Patents

Literature

408 results about "Support pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

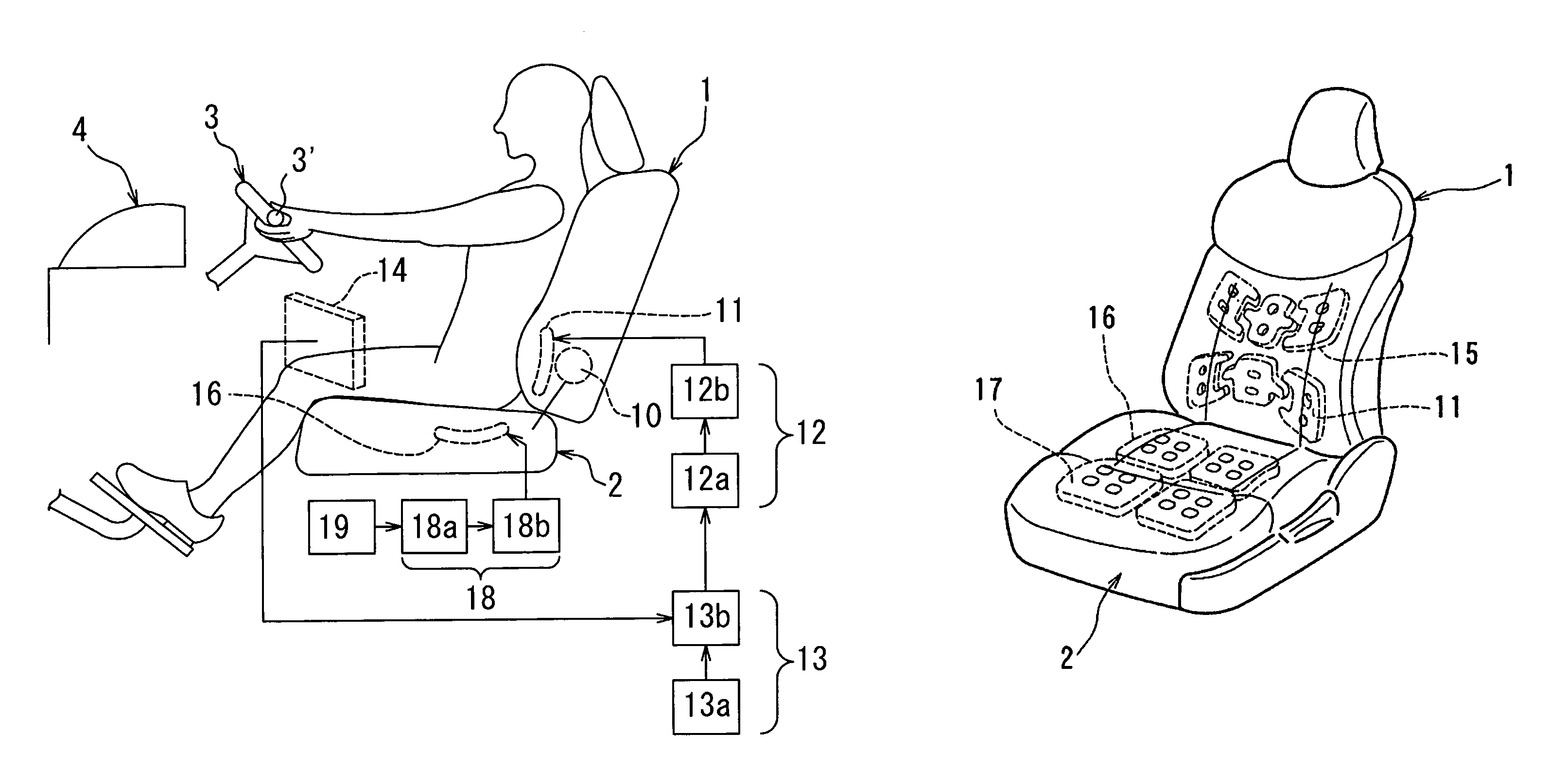

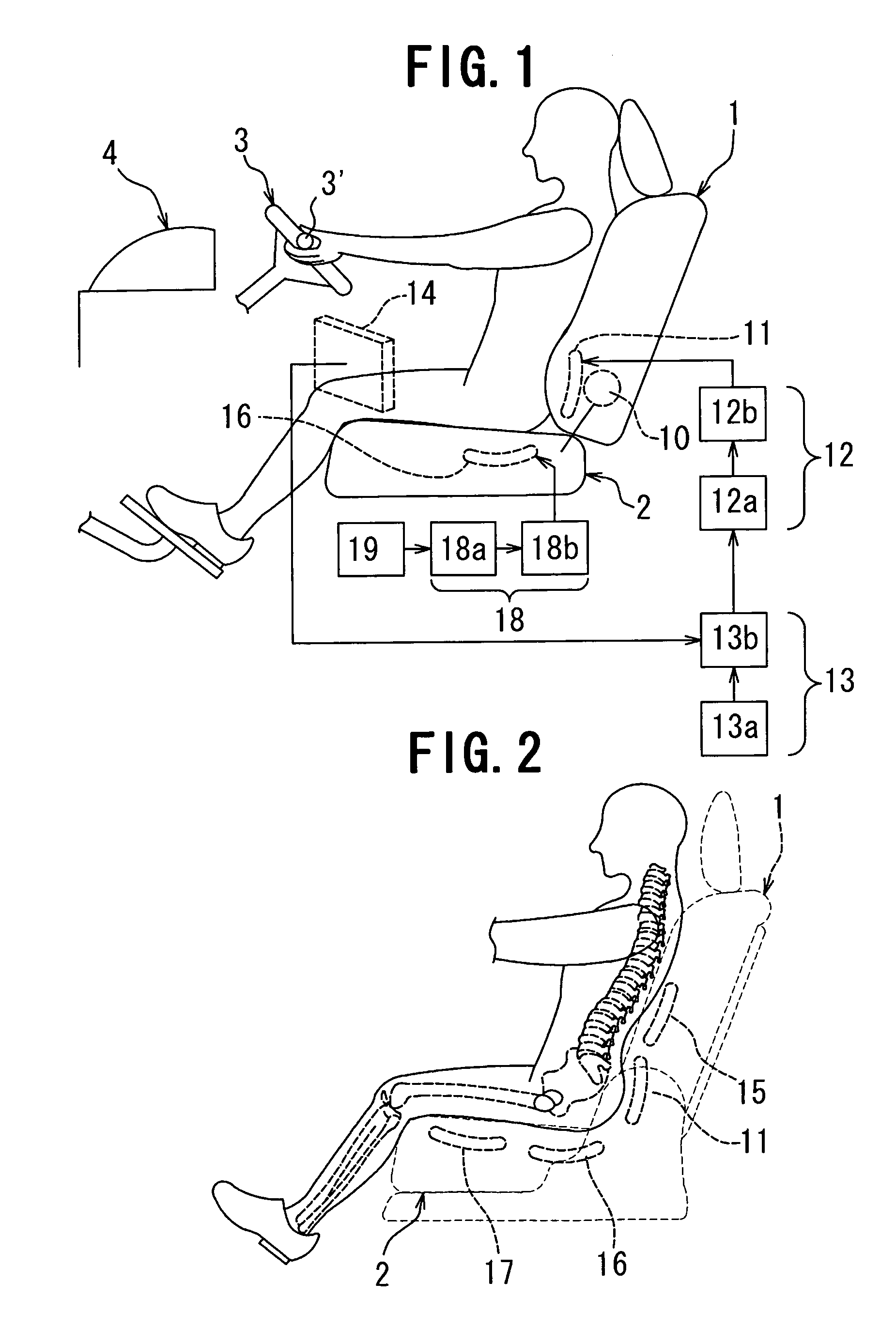

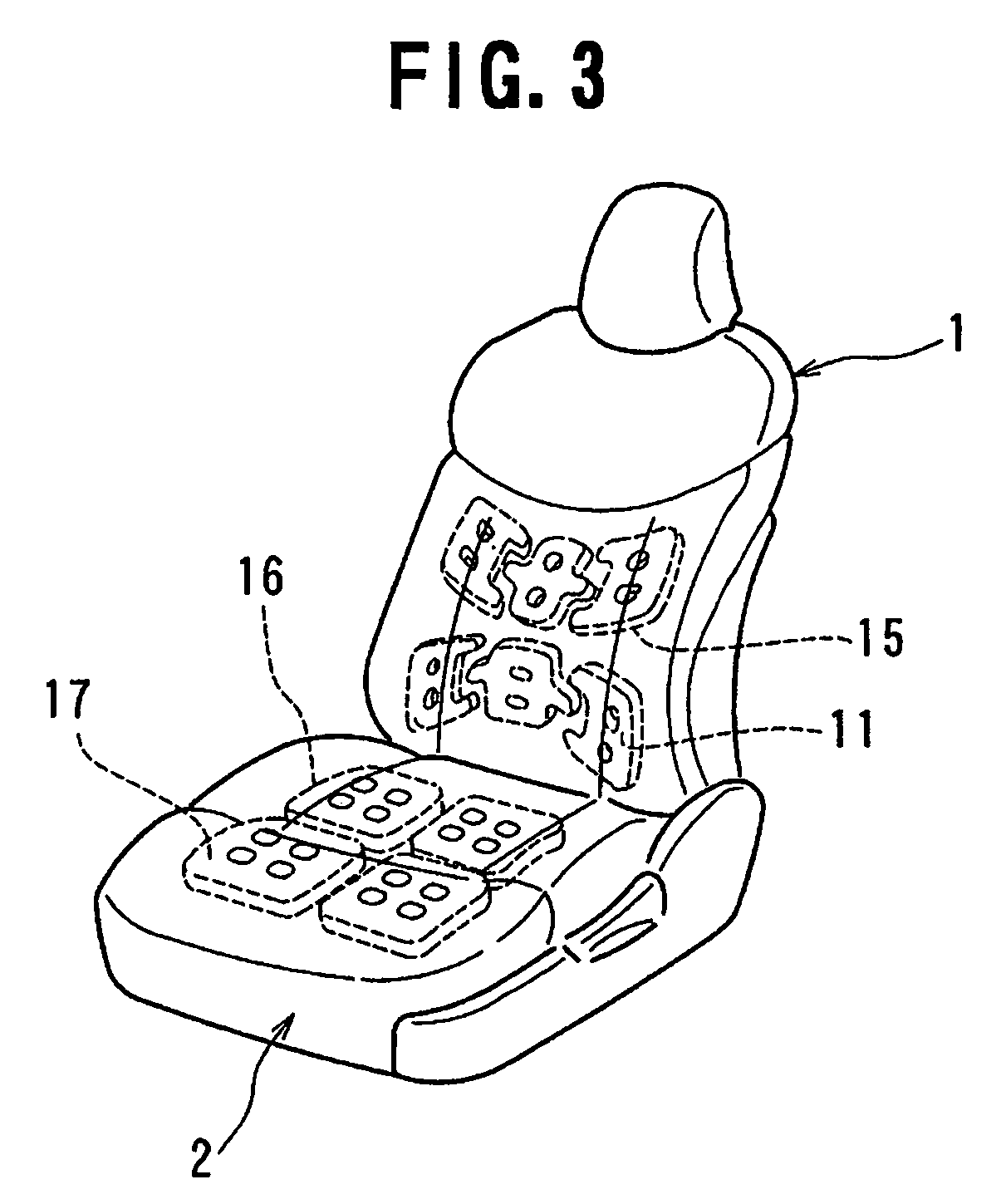

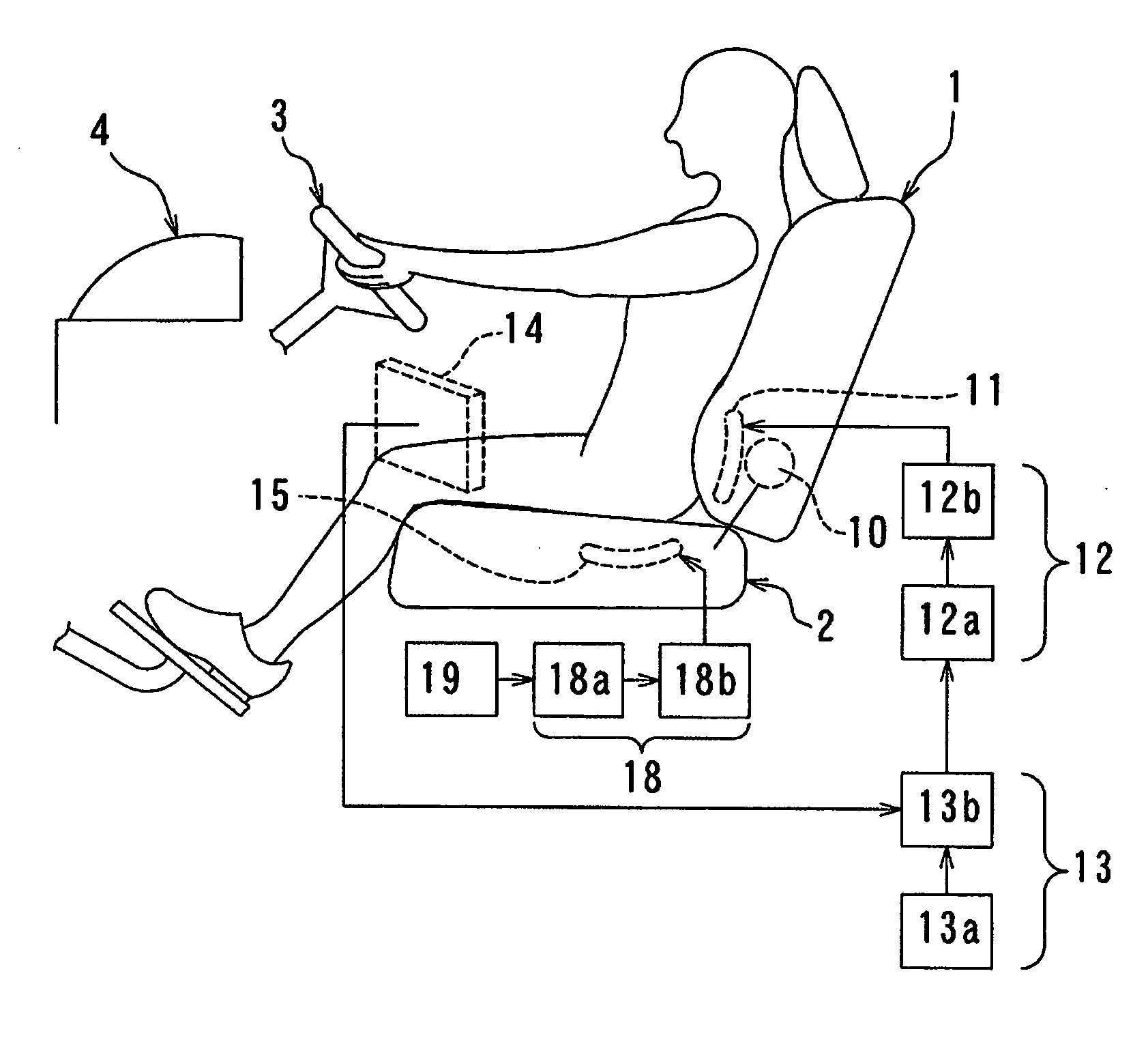

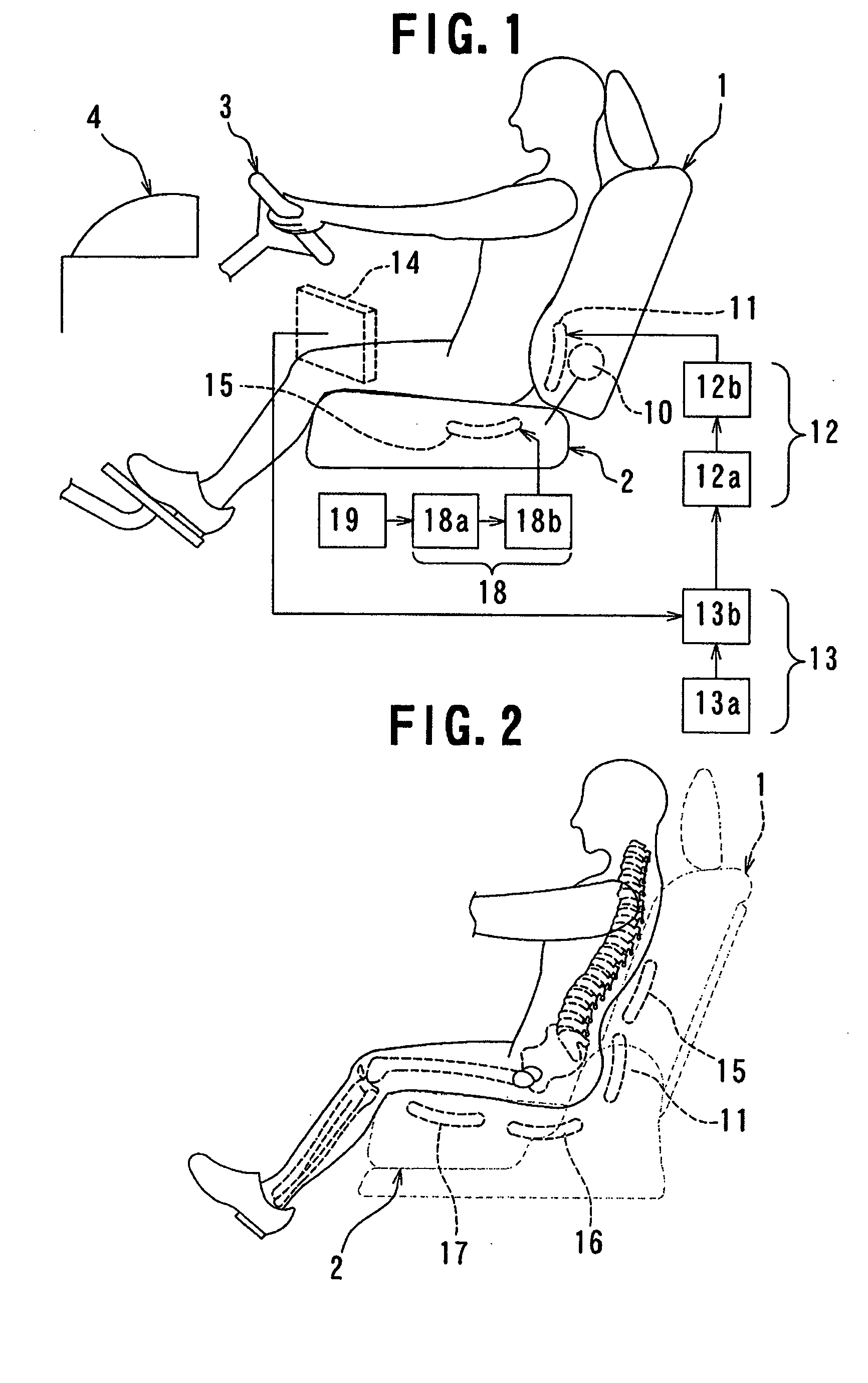

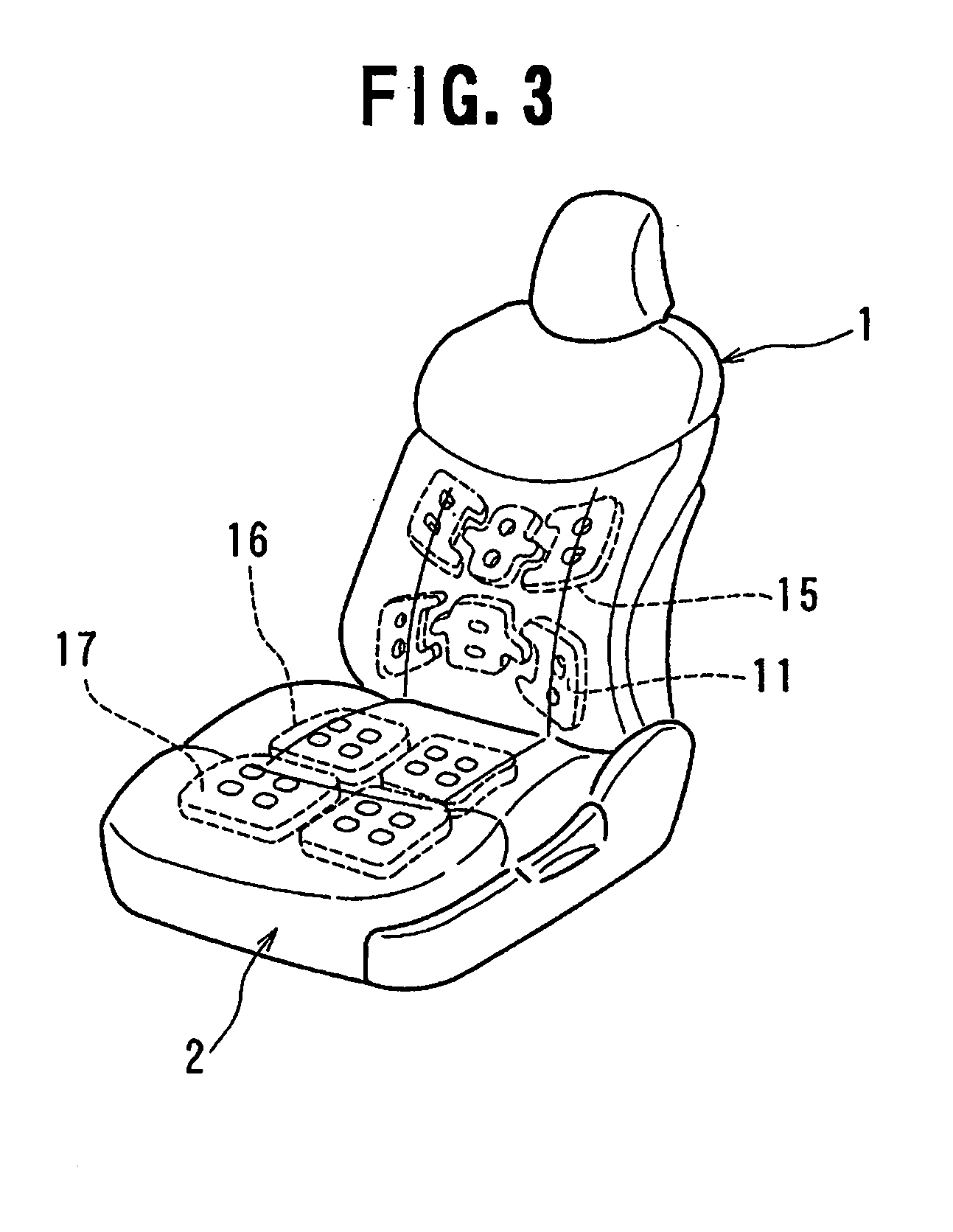

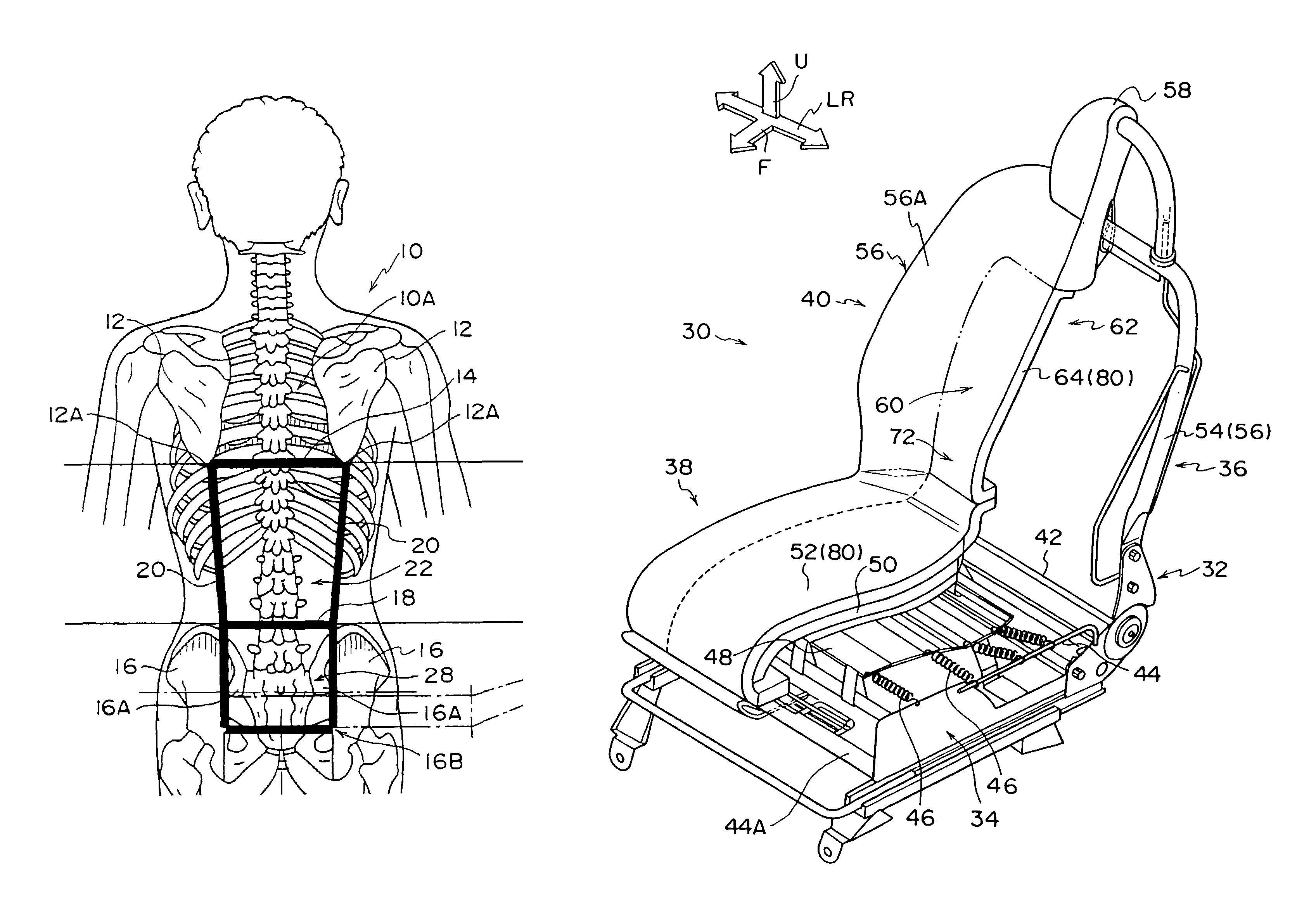

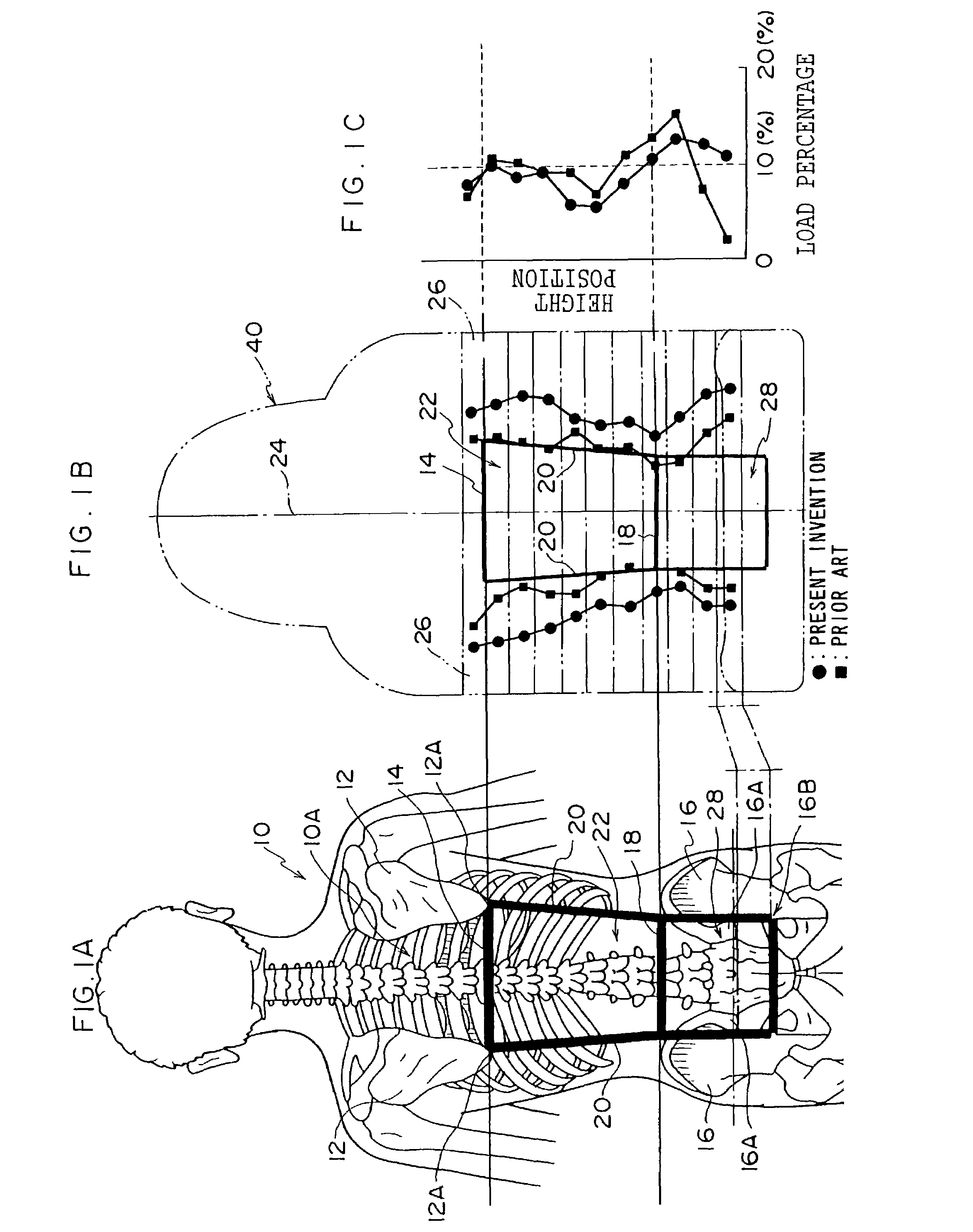

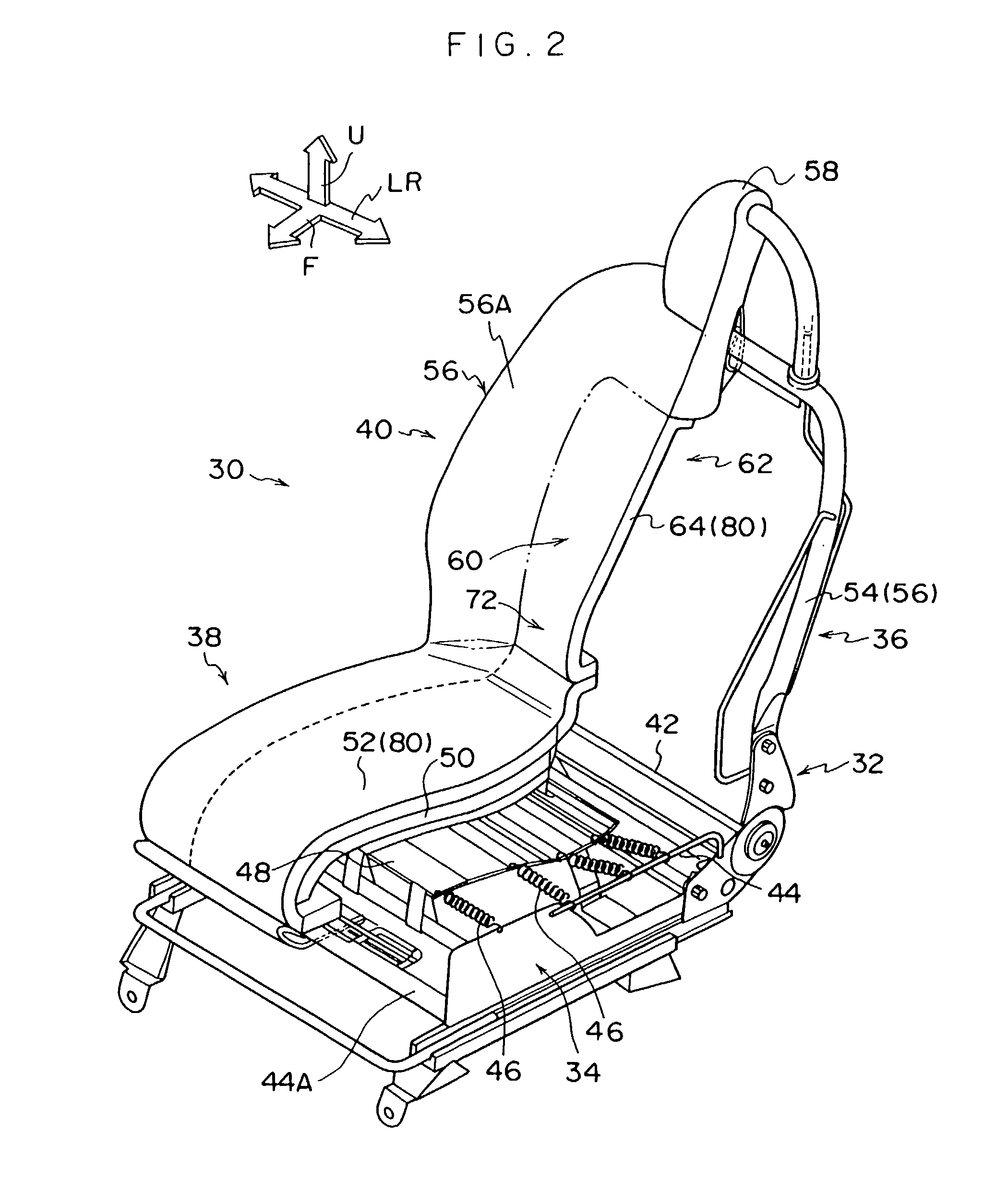

Vehicle seat with system for facilitating relieving of fatigue of person sitting on the seat

InactiveUS7152920B2Relieve fatigueImprove fatigueBack restsDismountable chairsPelvic regionElectricity

