Patents

Literature

94results about How to "Achieve drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

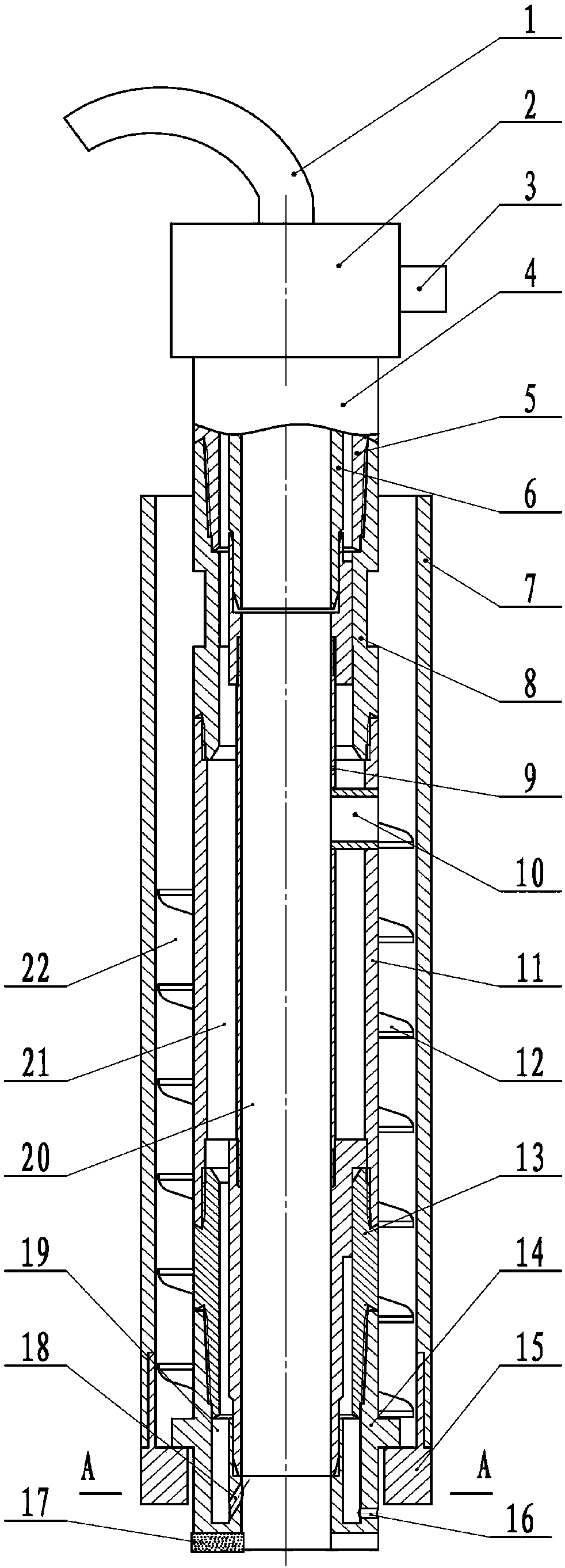

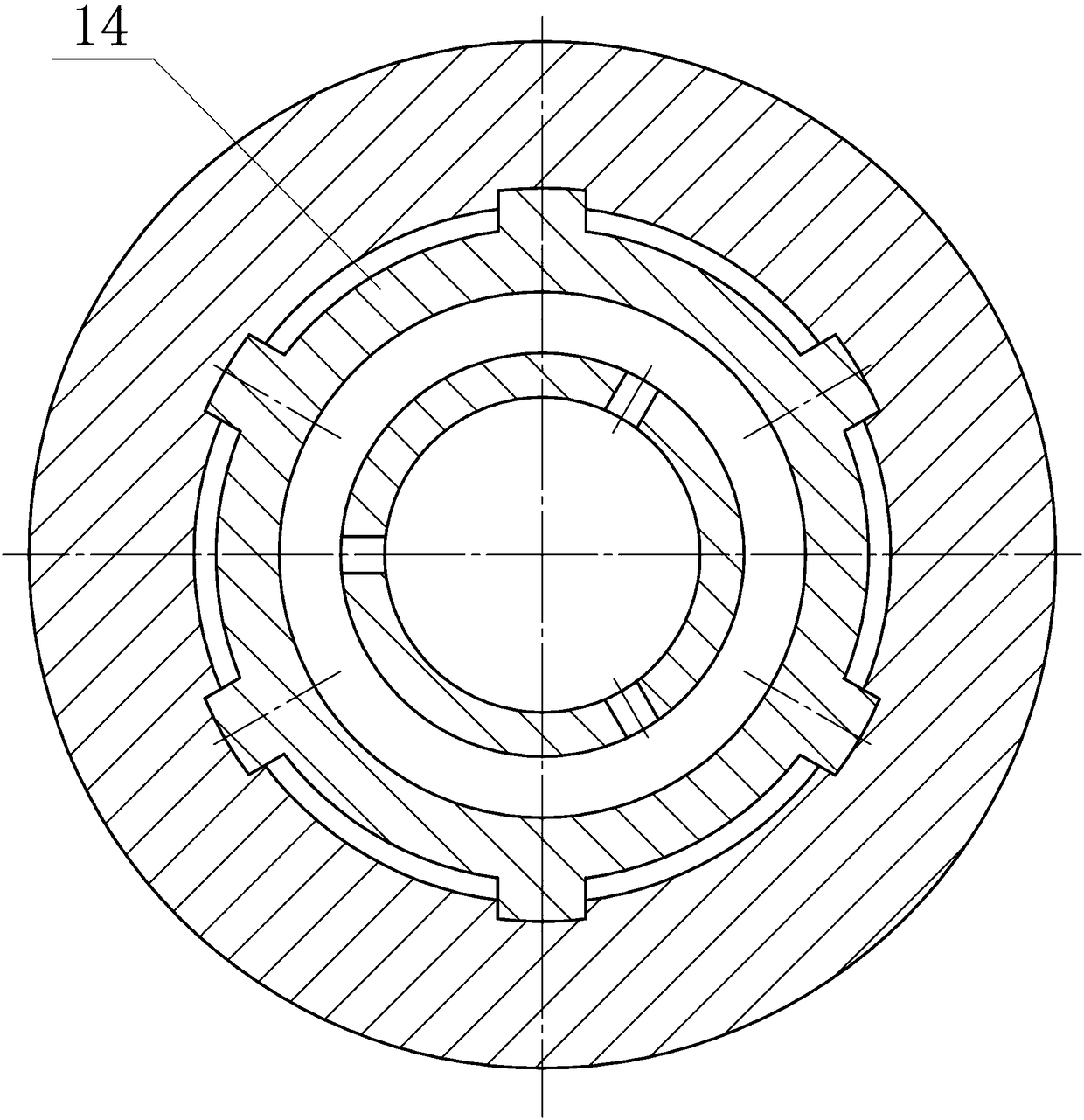

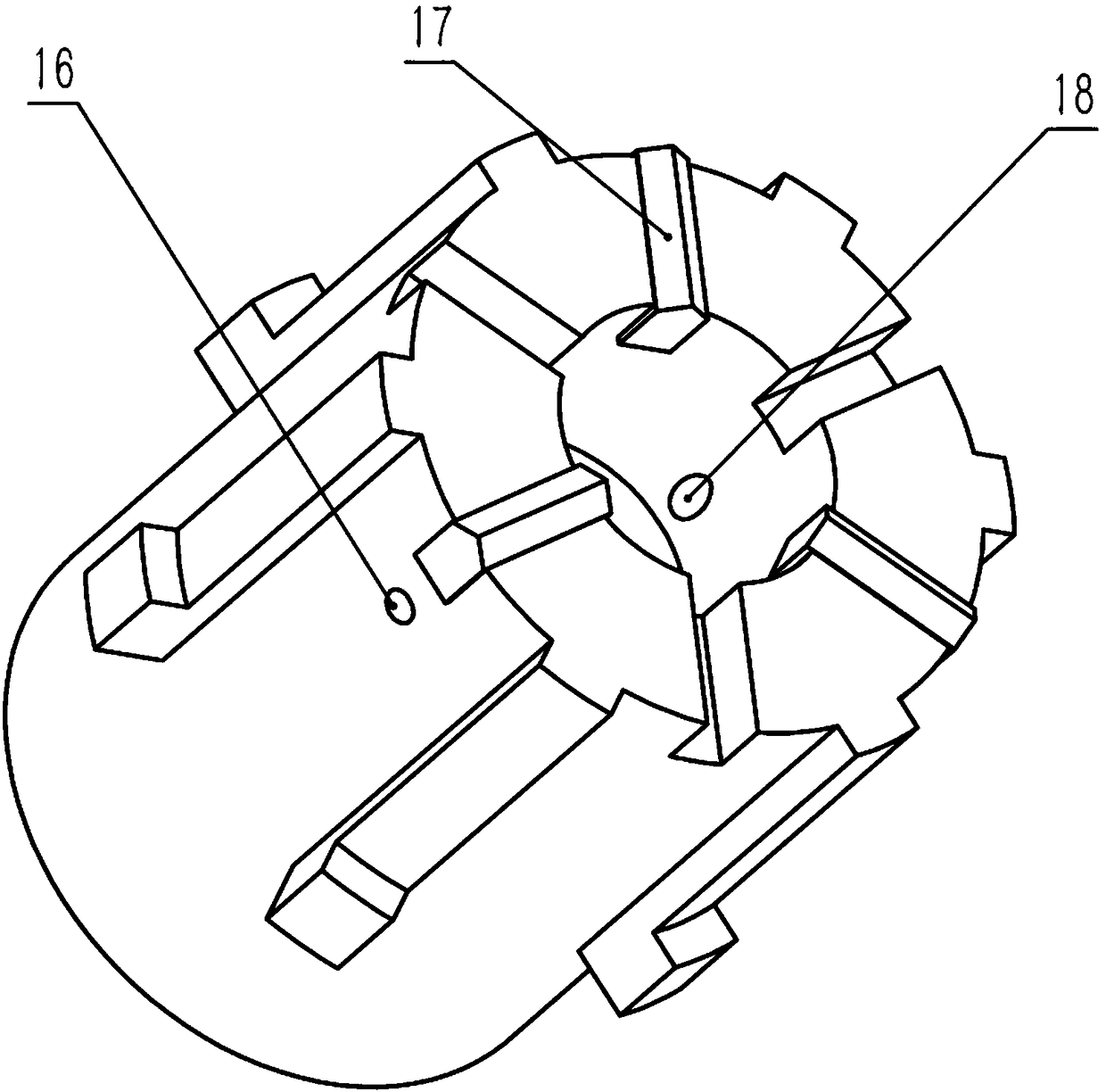

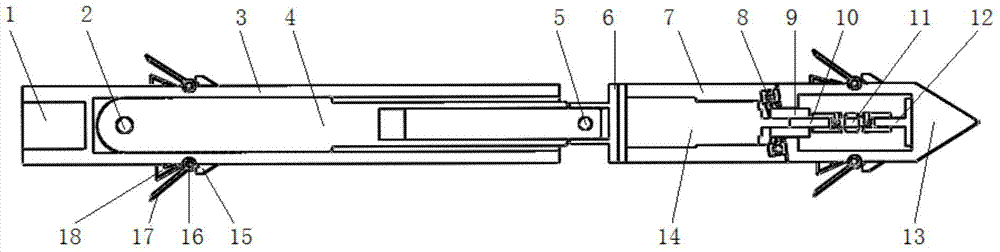

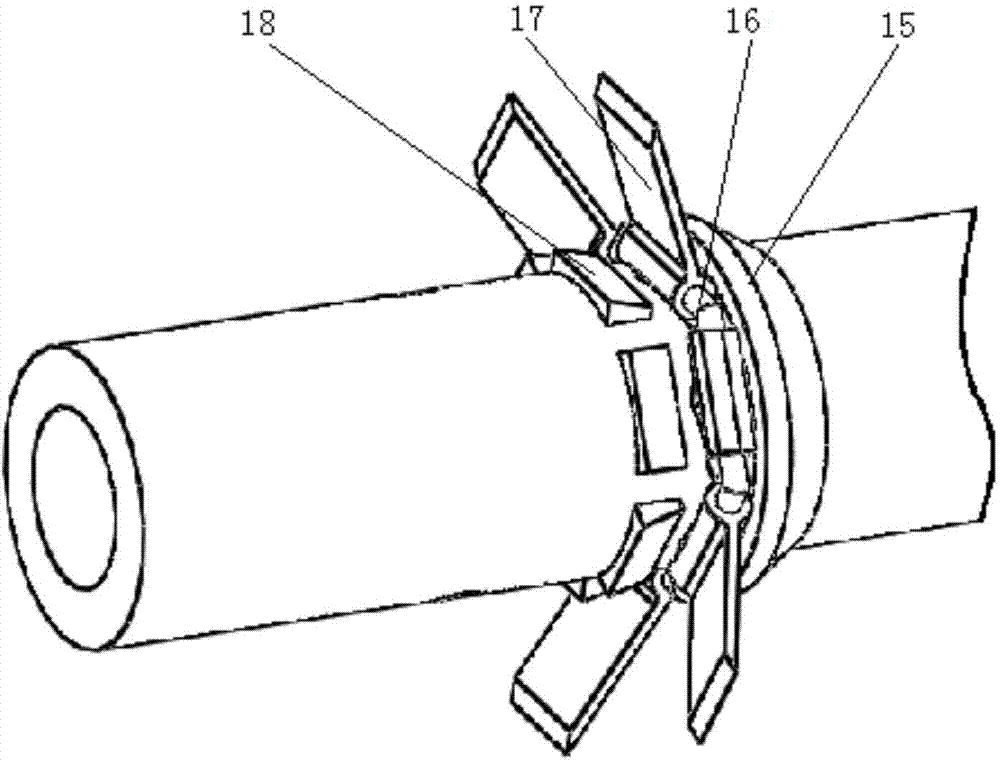

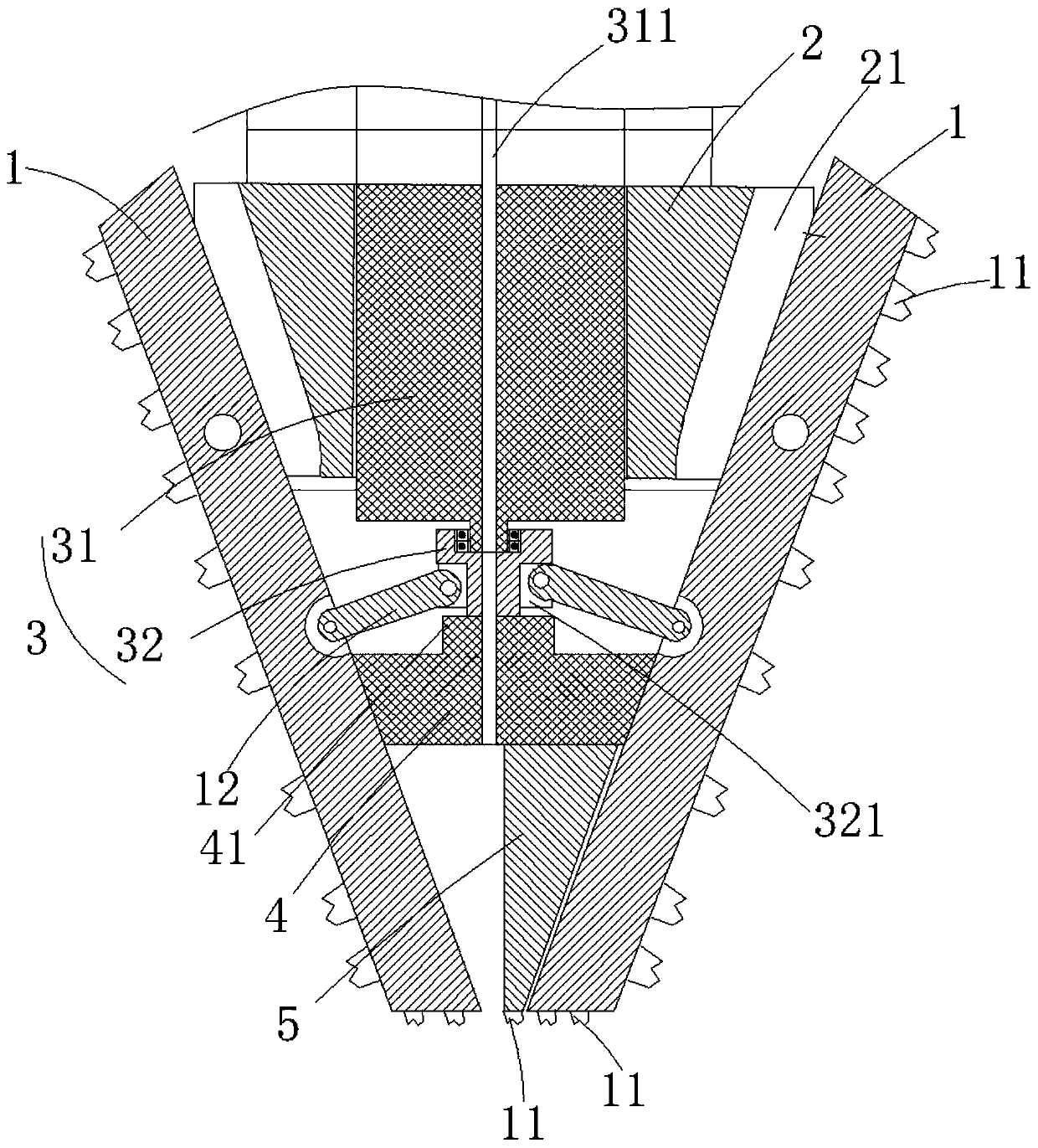

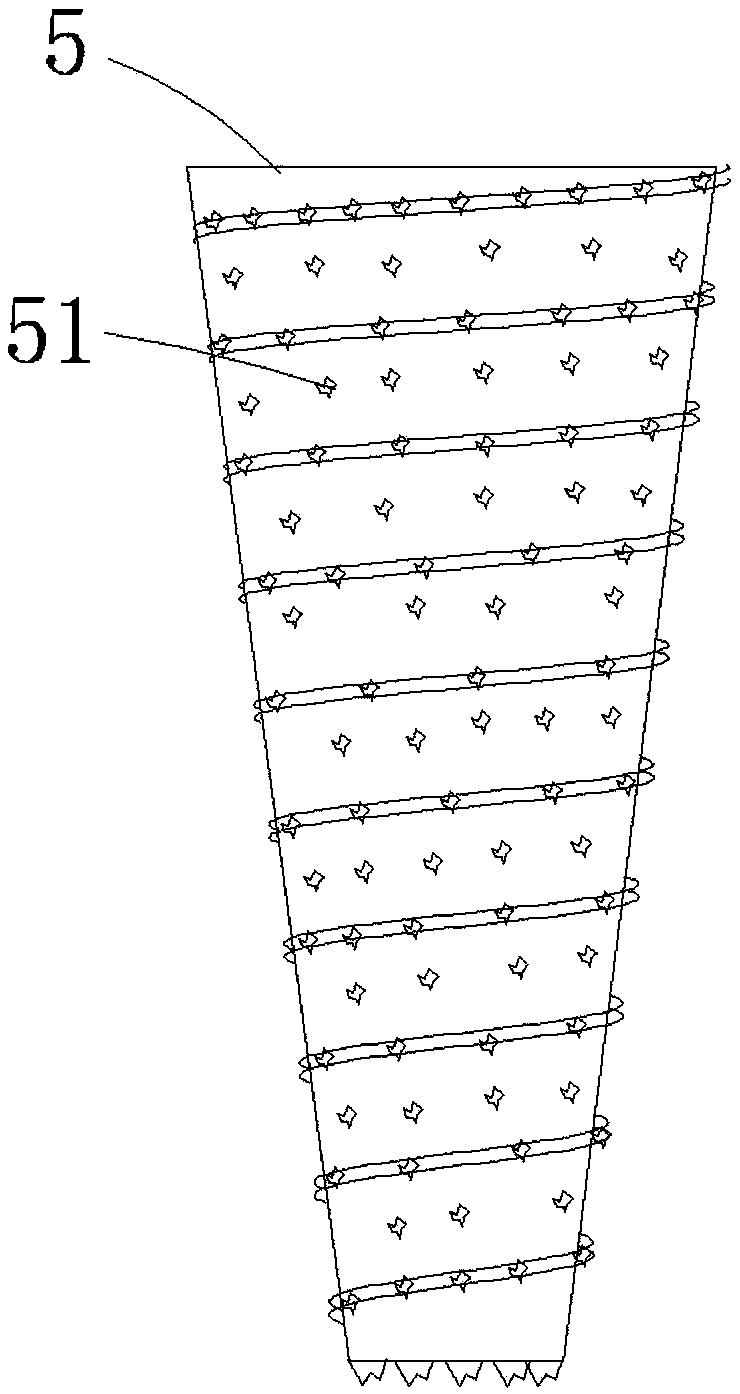

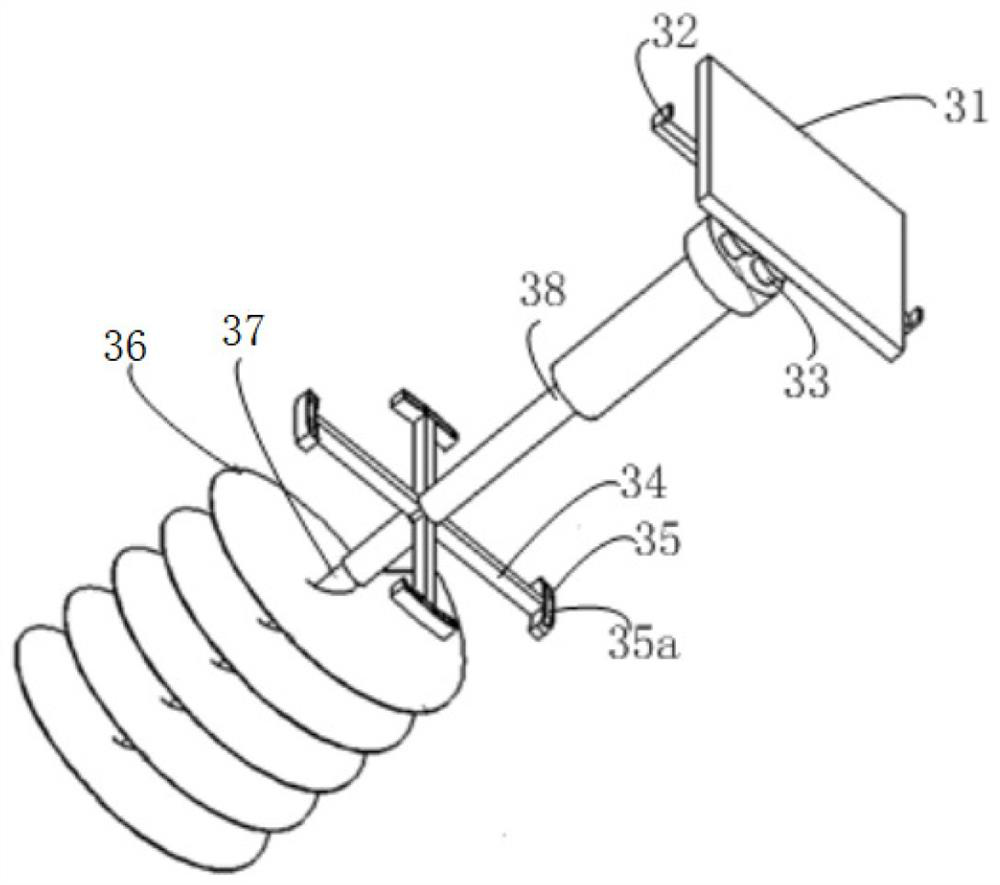

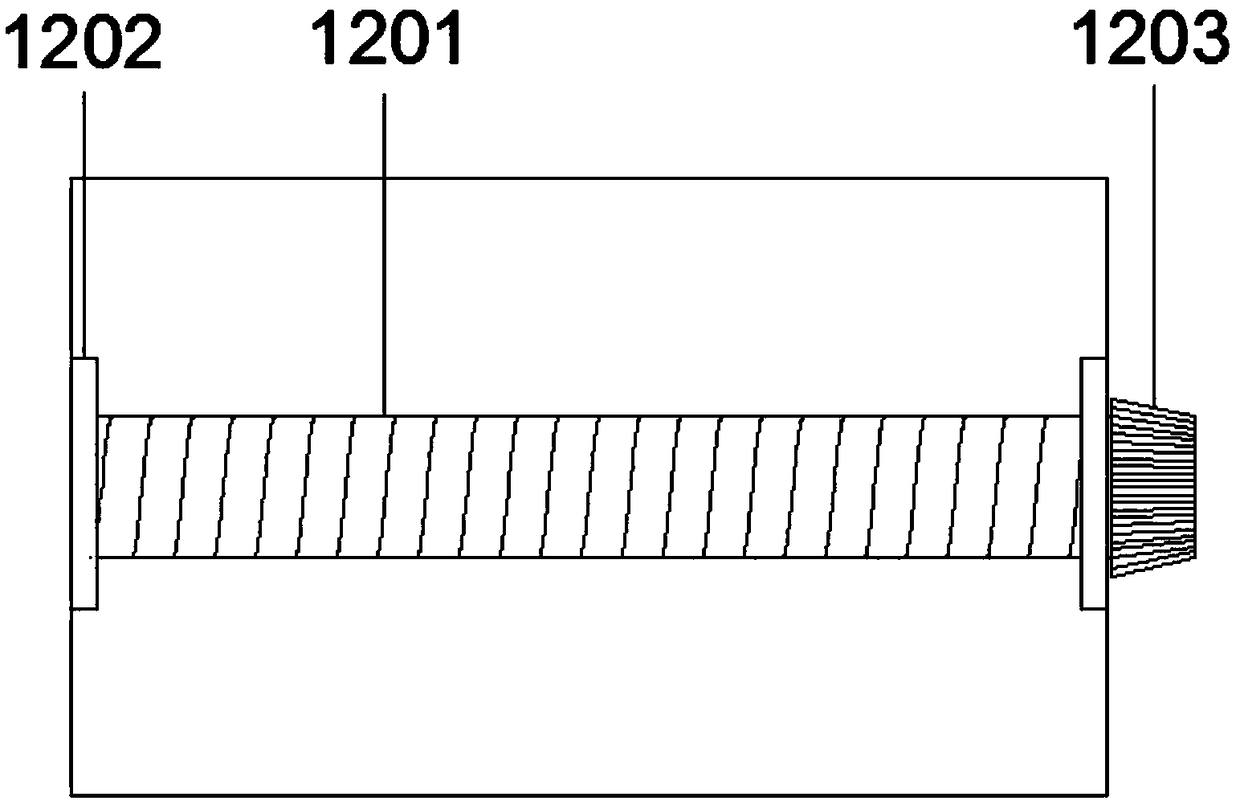

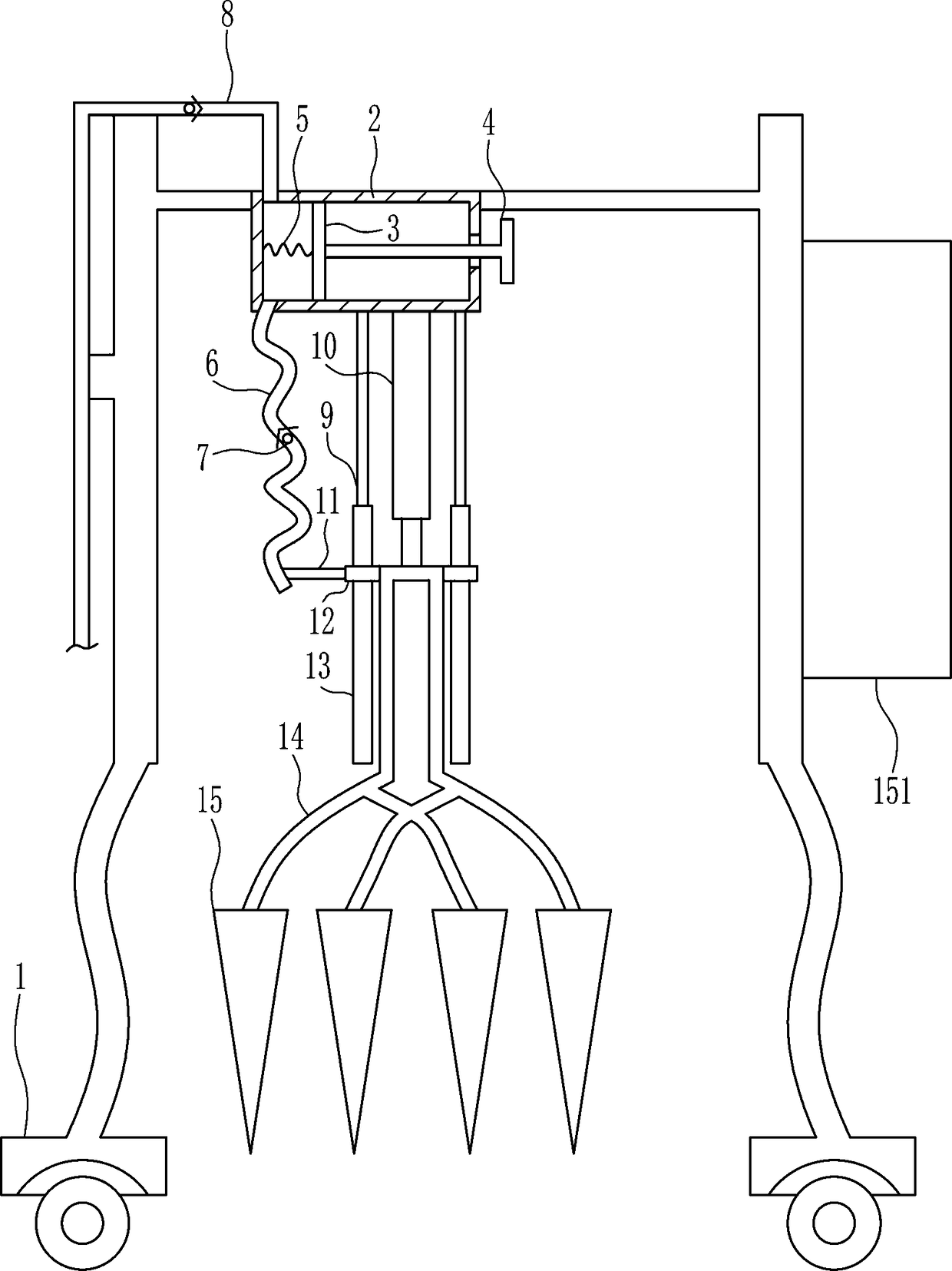

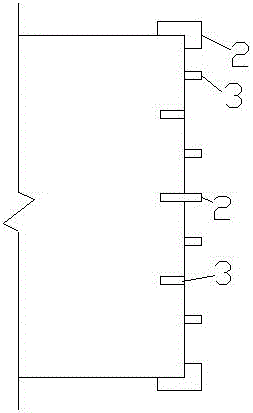

Loose-soft rock soil stratum reverse circulation casing-following drilling tool and drilling process

PendingCN108086930AImprove migration efficiencyImprove connection strengthDrilling rodsConstructionsAugerHelical blade

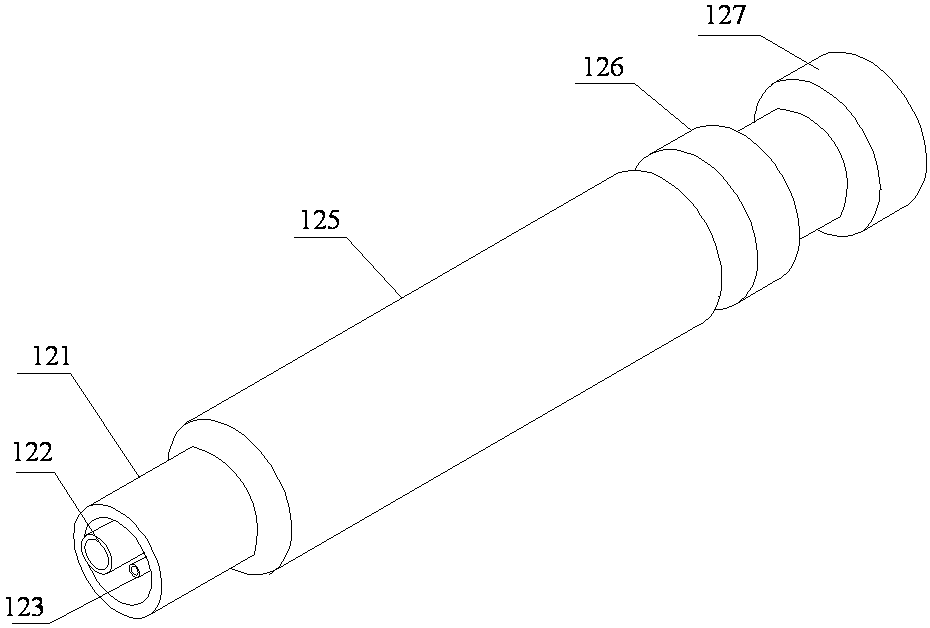

The invention discloses a loose-soft rock soil stratum reverse circulation casing-following drilling tool and a drilling process. The drilling tool is of a coaxial three-passage structure and comprises a double-wall drilling stem, an auger stem, a drilling bit, a casing and a casing shoe, a central hole of an inner tube of the double-wall drilling stem and a central hole of an inner tube of the auger stem form a slag discharging passage, an annular gap between the inner tube of the auger stem and an outer tube of the auger stem forms an air incoming passage, and an annular gap between the outer tube of the auger stem and the casing forms an outer ring passage; compressed air enters the drilling bit through the air incoming passage and then is diverted and used for assisting a cutting bladeto break a stratum and realize reverse circulation deslagging. Drillings suspended in the outer ring passage go up along spiral blades, enters a deslagging passage through a deslagging window and then returns to the ground surface. Reverse circulation deslagging through a fluid medium and deslagging assisted by the spiral blades are adopted in the process of drilling, so that casing-following drilling is realized to protect hole walls, the problems of bit burying and difficulty in deslagging and hole forming in the process of loose-soft rock soil drilling can be solved, and integration of drilling, collapse preventing, dedusting and wall protecting is realized.

