Patents

Literature

219 results about "Impact stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Impact of Stress on Health: Learning to Cope. Stress can have serious health implications, increasing the risk of cardiovascular disease and exacerbating medical conditions such as asthma, diabetes, and hypertension. Stress is unavoidable, but learning to manage it effectively is critical.

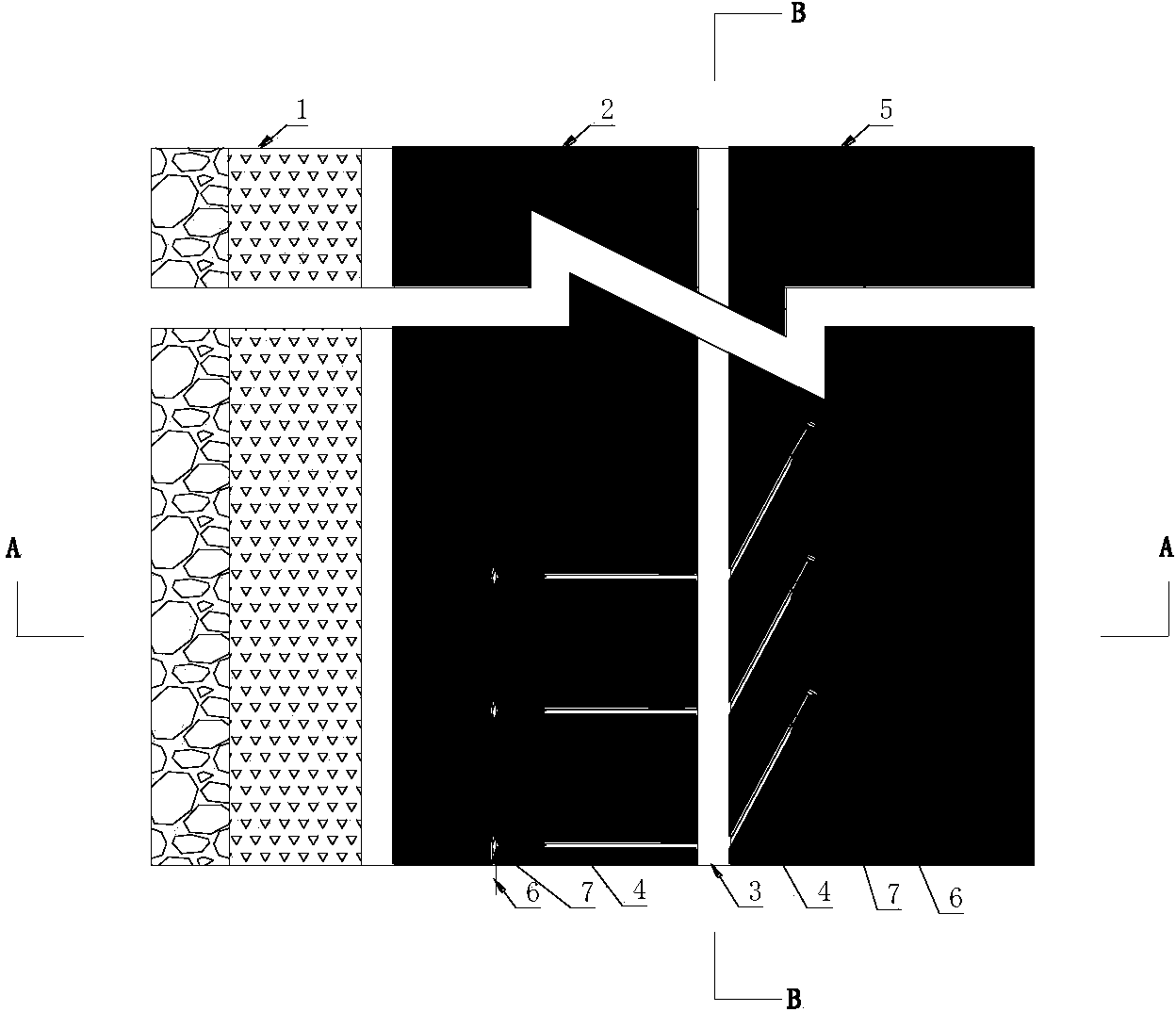

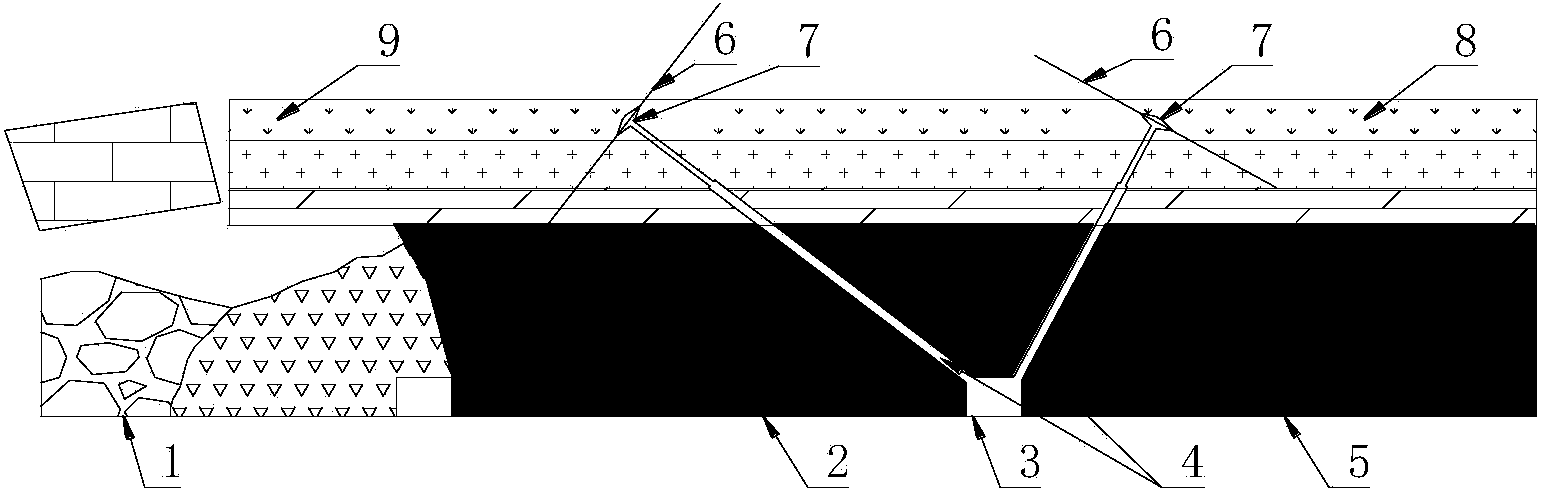

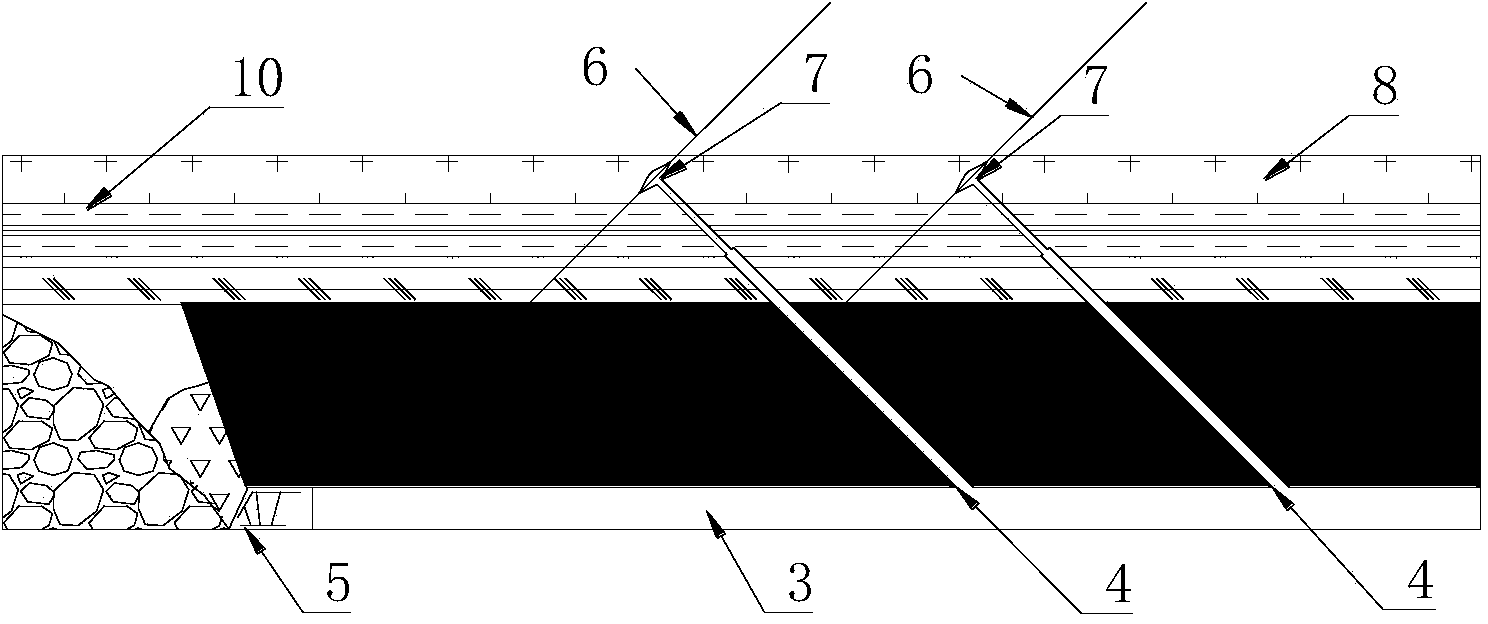

Method for controlling high mine pressure of open-air roadway by hydraulic fracturing

InactiveCN103758570ARelieve pressureReduce leading bearing pressureMining devicesAbutmentHydraulic fracturing

A method for controlling high mine pressure of an open-air roadway by hydraulic fracturing comprises the following steps of determining a hard rock stratum of a roof according to a geological information bar chart of a coal face; designing a control drilling hole; respectively controlling abutment supporting pressure and lateral supporting pressure; slotting or slitting in the bottom of the hole after hole drilling construction is finished so as to achieve the purpose of directional fracturing; applying a hydraulic fracturing process; and weakening the hard roof or cutting off the hard roof along a directional fracturing slot of the drilling hole so as to transfer stress or weaken surrounding rock and reduce the lateral supporting pressure and the abutment supporting pressure of the open-air roadway. A weakening zone in the surrounding rock can effectively absorb or weaken impact stress waves; a dynamic disaster of rock burst caused by the reason that the hard roof cracks suddenly is avoided; and large deformation of the open-air roadway is controlled. The method for controlling the high mine pressure of the open-air roadway by hydraulic fracturing is not only applicable to controlling the high mine pressure of the open-air roadway with the coal face with the hard roof, but also is applicable to controlling the high mine pressure of the roadway of which a work face is in tunnelling crossing with a work face of an adjacent roadway during mining. Moreover, the method is simple, effective, safe and reliable, and is low in cost.

Owner:CHINA UNIV OF MINING & TECH

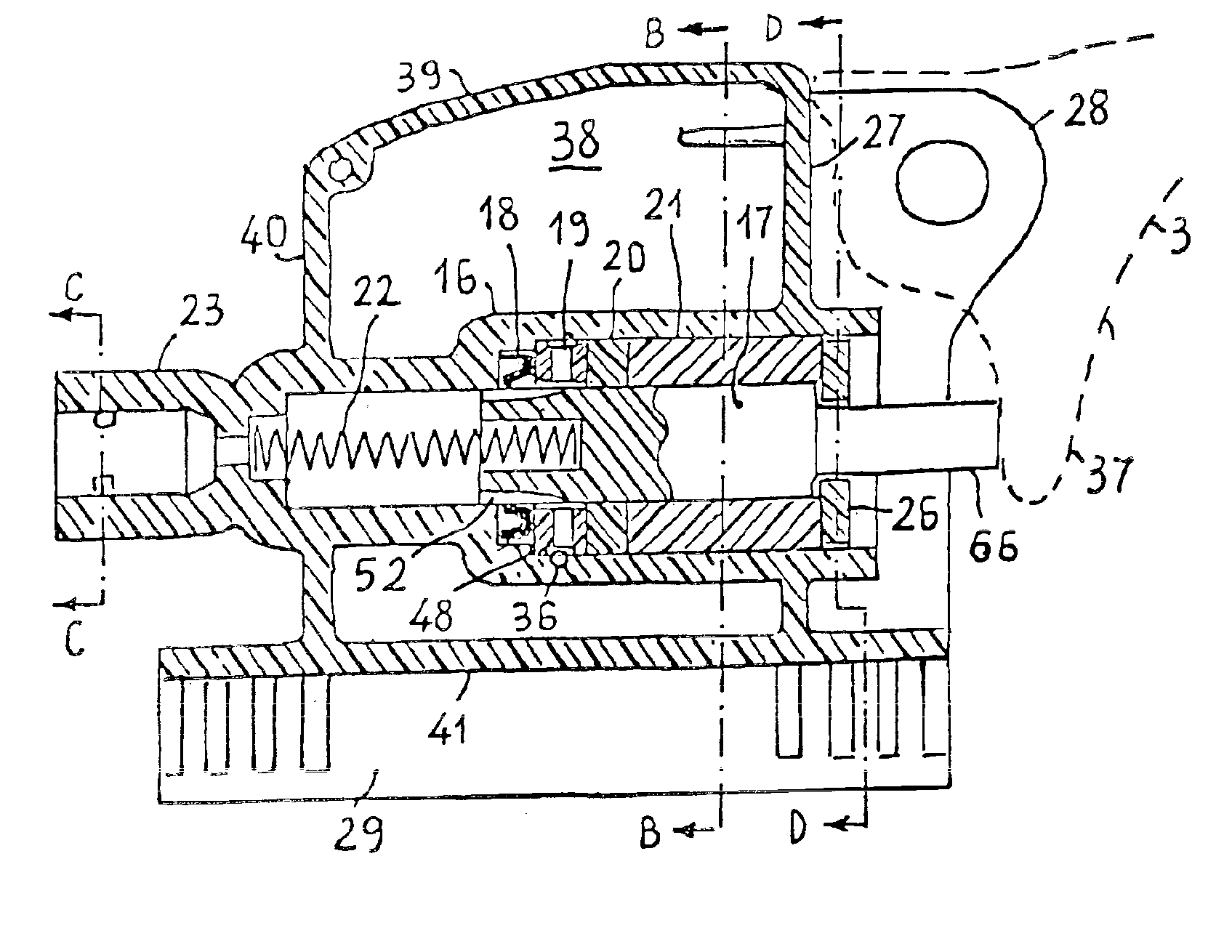

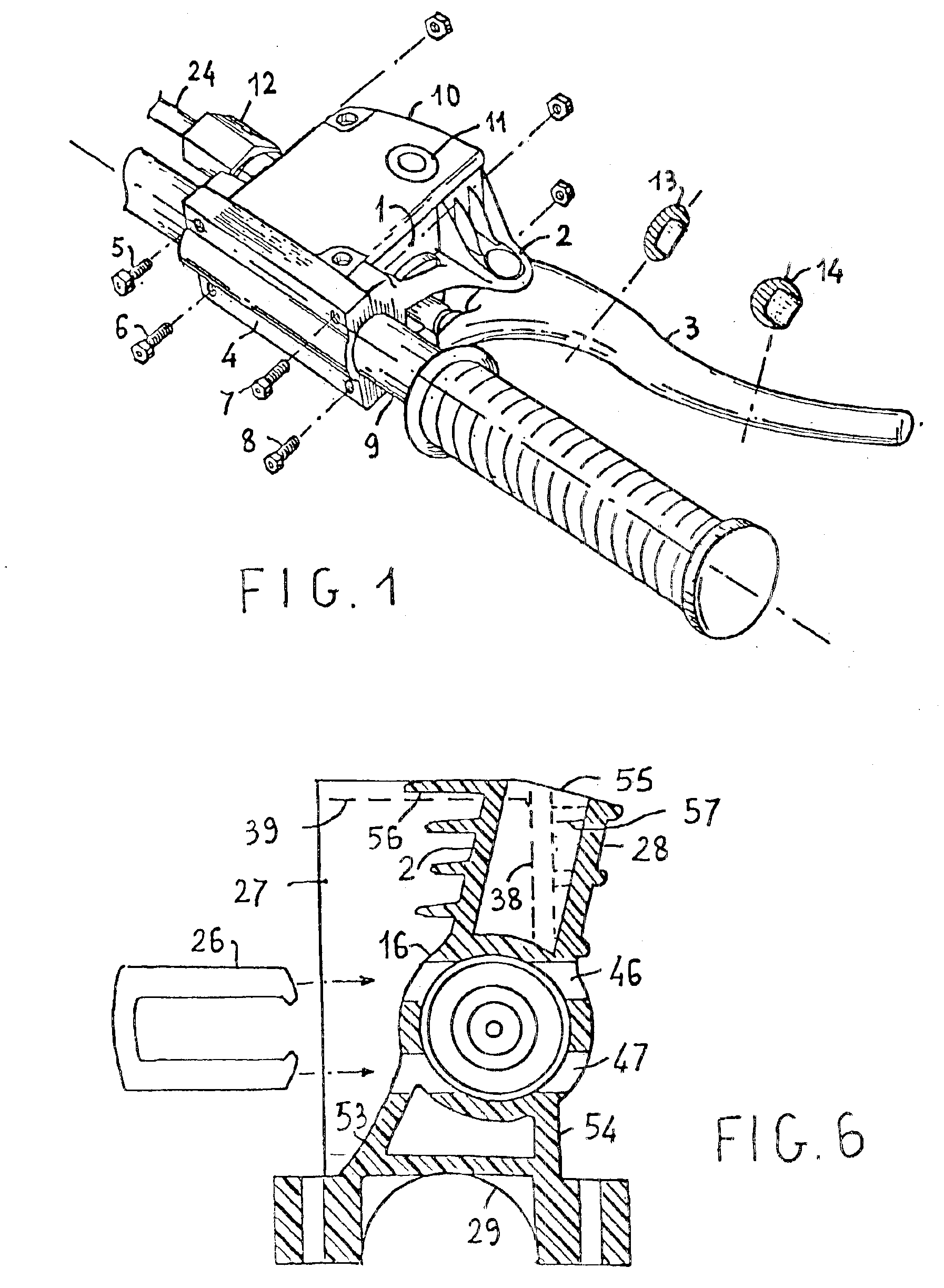

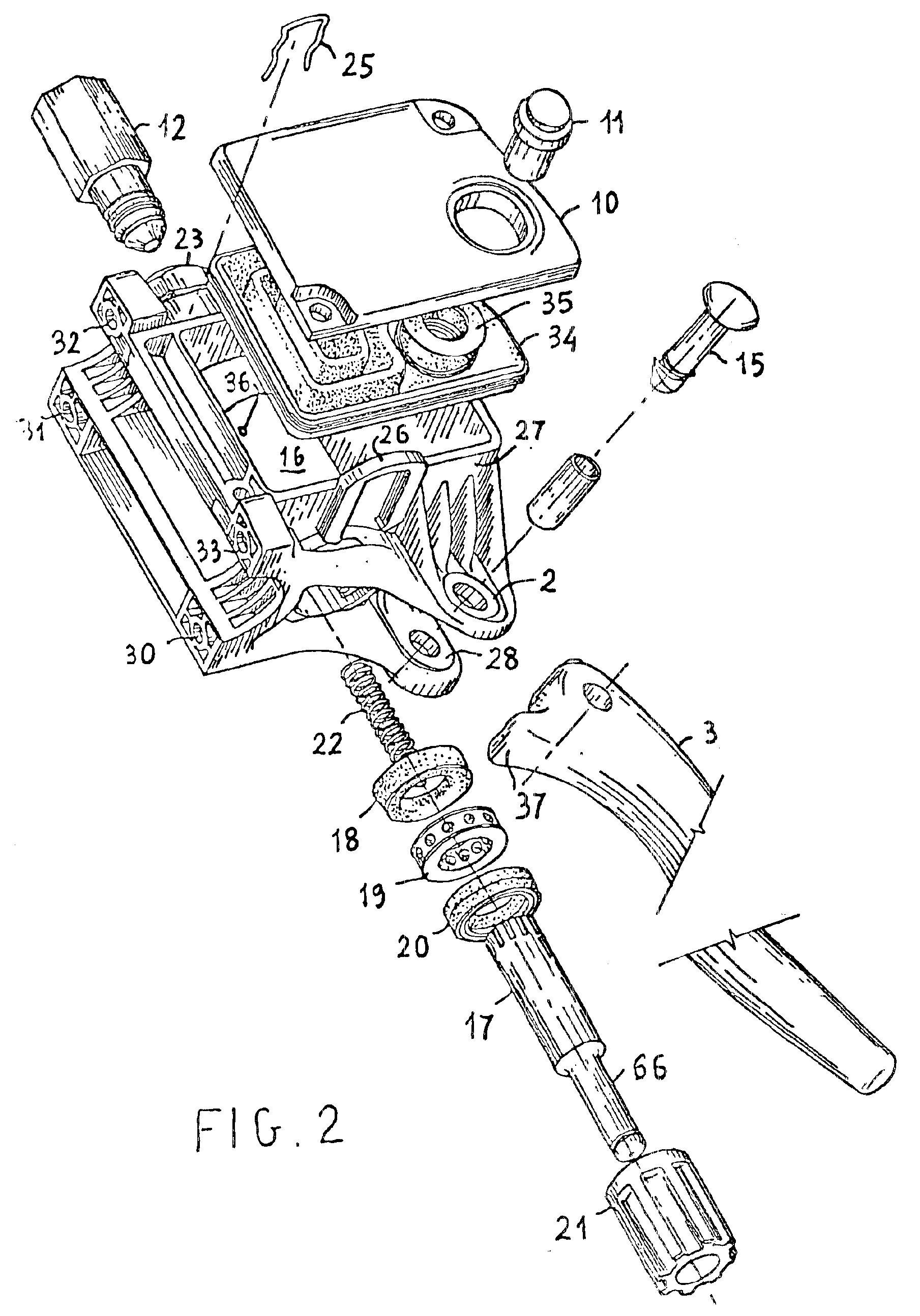

Master cylinder for a brake or clutch of a motorcycle or bike

InactiveUS6871729B2Simple structureRotary clutchesFluid actuated clutchesGlass fiberPlastic materials

A brake / clutch master cylinder for a motorcycle / bicycle or the like, with a body which is produced by moulding of plastics material reinforced by glass fibre without the need for machining operations or metal inserts and which forms, together with the cylindrical shell of the master cylinder, a hydraulic-fluid reservoir, a coupling sleeve for a male quick-fit hydraulic connector, and a seat for fixing to a handlebar, the body having a high degree of structural stiffness with respect to working stresses and adequate resilience for impact stresses imparted to the body by means of the hand operating lever.