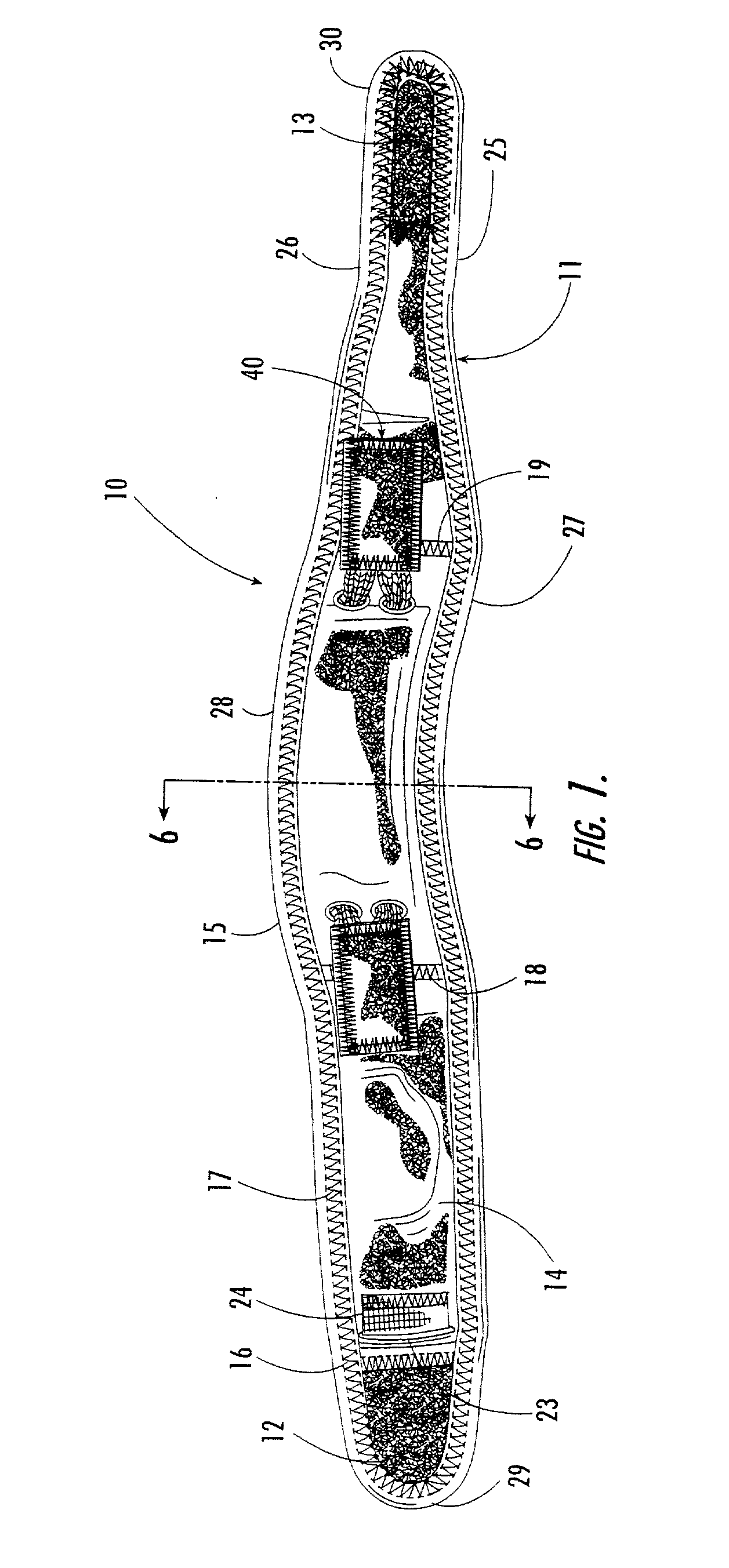

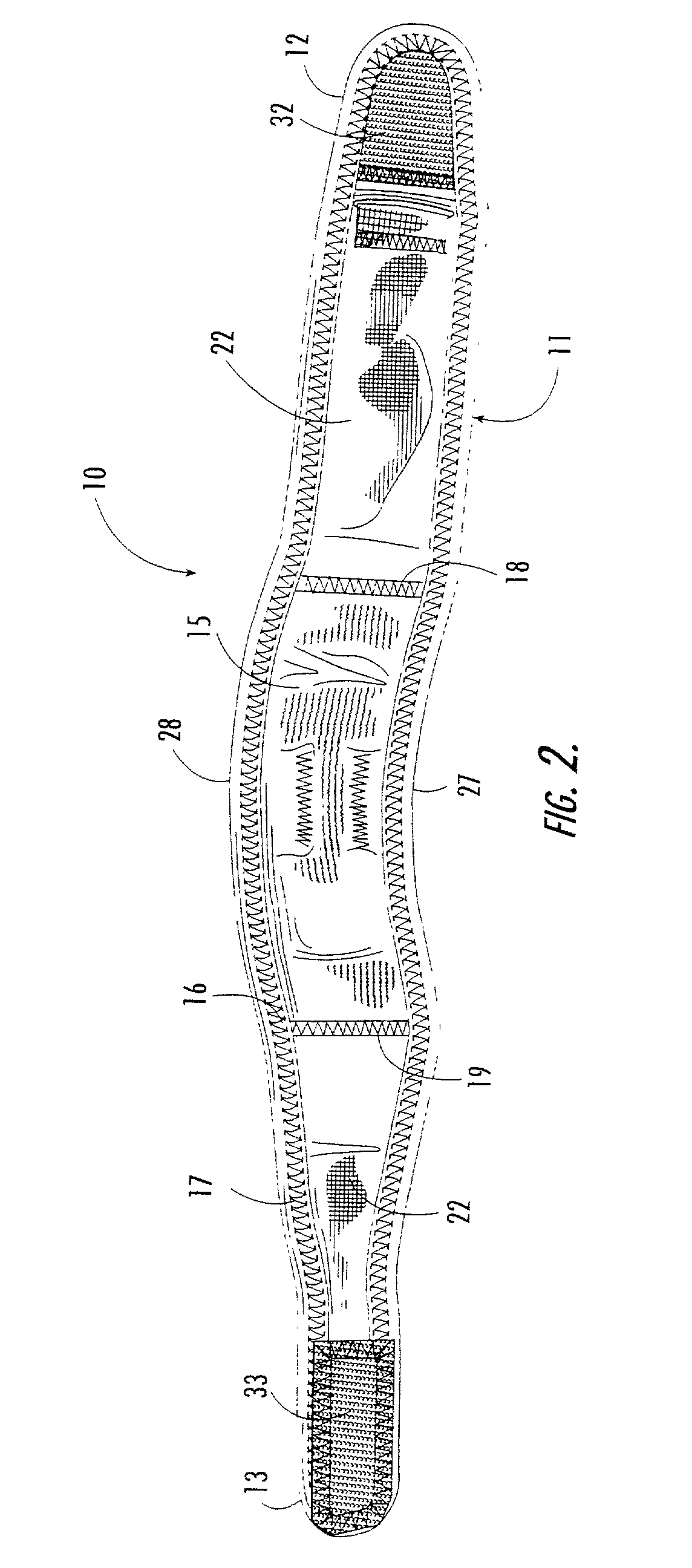

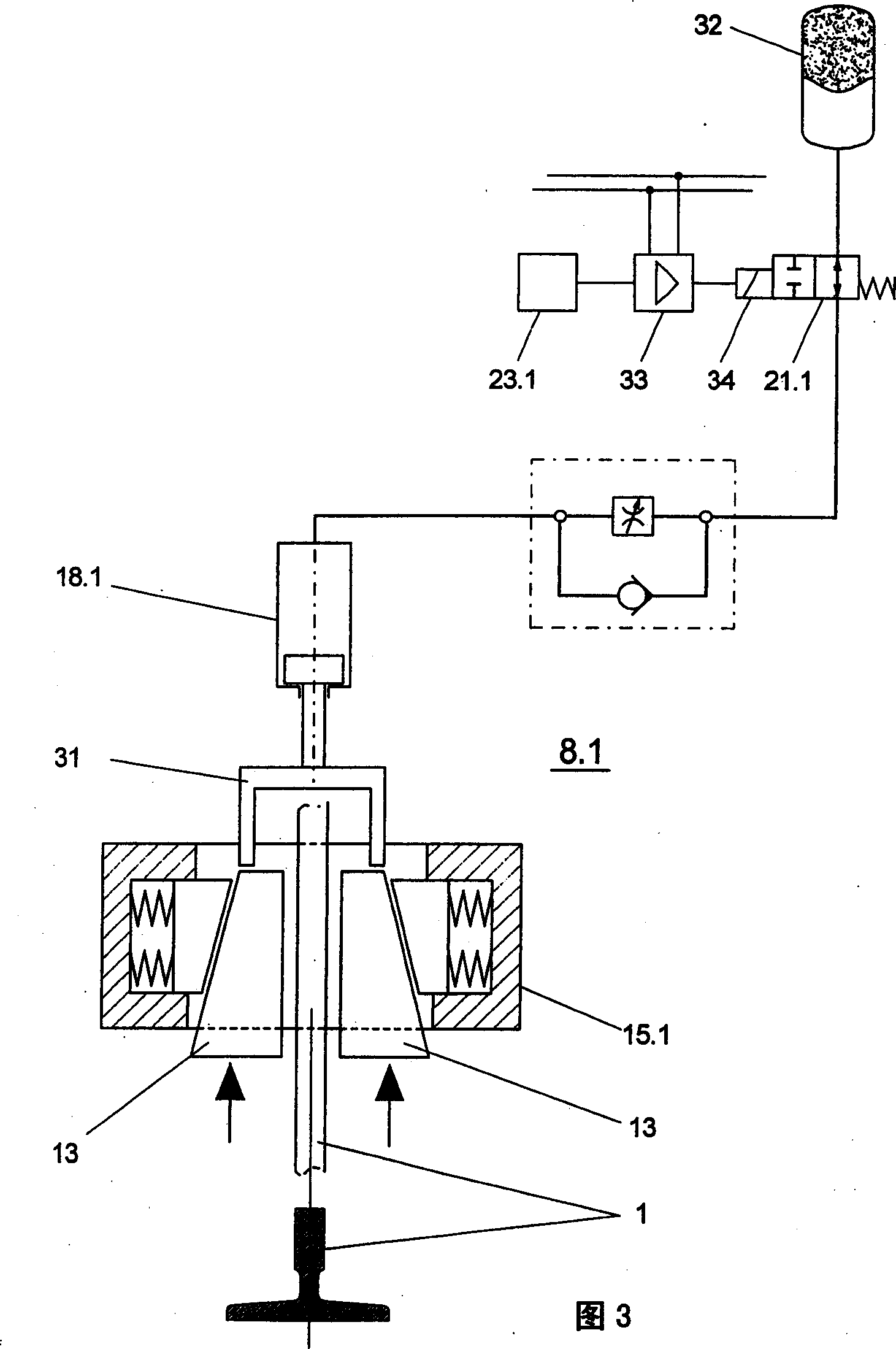

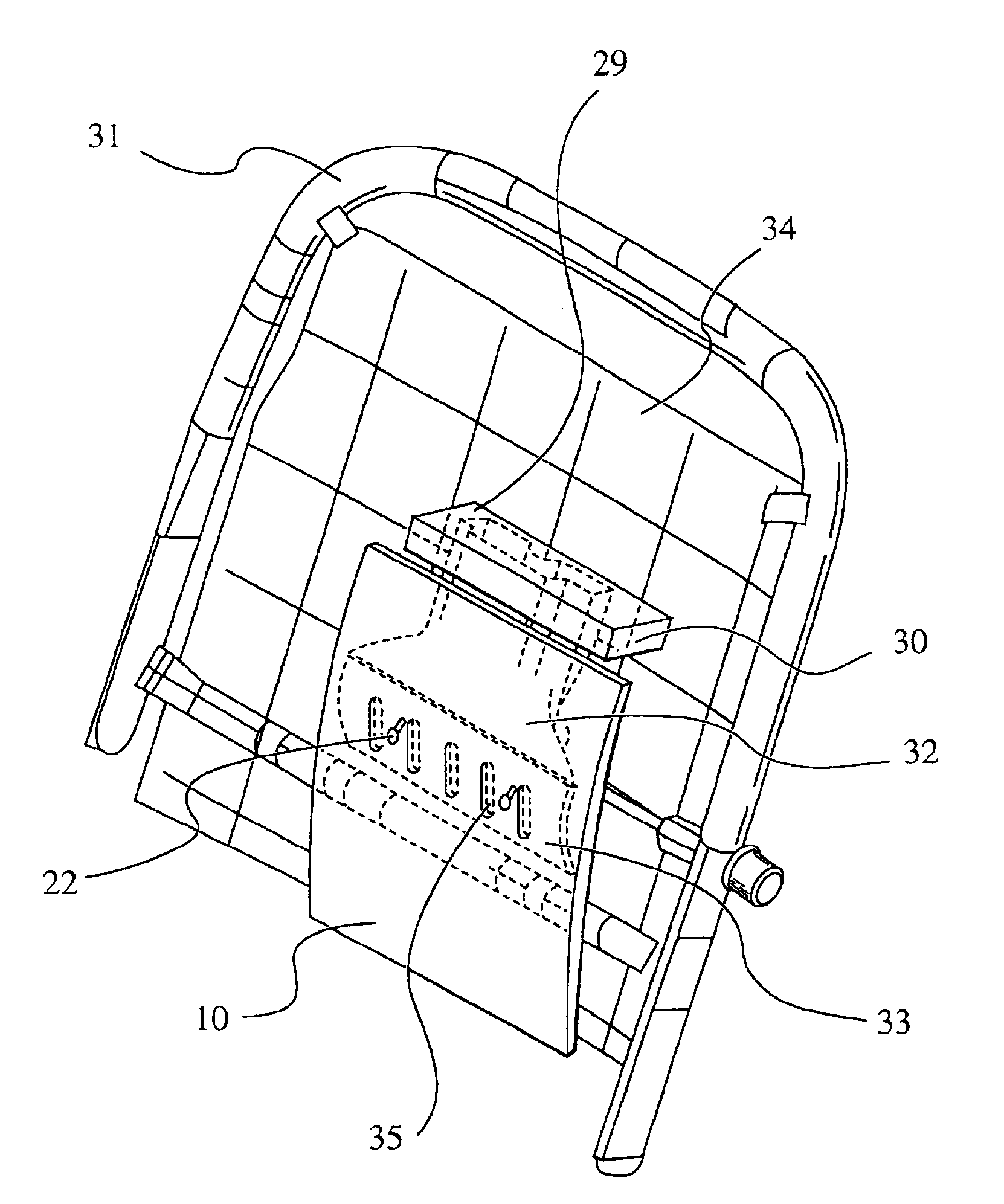

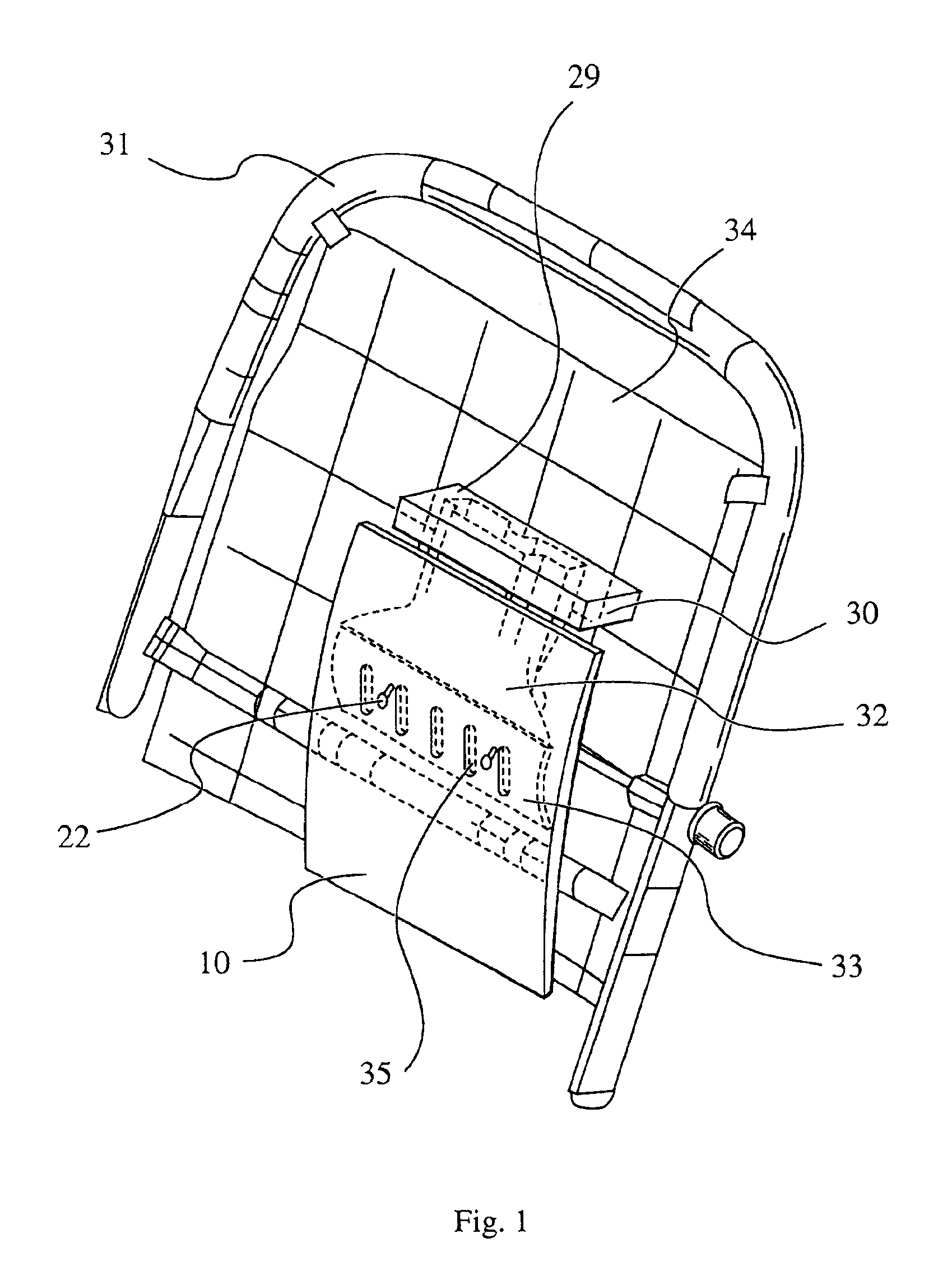

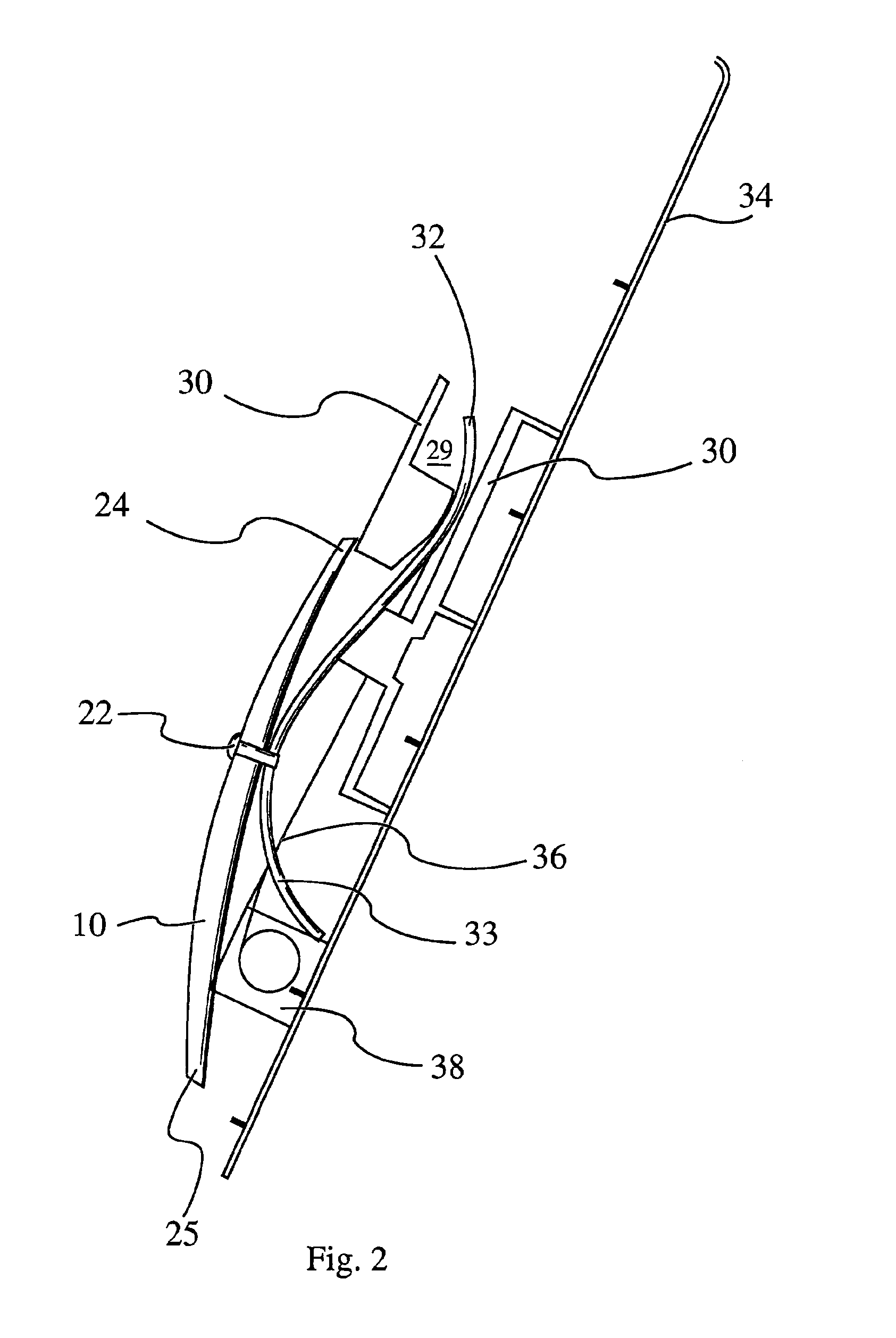

A vehicle seat includes a seat back, a seat cushion, and a system for facilitating relieving of fatigue of a person sitting on the vehicle seat for many hours. The system includes an angle sensor installed within the seat back for sensing variations in an angle of a pelvic region of the person sitting on the vehicle seat, an active device installed within the seat back for pressure-supporting the pelvic region of the person, an actuating device connected to the active device for actuating the active device and a sequential control unit electrically connected to the angle sensor and the actuating device for controlling the operation of the actuating device, the angle sensor being constructed so as to send the sequential control unit signals representing values of variations in the angle of the pelvic region of the person, the sequential control unit being constructed such that, when a value represented by a signal sent to the sequential control unit from the angle sensor is more than a predetermined value, the sequential control unit sends the actuating device a command to actuate the actuating device, whereby the active device is actuated, to thereby control supporting pressure that is applied to the pelvic region of the person.

Owner:TS TECH CO LTD

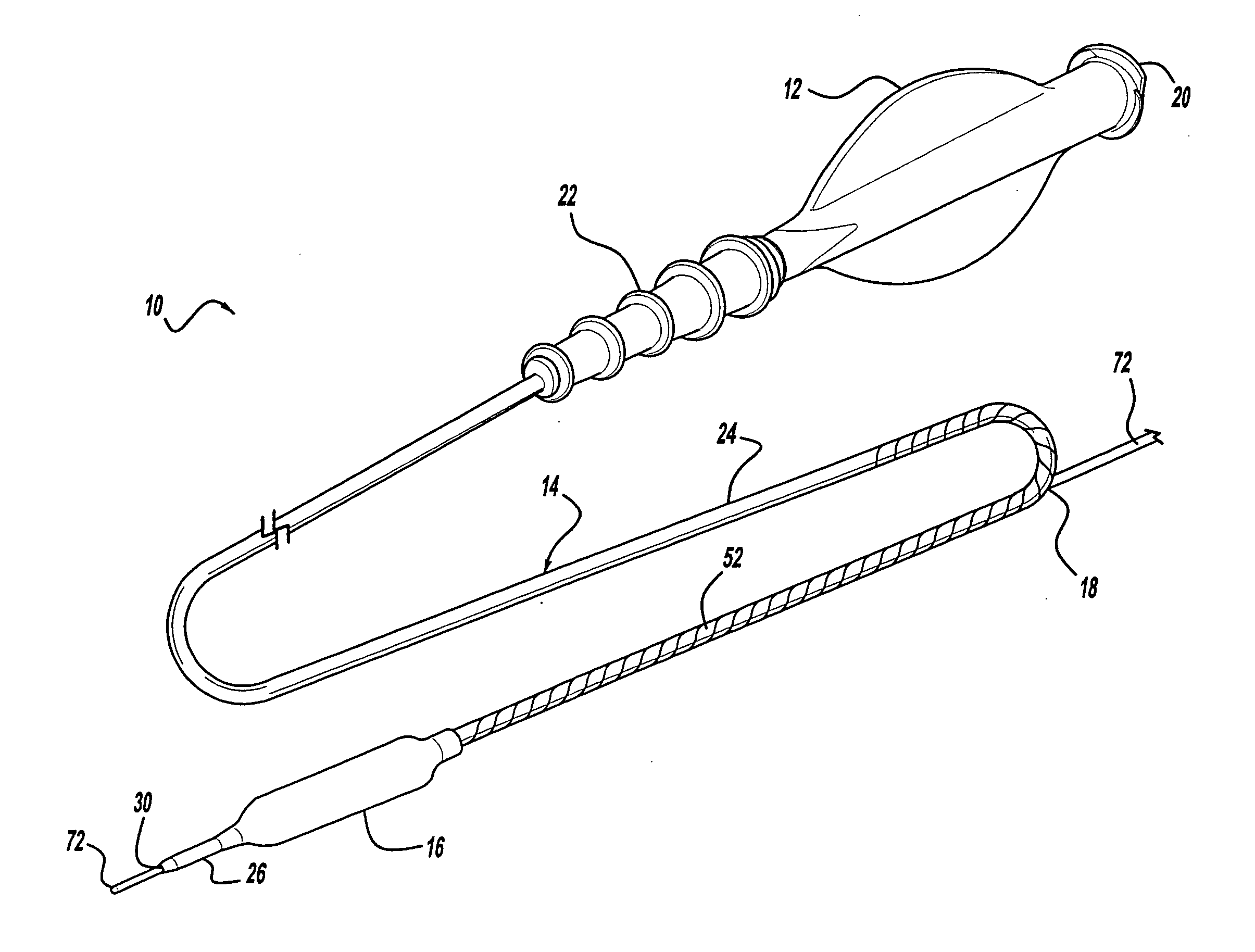

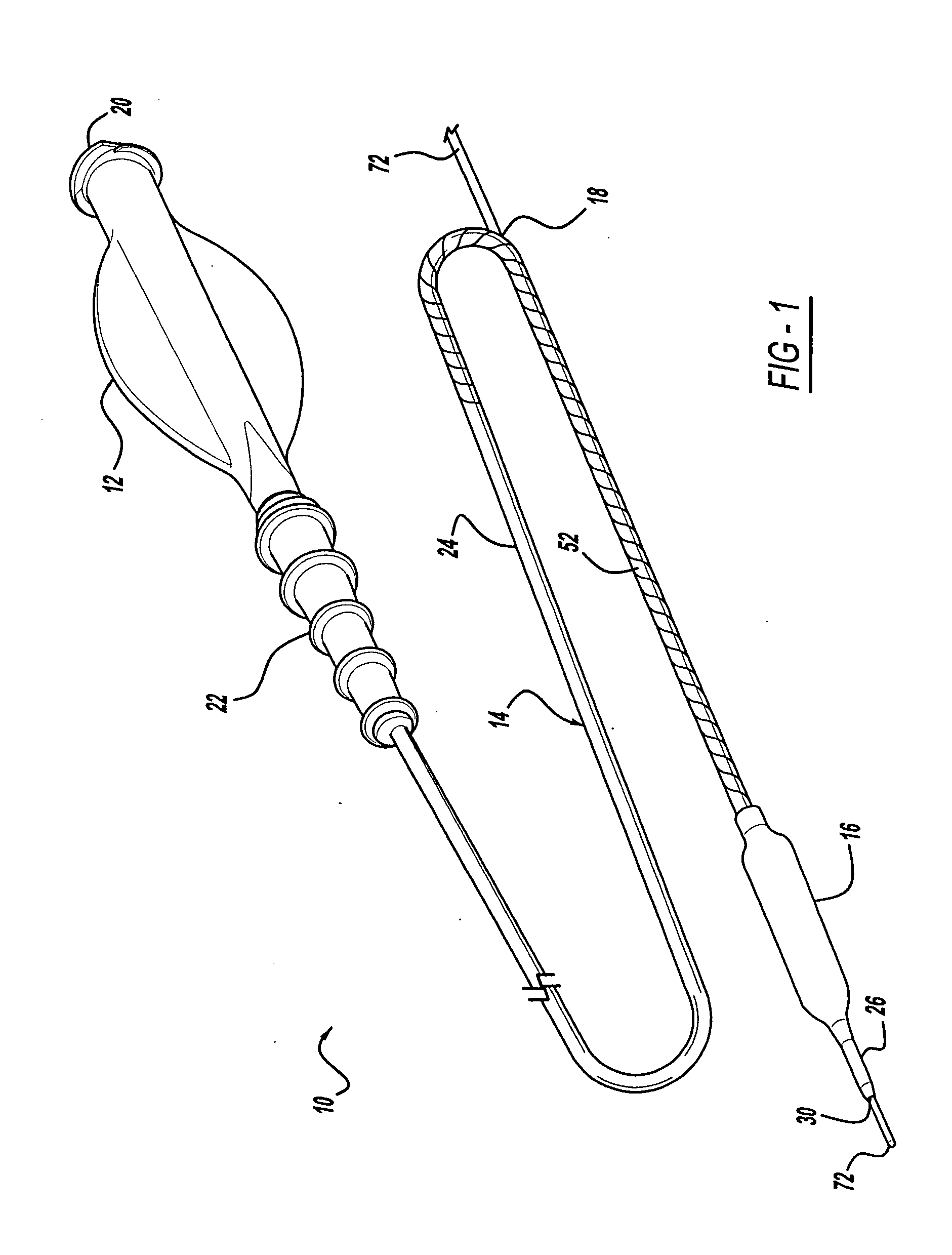

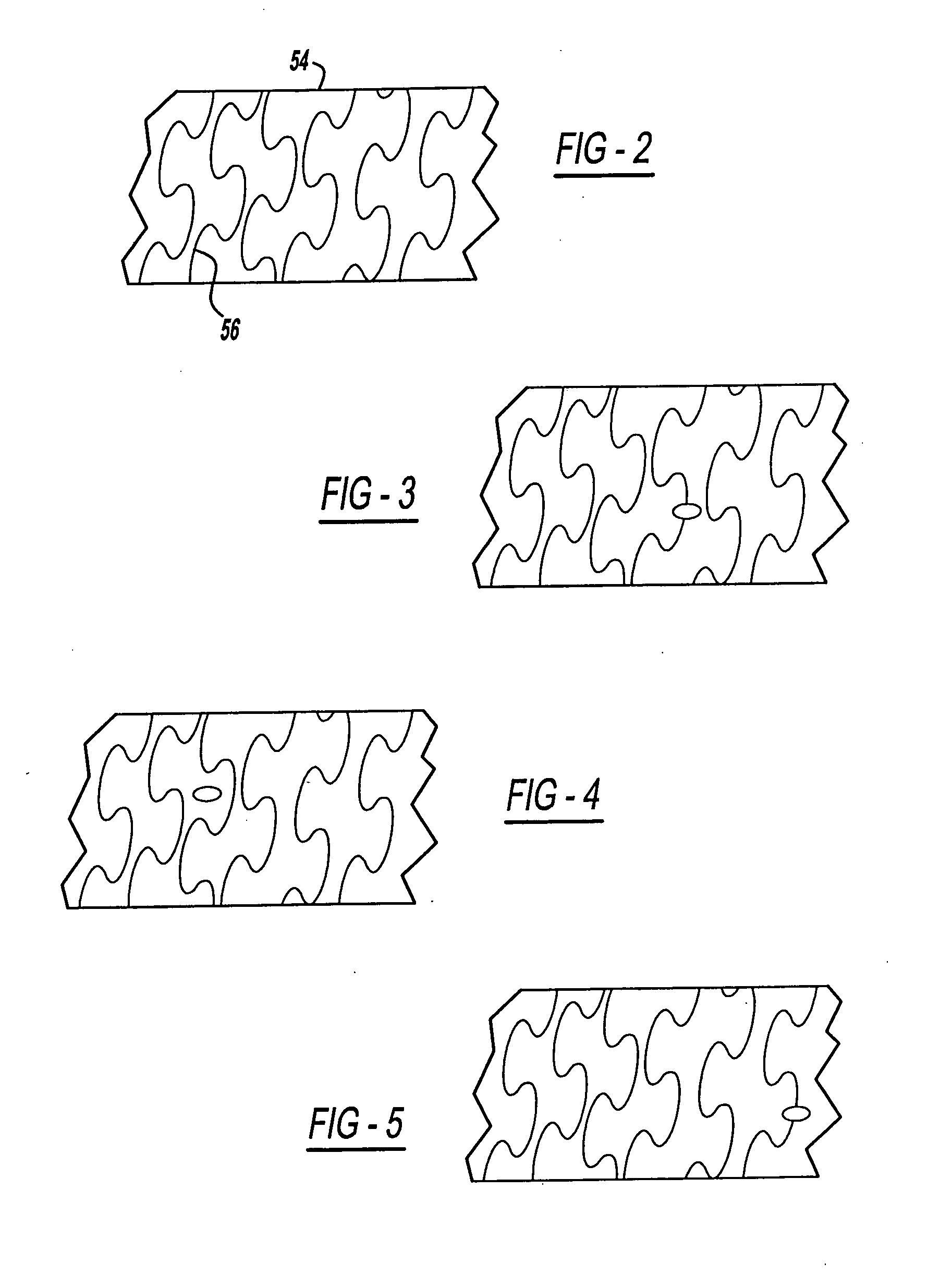

Rapid-exchange balloon catheter shaft and method

InactiveUS20080147001A1Reinforce the vessel wallIncrease blood flowStentsBalloon catheterBalloon catheterDelivery system

A balloon catheter or stent delivery system for medical treatment of a patient has a proximal hub, a balloon, and an improved shaft design. The catheter shaft has a rapid-exchange configuration, and a tubular outer body that includes a hypotube extending from the catheter proximal end to a position at or near a proximal leg of the balloon. An inner tubular body defines a guidewire lumen extending from a distal guidewire port at the catheter distal end to a proximal port located at a position between the balloon and the hub. A distal leg of the balloon is directly or indirectly affixed to the inner body, and a proximal leg of the balloon is affixed to the distal end of the outer body. The hypotube has an aperture for accepting the inner body proximal end, and a circumferential cut pattern. The cut pattern adds flexibility, and may extend from the hypotube distal end to a position proximal of the proximal guidewire port. The cut pattern may have any desired shape, including a spiral, a helical undulating path, or an overlapping serpentine path with inflection points, for example. The hypotube has a fluid-tight covering such as a heat-shrink polymer, so the outer body supports pressure of an inflation medium. The proximal guidewire port may be positioned on or between the individual portions of the cut pattern, or at a position beyond the cut pattern.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