Owner:JILIN UNIV

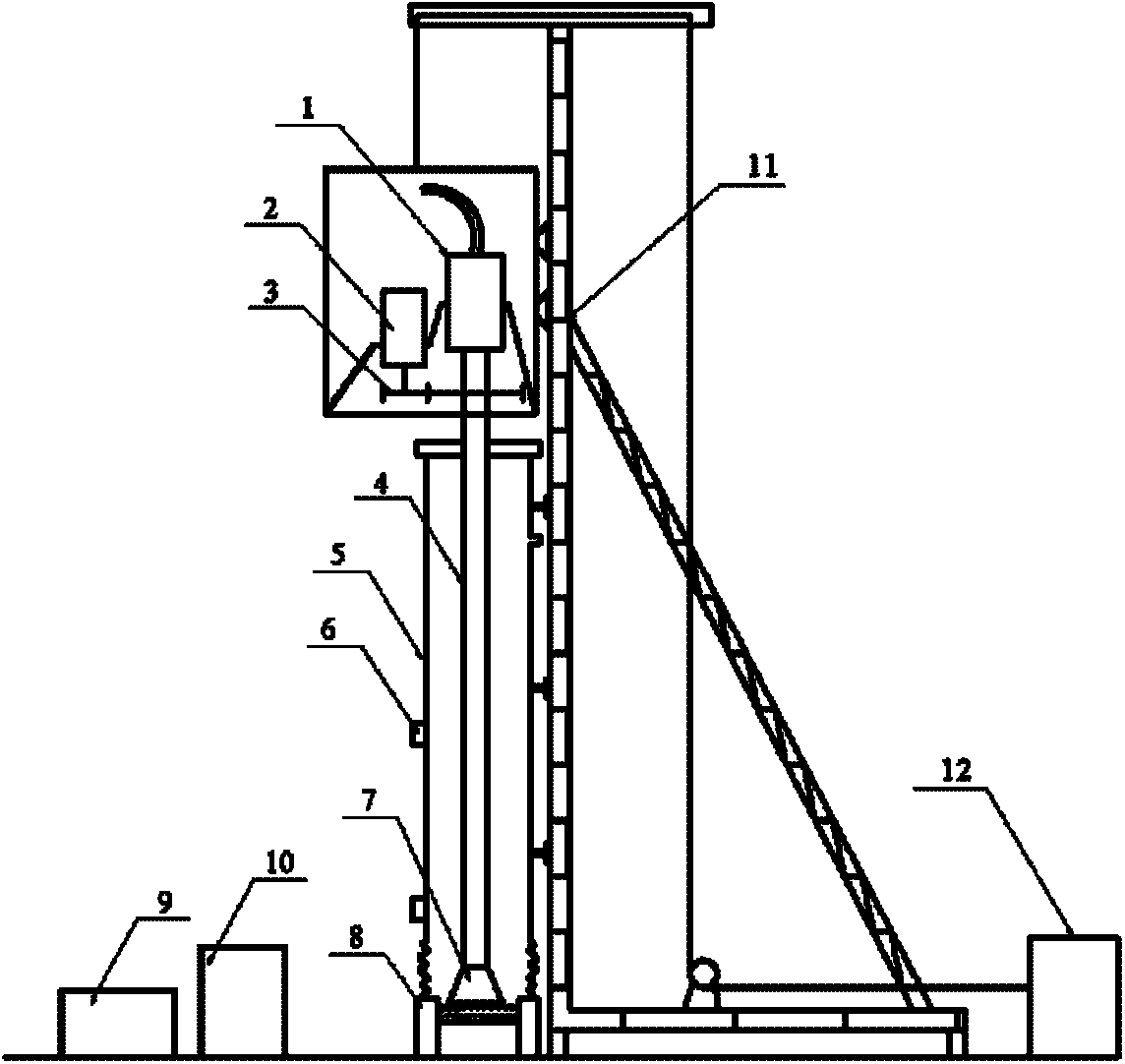

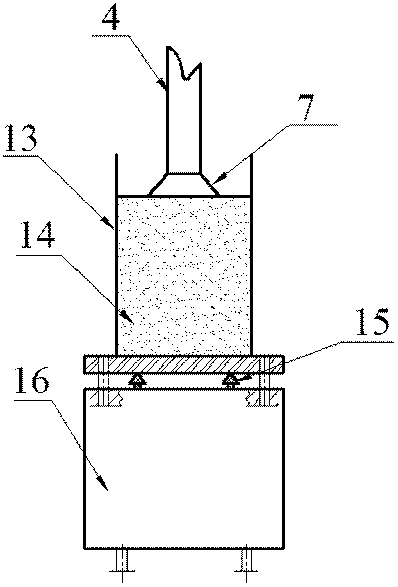

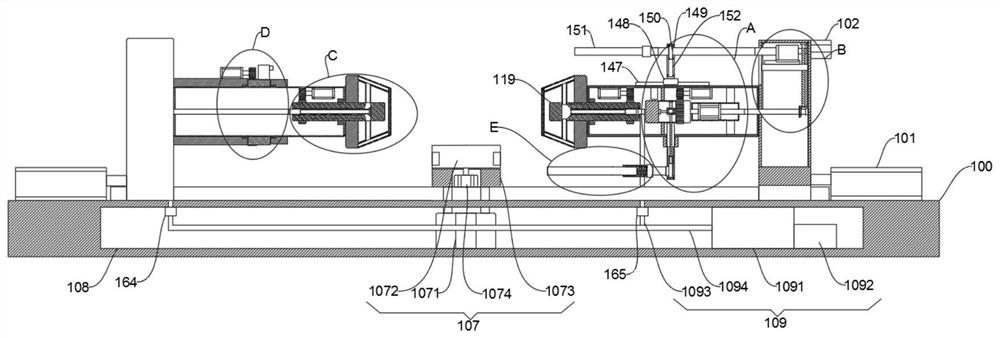

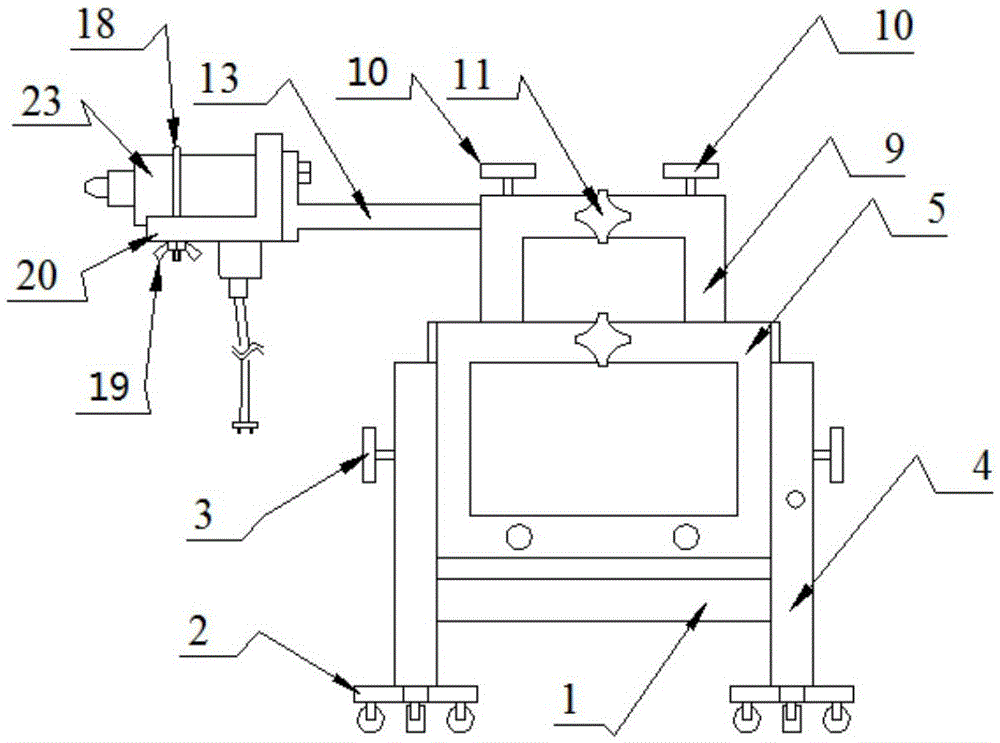

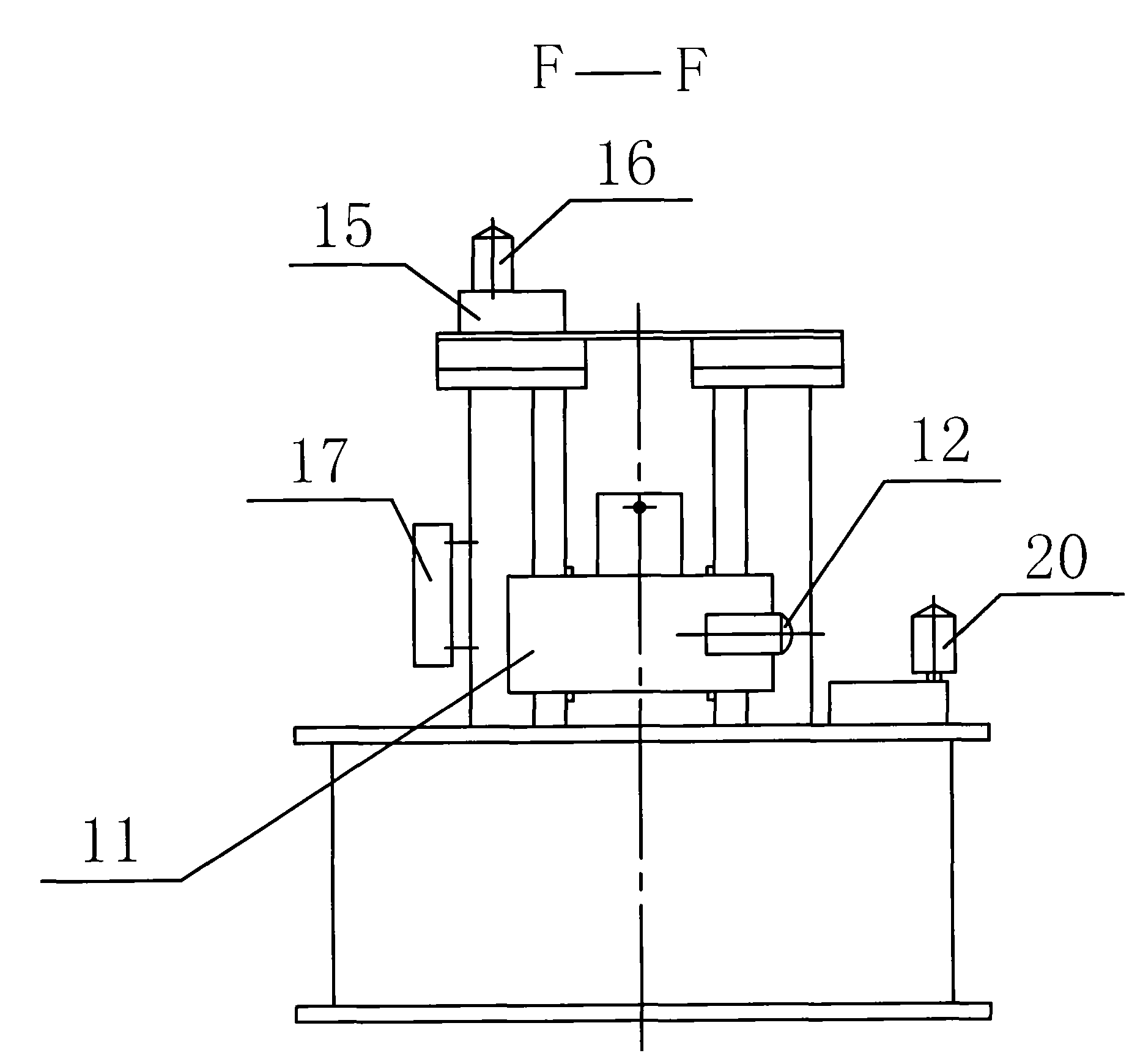

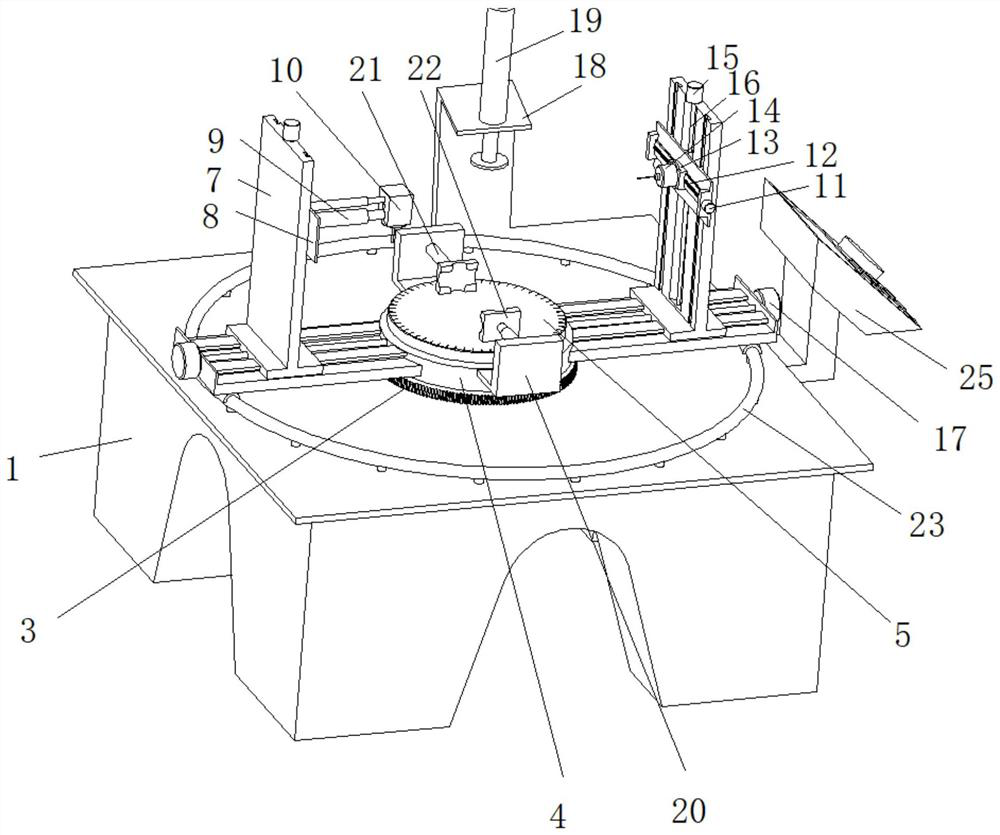

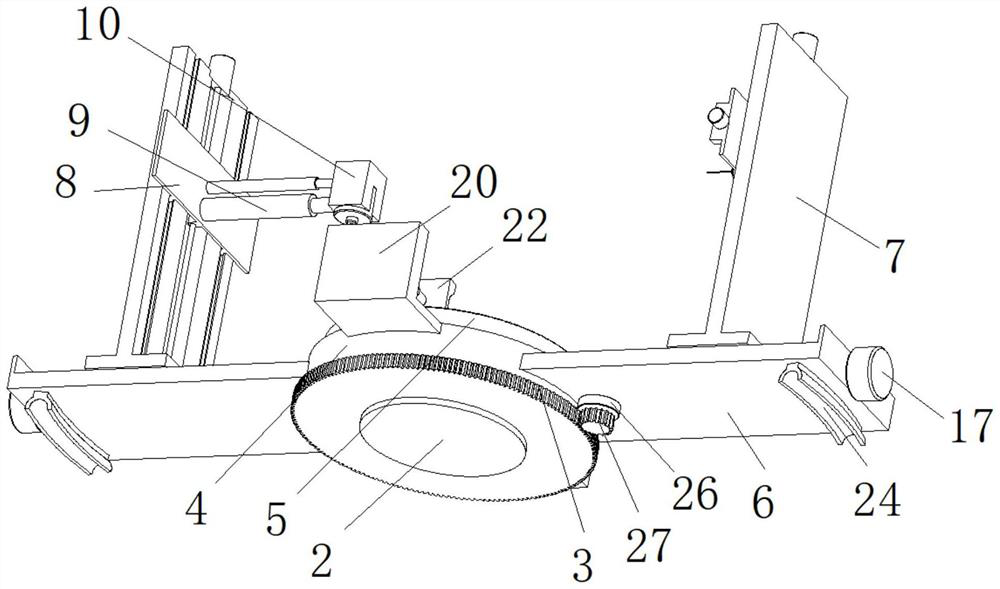

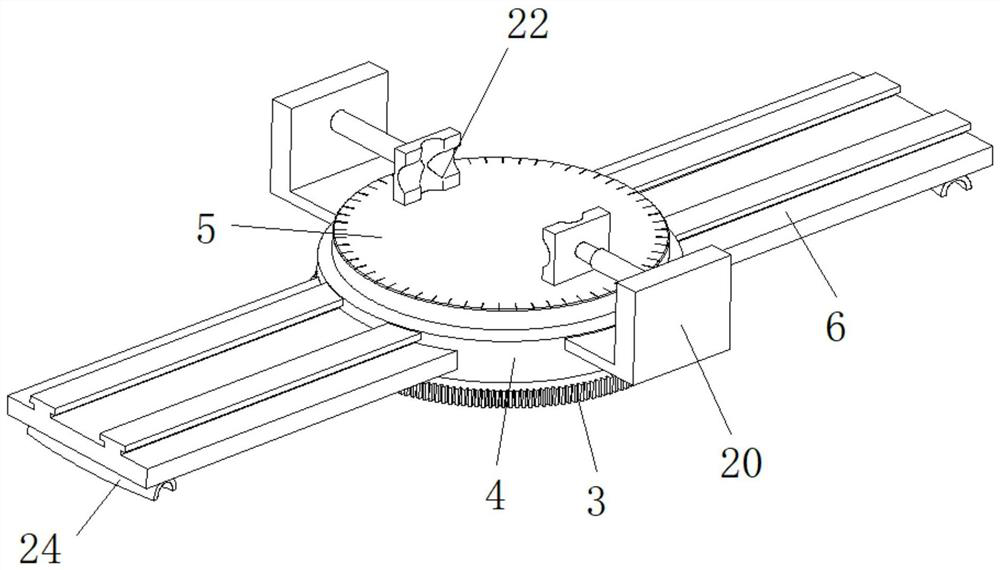

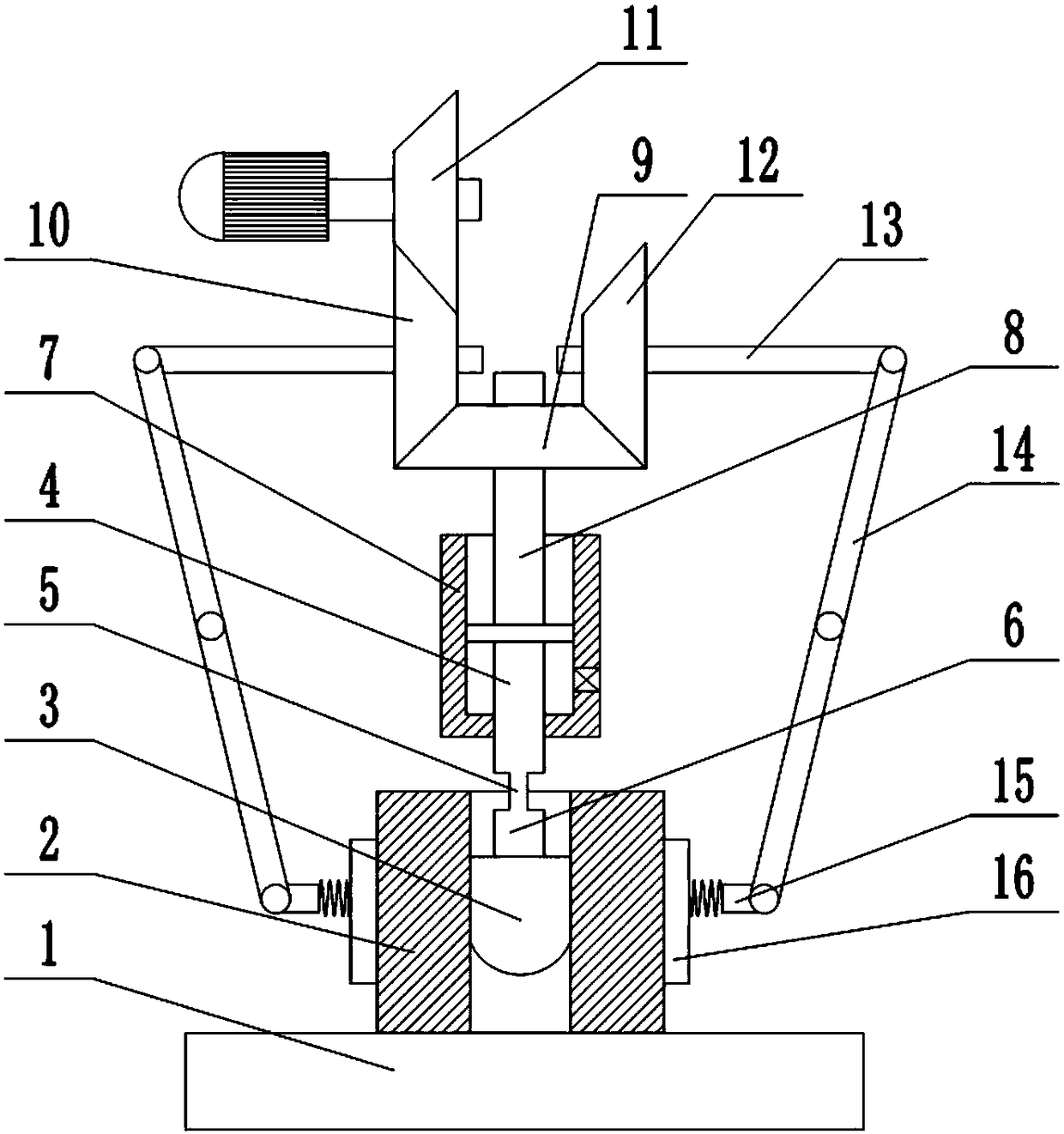

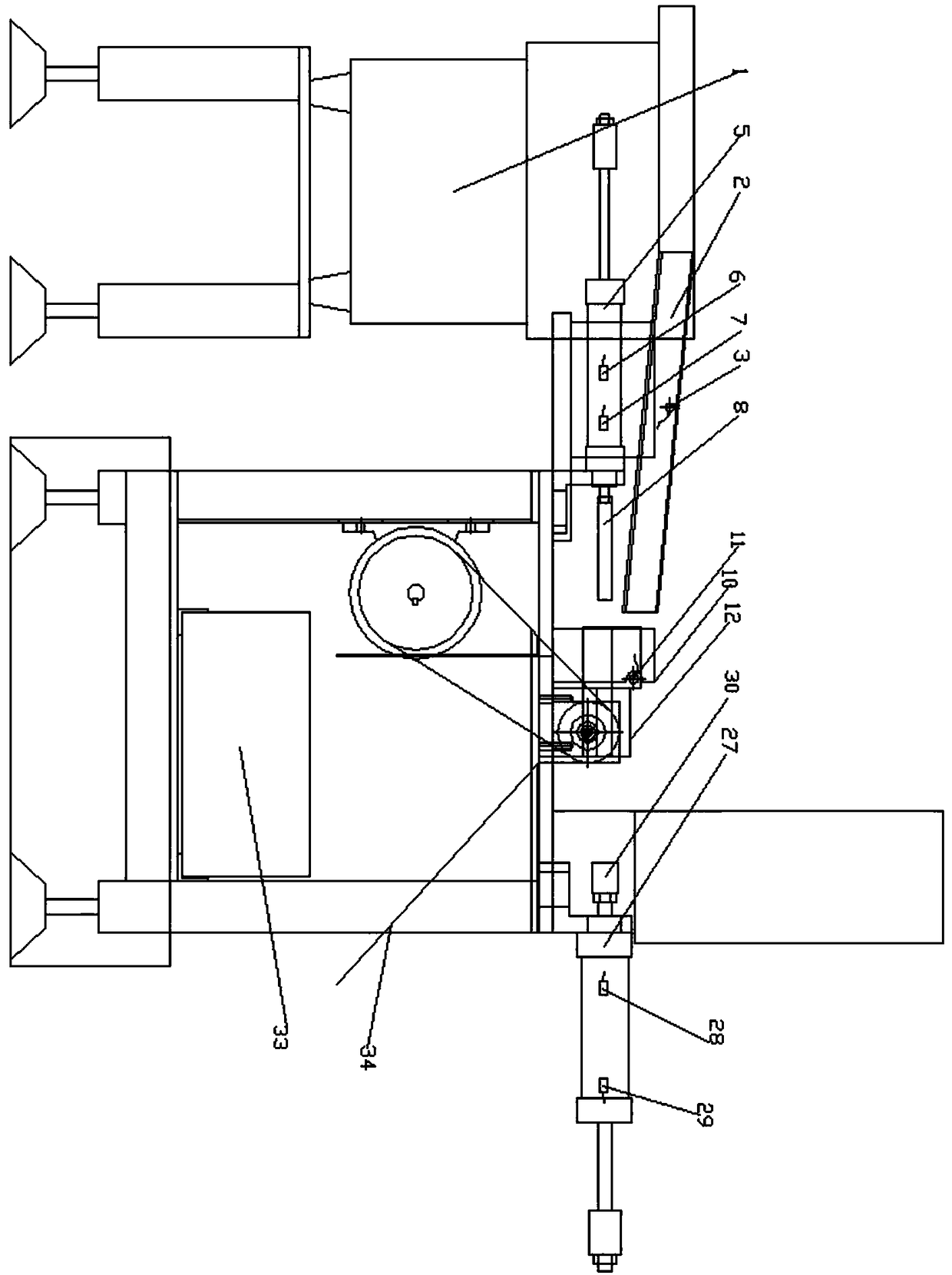

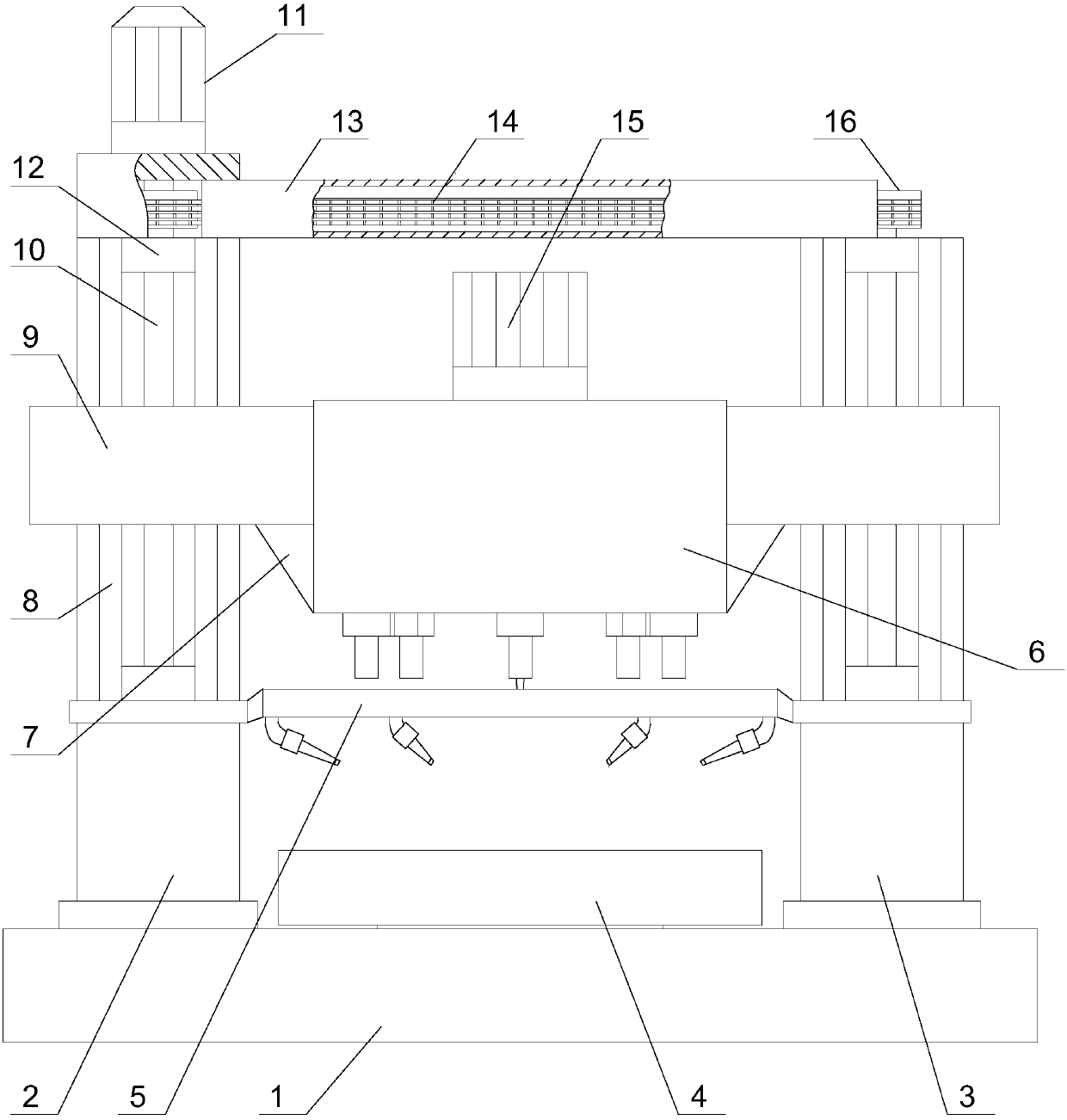

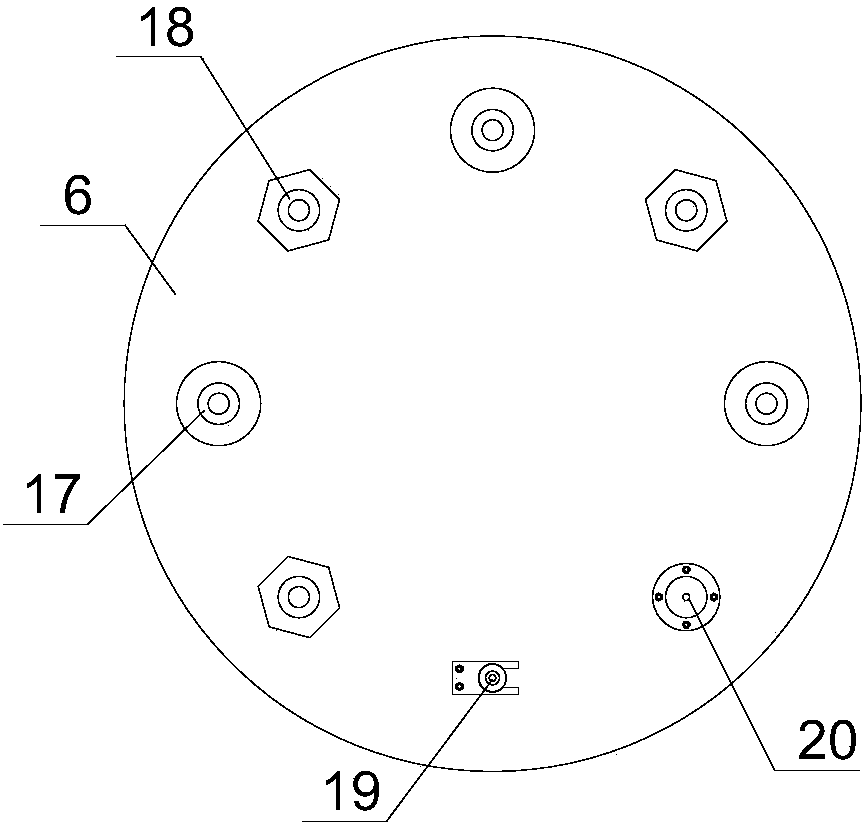

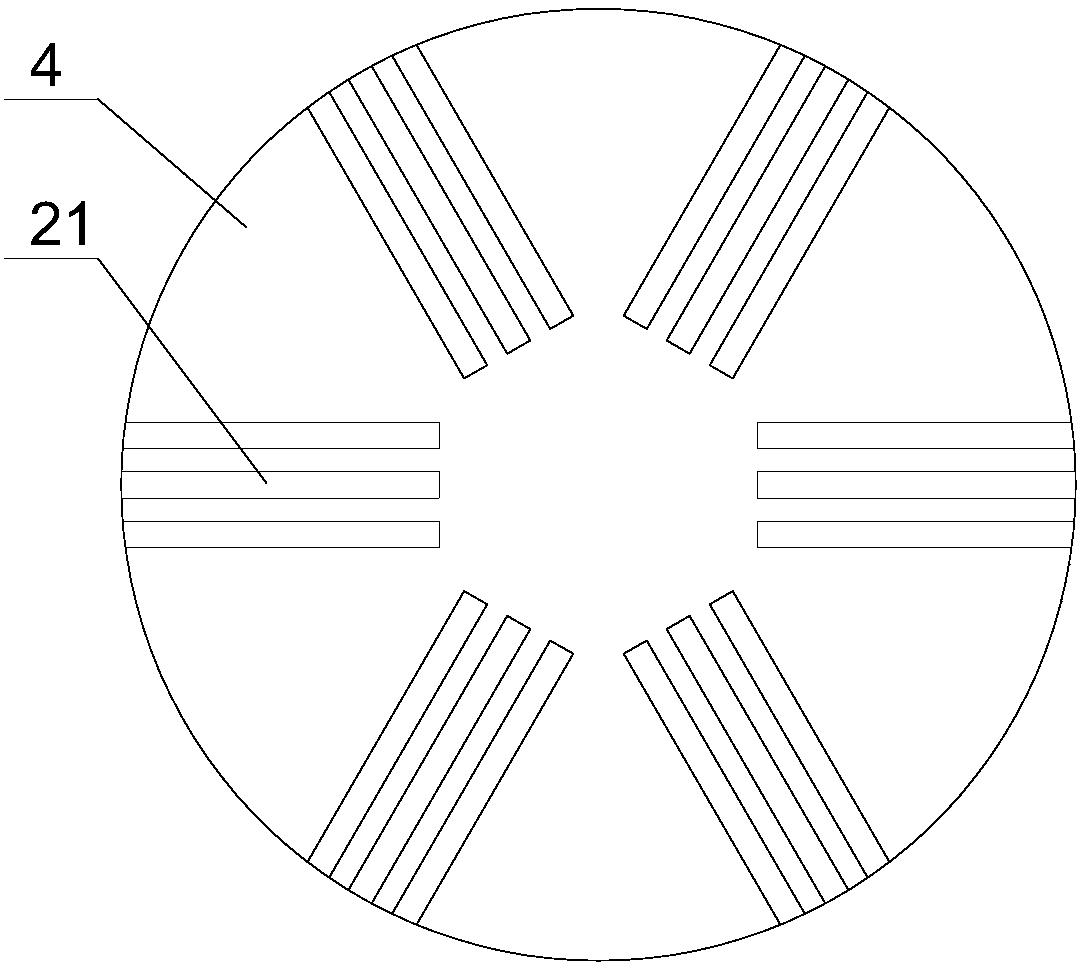

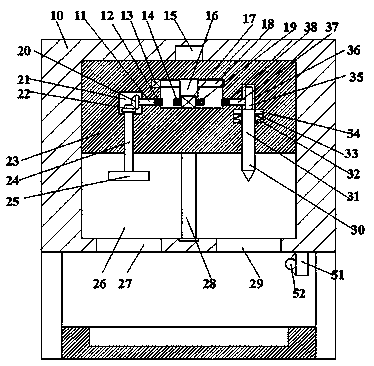

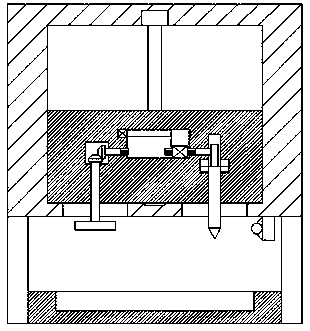

Experimental method for simulating dynamic mechanics characteristic of underground drilling rig of air well drilling

InactiveCN102305021AAchieve drillingRealize measurement while drillingSurveyConstructionsExperimental methodsWell drilling

The invention discloses an experimental method for simulating dynamic mechanics characteristic of underground drilling rig of air well drilling, which is characterized in that a rotary system is arranged on the upper part of a derrick to provide rotary torque and drilling torque for a drill stem; the bottom of a drill is provided with an excitation system to provide drilling pressure and a randomvibration excitation signal; the sizes of the drill stem, a shaft and the drill are selected according to on-site common well body structure size by the similarity principle; the shaft is provided with a monitoring system, drilling well fluid medium flow state observation and the dynamic mechanical behavior measurement while drilling of the drilling rig can be carried out in a simulated drilling process; each system is fixed on a positioned derrick with a rotatable angle to regulate the inclining angle of the derrick, and thus the dynamic mechanics characteristic simulation experiment of the drilling rig can be realized at different well inclining angles. The experimental method is suitable for the dynamics research of underground drilling rigs of petroleum and natural gas.

Owner:SOUTHWEST PETROLEUM UNIV

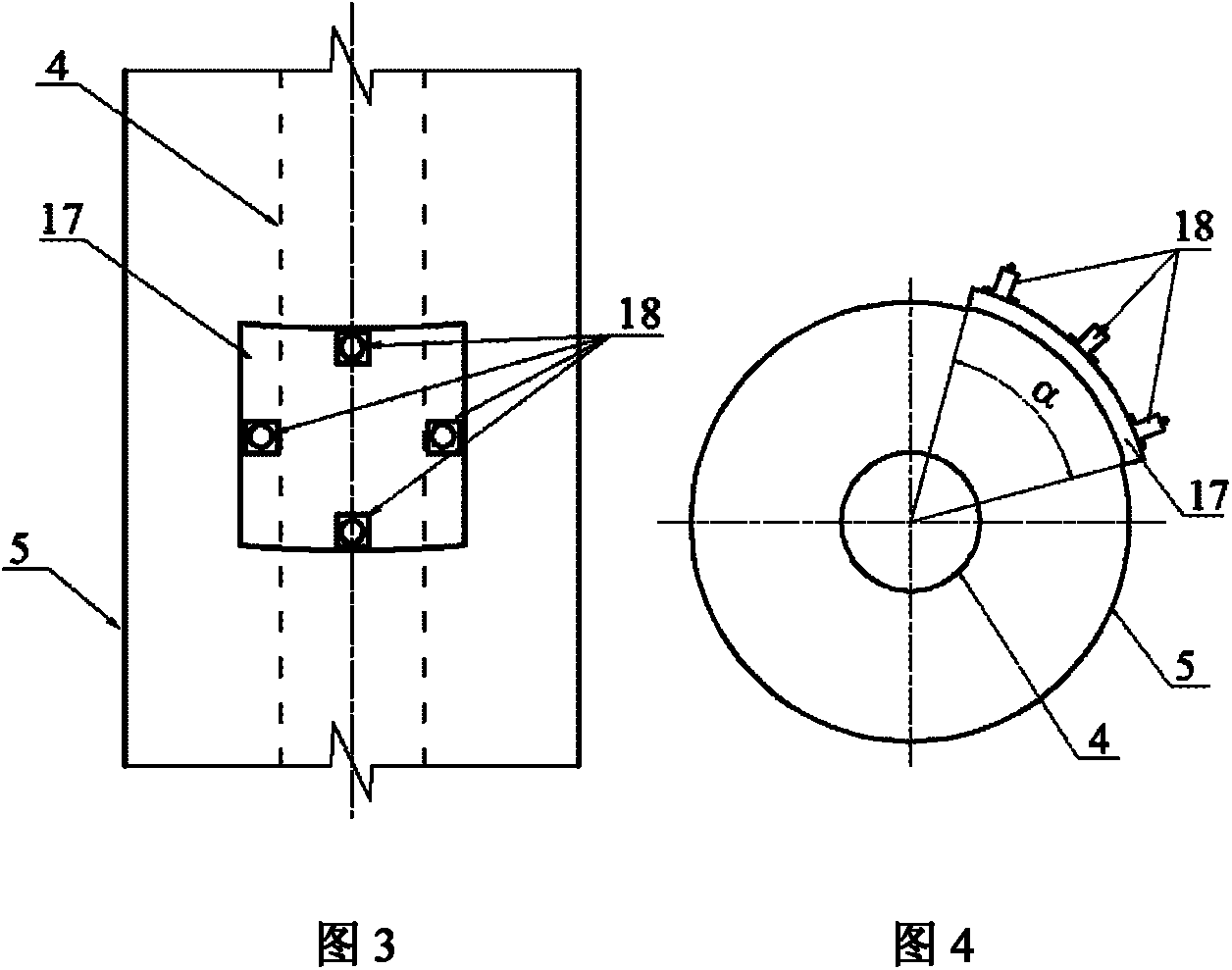

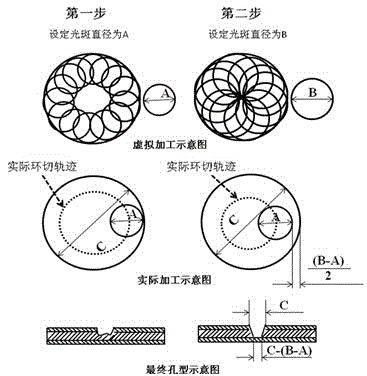

UV laser drilling method for preparing blind holes controllable in taper

The invention provides a UV laser drilling method for preparing blind holes controllable in taper in a printed circuit board. A laser beam scans needed micro-guide through holes in the surface of a workpiece within the set aperture range along a certain track. Each micro-guide through hole is molded through two steps, the blind holes controllable in taper are prepared by adjusting the energy, defocusing amount and light spots of each step of parameters, and the problem that the taper and quality of the blind holes can not be easily controlled through an existing preparation method is effectively solved.

Owner:AKM ELECTRONICS TECH SUZHOU

Industrial robot