Owner:FRENI BREMBO SPA

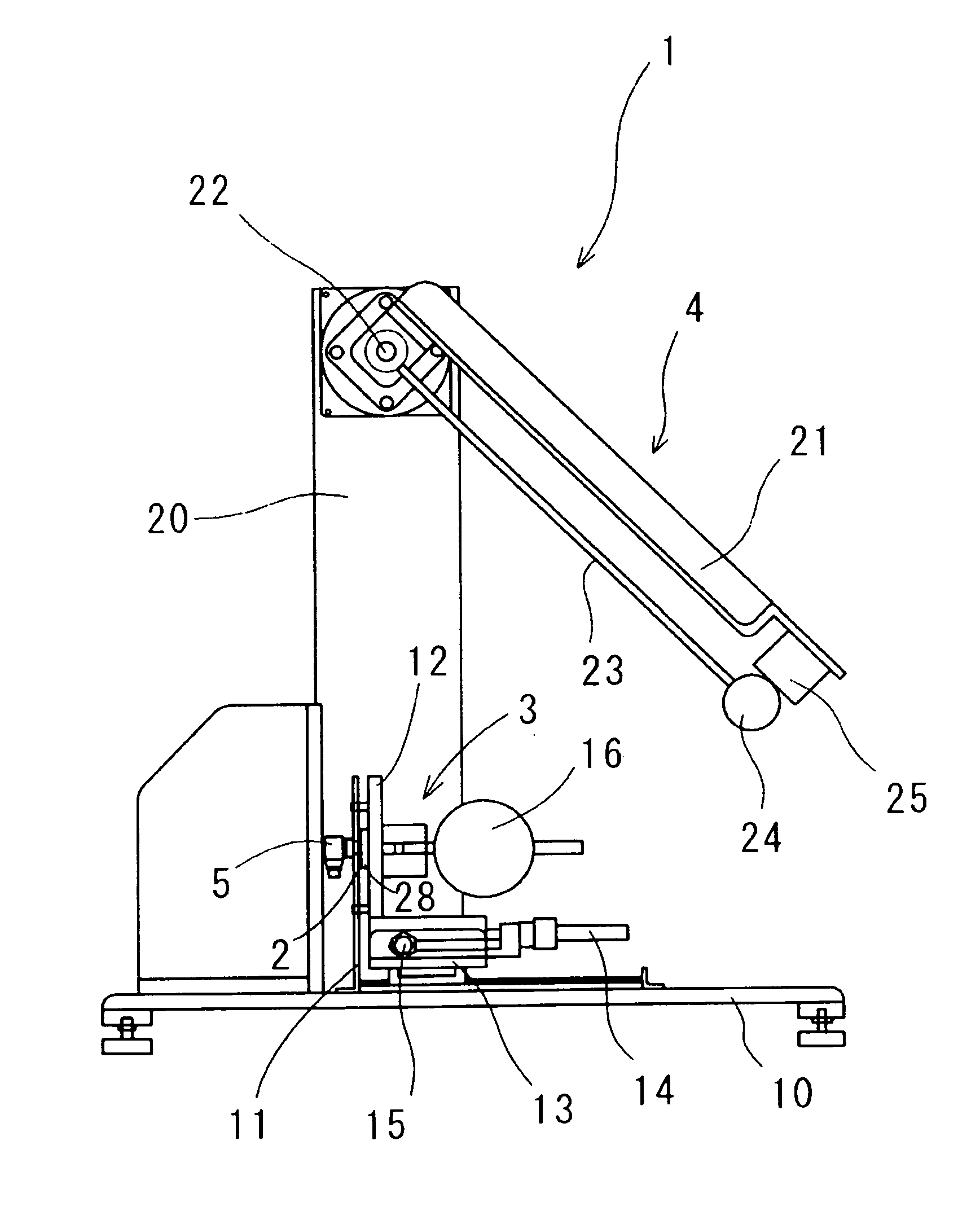

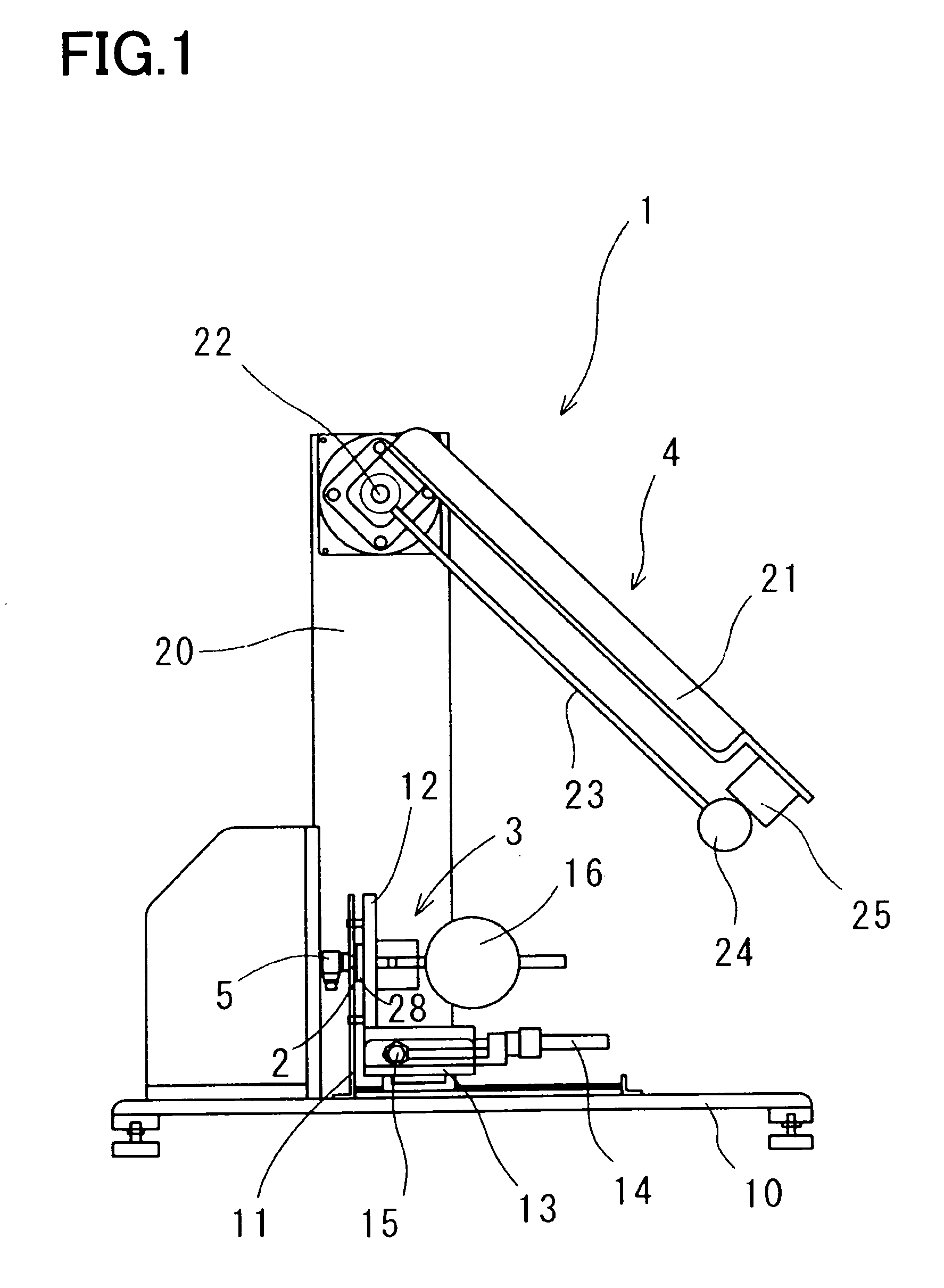

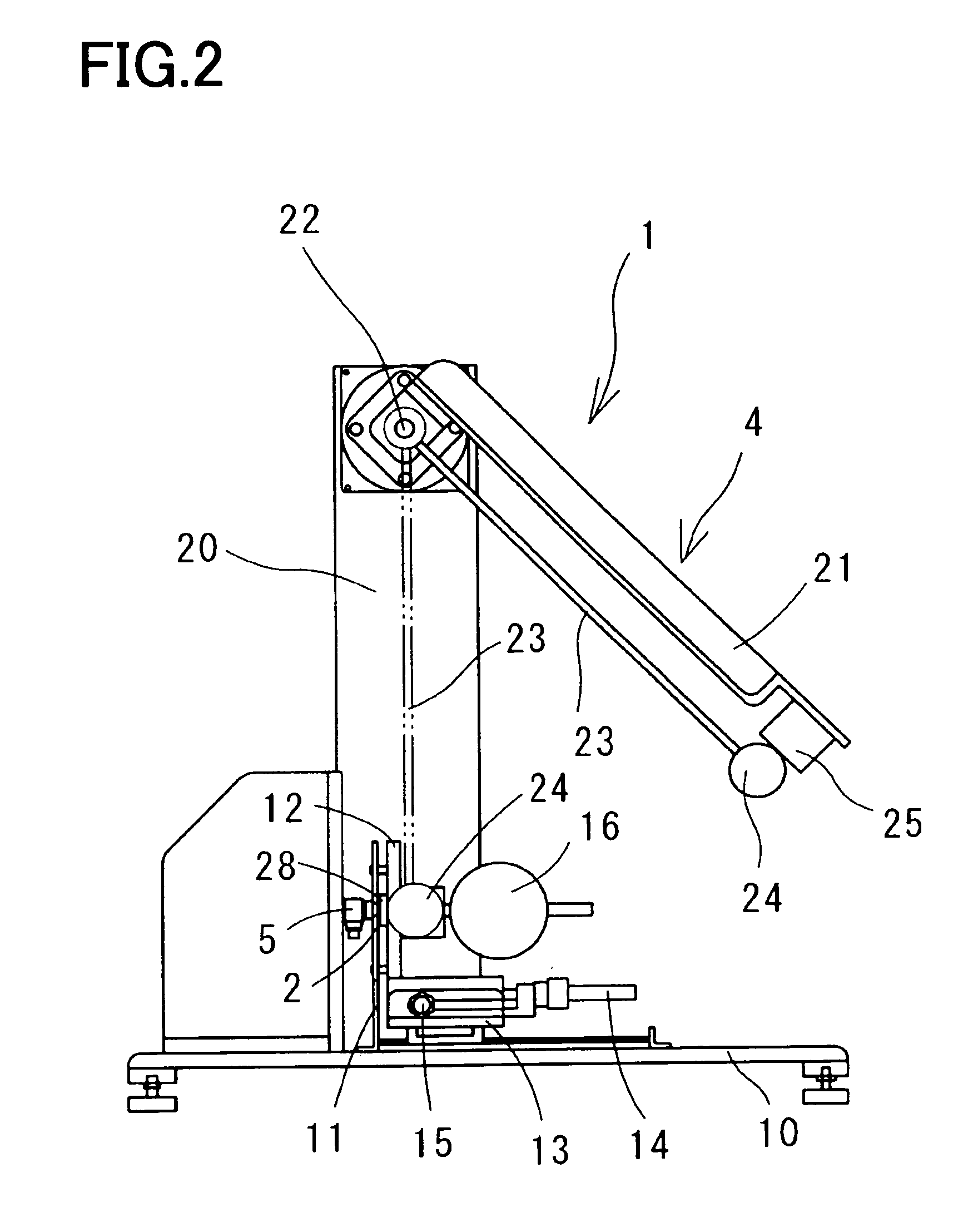

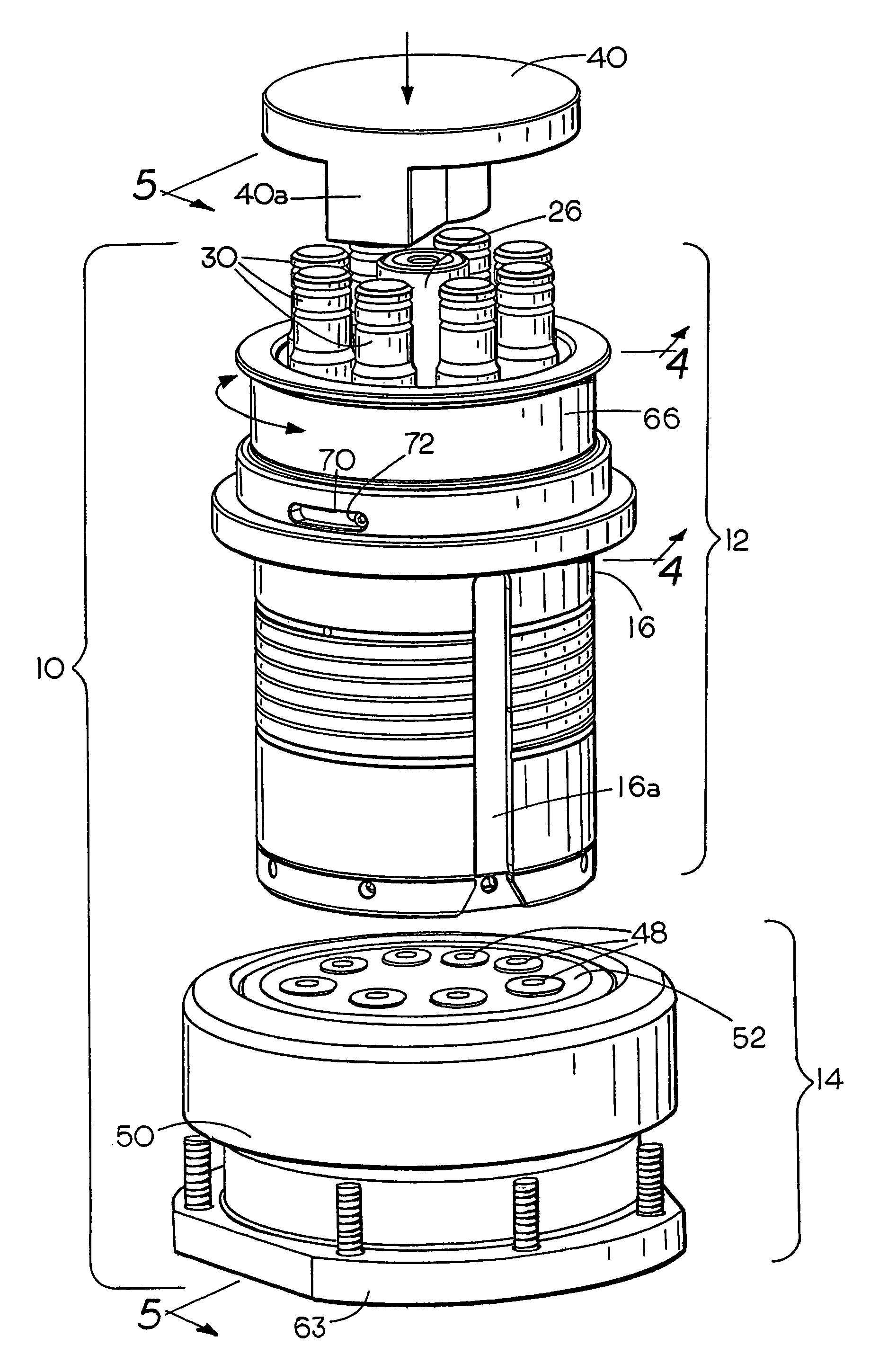

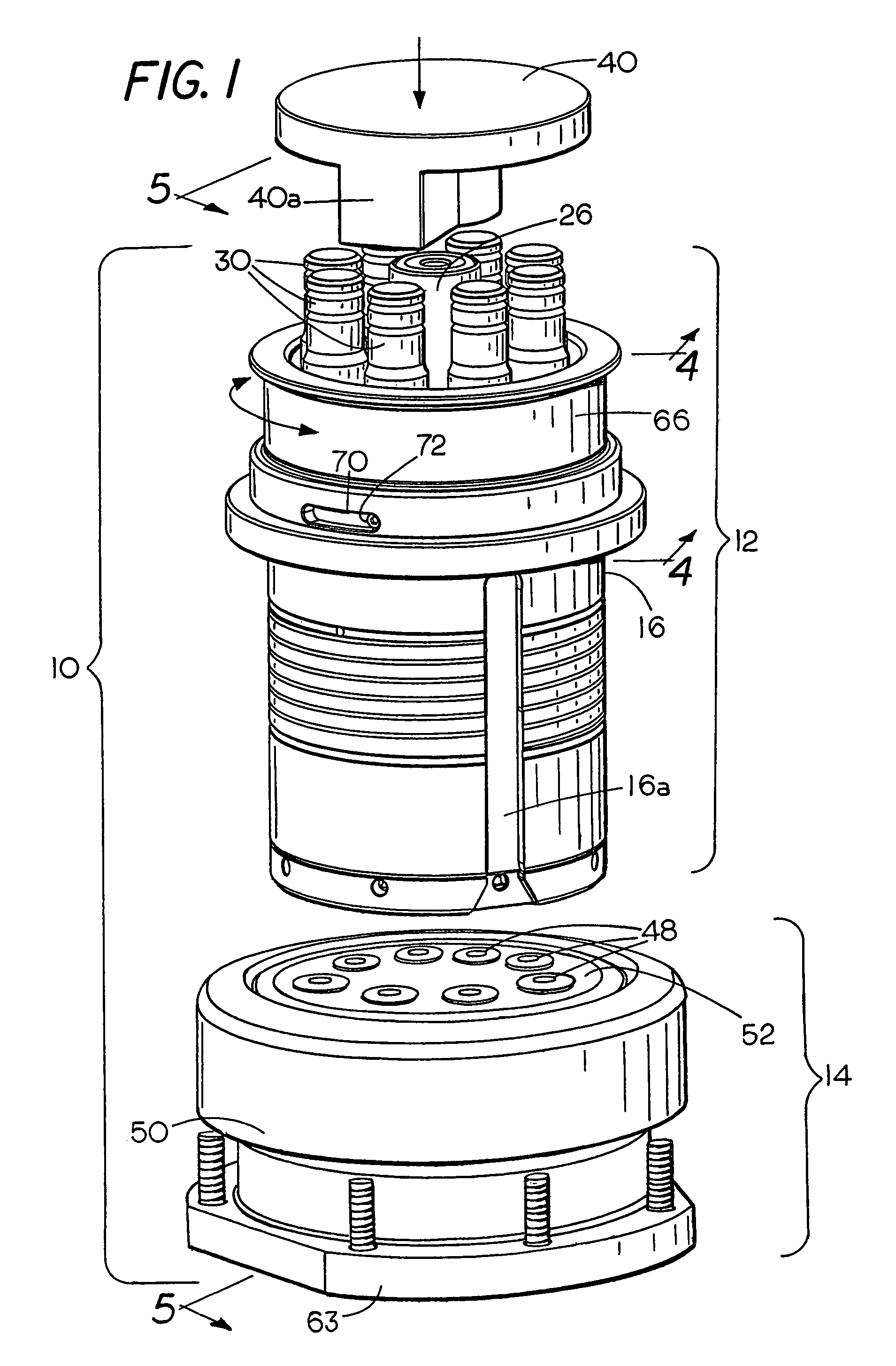

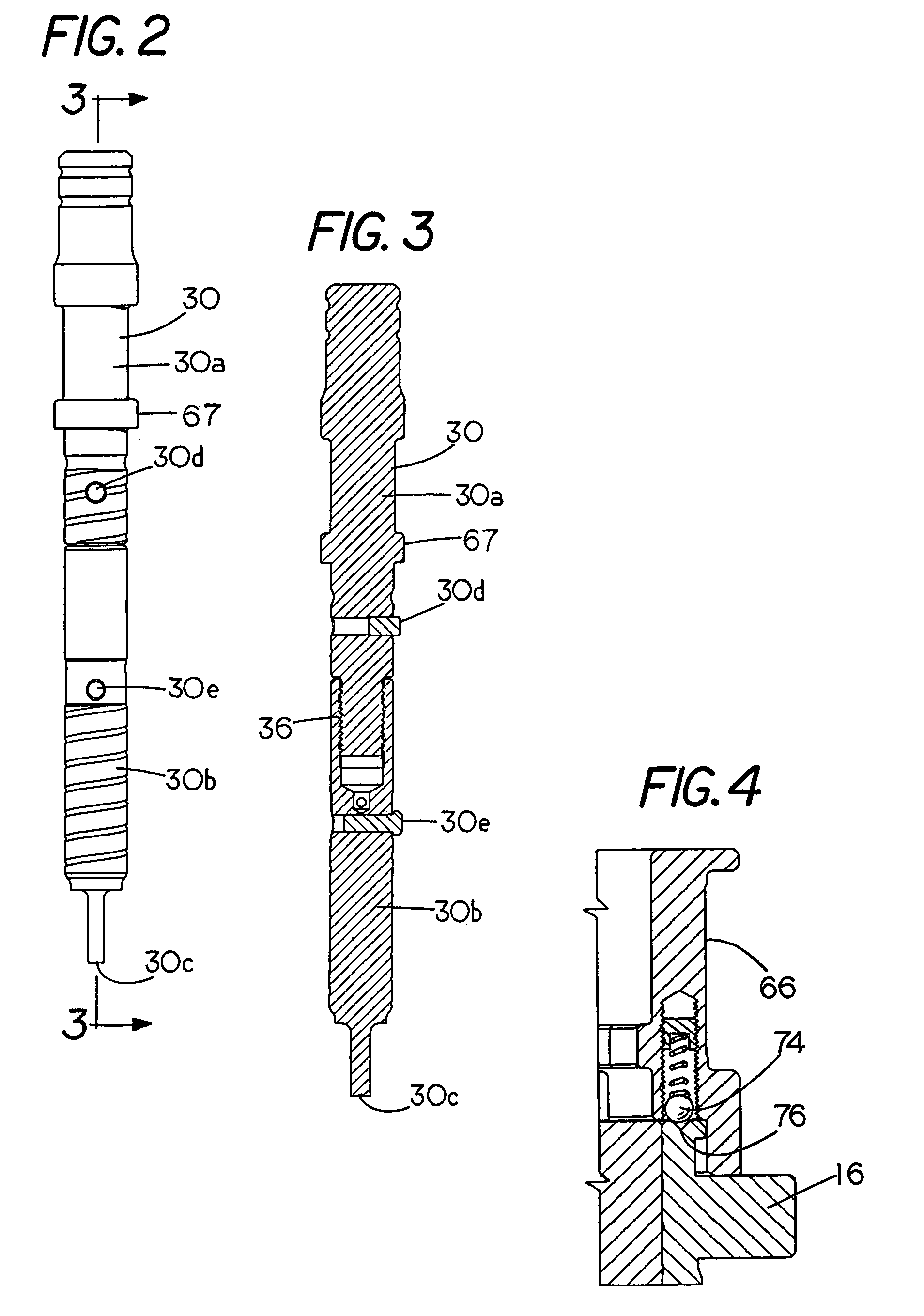

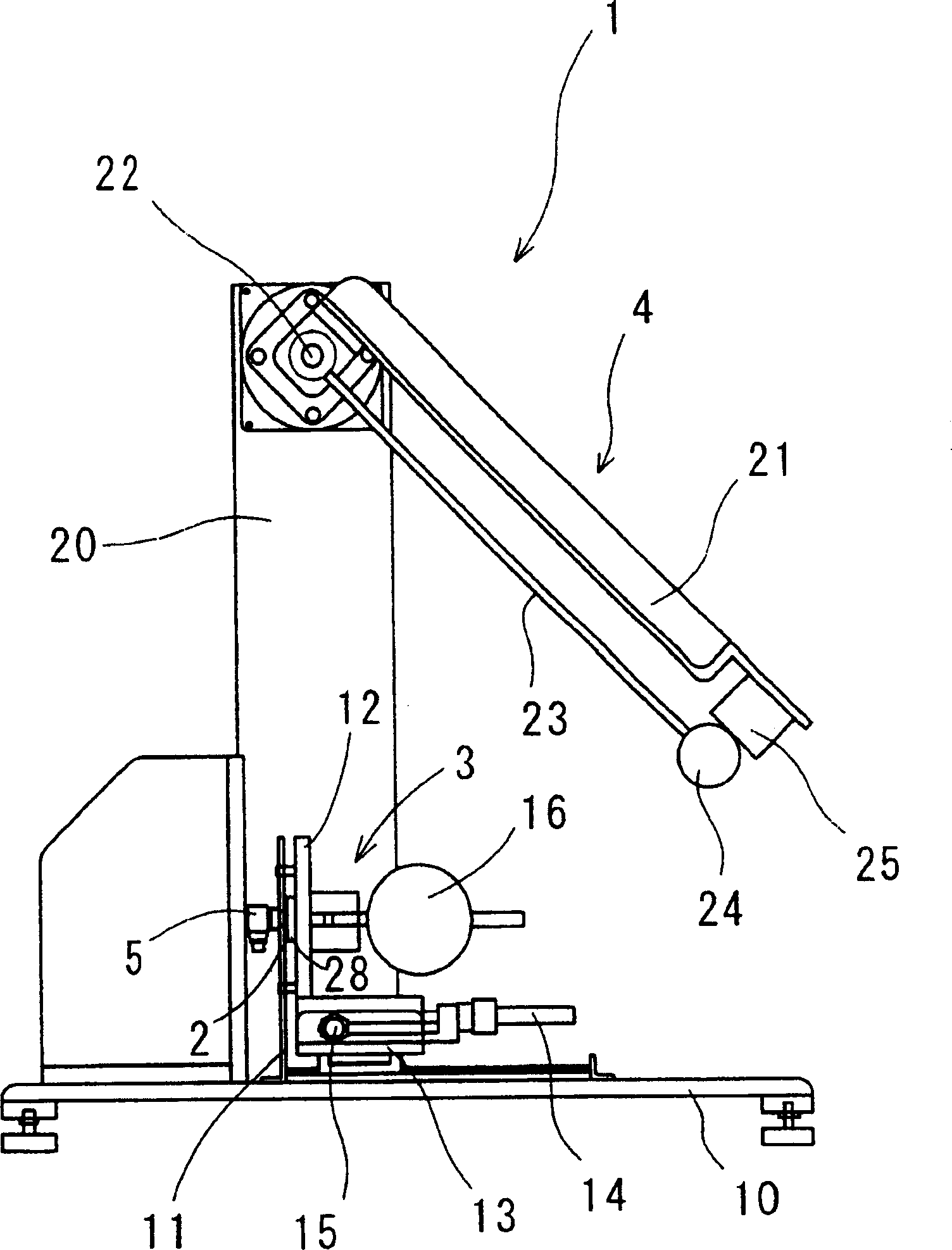

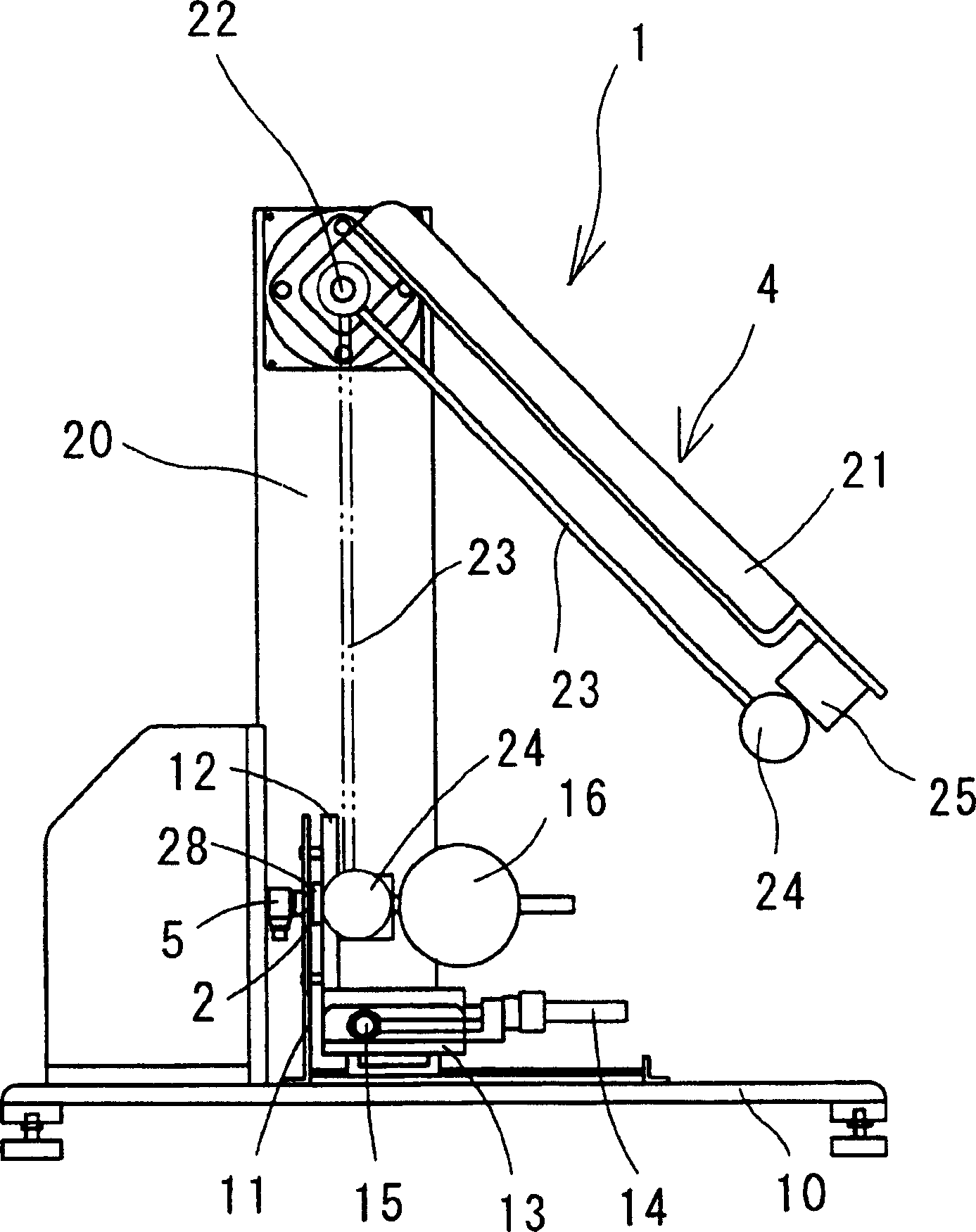

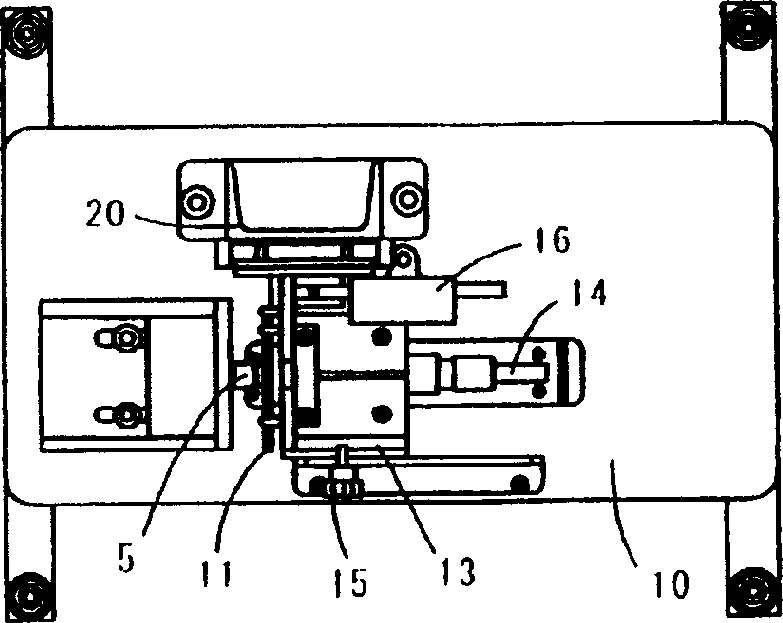

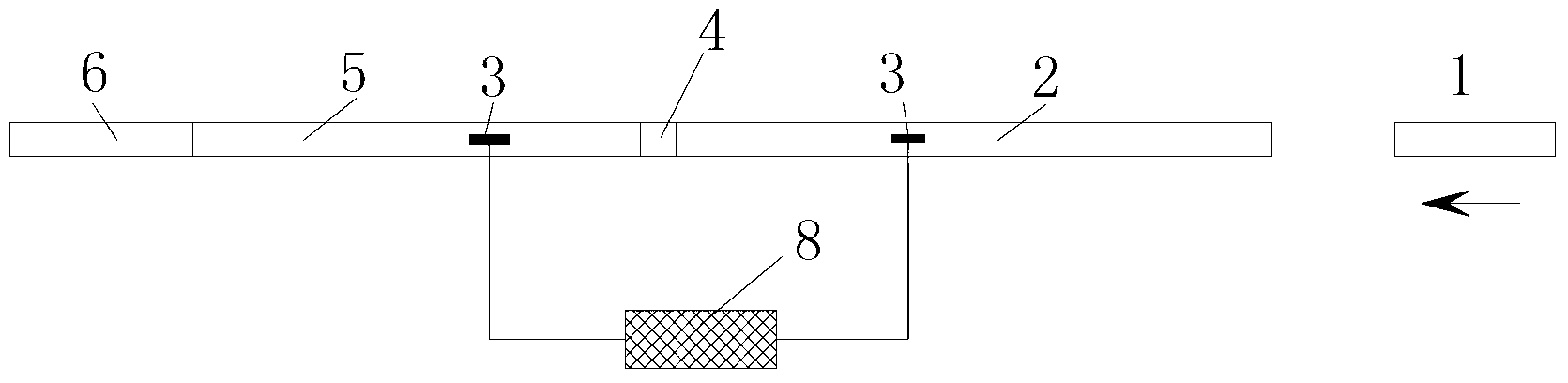

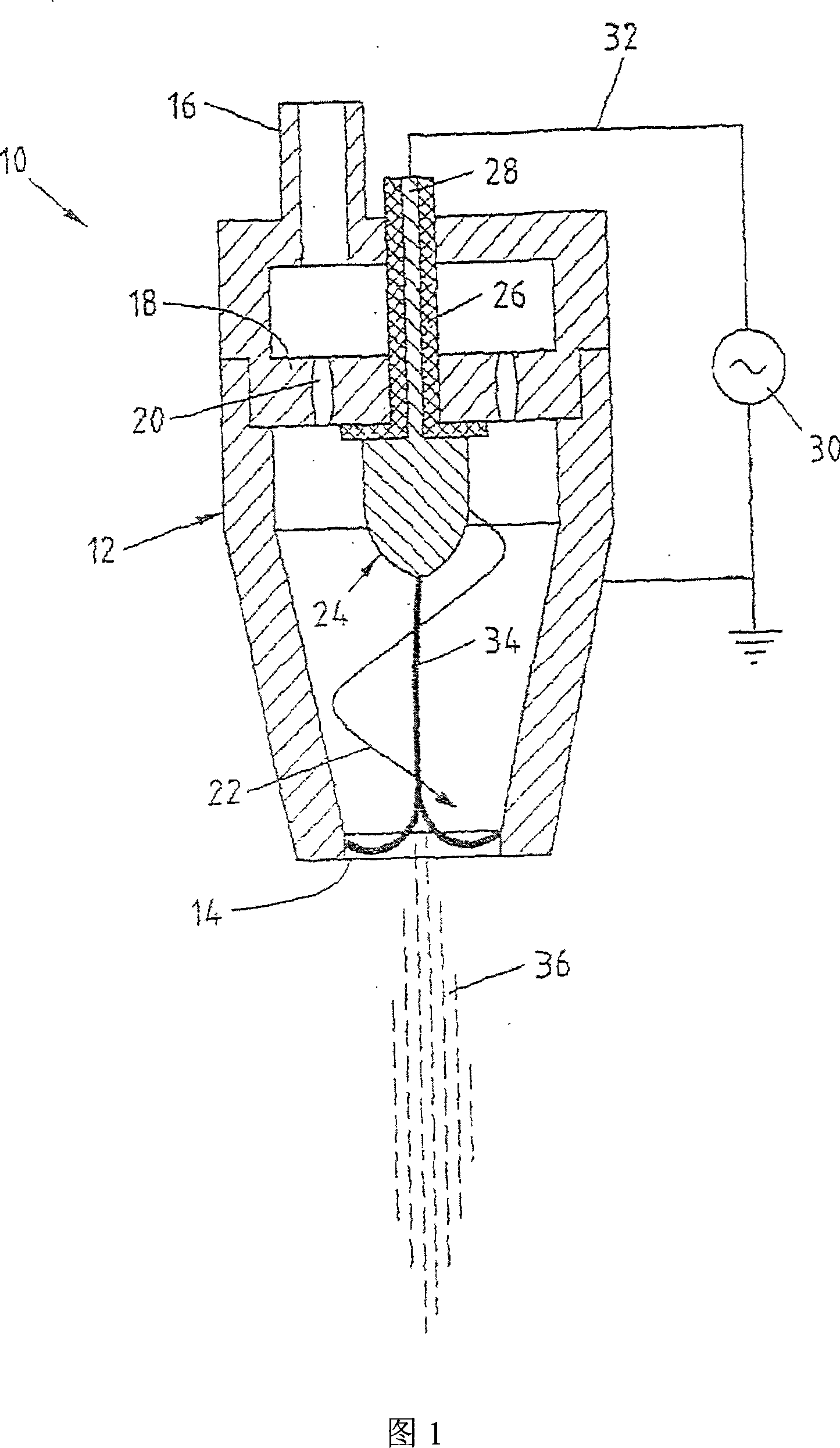

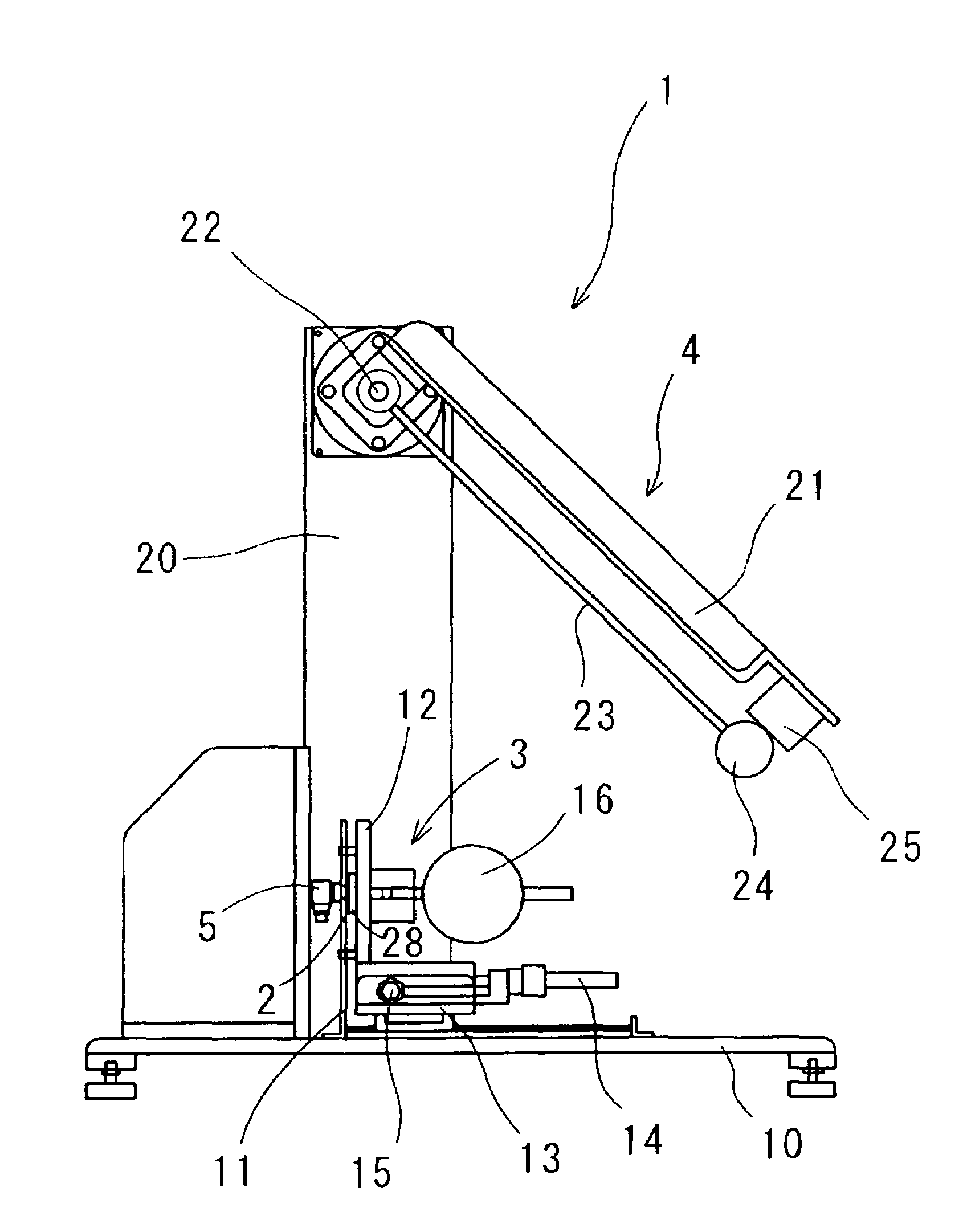

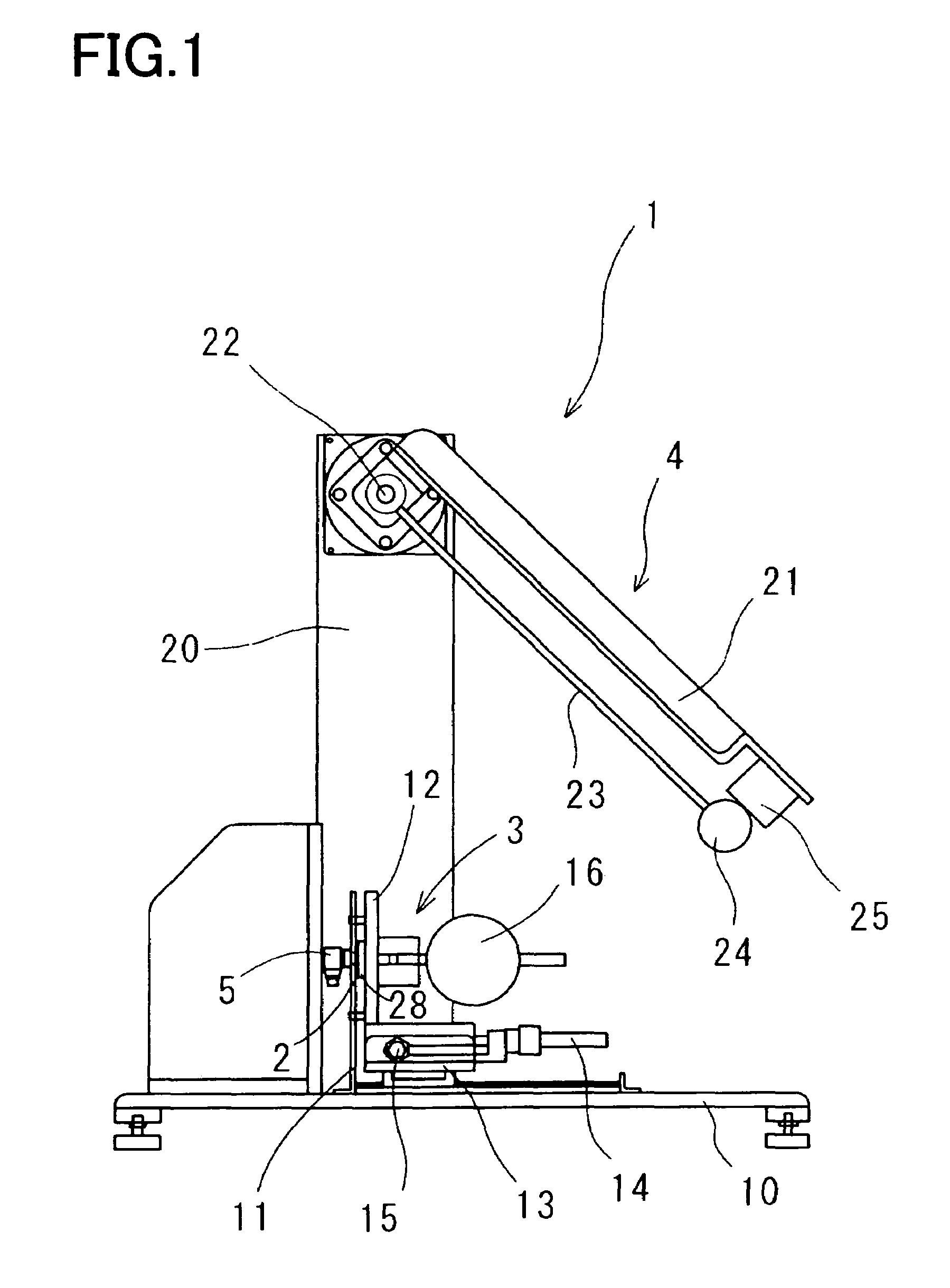

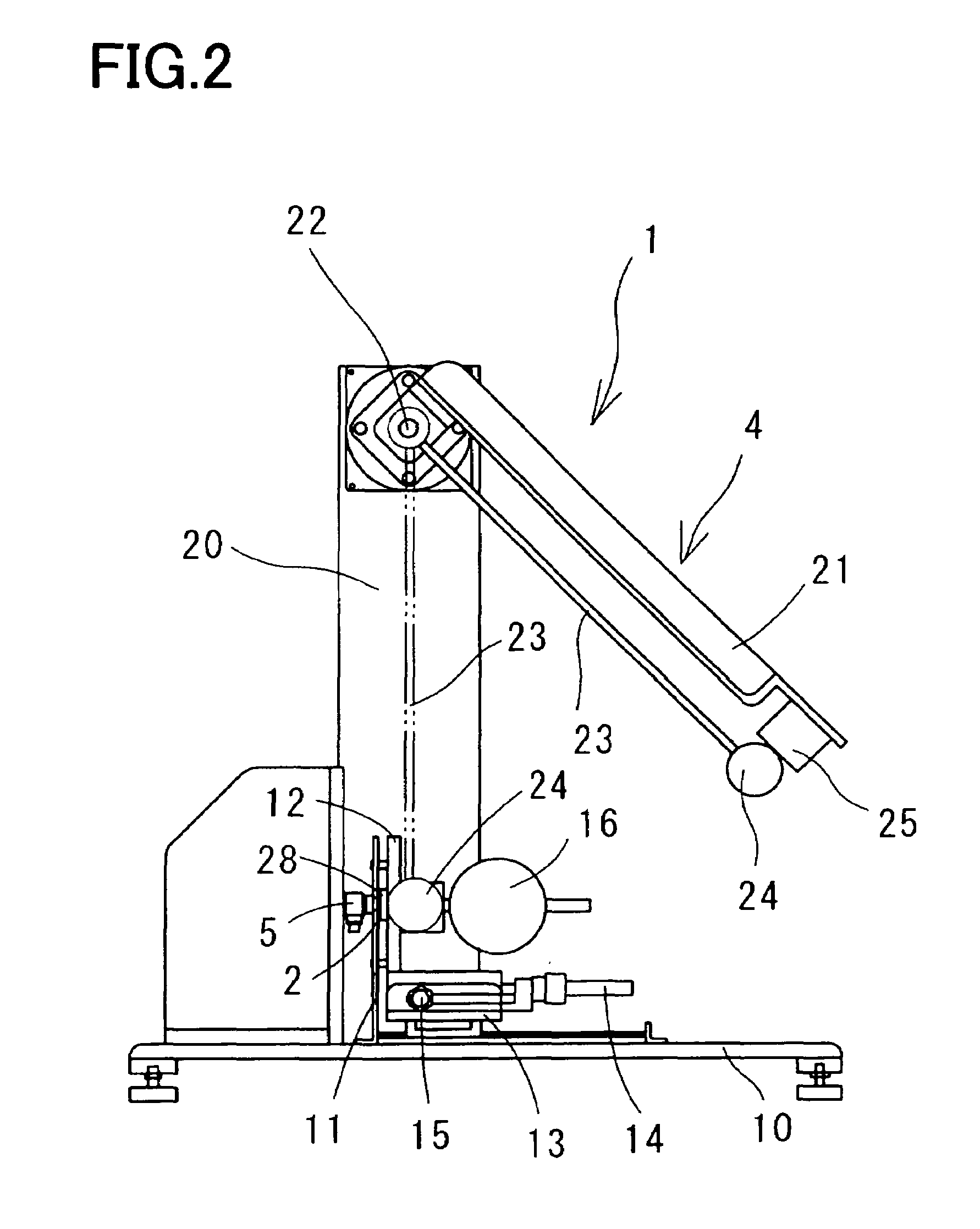

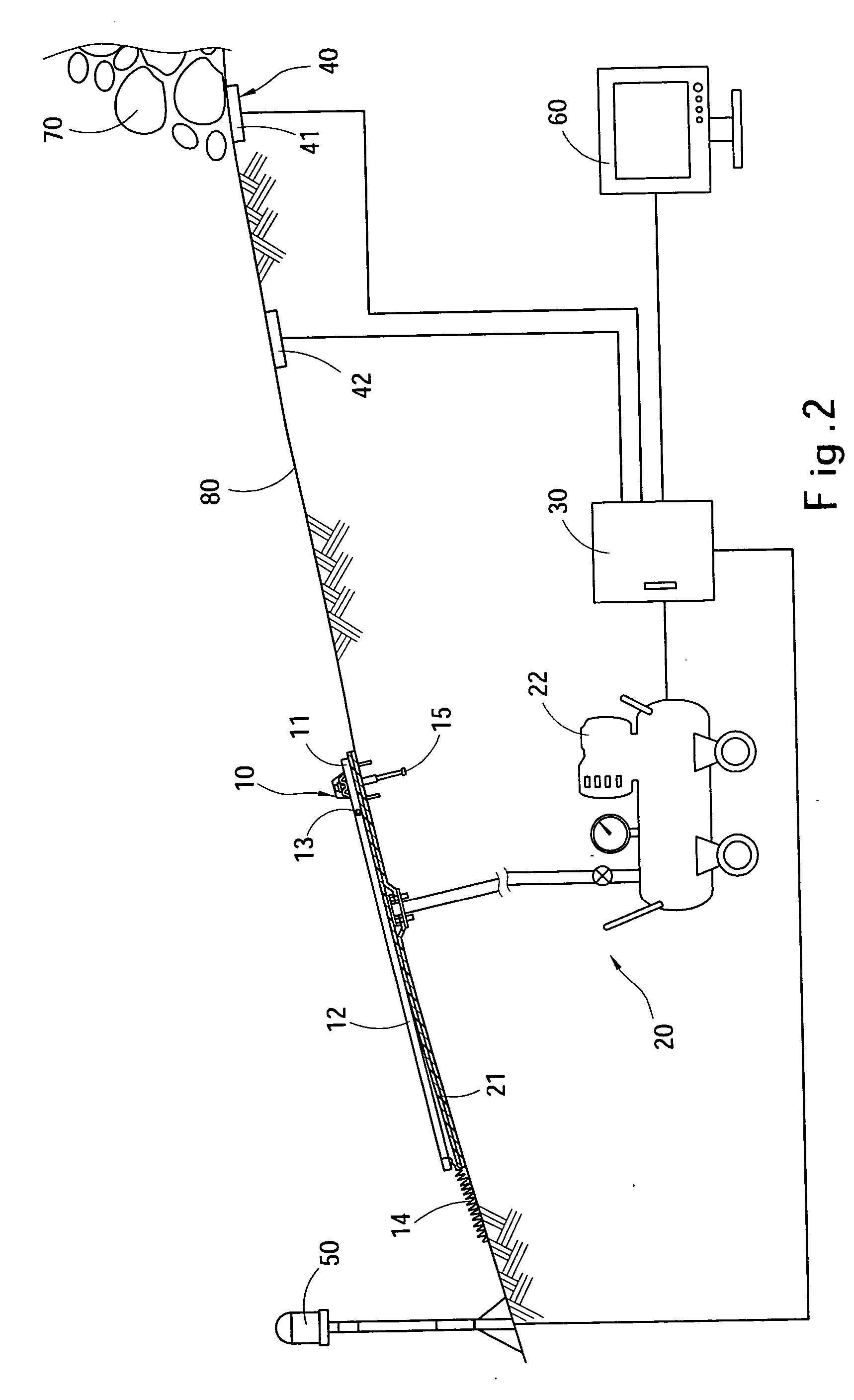

Impact test apparatus and impact test method

InactiveUS20060005606A1Acceleration measurementMaterial strength using single impulsive forceOutput deviceEngineering

An impact test apparatus includes a holding device for holding a test piece at an arbitrary holding force, an impact applying device for applying an impact force to the test piece held by the holding device, a force sensor for sensing the impact force applied to the test piece by the impact applying device, a high-speed camera for detecting a displacement of the test piece when applied with the impact force by the impact applying device, and an output device for synchronizing a signal from the force sensor with a signal from the high-speed camera and outputting an impact stress-strain characteristic curve when the impact force is applied to the test piece.

Owner:NITTO DENKO CORP

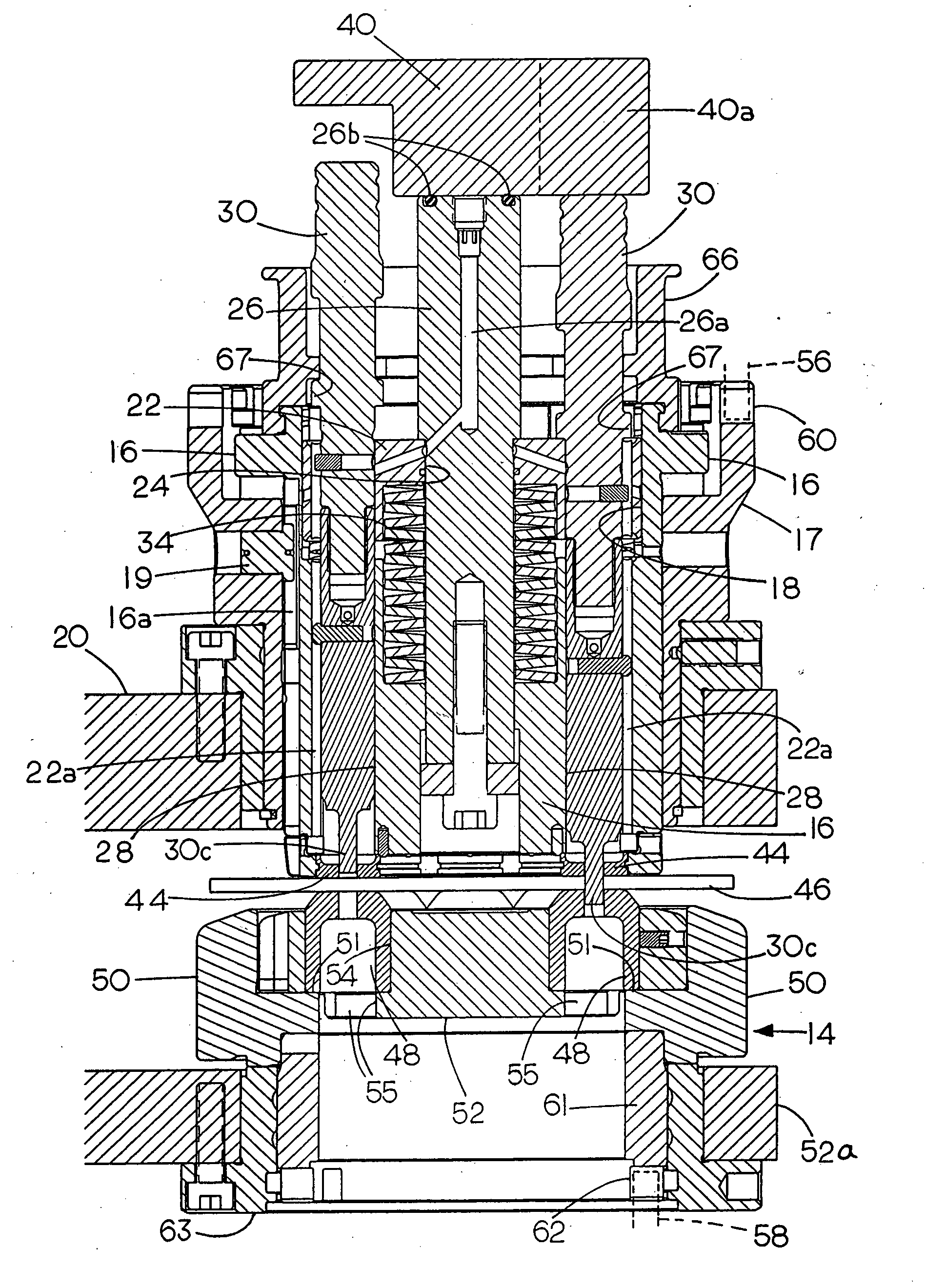

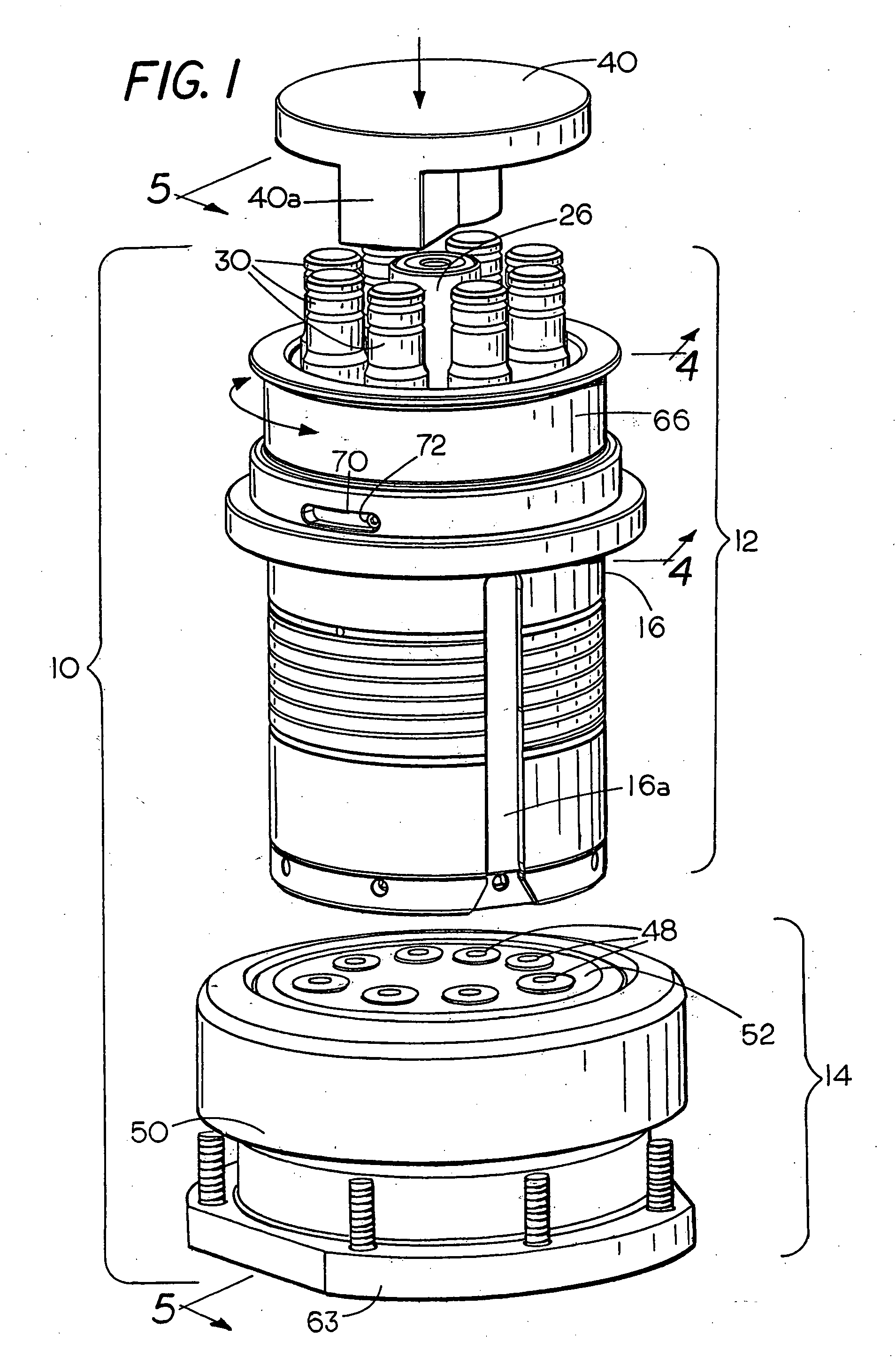

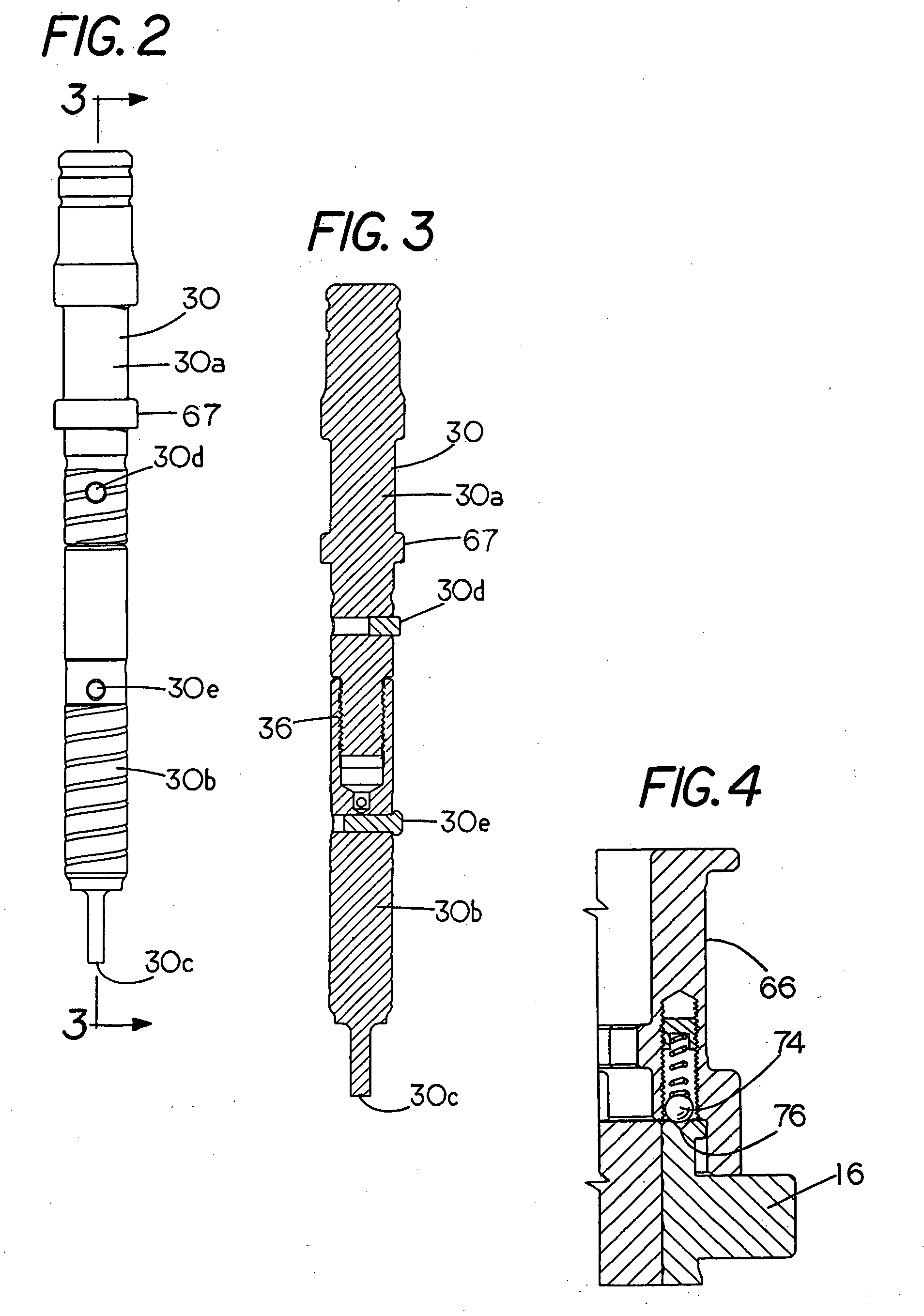

Multiple punch and die assembly providing hand disassembly, punch length adjustment and replacement

ActiveUS7726554B2Eliminate scoring and marking of sheet materialReduce impact stressDigitally marking record carriersPerforating toolsStress boneEngineering