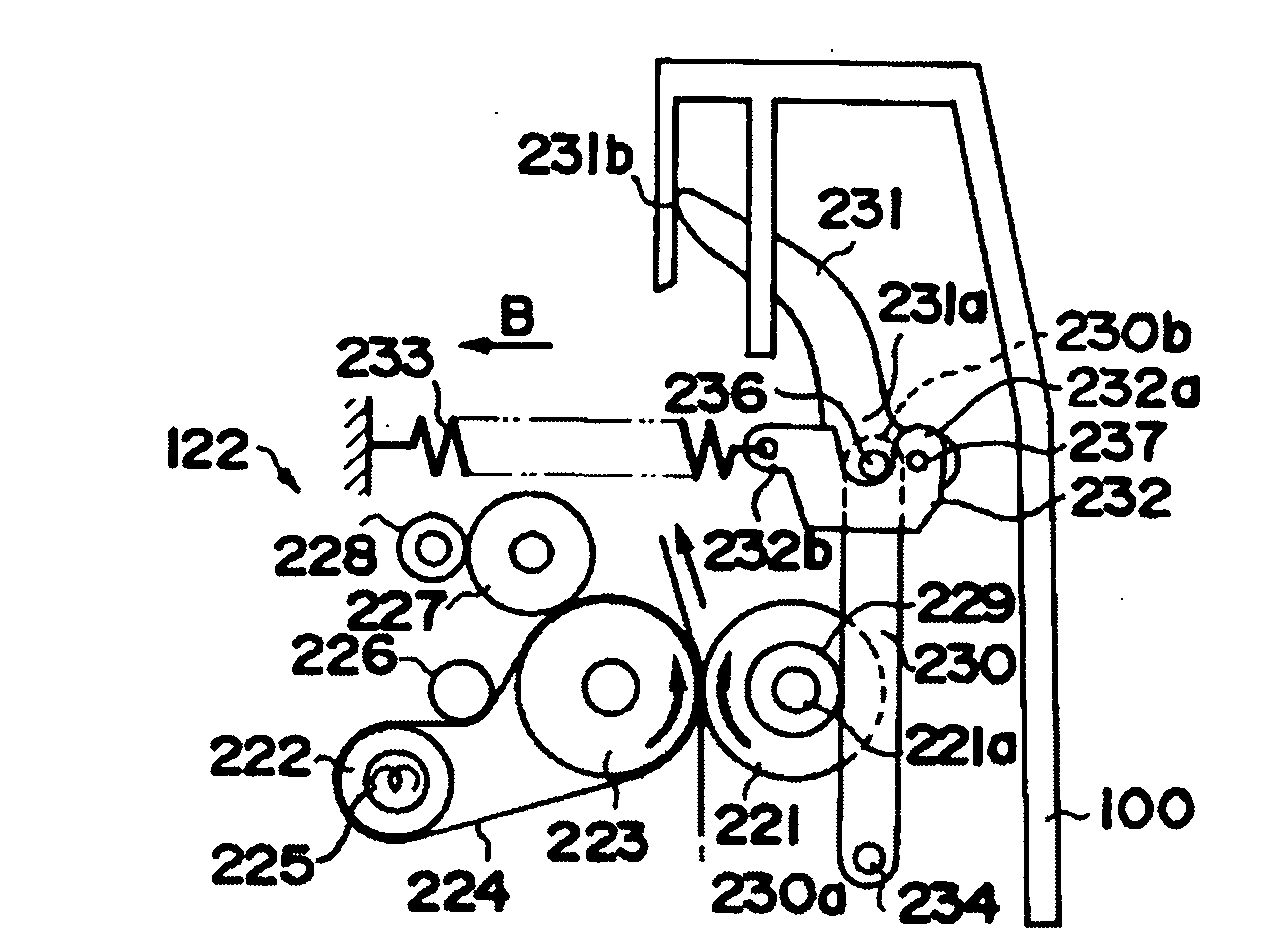

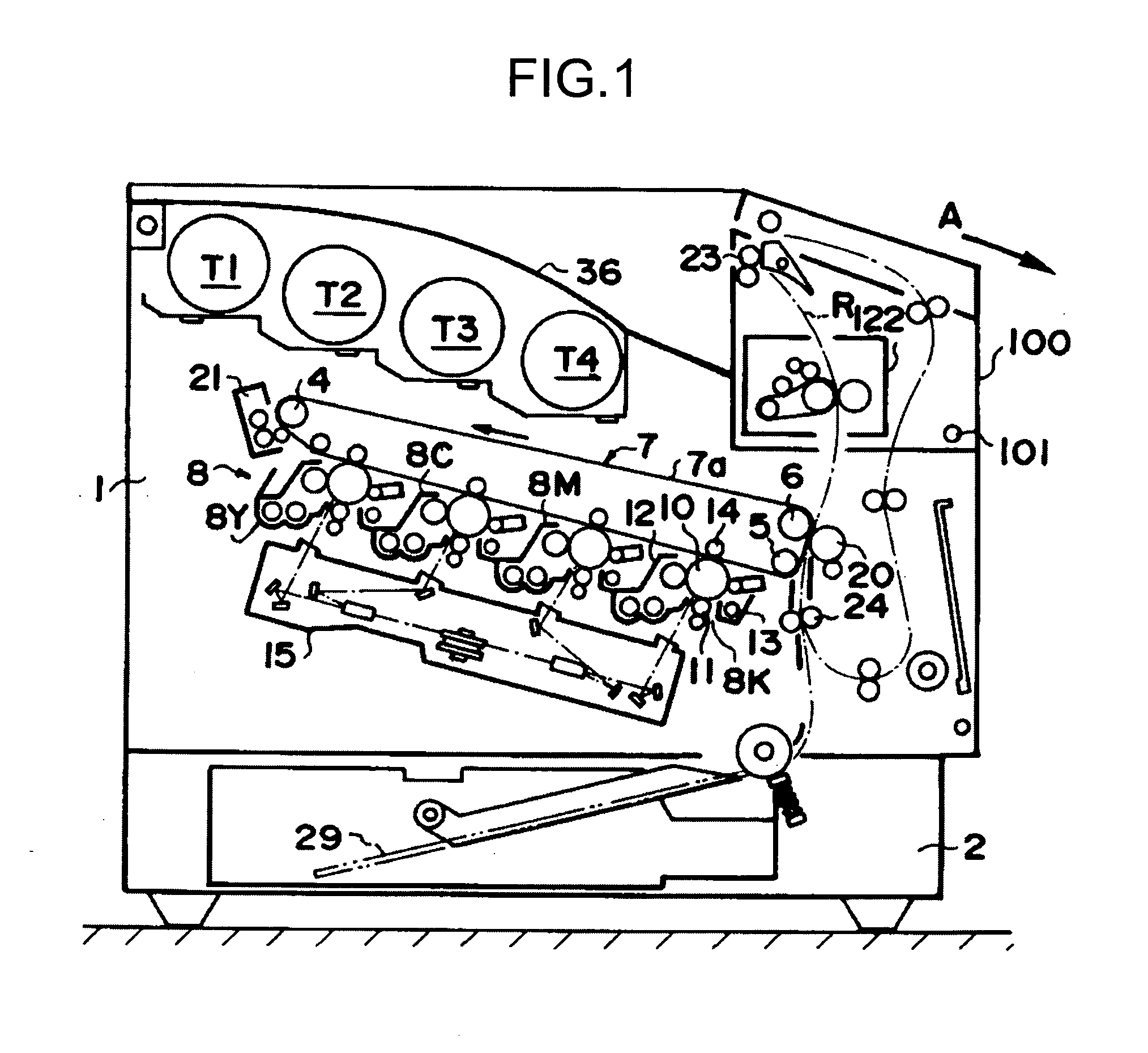

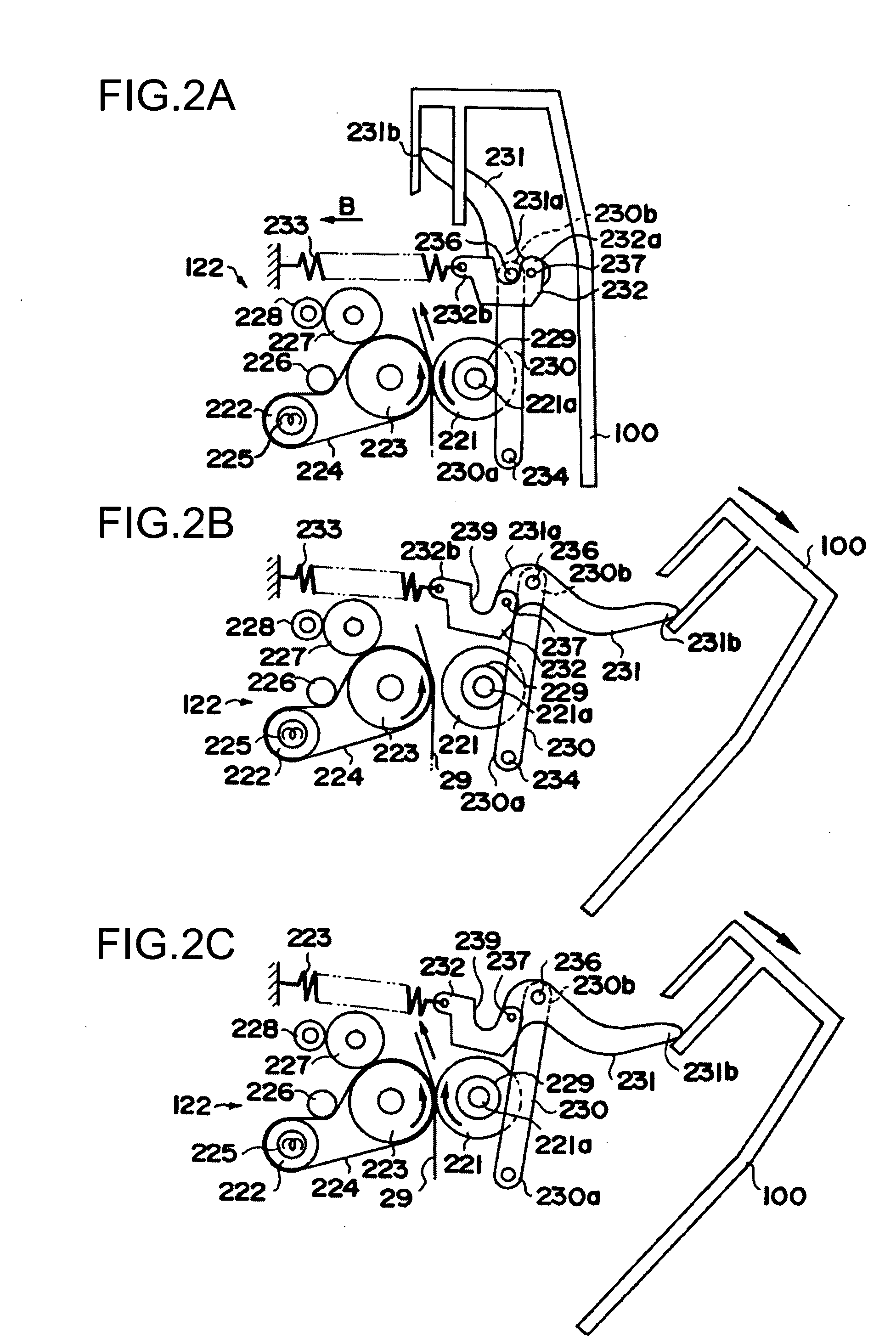

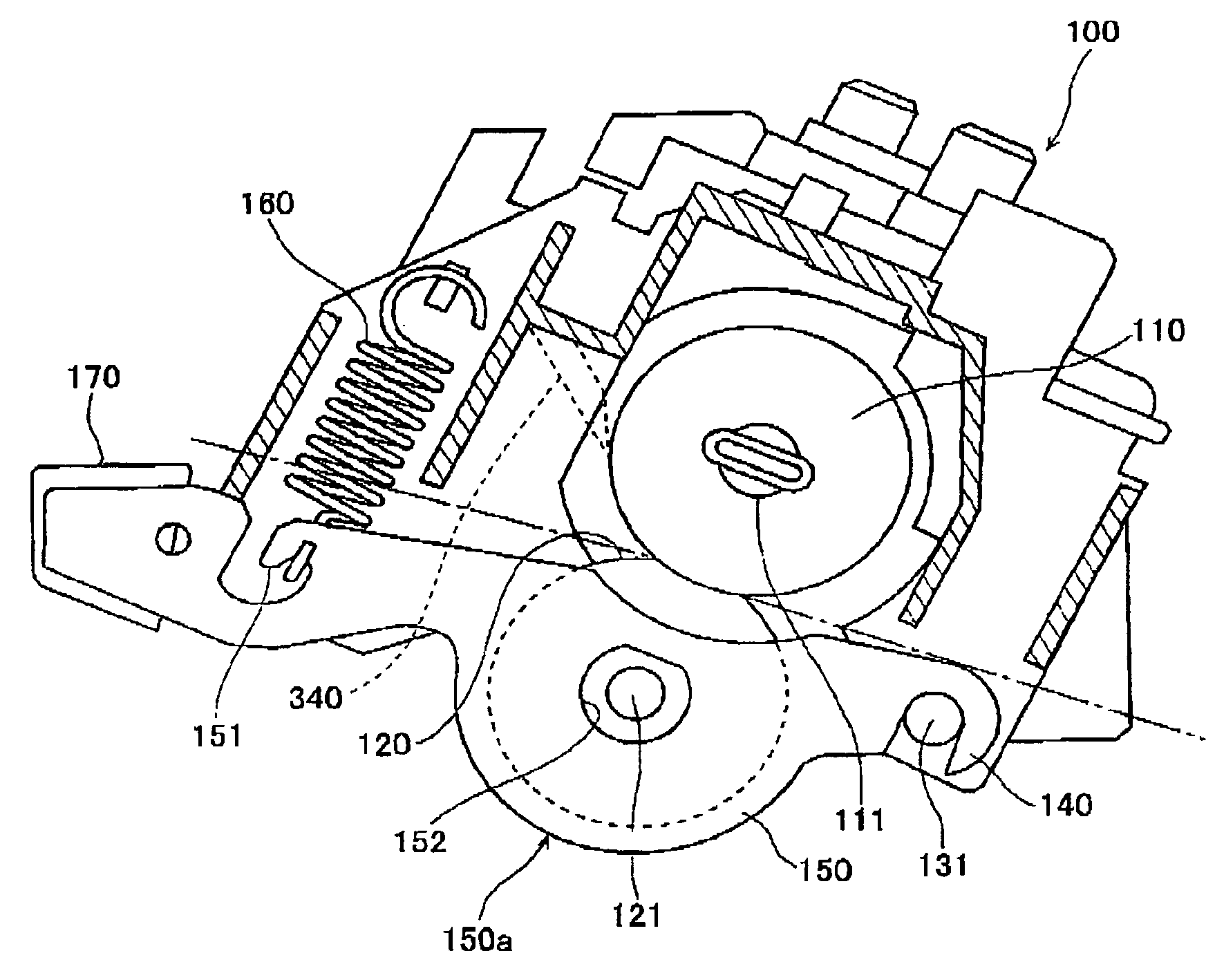

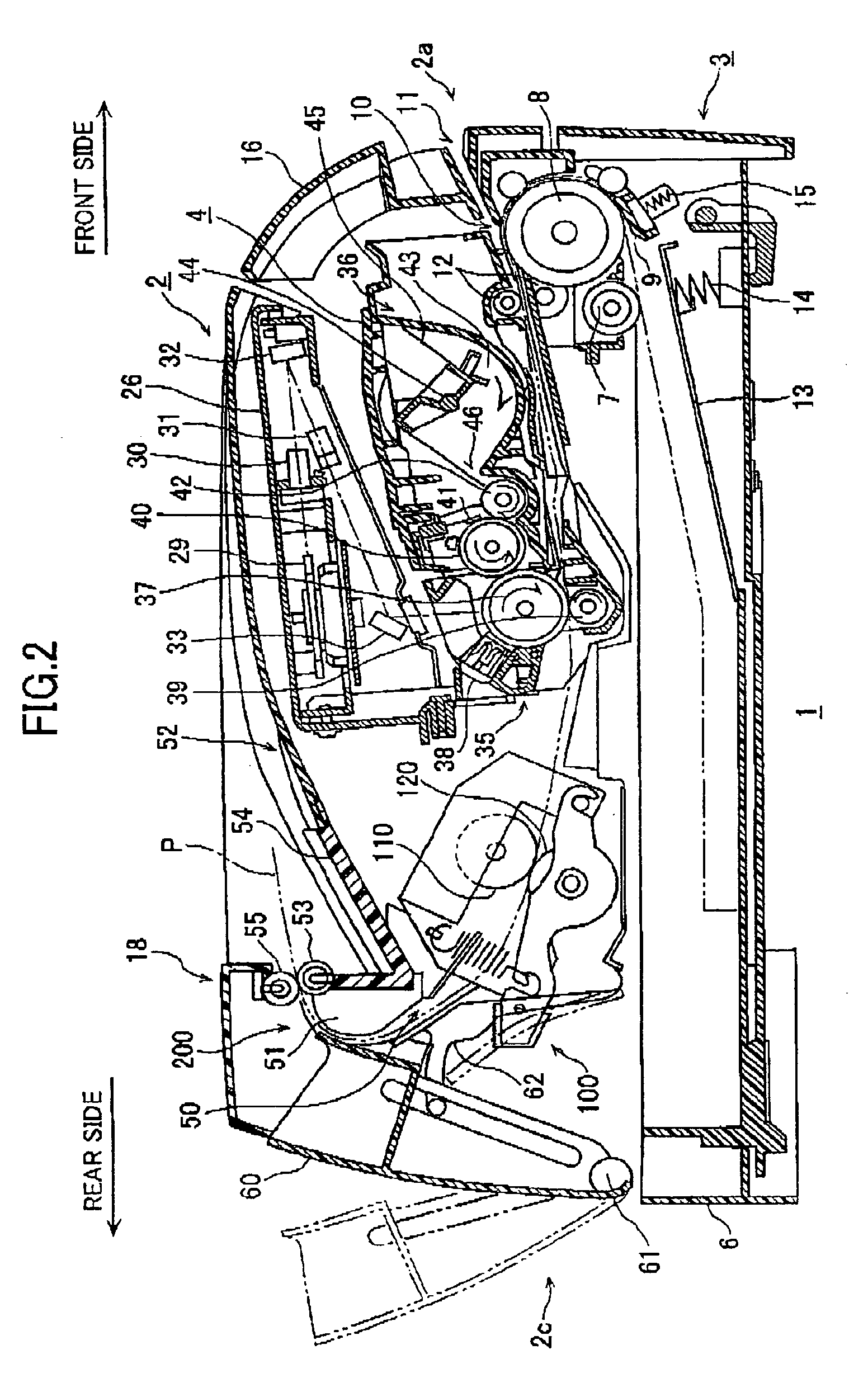

Fixing device and image forming apparatus

A pressure releasing lever is operated to switch the position of a locking member between a pressure exertion position and a pressure release position. In the pressure exertion position a pressure exerting roller exerts pressure against another roller via a pressure exerting lever and in the pressure release position the pressure exerting roller separates from the roller. An elastic member pulls the locking member and a second end of the pressure exerting lever in a locking direction. A core end of the pressure exerting roller is rotatably supported by a shaft bearing. The pressure exerting lever engages with the shaft bearing.

Owner:RICOH KK

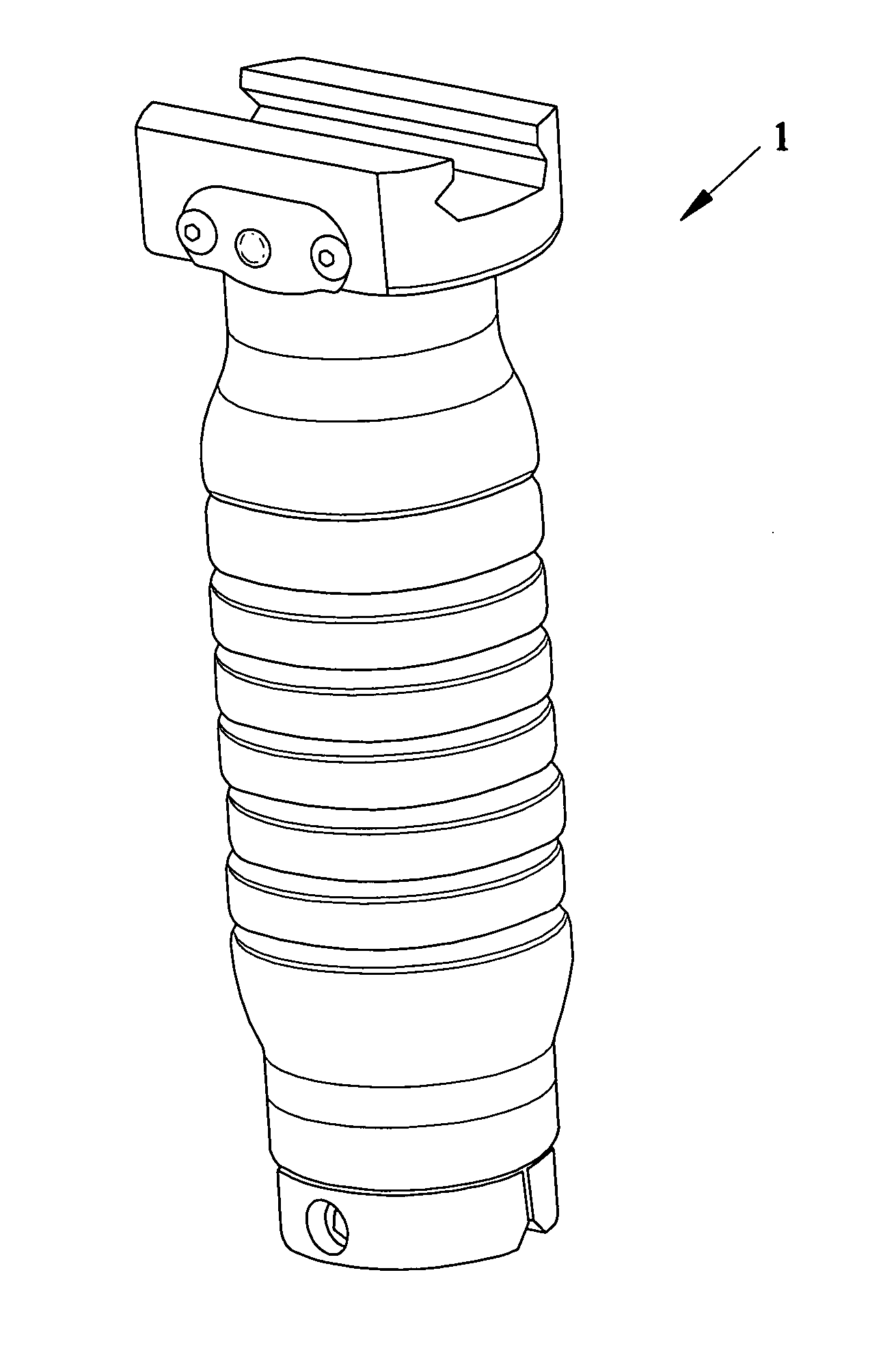

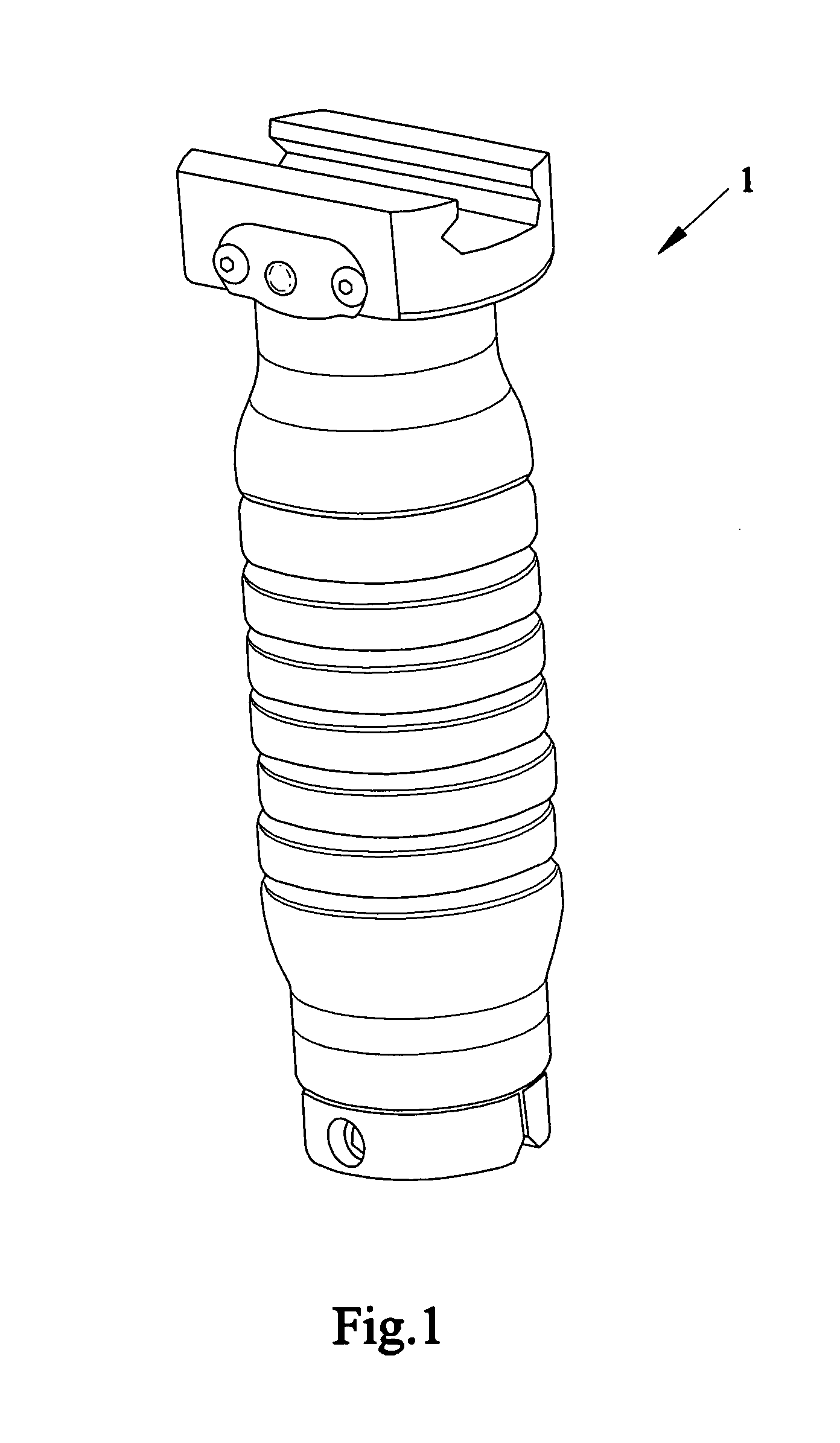

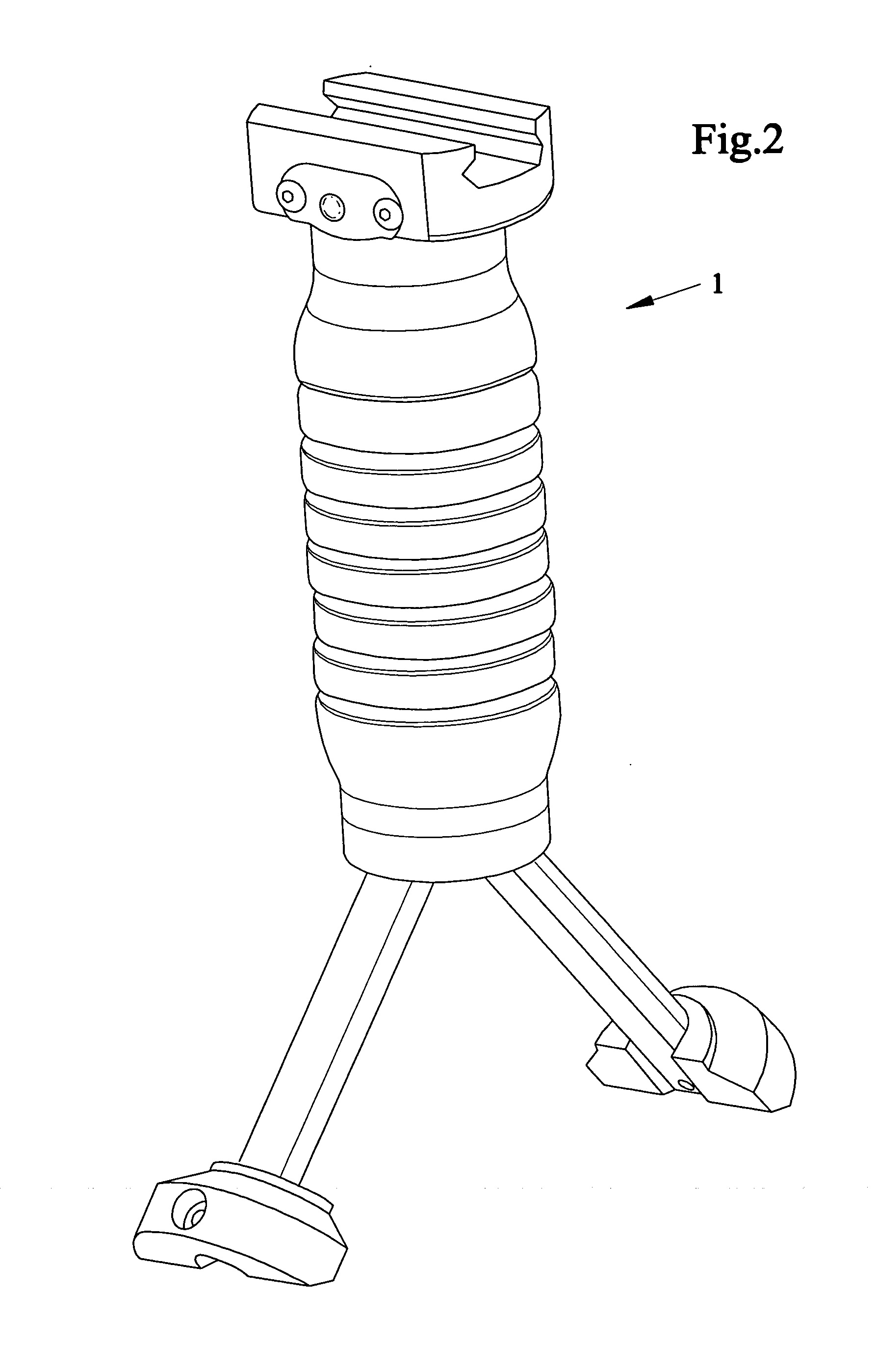

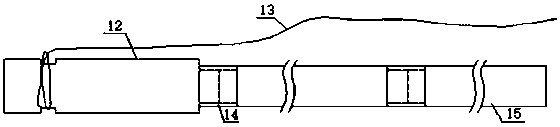

Vertical fore grip with bipod

ActiveUS20060277809A1Self containedSimple attachmentAmmunition loadingStands/trestlesTerrainLeg length

Devices, systems and methods of using an ergonomic fore grip / gun handle with a concealable and collapsible bipod. One version can have a tubular recess consisting of a first cylindrical cutout housing the bipod legs when concealed and a sliding piston that deploys the legs and a second cylindrical cutout housing a release mechanism and a void space for other accessories. The release mechanism has a compression spring positioned between the piston assembly and the bottom of the first cylindrical cutout and the compression spring. The legs are connected to the bottom of the piston assembly via a hinge and spring that when released from confinement within the fore grip, causes the legs to expand outward until fully deployed. Telescoping legs allow adjustment of leg length for use on uneven terrain. The grip portion has an outer surface with a flat surface on sides of the grip to provide a more stable grip, assist in orienting the mounted weapon and support pressure pads for lights.

Owner:GRIP POD SYST INT

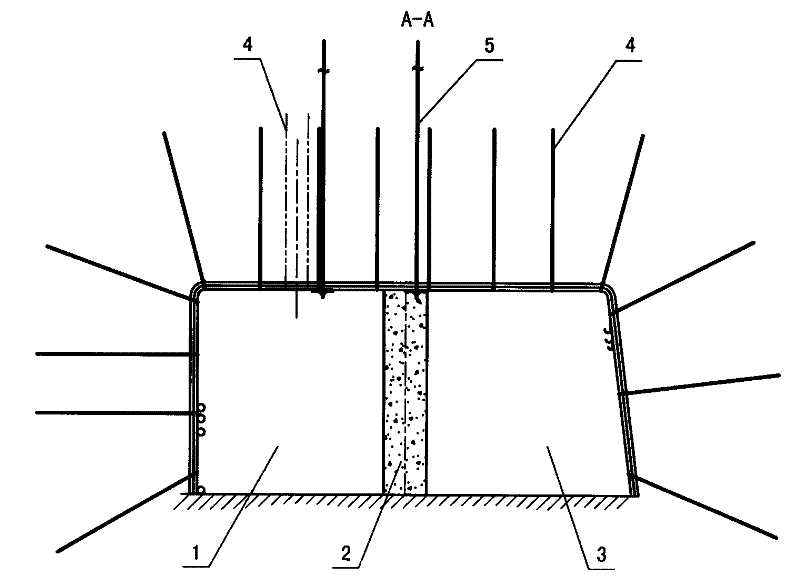

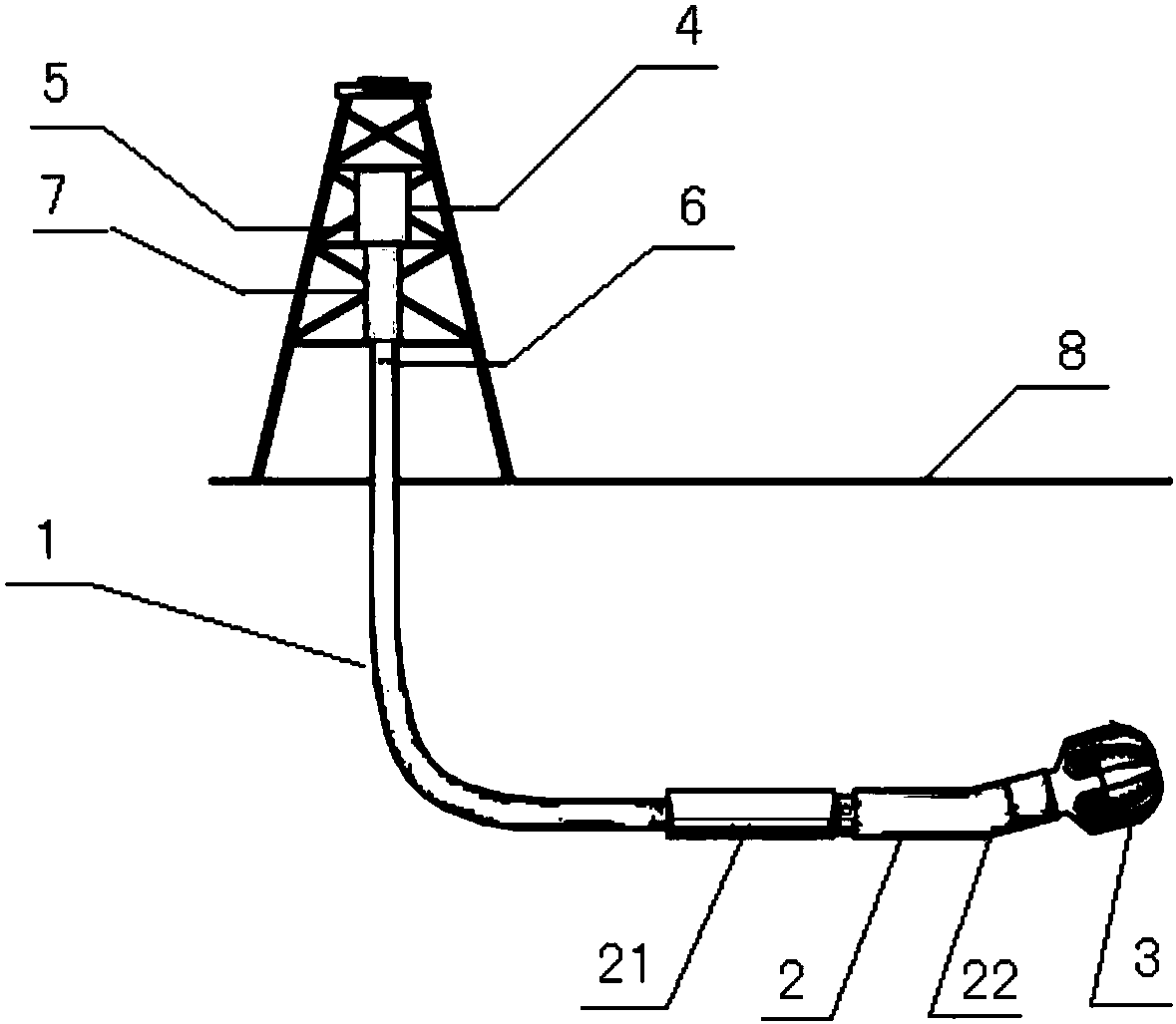

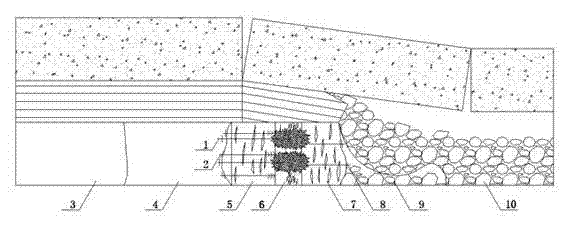

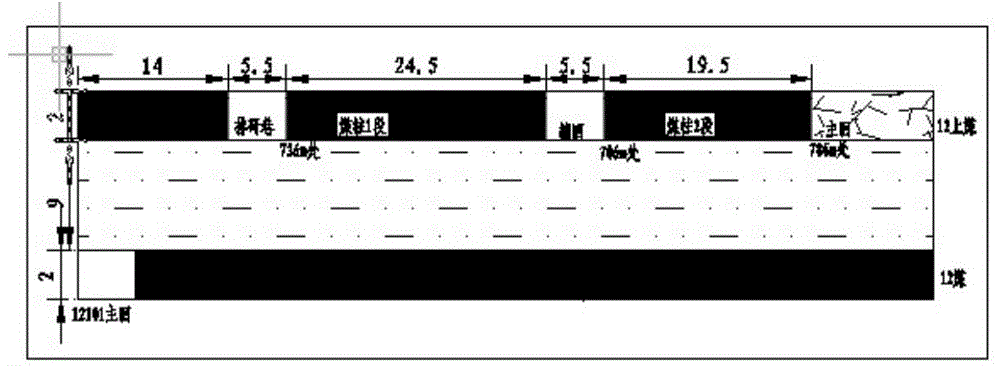

Method for controlling high mine pressure of open-air roadway by hydraulic fracturing

InactiveCN103758570ARelieve pressureReduce leading bearing pressureMining devicesAbutmentHydraulic fracturing

A method for controlling high mine pressure of an open-air roadway by hydraulic fracturing comprises the following steps of determining a hard rock stratum of a roof according to a geological information bar chart of a coal face; designing a control drilling hole; respectively controlling abutment supporting pressure and lateral supporting pressure; slotting or slitting in the bottom of the hole after hole drilling construction is finished so as to achieve the purpose of directional fracturing; applying a hydraulic fracturing process; and weakening the hard roof or cutting off the hard roof along a directional fracturing slot of the drilling hole so as to transfer stress or weaken surrounding rock and reduce the lateral supporting pressure and the abutment supporting pressure of the open-air roadway. A weakening zone in the surrounding rock can effectively absorb or weaken impact stress waves; a dynamic disaster of rock burst caused by the reason that the hard roof cracks suddenly is avoided; and large deformation of the open-air roadway is controlled. The method for controlling the high mine pressure of the open-air roadway by hydraulic fracturing is not only applicable to controlling the high mine pressure of the open-air roadway with the coal face with the hard roof, but also is applicable to controlling the high mine pressure of the roadway of which a work face is in tunnelling crossing with a work face of an adjacent roadway during mining. Moreover, the method is simple, effective, safe and reliable, and is low in cost.