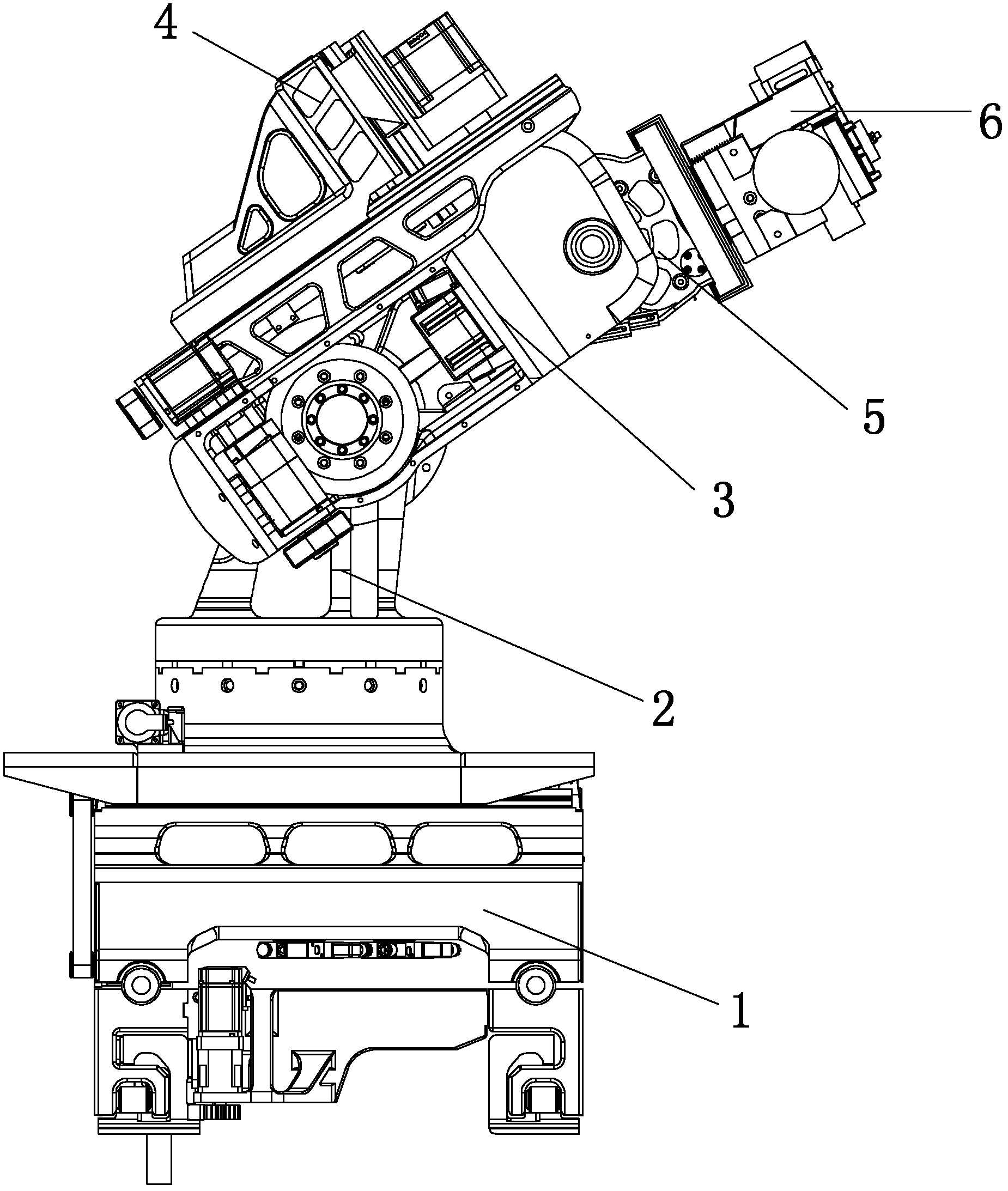

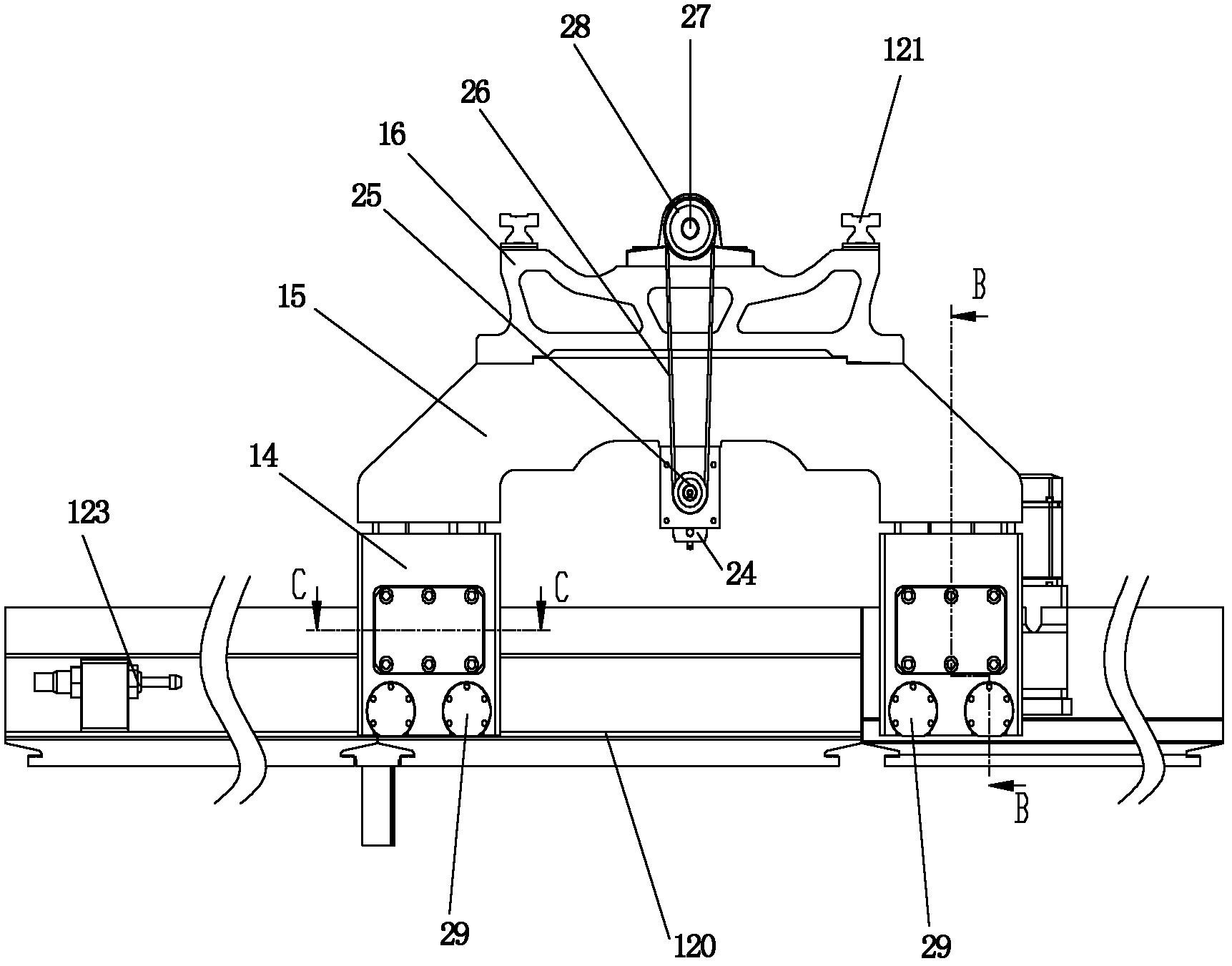

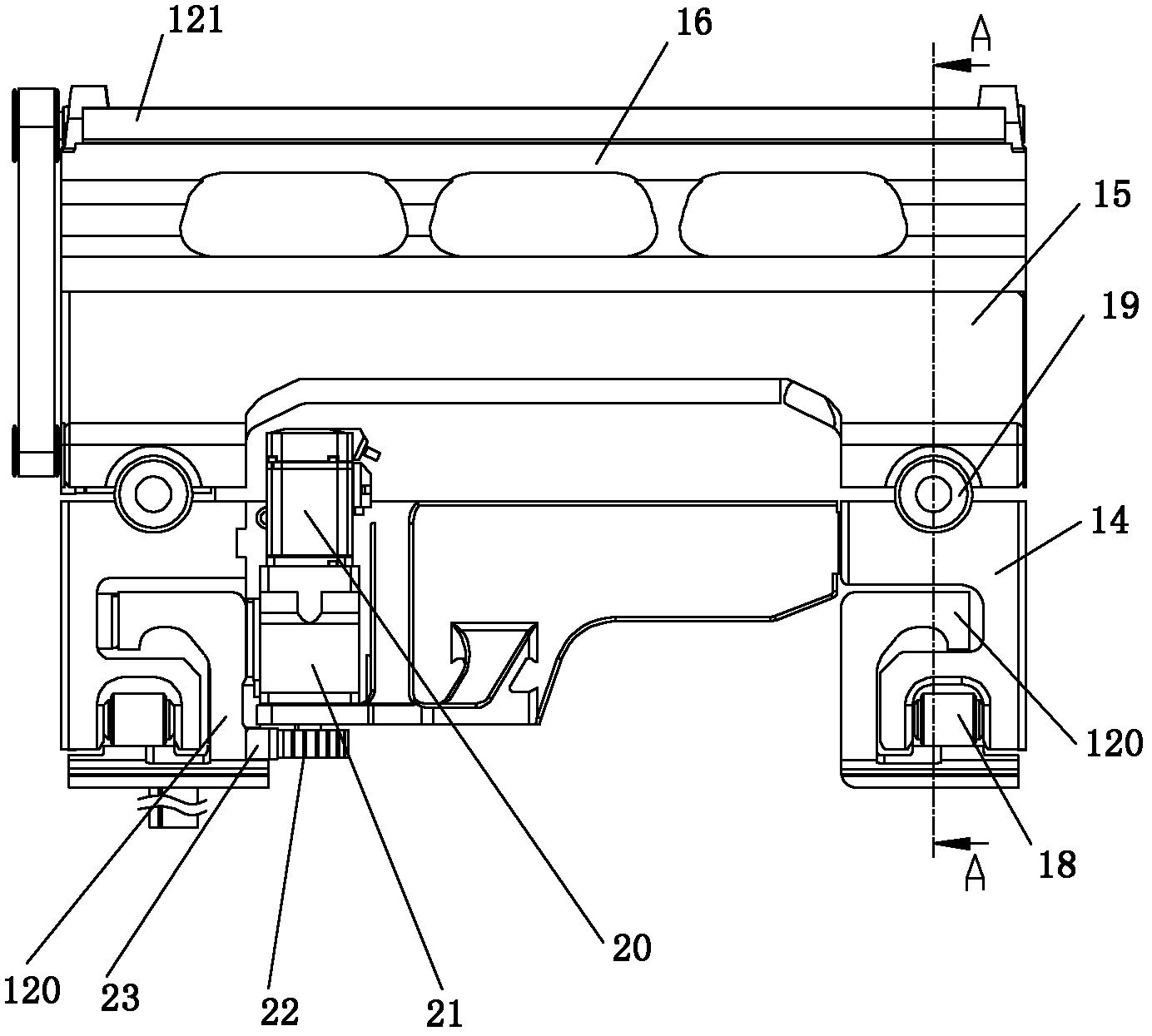

ActiveCN102658546ACrawl smoothlyRealize unmannedProgramme-controlled manipulatorJointsIndustrial engineeringIndustrial robot

The invention provides an industrial robot, which comprises a base guide rail component, a base component, a large arm component, an engraving and milling component, a wrist component and a claw component, wherein the lower end of the base guide rail component is matched with a guide rail I and can roll along the guide rail I; the lower end of the base component is matched with a guide rail II which is arranged at the upper end of the base guide rail component and can slide along the guide rail II; the base component consists of an upper component and a lower component, wherein the upper component can rotate around the lower component; a shoulder shaft on the large arm component is in floating fit with a shoulder shaft hole formed on the upper part of the upper component, and the large arm component realizes the action of lifting or lowering the arm; the lower part of the engraving and milling component is matched with a guide rail III which is arranged on the side of the large arm component, can slide along the guide rail III and realizes a drilling action; the wrist component is arranged in a mounting hole of the large arm component through a loop bar and finishes the action of lifting and lowering the wrist; and the side of the claw component is matched with a guide rail IV which is arranged on the wrist component, slides along the guide rail IV and realizes the action of opening and closing the claws.

Owner:刘朝龙

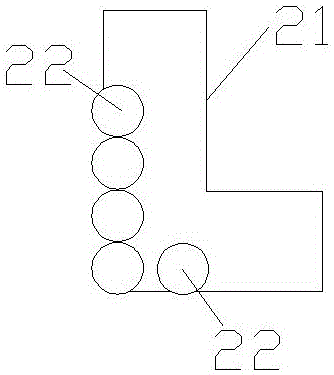

Creeping ground drilling robot

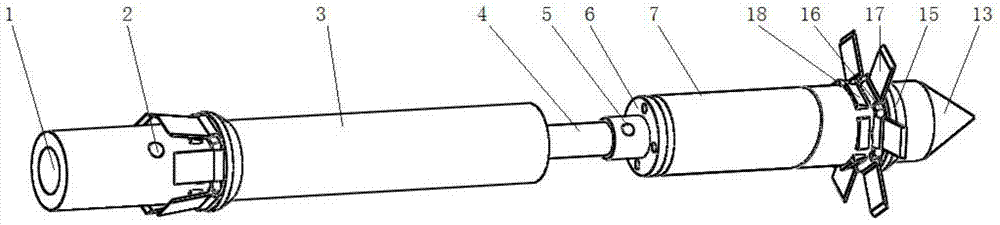

InactiveCN104727749AReduce resistanceStable thrustDrilling without earth removalEngineeringSearch and rescue

The invention relates to a creeping ground drilling robot which comprises an electric push rod mechanism, a motor steering mechanism and a drill bit mechanism which are sequentially connected. The outer wall of the electric push rod mechanism and the outer wall of the drill bit mechanism are each provided with a scale device capable of expanding and retracting, the electric push rod mechanism stretches and retracts periodically, each scale device expands or retracts under the action of soil body force and is used for providing supporting counterforce in the drilling direction, the motor steering mechanism adjusts steering of the drill bit mechanism, and a good platform is provided for the task that the robot is provided with a sensor to go deep into soil for geological prospecting, mine disaster search and rescue or soil sample collection in the future. Compared with the prior art, the robot has the advantages of being simple in structure, low in manufacturing cost, convenient to control and the like.