A multiple punch and multiple die assembly has a workpiece protector which is a punch lifter that is operatively associated with each punch for supporting each of the punches in an inactive position as an active punch is moved by the ram to the active, i.e. operating position to thereby eliminate scoring or marking of the sheet material or other workpiece that is being punched. To eliminate the need for hand tools and hand assembly or disassembly, a manually moveable retainer on the punch assembly is provided that can be moved by hand between a punch-releasing and punch-retaining position for holding the punches within the multi-punch assembly during operation. To prevent stress fractures that formerly occurred in die carriers, support of each die is distributed between two different die components thereby reducing impact stress on the carrier as the ram drives the punch through the workpiece.

Owner:MATE PRECISION TOOLING

Impact test apparatus and impact test method

InactiveCN1719225AObtaining Impact Stress-Strain PropertiesMaterial strength using single impulsive forceEngineeringOutput device

The present invention provides an impact test apparatus including a holding device for holding a test piece at an arbitrary holding force, an impact applying device for applying an impact force to the test piece held by the holding device, a force sensor for sensing the impact force applied to the test piece by the impact applying device, a high-speed camera for detecting a displacement of the test piece when applied with the impact force by the impact applying device, and an output device for synchronizing a signal from the force sensor with a signal from the high-speed camera and outputting an impact stress-strain characteristic curve when the impact force is applied to the test piece.