Owner:CHINA UNIV OF MINING & TECH

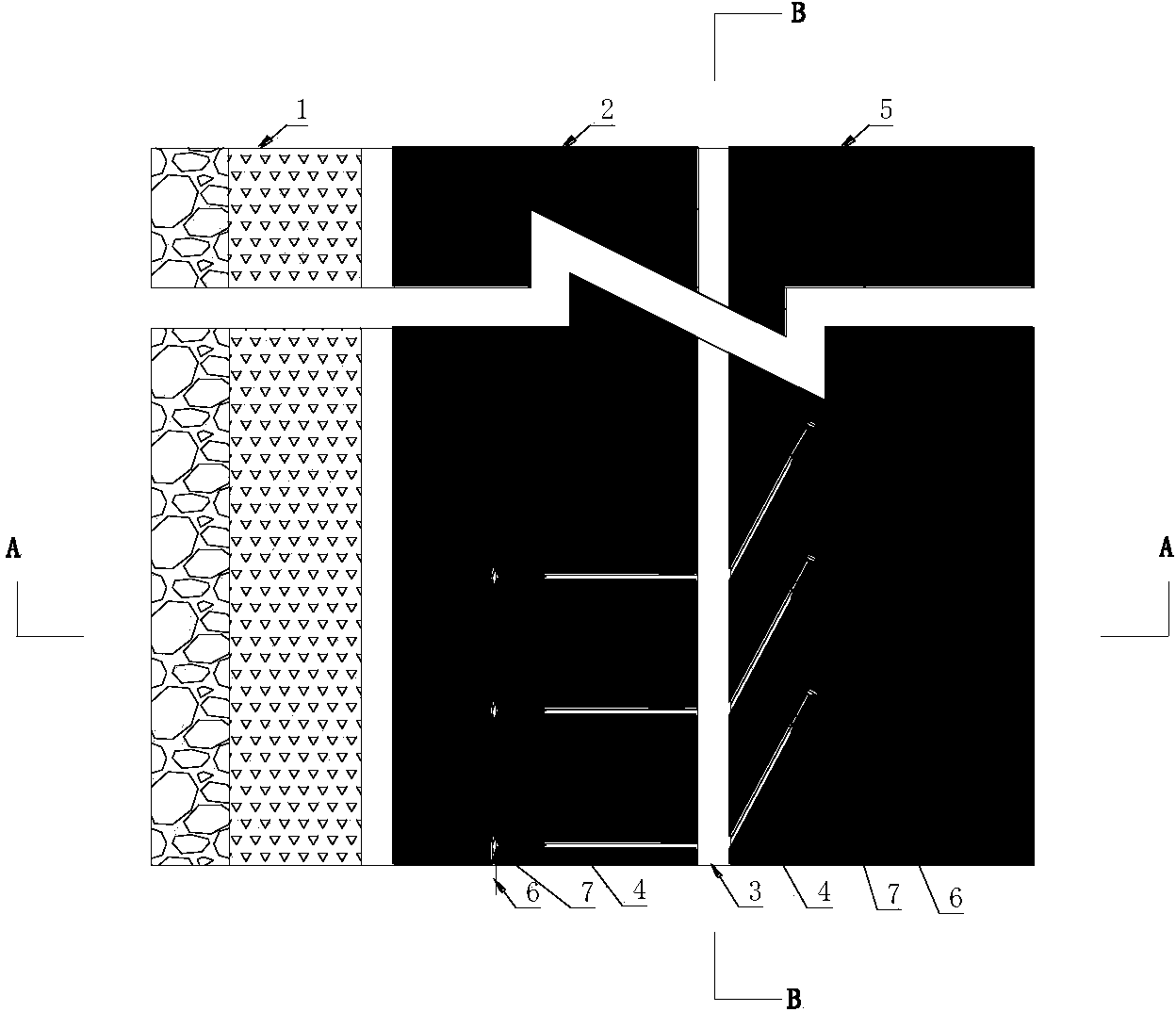

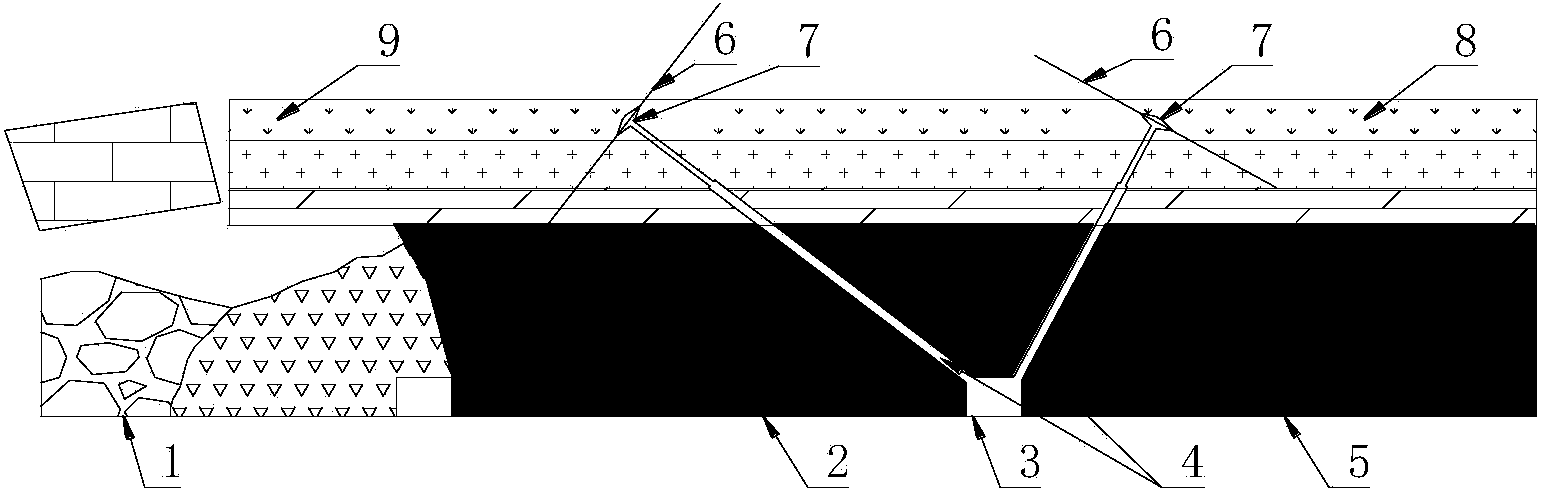

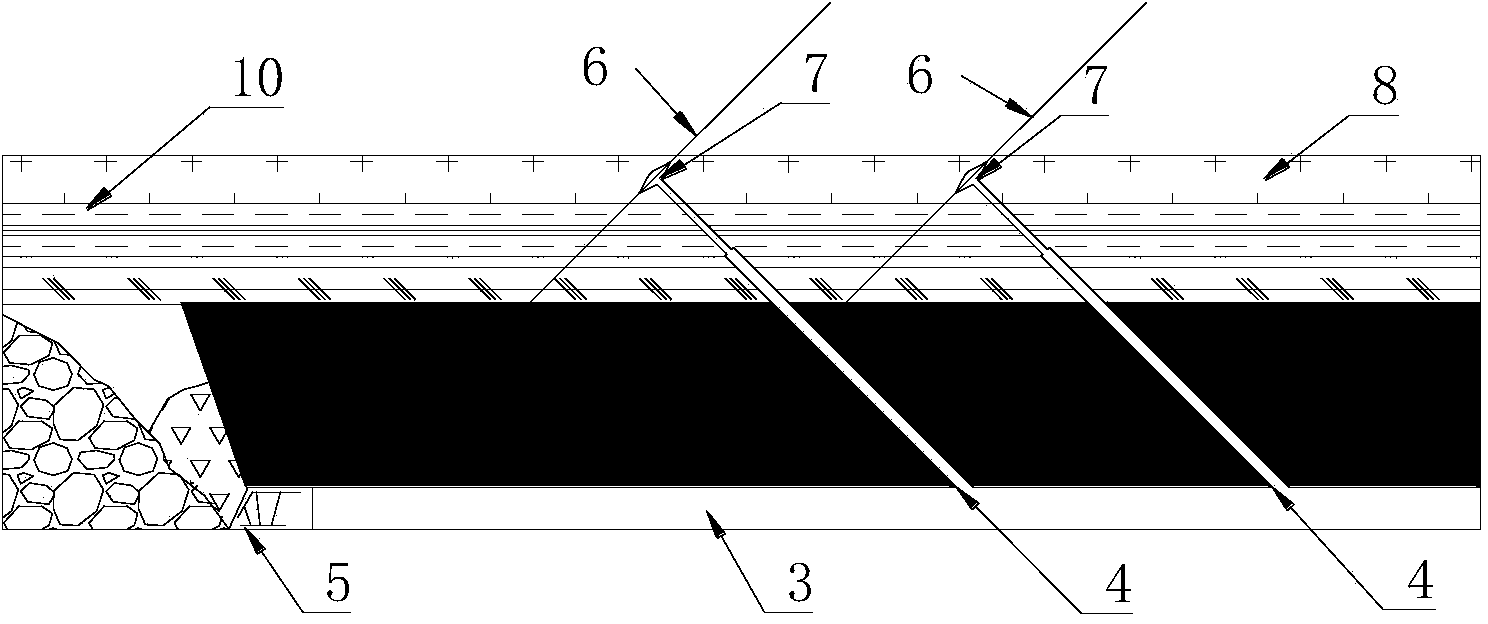

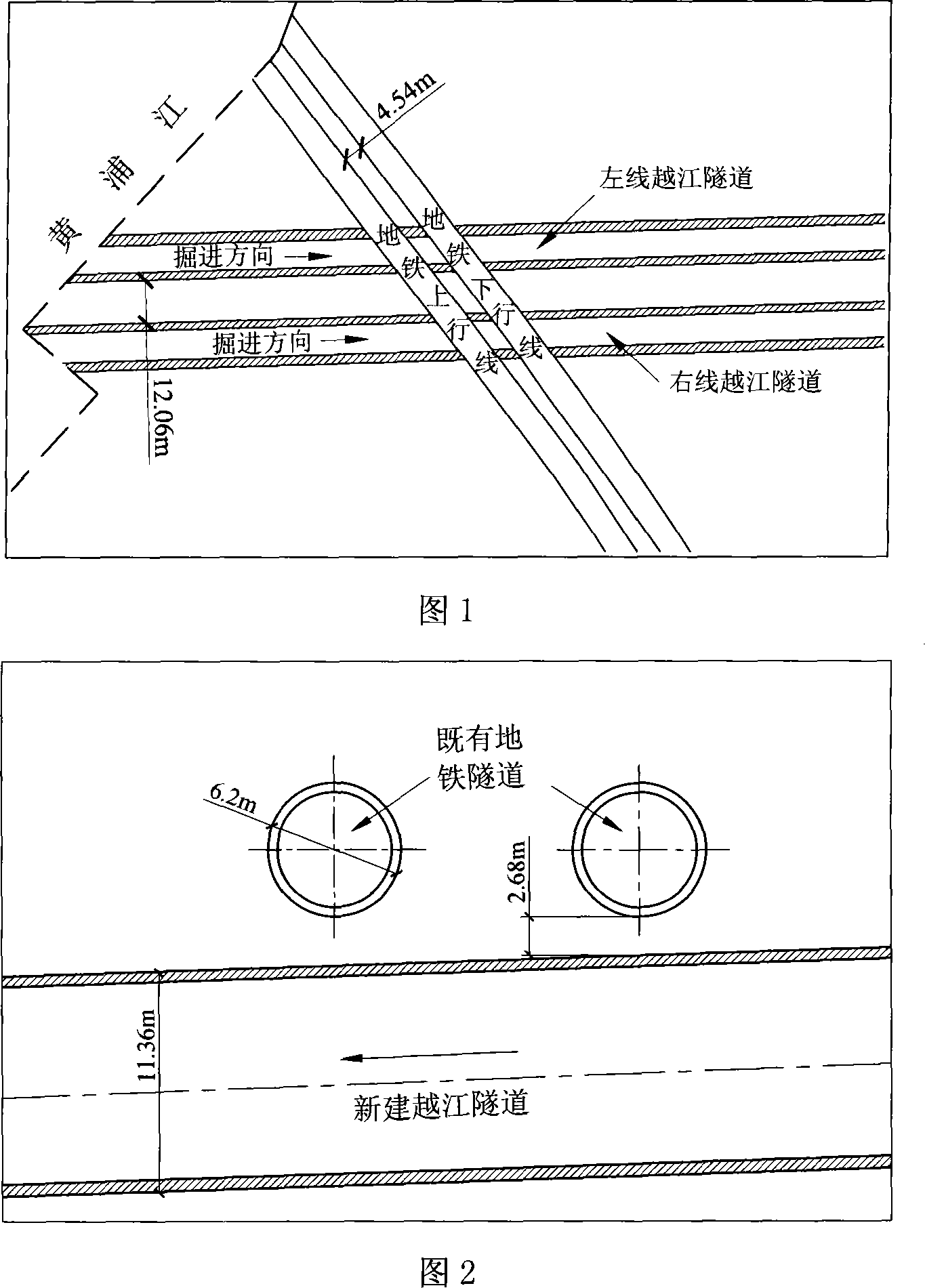

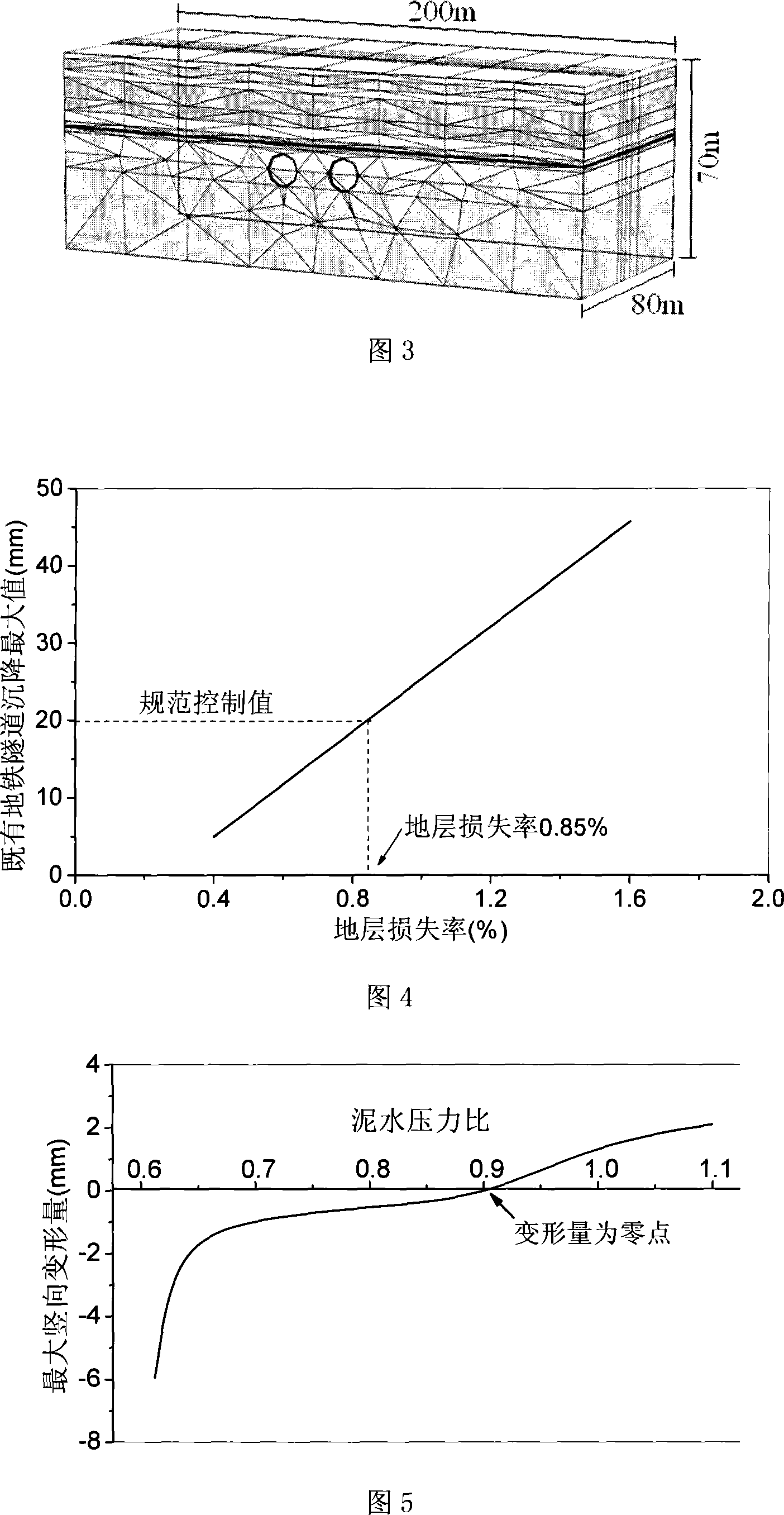

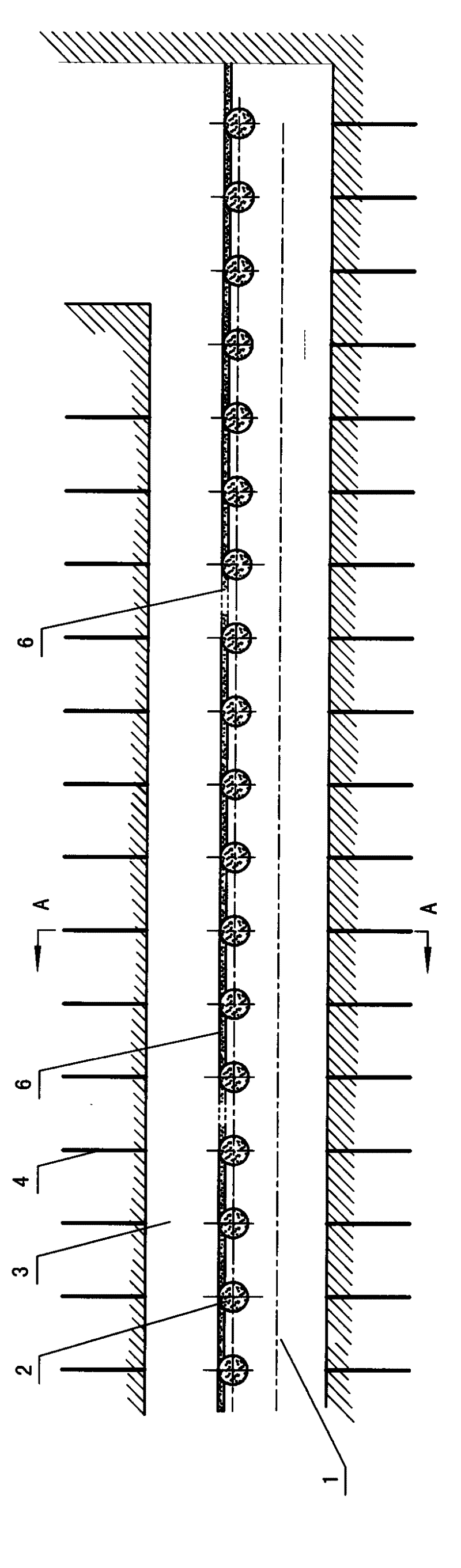

Large diameter tunneling close range down-traversing small diameter subway tunnel distortion control method

InactiveCN101215969AGuarantee smooth constructionEnsure safetyTunnelsUnderground tunnelFinite element method

The invention discloses a method for controlling distortion for deep large diameter shield tunnels to under-pass small diameter tunnels, which pertains to the technical field of tunnel engineering. According to the method, the control range of the stratum loss ratio of newly established tunnels and the optimum value of the support pressure of the shield cut surface are acquired by using the finite-element method; soil pressure in front of the shield cut surface is kept relatively balanced by setting the optimal value of the support pressure, and the support pressure fluctuation range of the cut surface is controlled to range from minus 10kPa to plus 10kPa; the stratum loss ratio of the newly established tunnels is controlled within the allowed range. According to the construction technique measures, a test propelling area is arranged before the shield reaches a cross position. In the area, construction is carried out according to the situation of the existing underground tunnels above; and construction parameters are controlled and regulated to adjust the support pressure, the propulsive velocity and the amount of the grout to be injected in time; the shield passes through the cross position in combination with the optimal values of the construction parameters of the test propelling area. The invention can not only ensure the construction of tunnels to be carried out safely and smoothly, but also minimize the influence of construction on ambient environment.

Owner:SHANGHAI JIAO TONG UNIV

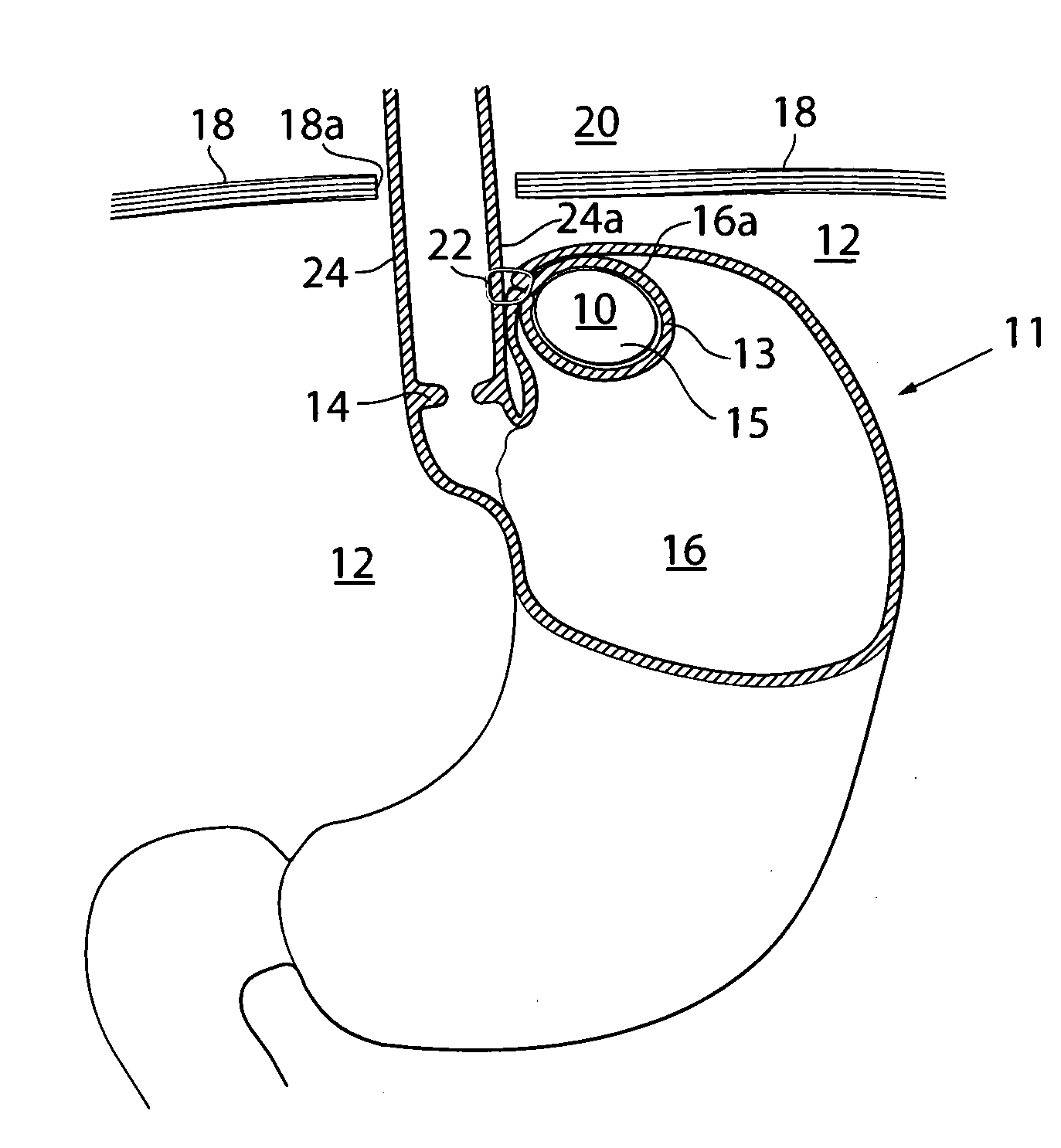

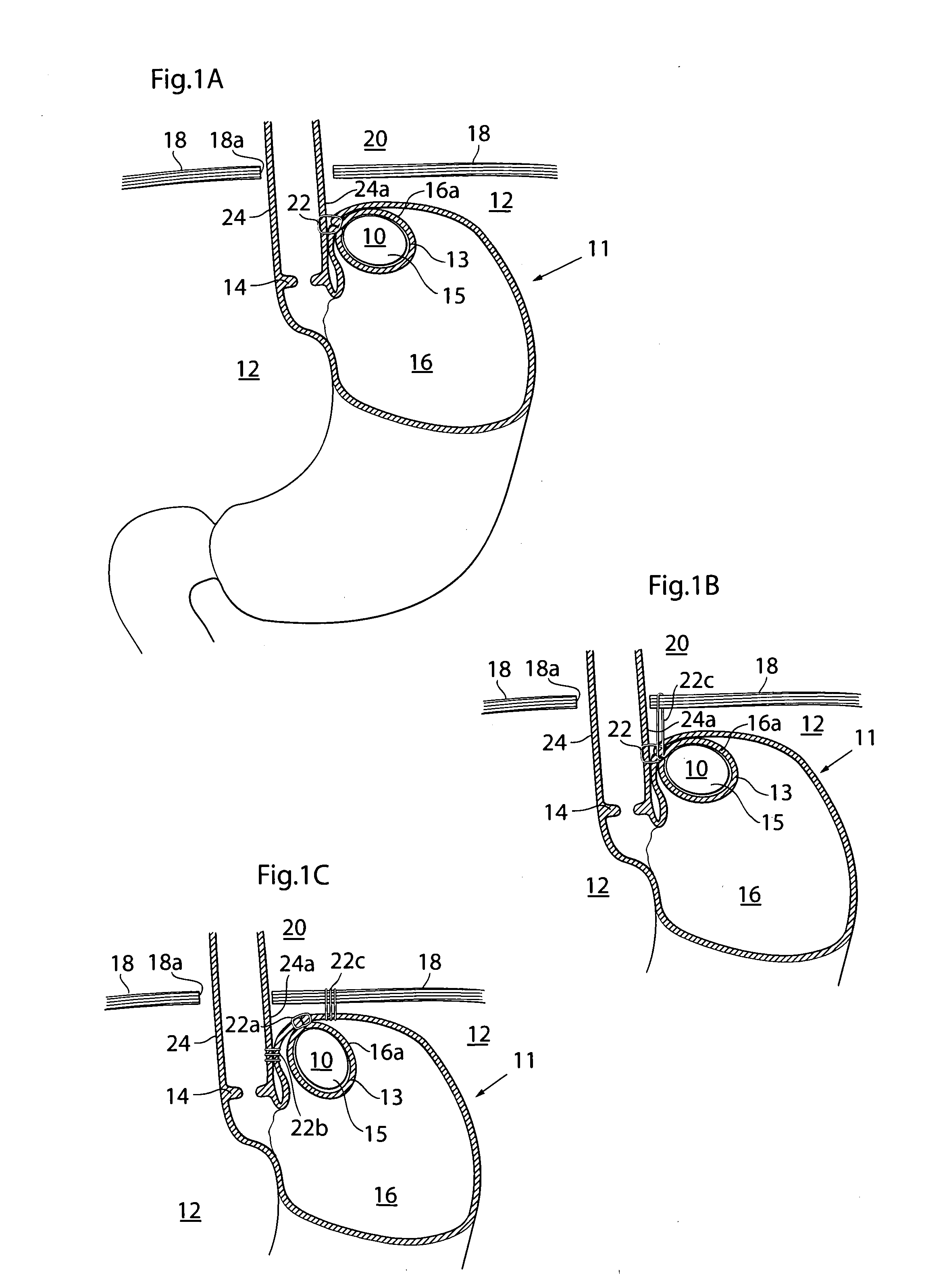

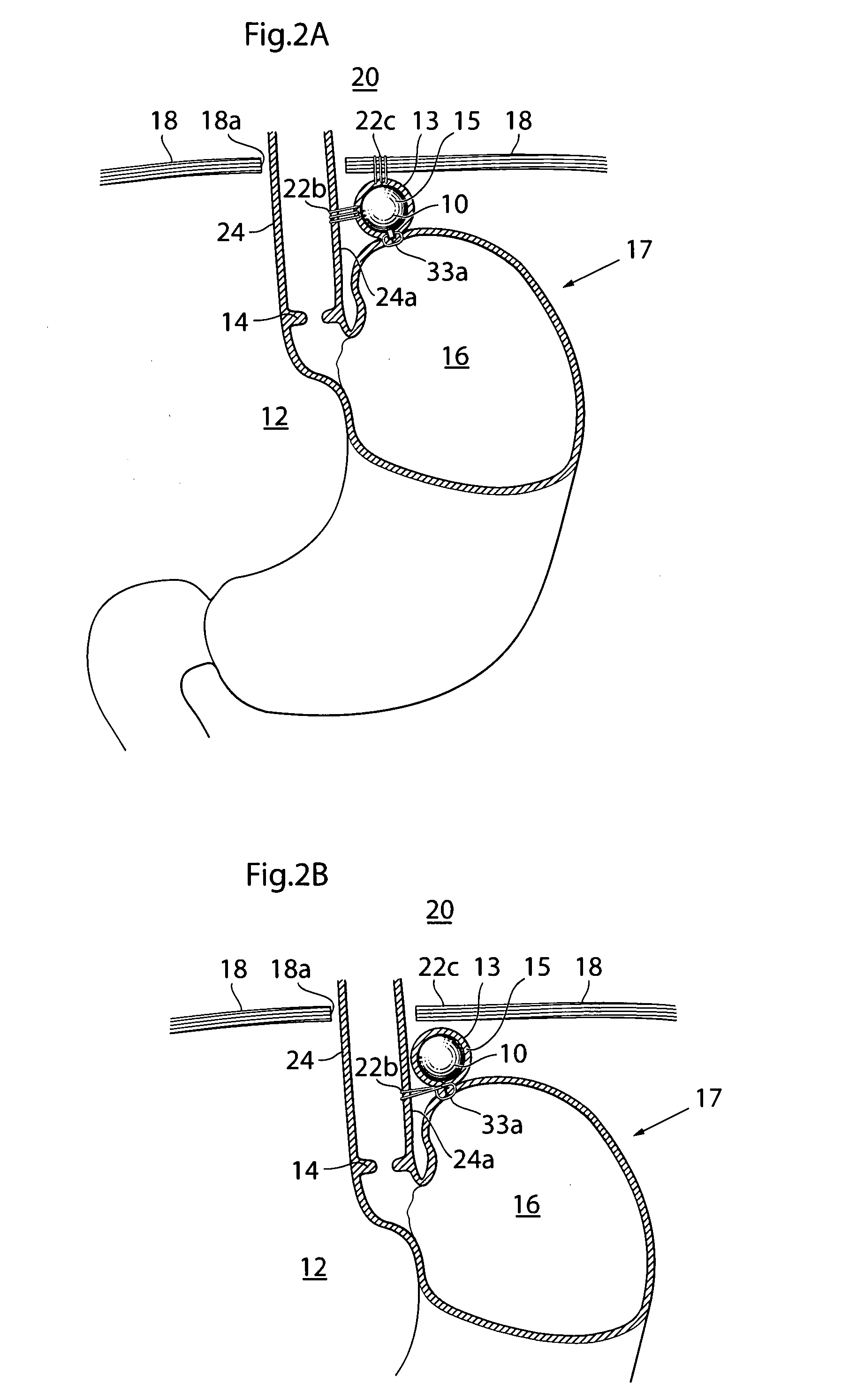

Apparatus for treating gerd

An apparatus for the treatment of acid reflux disease has an implantable movement restriction device adapted to be at least partly invaginated by a patient's stomach fundus wall. A substantial part of the outer surface of the movement restriction device is adapted to rest against the stomach wall without injuring the latter in a position between the patient's diaphragm and at least a portion of the lower part of the invaginated stomach fundus wall, such that movement of the cardiac notch of the patient's stomach towards the patient's diaphragm is restricted, to thereby prevent the cardia from sliding through the patient's diaphragm opening into the patient's thorax, so as to maintain the supporting pressure against the patient's cardia sphincter muscle exerted from the patient's abdomen. The movement restriction device has a size of at least 125 mm3 and a circumference of at least 15 mm.