Owner:TONGJI UNIV

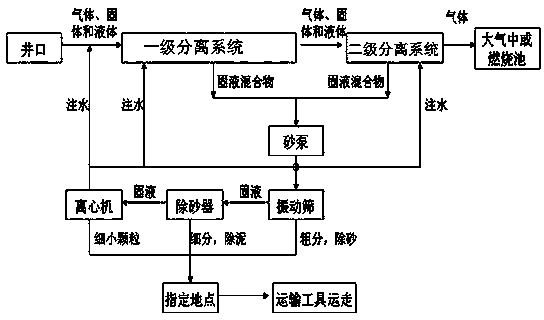

Rock debris separating method for gas drilling

ActiveCN103993845AImprove primary separation effectAchieve drillingConstructionsWater circulationEnvironmental geology

The invention discloses a rock debris separating method for gas drilling. The rock debris separating method for gas drilling comprises the steps of firstly enabling water in a whole system to circularly flow to achieve balance and beginning to perform gas drilling; mixing gas and solid with the water to form a mixed fluid to enable dust in the solid to be dissolve in the water during drilling and before the gas returned from a well mouth and the solid are separated; enabling the mixed fluid to firstly flow into a primary separation system to remove coarse particles, discharging the gas carried with fine particles, water drops or water mist into a secondary separation system; removing the fine particles, water drops or water mist so as to obtain purified gas and a solid-liquid mixture after water bath washing is performed; delivering the solid-liquid mixture to a circulating water treatment system, and separating the coarse particles through primary treatment separation; removing the fine particles through secondary treatment separation; removing fine particles through tertiary treatment separation. The rock debris separating method for gas drilling can achieve returned fluid treatment under the condition that a grit chamber does not exist through gas drilling, gas meeting the direct emission standard is finally obtained, and the gas drilling requirement under different conditions can be met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

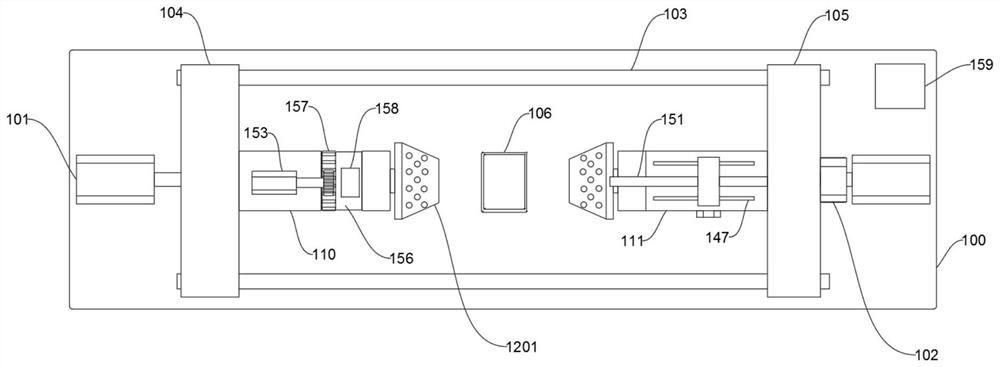

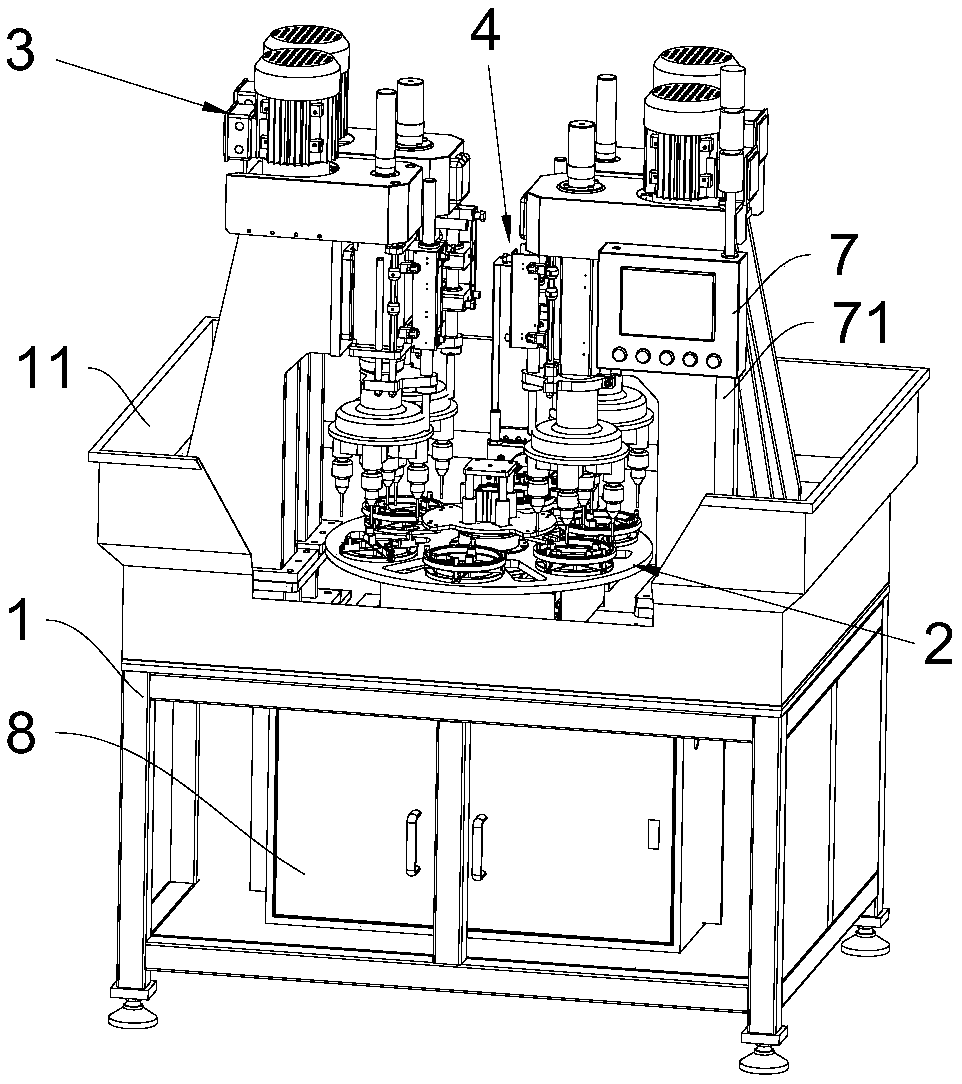

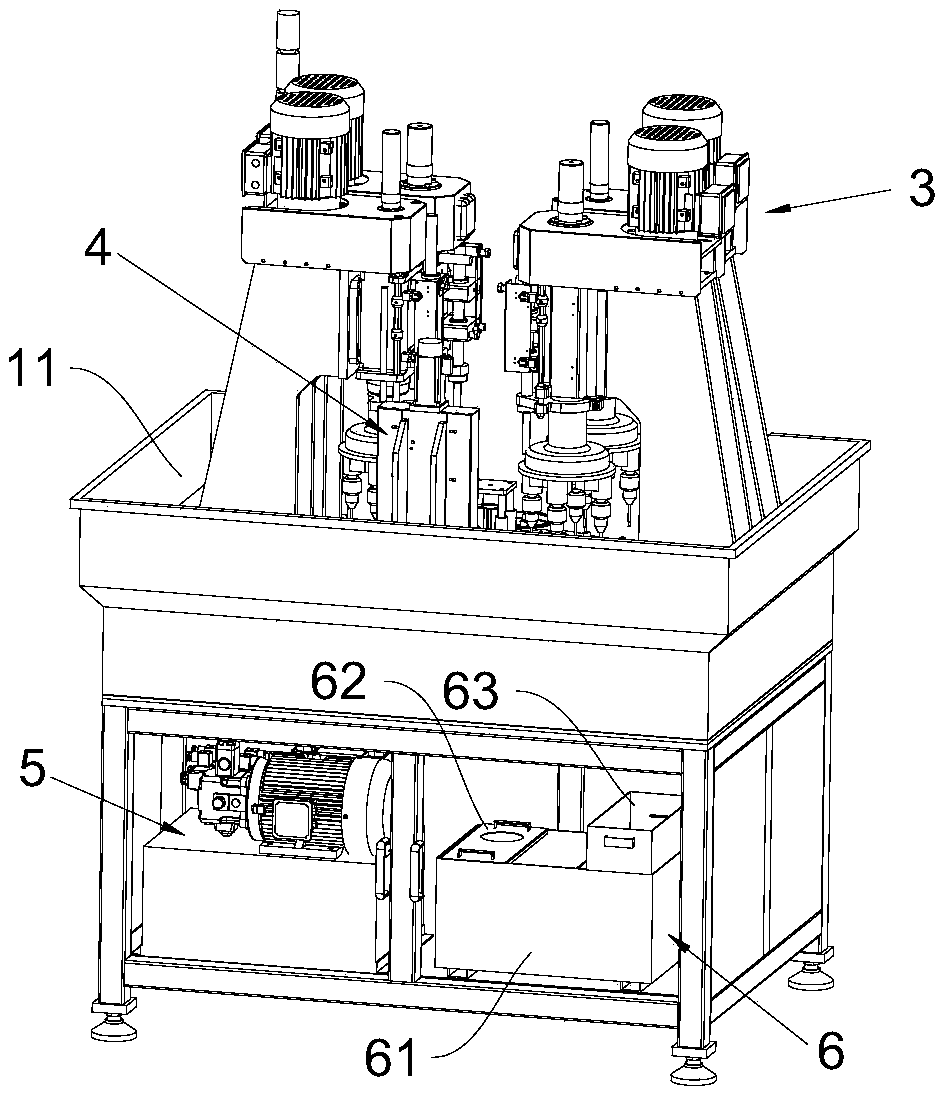

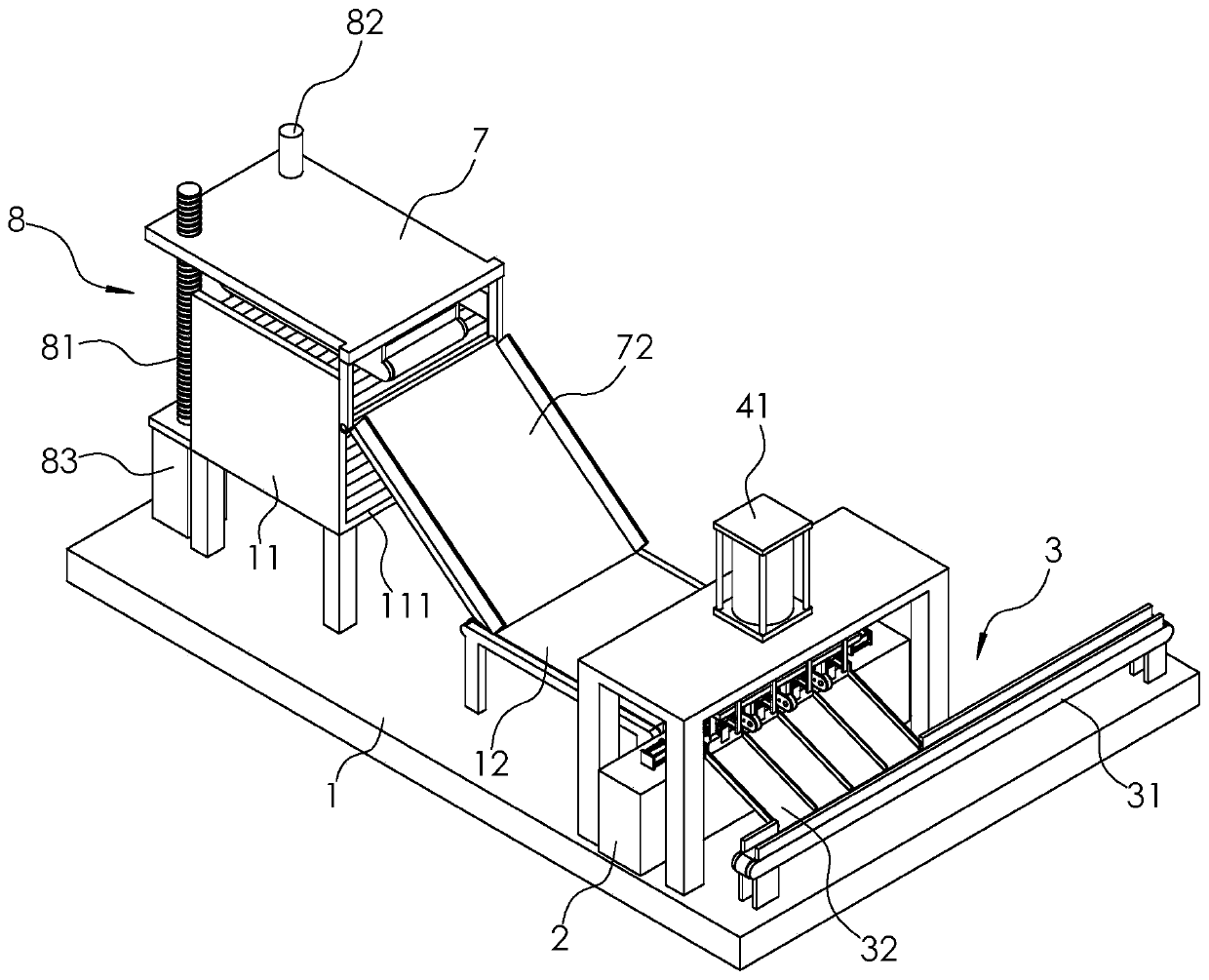

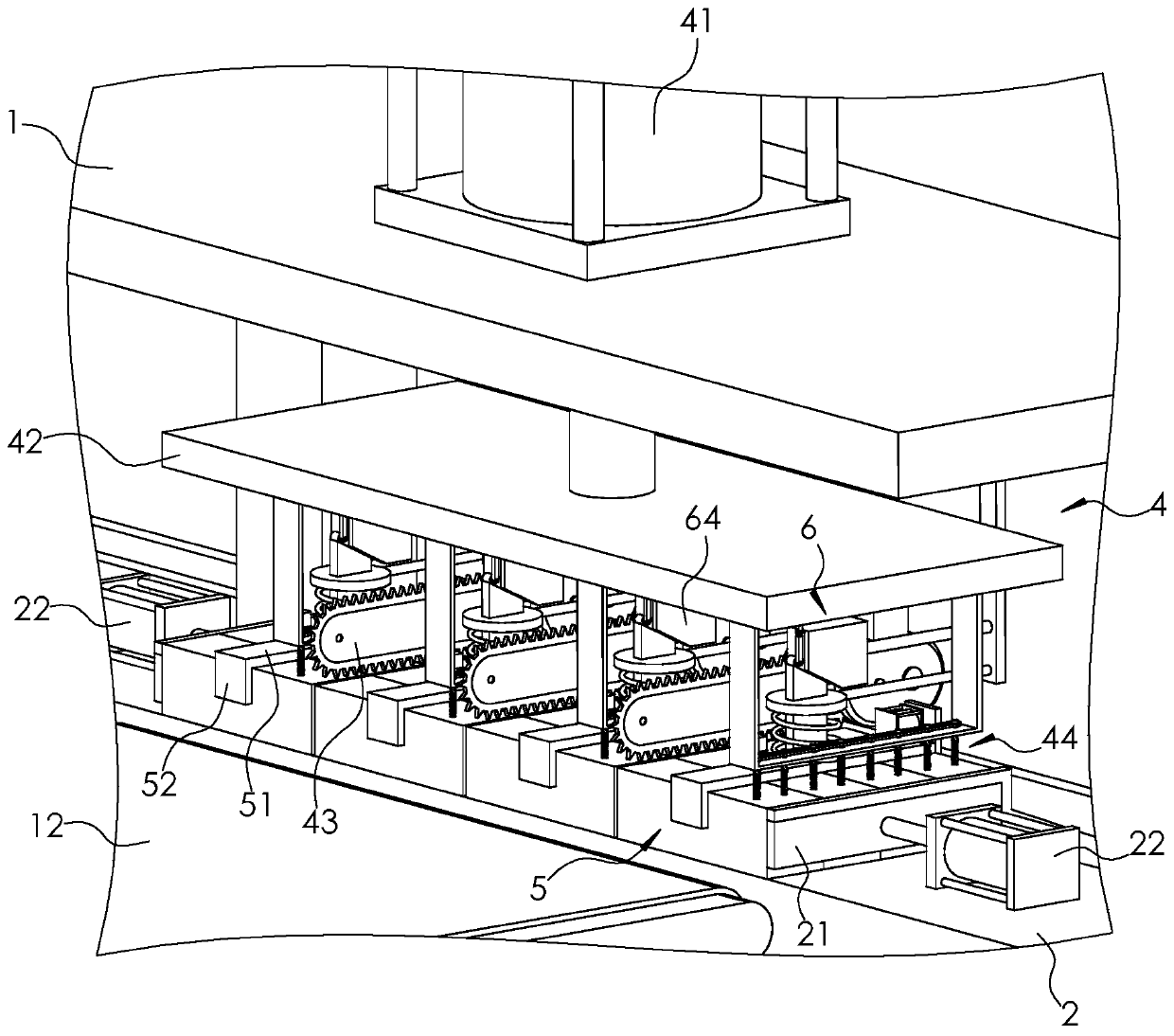

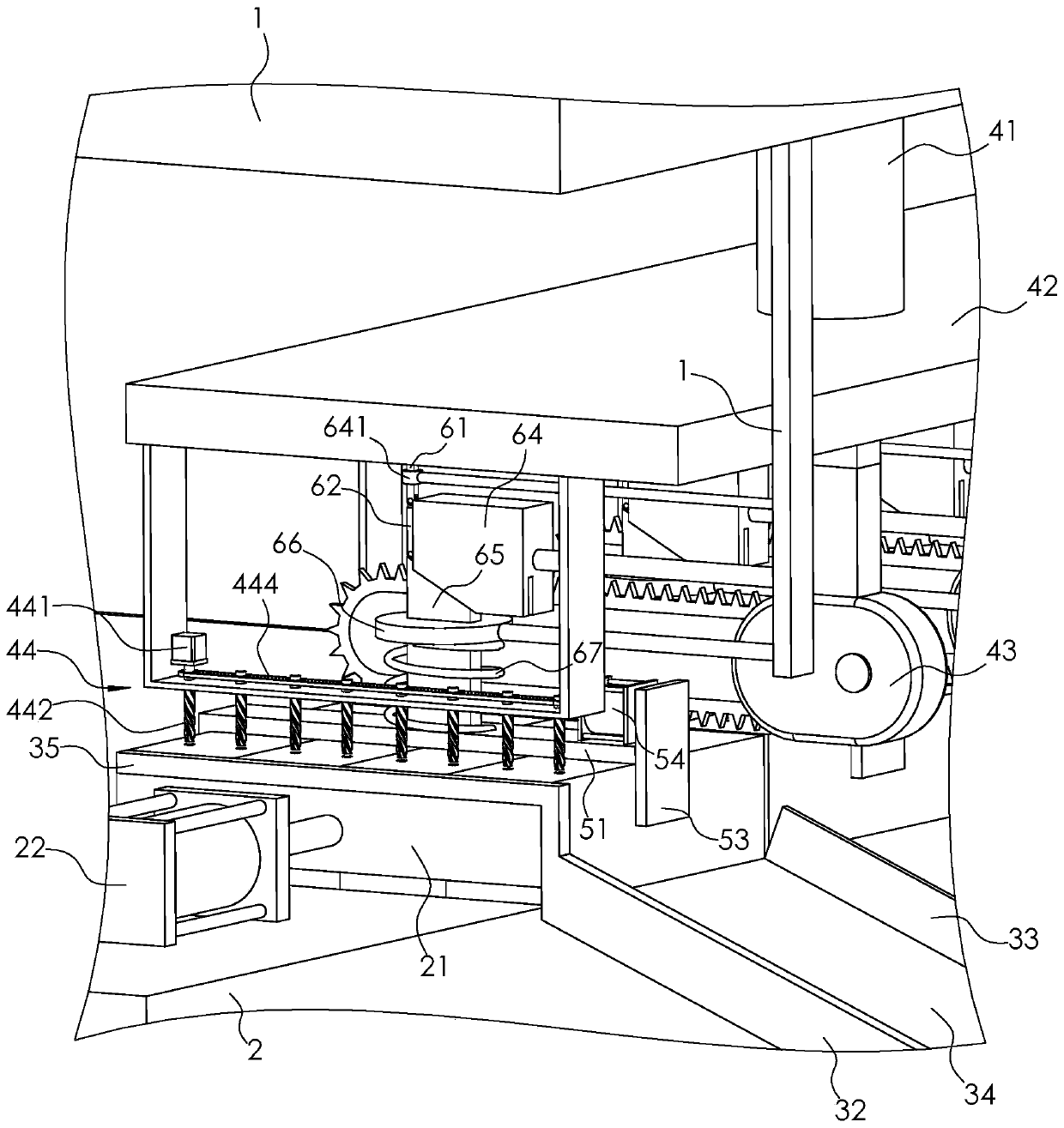

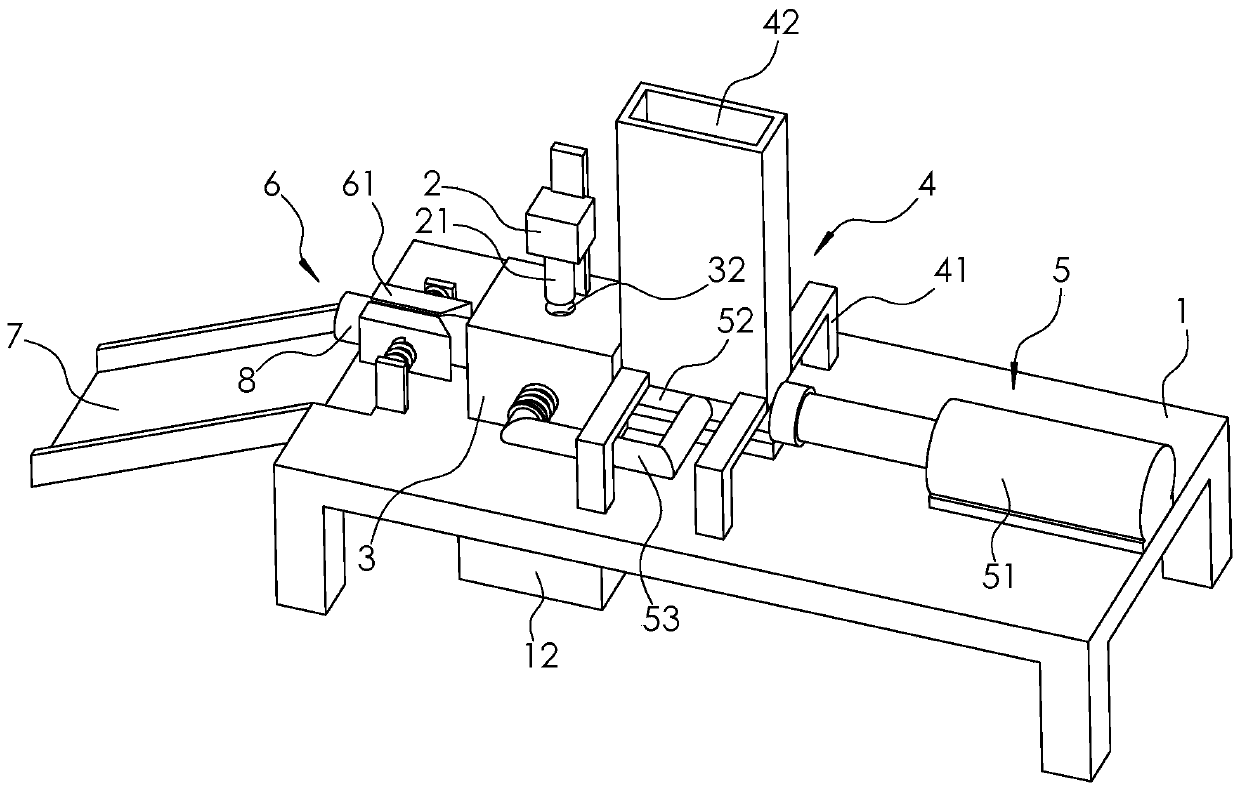

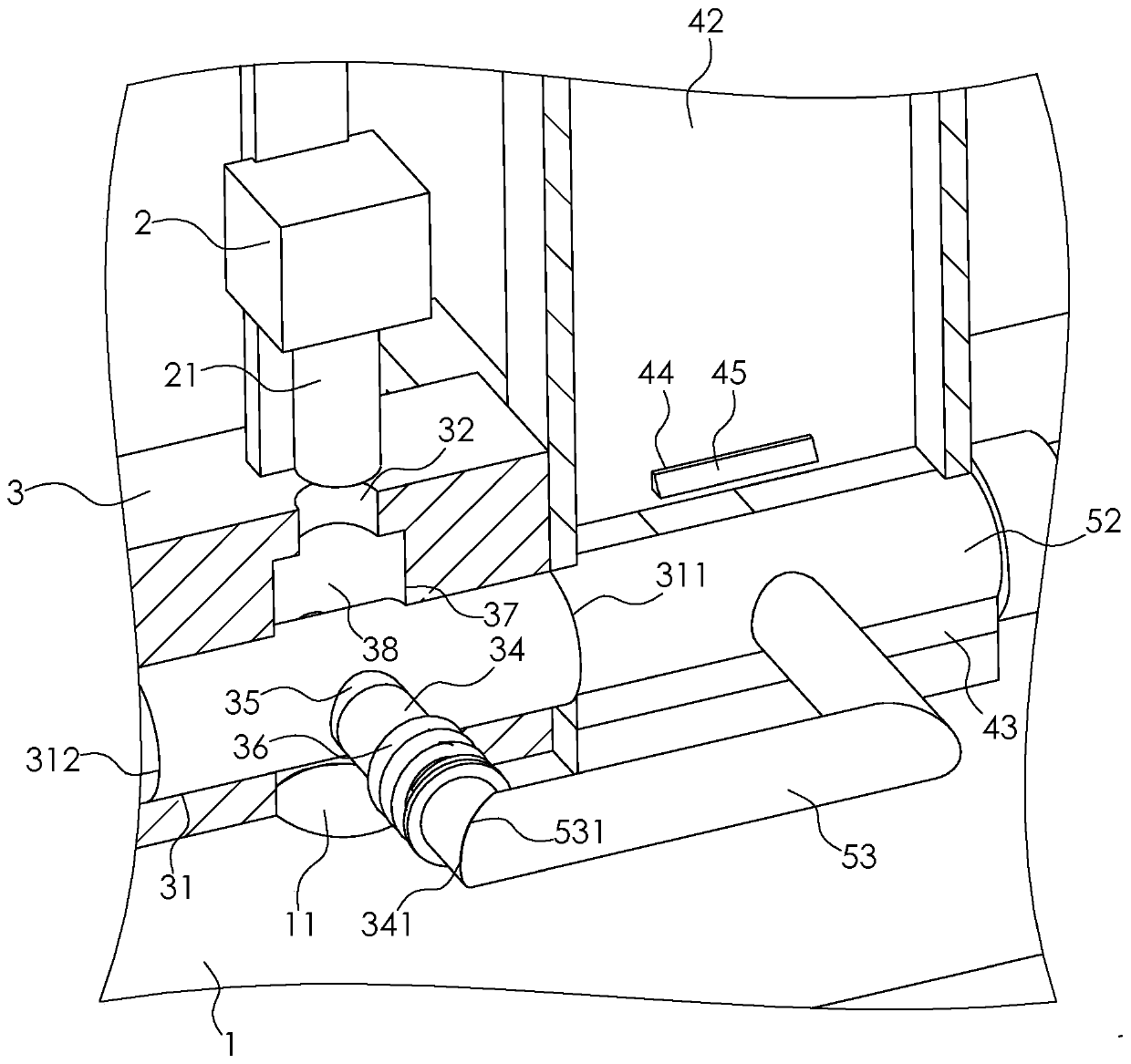

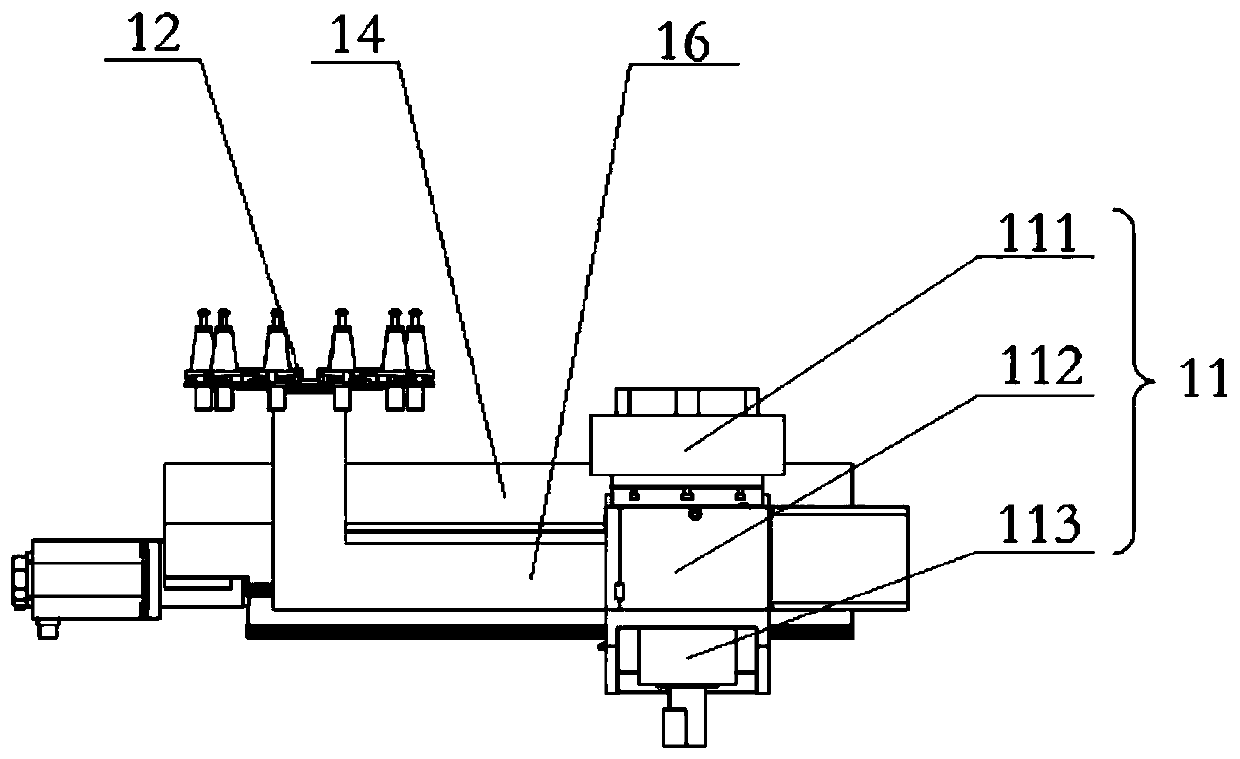

Drilling and grinding integrated machine for valve machining

ActiveCN112643345AAchieve drillingAchieve associativityGrinding drivesFeeding apparatusElectric machineryEngineering

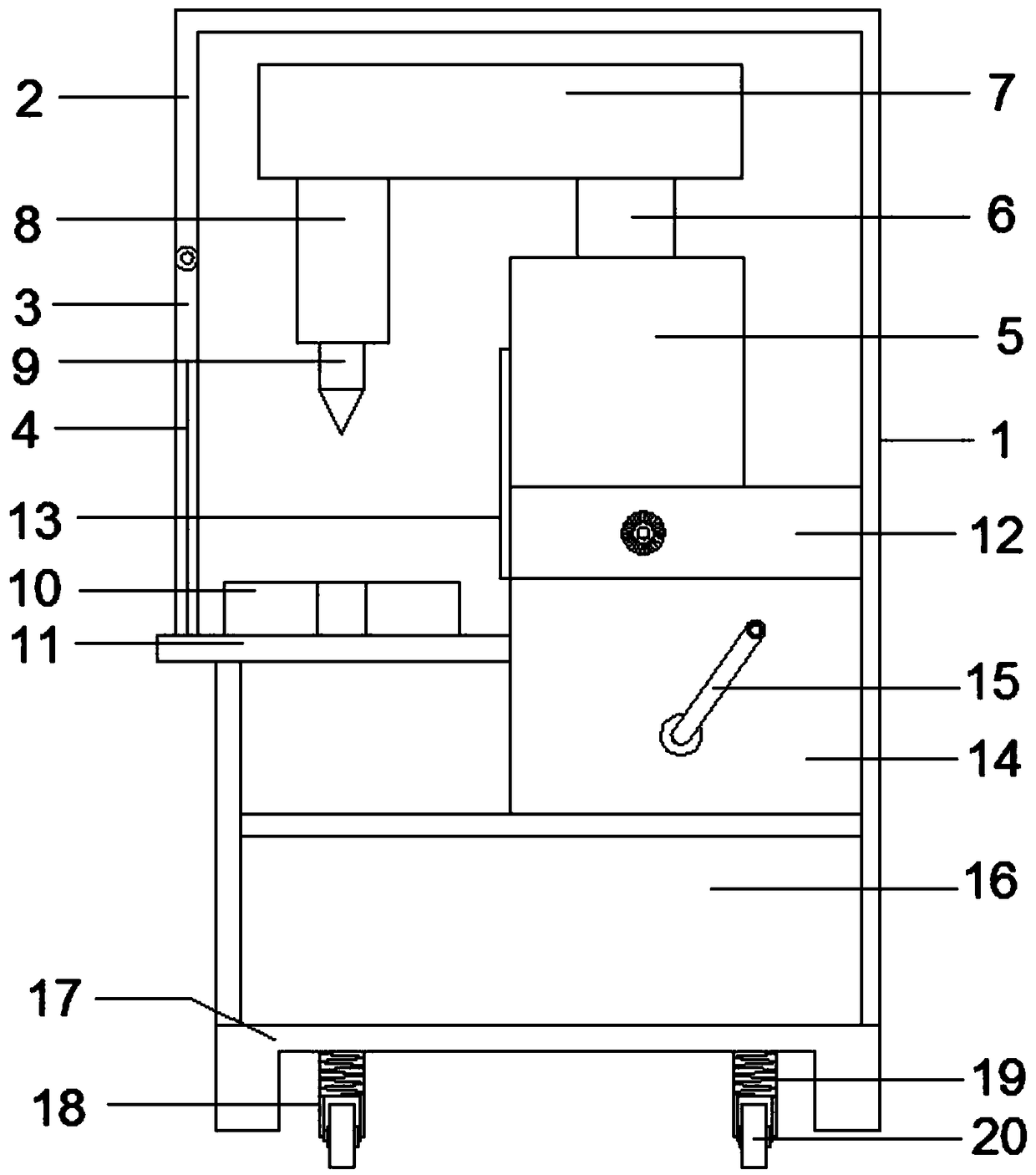

The invention discloses a drilling and grinding integrated machine for valve machining. The machine comprises a workbench, two electric cylinders and a propelling air cylinder, wherein a lifting mechanism is arranged in a lifting hole, a first cavity is formed in the workbench, a dust suction device is fixedly arranged in the first cavity, a set of propelling rails are transversely arranged on an adjusting plate, a drilling motor is slidably arranged on the propelling rails, a left rotating column and a right rotating column are sleeved with supporting rotating mechanisms correspondingly, the left end of a lower connecting rod is fixedly connected with a grinding mechanism, a first distance sensor is fixedly arranged on one side of a rack on a measuring ring, and a controller is fixedly arranged on the outer side of the workbench. According to the machine, a measuring motor drives the first distance sensor to rotate to detect the surface of one side of a valve, the size information of a flange on the side face of the valve is measured, the thickness of the flange on the side face of the valve is measured in cooperation with a second distance sensor, and the controller calculates the position distribution among drilled holes according to the size information of the side face of the valve and the required number of the drilled holes.

