Device and method for machining materials by combining electrochemical discharging and laser

A combined processing and electrochemical technology, applied in the direction of electric processing equipment, accessory devices, metal processing, etc., can solve the problems of not suitable for processing micro-holes, increasing the size of electrodes, etc., to avoid deformation or fracture, increase speed and stability performance and increase the energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

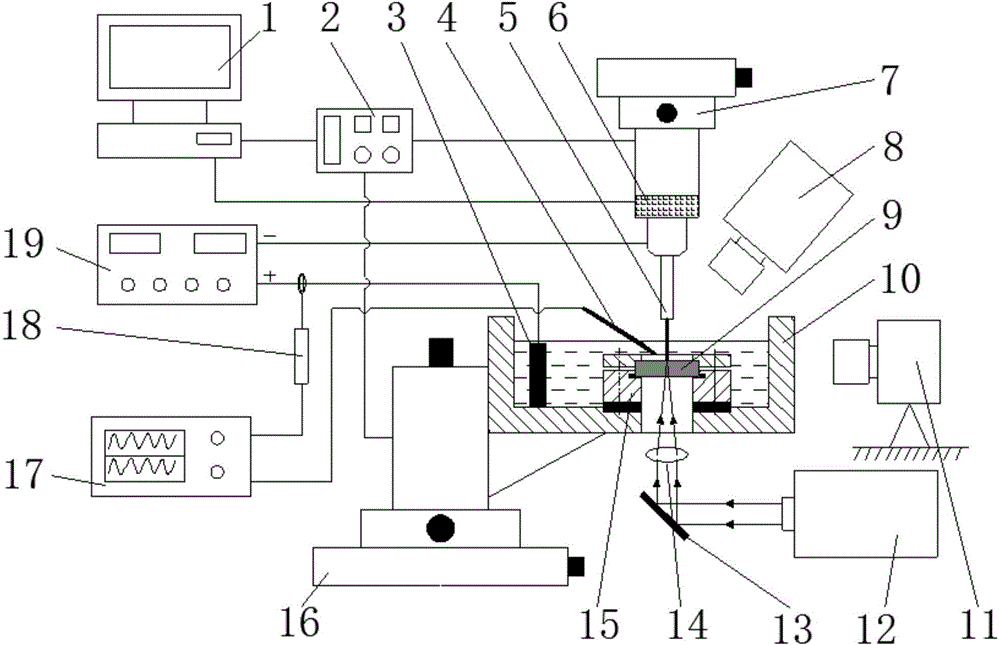

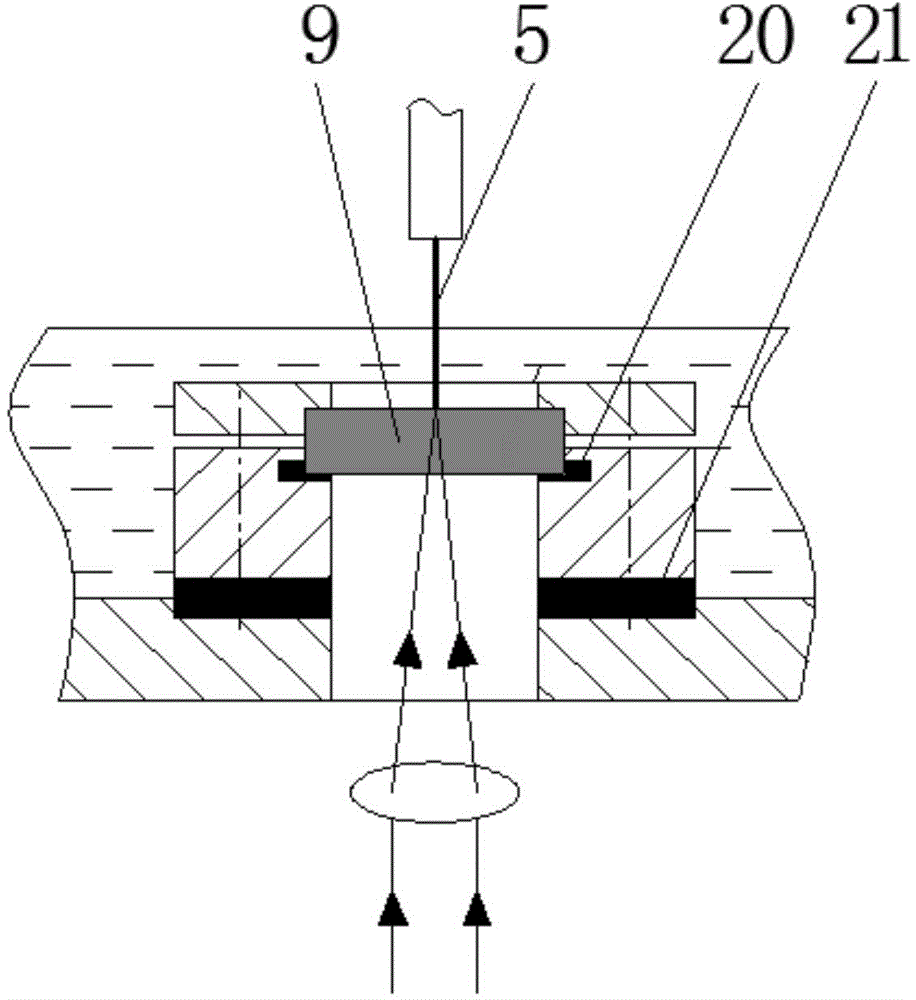

[0033] like figure 1 The shown electrochemical discharge and laser composite processing device includes a laser processing system, a motion control system and an electrochemical discharge processing system. The processing sample 9 is fixed at the through hole of the fixture 15, wherein the sample 9 and the fixture 15 An upper sealing ring 20 is installed between them, and a lower sealing ring 21 is installed between the bottom of the fixture 15 and the working chamber 10. The working chamber 10 is filled with alkaline electrolyte, and the working chamber 10 is fixed on the Z axis of the X-Y-Z three-coordinate numerical control platform 16. Above, the sample 9 is linked with the three-coordinate numerical control platform 16 in single-axis or multi-axis.

[0034] The outp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com