Owner:NITTO DENKO CORP

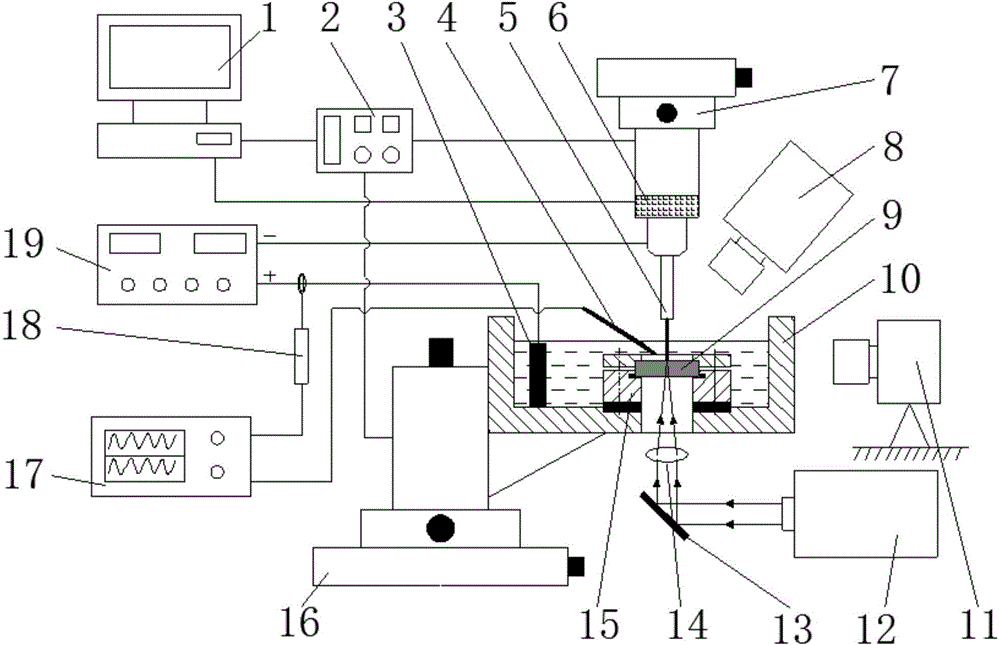

Device and method for machining materials by combining electrochemical discharging and laser

ActiveCN104942388AIncrease energy densitySpeed up erosionWelding/soldering/cutting articlesMetal working apparatusCavitationAuxiliary electrode

The invention provides a device and method for machining materials by combining electrochemical discharging and laser, and belongs to the field of non-traditional combined machining. Combined machining through electrochemical discharging and laser is carried out on transparent crisp and hard materials, an electrochemical discharging circuit is formed in an electrolyte solution through an auxiliary electrode and a tool electrode, a laser beam generates a focus on the surface of a sample, when energy reaches a certain value, impact stress and cavitation stress are formed, laser energy and spark discharging cooperatively act on a workpiece from an upper direction and a lower direction, effective combination of two kinds of energy is guaranteed, the energy density of a machining area is improved, and the corrosion removing speed of the machined sample is increased.

Owner:JIANGSU UNIV

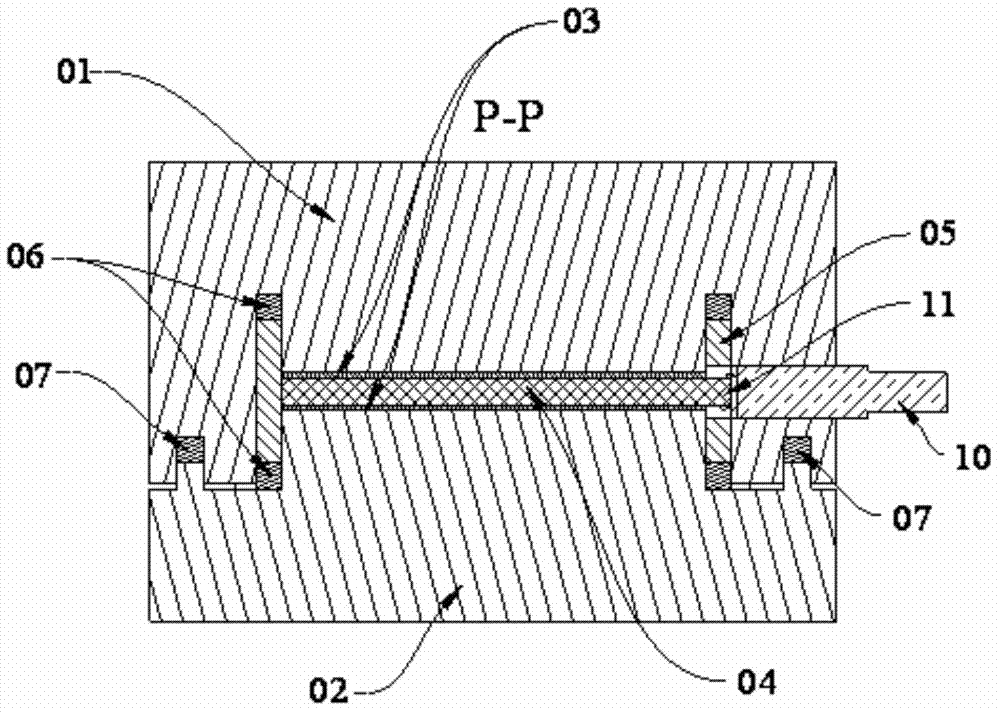

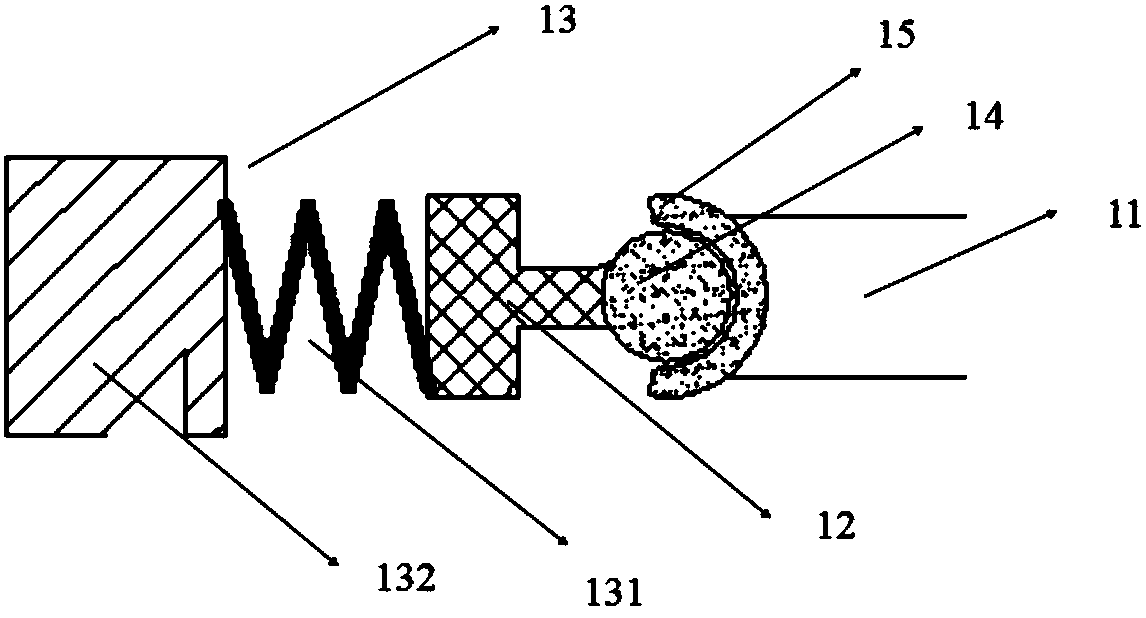

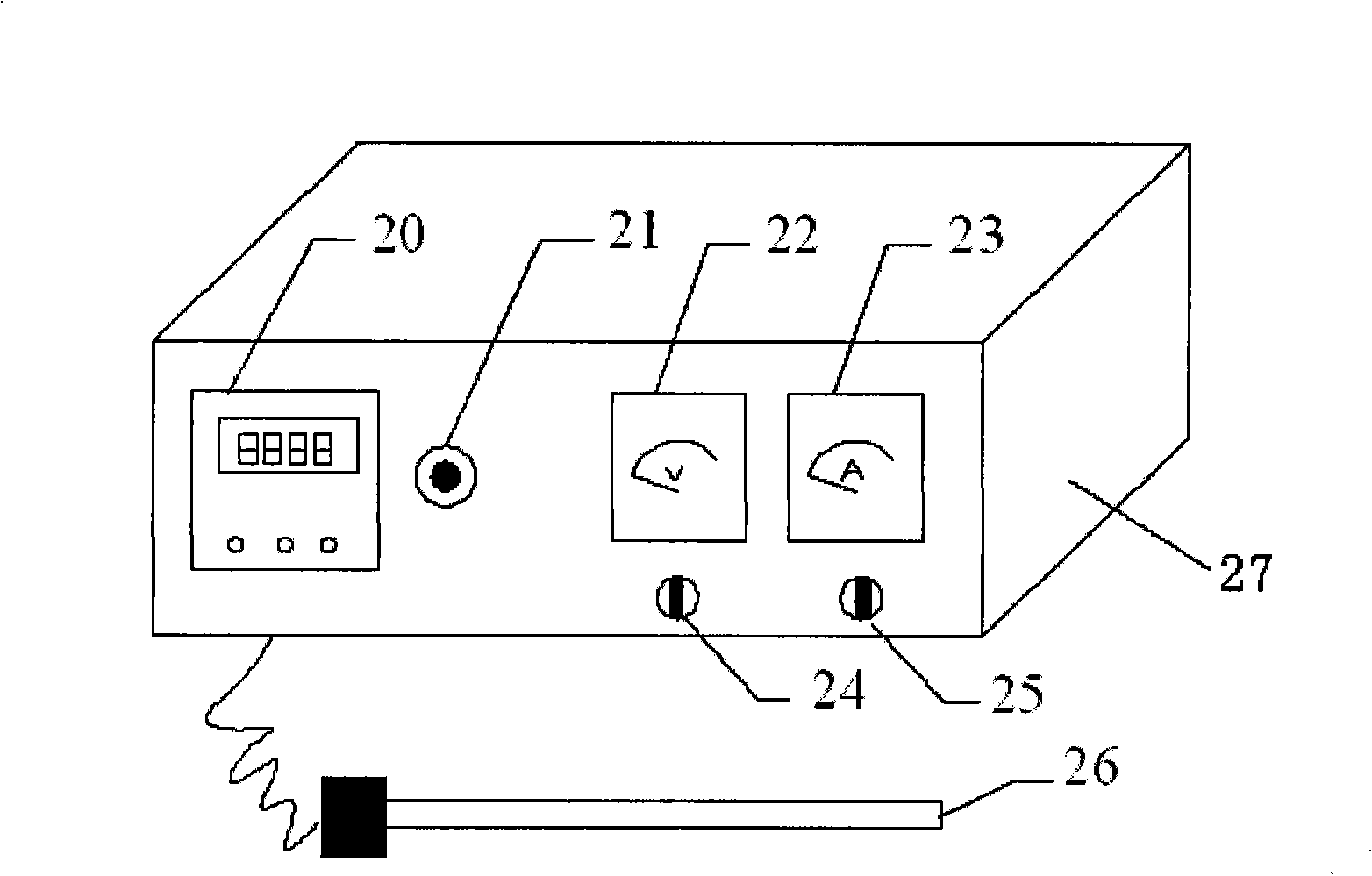

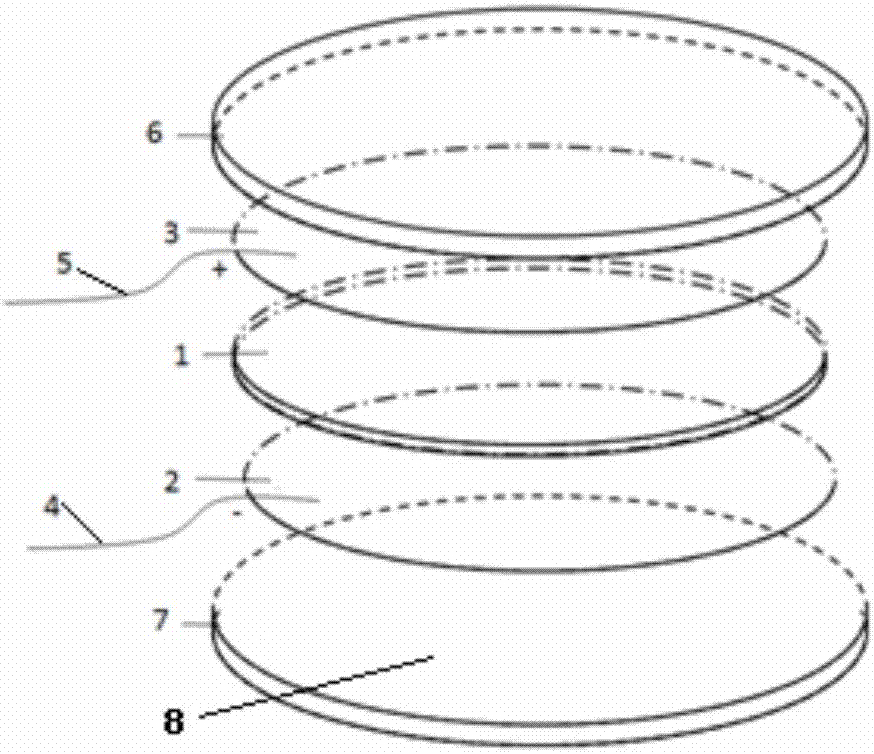

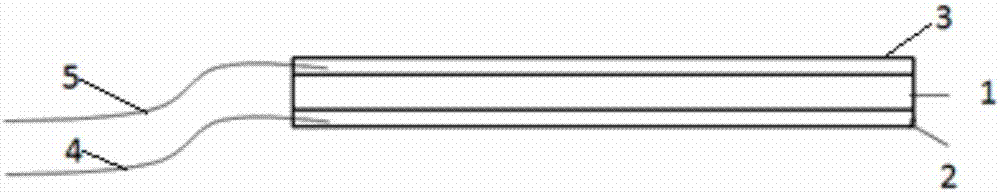

Concrete stress sensor by piezoelectric properties of PVDF (polyvinylidene fluoride) film

InactiveCN103674353AGood flexibilityHigh mechanical strengthForce measurement using piezo-electric devicesStrength propertiesPolyvinylidene difluorideEngineering

The invention discloses a concrete stress sensor by piezoelectric properties of a PVDF (polyvinylidene fluoride) film. The concrete stress sensor comprises an upper sensor shell, a lower sensor shell and the PVDF piezoelectric film, the upper sensor shell and the lower sensor shell are buckled together, the PVDF piezoelectric film is arranged between the upper sensor shell and the lower sensor shell, a nylon sleeve is sleeved on the periphery of the PVDF piezoelectric film, so that the PVDF piezoelectric film is positioned on a boss, insulating layers are respectively arranged on the upper end face and the lower end face of the PVDF piezoelectric film and closely contact with the upper sensor shell and the lower sensor shell, the nylon sleeve and the insulating layers form a sealed insulating space, so that a PVDF piezoelectric film and the sensor shells are separated in an insulating manner, and connection electrodes are respectively arranged on the upper surface and the lower surface of the PVDF piezoelectric film, so that piezoelectric signals are led to the outside of the sensor. The PVDF piezoelectric film is clamped between the two metal shells, a load is transmitted to the PVDF film by the aid of the sensor metal shells, the concrete stress sensor is sensitive in sensing, simple in structure, convenient to package and small in size, and can be embedded into concrete materials to finish an impact stress test.

Owner:CENT SOUTH UNIV

Multiple punch and die assembly providing hand disassembly, punch length adjustment and replacement

ActiveUS20080092711A1Avoid damageEliminate scoring and marking of sheet materialDigitally marking record carriersPerforating toolsStress boneRAM drive

A multiple punch and multiple die assembly has a workpiece protector comprising a punch lifter that is operatively associated with each punch for supporting each of the punches in an inactive position as an active punch is moved by the ram to the active, i.e. operating position to thereby eliminate scoring or marking of the sheet material or other workpiece that is being punched. To eliminate the need for hand tools and hand assembly or disassembly, a manually moveable retainer on the punch assembly is provided that can be moved by hand between a punch-releasing and punch-retaining position for holding the punches within the multi-punch assembly during operation. To prevent stress fractures that formerly occurred in die carriers, support of each die is distributed between two different die components thereby reducing impact stress on the carrier as the ram drives the punch through the workpiece.

Owner:MATE PRECISION TOOLING

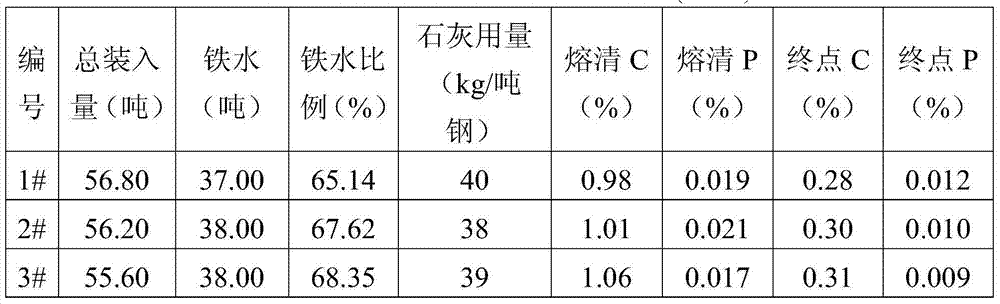

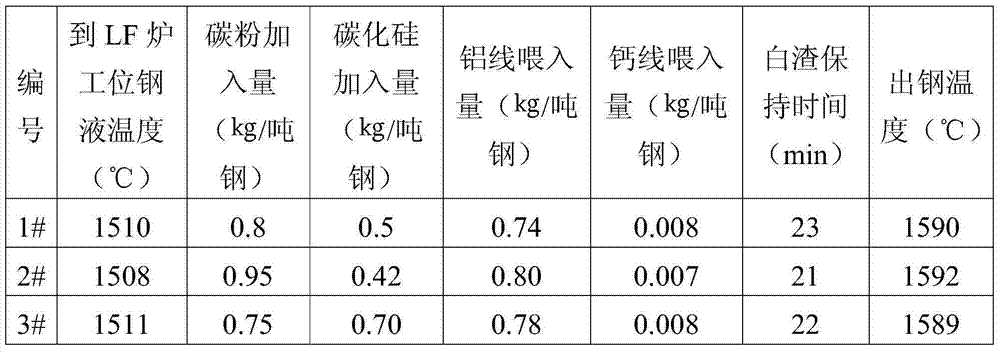

Steel for nitrogen vanadium microalloyed grinding rod and preparation method thereof

The invention discloses a steel for a nitrogen vanadium microalloyed grinding rod and a preparation method of the steel. The steel for the nitrogen vanadium microalloyed grinding rod comprises the following chemical components by weight percent: 0.65-0.72% of C, 0.20-0.30% of Si, 1.10-1.50% of Mn, less than 0.025% of P, less than 0.015% of S, 0.10-0.20% of Cr, 0.04-0.10% of V, 0.015-0.040% of Alt, less than 1.5*10<-4>% of H, 100*10<-4>-140*10<-4>% of N, less than 15*10<-4>% of T. O and the balance of Fe and unavoidable impurities. The preparation method of the nitrogen vanadium microalloyed grinding rod comprises the steps of carrying out primary smelting by an electric furnace, refining by a ladle refining furnace (LF), carrying out vacuum degassing (VD), continuously casting, slowly cooling a casting blank, rolling and finishing. The steel for the nitrogen vanadium microalloyed grinding rod is low in production cost, compact and even in structure, high in cleanliness, fine and small in crystal particles, and has the characteristics of high strength and toughness, wear resistance and the like; the requirement on the performances of the steel for the grinding rod under the low impact stress working condition can be met.

Owner:LAIWU IRON & STEEL GRP

Buffering structure, falling protection device, falling protection control method and mobile terminal

ActiveCN107566586AImprove protectionSolve problems such as damageTravelling carriersHoldersGround contactStress concentration

The invention provides a buffering structure. The structure comprises a connecting rod, a balancing weight and a buffering component, wherein the balancing weight is rotationally connected with the connecting rod; and the buffering component is connected with the balancing weight. The balancing weight automatically rotates according to a falling direction when an object to be protected is in a falling state, the buffering component can be come into contact with the ground vertically when falling in any direction, and instantaneous impact stress on the object to be protected is reduced under the action of the buffering component at a ground contacting moment, so that the aim of protecting the object to be protected is fulfilled, and the phenomenon of stress concentration is avoided.