Owner:ZHEJIANG HONGYE VALVE MFG CO LTD

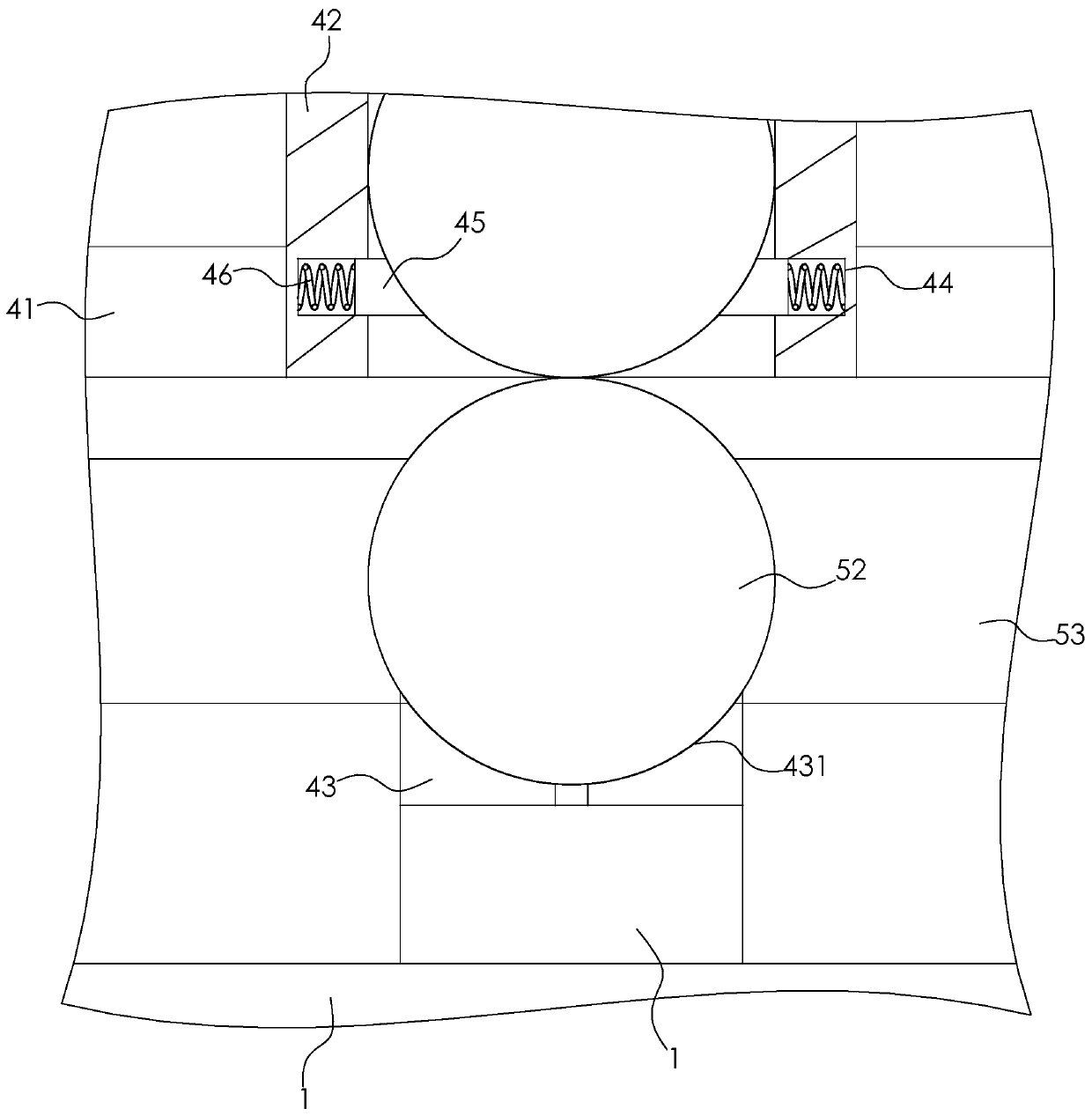

Diameter adjustable drill bit and drilling machine

InactiveCN109653682AStable structureRealize the function of diameter adjustmentDrill bitsConstructionsFrustumDrilling machines

The invention provides a diameter adjustable drill bit and a drilling machine and solves the problem of drilling diameter unadjustability in the prior art. The diameter adjustable drill bit comprisesat least two movable tool rests, a tool handle, a diameter adjusting module, an expansion core and a tool core, wherein the at least two movable tool rests are arranged in a circular mode and form aninternal big-end-up conical structure and an external big-end-up structure, and the outer wall and the lower end surface of every movable tool rest are provided with a plurality of tool bits; the lowend of the tool handle is provided with notches corresponding in number to the movable tool rest, and the movable tool rests are rotatingly arranged at the notches; the diameter adjusting module axially penetrates through the central hole of the tool handle, and the lower end of the diameter adjusting module is connected with the movable tool rests through connecting rods for driving the connecting rods to move up and down; the expansion core is in a big-end-up frustum structure, the upper end of the expansion core is fixed to the diameter adjusting module, and the outer wall of the expansioncore is in contact with the inner walls of the movable tool rests; the tool core is fixedly connected to the expansion core.

Owner:JIUJIANG VOCATIONAL & TECHN COLLEGE

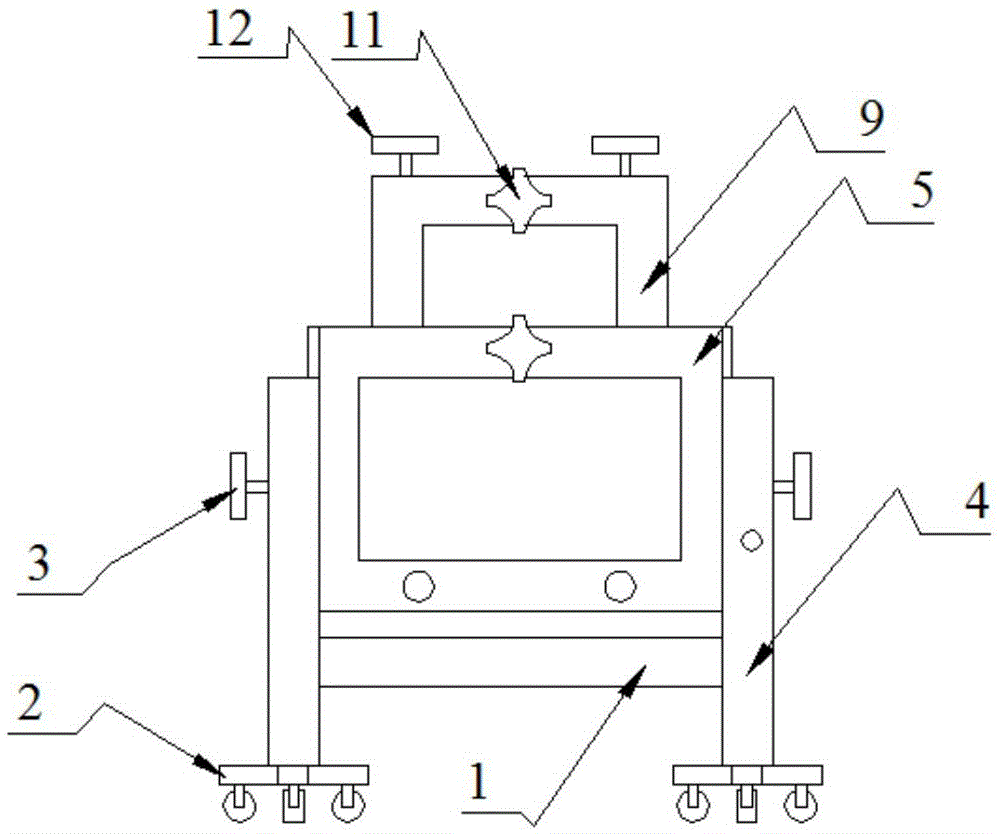

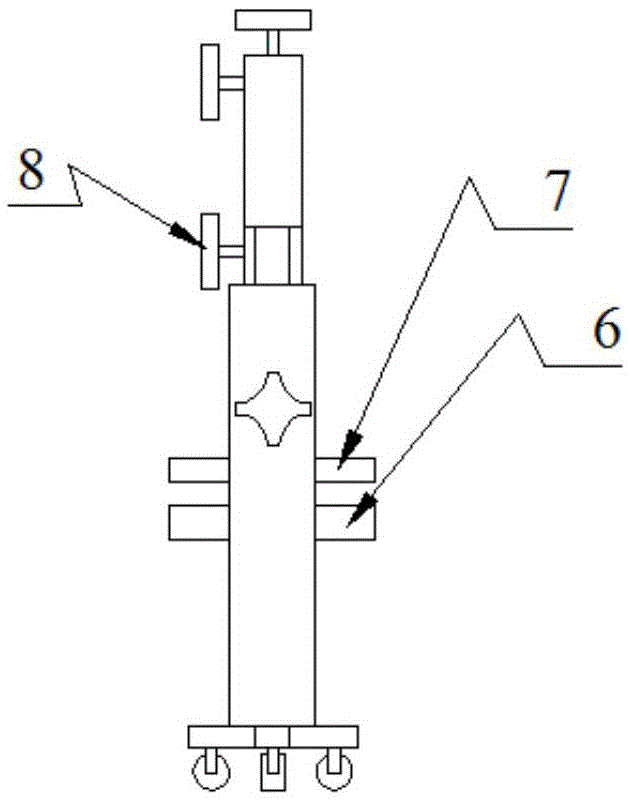

Single drilling device and method for high portion of building wall

ActiveCN105642949AIngenious designAchieve drillingWork benchesPortable drilling machinesDrill holeMechanical engineering

The invention relates to a single drilling device for a high portion of a building wall. The single drilling device comprises a movable support and an insertion fixing type supporting assembly. The movable support comprises a pair of stand columns, wherein the stand columns are in sliding fit with a sliding frame through vertical guide rails and can be locked to the sliding frame through first fastening screws. An installation support is fixedly arranged on the upper portion of the sliding frame and provided with a vertical clamping installation channel and a horizontal clamping installation channel. Lockable sliding wheels are arranged at the bottoms of the pair of stand columns. When the device is used for drilling holes vertically upwards, the insertion fixing type supporting assembly is installed in the vertical clamping installation channel, locking of the first fastening screws is removed, the lockable sliding wheels are locked, and an operator holds two vertical pushing handles with the hands and pushes the sliding frame upwards to carry out drilling operation. When horizontal drilling at a high portion is carried out, the insertion fixing type supporting assembly is installed in the horizontal clamping installation channel, the sliding frame slides upwards in place, locking is achieved through the first fastening screws, the lockable sliding wheels are unlocked, and the operator holds horizontal pushing handles with the hands to push forwards to carry out drilling operation.

Owner:ANHUI SCI & TECH UNIV

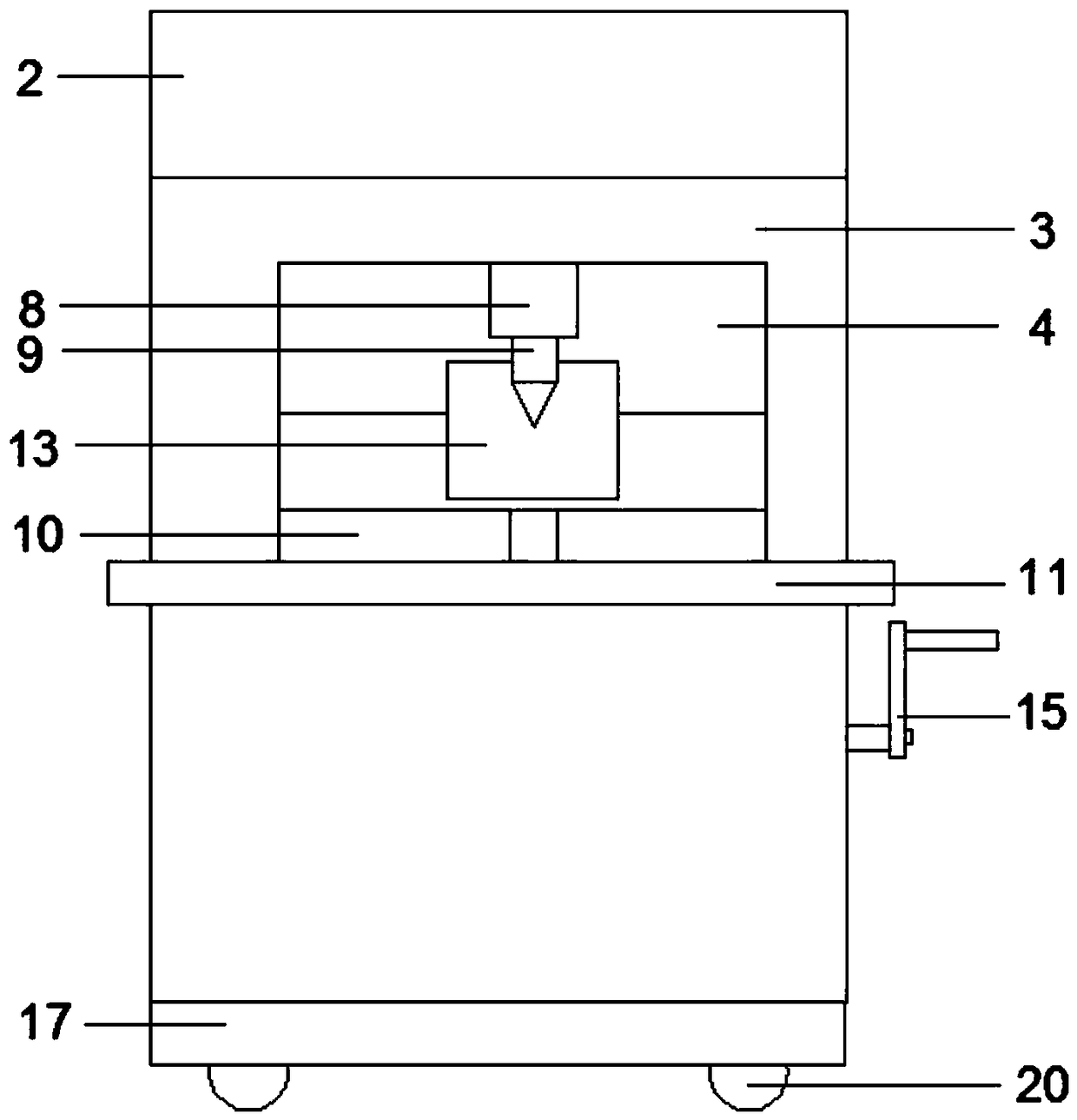

Special movable special drilling, milling and turning machine tool

InactiveCN101612701AAchieve millingAchieve drillingMeasurement/indication equipmentsOther manufacturing equipments/toolsArchitectural engineeringAlternating current

The invention discloses a special movable drilling, milling and turning machine tool, which comprises a cross-beam, wherein the cross-beam passes through the inside of an arranged vertical beam; the lower end of the vertical beam is connected with a round disc; one end of the cross-beam is connected with a tool holder device, while the other end is connected with a vertical milling device; the top of the cross-beam is provided with two parallel grooves; the inside of each of the two grooves is provided with a horizontal moving rack; the upper end of the outer wall of the cross-beam is provided with a groove; the inside of the groove is provided with a movable counterweight; four end points of the top of the vertical beam are all provided with counterweights; the four counterweights are all connected with pressing blocks; the top of the vertical beam is provided with a lifting tooth box; the lifting tooth box is provided with a vertical lifting motor; the rear side of the vertical beam is connected with an electric appliance box; two vertical limit switches are arranged at the upper part and the lower part of the cross-beam respectively; the upper end surface of the round disc is provided with a main rotating motor, an alternating current motor and an electromagnetic speed regulation motor; and the alternating current motor and the electromagnetic speed regulation motor are connected. The machine tool has the advantages that the machine tool can process large revolving members, save the time, and improve work efficiency.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Automatic-control numerical-control double-head milling and drilling integrated composite machine

ActiveCN111975366AReduce the difficulty of operationReduce the accumulative error of clampingOther manufacturing equipments/toolsPositioning apparatusHydraulic cylinderAutomatic control

The invention discloses an automatic-control numerical-control double-head milling and drilling integrated composite machine, relates to the technical field of machining devices, and particularly relates to an automatic-control numerical-control double-head milling and drilling integrated composite machine. The automatic-control numerical-control double-head milling and drilling integrated composite machine comprises a supporting base platform; and a rotating shaft is fixedly installed at the top of the supporting base platform. According to the automatic-control numerical-control double-headmilling and drilling integrated composite machine, two-stage clamping hydraulic cylinders at the front and rear sides are used for clamping a workpiece; the position of a milling motor is adjusted bya first servo motor, a second servo motor and a third servo motor so that the right side of the workpiece can be machined; a control table is used for controlling a fourth servo motor to drive a transmission gear to rotate; the position of the milling motor is adjusted to mill the left side of the workpiece; the control table is used for controlling a first-stage clamping hydraulic cylinder to drive a pressing disc to move downwards to clamp the workpiece; the two two-stage clamping hydraulic cylinders are controlled by the control table to release the workpiece; and the fourth servo motor isused for driving the milling motor to rotate 90 degrees.

Owner:黄朋飞

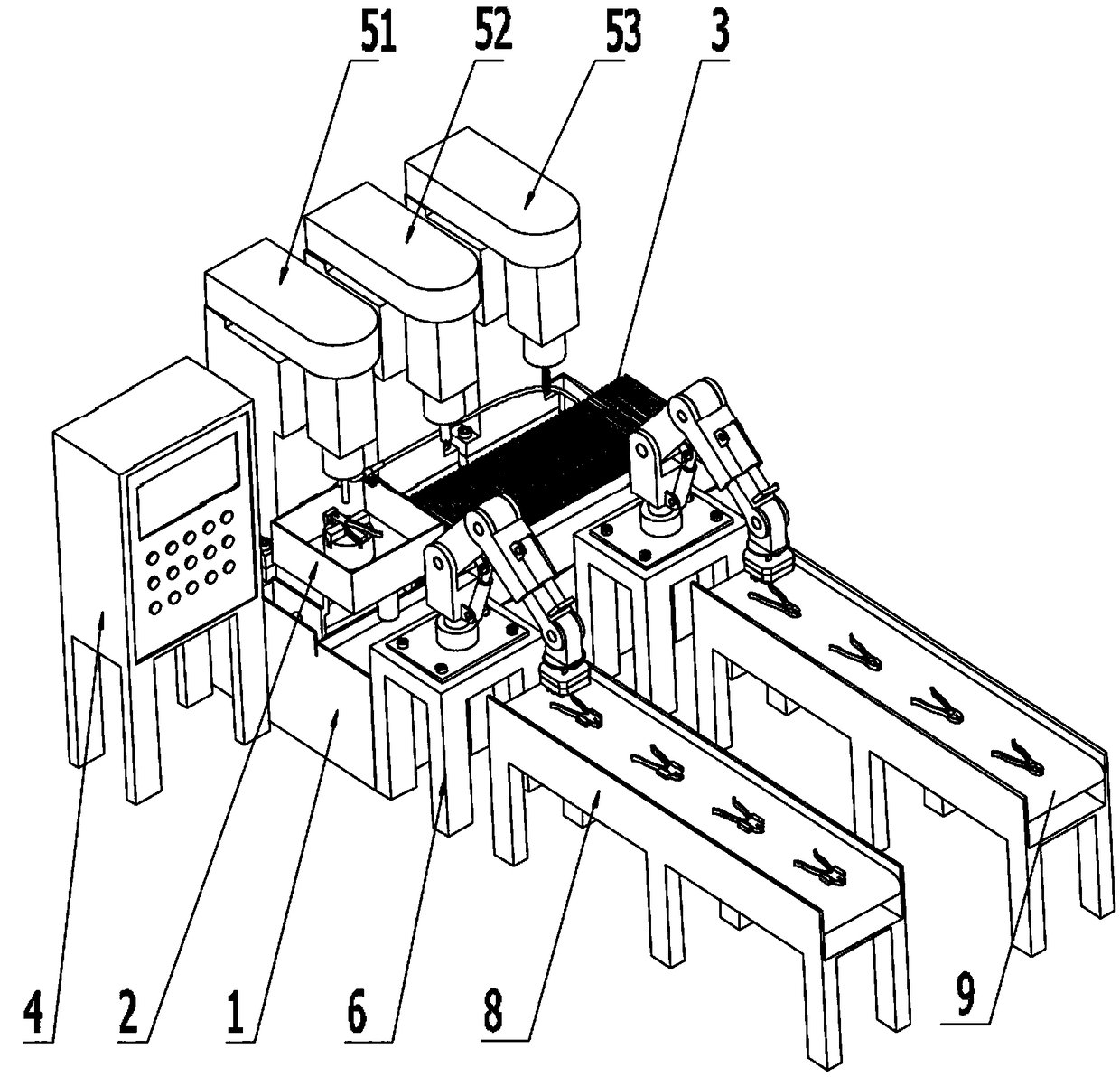

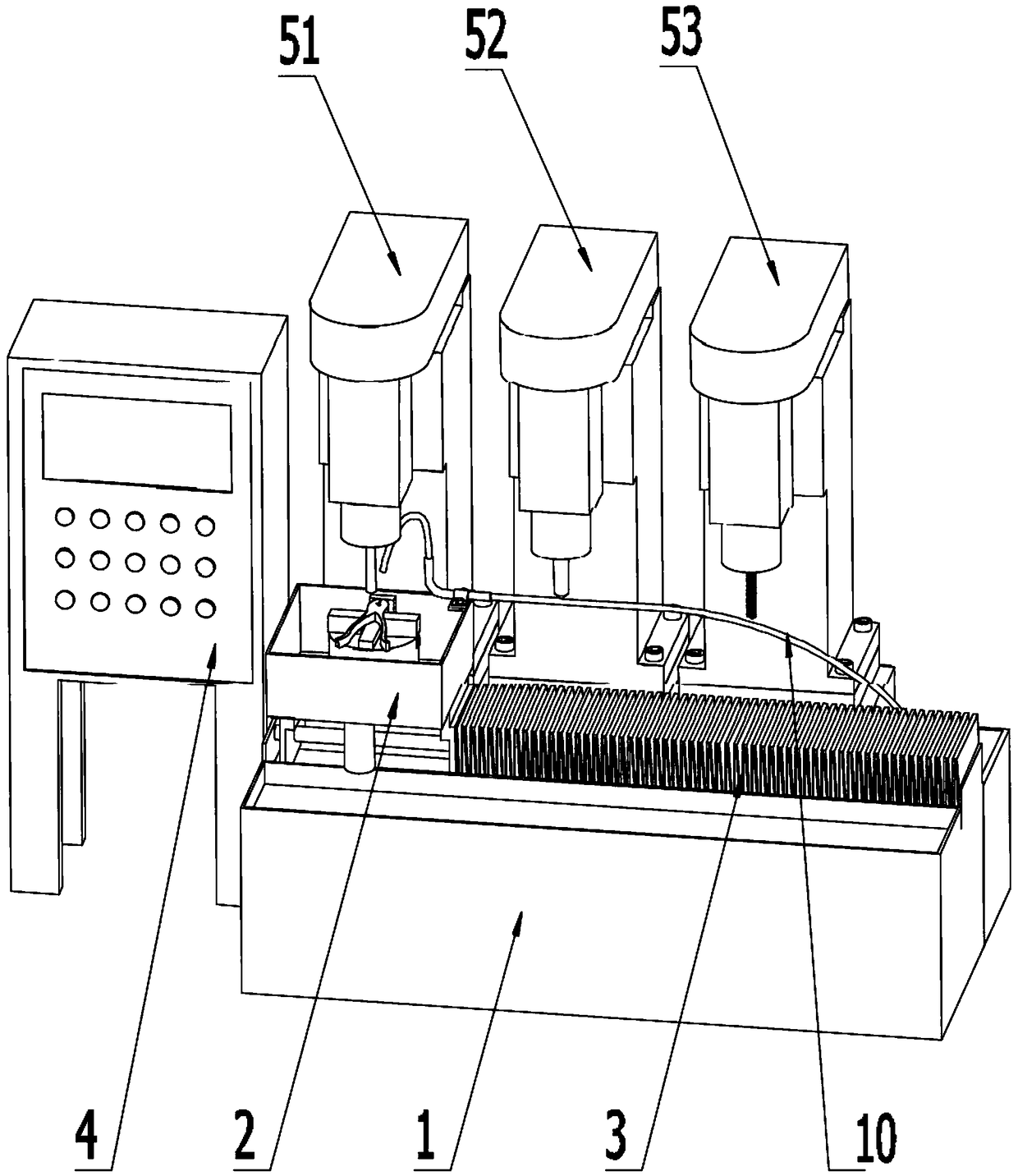

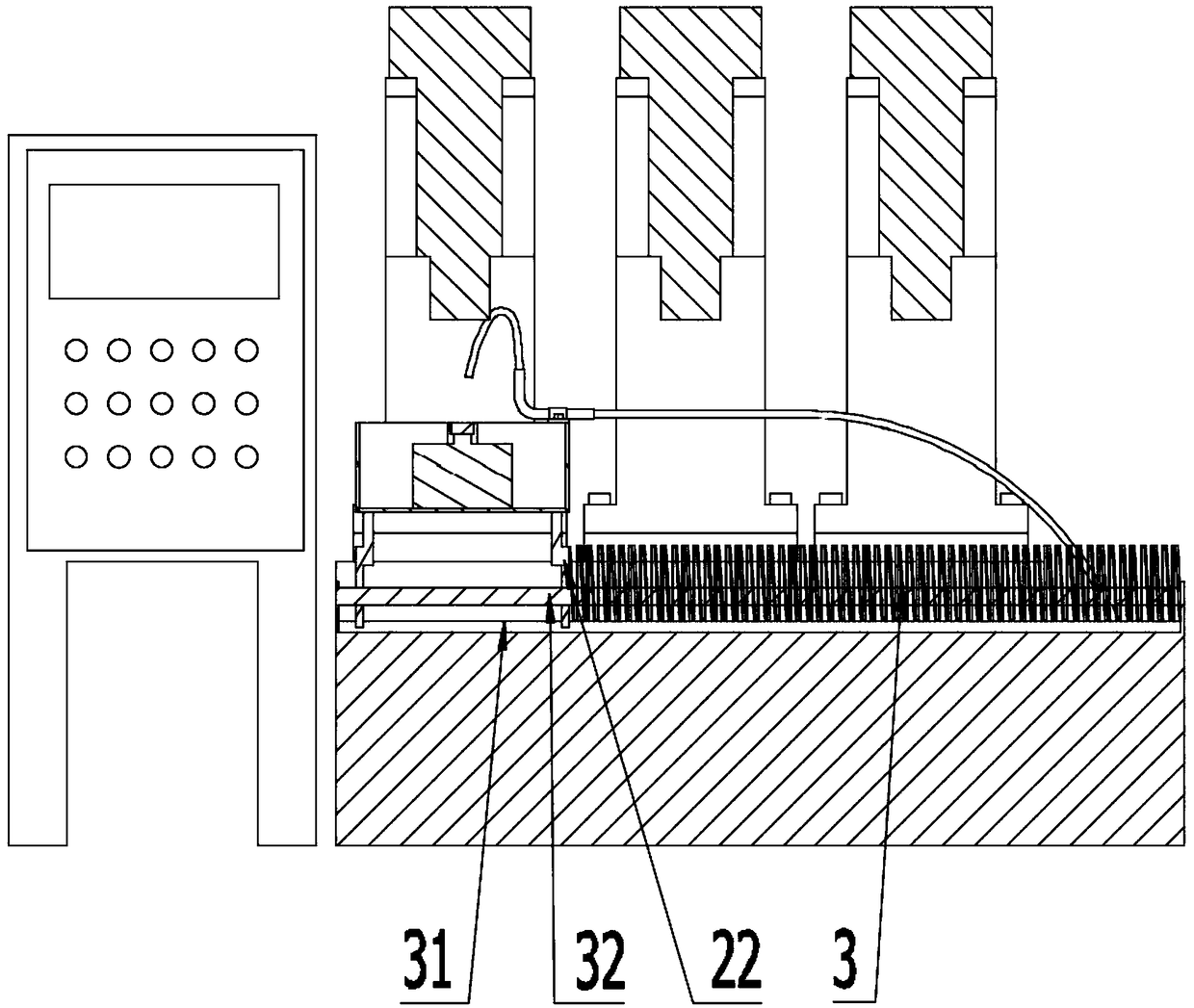

Drilling, chamfering and tapping integrated machine equipment for combination pliers

PendingCN108817967AAvoid drillingReduce precisionOther manufacturing equipments/toolsPositioning apparatusEngineeringDrilling machines

The invention relates to the field of processing and manufacturing of combination pliers and discloses drilling, chamfering and tapping integrated machine equipment for combination pliers. The drilling, chamfering and tapping integrated machine equipment comprises a working table, a moving shell, a telescopic air cushion and a control box, wherein the moving shell is concave; a drilling machine, achamfering machine and a tapping machine are sequentially arranged above the moving shell; support tables are arranged in front of the drilling machine and the tapping machine, mechanical arms are arranged on the support tables, and are suitable for clamping the combination pliers; and the control box is used for controlling the drilling, chamfering and tapping integrated machine equipment for the combination pliers. The whole equipment realizes the integration of drilling, chamfering and tapping of the combination pliers, and has high working efficiency.

