling device 3, traverse device 5 and drilling feed device 6 are assembled and passed through column adjusting device 4 ( figure 2 Shown) is connected with vehicle frame & drilling fine-tuning device 2, and then placed on the crawler walking device 1 by vehicle frame & drilling fine-tuning device 2, promptly constituted this crawler multi-head rock drilling rig.

[0023] Such as figure 1 As shown, the crawler running device 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com