Nitrogen well-drilling method in well-drilling field

A drilling and field technology, applied in the field of nitrogen drilling, can solve the problems that multi-process integrated technology has not yet started, and the gap in nitrogen drilling is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

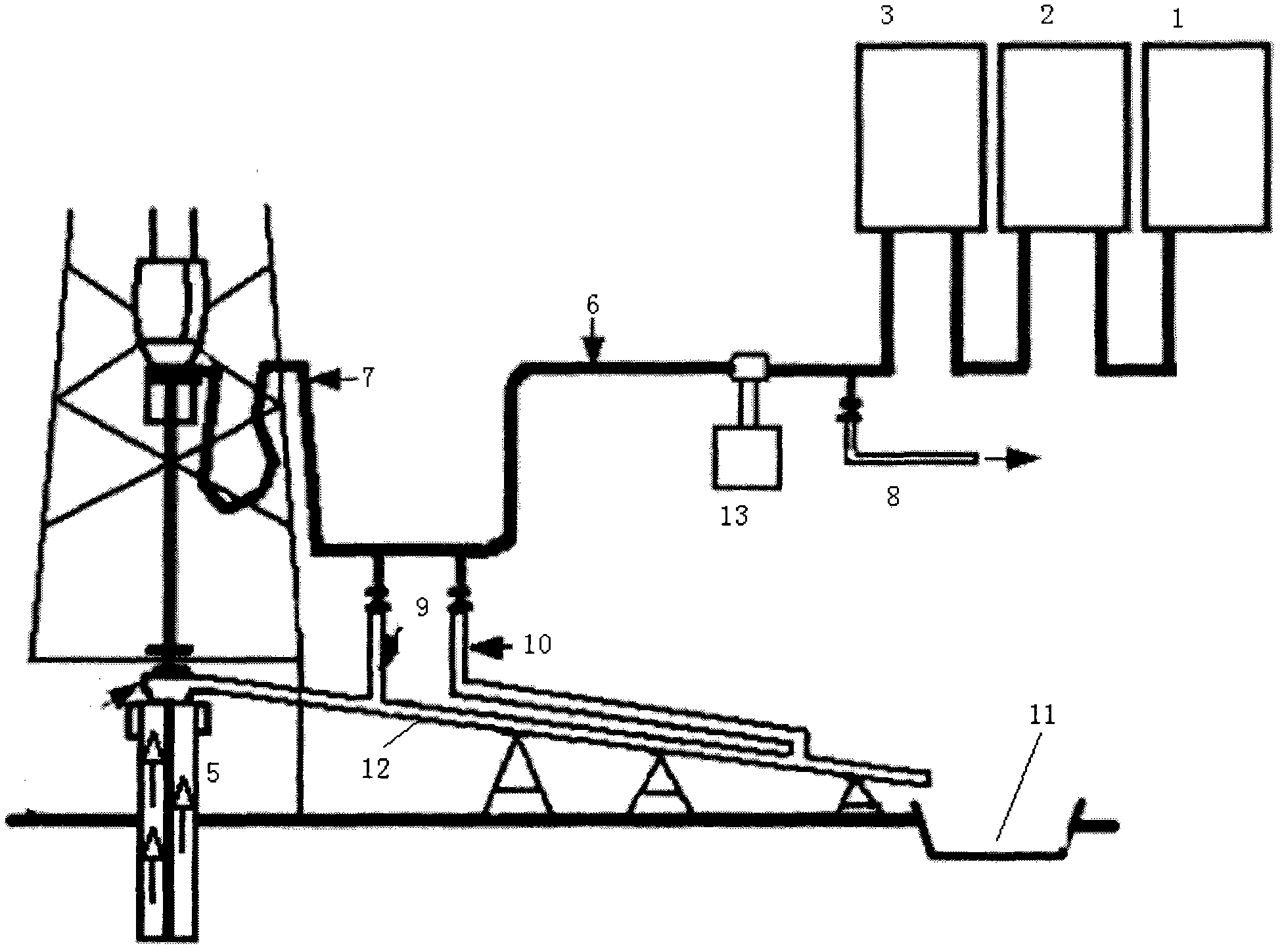

[0029] The nitrogen drilling method in the drilling field that the present invention relates to comprises the following steps:

[0030] (a) After the air is compressed by the air compressor, it enters the membrane separation nitrogen generator;

[0031] (b) The compressed air is separated by a membrane separation nitrogen generator to obtain nitrogen with a purity of more than 95%, and then enters a booster;

[0032] (c) After the compressed and separated nitrogen is further pressurized by the booster, it enters the manifold system;

[0033] (d) The nitrogen gas entering the manifold system is injected downhole after passing through the rotary blowout preventer;

[0034] (e) Nitrogen gas brings downhole drilling cuttings to the surface, passes through the rock discharge pipe and then enters the surface recovery pool, and the whole process ends.

[0035] During the drilling process, air defense is carried out through the vent pipe.

[0036] During the drilling process, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com