Owner:JIANGSU HONGBAO HARDWARE

Drilling tool for gear shafting rocker arm

InactiveCN108608029AAchieve clampingAvoid damagePositioning apparatusMaintainance and safety accessoriesEngineeringRocker arm

The invention belongs to the field of automobile part machining, and particularly discloses a drilling tool for a gear shifting rocker arm. A machine frame is fixedly connected with a workbench, a first bevel gear, a second bevel gear and a third bevel gear are rotationally connected to the machine frame and above the workbench, the first bevel gear and the third bevel gear each is in threaded connection with a first screw rod, a connecting rod is hinged to the machine frame, the upper end of the connecting rod is hinged to the first screw rod, and a clamping plate is hinged to the lower end of the connecting rod; the second bevel gear is in threaded connection with a second screw rod, a piston barrel is fixedly connected to the machine frame, a piston is slidably connected in the piston barrel, the lower end of the second screw rod is fixedly connected with the piston, and the lower side of the piston is fixedly connected with a hollow mandrel; and the mandrel comprises an air inlet section, a throat portion and an air outlet section which are arranged from top to bottom, the inner diameter of the air outlet section is larger than the inner diameter of the throat portion, and thelower end of the air outlet section is fixedly connected with a drill bit. By the adoption of the scheme, the problems that scrap iron generated during drilling is required to be cleaned manually, andtime and labor are wasted are solved.

Owner:重庆市乐珐机电有限责任公司

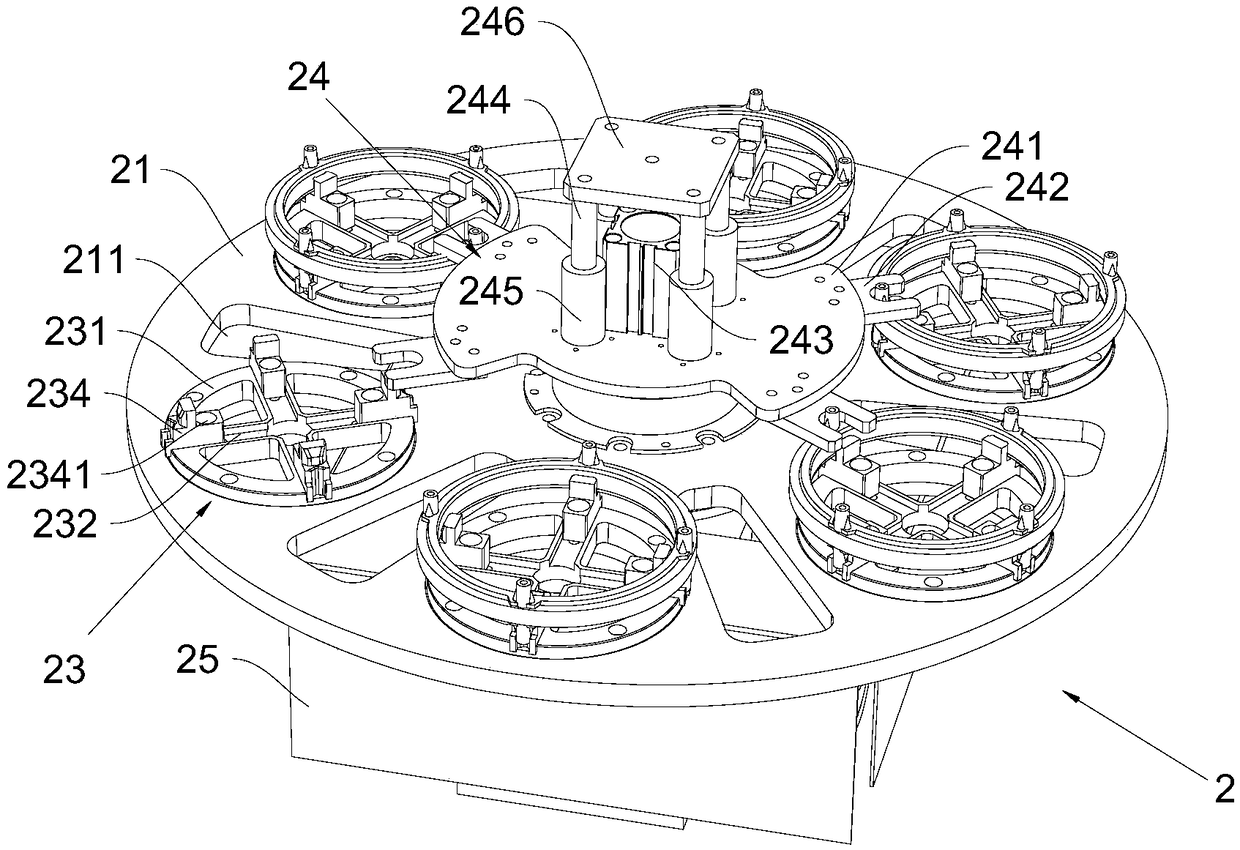

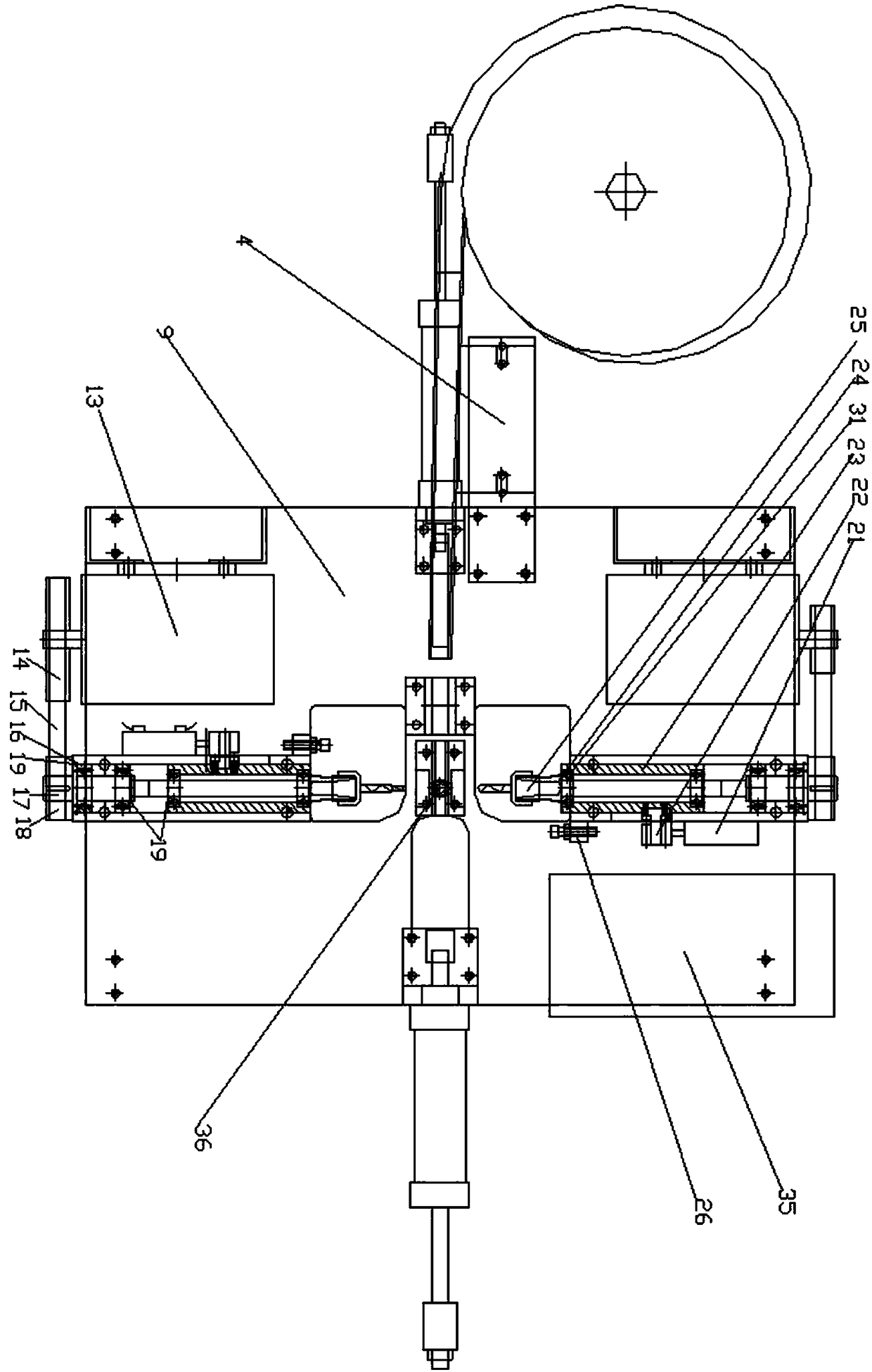

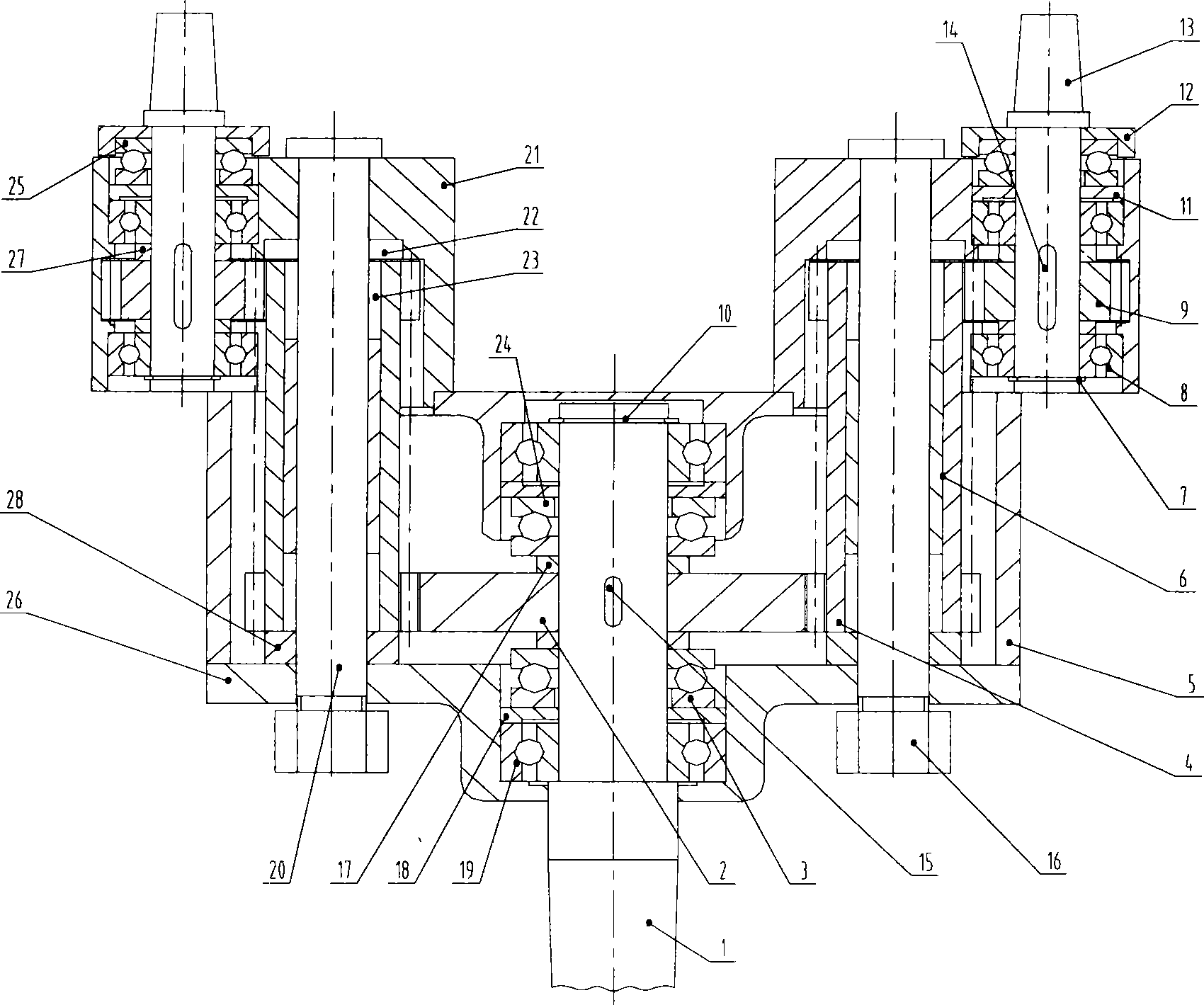

Drilling-tapping all-in-one machine

PendingCN109454457AReduce dependenceImprove processing efficiencyPrecision positioning equipmentOther manufacturing equipments/toolsTransport timeWorking environment

The invention provides a drilling-tapping all-in-one machine which solves the problem that an existing motor ring processing process is complex. According to the technical scheme, the key point is that the drilling-tapping all-in-one machine comprises a rack and an oil supply system, wherein an indexing positioning device which is rotatably connected with the rack is arranged on the rack; a turnover device for turning over workpieces is arranged on the rack; processing devices are arranged on the positions, at the two sides of the turnover device, of the rack; and each processing device comprises a drilling device and a tapping device. The indexing positioning device, the processing devices and the turnover device are arranged on the rack, so that the workpieces are transported to each station through the indexing positioning device, one workpieces is clamped once and processing of positive and negative surfaces is accomplished, multi-time calibration is not needed, processing time isshortened, and processing efficiency is improved; and moreover, the turnover device can automatically turn over the workpiece, equipment processing speed is increased, transportation time is saved, workpiece collision is avoided, working environment of a worker is improved, working strength is reduced, fatigue of the worker is reduced, and processing quality of the workpiece is guaranteed.

Owner:广东顶固集创家居股份有限公司

Full-automatic double-face drilling and chamfering machine

PendingCN108284321AAchieve drillingRealize chamferOther manufacturing equipments/toolsBoring/drilling machinesTransmission beltDrill

The invention relates to a full-automatic double-face drilling and chamfering machine. The machine comprises a feeding mechanism, a drilling mechanism, a limiting mechanism and an electric cabinet; the feeding mechanism is composed of a vibrating disc, a linear material channel, a material detecting sensor, a linear vibrator, a pushing air cylinder and a push rod; the drilling mechanism is composed of a material groove, a clamp, a motor, a first belt disc, a transmission belt, a first bearing, a spline sleeve, a second belt disc, a clamp spring, a shell, an air cylinder, a connecting block, asleeve, a second bearing, a spline shaft, a drill chuck and a limiting screw; the limiting mechanism is composed of a limiting air cylinder and a stop block; and the electric cabinet is used for allowing electrical equipment to be installed, the vibrating disc is arranged on a vibrating disc seat, and the rest parts are all arranged on a working table. The problem that after drilling is carried out through drilling equipment, manual face-turning needs to be carried out for chamfering and burr removing is solved, the technical innovation of full-automatic double-face drilling and chamfering isrealized, and the working efficiency of equipment is greatly improved.

Owner:金勇

Machining device for mechanical arm

ActiveCN111230501ARealize automatic loading and unloadingAchieve positioningOther manufacturing equipments/toolsMetal working apparatusRobot handMachining process

The invention relates to a machining device for a mechanical arm. The machining device comprises a rack and a first transfer belt, a shelf is arranged at the input end of the first transfer belt, a worktable is arranged at the output end of the first transfer belt, and a discharging assembly is arranged on the side, away from the first transfer belt, of the worktable. The two ends of the worktableare both provided with a withstanding plate and a driving piece, and a plurality of insertion columns are fixed to the sides, facing steel pipes, of the two withstanding plates; a plurality of cutting assemblies, a plurality of drilling assemblies and a plurality of pressing assemblies are arranged on the upper side of the worktable, and the rack is provided with a lifting assembly and a drivingassembly. In the steel pipe machining process, the first transfer belt conveys the steel pipes onto the worktable, the driving pieces drive the withstanding plates to withstand the end portions of thesteel pipes, then the pressing assemblies tightly press the steel pipe, and all the cutting assemblies and drilling assemblies machine the steel pipes. After the steel pipes are cut and drilled, themachined steel pipes are pushed by new steel pipes onto the discharging assembly. By means of the machining device, the steel pipe machining efficiency is greatly improved.

Owner:杭州现代机械有限公司

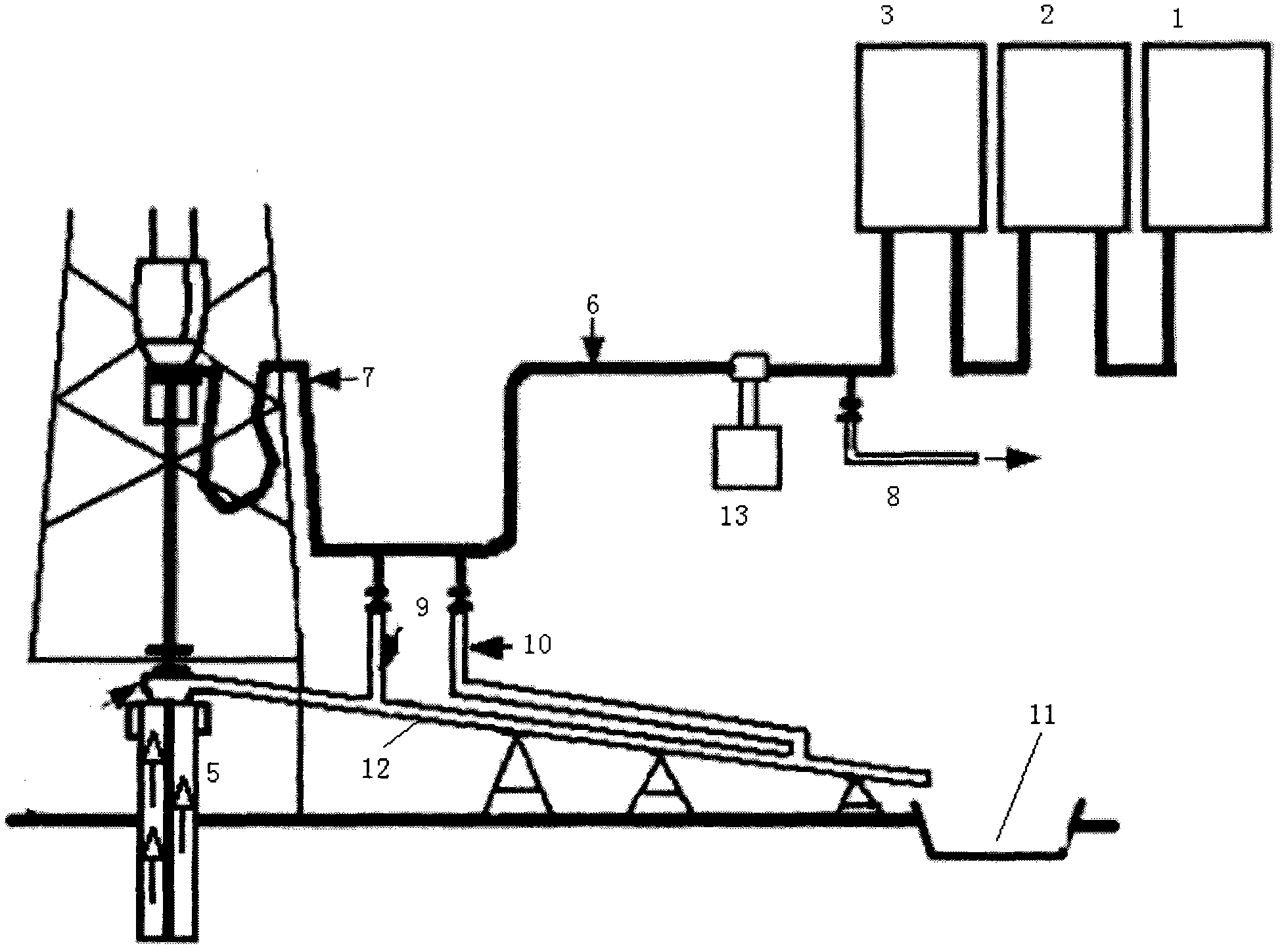

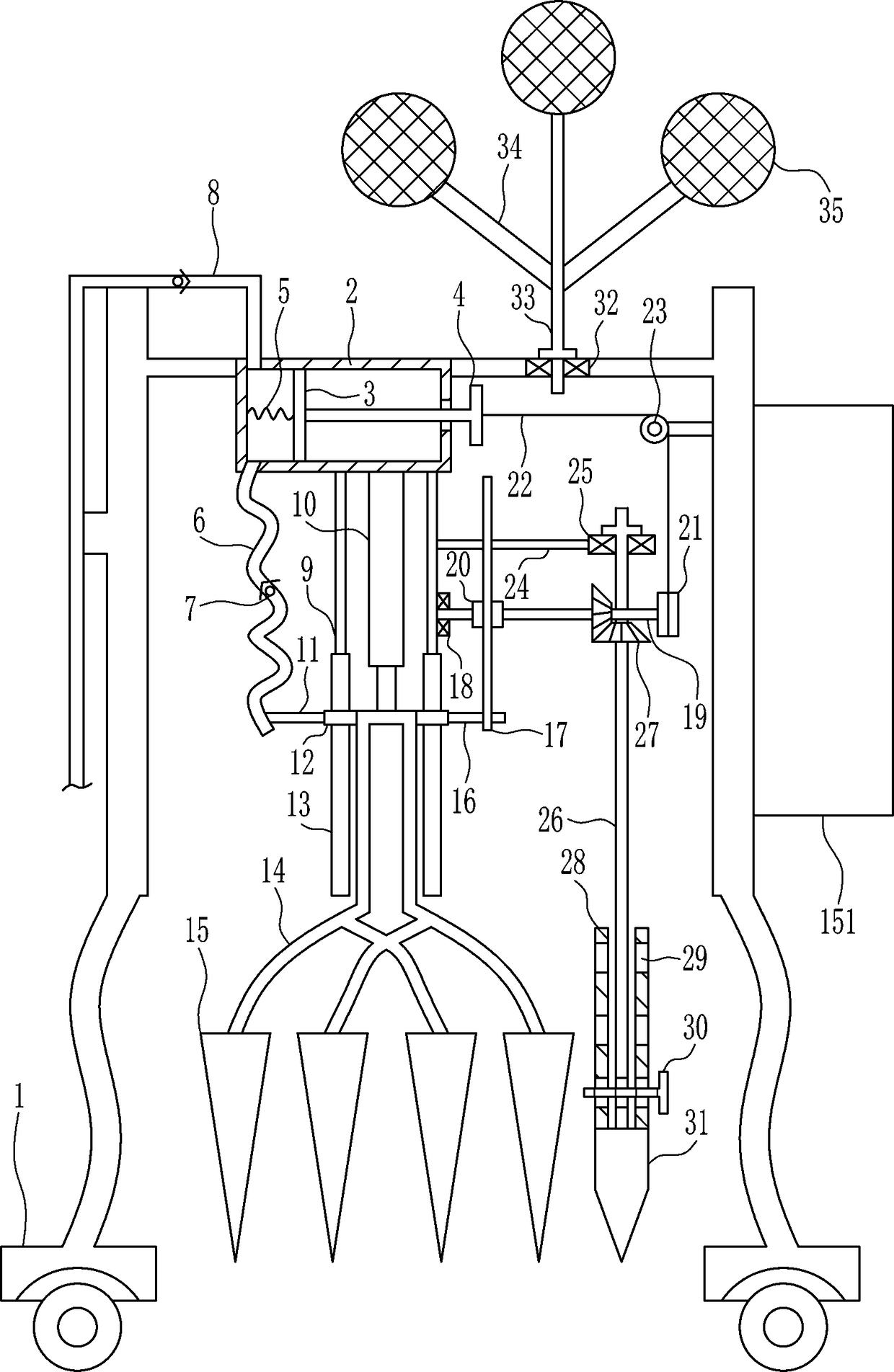

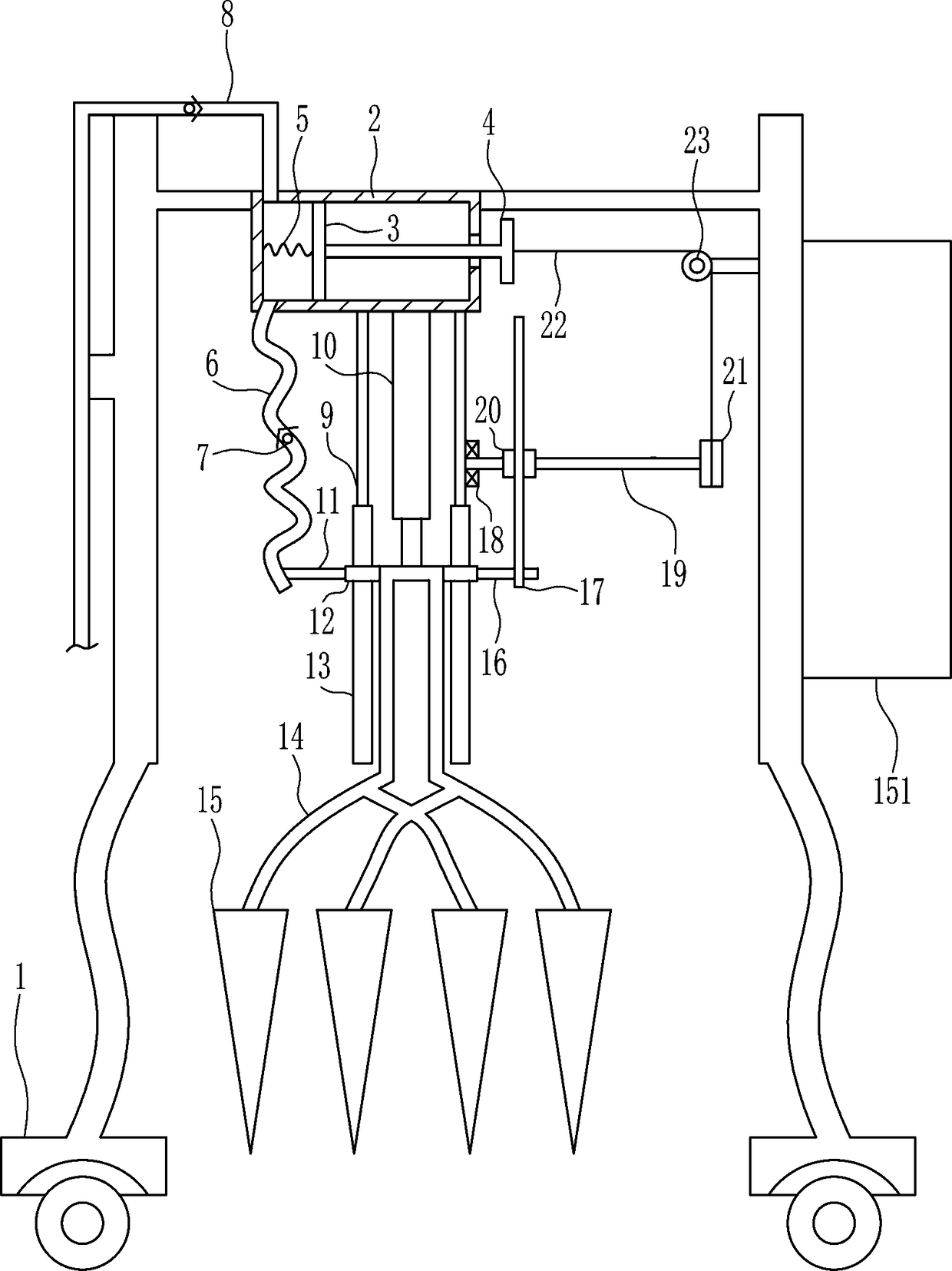

Nitrogen well-drilling method in well-drilling field

The invention discloses a nitrogen well-drilling method in the well-drilling field. The nitrogen well-drilling method comprises: (a) air enters into a membrane separation nitrogen making machine (2) after being compressed through an air compressor (1); (b) the compressed air is separated through the membrane separation nitrogen making machine (2), and nitrogen which is more than 95% in purity is obtained and enters into a supercharger (3); (c) the nitrogen which is compressed and separated is further supercharged through the supercharger (3) and then enters into a manifold system; (d) the nitrogen entering into the manifold system passes through a rotary blowout preventer (5) and then is injected under a well; and (e) the nitrogen enables drilling cuttings under the well to be brought onto the ground, the drilling cuttings pass through a rock discharging pipe (12) and then enter into a ground recovery pond, and the whole process is finished. By means of the nitrogen well-drilling method in the well-drilling field, nitrogen well-drilling can be achieved successively, new development is brought to petroleum and natural gas extraction of China, and meanwhile, continuous development of gas well-drilling equipment of China is also prompted.