Owner:BOE TECH GRP CO LTD +1

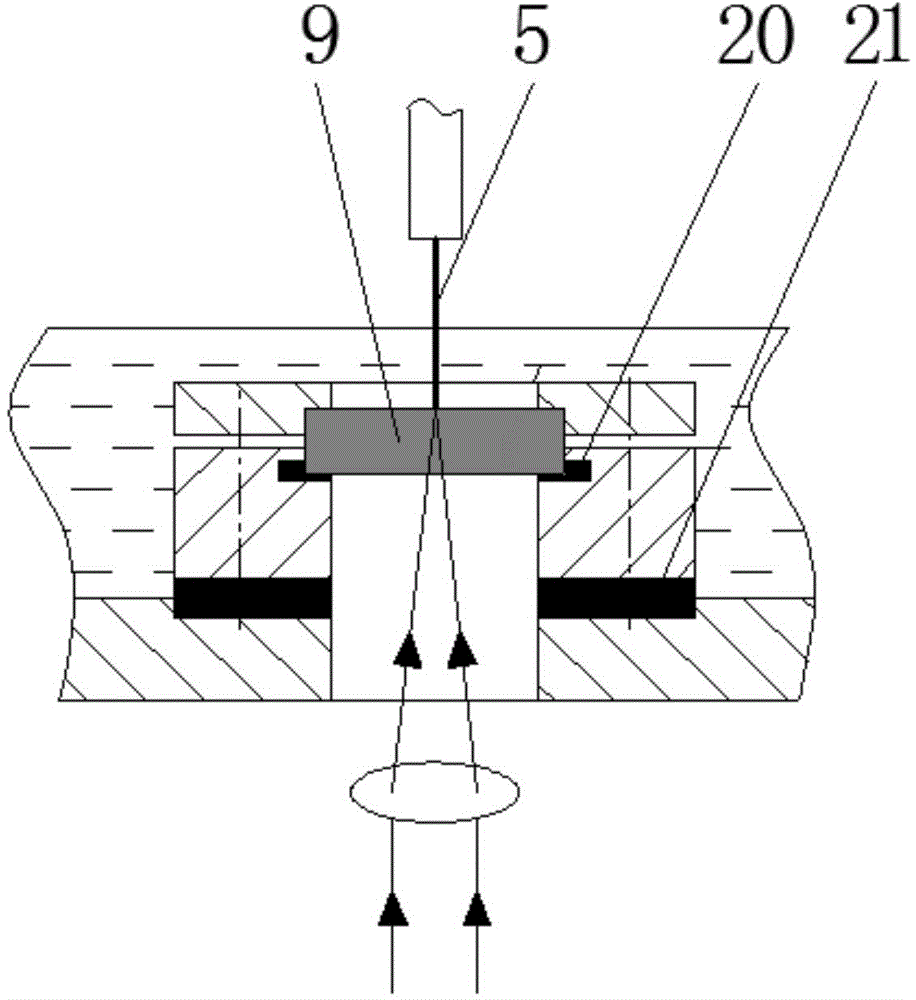

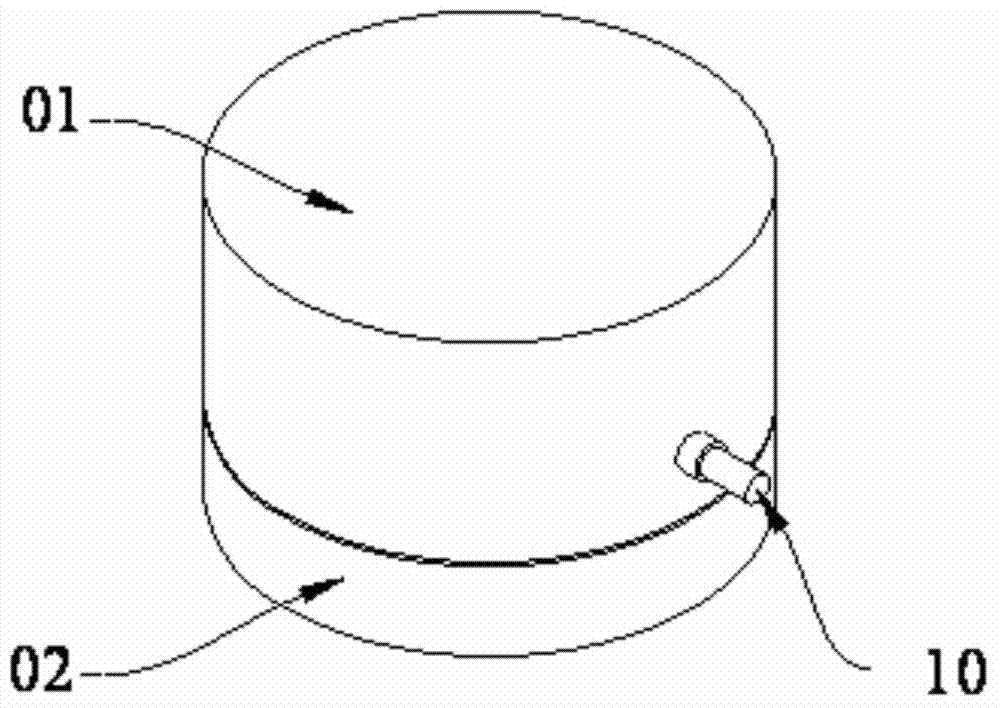

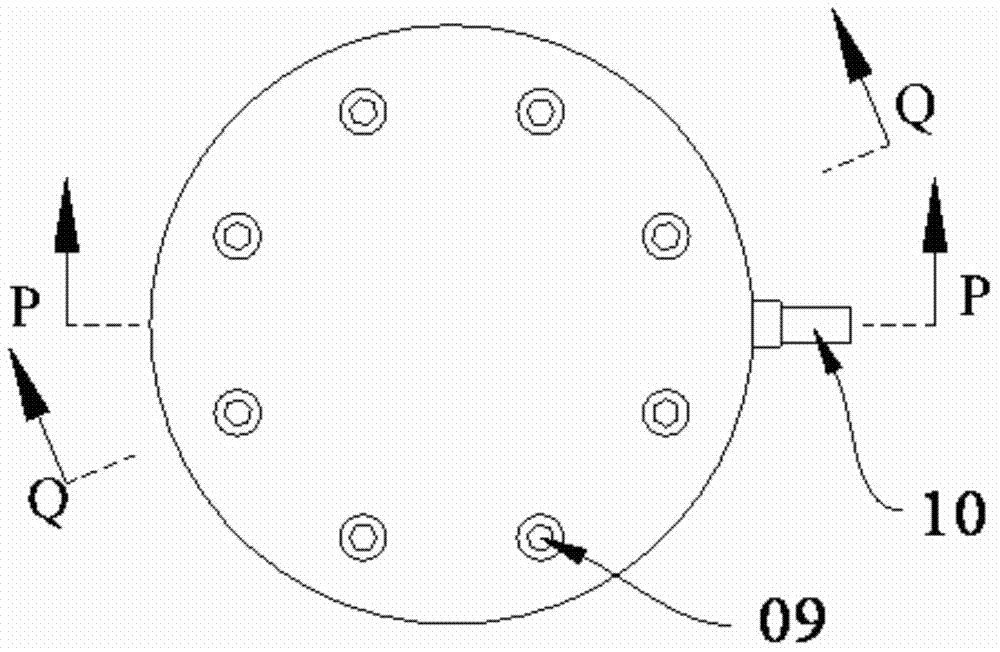

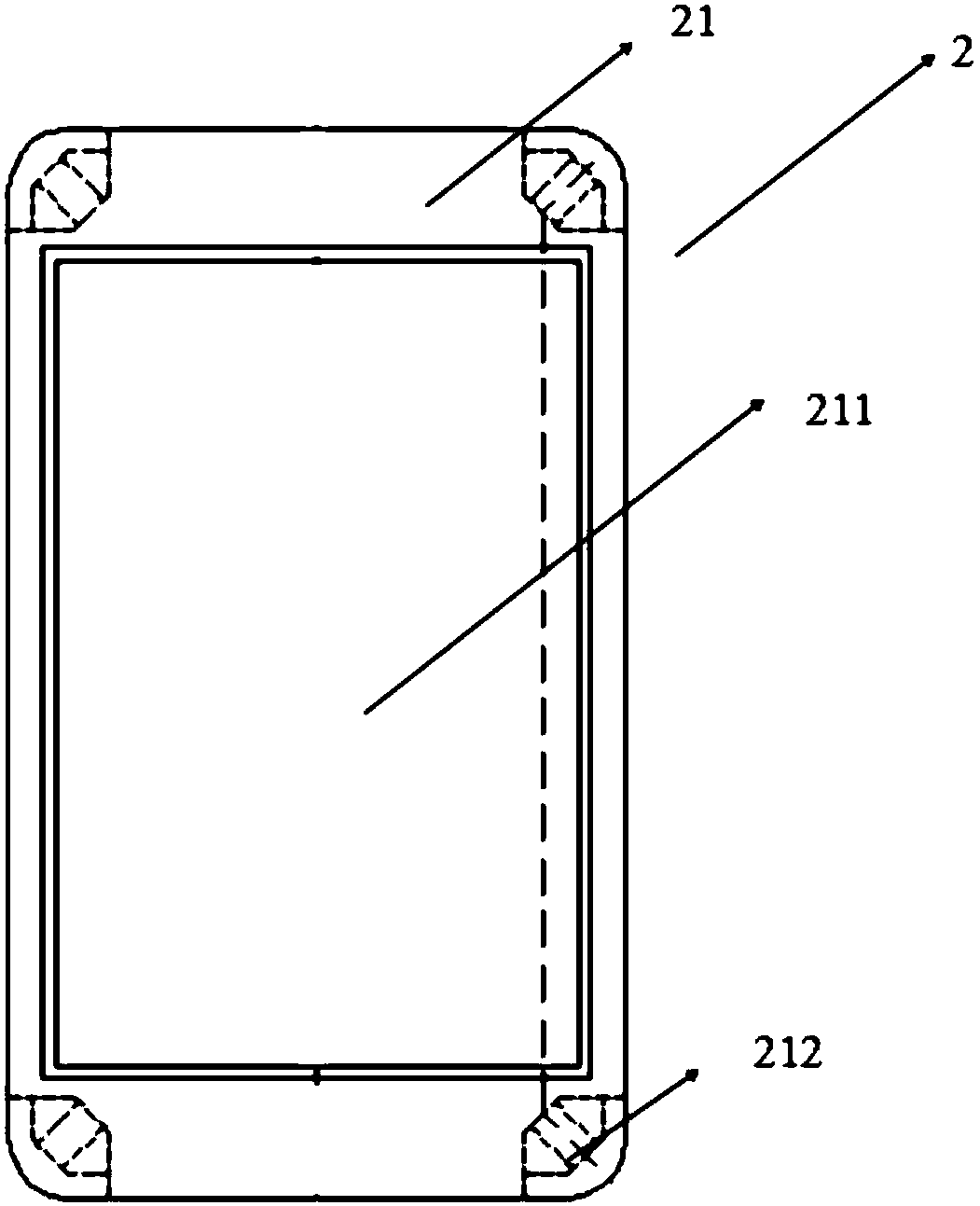

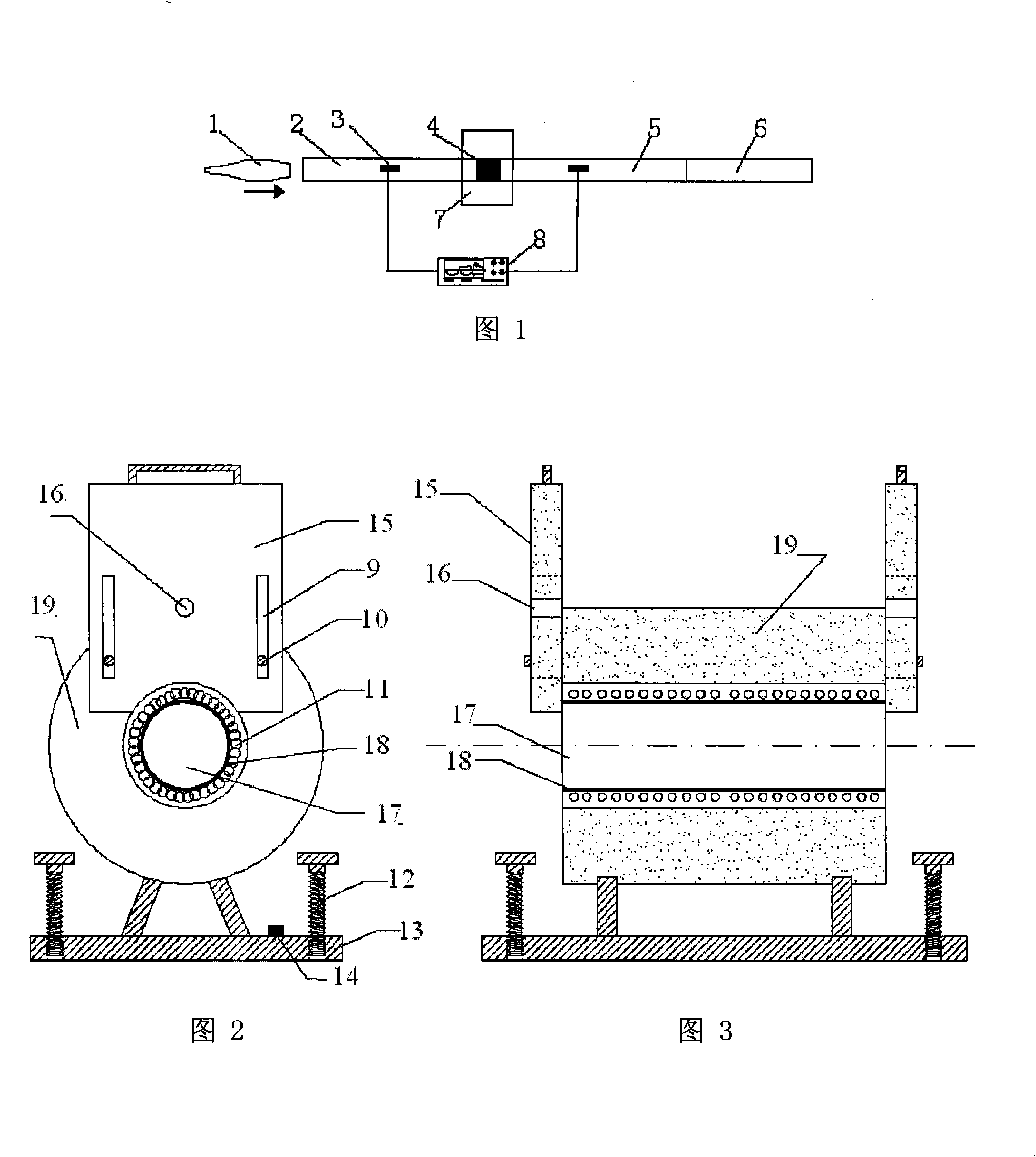

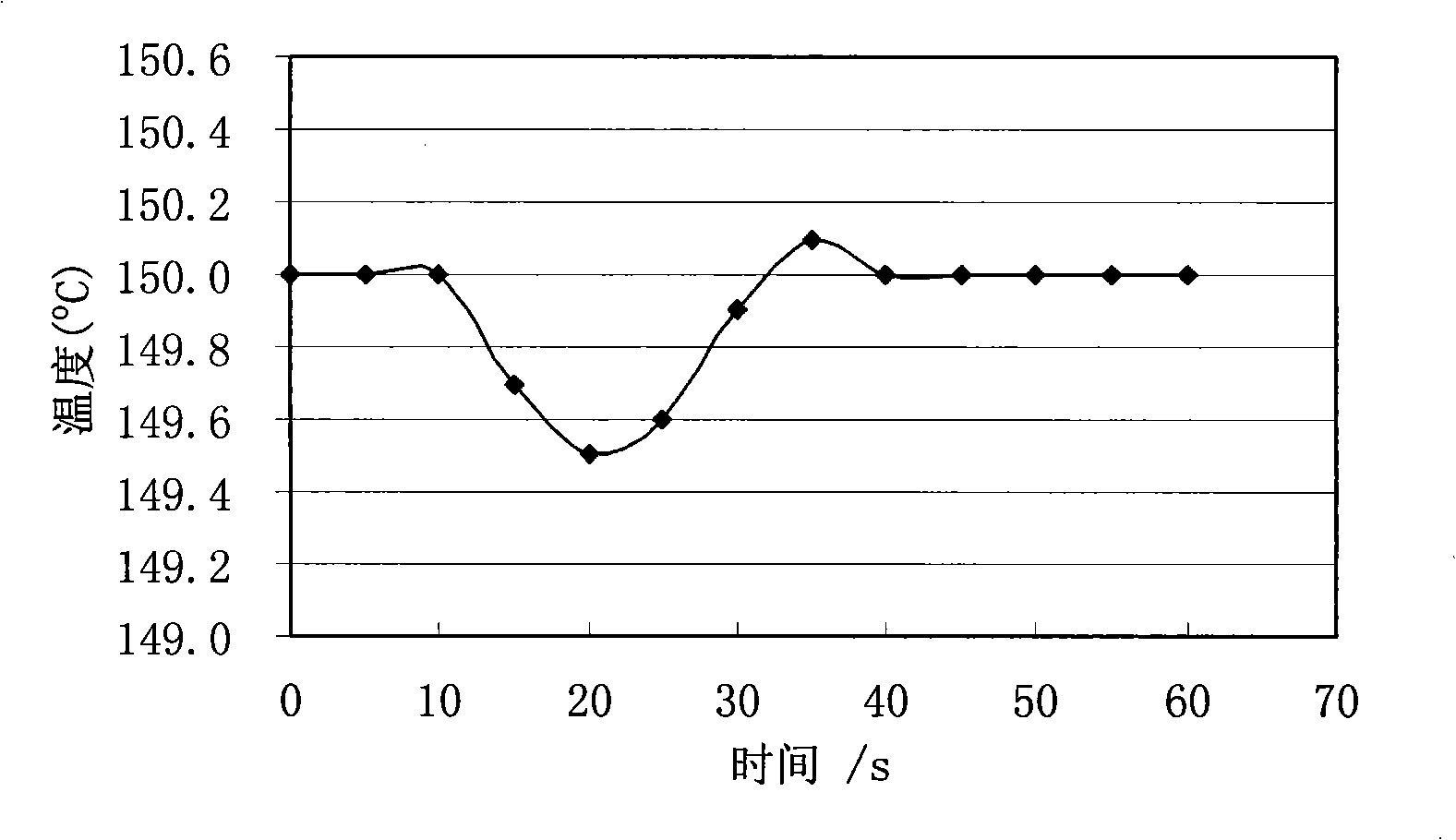

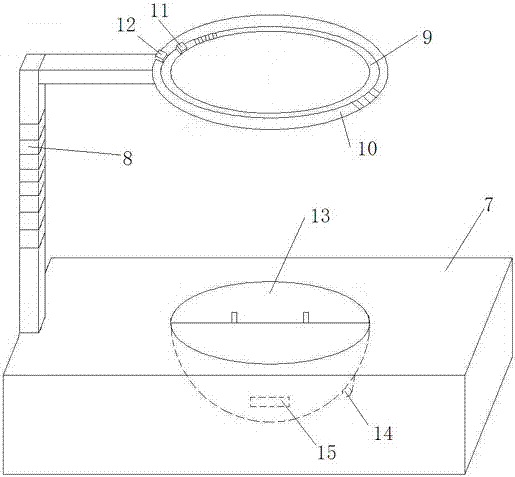

Sample heating apparatus used for rock impact experiment

ActiveCN101403665AEasy accessImprove impact resistancePreparing sample for investigationMaterial strength using single impulsive forceFiberElectrical resistance and conductance

The invention provides a sample heating apparatus used for a rock impact experiments as rock SHB and combined static-dynamic load and the like. and belongs to the rock mechanics study field. The apparatus comprises an adjusting slideway (9), a locating bolt (10), a resistance wire (11), leveling bolts (12), a bracket (13), a power-supply switch (14), an adjustable insulation bin-door (15), a thermocouple access hole (16), a heating cavity (17), a carbon-fiber reinforced alloy cylinder (18) and an insulation bin (19). The invention adopts the anti-impact and anti-high-temperature carbon-fiber reinforced alloy cylinder, the adjustable insulation bin-door and four leveling bolts at the seat of the apparatus to realize the synchronous processes of preserving the constant high temperature and the loading of impact stress wave during the rock impact experiment. The invention provides a special experimental apparatus for the further rock mechanics study.

Owner:CENT SOUTH UNIV

Heat-treated pressurized plastic containers

ActiveUS20050060953A1Reduce resistanceImprove impact resistanceCapsDecorative coversMechanical engineeringImpact stress

The present invention provides a heat-treated plastic pressurized container that is resistant to polar liquids and impact stresses and the process for making such container.

Owner:THE PROCTER & GAMBLE COMPANY

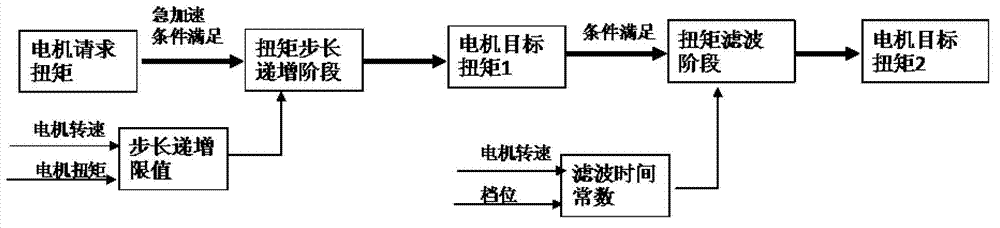

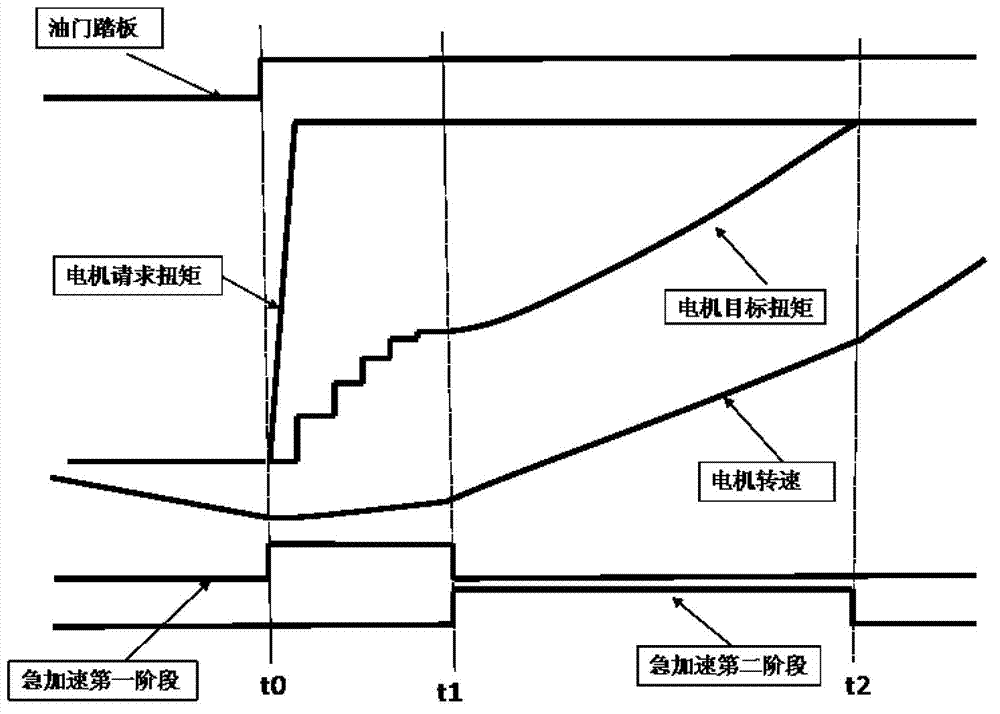

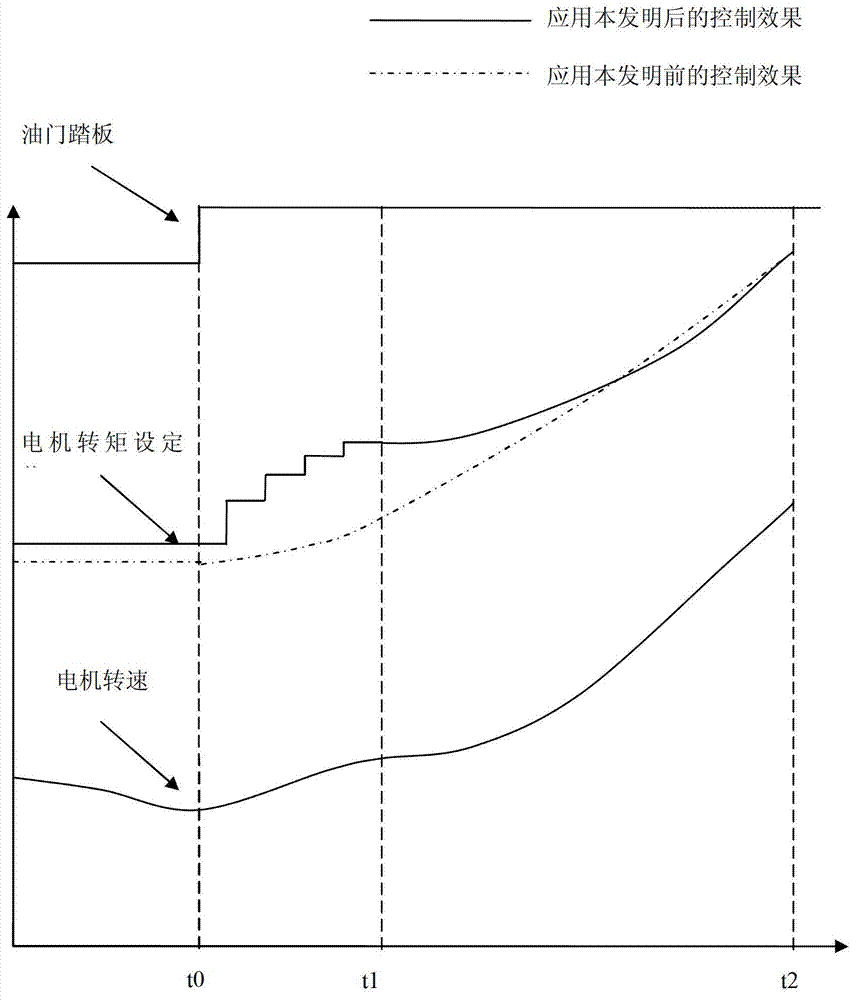

Control method for filtering sudden acceleration torque of pure electric automobile

InactiveCN102887080AReduce shockImprove control effectSpeed controllerElectric machineryMotor torque

The invention relates to a control method for filtering a sudden acceleration torque of a pure electric automobile, which comprises the following steps that: 1) after meeting a predetermined sudden acceleration condition, a motor requires that the torque is changed from an initial value before sudden acceleration to a first step torque target value; 2) when the target torque of the motor is close to a limited value of the first step torque target value, the first step control is finished, and the motor requires that the torque is changed from the first step torque target value to a second step torque target value; and 3) the target torque of the motor is gradually close to the second step torque target value by setting and adjusting the filter time of filter function. The invention has the beneficial effects that the sudden acceleration system of the pure electric automobile controlled by the method can effectively avoid fast motor torque changes caused in the sudden acceleration of the automobile and motor torque changes when the motor torque is close to zero torque, thereby reducing the impact stressed by the automobile and improving the driving comfort.

Owner:BEIJING ZHIXING HONGYUAN AUTOMOBILE CO LTD

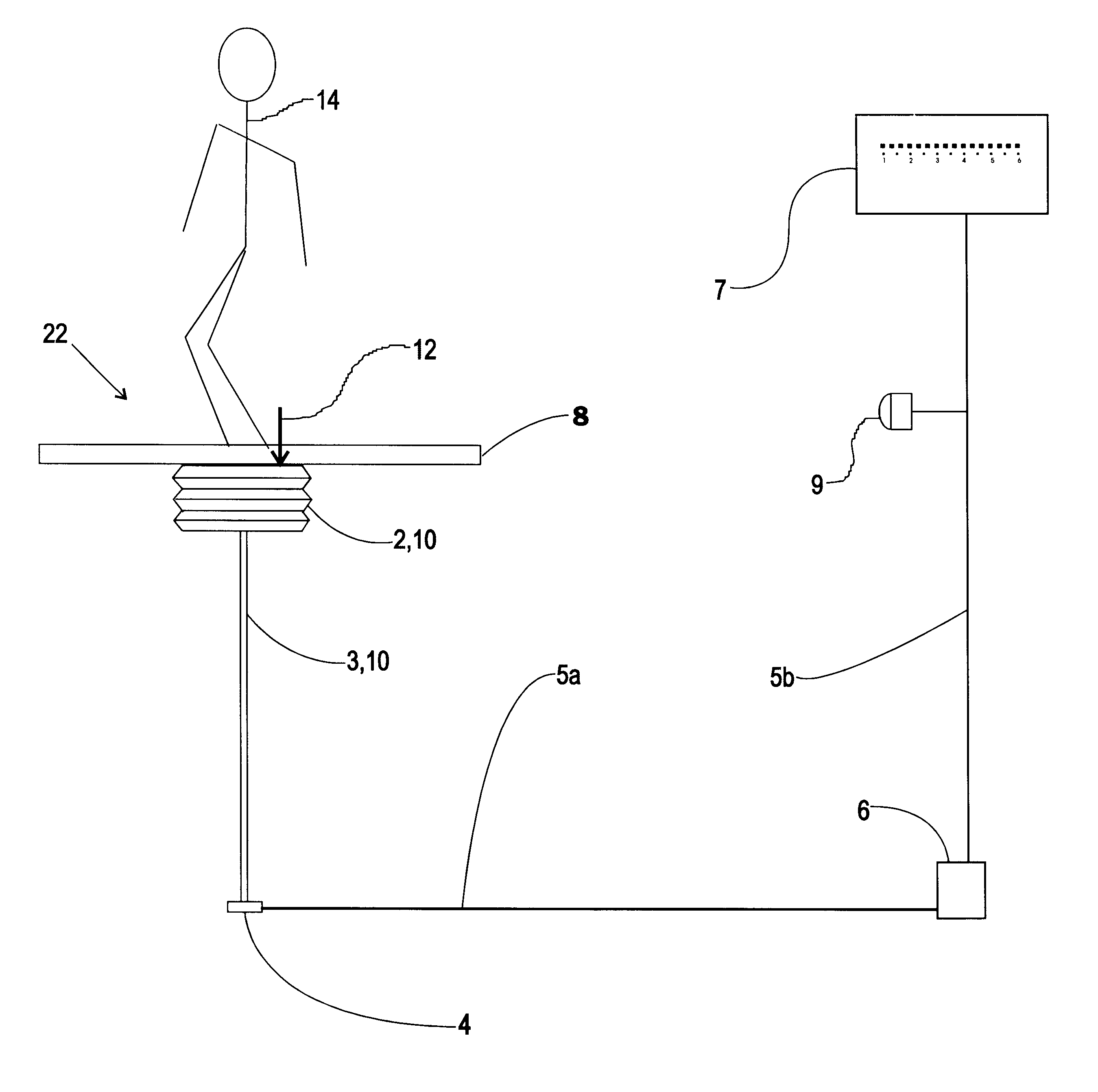

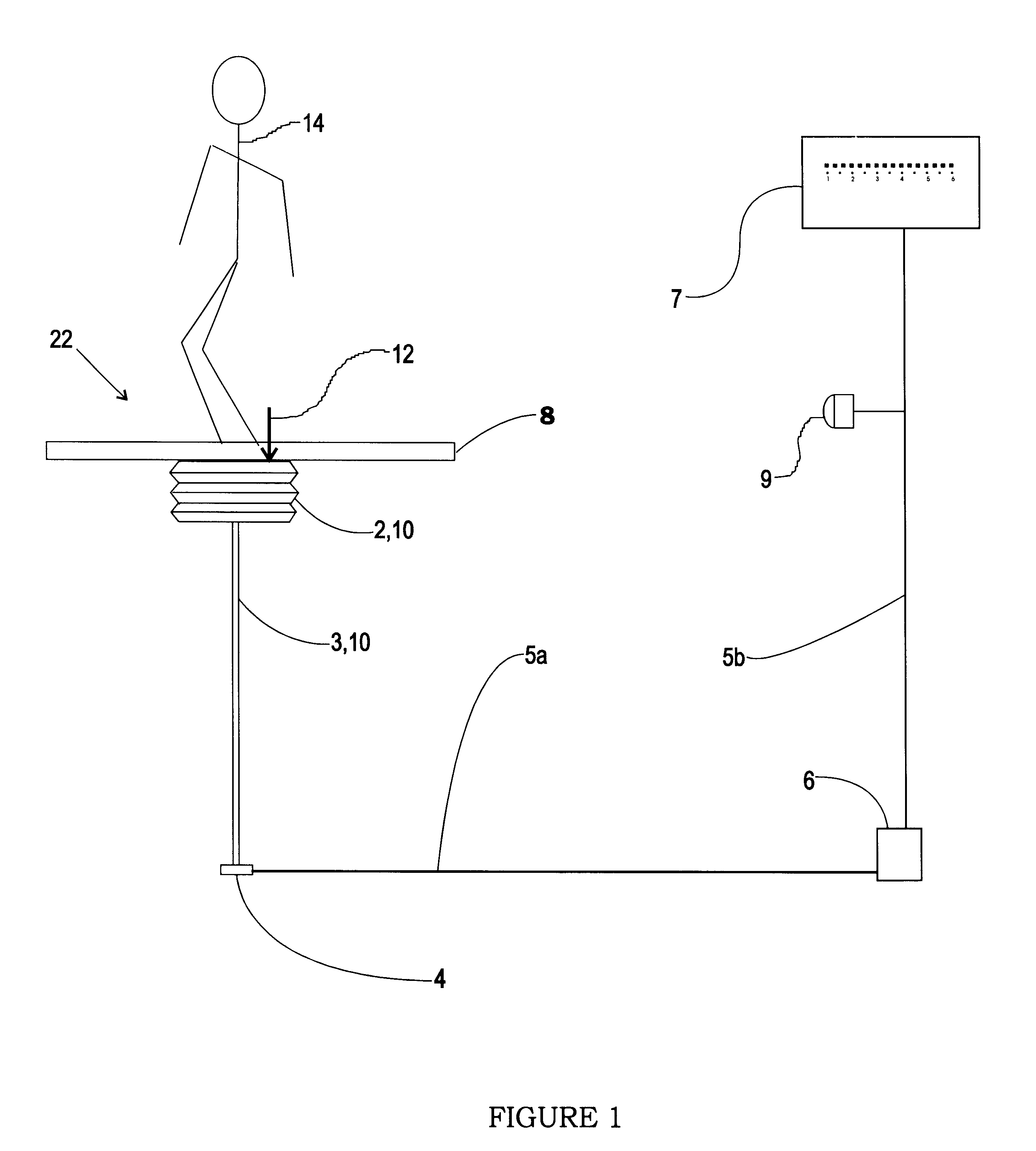

System of impact measurement and display

InactiveUS6533706B2Sure easySimple and accurate and inexpensiveClubsRace-coursesSimulationClassical mechanics

A system of monitoring impact stress, or acceleration forces on a user while exercising is disclosed. An exercise machine is equipped with sensing apparatus that measures the downward force exerted on the supporting surface by the lower extremities of the user. In this way, the corresponding impact forces are determined as a function of the user's body weight and communicated via a display monitor as "G-forces" or "Earth Gravity Units." This allows the user to keep exercise impact within limits desired by the user, a physical therapist, or other qualified professional.

