Heaving floor anchor protection multifunctional drill wagon for coal mine

A multi-functional, kick drum technology, applied in drilling equipment, mining equipment, earth-moving drilling, etc., can solve the problems of investing a lot of manpower and material resources, mine production and safety constraints, hindering transportation and pedestrians, etc., to improve work efficiency , The effect of ensuring drilling quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

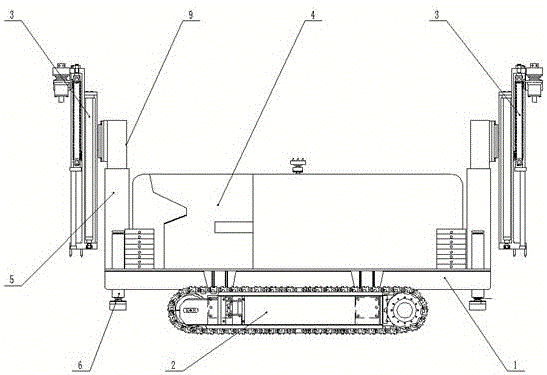

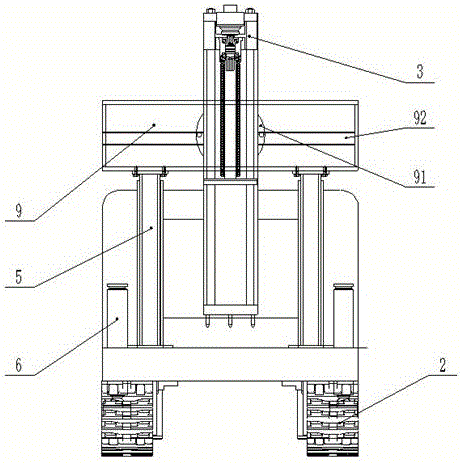

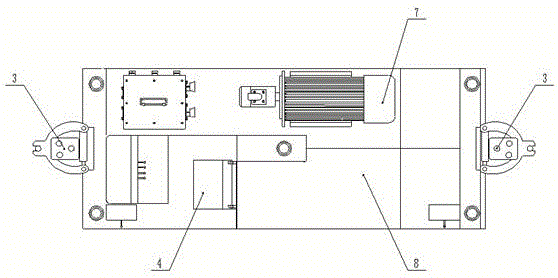

[0020] Such as figure 1 , figure 2 , image 3 As shown, a bottom drum anchor protection multifunctional drill carriage for coal mines of the present invention includes a frame 1, a walking part 2, a drilling rig part 3, a hydraulic part 8, and an electrical part 7. The walking part 2 is provided with a frame 1, and the machine The frame 1 is provided with a lifting device 5 symmetrically before and after. The lifting device 5 is provided with a rotating and traversing device 9 which is connected to the drilling rig component 3. The hydraulic component 8 and the electrical component 7 are arranged behind the frame 1; The device 9 includes a horizontal sliding rail 91 and a rotating disk 92. The horizontal sliding rail 91 is provided with a rotating disk 92, which is connected to the drilling rig part 3. The two sides of the horizontal sliding rail 91 are equipped with limit devices, and the walking part 2 is a crawler walking. The crawler walking mechanism is symmetrically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com