Owner:母东艳

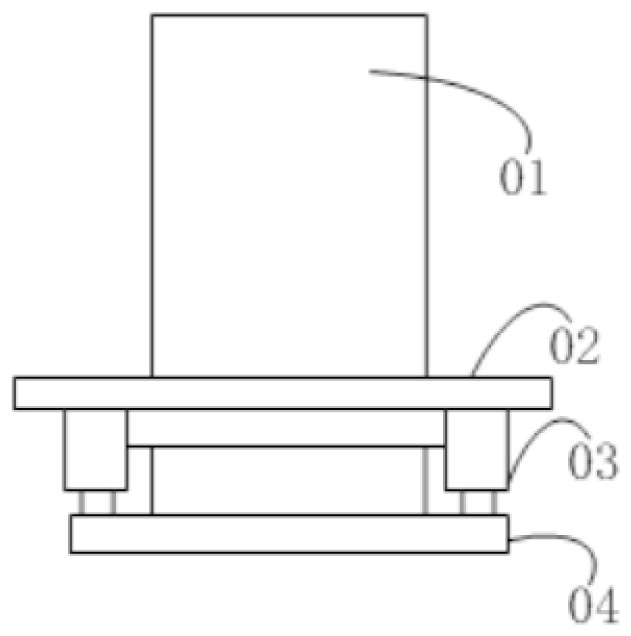

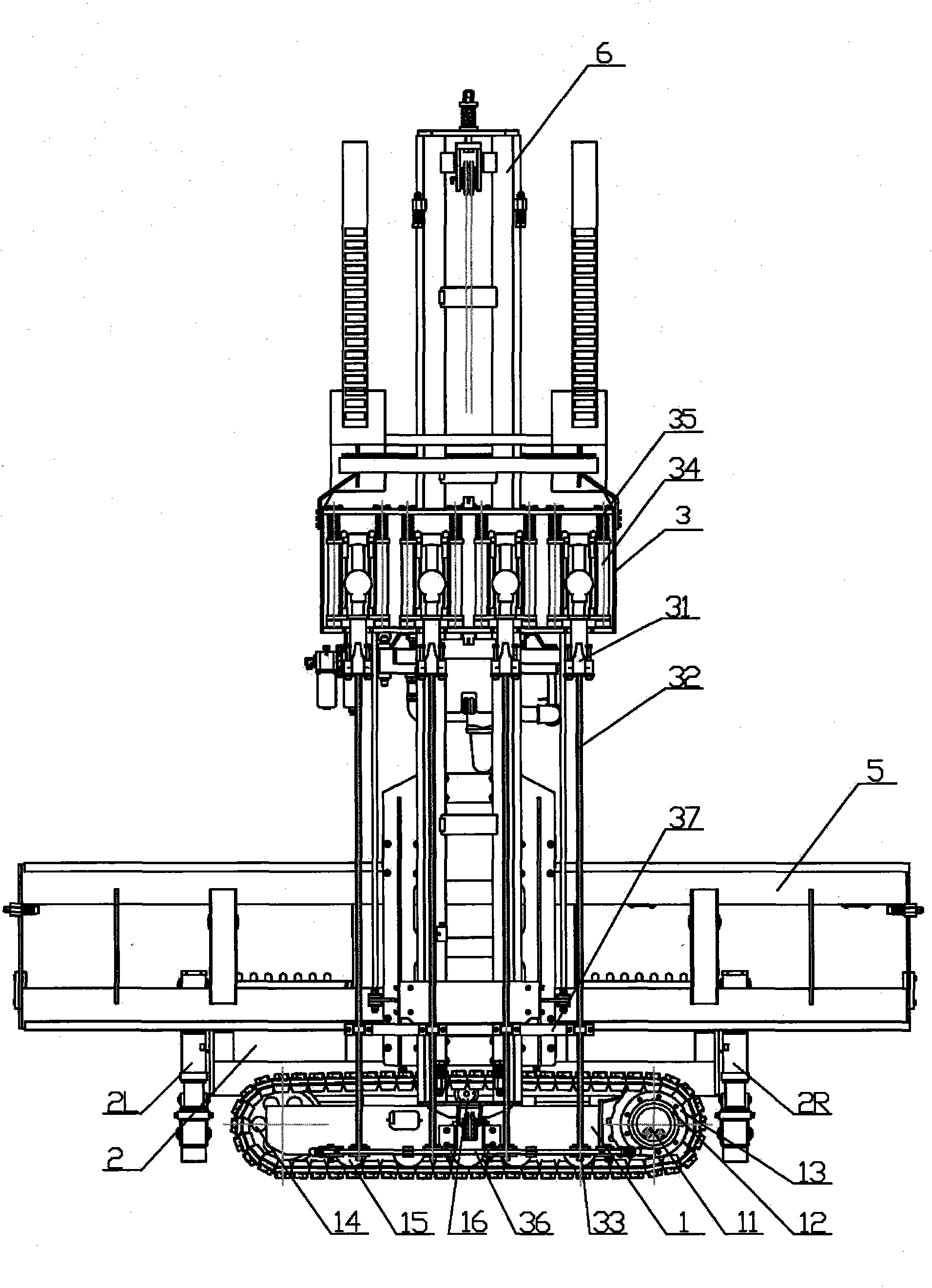

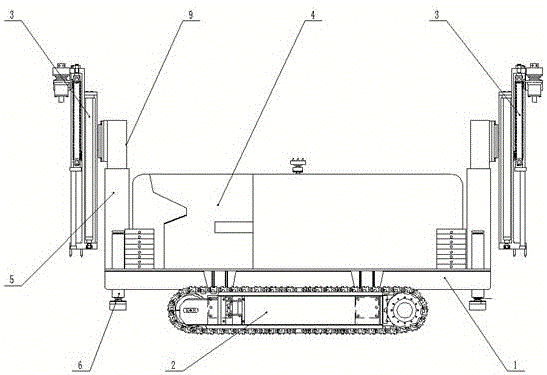

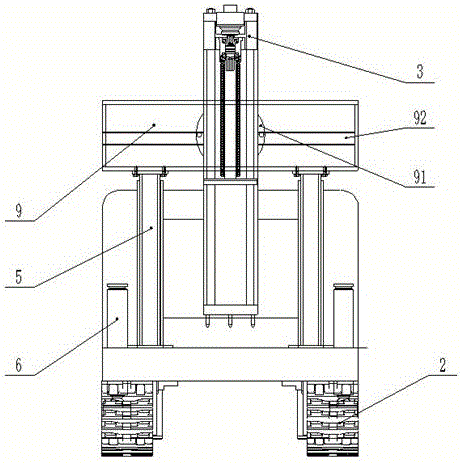

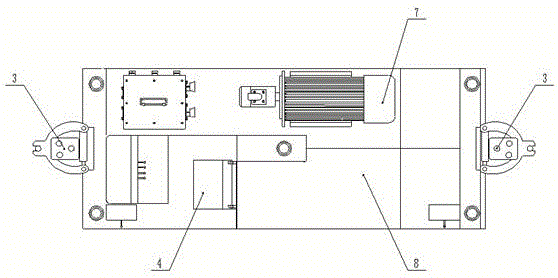

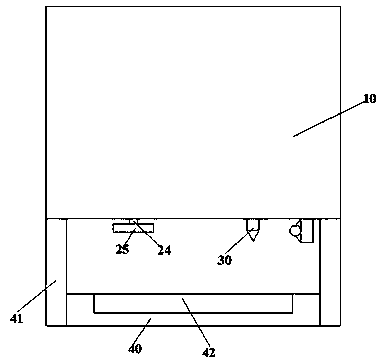

Full-casing full-slewing drilling machine device

ActiveCN113294138AAutomated accessAchieve drillingConstructionsRotary drillingControl engineeringStructural engineering

The embodiment of the invention provides a full-casing full-slewing drilling machine device, and relates to a mechanical equipment technology in a low-clearance construction environment. The full-casing full-slewing drilling machine device comprises a main machine frame, a slewing drilling mechanism and a controller, a casing hole used for being matched with a casing pipe is formed in a bottom plate of the main machine frame; a slewing drilling device is connected to the top of the main machine frame; the slewing drilling mechanism is provided with a drilling assembly, a detection piece and an adjusting assembly. The drilling assembly is used for driving the casing pipe to drill; the adjusting assembly is connected between the drilling assembly and the main machine frame; the detection piece is arranged on the main machine frame; the controller is electrically connected with the detection piece and the adjusting assembly, and the controller is used for controlling the adjusting assembly to adjust the perpendicularity of the casing pipe according to a detection result of the detection piece. According to the full-casing full-slewing drilling machine device, under the low-clearance construction environment, automatic taking and drilling of the casing pipe can be realized, automatic deviation correction of the casing pipe in the casing pipe drilling process is realized, and drilling and soil sampling can be realized at the same time.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

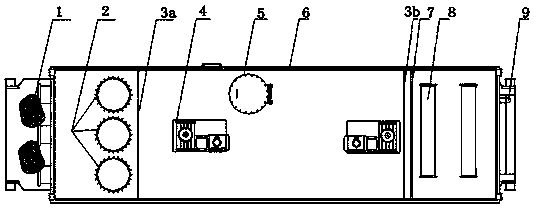

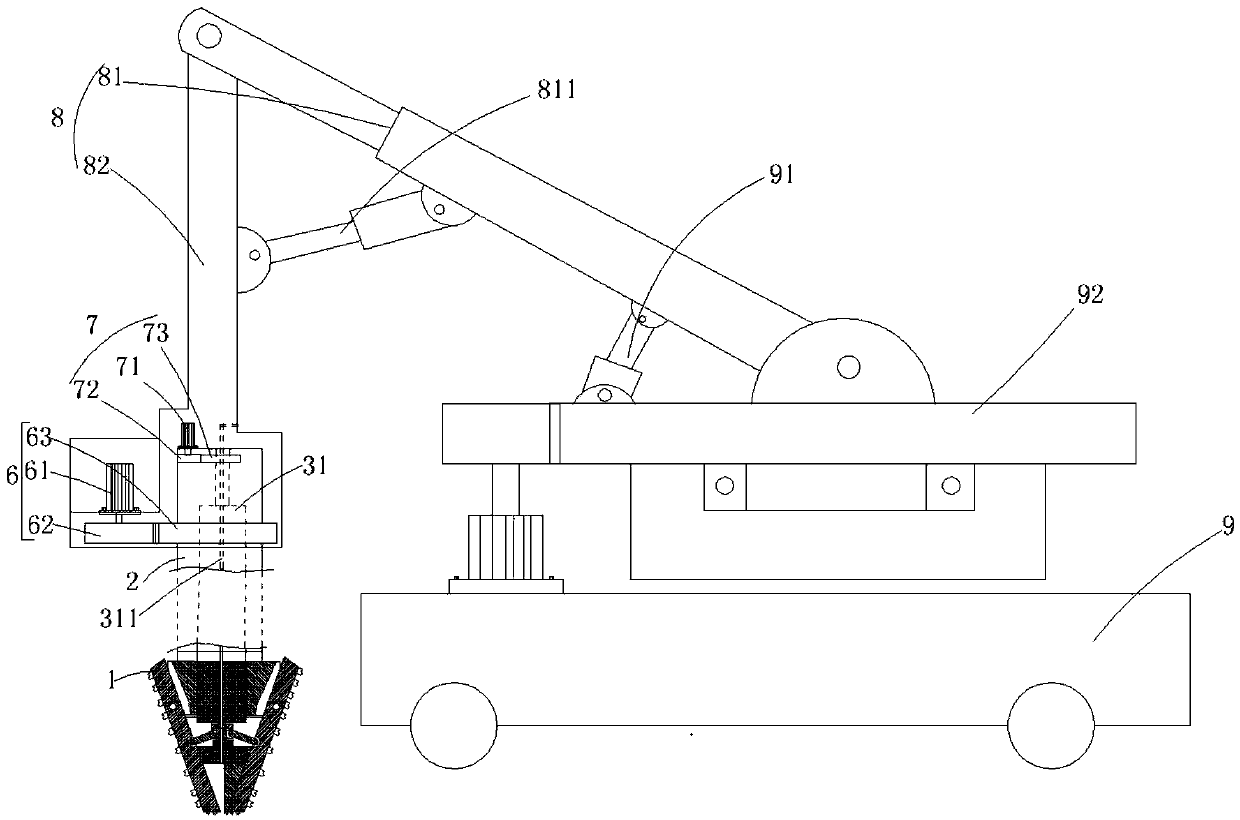

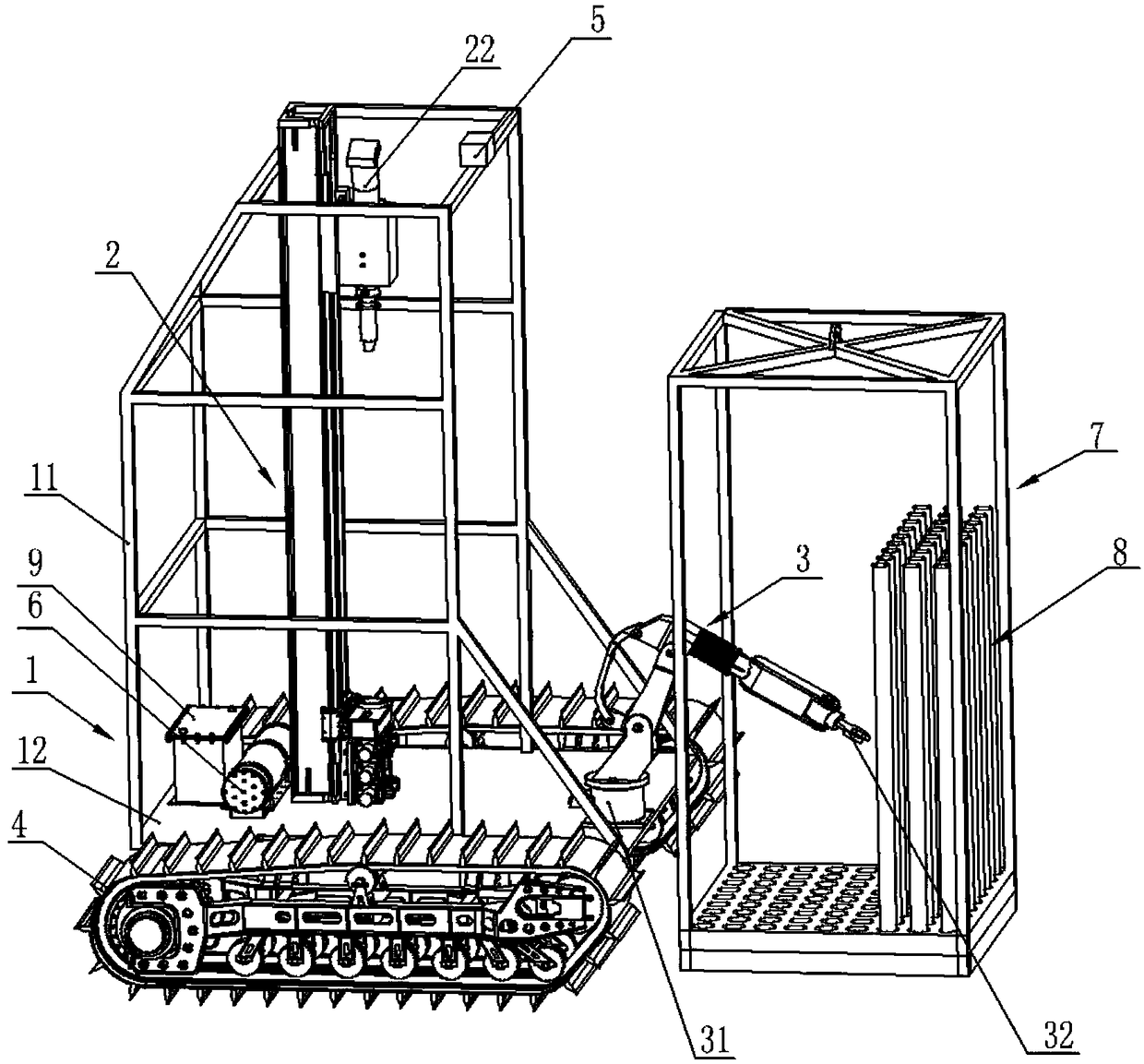

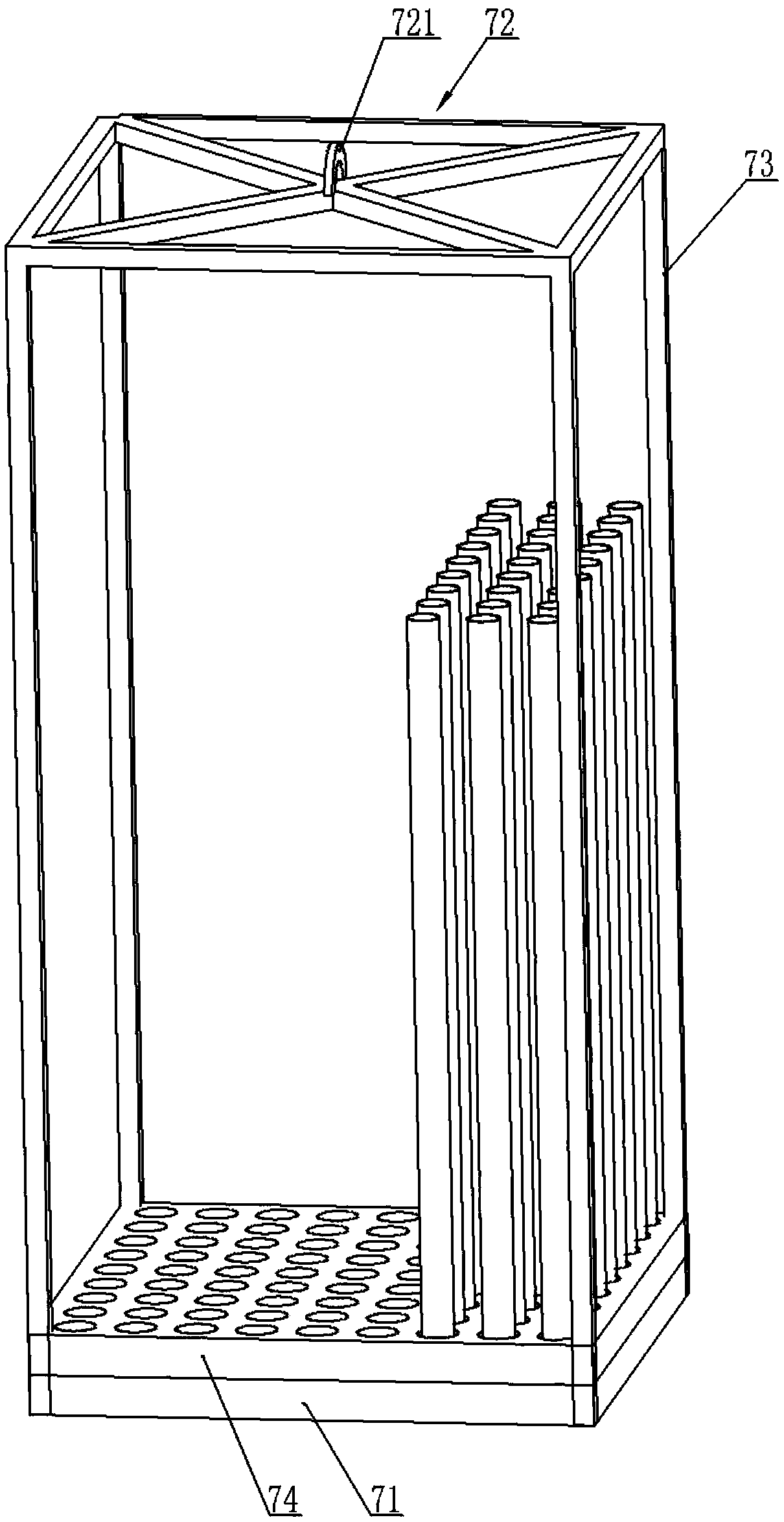

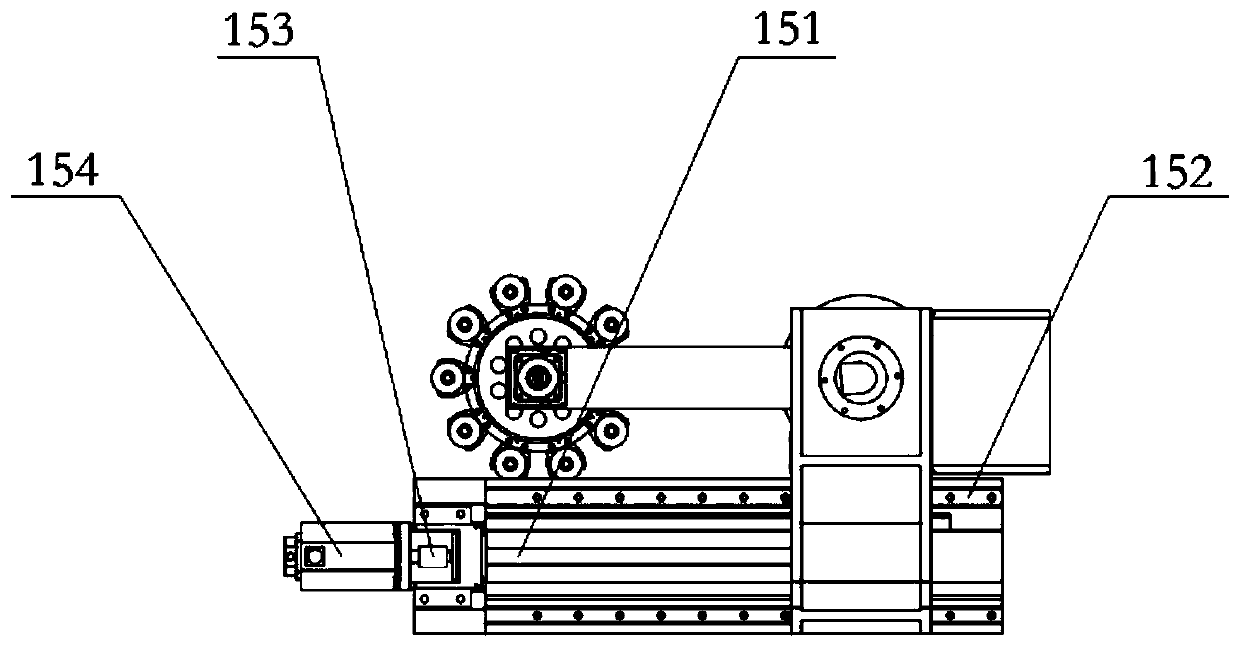

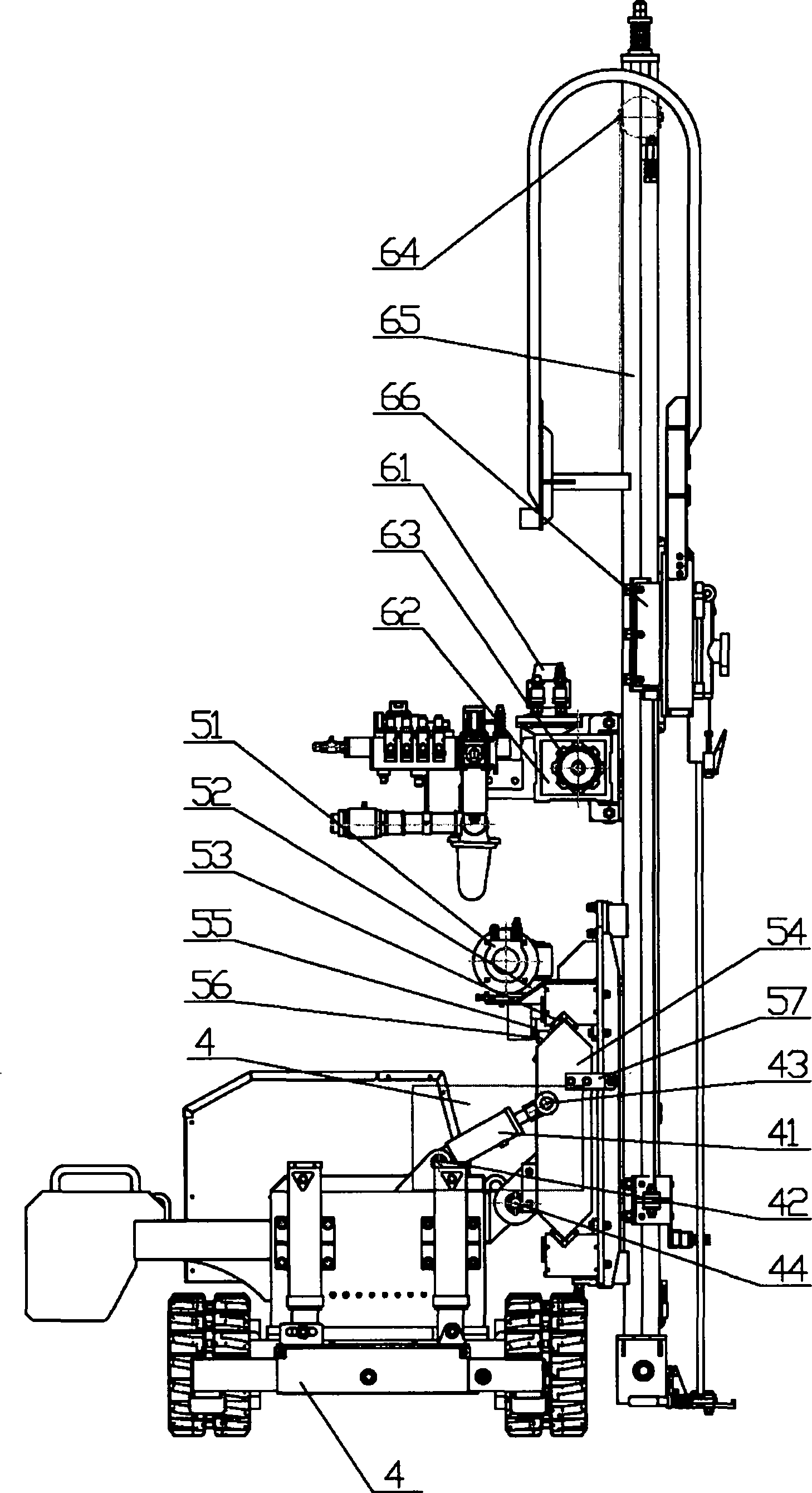

Seabed deep hole drilling machine and application method thereof

PendingCN108868612AReduce size and weightReduce weightDrilling rodsDrilling casingsDrilling systemDrill pipe

The invention discloses a seabed deep hole drilling machine and an application method thereof. The drilling machine comprises a frame and a pipe storage frame which are mutual independence, a bottom traveling track, a mechanical arm, a drilling system and an acoustic system are mounted on the frame, the pipe storage frame is used for storing drilling rods and / or drilling tools, and the bottom traveling track, the mechanical arm, the drilling system and the acoustic system form a drilling machine body. The pipe storage frame and the drilling machine body are sequentially placed into a sea bed,the drilling machine body searches the pipe storage frame through the drilling machine body, the bottom traveling track runs near the pipe storage frame, the drilling rods and / or drilling tools on thepipe storage frame is transferred to the drilling system by the mechanical arm in the working process, the drilling rods and / or drilling tools are connected by the drilling system to drill and sample, and the recovered drilling rods and / or drilling tools are transferred to the pipe storage frame. The pipe storage frame and the drilling machine body are placed into the sea bed, the weight and thesize of the pipe storage frame and the drilling machine body are greatly reduced, more drilling rods and / or drilling tools can be placed on the pipe storage frame through a take-up and pay-off mechanism supporting a mother ship, and a deep hole is drilled.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

High-efficiency drilling device

ActiveCN111299637ARealize fully automatic loading and unloadingAchieve drillingPositioning apparatusMetal working apparatusEngineeringWorkbench

The invention relates to a high-efficiency drilling device. The high-efficiency drilling device comprises a workbench, a drilling machine and a location block, wherein a location hole is formed in thetop of the location block, a transversal through hole is formed in the sidewall of the location block, and holes in the two sides of the transversal through hole are a charge port and a discharge port separately; and a loading assembly, a pushing assembly, an elastic clamping assembly and a guide element are arranged on the workbench. In a drilling process, a first group of workpieces are loadedthrough the loading assembly at first, and then are pushed into the transversal through hole through the pushing assembly; and then a second group of workpieces are loaded into the transversal throughhole through the pushing assembly, the elastic clamping assembly is enabled to clamp the first group of workpieces, at this moment, the first group of workpieces and the pushing assembly clamp the second group of workpieces in the transversal through hole, the abovementioned operation is repeated, and then fully-automatic loading, unloading and drilling for the workpieces can be realized. According to the high-efficiency drilling device, the drilling efficiency for the workpieces is greatly increased.

Owner:杭州顺钢机械有限公司

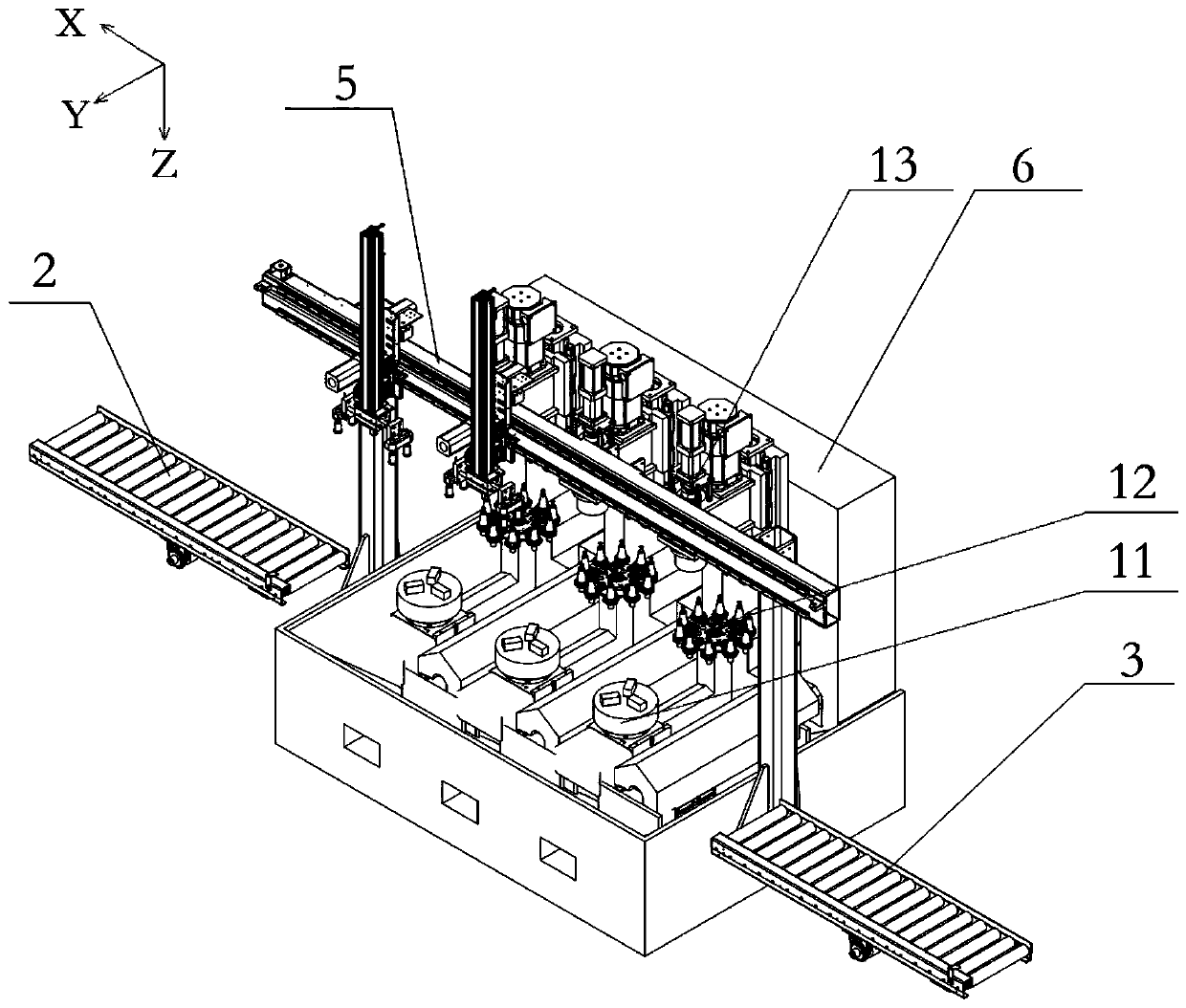

Airplane fastening hole processing equipment

ActiveCN107900683AImprove processing efficiencyImprove stabilityMeasurement/indication equipmentsFeeding apparatusJet aeroplaneEngineering

The invention discloses airplane fastening hole processing equipment. The airplane fastening hole processing equipment has the characteristic of high hole processing precision, and a main upright column and a secondary upright column are designed and are in transmission connection through a chain wheel transmission mechanism, so that cross beams can be lifted synchronously, and the airplane fastening hole processing equipment can guarantee that the main shaft has sufficiently high stability during processing, and the processing precision is improved; the airplane fastening hole processing equipment has the characteristic of high hole processing efficiency, and a plurality of drilling main shafts and reaming main shafts are arranged on the same main shaft box and arranged in a staggered way, so that a plurality of holes can be processed simultaneously, drilling and reaming operation can be realized simultaneously, and laser can be used for detecting whether the hole processing precisionreaches the standard or not at once after the holes are processed.