Owner:PLYO SYST

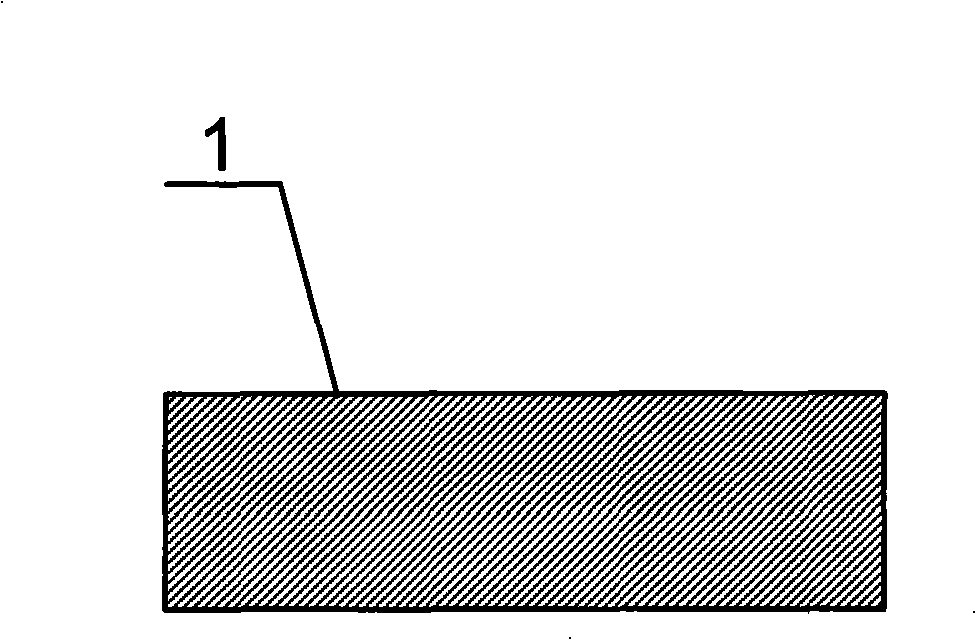

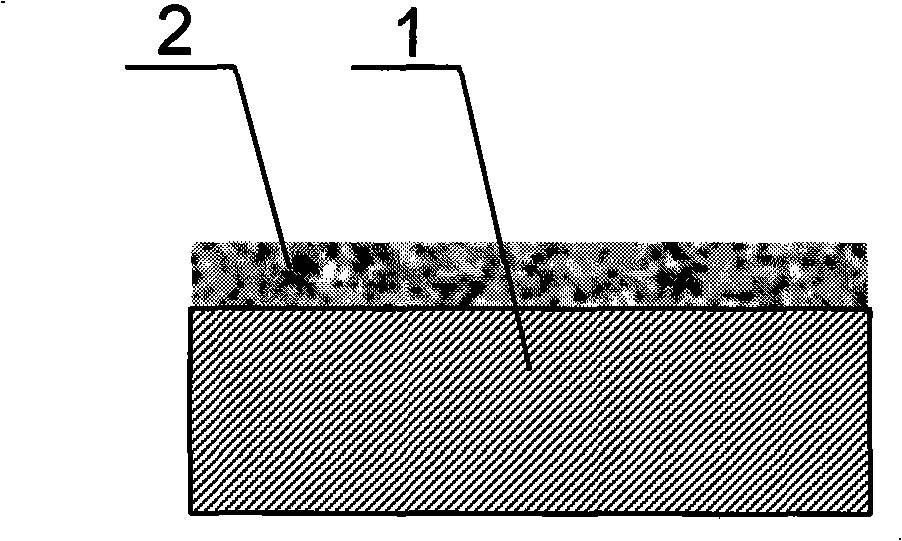

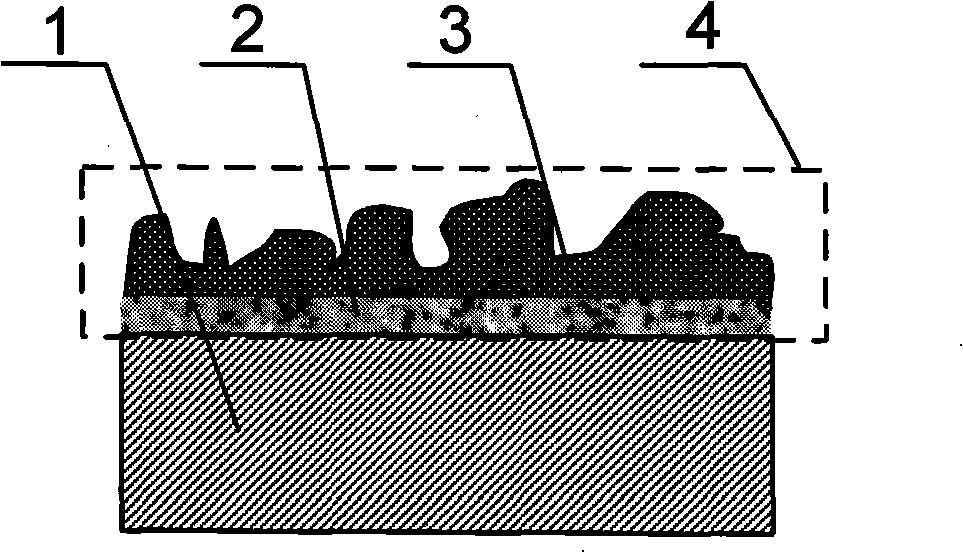

Method for increasing light alloy micro-arc oxidation coat endurance life

InactiveCN101260556AImprove fatigue lifeInhibition of germinationAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a method for improving the fatigue life of a light alloy micro-arc oxide coating. The invention relates to the metal surface modification technical field and solves the problem in the prior micro-arc oxidation technology that the abrasion resistant performance and the corrosion resistant performance of a matrix are improved and simultaneously the fatigue life of alloys after micro-arc oxidation is obviously reduced. The invention comprises the following steps: firstly, the metal surface of light alloys is grinded, polished and cleaned; secondly, nano crystallization of the surface is performed so as to form a nano crystal layer with the thickness of 10 to 20 micrometers; thirdly, light alloys after nano crystallization of the surface are arranged inside a stainless steel bath body which is provided with alkaline electrolytes, and a composite coating of the nano crystal layer and a micro-arc oxide layer is formed on the metal surface of the light alloys with the thickness of 10 to 20 micrometers through control of micro-arc oxidation electrical parameters. The method obviously improves the fatigue life of the alloys after micro-arc oxidation processing and can expand the application range of the light alloy micro-arc oxide coating under severe conditions of alternation or impact stress and so on.

Owner:HARBIN INST OF TECH

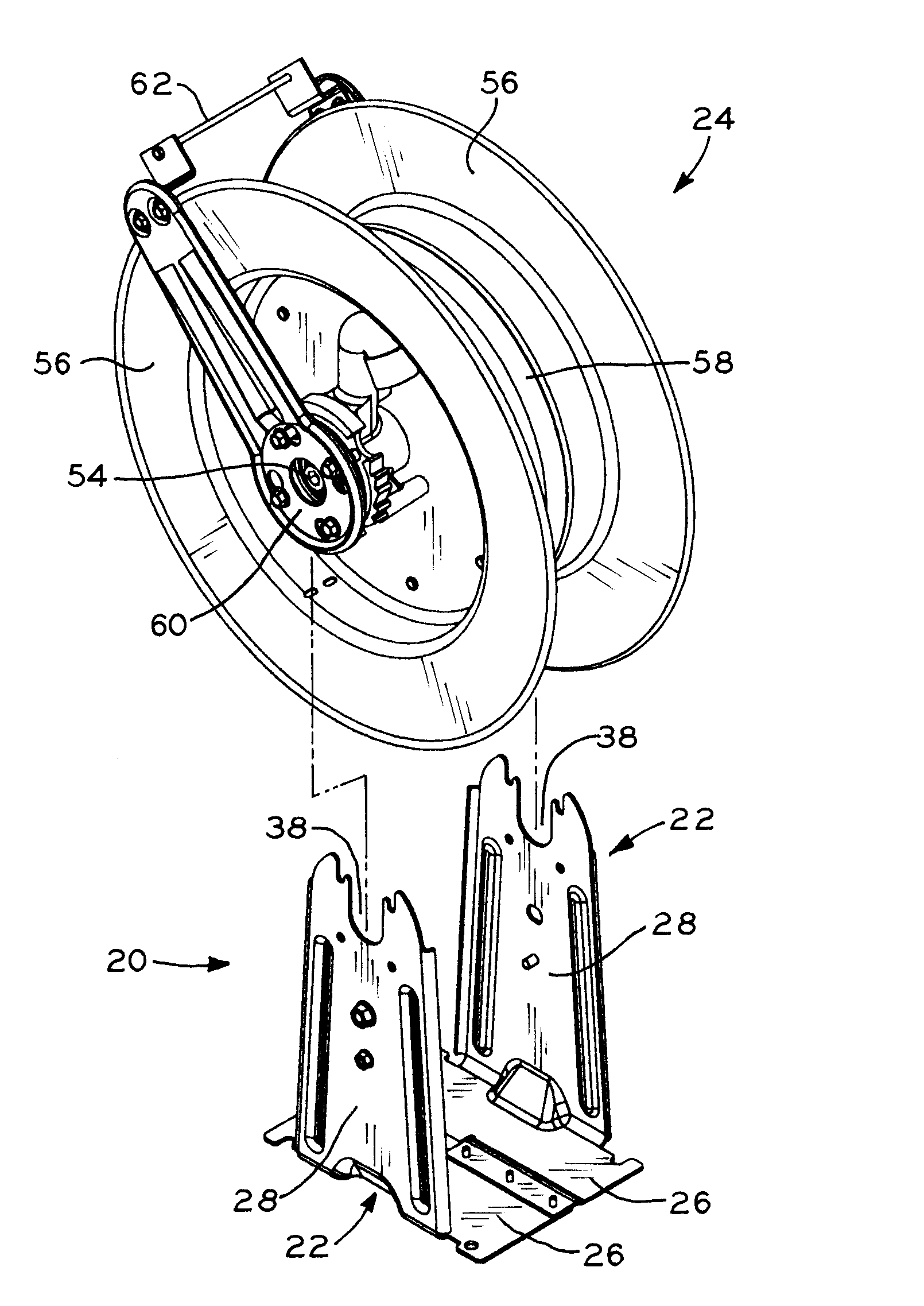

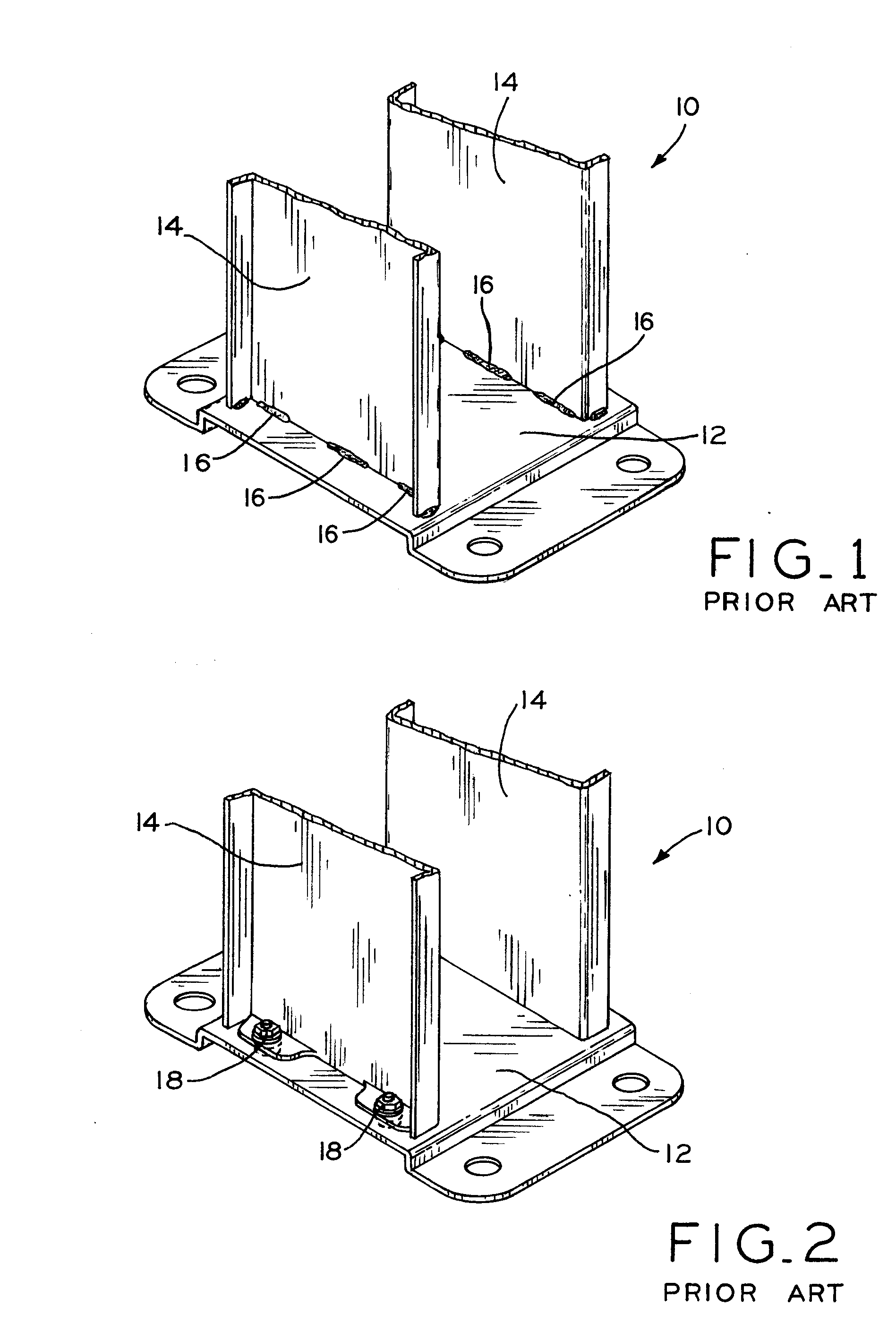

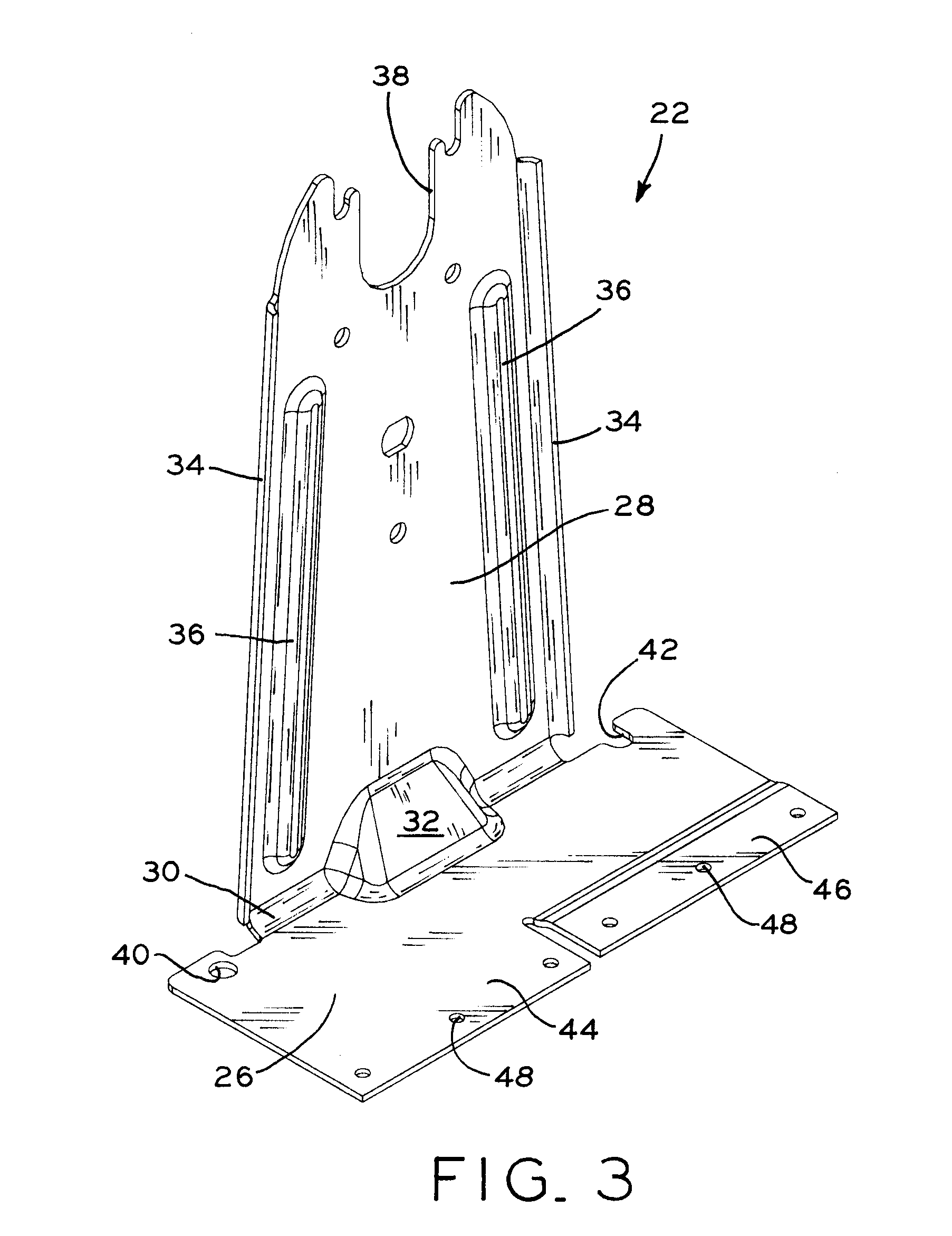

Reel base assembly

A base assembly for a reel, such as a hose reel, including two cooperating base components joined to one another and supporting a spool assembly. The base components may be identical to one another, and each include a base portion and an upright portion disposed 90° with respect to one another and formed monolithically from a single piece of material such as steel. The base components further include rigidifying structures such as gussets, edge bends, and reinforcement ribs or channels to rigidify the base components against vibration and impact stresses. Each of the base portions includes a connection plate and an offset connection flange, wherein the connection flanges overlap and are secured to respective connection plates when the upright components are mated and secured to one another with one upright component disposed at an orientation rotated 180° with respect to the other. The base assembly may be attached to a surface, such as a floor, wall, or other surface via suitable fasteners, and the connections between the upright components are substantially isolated from vibration and impact stresses imposed upon on the base assembly. In one exemplary embodiment, the connection between base components may be varied to provide modularity to the base assembly. In this embodiment, the base assembly may be configured to support spool assemblies of various dimensions.

Owner:REELCRAFT INDS

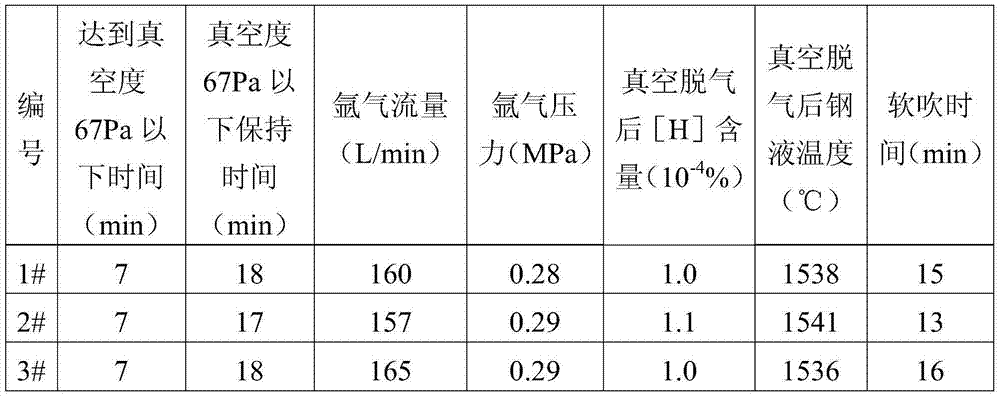

Laser real-time dynamic cladding repair and stress control system and method of damaged gears

ActiveCN107150175ACladding achievedTo achieve reinforcementMetal working apparatusLaser beam welding apparatusImpact systemControl system

The invention discloses a laser real-time dynamic cladding repair and stress control system of damaged gears. The system comprises an optical-infrared coupled dynamic monitoring and measuring system, a laser cladding system, a laser impact system and a clamping table respectively connected with a center control system; the cladding of cladding materials is realized through the heat effect of cladding laser; and impact waves generated by impacting on laser radiated materials are acted on the material surface of a laser cladding layer to realize reinforcement of the laser cladding layer and to eliminate such defects as air holes and loose structures generated in the cladding layer in the laser cladding process. The repair method is suitable for such failure forms as gear fatigue cracks, pitting, gear breakage and gear surface wear, and quickly realizes the shape recovery of gears through laser cladding repair without wasting classing materials; and through laser impact stress control, the defects generated in the laser cladding process are eliminated, the mechanical performances of the repaired gears are guaranteed, subsequent complicated machining is not needed, the repair efficiency is improved, and the gear repair cost is reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Elastomeric paint with protective coating upon styrenic block copolymer articles

A solvent based elastomeric paint coating composition contains styrenic block copolymer, mineral oil, solvents, pigments, and additives. The paint coating composition dries to form a layer on a substrate. The paint layer has high elongation, tensile strength, and excellent shape retention after high velocity impact stress conditions. The elastomeric protective coating contains styrenic block copolymer, alkyl cyanoacrylate, mineral oil, solvents and additives. The protective coating composition dries to form a layer on the paint area. Beside the properties of protective layer have moderate elongation, tensile strength, the protective layer provides unexpectedly good scratch resistance on the paint coating area. The coating process can be applied by various methods including pad printing, screen printing, brushing, and spraying.

Owner:APEX MATERIALS CORP

PVDF piezoelectric film impact monitoring sensor

PendingCN107356359AWon't hurtNormal monitoring impact load stress valueApparatus for force/torque/work measurementEpoxyProtection layer

The invention discloses a PVDF piezoelectric film impact monitoring sensor which comprises a PVDF piezoelectric film, a positive electrode layer, a negative electrode layer, an upper protection layer and a lower protection layer. The upper surface and the lower surface of the PVDF piezoelectric film are covered with the positive electrode layer and the negative electrode layer respectively. By means of double-side pressure welding, a positive electrode wire and a negative electrode wire are connected with the positive electrode layer and the negative electrode layer; the positive electrode layer and the negative electrode layer are covered with insulating layers, a groove is formed in the surface of the lower protection layer, and the PVDF piezoelectric film covered with the positive electrode layer, the negative electrode layer and the insulating layers is placed in the groove of the lower protection layer; the upper protection layer and the lower protection layer are attached together through epoxy resin to form an empty cavity so as to seal and protect the PVDF piezoelectric film; the positive electrode wire and the negative electrode wire are led out of the cavity. The PVDF piezoelectric film impact monitoring sensor comprises a receiver which can be arranged in an impacted monitoring area to be used for directly receiving impact signals so as to obtain the impact stress value under the impact load effect.

Owner:SHENYANG JIANZHU UNIVERSITY

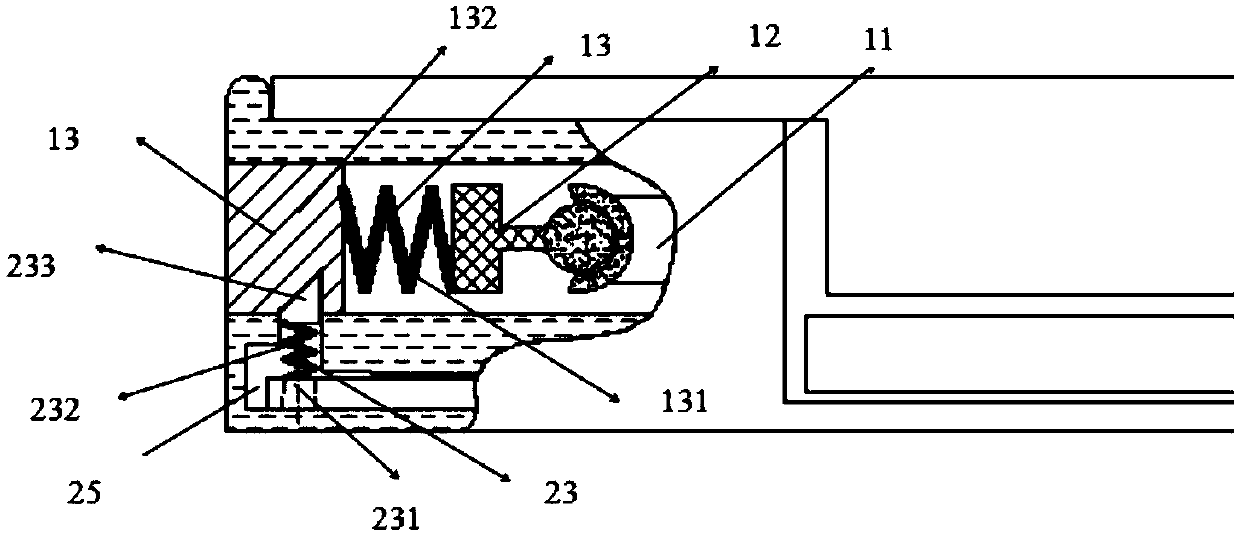

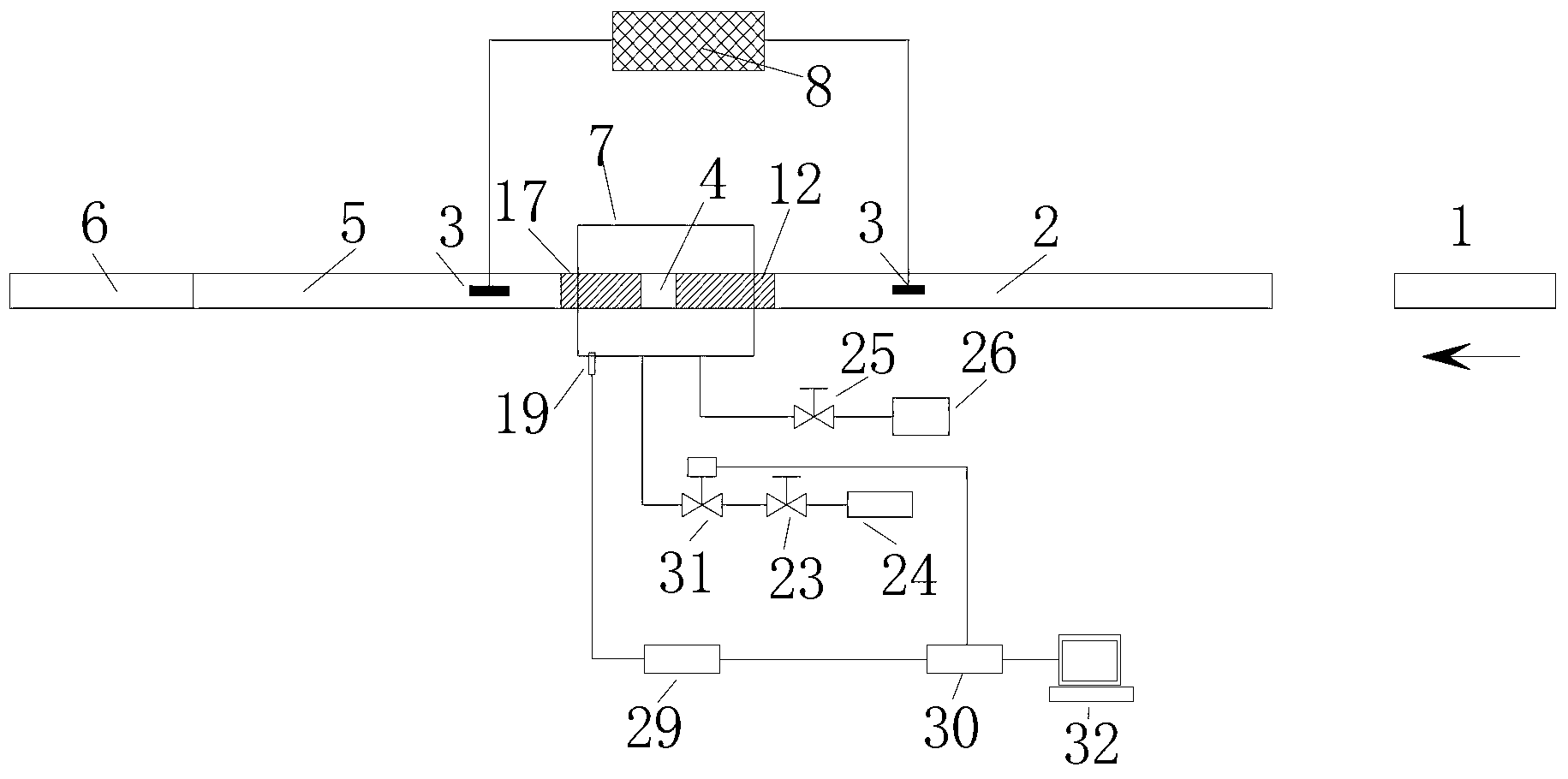

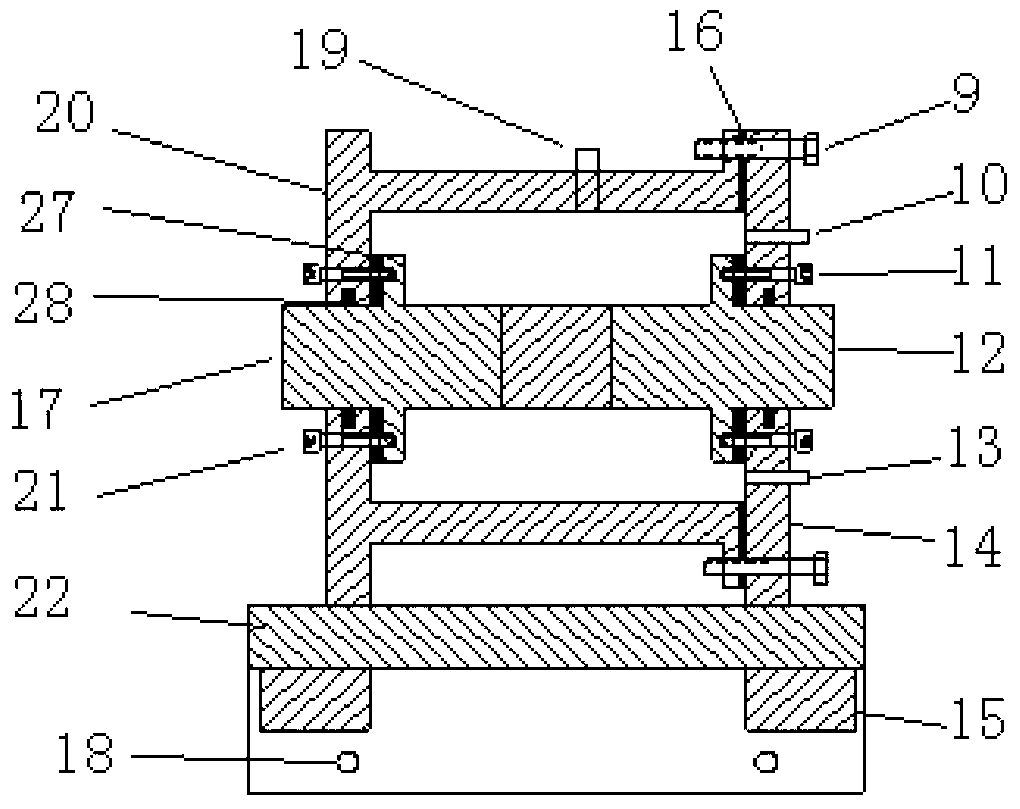

Gas sealing device and test method for coal rock impact test

ActiveCN103323328AKeep the position fixedResource securityMaterial strength using single impulsive forceAir pumpEngineering

The invention provides a test sample gas sealing device for a gas-enriched coal rock gas solid coupling state impact test so as to research the impact mechanical property of a gas-enriched gas coal rock. The device comprises a support, a gas sealing storehouse, a sealing storehouse cover, a transmission rod connecting end, an incident rod connecting end, a transmission rod, an incident rod, an O-shaped sealing ring, a YX-shaped sealing ring, an incident rod connecting end and storehouse cover fixing bolt, a transmission rod connecting end and sealing storehouse fixing bolt, a gas inlet hole, a gas outlet hole, an electromagnetic adjusting control valve, a gas inlet adjusting gas valve, a gas tank, a gas outlet gas valve, a gas suction pump, a high-frequency gas gas-pressure sensor, a super-dynamic gas pressure acquisition instrument, a gas pressure monitoring instrument, a computer, a balance adjusting bolt and a fixing bolt. By adoption of the device, the gas content of a test sample is constant in the impact stress wave loading process in the gas-enriched gas coal rock impact test process. A unique test device is provided for research on the mechanical property of the gas coal rock.