Owner:FORSELL PETER

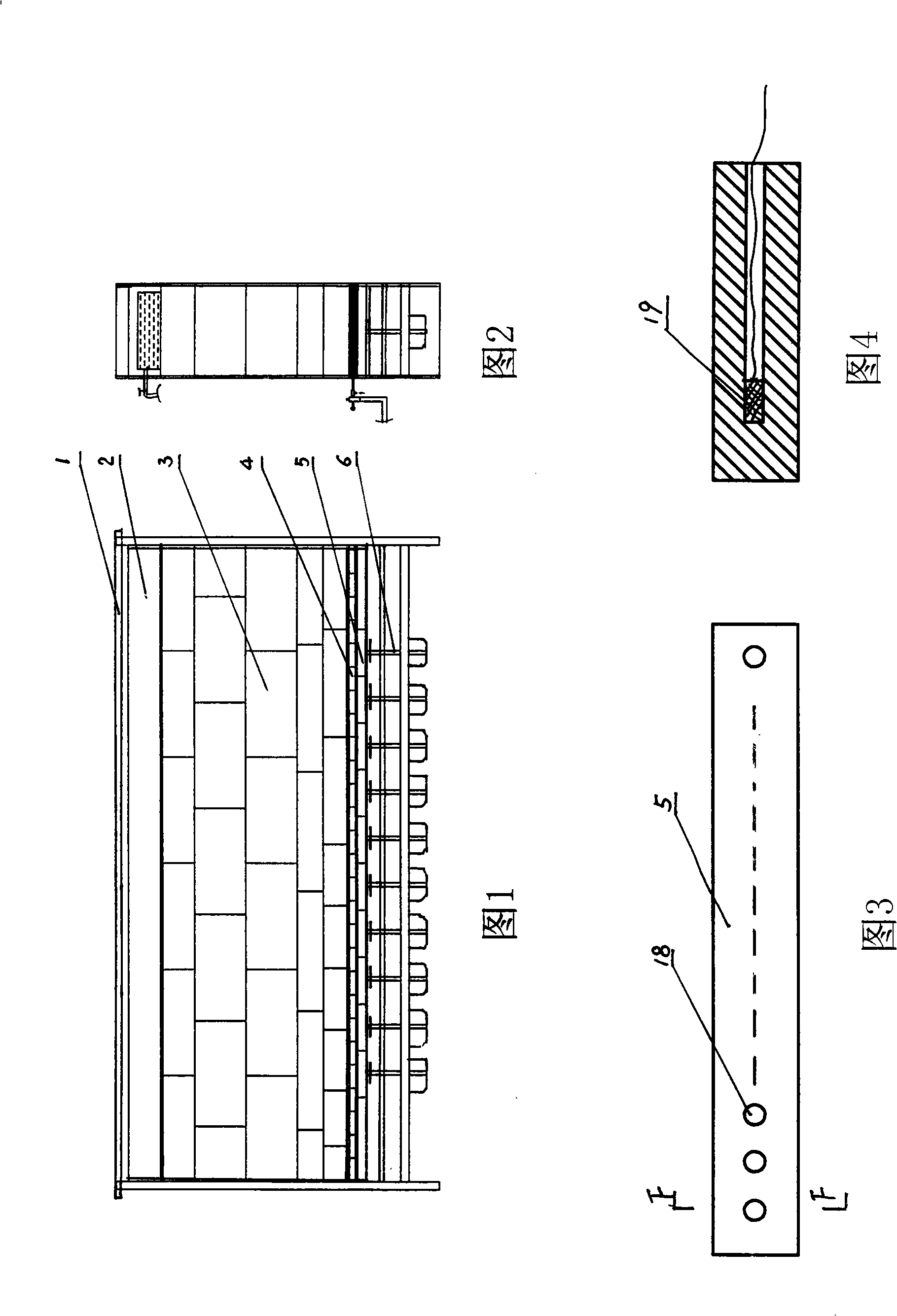

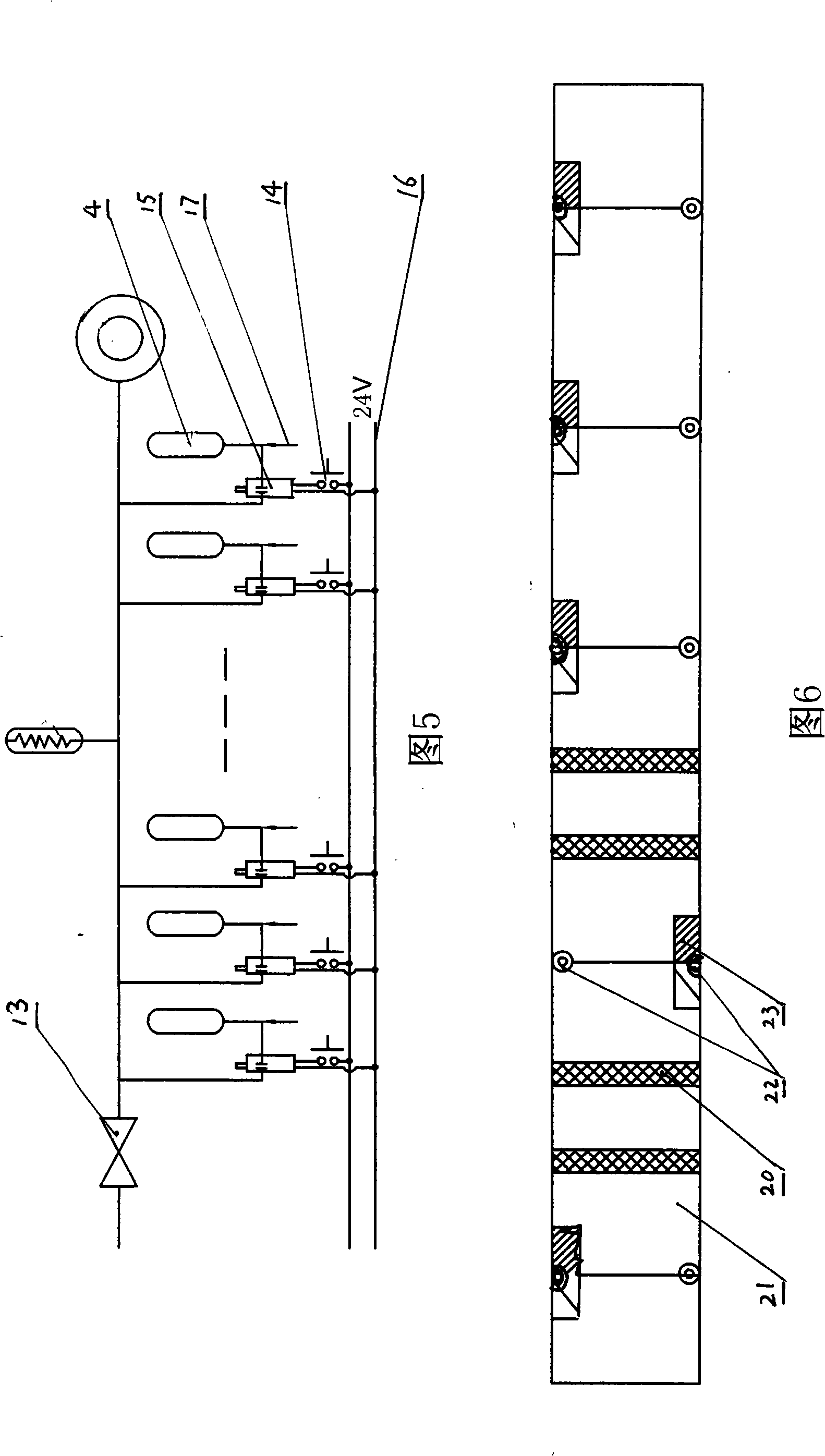

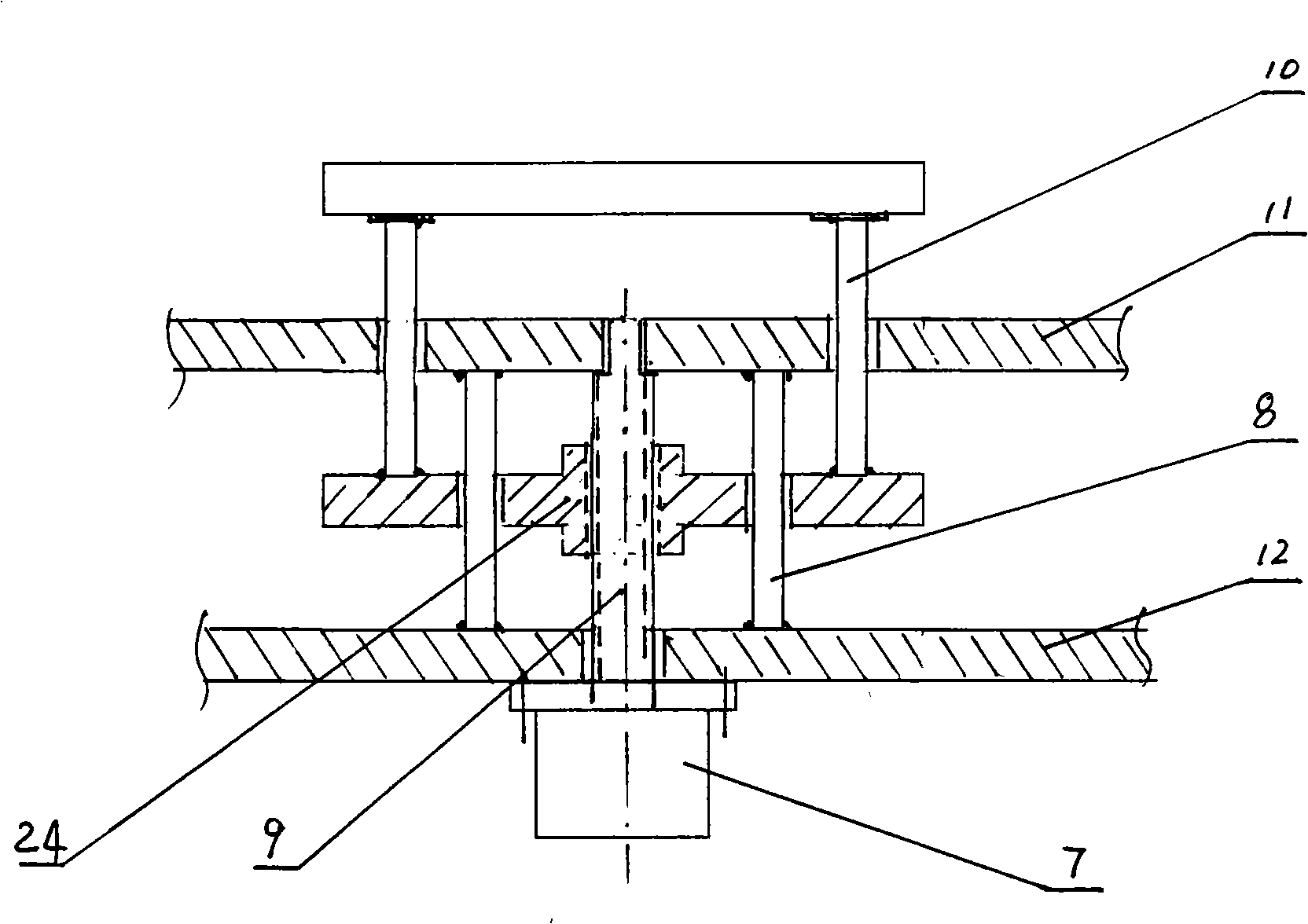

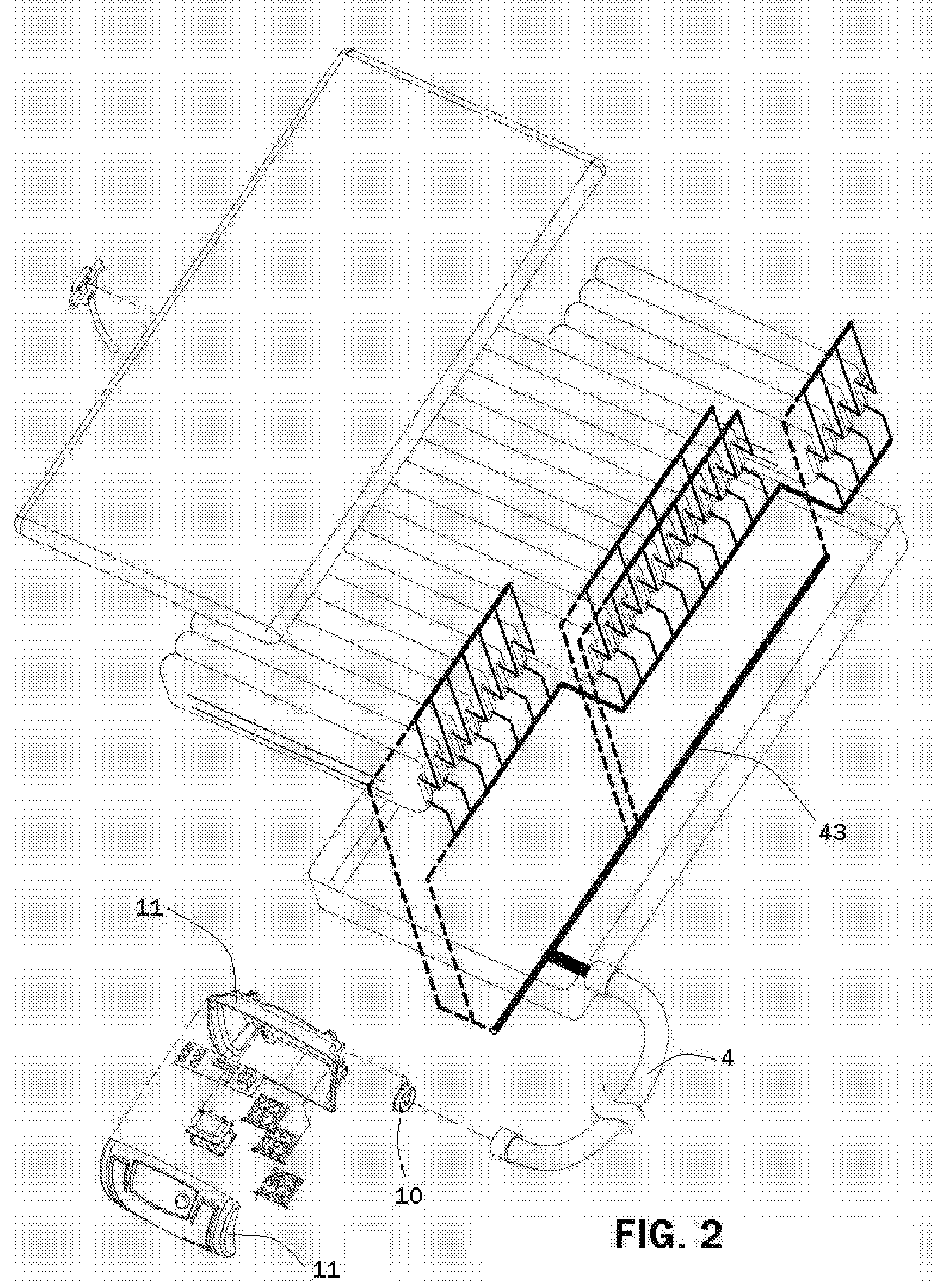

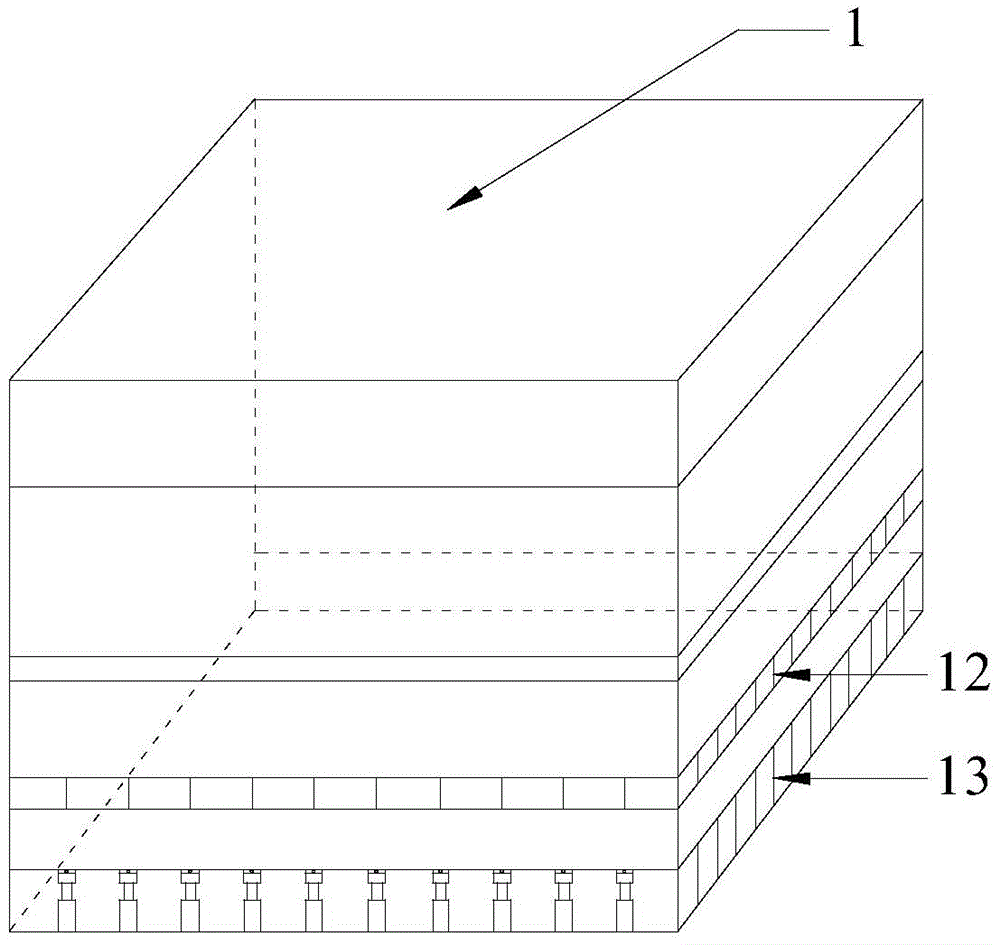

Simulation experiment bench for stope mining machinery

InactiveCN101315306AMeet the requirements of the plastic indexEnsure consistencyForce measurementEngineeringCoal

The invention discloses a stope mine pressure mechanical simulation test bed that combines analog simulation and physical simulation. The test bed is formed in the way that a simulation mining height hoisting device, a simulation coal floor rubber plate, a simulation coal seam air sac, a simulation upper roof model block of a layer-shaped structure and a loading air sac are arranged from top to bottom on a cuboid testing frame. The test bed is used for studying the relations between the kinestate of overlaying strata and the change of a coal seam support pressure in the stope advancing process, the relations between the support resistance and the kinestate of the overlaying strata during the weighting of stope, the relations among the kinestate of the overlaying strata, the coal seam support pressure and the distribution of stress on a bottom plate in the stope advancing process, etc.

Owner:SHANDONG UNIV OF SCI & TECH

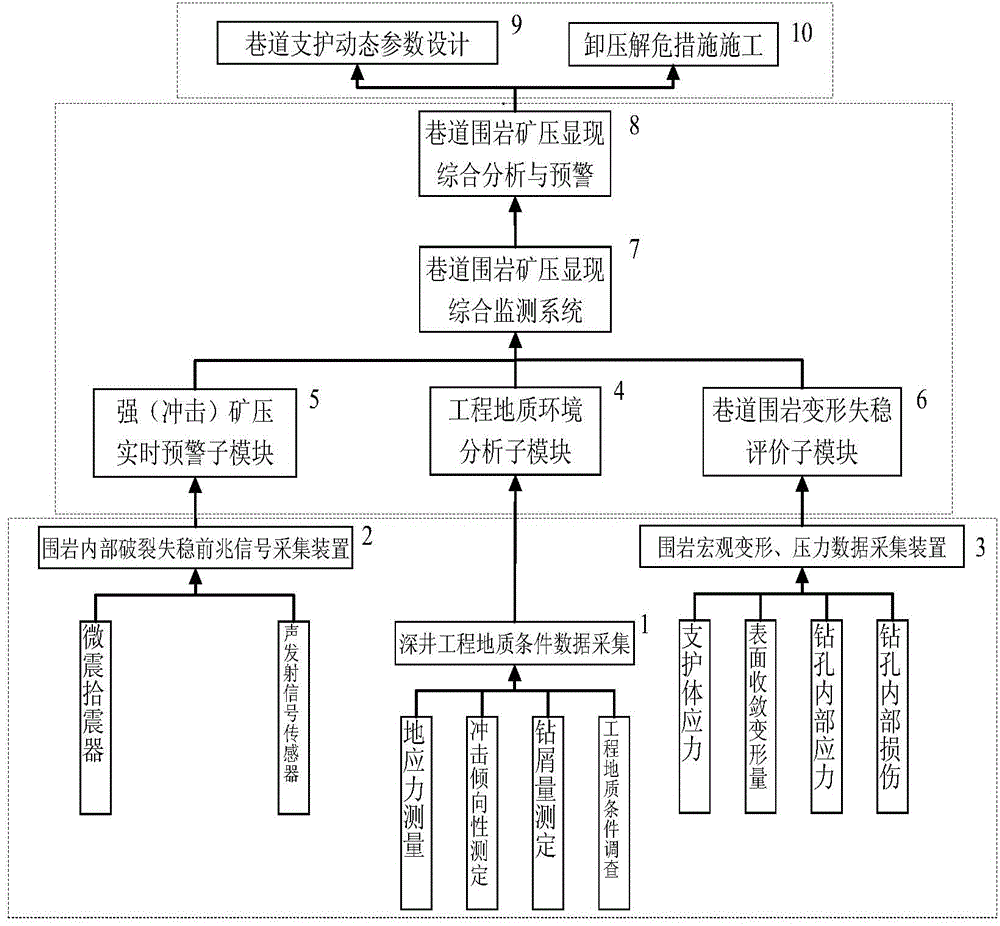

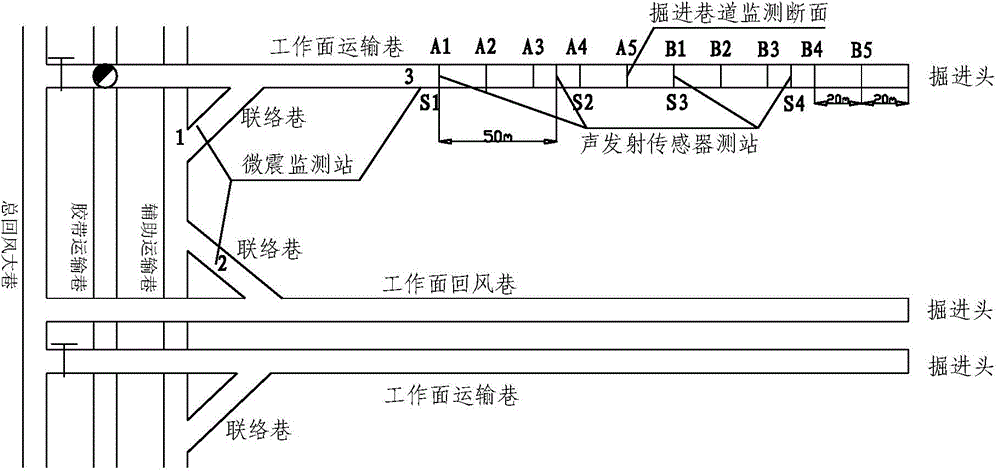

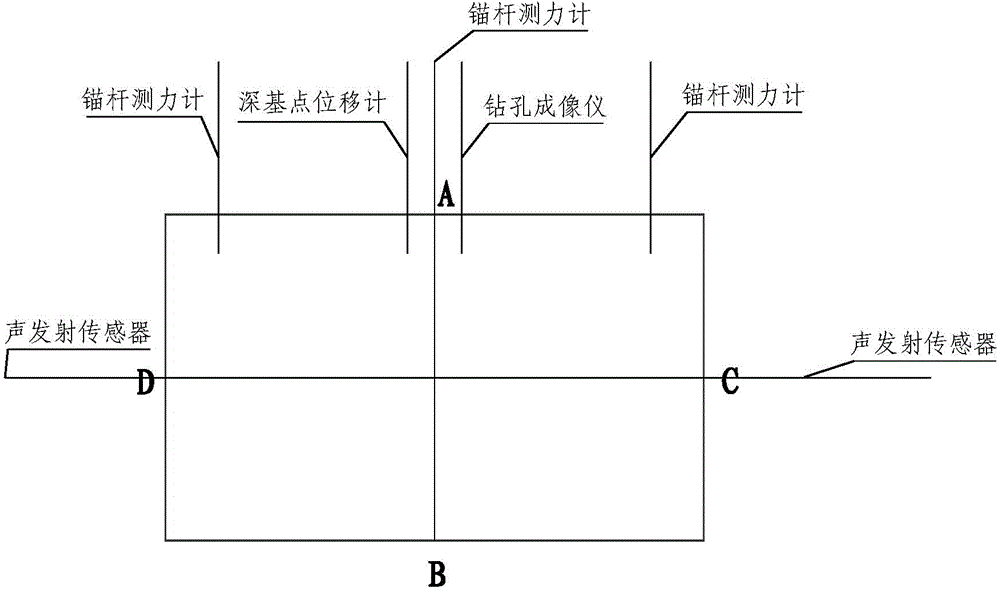

Integrated monitoring and early warning system and early warning method for dynamic condition of deep well drivage construction

The invention discloses an integrated monitoring and early warning system and early warning method for dynamic condition of deep well drivage construction. The system comprises a monitoring and controlling system platform and a system signal collection unit. The method comprises collecting geological condition data about the deep well drivage construction, arranging an acoustic emission signal sensor and a microseismic pick up seismic station on the roadway to collect internal fracture and instability precursor signals of surrounding rocks, arranging a macroscope deformation and pressure data collecting device for surrounding rocks is arranged, transmitting the internal fracture and instability precursor signals of surrounding rocks, crustal stress, impacting tendency of coal-rock mass, drilling yield, construction geological condition data, support pressure, surface convergence deformation, drilling inner stress and drilling inner damage signal to a monitoring system unit, laying out controlling scheme and construction solving method by the system when an early warning unit delivers early warning. The integrated monitoring and early warning system and early warning method for dynamic condition of deep well drivage construction is scientific in system, safe and practical, and strong in effectiveness. In-time monitoring and early warning for well construction under high stress is realized.

Owner:XIAN UNIV OF SCI & TECH

Vehicle seat with system for facilitating relieving of fatigue of person sitting on the seat

InactiveUS20050127728A1Relieve fatigueImprove fatigueBack restsOperating chairsPelvic regionElectricity

A vehicle seat includes a seat back, a seat cushion, and a system for facilitating relieving of fatigue of a person sitting on the vehicle seat for many hours. The system includes an angle sensor installed within the seat back for sensing variations in an angle of a pelvic region of the person sitting on the vehicle seat, an active device installed within the seat back for pressure-supporting the pelvic region of the person, an actuating device connected to the active device for actuating the active device and a sequential control unit electrically connected to the angle sensor and the actuating device for controlling the operation of the actuating device, the angle sensor being constructed so as to send the sequential control unit signals representing values of variations in the angle of the pelvic region of the person, the sequential control unit being constructed such that, when a value represented by a signal sent to the sequential control unit from the angle sensor is more than a predetermined value, the sequential control unit sends the actuating device a command to actuate the actuating device, whereby the active device is actuated, to thereby control supporting pressure that is applied to the pelvic region of the person.

Owner:TS TECH CO LTD

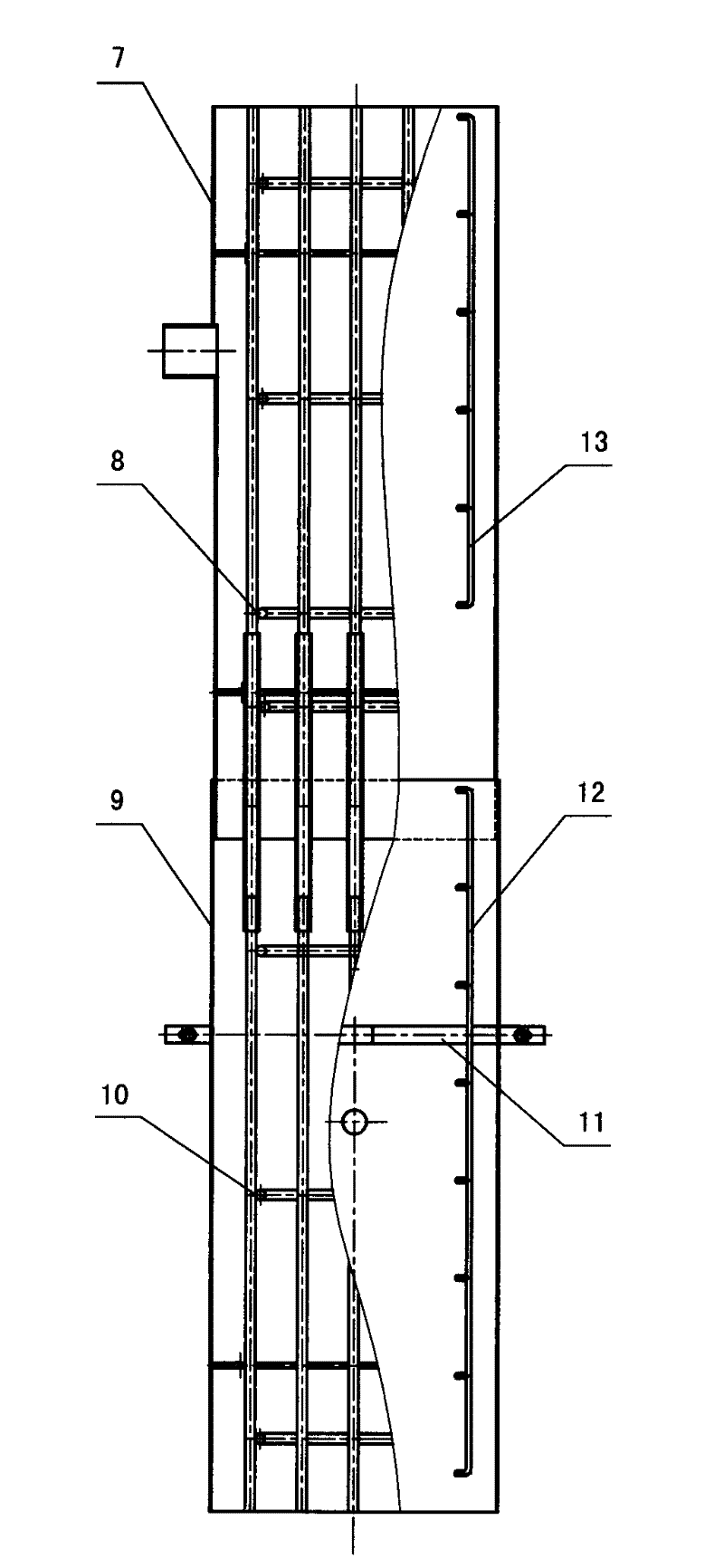

Method for retaining gob-side tunnel

InactiveCN102337904AAchieve miningTake advantage ofMining devicesUnderground chambersEngineeringStructural engineering

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

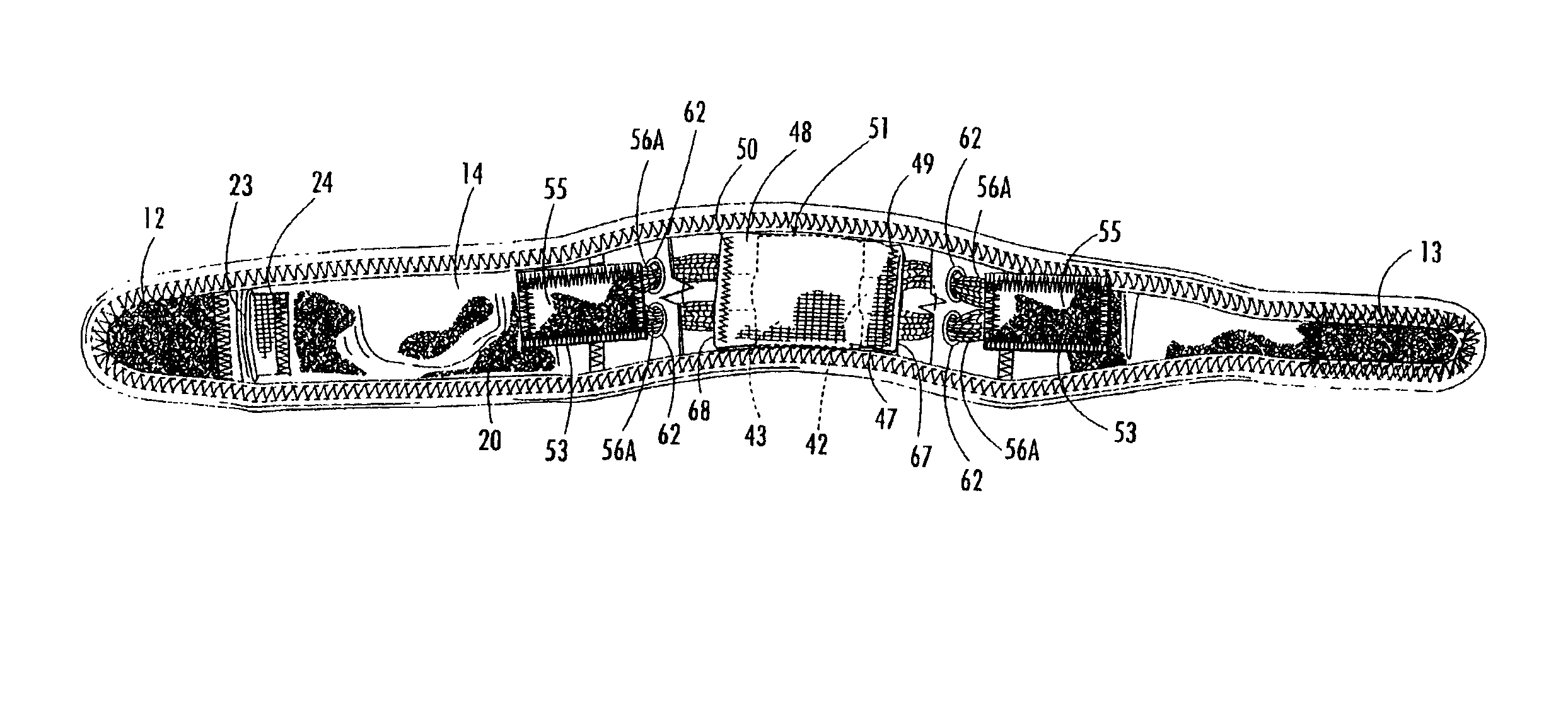

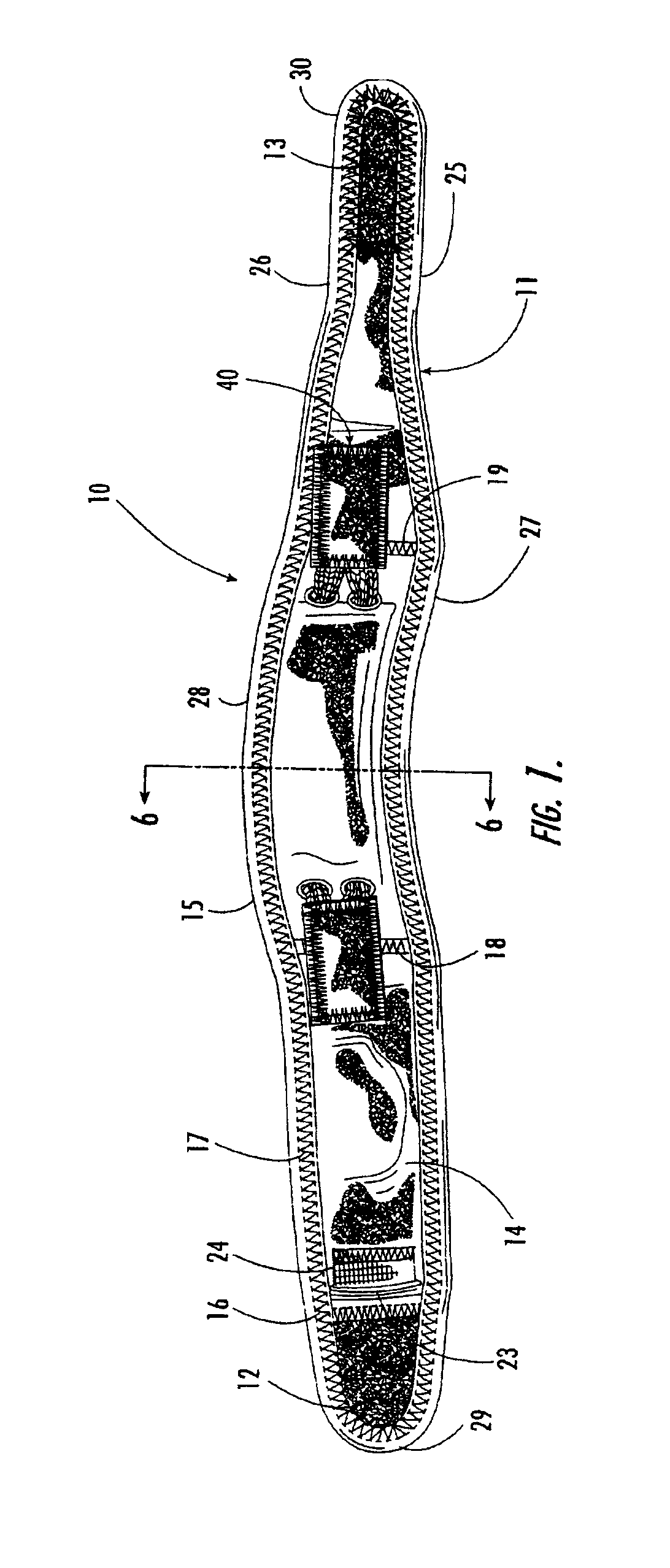

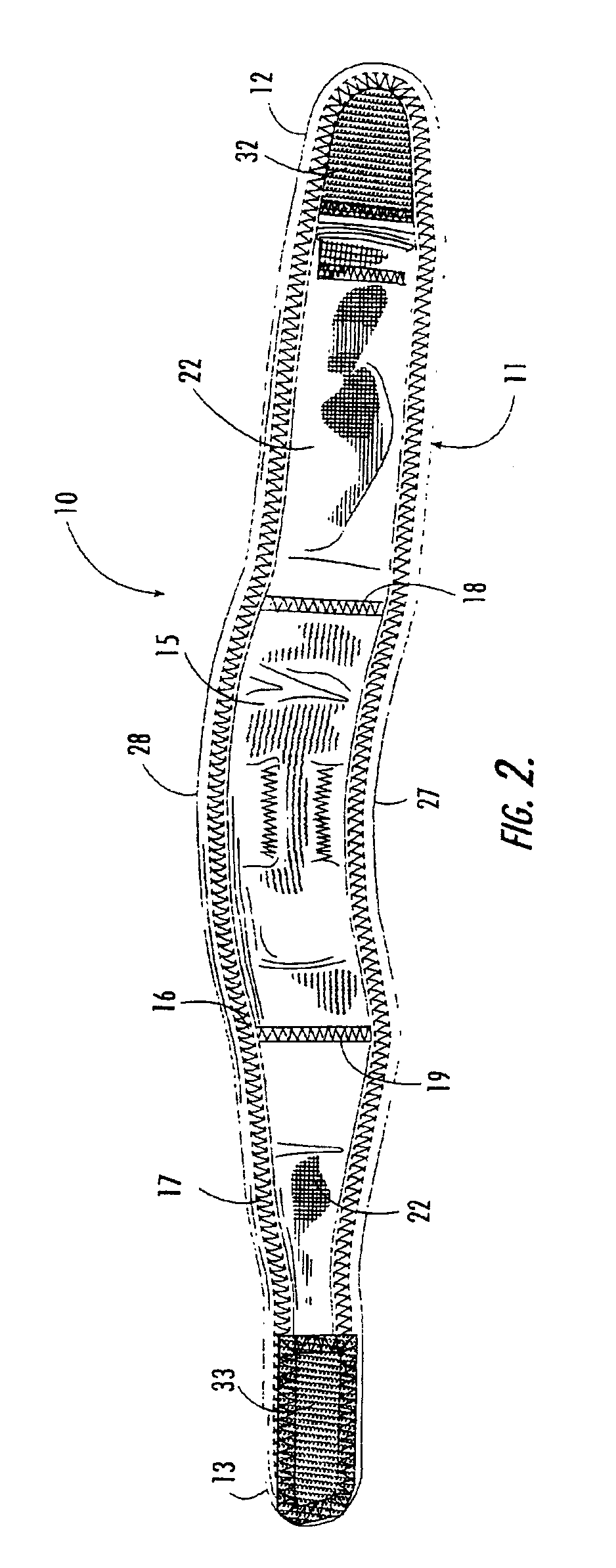

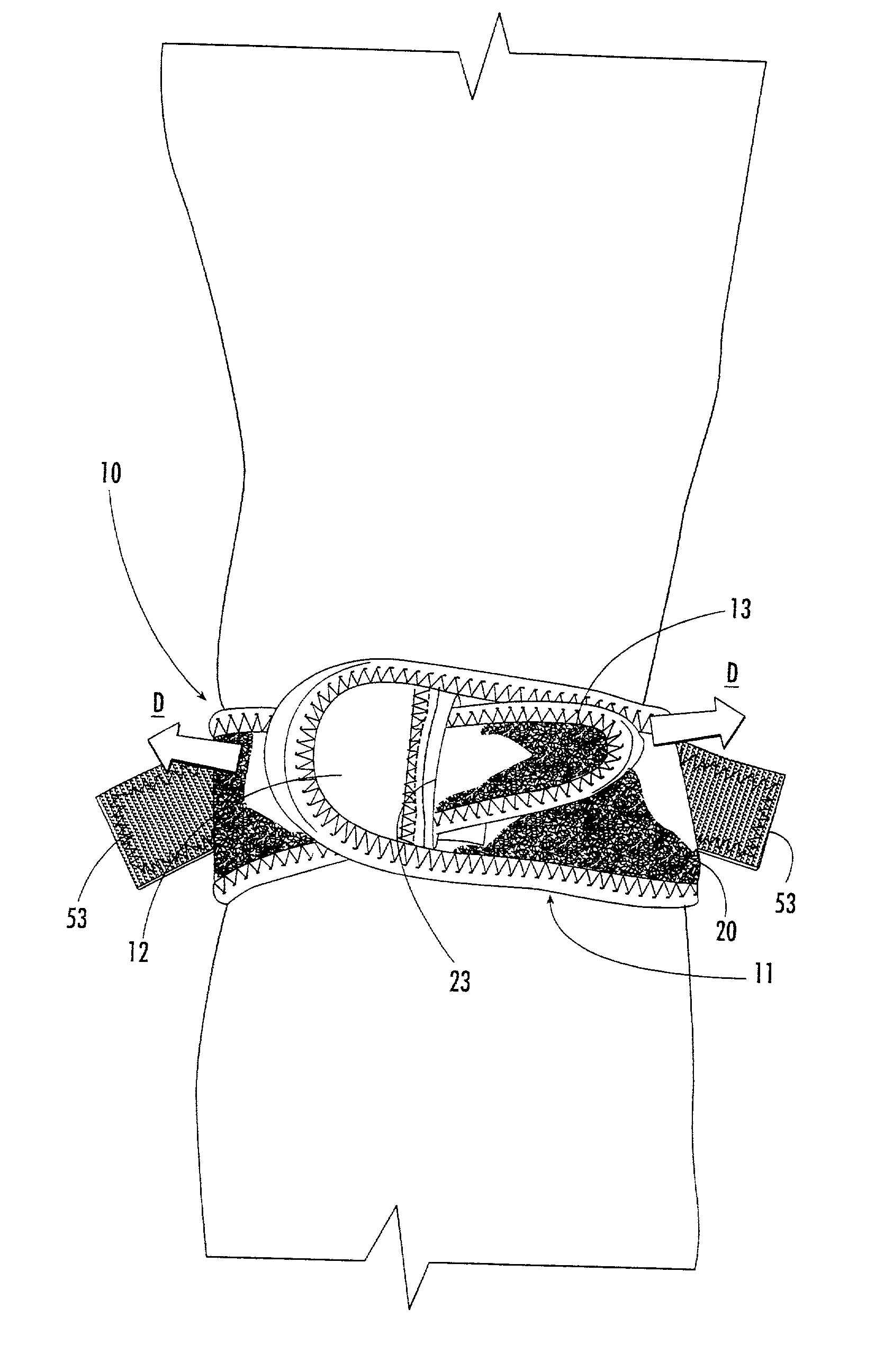

Knee support device for applying radial pressure

InactiveUS6852088B2Relieve symptomsAvoid lostFeet bandagesNon-surgical orthopedic devicesKnee supportKnee Joint

Owner:MEDICAL SPECIALTIES

Adjustable support device for the knee

InactiveUS20030187375A1Avoid lostReduce tensionFeet bandagesNon-surgical orthopedic devicesKnee supportEngineering

An adjustable support device for the knee, including a strap having at least one elastic portion and first and second ends. A primary tensioning device is positioned on the strap for securing the strap around the knee and positioning the strap in a primary tensioned position relative to the patella, knee joint, and attachment sites of the connective tissues of the knee joint. A secondary tensioning device is also carried by the strap and includes an elastic element and at least one attachment member for being placed in a secondary tensioned position relative to the strap for increasing the tension of the strap and applying concentrated radially-directed support pressure to, the knee joint, attachment sites of the connective tissues of the knee joint, and an anterior aspect of the patella.