Owner:贵州厚诚发科技有限公司

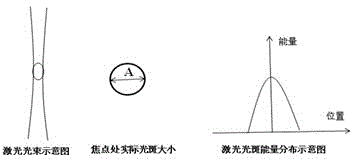

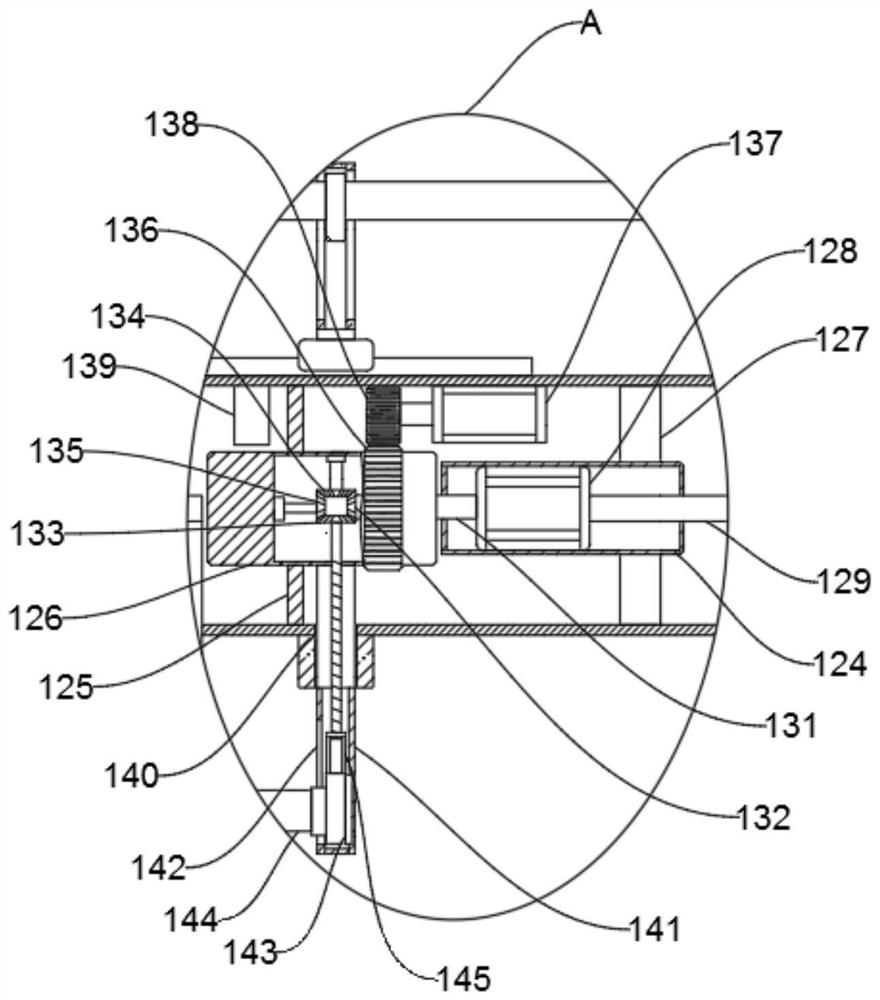

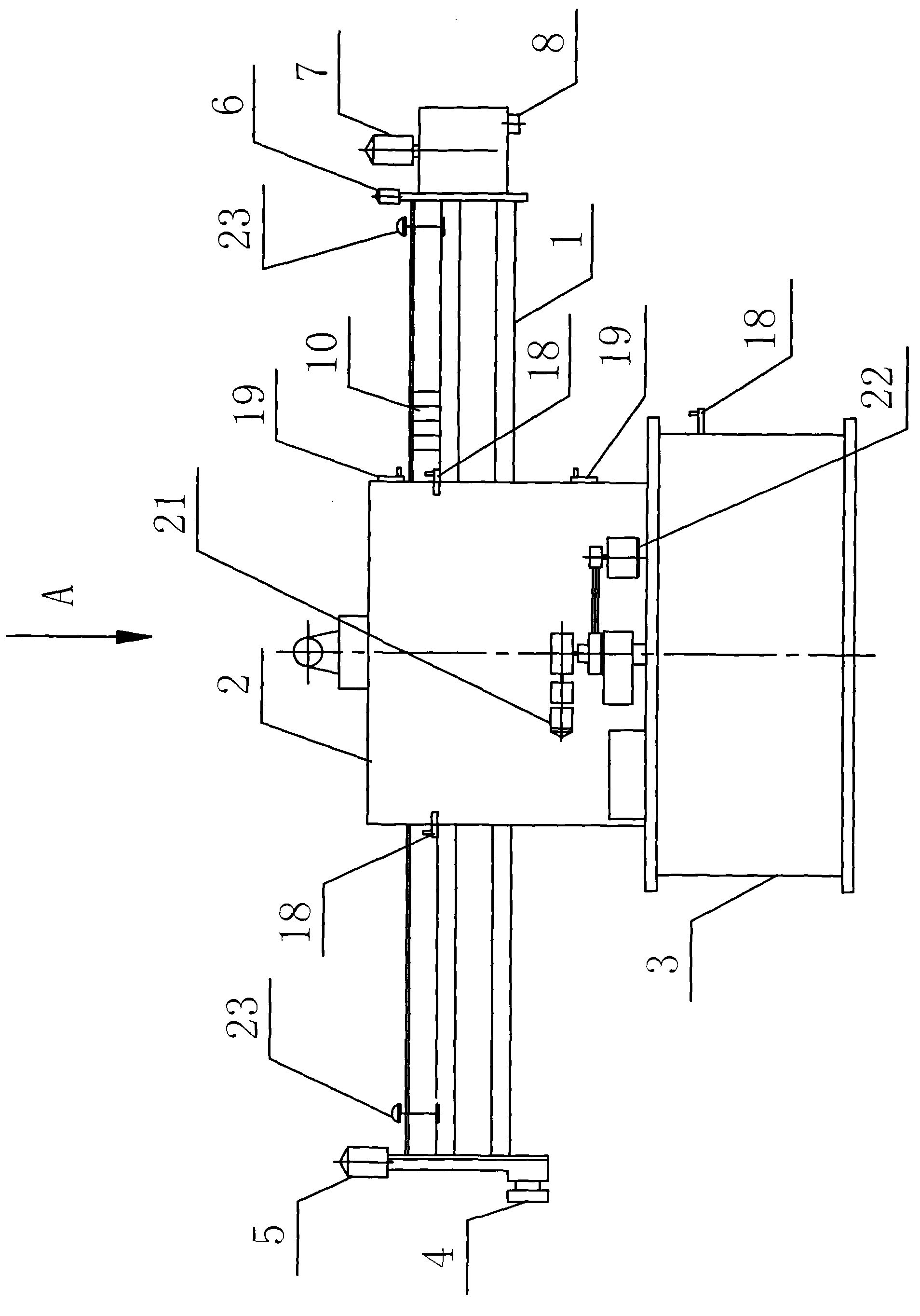

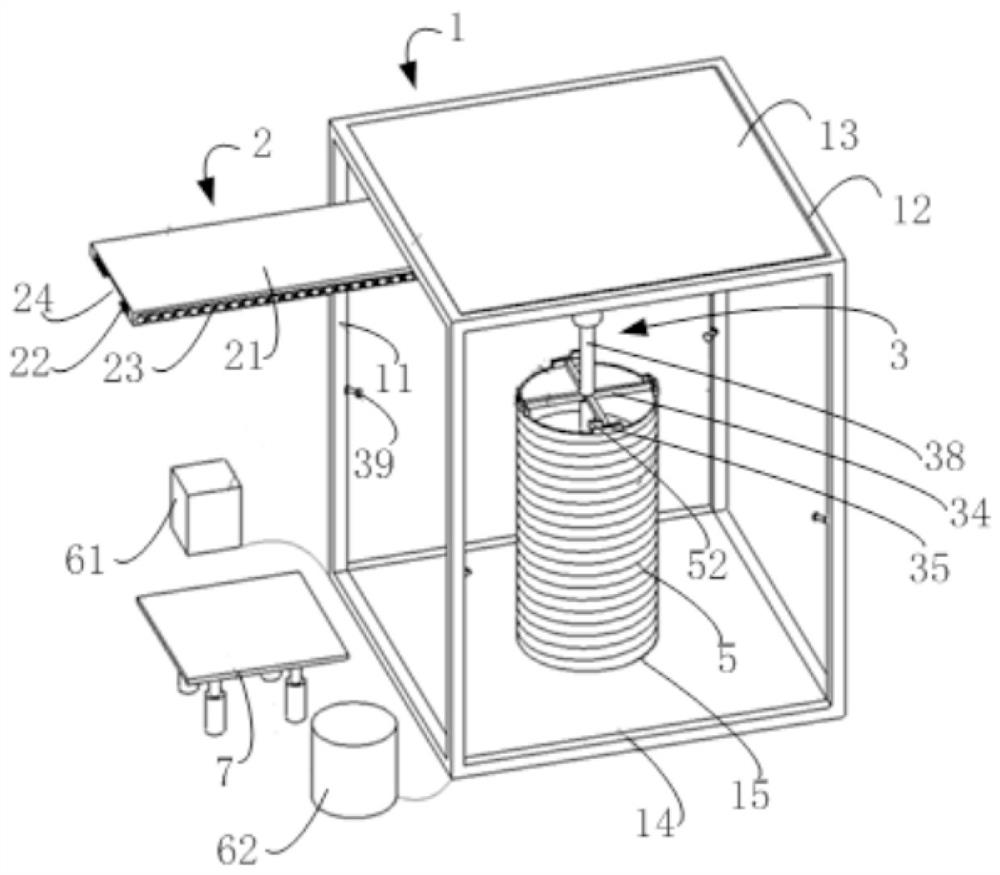

Bidirectional loading gas extraction leakage simulation experimental device and method

PendingCN107942030AMonitoring DisturbanceAchieve drillingFuel testingEngineeringStructural engineering

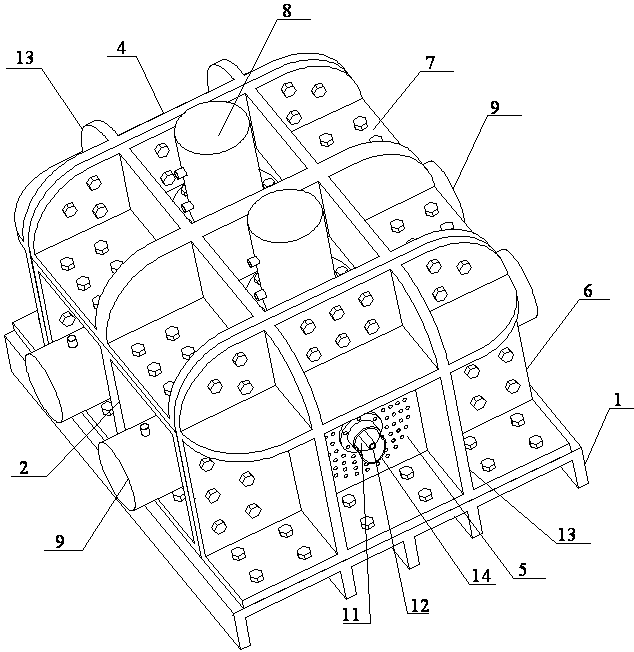

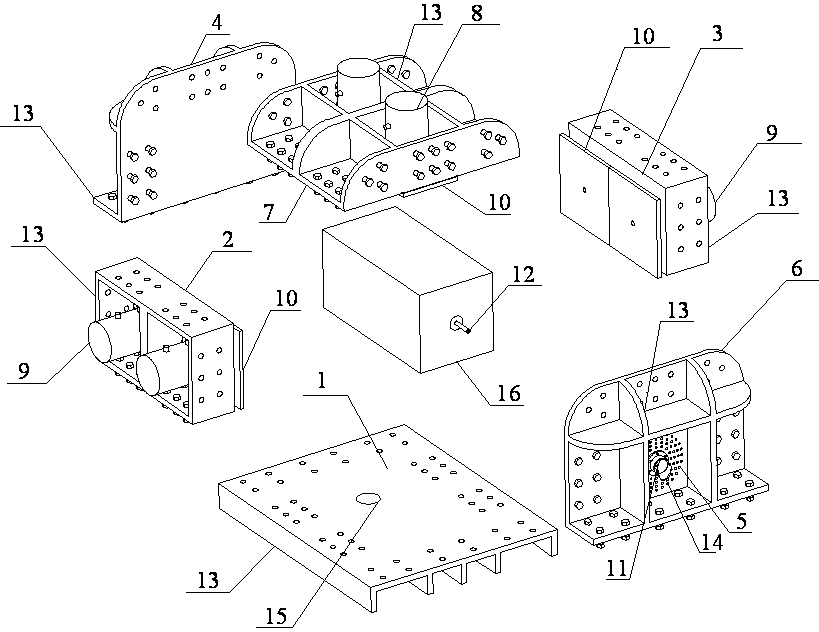

The invention discloses a bidirectional loading gas extraction leakage simulation experimental device which comprises a base, wherein side plates are arranged at the periphery of the upper part of thebase; an upper cover plate is covered on the upper parts of the side plates; the side plates comprise a left side plate, a right side plate, a rear plate and a front plate; the left side plate and the right side plate are arranged on the left and right sides of the base; the rear plate is arranged on the rear side of the base; the front plate is arranged on the front side of the base and is provided with a plurality of air holes; at least one vertical stress loading cylinder is arranged on the upper cover plate; at least one horizontal stress loading cylinder is respectively arranged on the left side plate and the right side plate; and a circular drilling opening is formed in the middle of the front plate. The experimental device is simple in structure and convenient to mount and operate,drilling cuttings discharged out of drill holes can be subjected to collection experiment, coal seam sealing and crack plugging experiments in a loading state, and extraction and leakage experimentscan be conducted.

Owner:HENAN POLYTECHNIC UNIV

Anti-seismic perforating machine with adjustable observation direction for engineering building detection

InactiveCN108746704AImprove protectionExtended service lifeLarge fixed membersMaintainance and safety accessoriesArchitectural engineeringDrill bit

The invention relates to the technical field of building tools, in particular to an anti-seismic perforating machine with an adjustable observation direction for engineering building detection. The anti-seismic perforating machine comprises a machine body, a shell, a stretching door, a visual window, a lifting cylinder, a telescopic wall, a rotating wall, a motor, a drill bit, a clamp, a placementtable, a lens adjusting chamber, a lens, a direction adjusting chamber, a rotating handle, a damping chamber, a base, a wheel frame, damping springs and wheels; the shell is arranged above the middlepart of the machine body, the stretching door is arranged on one side of the shell, the visual window is formed in the middle of the stretching door, the lifting cylinder is fixedly arranged in the middle of an inner cavity of the shell, a telescopic arm is rotationally connected above the top of the lifting cylinder, the top of the telescopic arm is rotationally connected with a rotating arm, the side, far away from the telescopic arm, of the rotating arm is fixedly connected with the motor, the drill bit is arranged at the power output end of the motor, and the clamp is arranged under the drill bit. The effective damping and anti-seismic effect can be provided, moreover, multi-angle perforating can be realized, and the effect of multi-angle adjustment for observation and detection can be realized during perforating.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

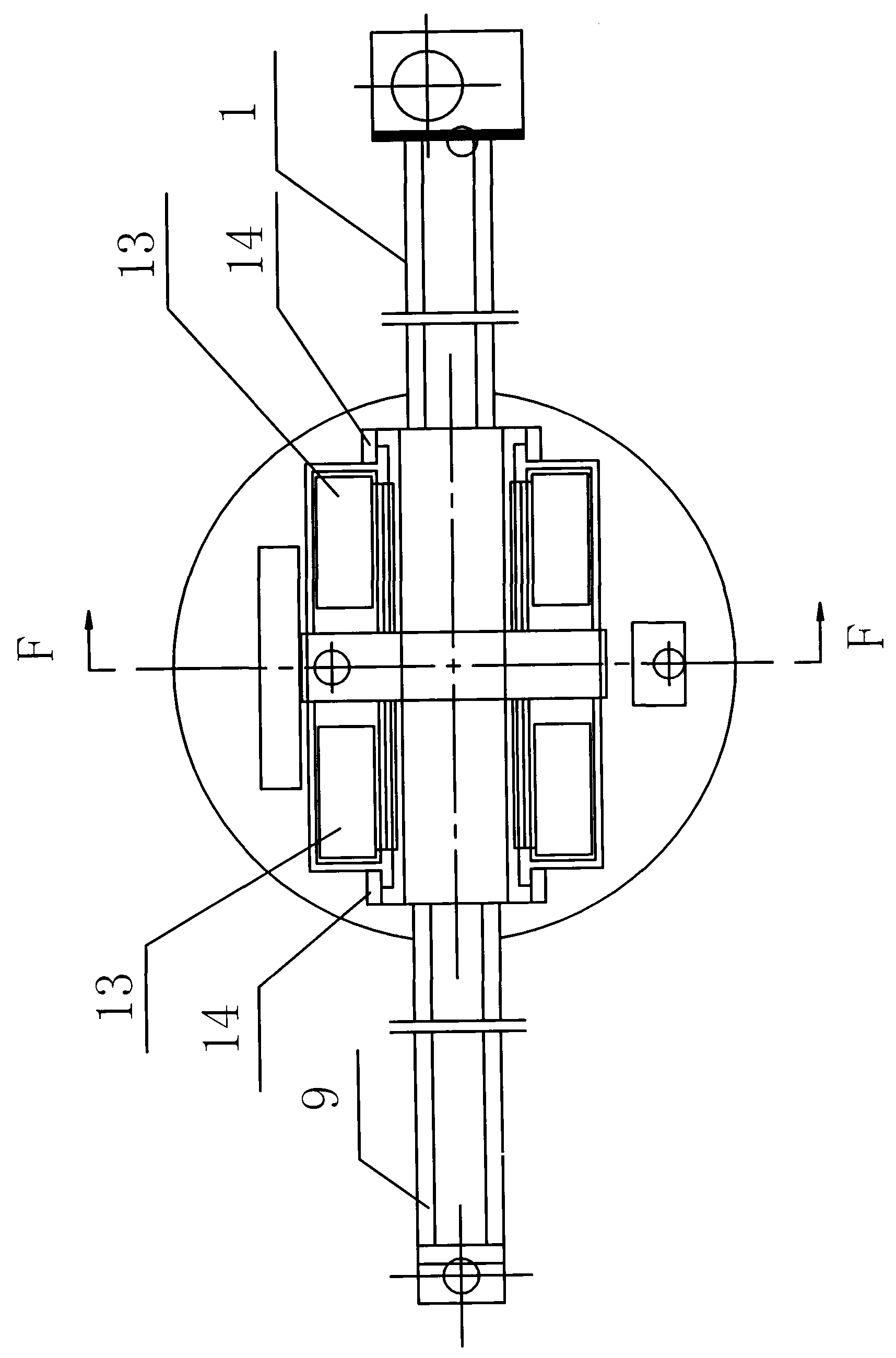

Adjustable pitch multi-head drill

InactiveCN101456084AFast processingRealize one machine with multiple functionsBoring/drilling componentsBoring/drilling machinesGear wheelEngineering

The invention aims to provide a multi-head drill with adjustable hole pitch, which is structurally characterized in that an input shaft is connected with an input supporting bearing, a main transmission bearing I, a driving gear, an input shaft key, a spacer bush and a snap spring, and is fixed on a box body through a box cover; an output shaft is fixed on a rocker arm through a rocker arm bearing II, a baffle ring, a spacer bush, a rocker arm spacer bush, a driven gear, a rocker arm bearing I and an output shaft snap spring to form a rocker arm assembly; an intermediate drive gear is supported on a middle supporting shaft through an intermediate drive gear spacer bush, a rolling needle, a middle supporting shaft spacer bush I and a middle supporting shaft spacer bush II; the rocker arm assembly is fastened on a main shaft box through the middle supporting shaft and screw nuts; and a main transmission gear and the intermediate drive gear are mutually engaged and the intermediate drive gear and the driven gear are mutually engaged.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Multi-station numerical control drilling center

ActiveCN110899755AEasy to set upThe movement form is simple and easy to controlPositioning apparatusBoring/drilling componentsNumerical controlPhysics

The invention discloses a multi-station numerical control drilling center. The multi-station numerical control drilling center comprises a plurality of operation stations and feeding stations arrangedadjacent to all the operation stations, wherein each operation station comprises a transverse linear rail provided with a workpiece clamp and a tool magazine and a vertical linear rail rotationally connected with a main shaft unit, the workpiece clamps and the tool magazines are arranged at intervals in the length direction of the transverse linear rail, the tool magazine is provided with a plurality of tools with upward tool handles, the main shaft unit is provided with a cutter groove arranged downwards, and the main shaft unit clamped with the tool rotates relative to the workpiece. The workpiece clamps and the tool magazine are located on the transverse linear rail and move to the position under the main shaft unit along with the transverse linear rail, the main shaft unit is locatedon a vertical linear rail and makes contact with and is separated from stations and tools along with movement of the vertical linear rail, and then drilling and tool changing are conducted. The drilling control center is advantaged in that a plurality of structures and driving devices are simplified, so a plurality of operation stations can be arranged to synchronously machine a plurality of workpieces, automatic machining efficiency is improved, and cost is reduced.

Owner:吉林省金沙数控机床股份有限公司

Soil loosening machine used for garden seedling planting

InactiveCN108476624AOutflow automatic interruptionGood loose soilSpadesWatering devicesMoving frameSeedling

The invention relates to a soil loosening machine, and in particular relates to a soil loosening machine used for garden seedling planting. A technical problem to be solved by the invention is to provide the soil loosening machine used for the garden seedling planting, wherein the machine can loosen soil by means of moistening the soil, conveniently provide electric energy when loosening the soiloutdoors, and can repel mosquitoes in the process of loosening the soil. The invention provides the soil loosening machine used for the garden seedling planting. The machine comprises a moving frame,a cylinder body, a piston, a first push rod, a spring, a water outlet pipe, a one-way valve, a water inlet pipe, fixing rods, an electric push rod, a first cross bar and the like; and the left side ofthe top of the moving frame is connected with the cylinder body in an embedded manner, the piston is arranged in the cylinder body, and the first push rod is connected to the middle part of the rightside of the piston. The machine provided by the invention achieves the effect of being able to loosen the soil by moistening the soil, conveniently providing the electric energy when loosening the soil outdoors, and being capable of repelling the mosquitoes in the process of loosening the soil; and the electric push rod, the first cross bar and a sliding sleeve are arranged, so that automatic soil loosening is realized.

Owner:胡州生

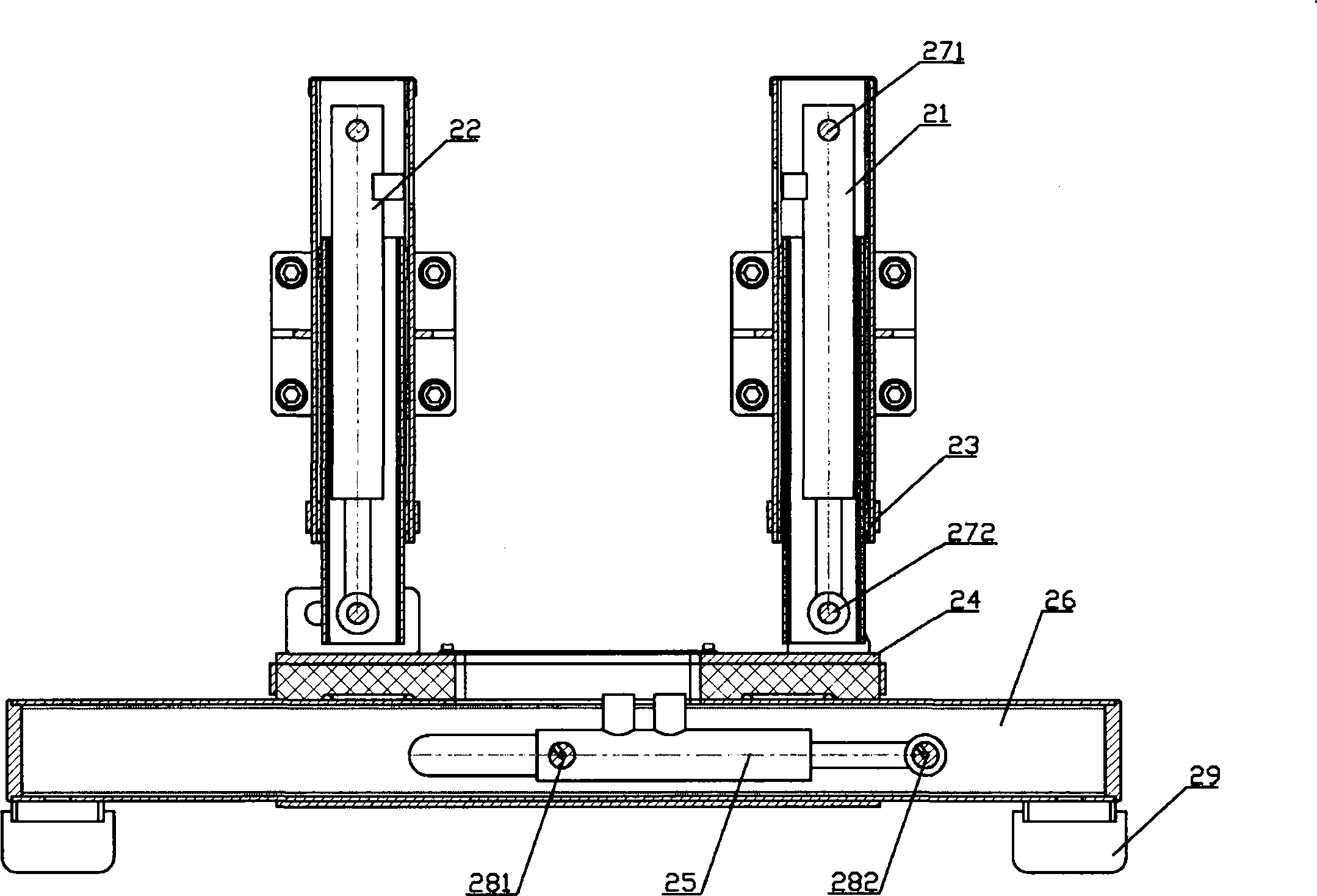

Track-type multi-head rock drilling machine for mine

ActiveCN103967409AReduce labor intensityProvide work efficiencyDrilling machines and methodsVehicle frameDrill hole

The invention discloses a track-type multi-head rock drilling machine for a mine. The machine is formed in the mode that a rock drilling device, a transverse moving device and a drilling feeding device are assembled and are connected with a vehicle frame and drilled hole trimming device through an upright column adjusting device, and then arranged on a track walking device through the vehicle frame and drilled hole trimming device. The drilling machine is characterized in that needed moving forward, moving backward, steering and other functions can be easily achieved by means of track walking. A remote electric control device can achieve remote control of the drilling machine, and enables the drilling machine to move away from equipment and avoid dust and other damage during operation. Meanwhile, operation situations of parts in all directions during drilling can be taken into consideration. Compressed air serves as a power system. By means of the system, gas-liquid conversion and gas-electric conversion functions are achieved, and centralized control and analysis are carried out by means of an electric control console.

Owner:泉州华大超硬工具科技有限公司

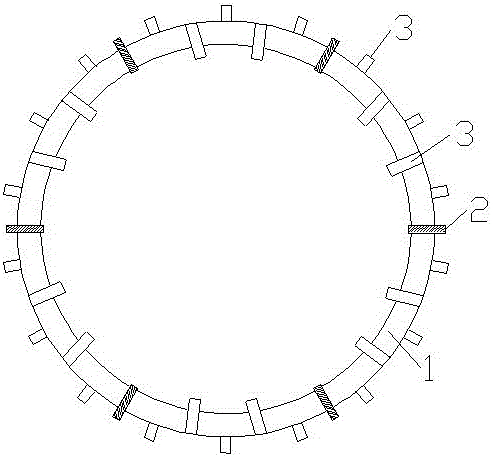

Heaving floor anchor protection multifunctional drill wagon for coal mine

The invention discloses a bottom drum anchor protection multifunctional drilling rig for coal mines, which belongs to the field of coal mine machinery; the technical problem to be solved is to provide a floor drum anchor protection multifunctional drilling rig with simple structure, high degree of mechanization and fast cleaning speed car; the technical solution adopted to solve this technical problem is: a multifunctional drilling rig with bottom drum anchor protection for coal mines, including a frame, a traveling part, drilling rig parts, hydraulic parts, and electrical parts. The front and rear of the frame are symmetrically equipped with a lifting device, and the lifting device is equipped with a rotary traverse device. The rotary traverse device is connected with the drilling rig components. The hydraulic components and electrical components are arranged at the rear of the frame. It is symmetrically arranged on the left and right sides of the bottom of the frame, the frame is provided with an operation table, and legs are provided on both sides of the frame; the invention can be widely used in the field of coal mine machinery.

Owner:CHANGZHI ZHONGRUI PRECISION BEARING MFGCO

PDC drill bit of rotary drilling rig

The PDC bit of the rotary drilling rig, including the barrel drill bit, evenly welds several PDC rib teeth and several PDC plate teeth on the barrel drill bit. The number of PDC rib teeth and PDC plate teeth is set according to a certain ratio. A plurality of composite sheets are inlaid, and a plurality of composite sheets are inlaid on the plate tooth body of the PDC plate tooth. The drill bit of the rotary drilling rig of the present invention uses PDC rib teeth and PDC plate teeth to replace the existing picks, uses a composite sheet to strengthen the hardness of the drill teeth, and can realize drilling into rock formations without a large torque drill, improving the Drilling efficiency, with the advantages of good wear resistance, high hardness, low operating cost and low vibration.

Owner:丁栋

Efficient plastic processing equipment

InactiveCN109015867AAchieve drillingSimple structureGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention discloses efficient plastic processing equipment. The efficient plastic processing equipment comprises a fixed base body, wherein a first notch and a second notch are formed in the bottom of the fixed base body in the form of left-right symmetry; a cavity body is formed in the fixed base body; a first motor is fixedly arranged in the inner top wall of the cavity body; a first screw rod is connected to the bottom of the first motor in a manner of power fit; a slide base body is connected to the first screw rod in a manner of spiral line fit; the slide base body is connected with the inner sidewall of the cavity body in a manner of slide fit; a slide cavity is formed in the middle of the slide base body; and a second motor is fixedly arranged at the top of the outer wall of theleft side of the slide cavity. The equipment is simple in structure and convenient to operate, automatically drills the surface of plastic, and is capable of grinding the surface of the plastic, saving time and labor, and achieving high efficiency.

Owner:郭林惠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com