Owner:ANHUI UNIV OF SCI & TECH

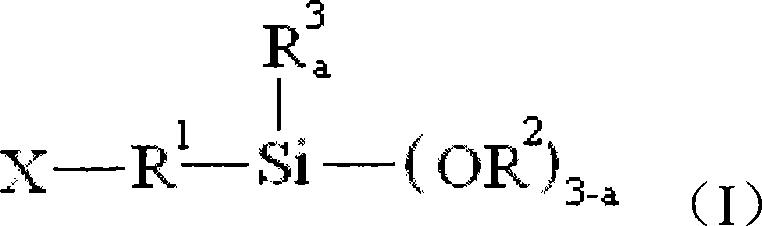

Method for treating and sticking work pieces made of metal or a metal alloy comprising a hydrated oxide and/or hydroxide layer

InactiveCN101068897APolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentMetal alloyEngineering

An impact test apparatus includes a holding device for holding a test piece at an arbitrary holding force, an impact applying device for applying an impact force to the test piece held by the holding device, a force sensor for sensing the impact force applied to the test piece by the impact applying device, a high-speed camera for detecting a displacement of the test piece when applied with the impact force by the impact applying device, and an output device for synchronizing a signal from the force sensor with a signal from the high-speed camera and outputting an impact stress-strain characteristic curve when the impact force is applied to the test piece.

Owner:SIKA TECH AG

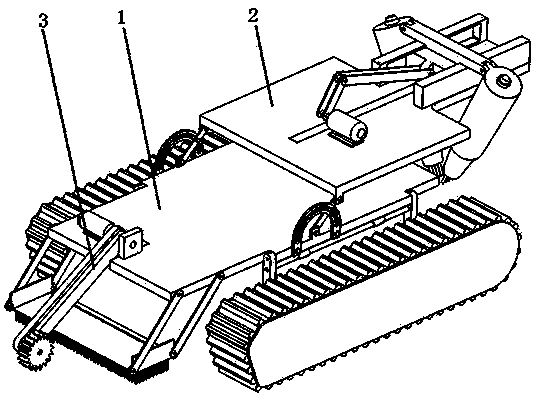

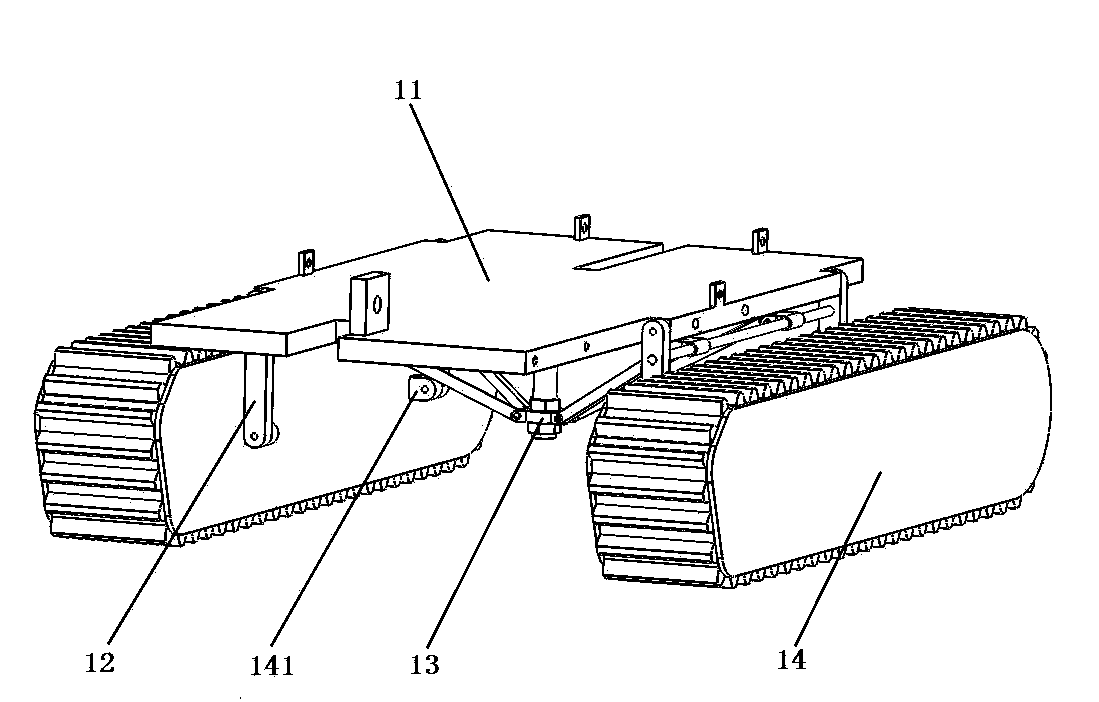

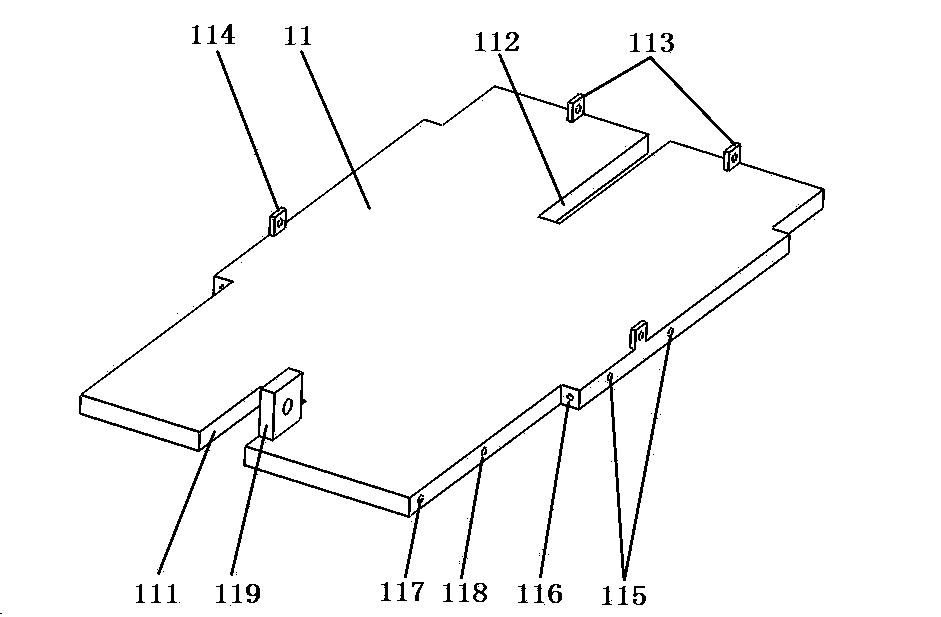

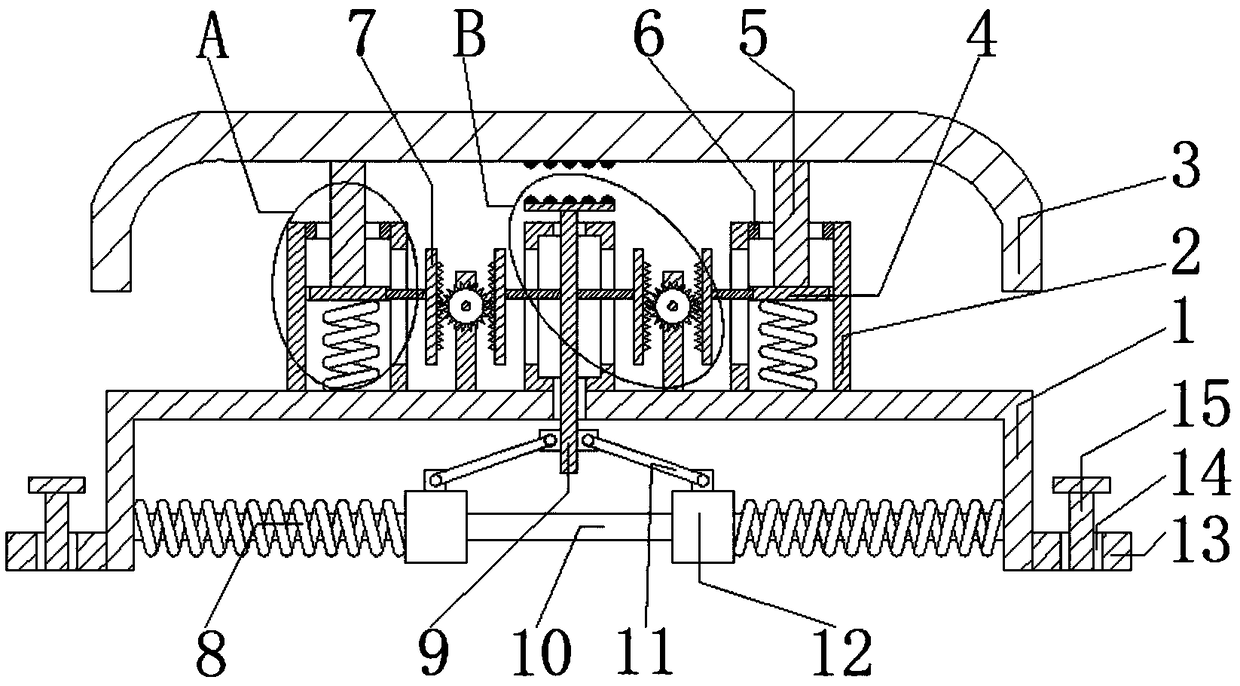

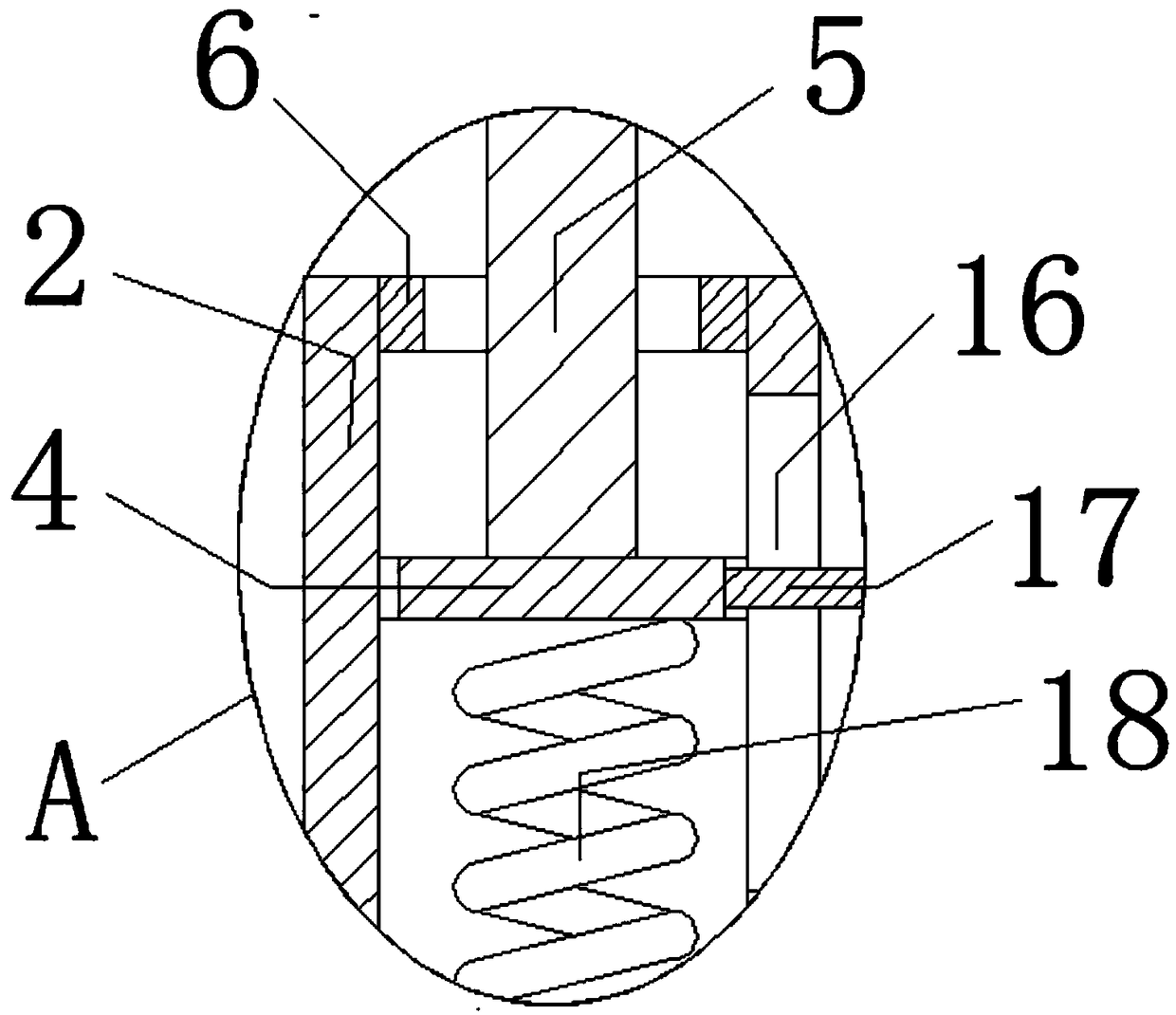

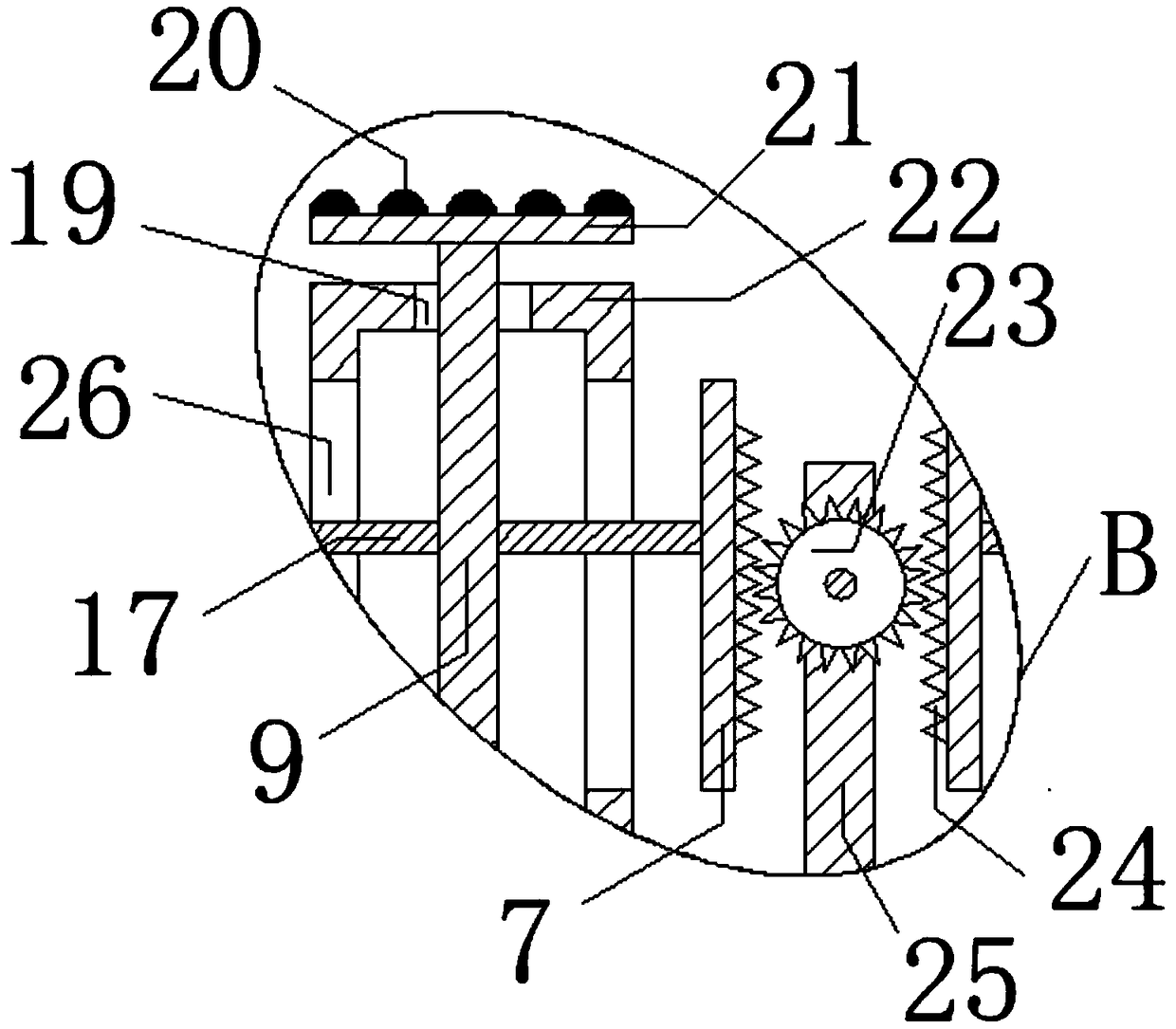

Automatic ultrasonic impact device for straight welding line in pipeline

InactiveCN103627884AReduce residual stressImprove fatigue strengthWelding/cutting auxillary devicesAuxillary welding devicesStress distributionSlag

The invention belongs to the field of metal welding and in particular relates to an automatic ultrasonic impact device for a straight welding line in a pipeline, which is used for improving the stress distribution of welding joints and improving the comprehensive performance of the welding joints. The automatic ultrasonic impact device for the straight welding line in the pipeline comprises a traveling mechanism, a stress elimination mechanism and a slag clearing mechanism and is characterized in that the traveling mechanism is a main body of the automatic ultrasonic impact device for the straight welding line in the pipeline and can be used as a bearing structure for crawling in the pipeline; the stress elimination mechanism is arranged on the rear part of the traveling mechanism and can be used for performing ultrasonic stress elimination processing on the straight welding line in the pipeline; the slag clearing mechanism is arranged on the front part of the traveling mechanism and is used for clearing away welding slag of the straight welding line in the pipeline. The automatic ultrasonic impact device for the straight welding line in the pipeline can synchronously implement the welding slag clearing work and the ultrasonic impact stress elimination work for the straight welding line in the pipeline, so that residual stress at a weld toe is eliminated, and the fatigue strength is improved; therefore, the postweld treatment efficiency is greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Heat-treated pressurized plastic containers and method of making

ActiveUS6959524B2Reduce resistanceImprove impact resistanceCapsDecorative coversEngineeringMechanical engineering

The present invention provides a heat-treated plastic pressurized container that is resistant to polar liquids and impact stresses and the process for making such container.

Owner:PROCTER & GAMBLE CO

Impact test apparatus and impact test method

An impact test apparatus includes a holding device for holding a test piece at an arbitrary holding force, an impact applying device for applying an impact force to the test piece held by the holding device, a force sensor for sensing the impact force applied to the test piece by the impact applying device, a high-speed camera for detecting a displacement of the test piece when applied with the impact force by the impact applying device, and an output device for synchronizing a signal from the force sensor with a signal from the high-speed camera and outputting an impact stress-strain characteristic curve when the impact force is applied to the test piece.

Owner:NITTO DENKO CORP

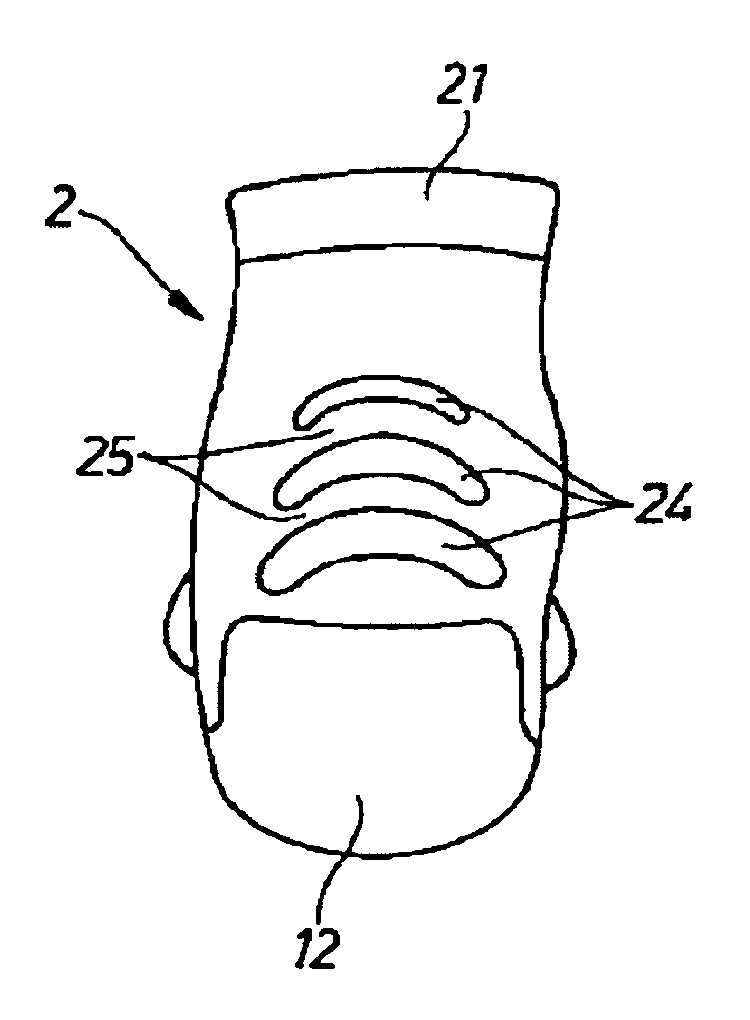

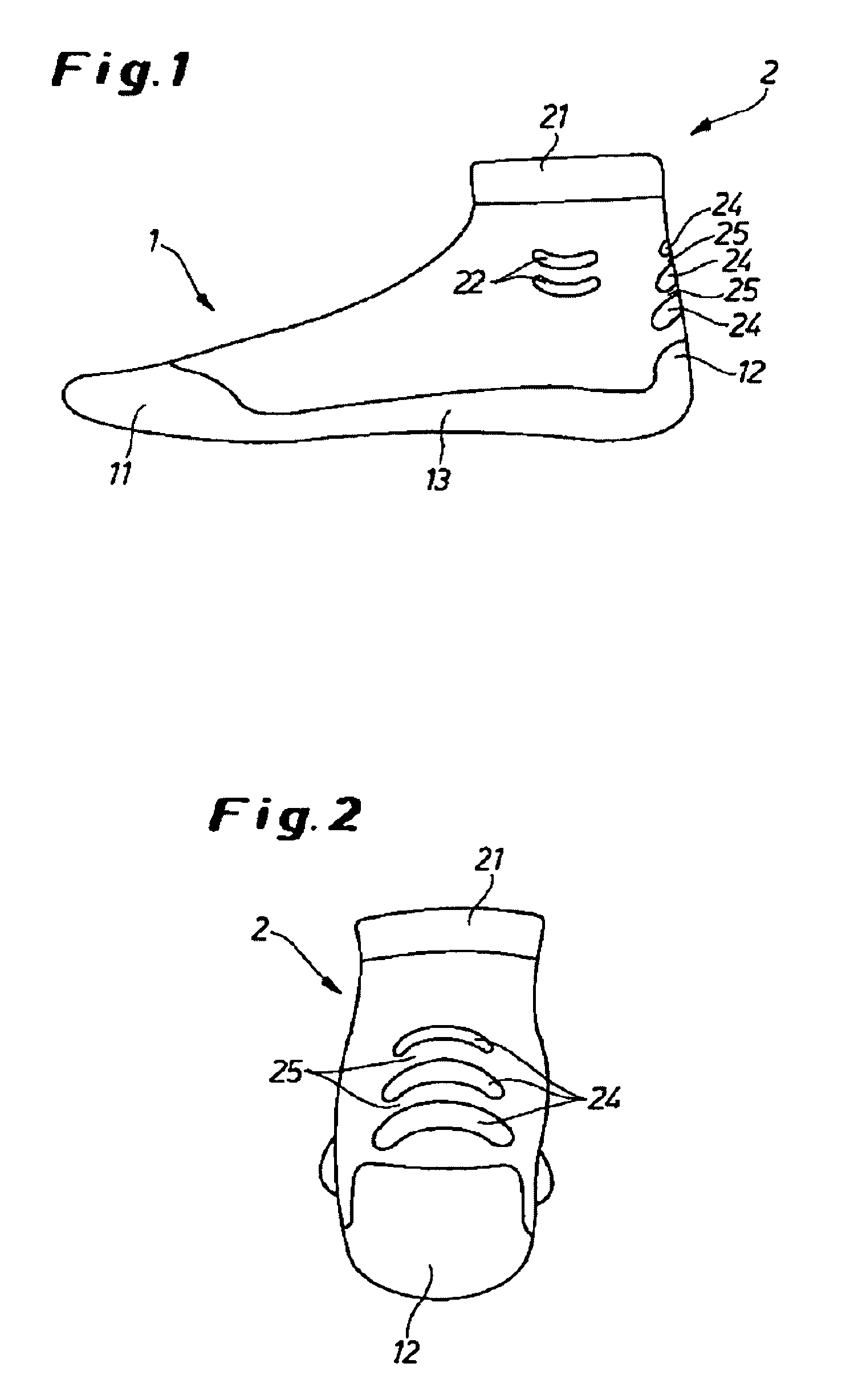

Sock

ActiveUS8230525B2Improve protectionImprove mobilityGarment special featuresInsolesSports activityCushioning

This invention relates to a sock for use in sports activities. The sock, includes cushioning in the area of the Achilles tendon for absorbing frictional and impact stresses without force being applied to the Achilles tendon. In one embodiment, the cushioning comprises elongated vertically spaced apart cushions that are in a bent shape. In another embodiment the cushioning comprises vertically spaced apart cushions that are divided by a vertically oriented ridge.

