Airplane fastening hole processing equipment

A technology for processing equipment and fastening holes, which is applied to metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems affecting processing accuracy, low processing efficiency, and shaking of the spindle box, so as to improve processing accuracy, The effect of high processing efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

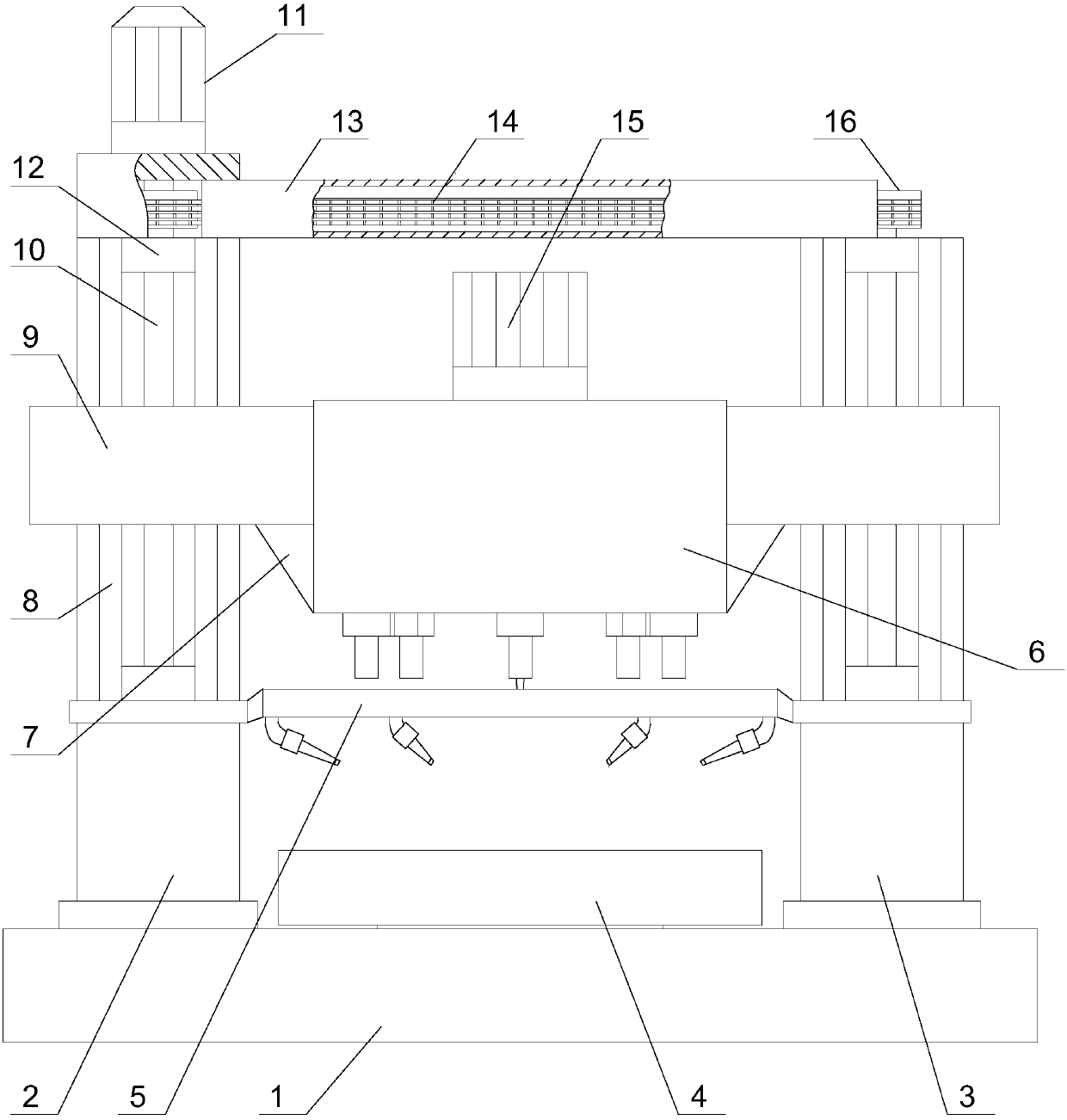

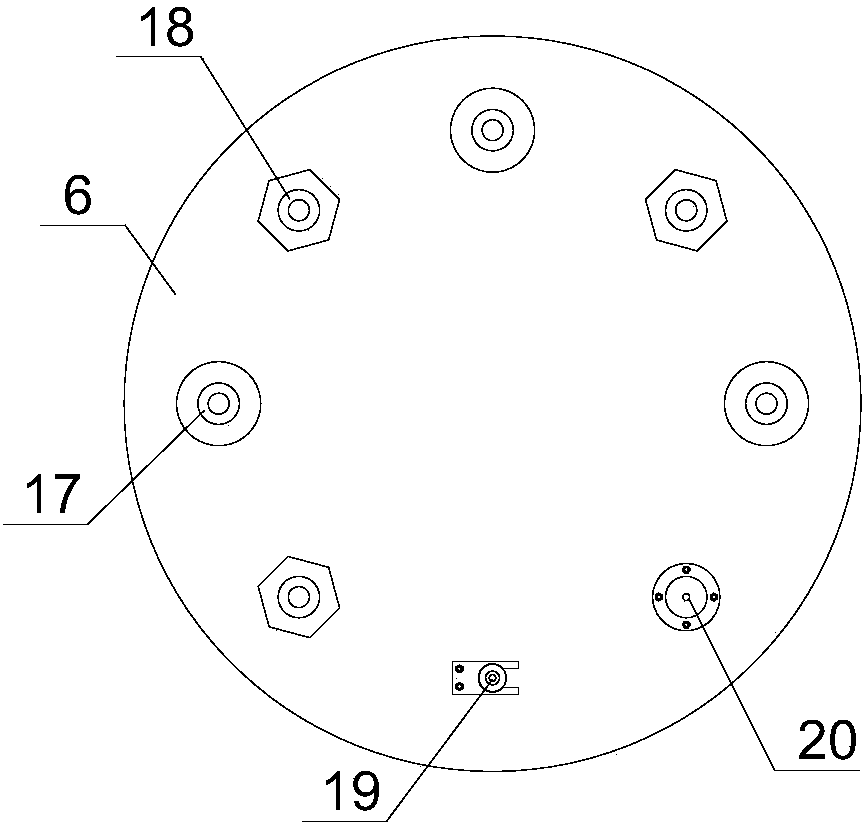

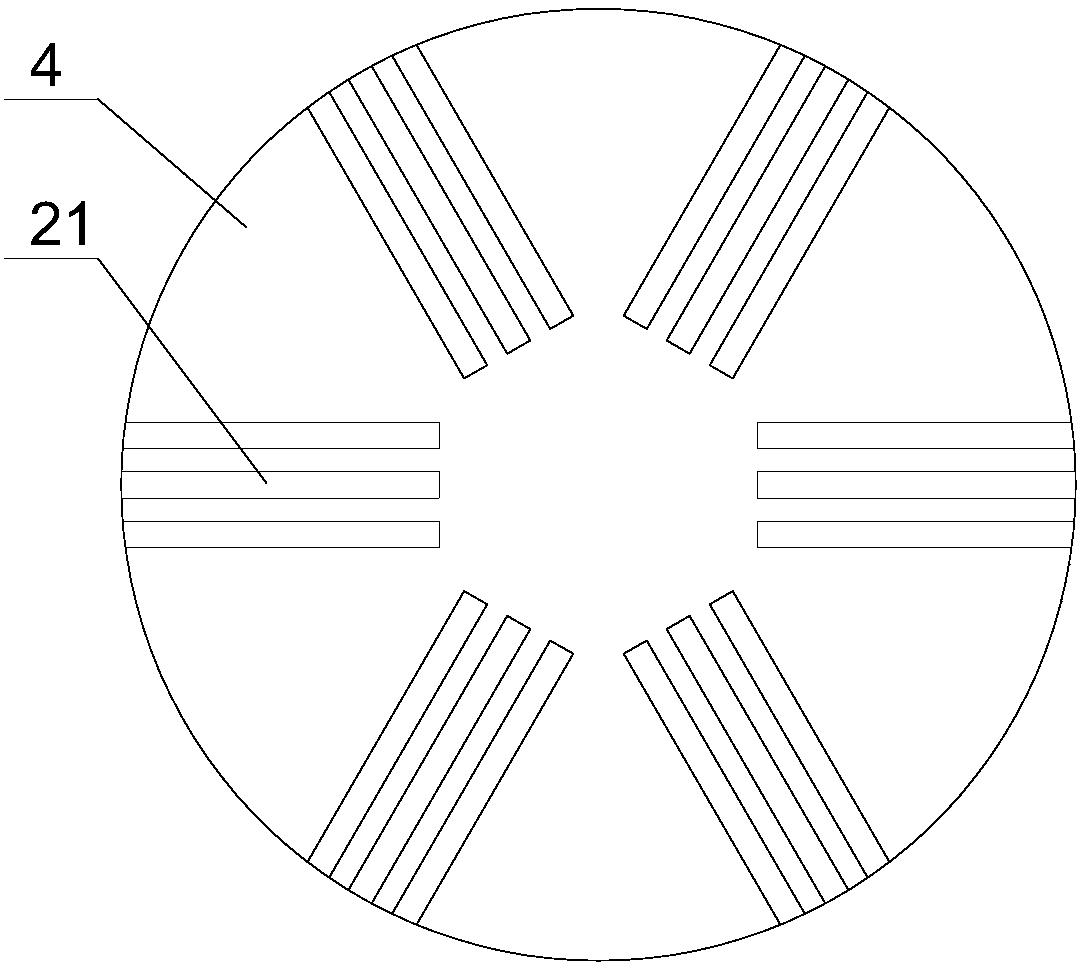

[0033] combine figure 1 , figure 2 , image 3 and Figure 4 Shown, the present invention comprises following structure:

[0034] Two columns installed on the same base 1 are respectively the main column 2 and the auxiliary column 3, both of which are equipped with screw drive mechanisms, the top of the main column 2 is equipped with a longitudinal feed motor 11, and the longitudinal feed motor 11 It is connected with the screw mandrel 10 of the main column 2, and the screw mandrel of the main column 2 is connected with the screw mandrel of the auxiliary column 3 through a sprocket transmission mechanism;

[0035] The crossbeam 9 is installed horizontally, and the left and right parts are respectively fixedly connected with the transmission nuts of the screw drive mechanisms of the two columns, and the two columns are provided with longitudinal limit guide rails 8 for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com