Owner:MEDICAL SPECIALTIES

Safety brake iwth relative delayed brake force

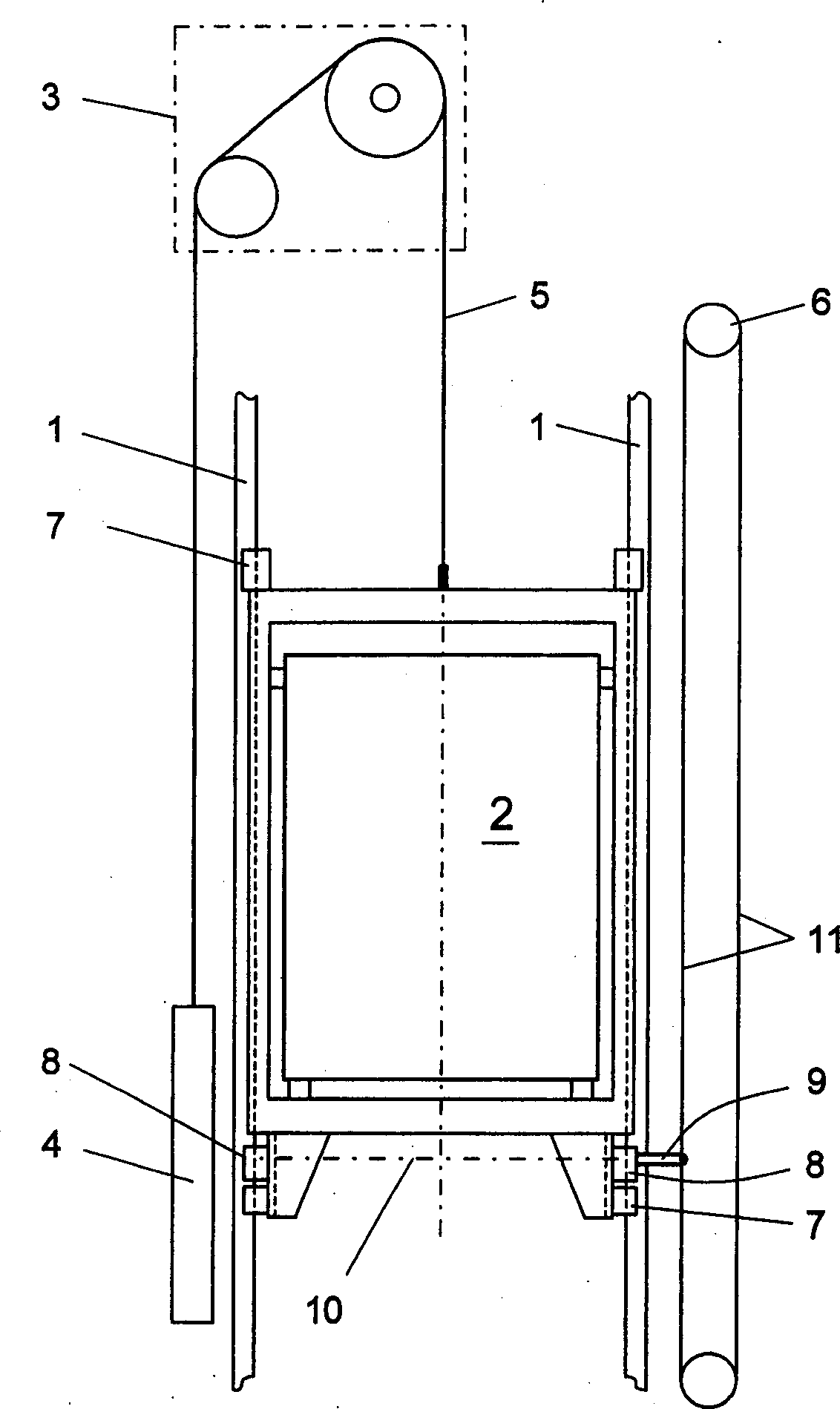

InactiveCN1357488AGuaranteed reliabilityEasy to understandSelf acting brakesElevatorsEngineeringMechanical engineering

A safety brake for a load receiving means of a lift, in which at least one brake wedge (13) penetrates into a tapering gap between a resiliently supported pressure body (14) and a guide rail (1) of the load receiving means (2) and thereby generates a braki ng force, is equipped with a device (18) which limits the stroke of the brake wedge and thus the braking force in dependence on the retardation occurring at the load receivi ng means.

Owner:INVENTIO AG

Push lumbar support with flexible pressure surface

InactiveUS6908152B2Simple in design and movementEconomical to assembleBack restsStoolsEngineeringLumbar

An ergonomic weight support device for a seat has a flexible pressure plate attached to an extending paddle for lumbar support. The paddle extends from a housing having a channel into which the paddle may be retracted for the lumbar support to be flat, or from which the paddle may be extended for lumbar support. The flexible pressure plate distributes lumbar supporting pressure across a greater area for comfort.

Owner:L & P PROPERTY MANAGEMENT CO

Inclined mattress pad

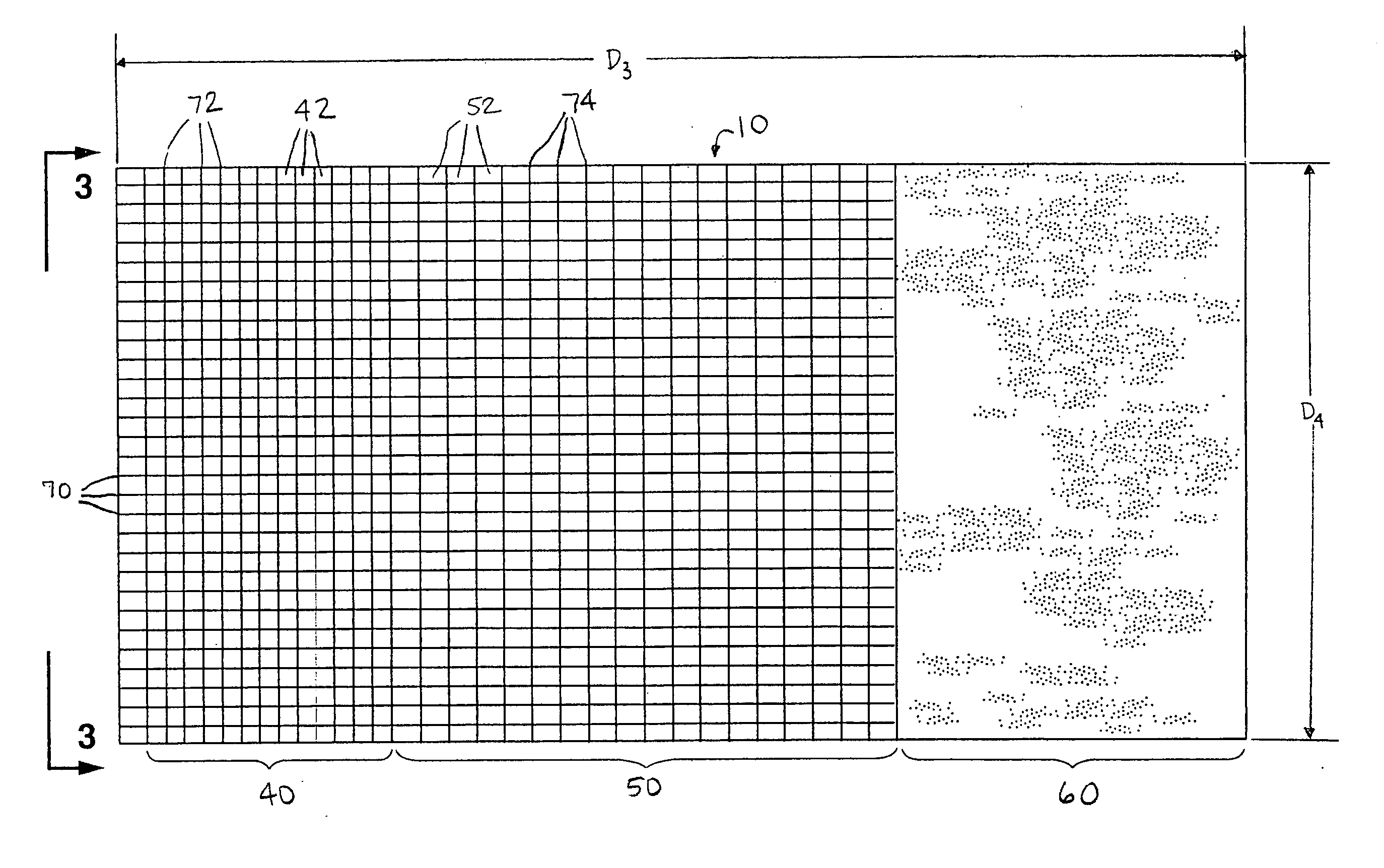

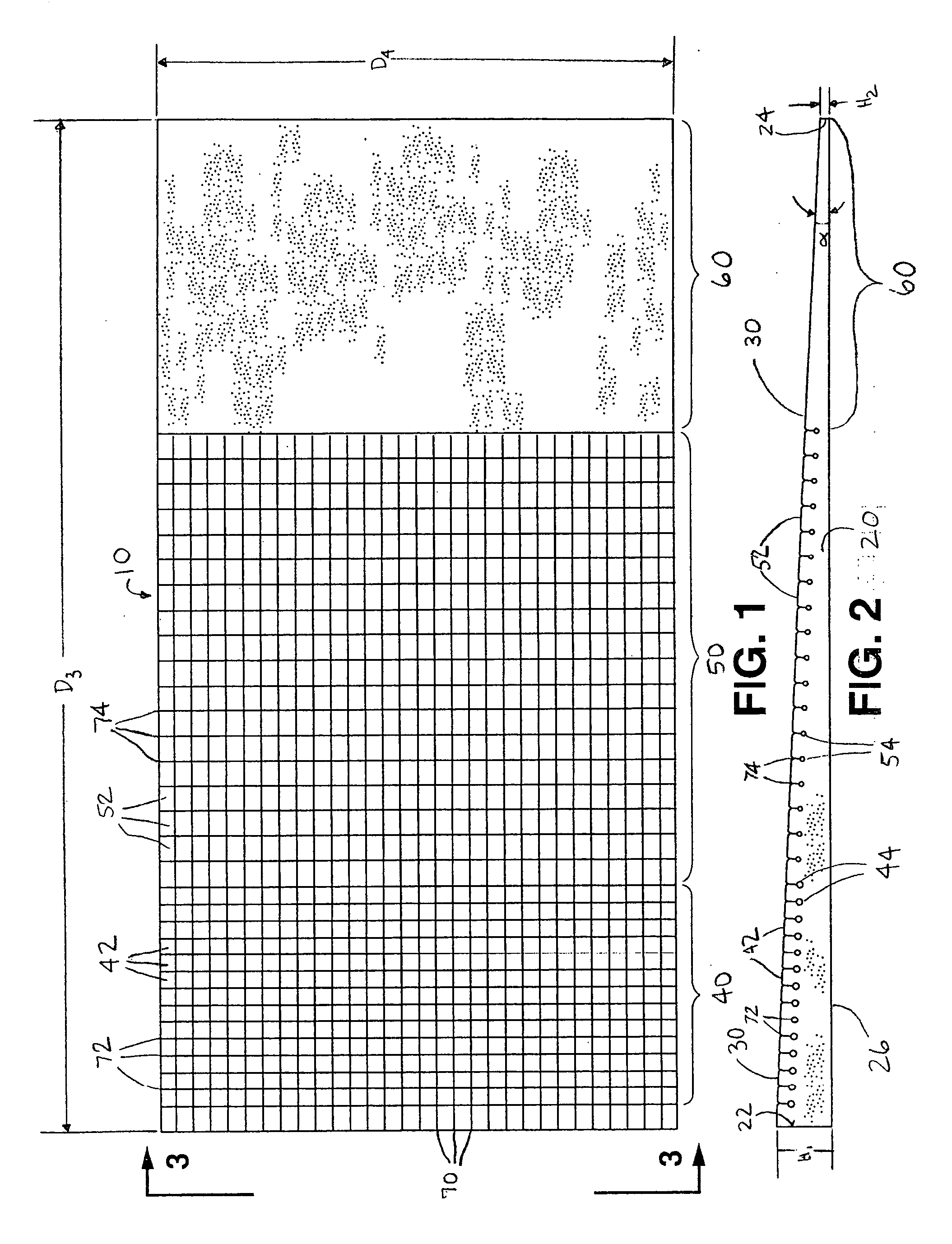

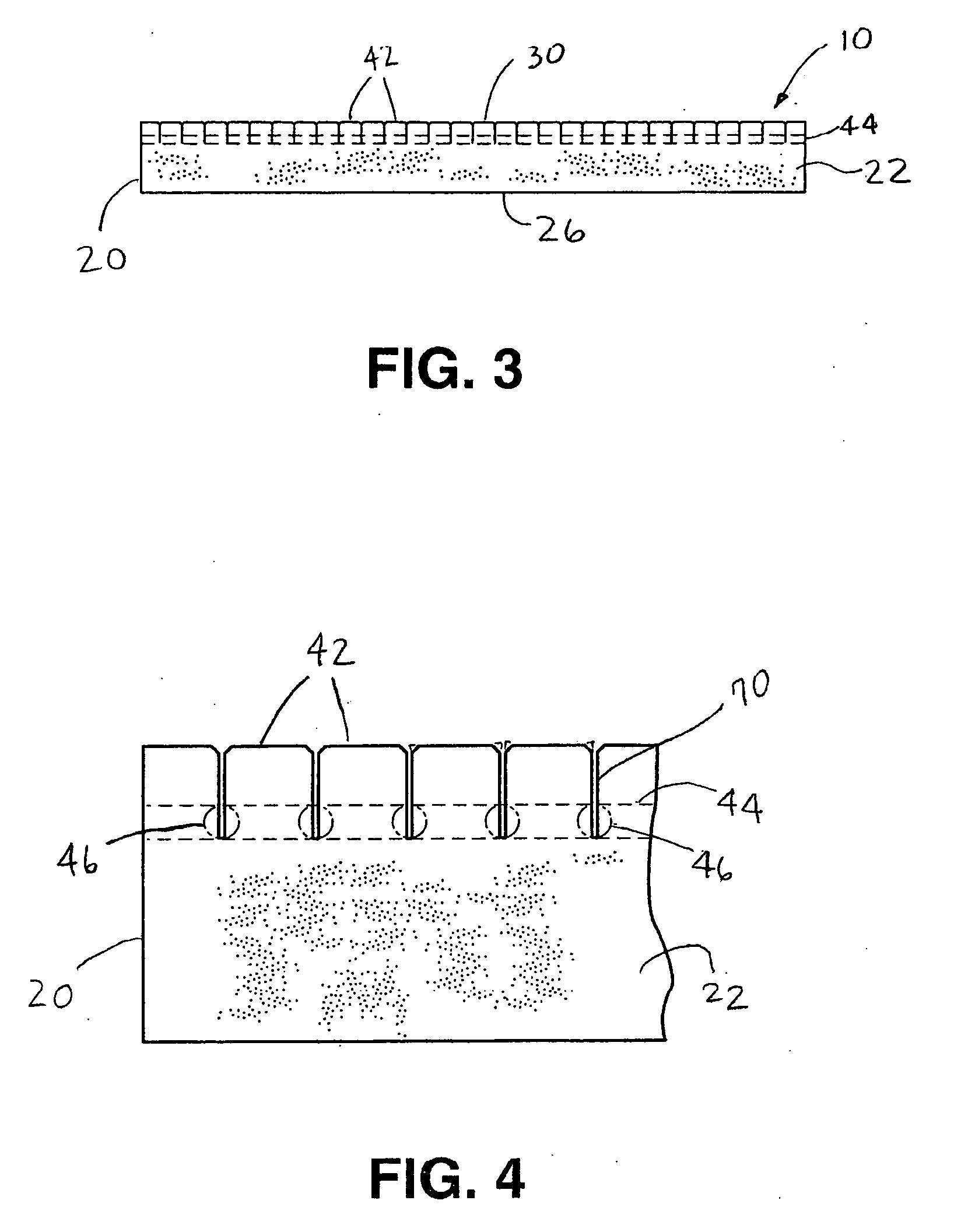

InactiveUS20060179580A1Precise positioningReduce morbidityStuffed mattressesSpring mattressesEngineeringLoad deflection

A full length mattress pad is provides improved patient support for all parts of the user's body through provision of a support surface supplement for use with existing support surfaces, such as for use on top of a conventional mattress or hospital bed. The pad has a body of resilient material having a relatively flat, planar lower surface for being received on top of the existing support surface, and has a length at least generally the same as that of the mattress, or at least long enough to support the full length of a user. An inclined upper surface is defined by the body of resilient material, and has a plurality of different longitudinal sections. The plurality of different longitudinal sections collectively define a predetermined angle of inclination for the inclined upper surface which is relatively constant along the entire length of the body of resilient material relative to its planar lower surface. At least one of the plurality of different longitudinal sections has a relatively flat surface inclined at the predetermined angle of inclination, while at least one other of the plurality of different longitudinal sections has a surface formed with respective or different projections therein, so that improved patient support is provided through a combination of the inclined upper surface and the plurality of different longitudinal sections. Preferably, the predetermined angle of inclination is no more than about 10°. Characteristics of the plurality of longitudinal sections are selected based upon one or more of the type of resilient material used, the thickness of such material, the change in thickness of such material due to the predetermined angle of inclination, the material density, and the indention load deflection characteristics of such material, with such selection and combination of characteristics determined so as to optimize the inclined pad for support for the user's body which is engineered on the basis of the intended end use of said mattress pad. The longitudinal sections are also formed by one or both of longitudinal and lateral cuts within a selected portion of the inclined upper surface, also preselected to address the relieving of support pressure points to decrease the chance of decubitus ulcers in users of the mattress pad. At least one of the depths, widths, and lengths of such cuts, forming cross-sectional shapes of the different or respective projections, are preselected on the basis of the intended end use of said mattress pad. A plurality of channels may be formed between adjacent of the respective projections, for dissipating heat and moisture from a user who is supported on the inclined upper surface, to increase the health and comfort of such user.

Owner:SPAN-AMERICA MEDICAL SYSTEMS

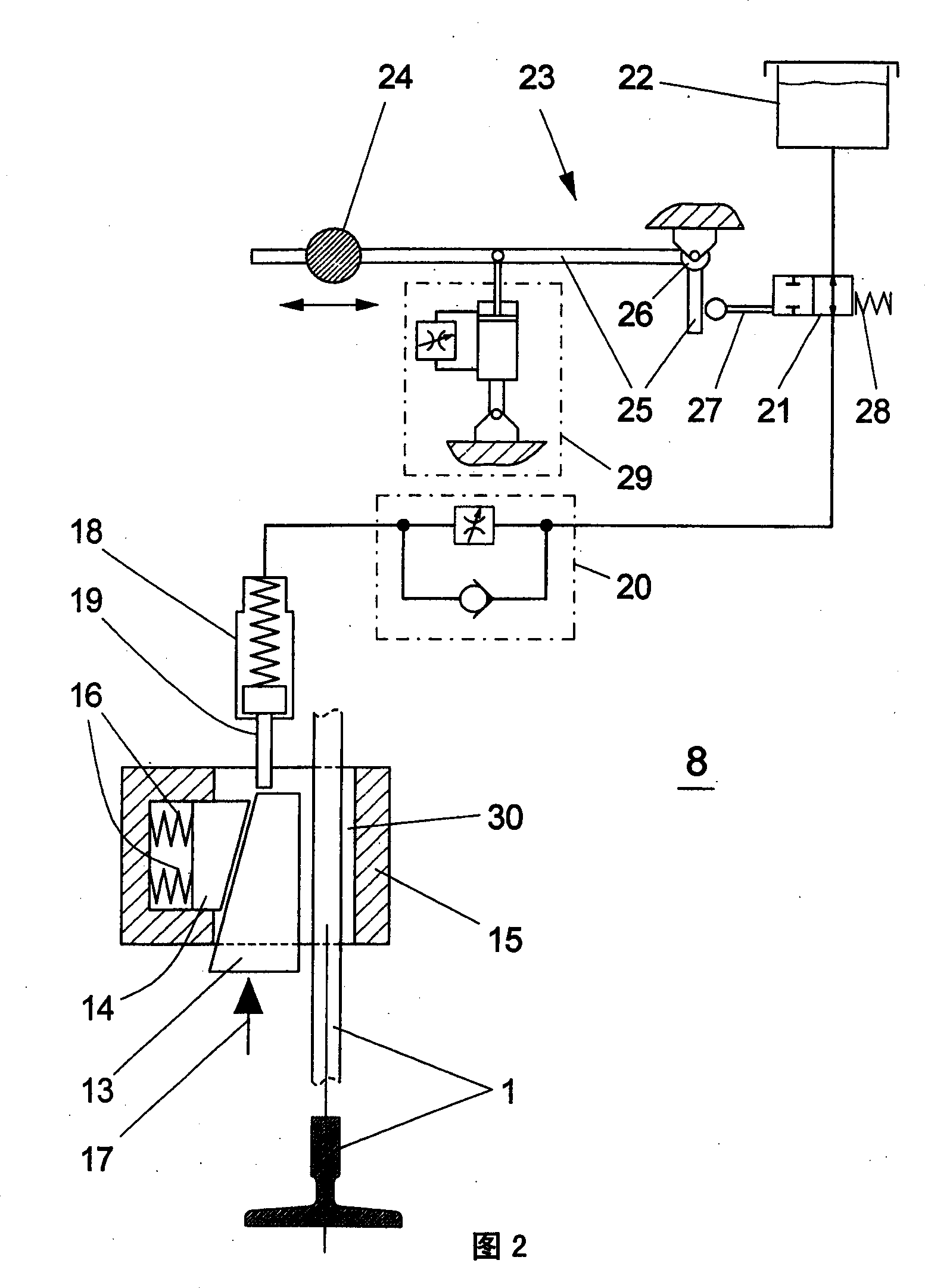

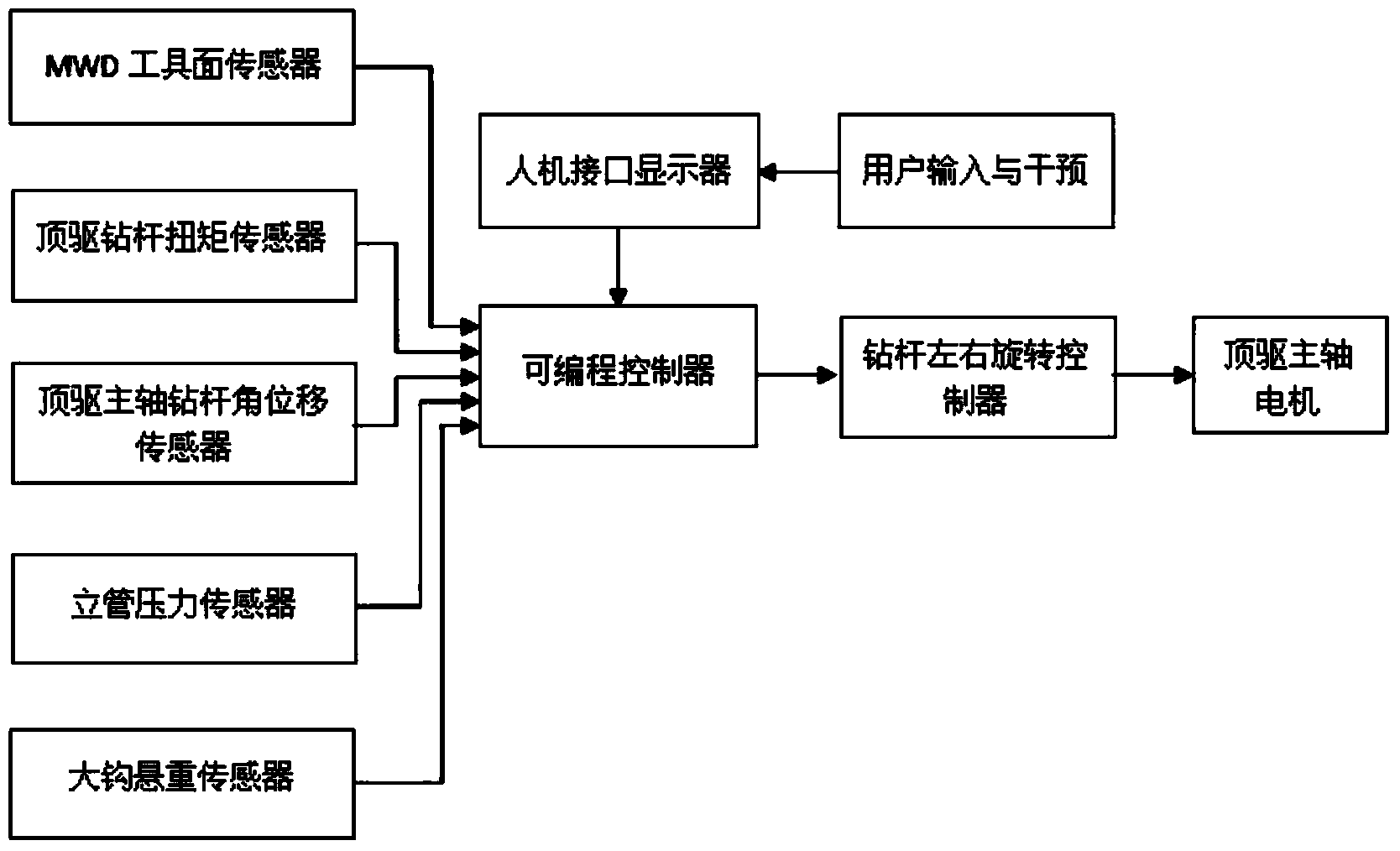

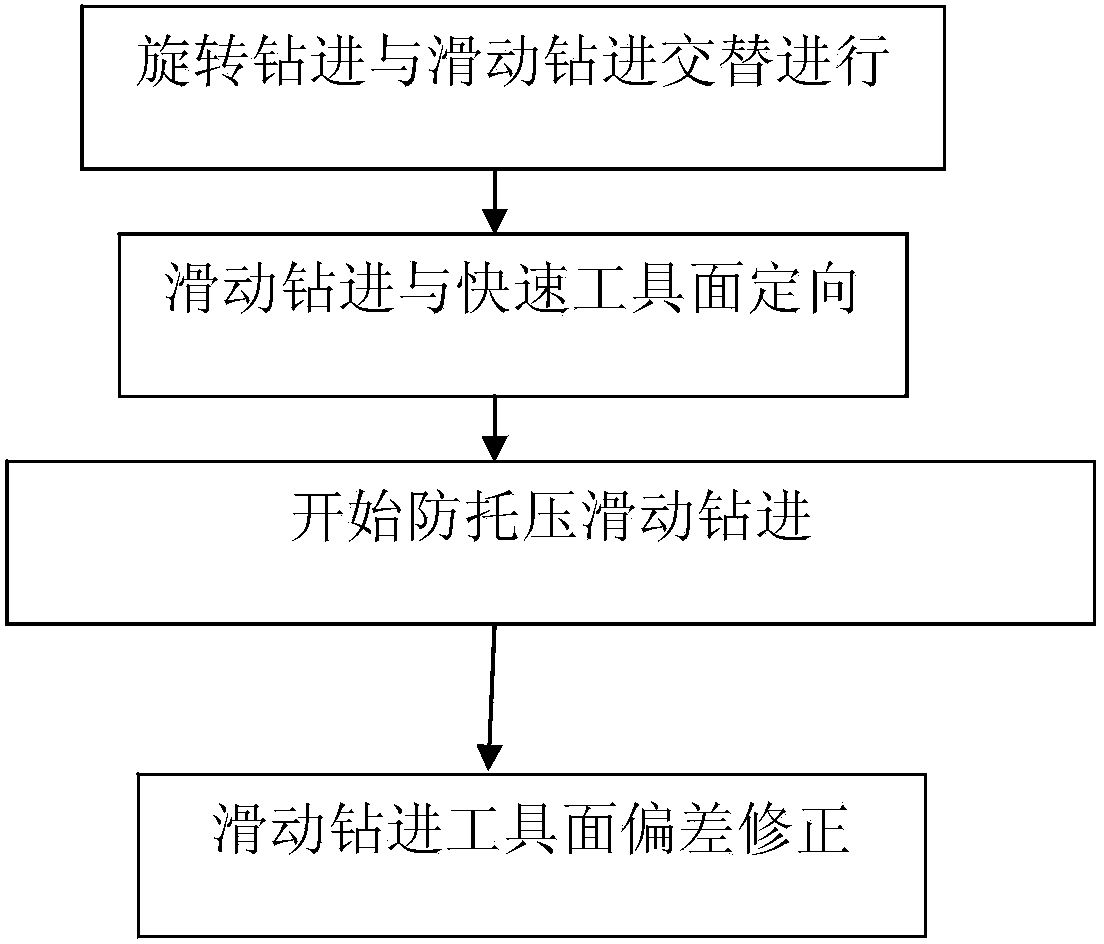

Directional sliding drilling monitoring while drilling control device and control method of directional sliding drilling monitoring while drilling control device

InactiveCN104141482ASolve orientation problemsFix fixesDirectional drillingAutomatic control for drillingTop driveWell drilling

The invention discloses a directional sliding drilling monitoring while drilling control device and a control method of the directional sliding drilling monitoring while drilling control device. The directional sliding drilling monitoring while drilling control device comprises data collecting sensors, a programmable controller, a drill rod left and right rotation controller and a monitor, wherein the the sensors include a drill rod torque sensor, a drill rod rotating angle deflection sensor, a vertical pipe pressure sensor, a large hook hanging load sensor and a motor tool surface angle sensor, the programmable controller carries out calculation and analysis on data collected by the sensors, combines a direction drilling experience model with a logic reasoning method for obtaining control parameters and controls a top drive main shaft to rotate and act. The control method comprises the steps of rotating drilling, sliding drilling, tool surface orienting, supporting pressing sliding prevention drilling and sliding drilling tool surface deviation correcting. The control device and the control method provided by the invention have the beneficial effects that the fast and accurate tool surface orienting, correcting and controlling in the directional sliding drilling process are realized; the incapability of drilling pressure or drilling supporting pressure exertion onto a directional sliding drilling drill bit due to well hole friction resistance increase is reduced; the drilling speed and the well drilling efficiency of sliding drilling machinery are respectively and obviously accelerated and improved.

Owner:CNPC BOHAI DRILLING ENG

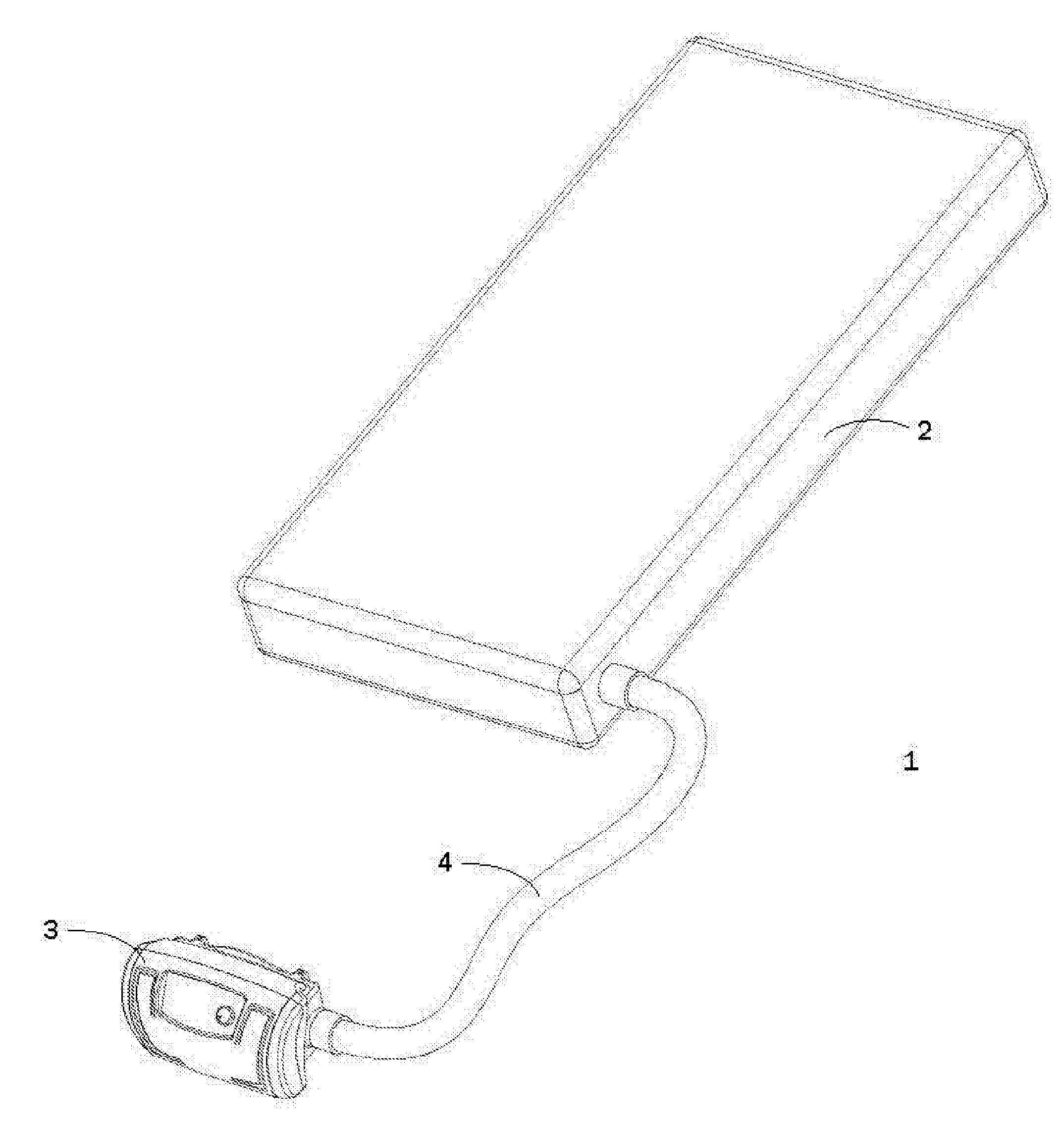

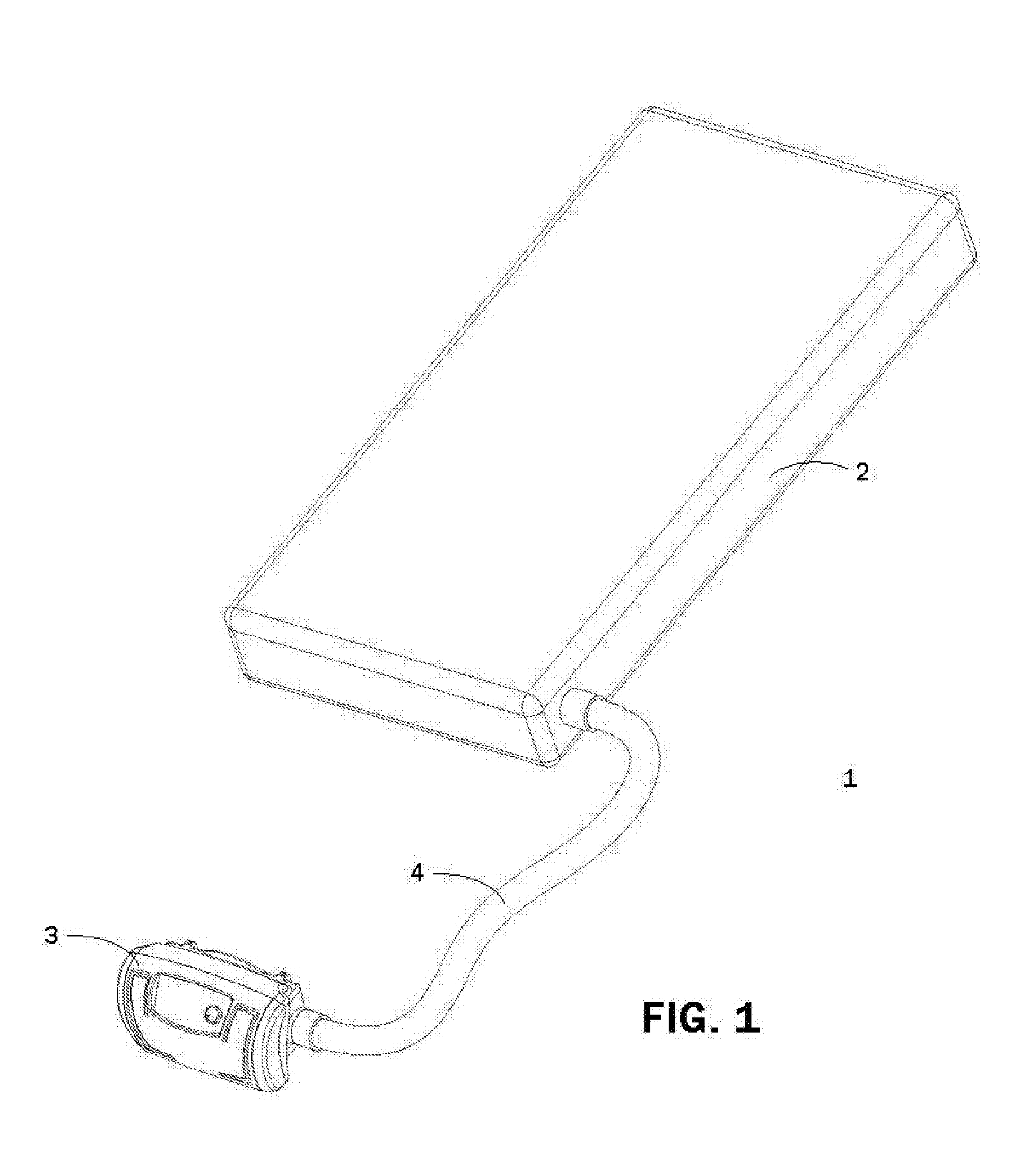

Mattress System

InactiveUS20140283308A1Simple structureEffective pressure rangeElectrotherapyStuffed mattressesTherapeutic effectEngineering

A mattress system devised to achieve a function of automatic detection, mainly including a mattress having a simple structure; a control unit equipped with a unique user interface for caregivers to simultaneously adjust three major functions, namely, therapy mode, therapy intensity and comfort level; and a connection pipe for supplying air and power. The system is further provided with a built-in auto-setting function to sense the body characteristics of the patient lying on the mattress and determine an effective supporting pressure range for the patient. By detecting a pressure difference representing the body characteristics of the patient lying on the mattress and comparing with the data stored in a built-in database, the system can always provide the patient with not only a well-proved therapeutic effect through the auto-setting function, but also an adjustable comfort level on the patient's request through the user interface.