Owner:X TECH SWISS

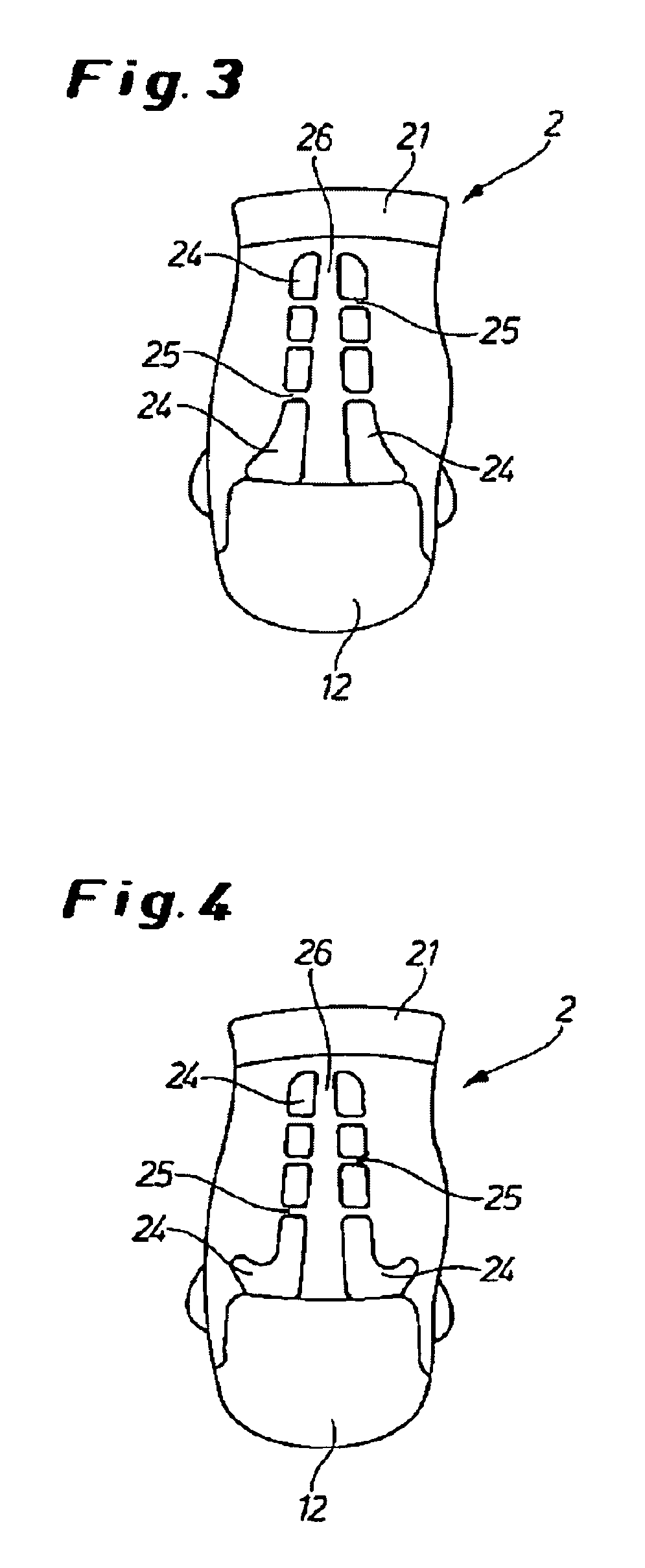

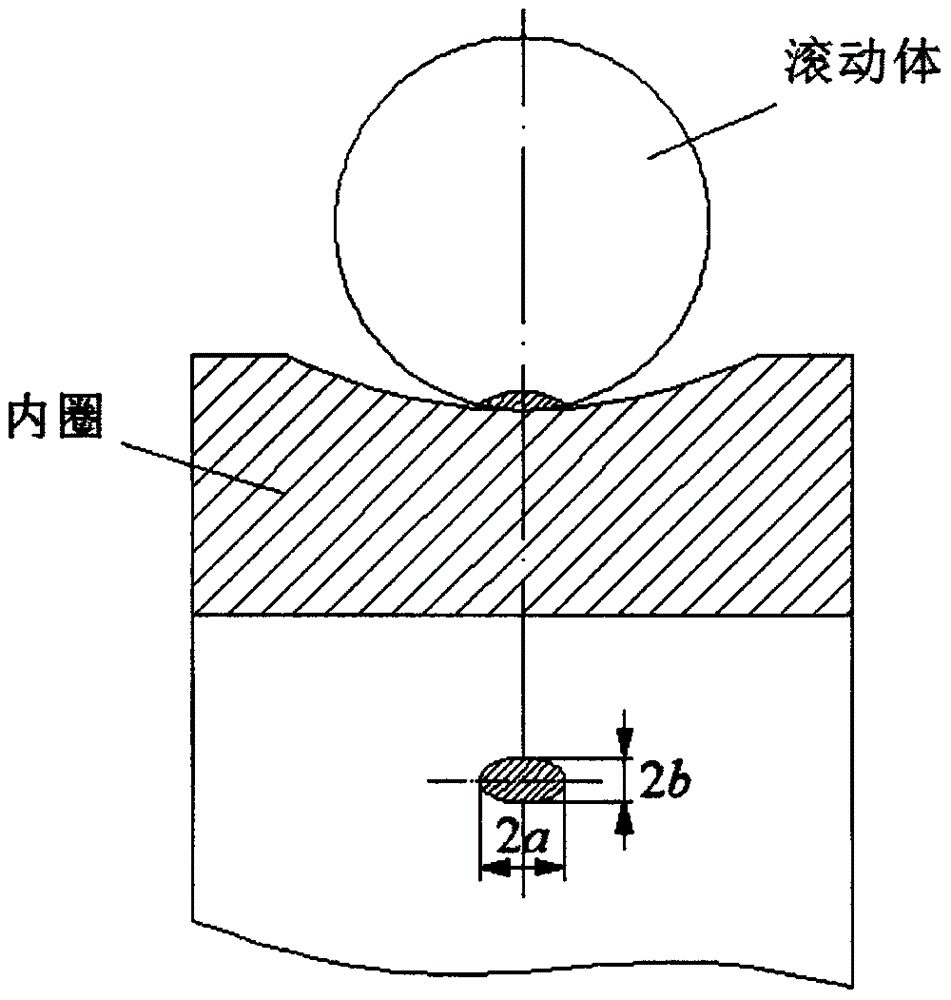

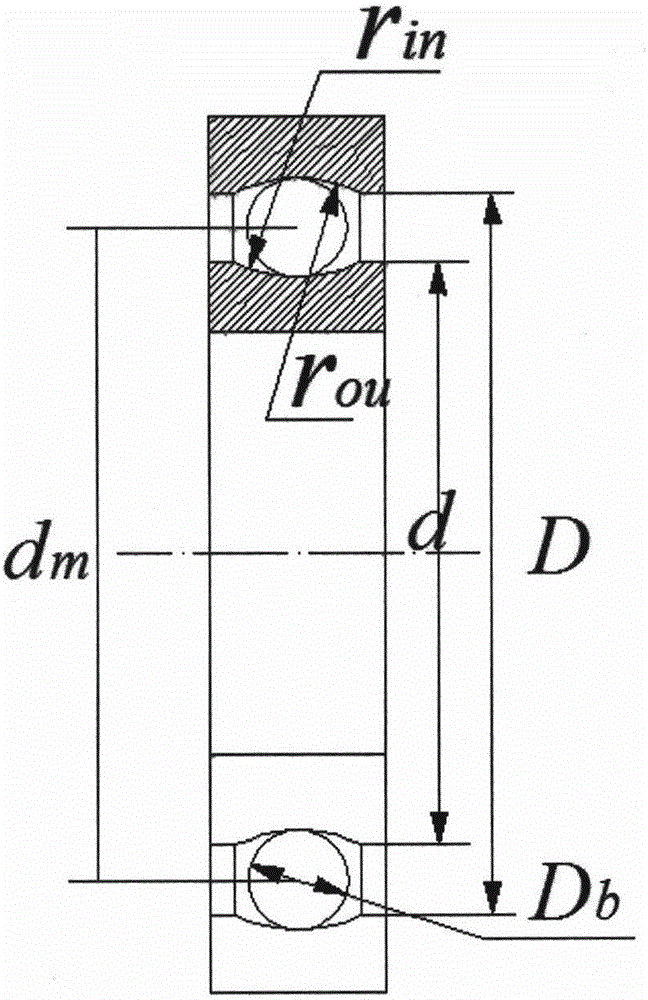

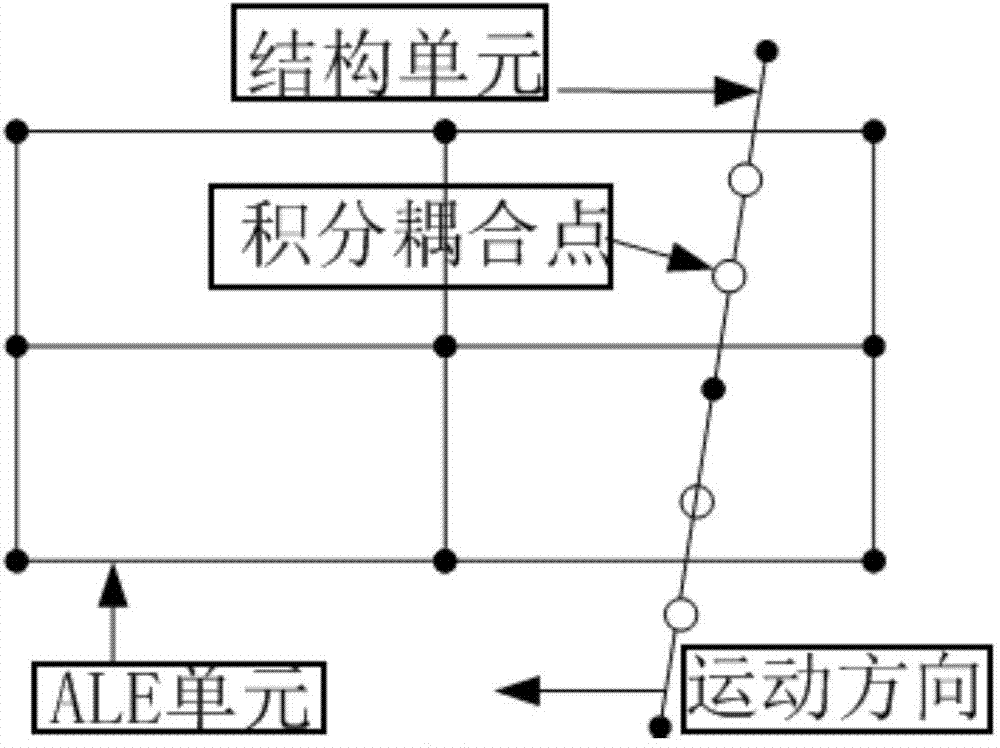

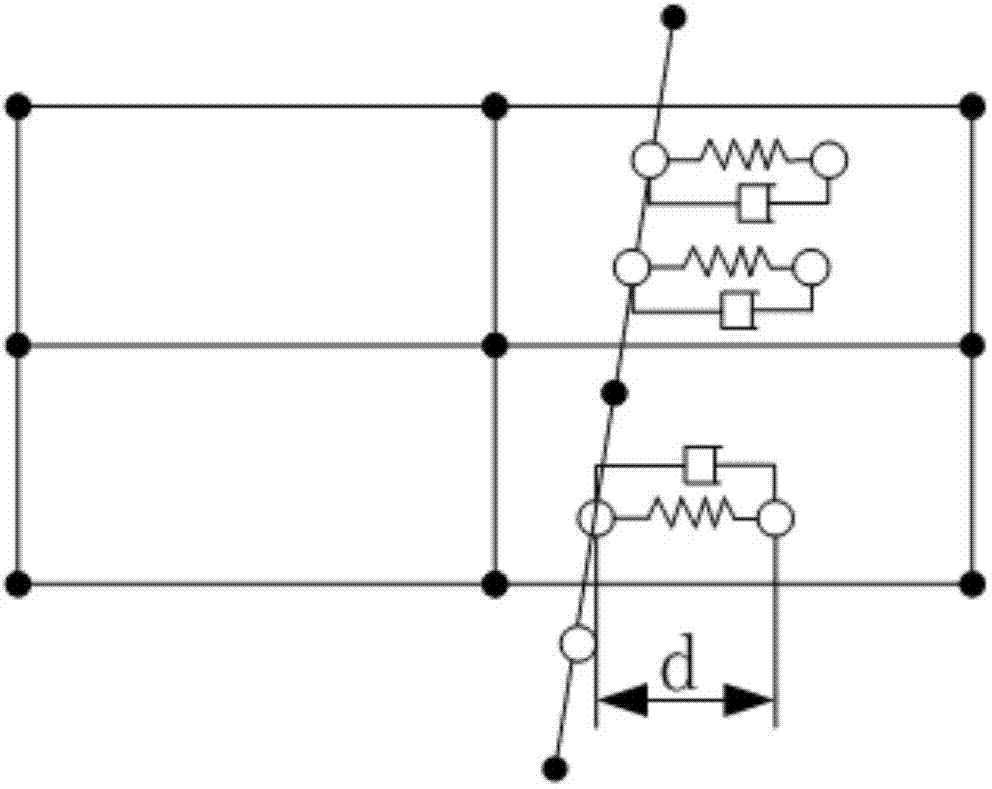

Ball bearing reliability design method

A ball bearing reliability design method is based on the following prerequisites: 1, the contact between an antifriction bearing rolling body and internal / external raceway satisfies the Hertz contact theory, and the contact type between the rolling body and the bearing internal / external raceway is point contact or / and line contact; 2, the ball bearing reliability design method satisfies the following requirements: firstly building a deep groove ball bearing flexible multi-body contact dynamics model, simulating and parsing a deep groove ball bearing rotation process so as to obtain each part angular velocity and dynamic contact impact stress changing rules, and using obtained data to finish the ball bearing reliability design. The invention provides the reference method for ball bearing reliability design and fatigue life research; related principles can be promoted to all transplantable related technical fields; the ball bearing reliability design method has large latent economy value and social value.

Owner:梁明轩

Anti-collision beam for unmanned vehicle, being able to sufficiently absorb impact stress

InactiveCN109177903AEffective absorptionPromote absorptionBumpersArchitectural engineeringImpact stress

The invention discloses an anti-collision beam for an unmanned vehicle, being able to sufficiently absorb impact stress, including a U-shaped mounting bracket, an anti-collision plate, tension springsand compression springs, wherein the U-shape mounting bracket has an opening face downward; the top, close to two sides, of the U-shape mounting bracket is fixedly connected with thick pipes; the compression springs are arranged in the two thick pipes; the bottom end of the each compression spring is fixedly connected with the top of the U-shaped mounting bracket; a movable block is fixedly connected with the top end of the each compression spring; the movable block is slidably connected with the inner wall of the thick pipe; a thin rod is fixedly connected to the top of the movable block; the top end of the thin rod passes through the nozzle of the top of the thick pipe, and extends to the outside of the thick pipe to be fixedly connected with the bottom of the anti-collision plate; a mounting box is arranged between the two thick pipes; the bottom of the mounting box is fixedly connected with the top of the U-shaped mounting bracket; vertical rods are arranged in the mounting box; and through holes matching with the vertical rods are formed in the top and bottom of the mounting box and the U-shaped mounting bracket.

Owner:唐燕

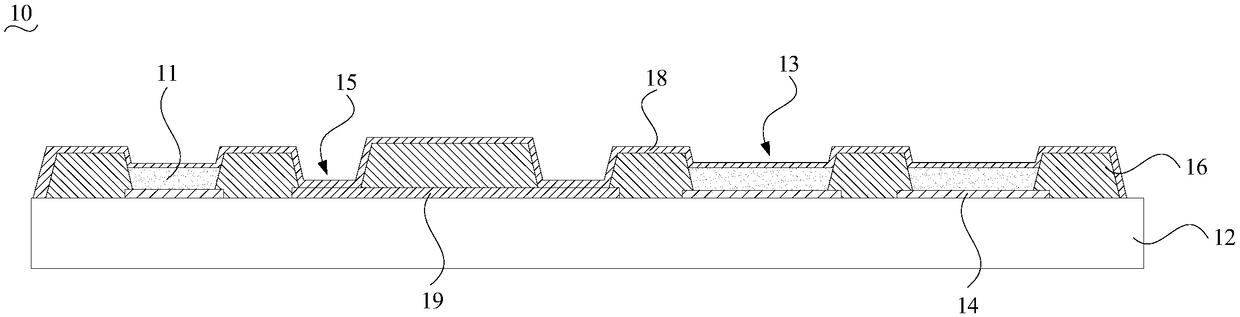

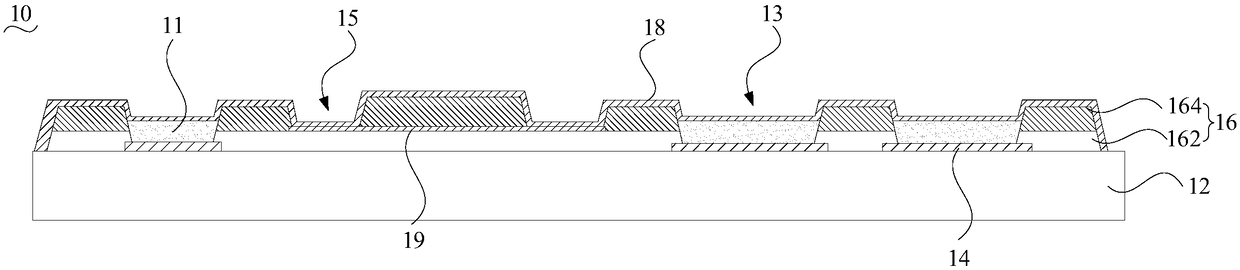

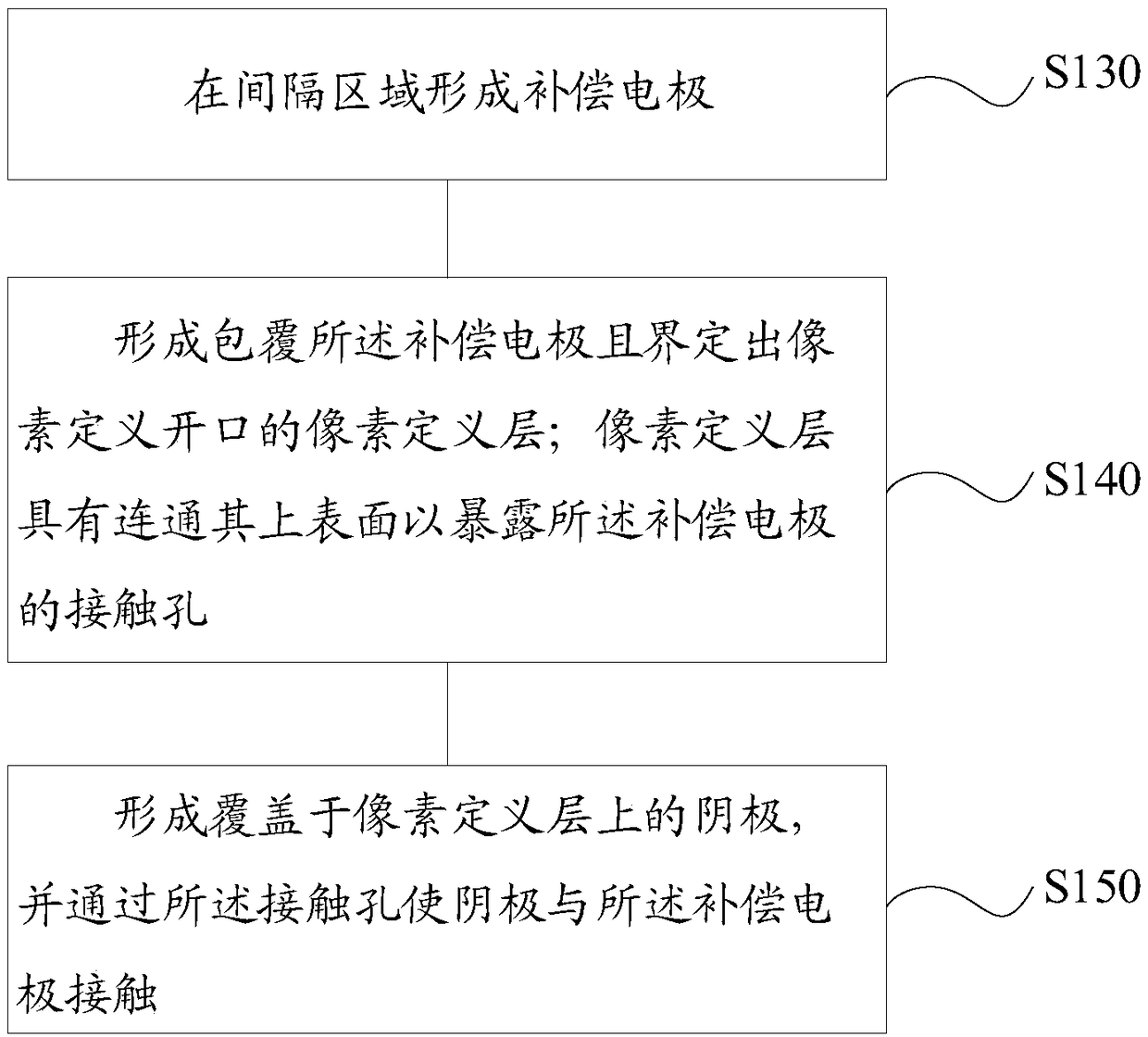

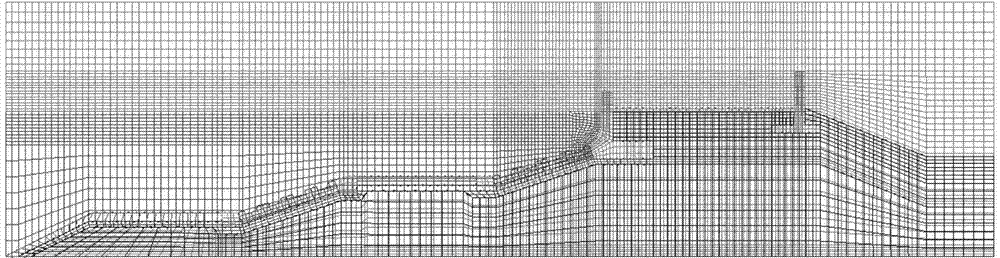

Display panel, manufacturing method thereof, and display device

ActiveCN109004005AImprove bending strengthAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingDrop impactFlexural strength

The invention relates to a display panel, comprising a pixel definition layer, a cathode and a compensation electrode. The pixel definition layer defines a plurality of pixel definition openings and aspacing area between the pixel definition openings. A cathode is overlaid on the pixel definition layer. The pixel definition layer is configured to cover the compensation electrode and has a contacthole communicating with an upper surface thereof so that the cathode contacts the compensation electrode through the contact hole. As that display panel is subject to drop impact or multiple bending,The thin film encapsulation layer is bent downward along the direction of the applied force, and the impact force is transmitted to the cathode layer. The compensation electrode and the cathode layeroverlap each other through the contact hole to form a three-dimensional three-dimensional network structure, which can support the cathode layer and disperse the impact stress, thereby preventing thecathode from breaking or being separated from the organic light-emitting unit. Thus, the bending strength and the impact strength against drop of the display panel are improved. Also provided are a method for manufacturing a display panel and a display device.

Owner:YUNGU GUAN TECH CO LTD

Wave impact resistance value detection method of nuclear power station breakwater

ActiveCN103542999AGuaranteed accuracyEasy to operateHydrodynamic testingShock testingNuclear powerGeometric design

The invention discloses a wave impact resistance value detection method of nuclear power station breakwater. The method includes the following steps: providing three-dimensional geometrical reconstruction information of the breakwater according to geometrical section parameters and axial spatial geometrical parameters of the engineering breakwater; providing material property information of the breakwater according to used face-protecting structures and breakwater body engineering materials of the engineering breakwater; according to past hydrology record information of the breakwater, providing environmental information of wave impact resistance detection of the breakwater; establishing a three-dimensional local breakwater model by the aid of the material property information and geometrical design parameters of the breakwater; establishing a three-dimensional overall breakwater model by the aid of the material property parameters, the three-dimensional spatial geometrical parameters and calculation parameters prepared in the third step, and analyzing surface wave pressure and structural impact stress response distribution of the breakwater along the horizontal direction. By the method, the problem about local and overall performance detection of the coastal breakwaters is solved, design efficiency is improved effectively, and test randomness and capital investment are reduced.

Owner:SHANGHAI JIAO TONG UNIV SUBEI RES INST

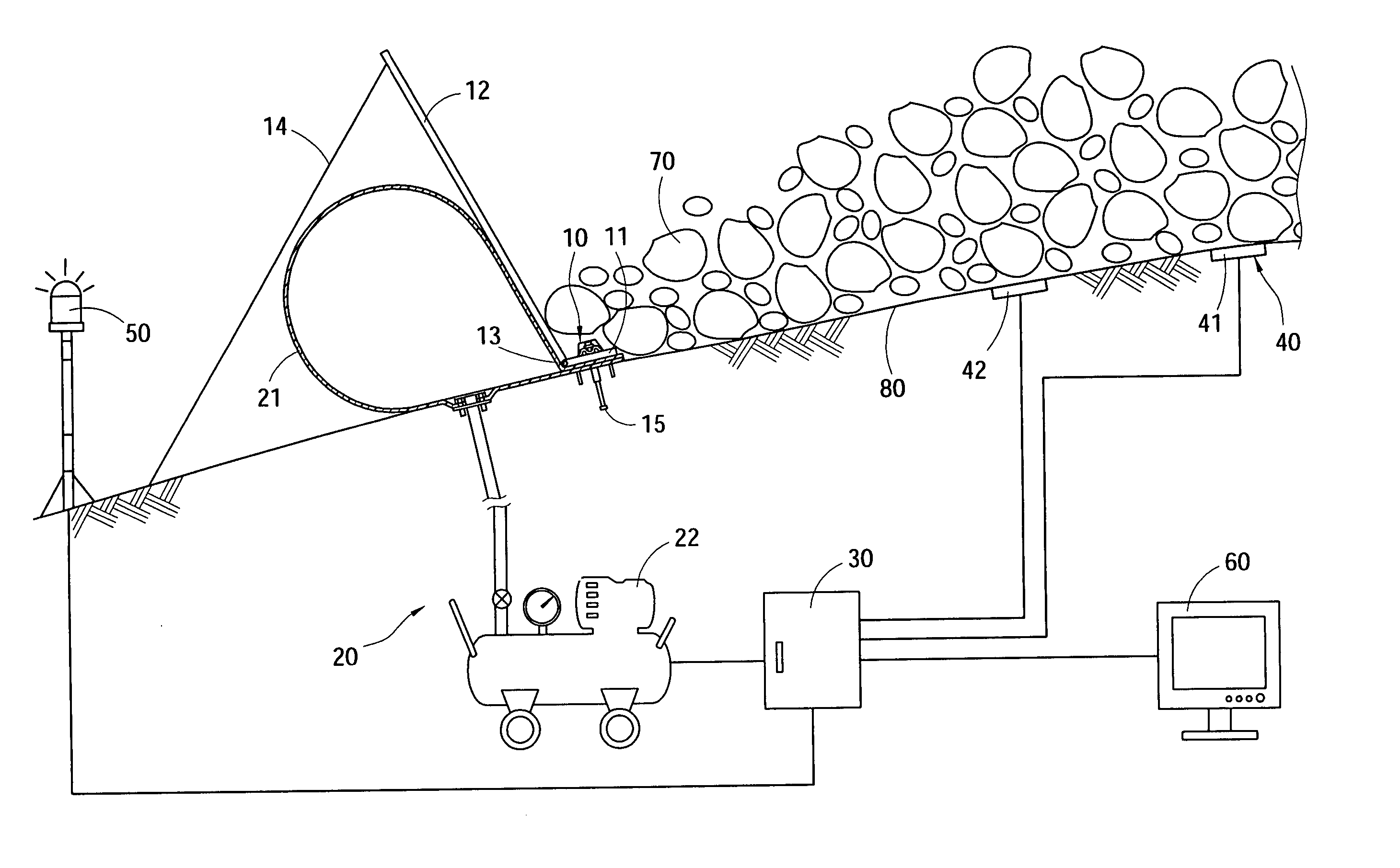

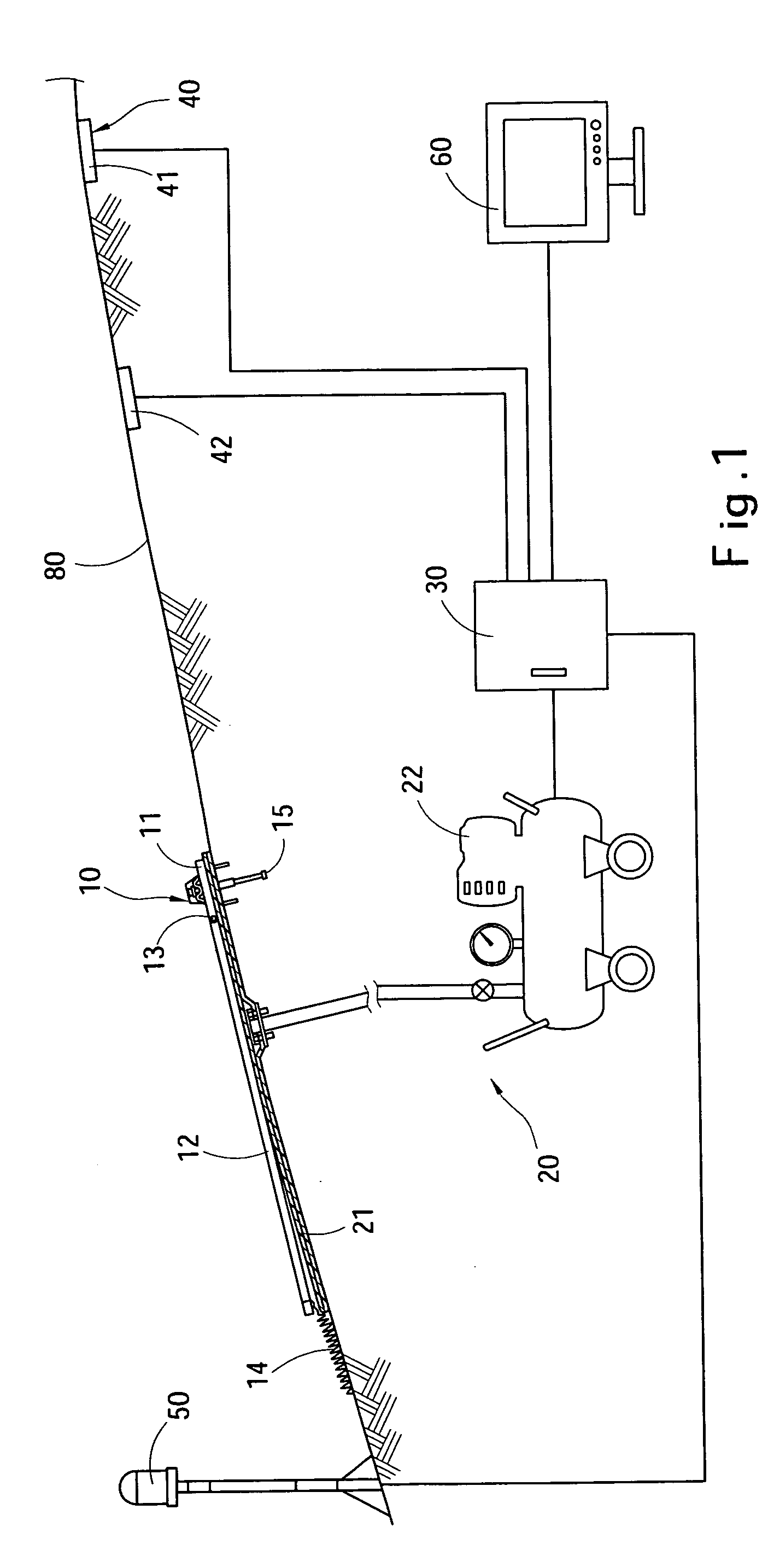

Debris flow retaining apparatus

InactiveUS20060056923A1Reduce harmHard structureArtificial islandsProtective constructionEngineeringAir compressor

A debris flow retaining apparatus located in a debris flow active area to provide buffering retention. It includes a retaining unit anchored on a ground surface movable up and down relative to the ground surface and a buffer unit which has an air mattress located between the ground surface and the retaining unit and an air compressor to inflate the air mattress. When a debris flow occurs, the air compressor inflates the air mattress to raise the retaining unit and absorb the impact stress resulting from the impact of the debris flow to prevent the retaining unit from immediate crumpling and reduce damages caused by the debris flow.

Owner:HWANG JYH YEONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com