Method for controlling high mine pressure of open-air roadway by hydraulic fracturing

A technology of hydraulic fracturing and strong mine pressure, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of high stress concentration, high pressure from the roof, and difficult support, so as to reduce the lateral Bearing pressure, avoiding the problem of rock burst, and protecting the effect of the roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

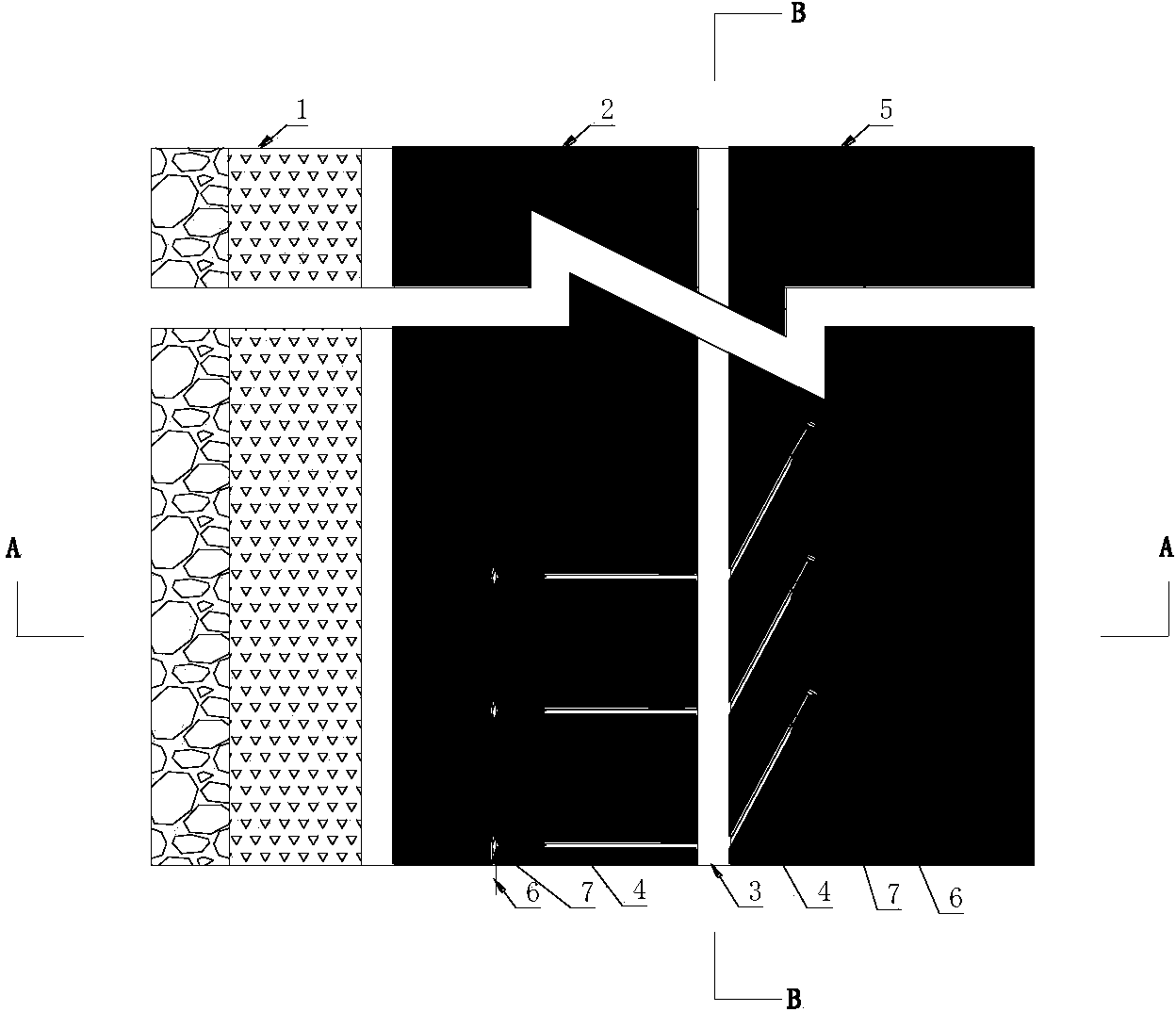

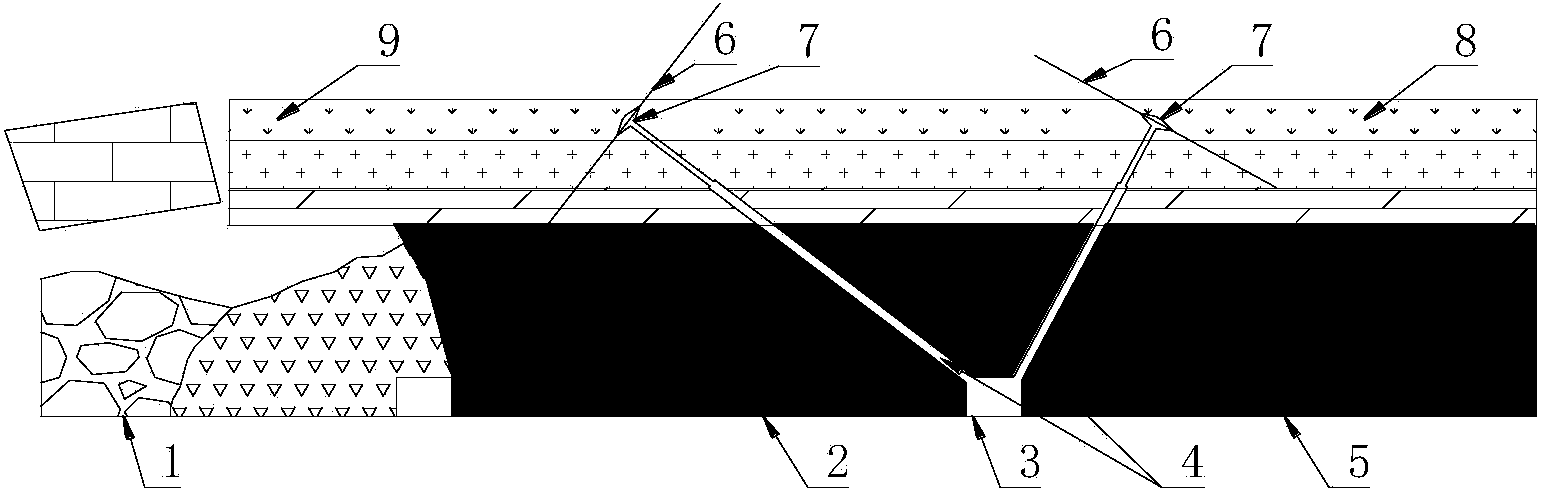

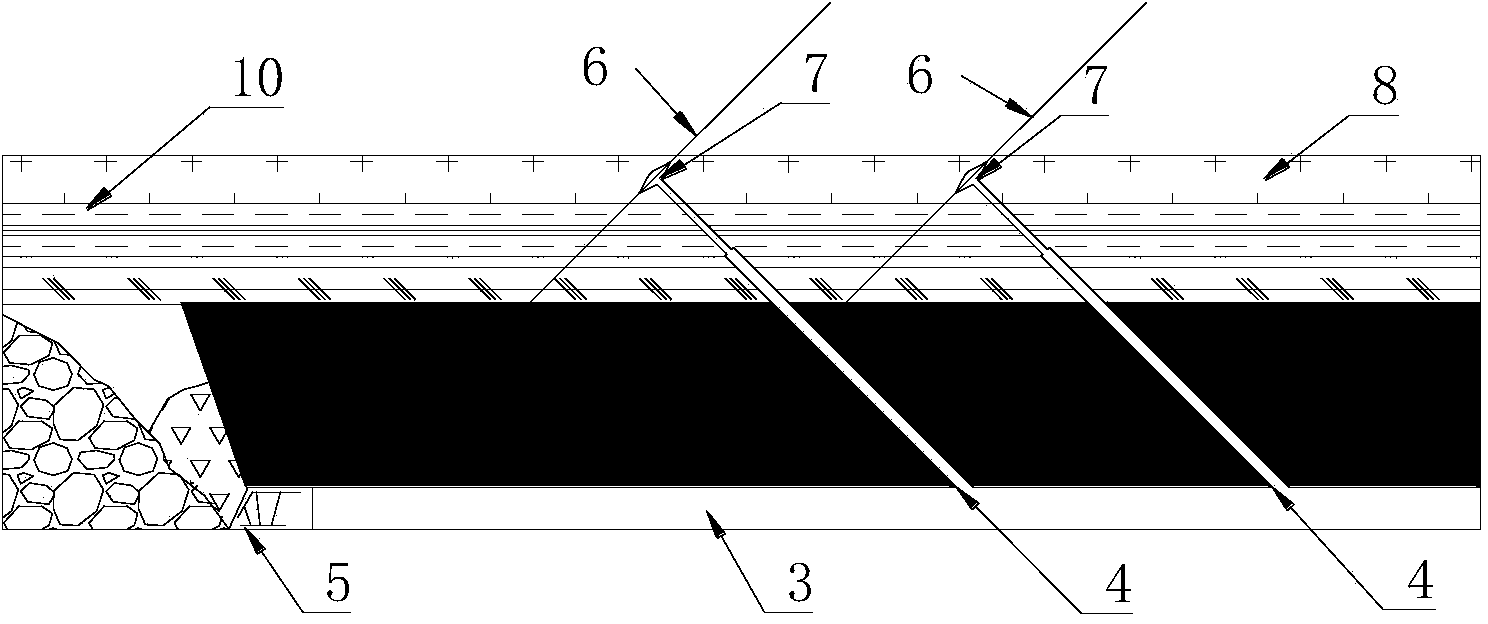

[0016] Example 1. The average thickness of the coal seam at the working face of a mine is 15.49m, and the buried depth is 377.6-519m. The height of machine mining is 3.9m, and the height of coal caving is 11.59m. The eastern part of the working face is the solid coal area; the northern part is the goaf; the western part is the three lanes of the panel area; the southern part is the solid coal area. The old top of the working face is silty-fine sandstone and gravel-bearing coarse sandstone, and gray-white gravel-bearing coarse sandstone. The immediate top is siltstone and carbonaceous mudstone. The siltstone has horizontal bedding and contains coal dust. The carbonaceous mudstone is massive, easy to stain hands, and contains plant stem and leaf fossils. During the mining process, the work is faced with large deformation and shock ground pressure in the airside roadway.

[0017] According to the histogram information of the coal seam roof, after determining the hard rock layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com