Owner:SHL GRP AB

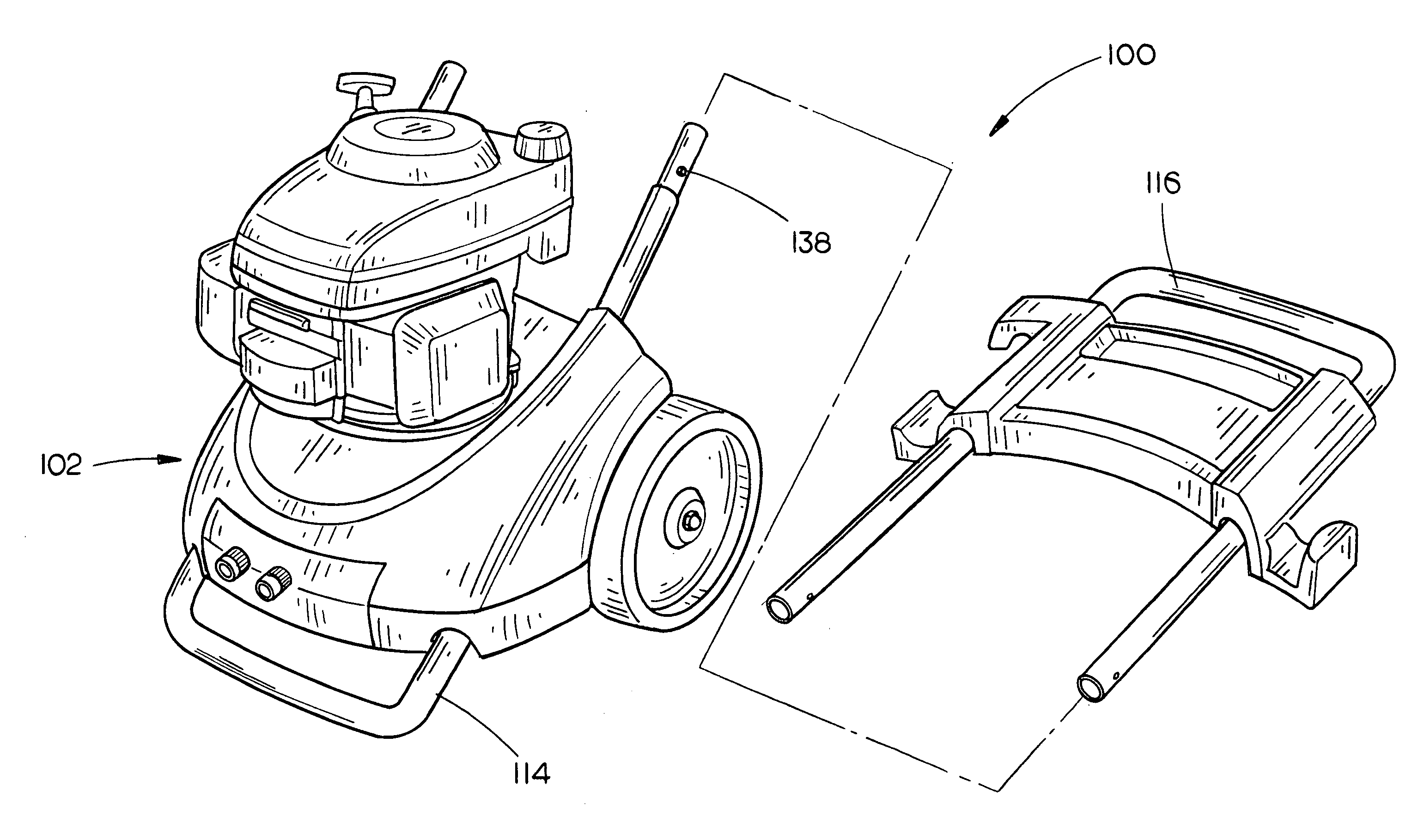

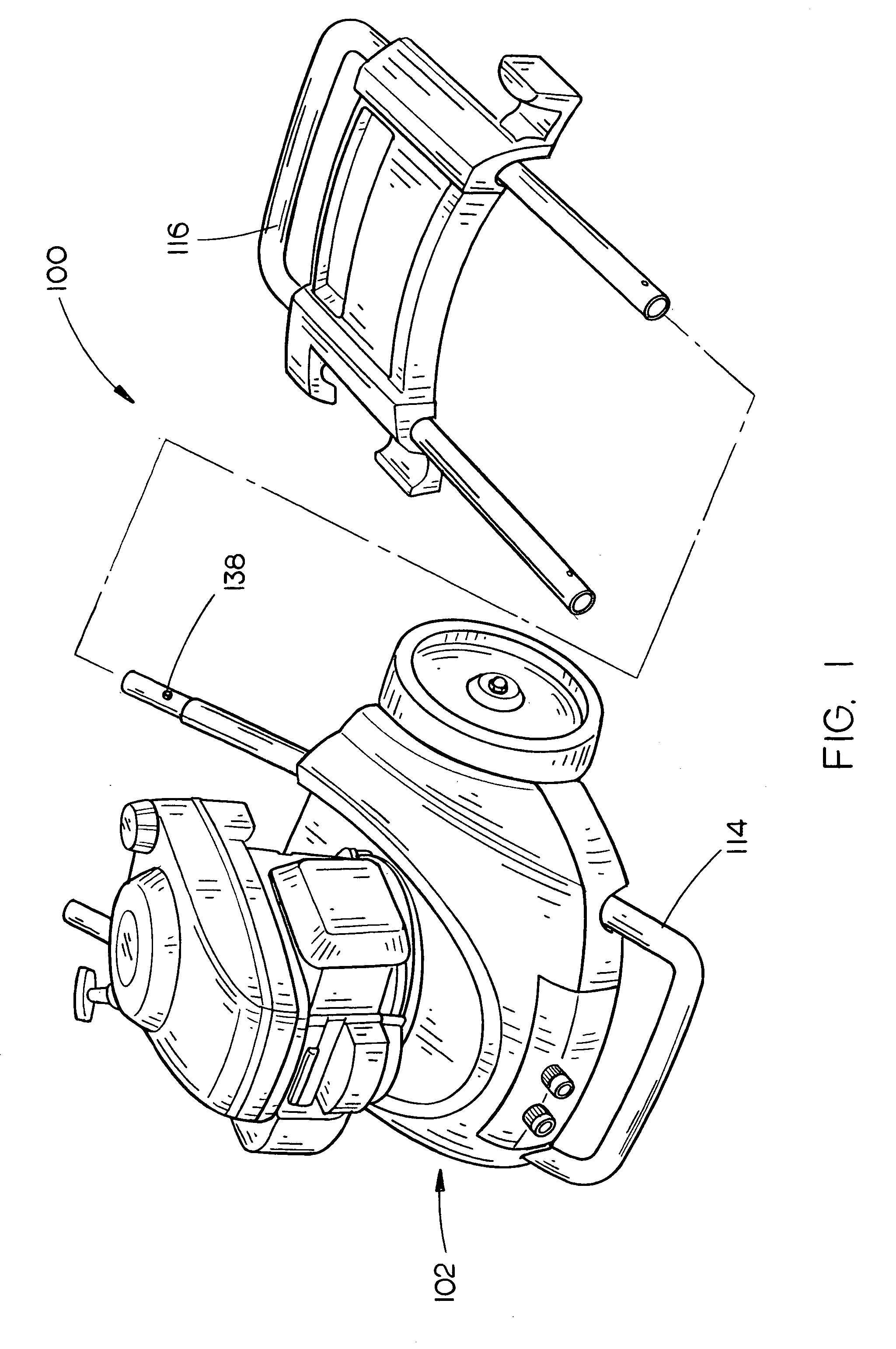

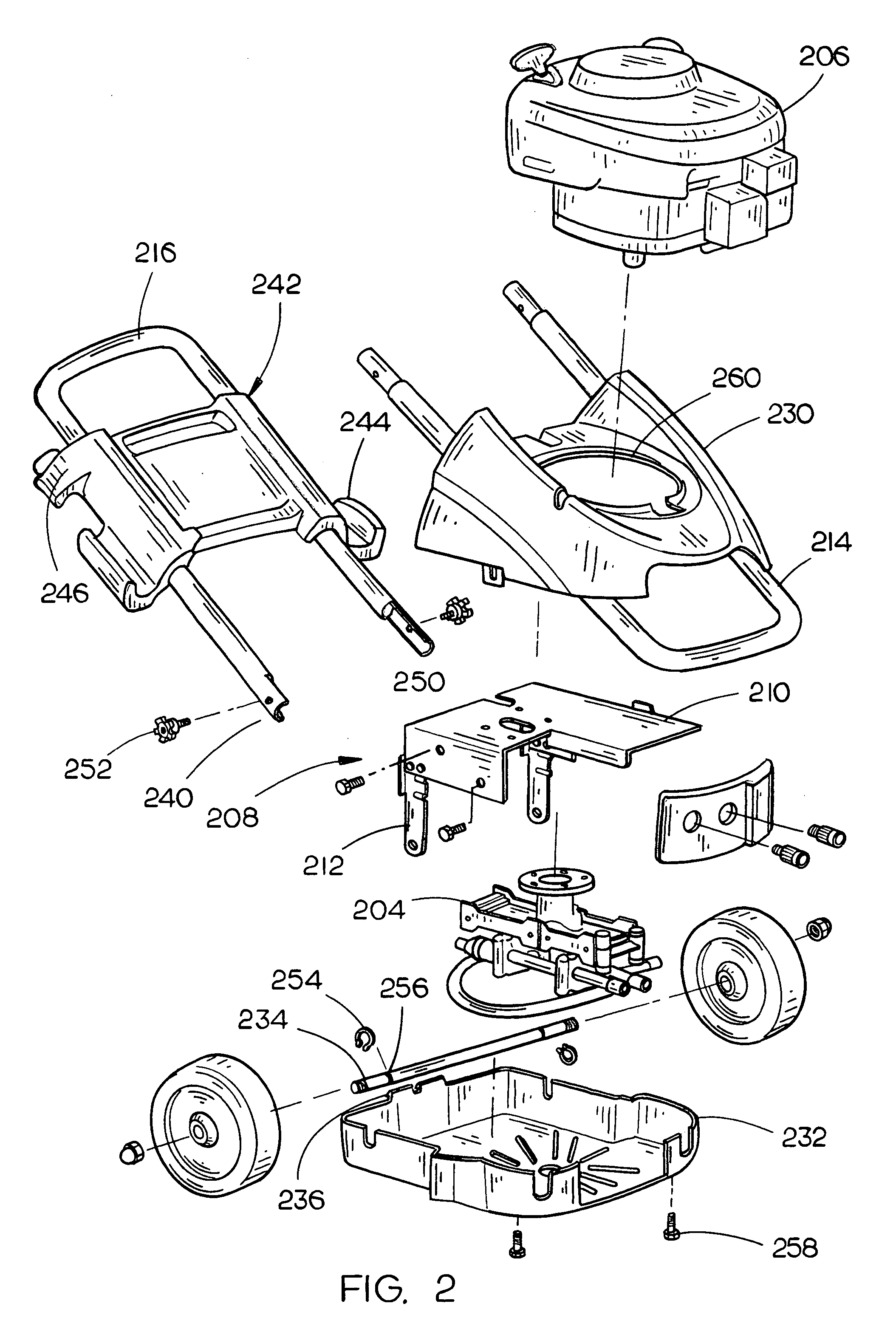

Pressure washer

InactiveUS20060102212A1Avoid damageElectrostatic cleaningCleaning using liquidsEngineeringSupport surface

The present invention is directed to a pressure washer having an internal mounting and outer clam shell housing. Accordingly, a pressure washer includes an engine for mechanically coupled to a pump. An internal mounting assembly including a folded portion is disposed generally between the engine and the pump so as to mount / support the engine and pump structure. In embodiments, various axle mounting structures such as a unitary axle bracket, a separate axle bracket, or the like is integrated with a folded main mounting into the mounting assembly. An axle assembly having at least two spaced apart wheels pivotally mounted to an axle which extends through the internal mounting axle bracket is included in the pressure washer. A generally U-shaped frame member is secured to at least one of the internal mounting / engine. The U-shaped frame member is implemented to support the pressure washer in a tripod like fashion with the wheels when disposed on a support surface. A plastic outer housing is utilized to substantially encompass the pump so as to prevent damage, minimize the need for refinement of the internal mounting assembly (for ascetics, for corrosion protection, finishing), and the like. Preferably, the outer housing implements clam shell portions with corresponding mechanical interconnects to mechanically secure the various sections. A fastener may be implemented to secure the shell portions generally adjacent a side opposite the mechanical interconnects.

Owner:BLACK & DECKER INC

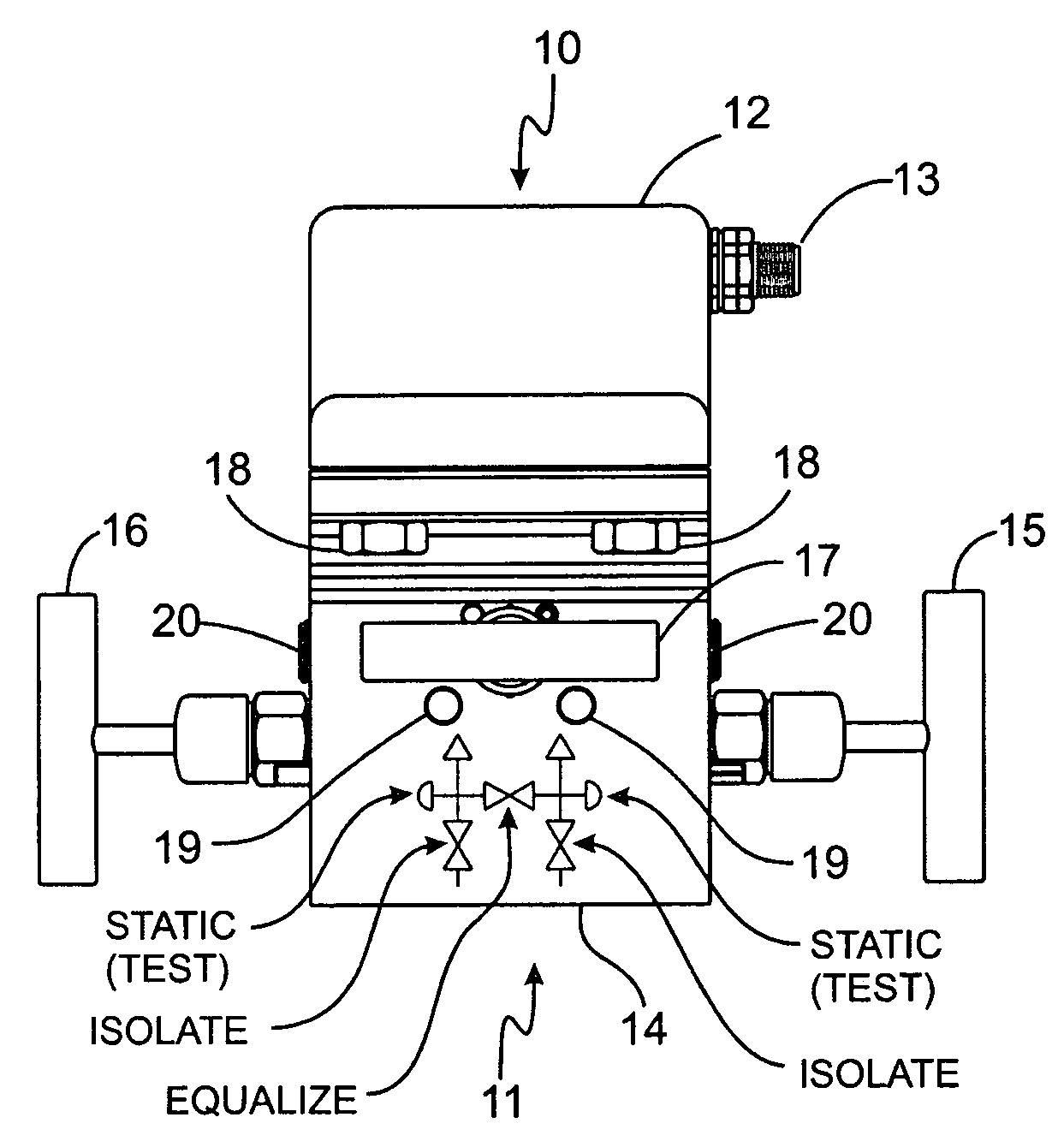

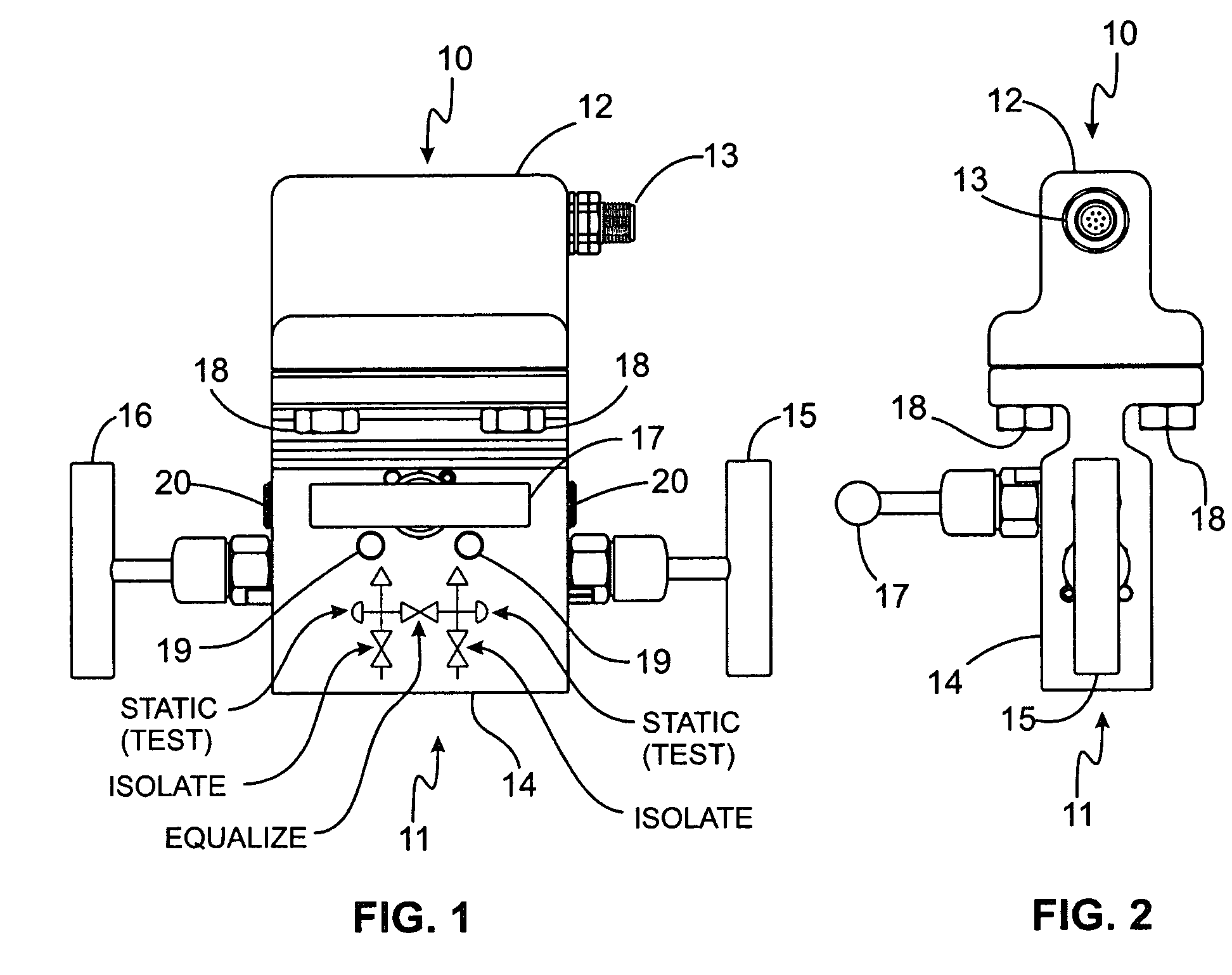

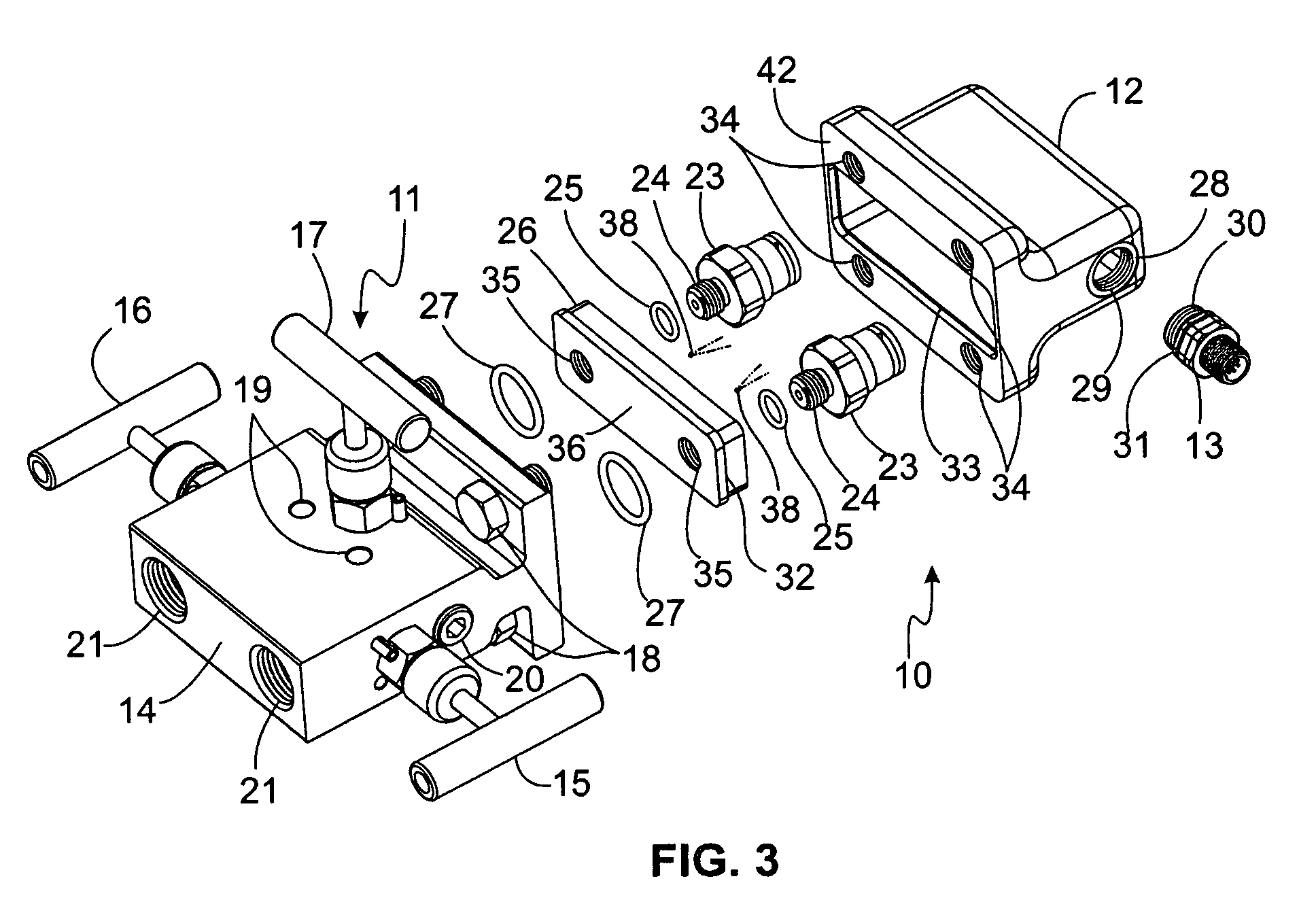

Manifold valve and pressure transducer assembly

InactiveUS7231831B1Simple designDistance minimizationValve arrangementsContainer filling methodsSignal processing circuitsIsolation valve

An assembly for measuring differential pressures includes a manifold valve and pressure transducer assembly including two pressure transducers. The manifold valve includes two pressure inlet ports and two pressure outlet ports that communicate through the manifold's isolation valves. An equalization valve connects the two pressure lines. Mating flanges on the manifold valve and pressure transducer assembly are bolted together to form a pressure tight seal between the manifold valve outlet ports and the pressure transducer assembly inlet ports. The pressure transducer assembly also includes a mounting plate for supporting the pressure transducers. The transducers generate an electrical signal corresponding to inlet pressure. Signals from pressure transducers and an optional thermistor for each are wired to an electrical connector mounted on the side of the assembly. The signals are electronically compared with an external signal processing circuit that outputs a representative signal of the differential pressure.

Owner:NOSHOK

Deformation control method when shield traverse building within short distance

The invention discloses a deformation control method when a shield traverses a building within a short distance. The deformation control method comprises the following steps of: firstly, analyzing effects of shield tunneling on a stratum and the building under the conditions of different support pressure ratios and different grouting effects by using a numerical analysis method, and putting forward an optimal support pressure ratio and demands on slurry property; secondly, reinforcing shielding excavation surface stability control, improving muck inside a pressure chamber into be at a liquid-plastic state by a muck conditioning mode, reducing fluctuation of pressure control, and controlling overexcavation by comparison of actual slag quality and theoretical slag quality; and finally, reinforcing wall grouting liquid performance control, and timely filling a shield tail gap without loss of slurry by adopting high-intensity slurry with thixotropy. In a shield tunneling process, security monitoring can be reinforced; a shield tunneling parameter can be timely adjusted, and the security of an adjacent building is ensured. According to the method, a large amount of stratum reinforcing expense is reduced, and an underground space is utilized relatively effectively.

Owner:HOHAI UNIV

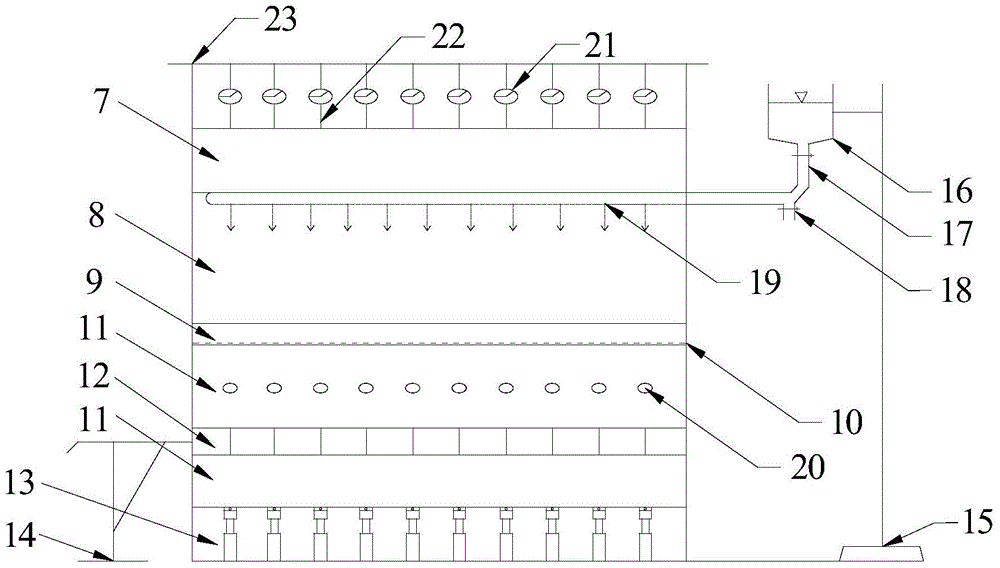

Coal seam group mining and top plate and goaf water dynamic seepage three-dimensional simulator

InactiveCN105719551AAccurately grasp the directionCcurate grasp of pressureEducational modelsMining engineeringWater source

The invention provides a three-dimensional simulation device for coal seam group mining and water dynamic seepage in the roof and goaf, including a test bench, a rock-soil layer for testing, a mobile observation device for the ground surface, and a water source supply for the aquifer of the rock-soil layer For the device, the upper coal seam and the lower coal seam of the rock and soil layer used for the test are replaced by a hydraulic pillow structure and / or a jacking jack structure, and the hydraulic pillow structure realizes the mining of the simulated coal seam through a side pulling power device arranged outside the test bench. The present invention is provided with a hydraulic pillow structure replacing the upper layer coal and mining and a lifting jack structure replacing the lowermost layer coal and mining in the test frame, which can accurately grasp the direction and tendency of the upper layer coal and the lower layer coal after mining. The law of supporting pressure distribution; The water replenishment structure provides the required amount of water for the aquifer, so that the coal mining and the continuous water supply of the aquifer can be carried out simultaneously, and the effects of effectively simulating the three-dimensional roof dynamic movement damage and fracture seepage of multi-coal seam mining in the area can be realized.

Owner:SHAANXI COAL & CHEM TECH INST

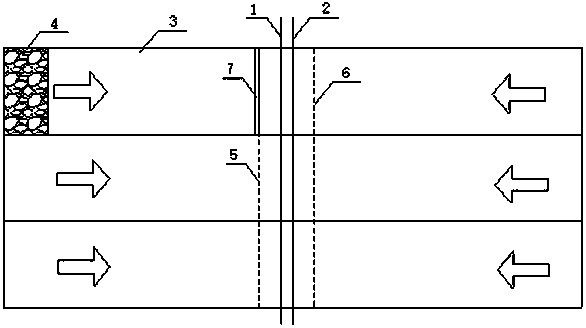

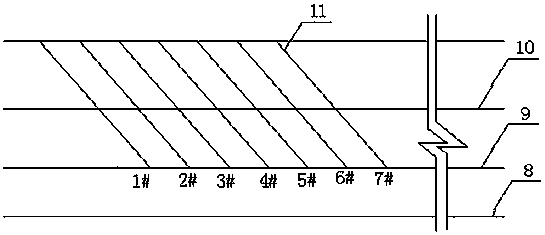

Roof-cutting and pressure relief roadway-protecting method for end-mining equipment remove gateway of coal face

ActiveCN108661643AReduce mining impactEnsure safety and stabilityUnderground miningSurface miningEngineeringPre cracking

The invention discloses a roof-cutting and pressure relief roadway-protecting method for an end-mining equipment remove gateway of a coal face, and belongs to the technical field of mining engineeringmine pressure control and roadway maintenance. The problem that the mining rate of a mining area is low due to the large size of a protection coal pillar between an existing working face stop line and a mining area main roadway is solved. According to the roof-cutting and pressure relief roadway-protecting method for the end-mining equipment remove gateway of the coal face, the working face support equipment remove gateway is excavated in advance along the stop line position and a propagation path of the working face mining advanced supporting pressure is cut off through deep hole pre-cracking of a coal seam roof. The mining area main roadway is protected from the mining action of the mining face on both sides and the width of the protection coal pillar between the working face stop lineand the mining area main roadway is reduced, so that the mining rate of the mining area is improved. The mining rate of the mining area of non-renewable coal resources is improved under the premise ofensuring the safety and stability of the mining area main roadway.

Owner:TAIYUAN UNIV OF TECH

Trinity coupling support stability control method for gob-side entry-driving coal pillar

InactiveCN103244122AMaintain stabilityStability replayUnderground miningSurface miningPre stressInstability

The invention provides a trinity coupling support stability control method for a gob-side entry-driving coal pillar, which is particularly suitable for a large-deformation gob-side roadway with an unstable overlying rock. A pre-stress threaded steel anchor rod is used on the gob-side entry-driving coal pillar on an upper zone roadway coal pillar side to tension a coal pillar goaf-side coal body; a short anchor rod on a lower zone gob-side entry-driving coal pillar side is used for controlling the integrity of a whole displacement region of a coal pillar roadway side; and meanwhile, a long grouting anchor cable is matched to reinforce an anchoring point so as to limit the development of an inner separation layer in the whole displacement region. A range of generating a crushed region of the coal pillar under the effect of lateral supporting pressure can be relieved under the expression of a haling effect of the pre-stress threaded steel anchor rod, so as to prevent an instability state of the coal pillar from worsening; and 'controlling by the short rod and grouting by the long rod' of the short anchor rod and the long grouting anchor cable are given into fully play so as to prevent a coal pillar support structure from losing effect and re-achieve the supporting capability of a remained anchoring structure in the coal pillar, so that coupling support with alternative anchor net support and anchor grouting support is formed between the gob-side entry-driving coal pillar side and a goaf side.

