Method for treating and sticking work pieces made of metal or a metal alloy comprising a hydrated oxide and/or hydroxide layer

A technology of hydroxide and metal alloys, applied in surface pretreatment bonding methods, bonding methods, polyurea/polyurethane adhesives, etc., can solve difficult adhesives, insufficient connection of bonding areas, Problems such as wetting the oxide layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

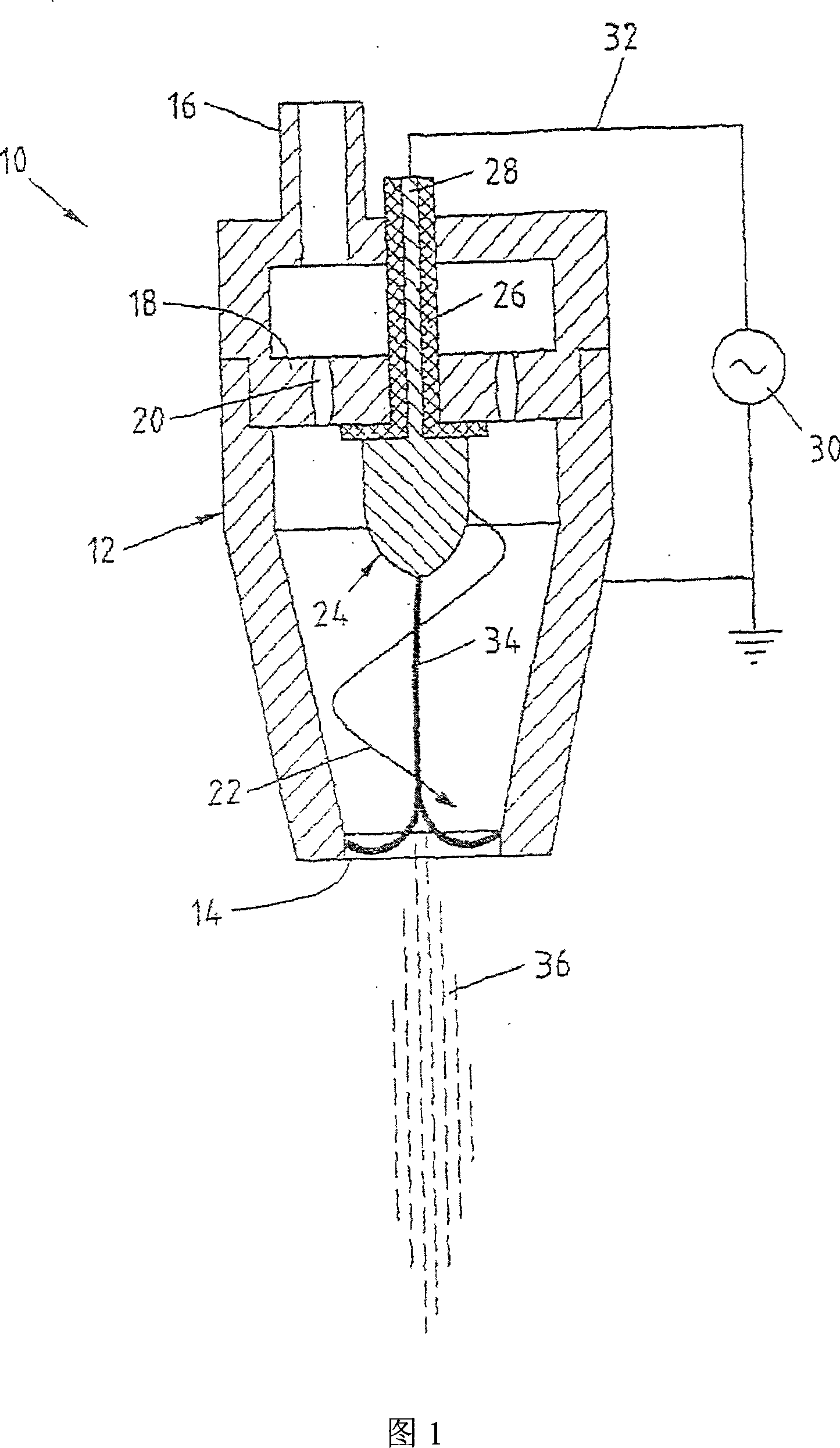

Image

Examples

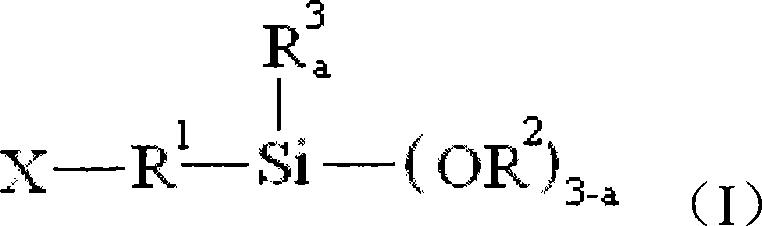

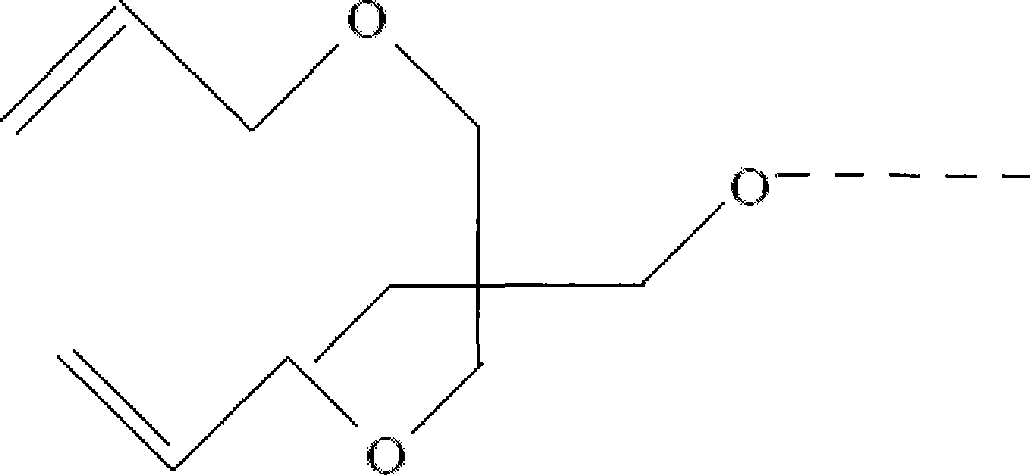

Embodiment Construction

[0018] In the present invention, metals or metal alloys having a hydrated oxide and / or hydroxide layer specifically include the metals titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, tin, magnesium, aluminum and their combinations Alloys of another kind or their alloys with other alloying constituents such as silicon or carbon. Among these alloys, various steels and aluminum alloys are particularly preferable. Particular preference is given to non-ferrous metal materials, such as aluminum, magnesium or titanium materials. A preferred material with a layer of hydrous oxide and / or hydroxide is aluminum. Finally, materials such as silicon and silicon oxide (glass) can also have oxide and / or hydroxide layers and thus also fall within the scope of application of the present invention.

[0019] The invention is described below using aluminum as a material. However, the present invention is not limited to aluminum materials. Generally, the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com