Owner:CHINA UNIV OF MINING & TECH +1

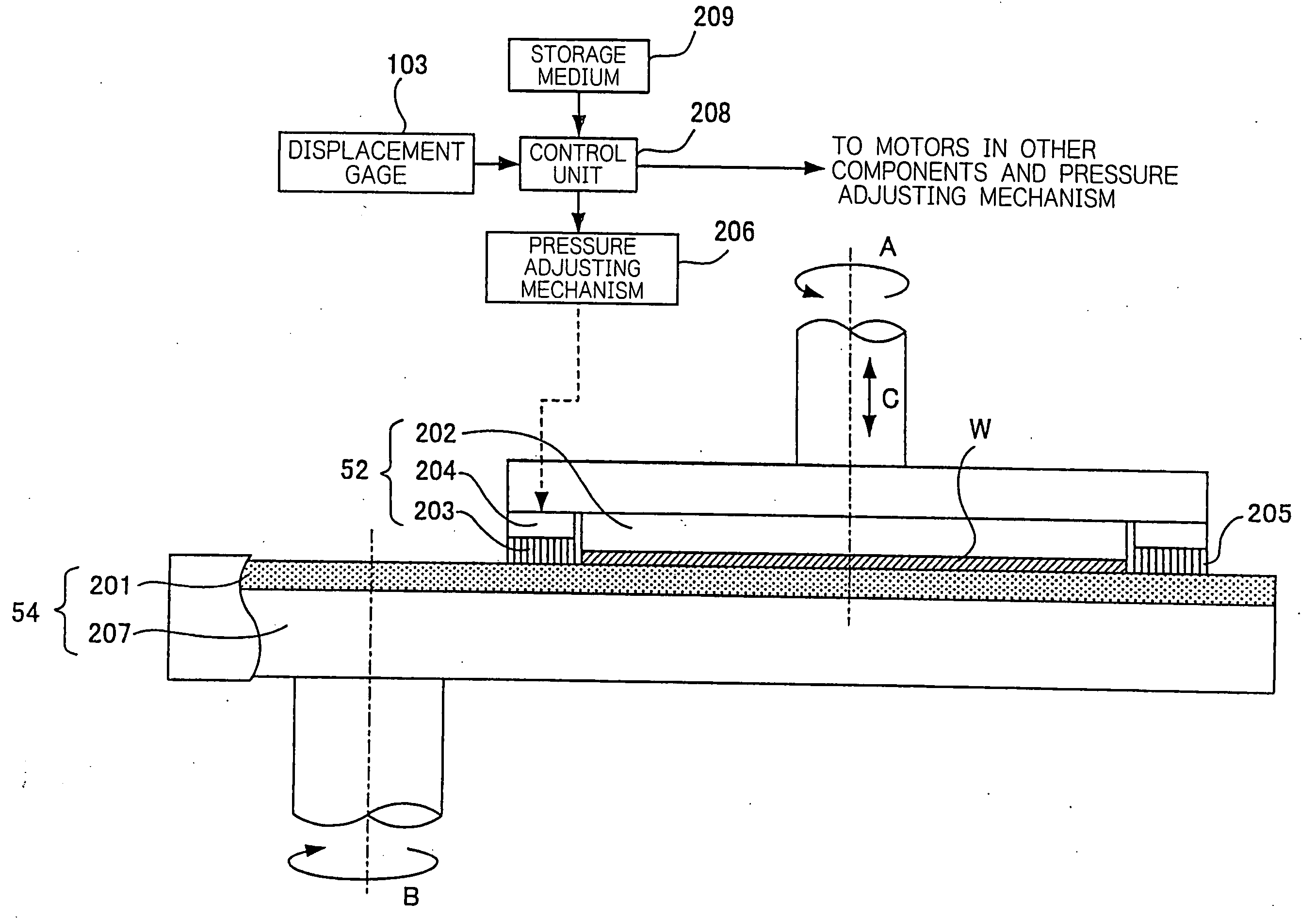

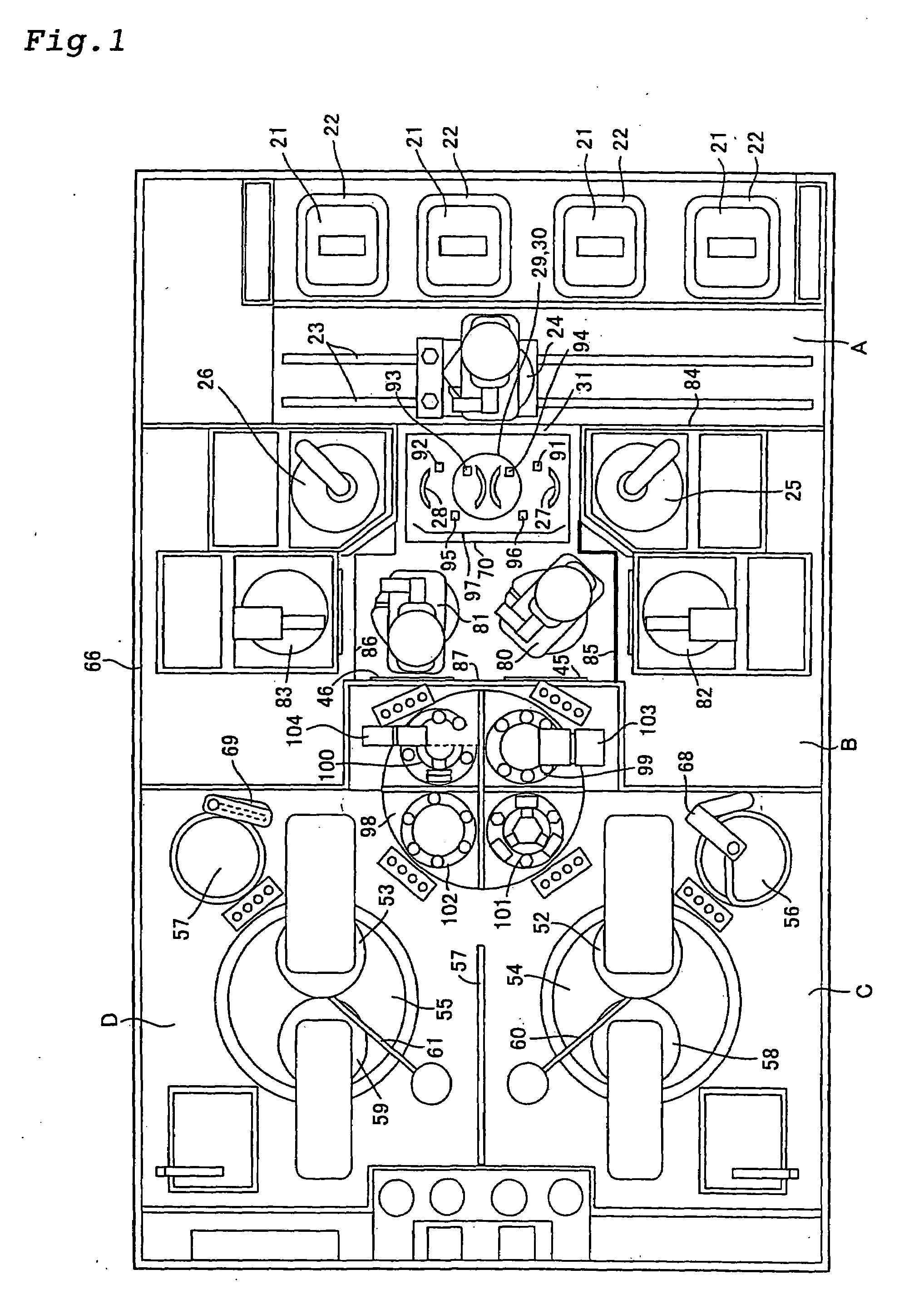

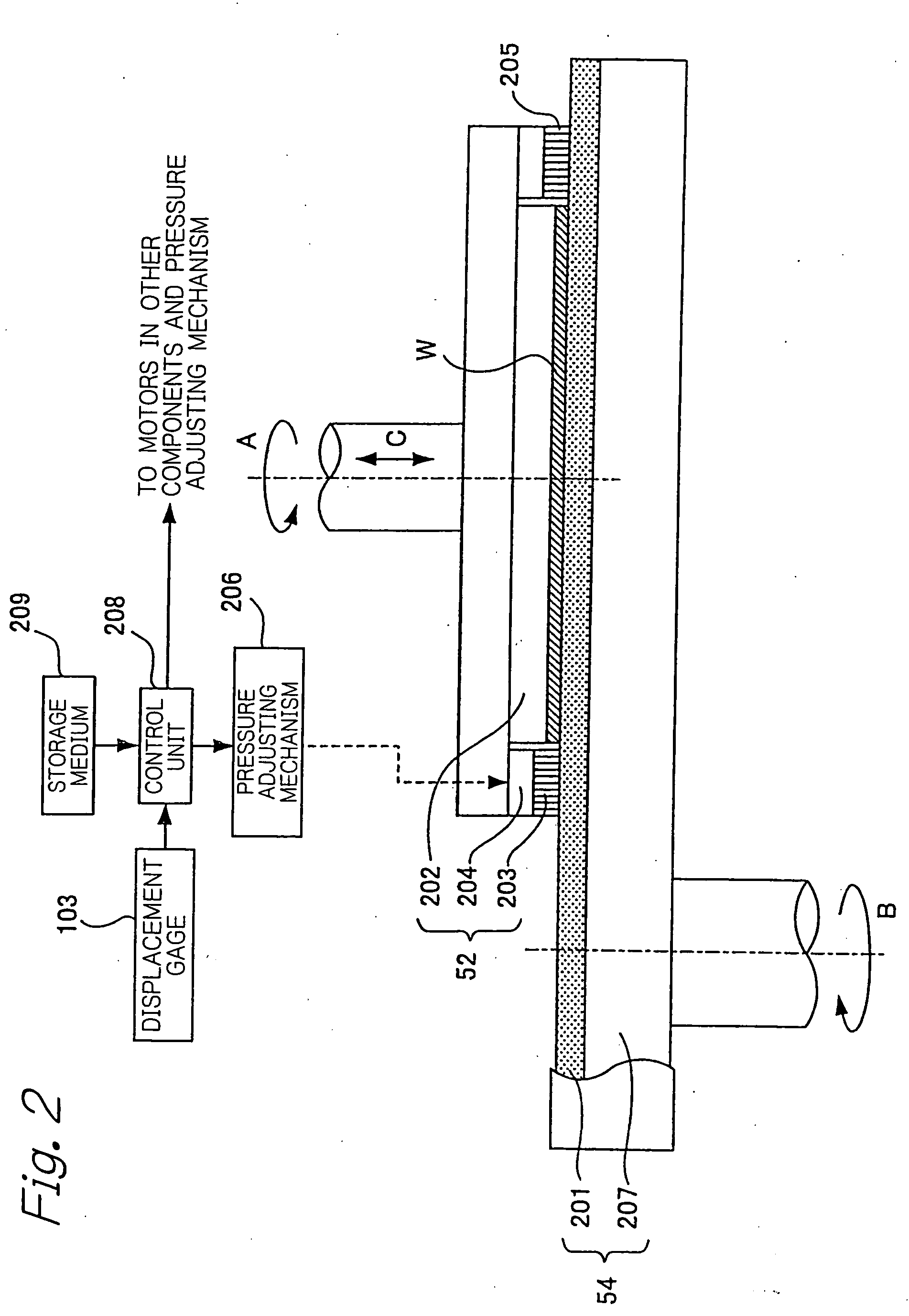

Polishing Apparatus and Polishing Method

ActiveUS20090239446A1Polishing machinesRevolution surface grinding machinesMechanical engineeringYield rate

A polishing apparatus is provided for polishing wafers at a high yield rate even if roll-off exists. The polishing apparatus polishes a wafer W by applying a pressure between a polishing member (polishing pad) 201 and the wafer W held by a holding member (top ring) 52 and relatively moving the polishing member 201 to the wafer W. The polishing apparatus comprises a top ring 52 for holding the wafer W, a pressure adjusting mechanism 206 for adjusting a supporting pressure with which the wafer W is supported on a supporting surface by a retainer ring 203, and a control unit 208 for controlling the pressure adjusting mechanism 206 to bring the supporting pressure to a desired pressure based on a roll off quantity of the wafer W. The top ring 52 comprises an air bag 202 for pressing the wafer W against the polishing pad 201, a retainer ring 203 which surrounds the wafer W, and an air bag 204 for pressing the retainer ring 203.

Owner:EBARA CORP

Seat

ActiveUS7600821B2Reduce muscle fatigueInhibitionSeat coveringsWeft knittingPosterior regionInferior angle of the scapula

A seat provides a band-like support for the body sides of a user so as to reduce the supporting pressure on the user's lumbar and to hold the user's upper body stably. In this seat, the center of a load to be received in regions symmetrically divided to a vertical central line of the seat are positioned outside of a back region defined by left and right angulus inferior scapulae and by the upper ends of iliac bones. Moreover, the load ratios in the individual regions are not more than 25% in the region corresponding to a region extended downward from the back region.

Owner:DELTA TOOLING CO LTD

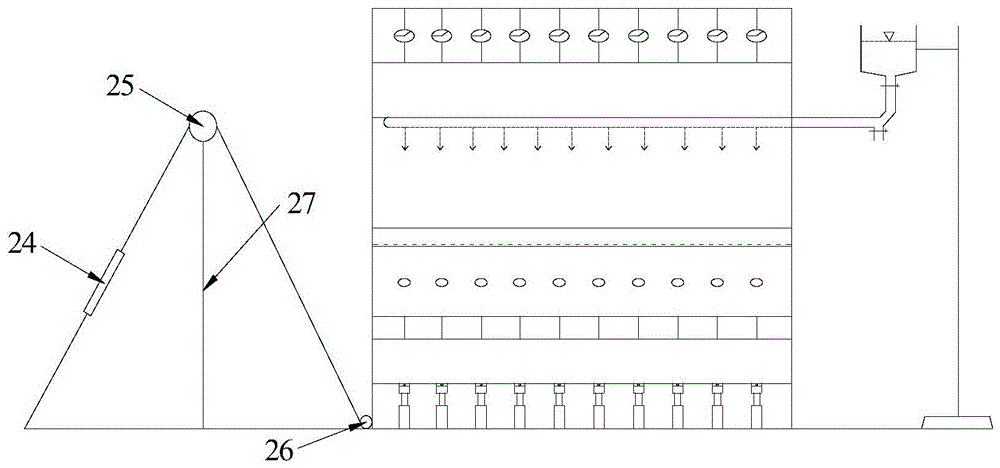

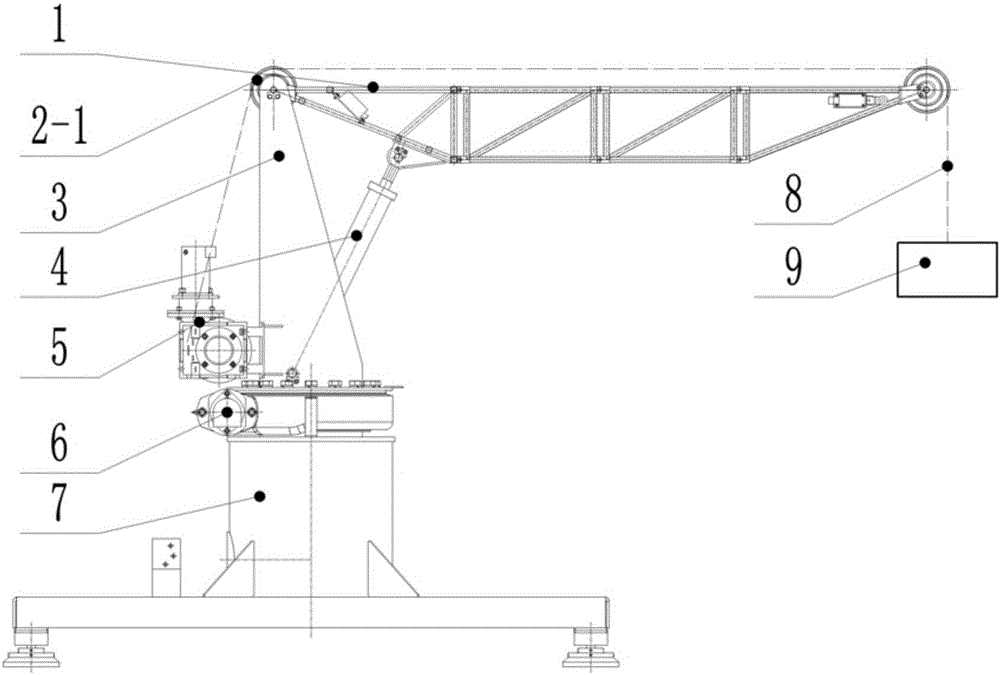

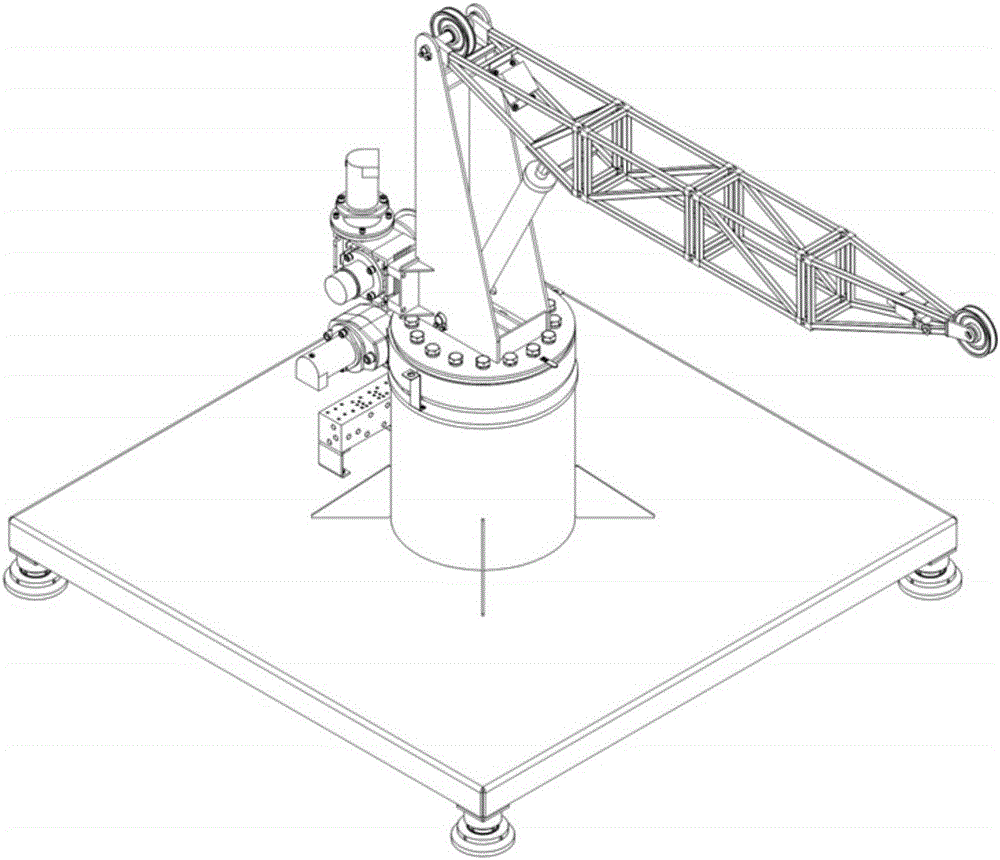

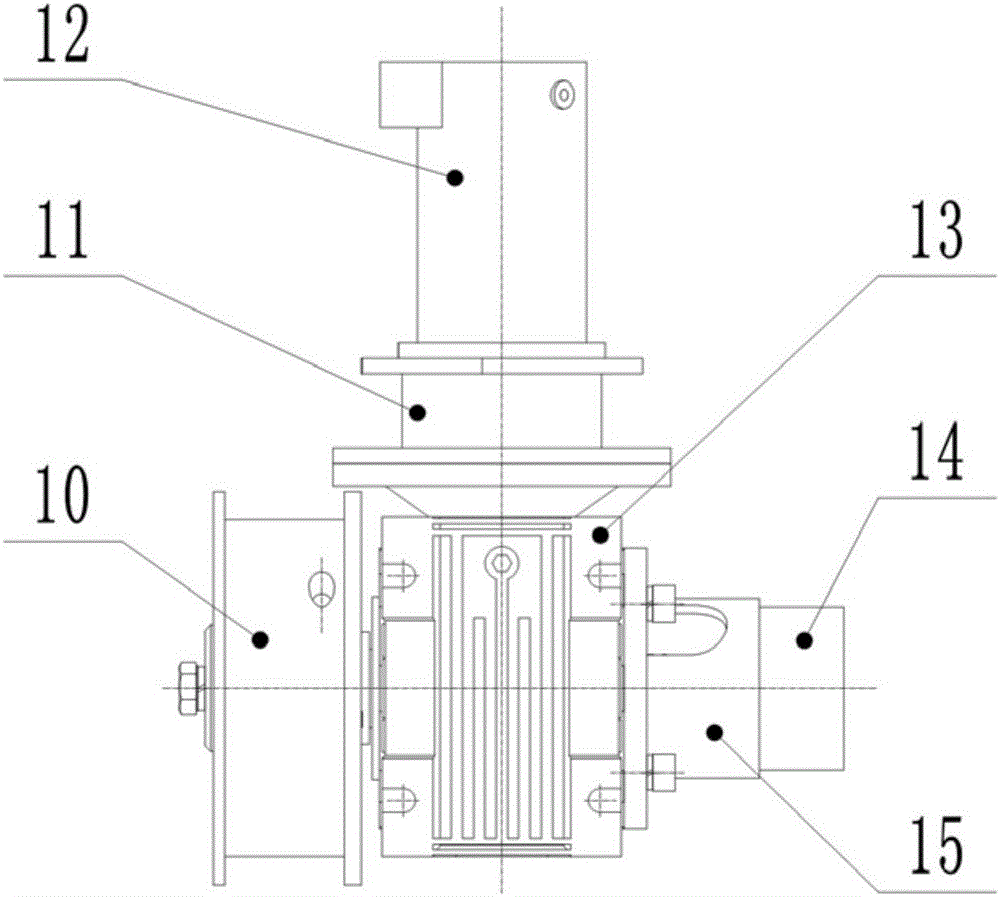

Crane teaching experiment platform

InactiveCN105047064AIncrease interest in learningStimulate the desire to seek deeper knowledgeEducational modelsHydraulic cylinderElevation angle

The invention provides a crane teaching experiment platform. A maximum hoisting load is 50kg and a maximum hoisting speed is 0.4m / s. A rated rotating speed is 2.0 r / min, a variable amplitude period is 20s and a maximum lifting altitude is 2.5m. The platform possesses lifting, rotation and variable amplitude mechanisms. A system adopts volume speed regulation hydraulic transmission. A frequency-conversion hydraulic pump station provides a power source. Lifting and rotation mechanism actuator adopts a gerotor motor and the variable amplitude mechanism adopts a hydraulic cylinder. A strain gauge is pasted on an arm frame so as to measure a dynamic stress on the arm frame of different mechanism motion under different conditions. Speeds of rotation and lifting and an accelerated speed are measured by an encoder installed on an output shaft of a corresponding decelerator. An elevation angle of the arm frame is measured by an inclination angle sensor installed on the arm frame. Heights of four support legs are adjusted so as to simulate a crane inclination condition. The four support legs are equipped with load sensors so as to measure experiment platform support pressure distribution. The experiment platform can complete a demonstration experiment, a mechanical analysis integration experiment and an open PLC programming experiment.

Owner:DALIAN UNIV OF TECH

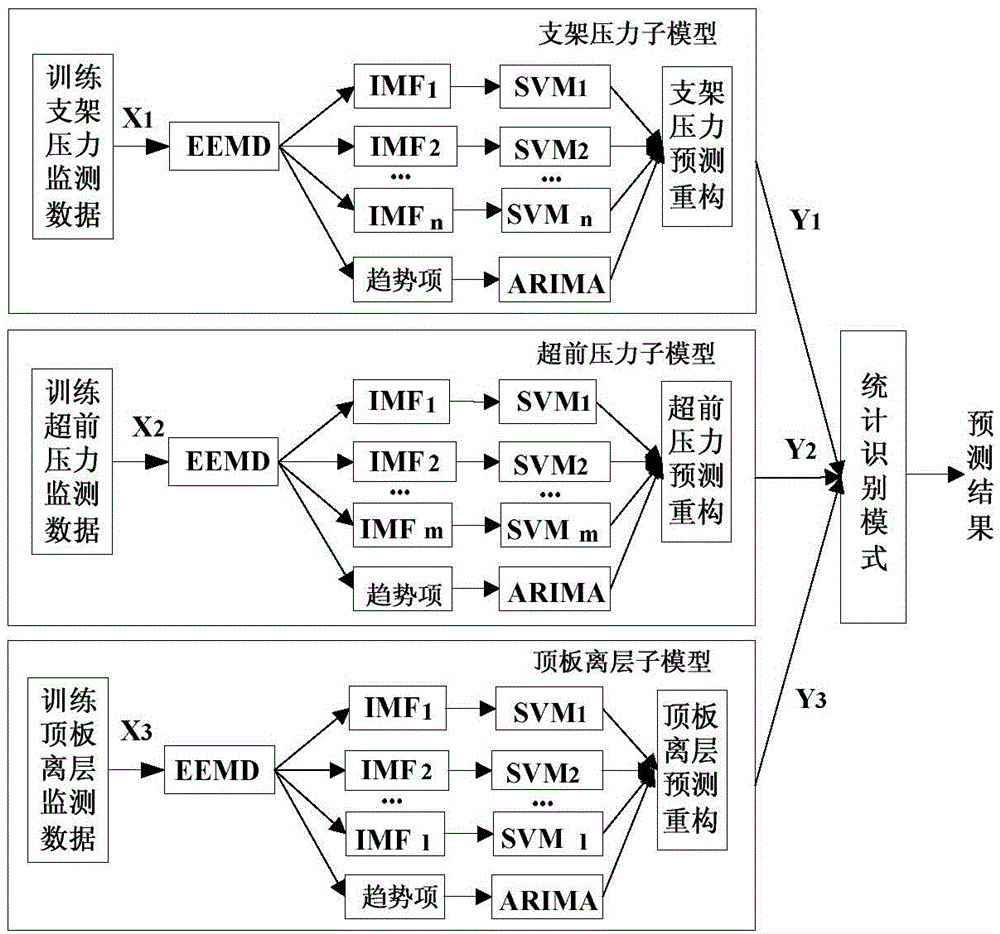

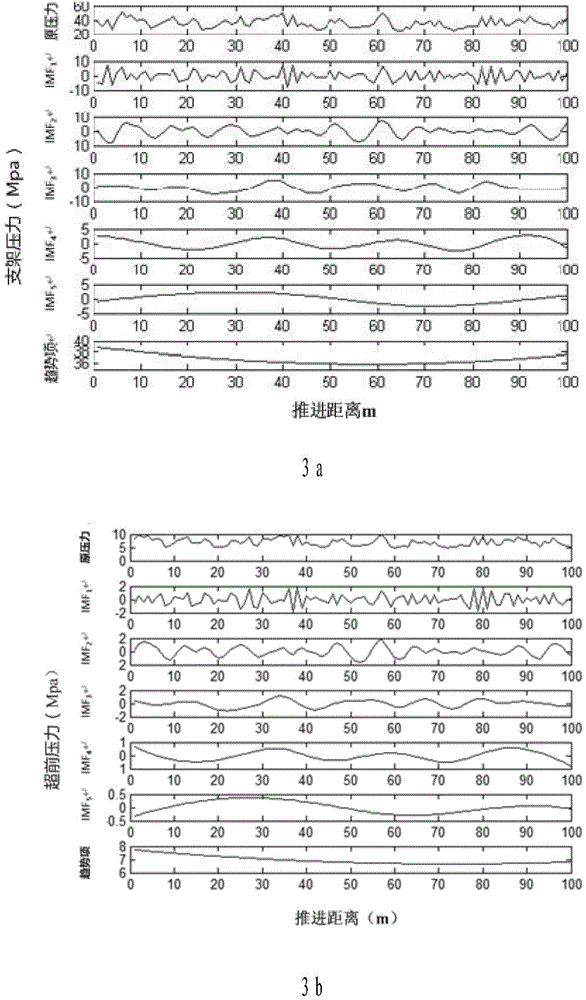

Multi-model mine roof safety early warning model based on decision fusion

The invention discloses a multi-model mine roof safety early warning model based on decision fusion. Real-time pressure monitoring data are collected through sensors, and an average value is selected as a training support pressure monitoring datum X1 to be used for establishing a support pressure submodel; stress distribution information of a coal bed or a rock stratum is collected through a leading pressure sensor to obtain a training leading pressure detection datum X2, and a leading pressure submodel is established; a separation layer indicator collects the separation layer situation of rock in a roof rock pillar near a working face and conducts processing to obtain a training roof separation layer monitoring datum X3, and a roof separation layer submodel is established; the data in the submodels are reconstructed to form corresponding prediction values, namely, Y1, Y2 and Y3, normalized decision fusion is conducted on the prediction values in a statistical recognition mode, and fused information is obtained. The multi-model mine roof safety early warning model is high in prediction and generalization capacity.

Owner:XIAN UNIV OF SCI & TECH

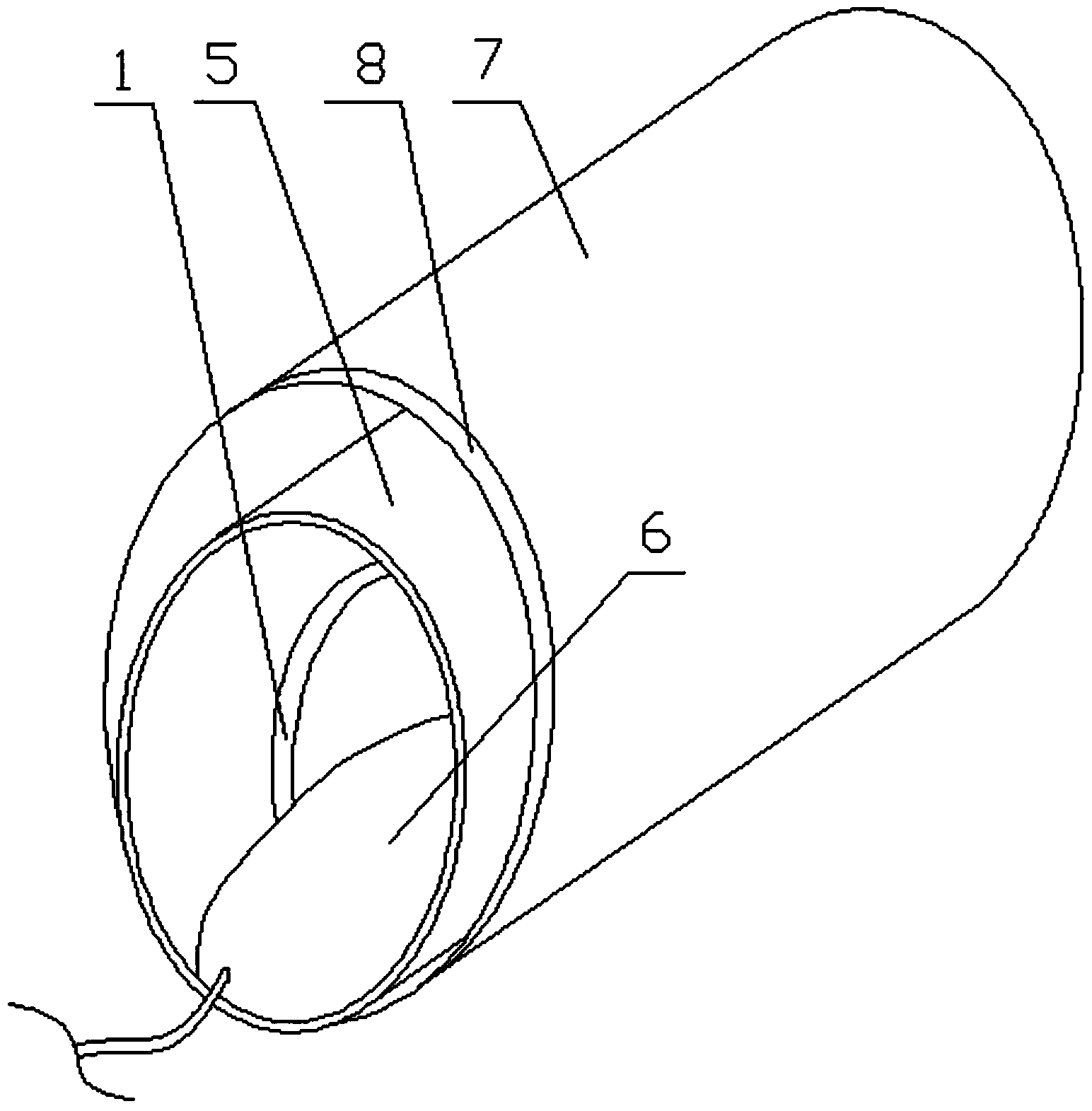

Fixing unit and image-forming device using the same

Owner:BROTHER KOGYO KK

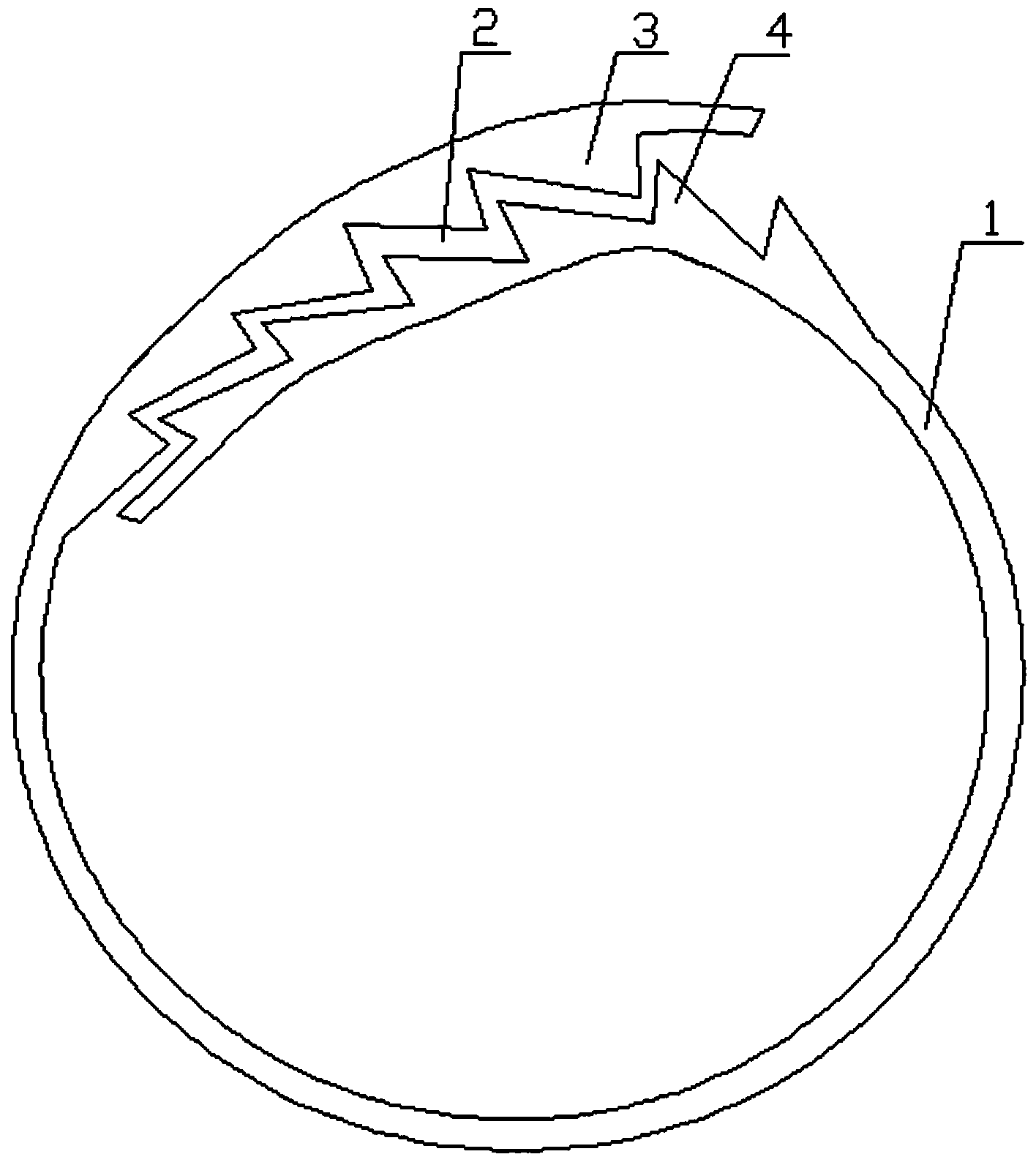

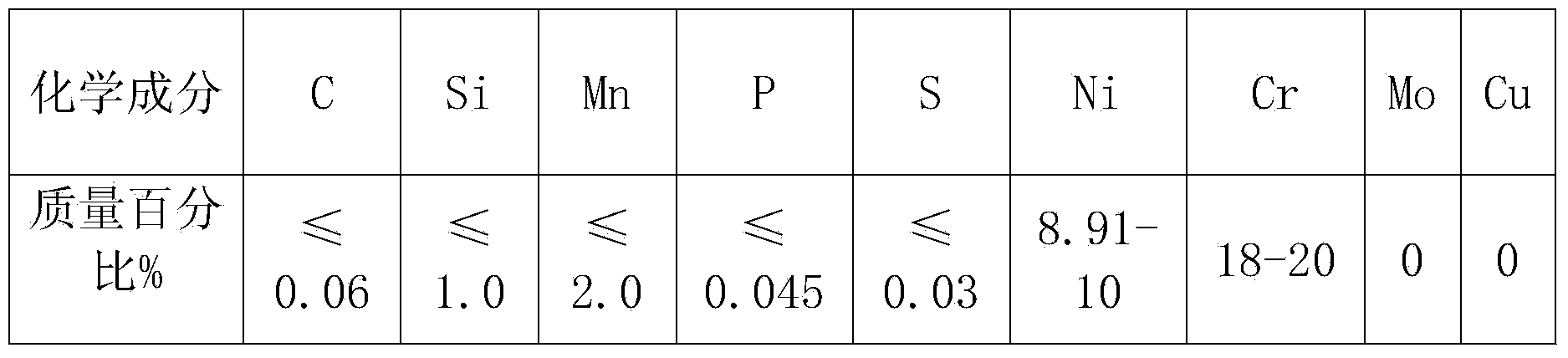

Pipeline connector repair device and method

The invention relates to the field of construction connection of pipeline projects, and discloses a pipeline connector repair device. The pipeline connector repair device comprises a winding drum, a stainless steel buckle and an air bag, wherein the stainless steel buckle is arranged on the inner side of the winding drum, the air bag is arranged in the winding drum, a foaming agent layer is arranged on the outer surface of the winding drum, an opening is formed in the stainless steel buckle, first locating clamping teeth are arranged at one end of the opening, and second locating clamping teeth meshed with the first locating clamping teeth are arranged at the other end of the opening. The invention further discloses a pipeline connector repair method using the pipeline connector repair device. According to the pipeline connector repair device, the lateral support pressure of the stainless steel buckle is 5 psi, and the safety coefficient of external static waterpower pressure ranges from 2.5 to 3.0; the stainless steel buckle is made of austenitic stainless steel, a water-soluble polyurethane plugging agent layer or an oil-soluble polyurethane plugging agent layer is adopted as the foaming agent layer, and it is ensured that the normal service life of the repair portion of a pipeline can be longer than 15 years generally; after a pipe section with slight damage is repaired, the service life of the repaired pipe section can be equal to that of a new pipe.

Owner:CHENGTONG KAISHENG ECOLOGICAL CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com